#Centrifugal Fans

Explore tagged Tumblr posts

Text

Fluctuating Air Pressure at the Outlet of a Centrifugal Fan: Causes and Cleaning Methods for Dust Accumulation in the Volute

Centrifugal fans are widely used in industrial ventilation, HVAC systems, and thermal management solutions. However, one common issue many operators face is fluctuating air pressure at the fan outlet. If your centrifugal fan is experiencing unstable airflow or irregular pressure levels, a key factor to investigate is dust accumulation inside the volute (scroll housing).

Why Does the Air Pressure Fluctuate?

Over time, particles such as dust, debris, or fine fibers may build up inside the volute casing of the centrifugal fan. This buildup affects the aerodynamic profile of the airflow path, causing turbulence and disrupting the fan’s ability to deliver stable pressure. The result is inconsistent outlet pressure, which may compromise the efficiency of your ventilation or cooling system.

Common Signs of Dust Accumulation:

Abnormal noise or vibrations

Fluctuating airflow or inconsistent pressure

Reduced overall performance despite normal motor operation

Visual inspection shows residue buildup in the housing

How to Clean the Volute Effectively:

Power Off the Fan: Always ensure the fan is disconnected from the power source before performing maintenance.

Disassemble the Housing: If possible, remove the volute cover to expose the internal chamber.

Vacuum or Blow Off Dust: Use compressed air or an industrial vacuum to remove loose dust. For sticky residue, a damp cloth with mild detergent may help.

Inspect Impeller and Blades: While cleaning the volute, check the impeller for any deposits or imbalance.

Reassemble and Test: Once cleaned, reassemble all components securely and test for pressure stability.

Preventive Maintenance Tips:

Schedule routine cleaning, especially in dusty or high-particulate environments

Install filters or dust barriers upstream when applicable

Choose centrifugal fans with anti-dust or corrosion-resistant coatings for challenging applications

At Cooltron Technology, we offer customized centrifugal fans designed for industrial durability, stable pressure output, and easy maintenance access. Contact us to explore tailored solutions for your application.

0 notes

Text

primary air fans and ID fan from Reitz India are custom designed to serve the needs of various processes in industries like cement, iron & steel, power plants, fertilizers/ chemicals and more. As a top quality Reitz India's PA fans and SA fans, has set a benchmark in delivering superior fans with high quality features and better industrial standards.

0 notes

Photo

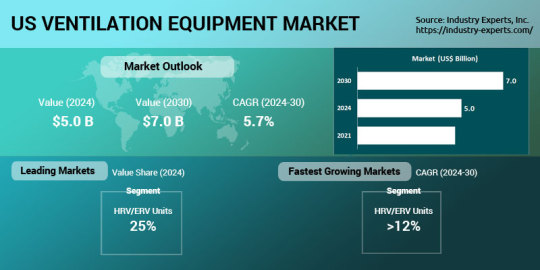

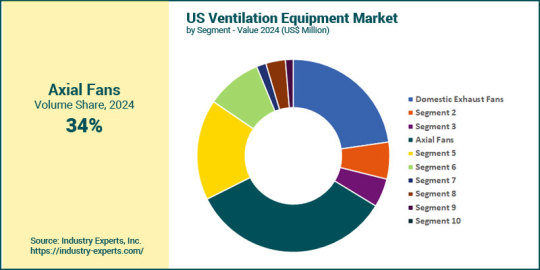

(via Ventilation Equipment Market | Axial Fans, Centrifugal Fans) The market for United States Ventilation Equipment by product segment analyzed in this report include Axial Fans, Centrifugal Fans, Centrifugal Blowers, Tangential/Cross Flow Fans, Domestic Exhaust Fans, Power Roof Ventilators, Range Hoods, Industrial Propeller Fans, Air Handling Units (AHUs) for Ventilation, and Heat Recovery/Energy Recovery Ventilation Units. Shipment value of the United States ventilation equipment is projected to grow by a CAGR of 5.7% over the forecast period, reaching US$7 billion by 2030, attributed mainly to high growth in sales of high valued HRV/ERV Units.

#US Ventilation Equipment Market#ventilation equipment market#Axial Fans#centrifugal fans#centrifugal blowers#Tangential/Cross Flow Fans#Domestic Exhaust Fans#power roof ventilators#range hoods#Industrial Propeller Fans#air handling units#heat recovery ventilation

0 notes

Text

#Centrifugal Fans#Centrifugal blowers manufacturer Chennai#Centrifugal Fans and blowers manufacturer Chennai#dust collector manufacturer Chennai#mini dust collector manufacturer Chennai#Dust extraction system manufacturers Chennai

0 notes

Text

Beyond Filtration: Crafting Cleaner Futures with Innovative Bag Filters

In the realm of industrial filtration, where purity and efficiency reign supreme, there exists a cadre of pioneers: Bag Filter Manufacturers. But what sets these artisans of cleanliness apart from the rest? Let's delve into the unique narrative of one such visionary:

Meet EcoPure Filtration, where the science of purification meets the art of sustainability. Far beyond the conventional realm of bag filter manufacturing, EcoPure embraces a holistic ethos, intertwining innovation with environmental stewardship.

At the heart of EcoPure's mission lies a commitment to redefine industry standards. No longer content with mere filtration, they've embarked on a journey to engineer solutions that transcend expectations. Picture this: a bag filter system that not only captures pollutants but transforms them into reusable resources. It's not just about cleaning the air or water; it's about creating a cycle of regeneration.

But innovation without conscience is merely progress without purpose. That's why EcoPure operates on a principle of eco-consciousness at every turn. From sourcing sustainable materials to minimizing waste in production, every step is a testament to their dedication to the planet.

Yet, the true mark of distinction lies in EcoPure's unwavering dedication to collaboration. Recognizing that the most profound advancements stem from collective wisdom, they foster partnerships across industries. Whether it's working alongside chemical engineers or collaborating with environmental scientists, EcoPure believes in the power of unity to forge a brighter, cleaner future.

#Centrifugal Fans#Fume Extraction Systems#Cyclone Separators#Tube Axial Flow Fan#and Venturi Scrubbers among others.

0 notes

Text

Explore the distinctions between fans and blowers in our comprehensive guide. Learn about their functions, types, energy consumption, and applications to make informed choices for your specific needs.

0 notes

Text

more lbp doodles!! wahoo!! i might try doing a full piece next time!! yippee!!!

just wanted to draw a few things again, though a bit less i really appreciate how much people liked my last set of doodles from a while back :)

#art#fan art#lbp#newton lbp3#littlebigplanet#little big planet#sacknana#MAN! i have to play the most recent sackboy game#ill probably draw fanart of that if i finish it lul#i really really like avalon centrifuge... i need to draw his brother next

374 notes

·

View notes

Text

Avalon moments before being put in baby jail in the Cosmos

#avalon centrifuge#lbp avalon#littlebigplanet#littlebigplanet 2#little big planet#little big planet 2#lbp#lbp2#fan art#digital illustration#digital art#my art#draconifay art#ibispaint x#art#i may make a darker skinned version of this eventually if im not busy w school stuff#I swear this was just meant to be a reaction image for my Avalon rp blog but then it became this

97 notes

·

View notes

Text

TWIN LOBE ROOTS AIRBLOWERS

S.V.ENGINEERS

About Us: S.V. Engineers

www.svblowers.in

Welcome to S.V. Engineers, where every journey begins with a vision and every success story starts with dedication. Established in 2009 in the vibrant city of Chennai, Tamil Nadu, S.V. Engineers embarked on its entrepreneurial voyage under the dynamic leadership of A. Sankar, a visionary at the tender age of 23. With divine grace, the blessings of elders, and the unwavering support of friends and family, what started in a modest space spanning below 100 sq.ft blossomed into a thriving enterprise.

In its nascent stages, S.V. Engineers focused on the meticulous servicing of air blowers and pumps, catering exclusively to the Chennai market. However, fueled by ambition and a commitment to excellence, within three years, the company witnessed exponential growth. A pivotal turning point was reached when S.V. Engineers diversified its offerings to include sales of a myriad of esteemed brands encompassing air blowers (Everest, Kay, Ingersoll Rand) and pumps and motors (Kirloskar, CG, CRI).

The driving forces behind S.V. Engineers' meteoric rise are rooted in Sankar's indefatigable work ethic, unwavering positivity, and lofty aspirations for his business. With each passing day, the company's footprint extended beyond Chennai, encompassing the entirety of Tamil Nadu, Kerala, Andhra Pradesh, Telangana, Karnataka, Puducherry, and Goa.

Our Services

At S.V. Engineers, we specialize in the sales and service of industrial air and water application products. Our comprehensive range of offerings includes:

Industrial Air Blowers: From twin lobe roots air blowers to centrifugal blowers, inlet blowers, axial fans, cabinet & circular inline fan blowers, fresh air ventilation blowers, and exhaust blowers, we cater to various industrial applications with precision and reliability.

Industrial Water & Wastewater Plant Equipments: We provide sales and service for all types of water pumps, STP & ETP sludge filter presses, oil skimmers, and aeration air blowers, ensuring the smooth operation of water treatment facilities.

Our Clientele

S.V. Engineers takes pride in its esteemed clientele, comprising leading companies across South India. Our commitment to excellence and customer satisfaction has garnered us a reputation as a trusted partner in the industrial sector.

Present Day: 2024

Fast forward to the present day, and S.V. Engineers operates from a spacious 1000 sq.ft facility located in Velapanchavadi, Chennai. Despite the growth and expansion, our core values remain unchanged – integrity, quality, and customer-centricity.

Join us at S.V. Engineers as we continue to redefine standards and push the boundaries of excellence in the industrial sector. Experience the difference with S.V. Engineers, where innovation meets reliability, and every solution is crafted with care.

#airblowers#aeration system#twin lobe roots blowers#stp blowers#etp blowers#sales & service#tamilnadu chennai#ring blowers#side channel blowers#centrifugal blowers#id fan blowers#inline & inlet bllowers

2 notes

·

View notes

Text

Ventilation by Exhaust Fans

An exhaust fan is a mechanical ventilation device that helps to draw out stale and impure air from your home and bring in fresh air, thereby improving the quality of indoor air. Exhaust fans are typically ducted to the exteriors of your house, through which bad indoor air can effectively be removed from your living space.

Exhaust fans are classified into various types, mainly depending on the type of mount and the location where you need to install the fans. The different types are:

Ceiling Mounted Exhaust Fans: As the name suggests, ceiling exhaust fans are those which are installed in the ceiling. Such fans expel stale air from your home upwards through the roof. The fan is connected to ducting, which is exhausted outside the home via an external vent, like a roof cap or soffit exhaust vent.

Inline Exhaust Fans: Unlike ceiling exhaust fans that are installed directly into the ceiling, inline exhaust fans are typically mounted in-between ducting, hence the name inline fan. For instance, if you wanted to ventilate an area that did not have clearance or space for a ceiling mount fan, you would make use of inline exhaust fans to ventilate such areas. The exhaust fan would be placed in between the ductwork and the stale air would travel through the ducts and ultimately be expelled from your home. Since inline fans are not mounted directly to the ceiling, they are very quiet. When installing an inline fan, to reduce noise, we recommend using an insulated flex duct that is at least eight feet long from the intake port on the ceiling to the inline fan. Inline exhaust fans are ideal for exhausting areas or rooms where you cannot, or do not wish to install the exhaust fan directly. Since these types of exhaust fans are mounted in remote areas, they are also referred to as remote mounted exhaust fans. Inline exhaust fans can either be single-port (exhausting from a single area) or multi-port (exhausting from multiple areas).

Wall Mounted Exhaust Fans: These exhaust fans are installed on walls. Since they are installed on exterior walls of the home and not on interior walls, the stale air has a direct route to the outside of your home and thus no duct work is required in installing these exhaust fans.

Combination Exhaust Fans: Exhaust fans are also available as combination units. You have the choice of a fan-light combination where the exhaust fan provides illumination as well, or heat-fan-light combination wherein you get a heater, light and ventilating fan all in a single device.

Exterior Remote Mounted Exhaust Fans: While most other exhaust fans are installed inside your home and push stale air out, exterior remote mounted fans are installed outside your home and pull out stale indoor air instead of pushing it out. The main benefit of these exhaust fans is that regardless of however noisy they are, most of the noise remains outside your home.

Kitchen Range Exhaust Fans: These fans are mounted inside the range hood over your kitchen stove. Such fans not only help to rid your kitchen of stale air but also help to expel bad odors and reduce moisture levels in your cooking area.

These several types of exhaust fans can be used for complete ventilation of your bilding including intermittent local ventilation for baths, kitchens, dryer rooms; continuous whole building ventilation, and for exhausting hard-to-air spaces such as crawl spaces, attics, and basements.

Canada Blower exhaust fans are very effective at ventilating your home and other living spaces. Without proper ventilation, the air inside your home can get filled with harmful contaminants and disease causing pathogens.

Pollutants such as pesticides, harmful gases, smoke, pet dander, lead, asbestos, dust mites, paint fumes, grease etc get released into indoor air due to daily activities such as cooking, smoking, burning fuel, bathing, renovating etc. In addition to these pollutants, activities such as bathing, cooking, and washing also release excess moisture in the air and make indoor air extremely humid. If not ventilated adequately, these added pollutants and increased moisture levels can decrease the quality of indoor air greatly, thereby leading to various problems such as:

Health problems including asthma, allergies, nose bleeds, skin rashes, headaches, nausea, and other breathing disorders. In fact, according to the Environmental Protection Agency, a large percentage of the over 20 million annual asthma cases in the US alone can be attributed to bad indoor air quality.

Split, warped and rotted furniture due to excess humidity.

Cracked and peeling paint on the walls.

Formation of fungus, mold spores, and mildew, which in turn lead to severe health problems.

Thus, by using exhaust fans to ventilate your building efficiently and completely, thereby improving indoor air quality, you can avoid of all these problems ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net.

When sizing a Canada Blower exhaust fan that does not open directly to the outside but is ducted, it is important to ensure that the exhaust fan has the capability to move stale air throughout the duct and ultimately to the outside. Here, we first need to understand what static pressure and equivalent duct length is.

Inside every duct, there is a constant pressure being exerted at any point from all directions. When an exhaust fan moves air through the duct, the air counters resistance from this pressure which is known as static pressure. Thus, an exhaust fan has to have the ability to overcome the static pressure in a duct so as to effectively duct stale air to the outside of your home. This can be done by calculating the equivalent duct length of any duct.

#Canada Blower#fan#blower#ventilator#Chicago Blower#pressure blower#high temperature ventilator#centrifugal fan#axial ventilator#scroll cage blower#blower wheel#ventilator blade#fan impeller#radial ventialtor#propeller ventilator#vaneaxial blower#tubeaxial blower#inline fan

2 notes

·

View notes

Text

POPULA Fan Smoke Exhaust Pipeline Centrifugal Fan Ventilation Industry 4-72 C Series Centrifugal Fan

0 notes

Text

Induced draft fans and forced draft fans from Reitz india are custom designed to serve the needs of various processes in industries like cement, iron & steel, power plants, fertilizers/ chemicals and more. As a top quality Reitz India's PA fans and SA fans, has set a benchmark in delivering superior fans with high quality features and better industrial standards.

0 notes

Text

Centrifugal Fan Vibrating After Installation? 4 Critical Checkpoints for Base Fixing & Duct Connection

While minor vibration during fan operation is normal, excessive shaking or noise often indicates installation flaws. Drawing from 20+ years of field experience serving global clients, Cooltron's engineering team reveals the root causes and actionable troubleshooting methods.

1. Uneven Foundation Causing Stress Concentration

40% of vibration issues originate from improper base installation:

Leveling deviation: Use laser levels to ensure ≤0.2mm/m tolerance

Grouting defects: Tap the base plate to detect hollow spots, especially within 30cm around anchor bolts

Curing shortcuts: Maintain 7-day wet curing (extend to 14+ days in winter)

Case Study: A 2023 Vietnam chemical plant reduced vibration from 8.7mm/s (3×ISO limit) to 2.1mm/s by correcting foundation settlement.

2. Improper Anchor Bolt Preload Distribution

Uneven bolt tension creates harmonic vibrations:

Cross-tightening sequence: Apply torque in 3 stages (30%→70%→100%) diagonally

Anti-loosening checks: Compress spring washers to 2/3 thickness; maintain 5-8mm gap between double nuts

Embedment depth: Minimum 20× bolt diameter

Torque Specifications:

3. Vibration Isolation Mistakes

Critical considerations for shock absorption:

Rubber isolator selection: Maintain 10-15% static compression

Resonance prevention: Isolator natural frequency < 1/3 of fan RPM

Multi-unit spacing: Keep >1.5× equipment length between adjacent units

4. Duct System Stress Transfer

Improper duct connections induce mechanical loads:

Flexible connector installation: Allow 10-15% expansion margin

Support spacing: Install brackets every 10ft (horizontal) / 5ft (vertical)

Pulsation detection: Use strobes to verify <0.2" connector fluctuation

Diagnosis Flow: Start fan → Measure vibration unloaded → Retest with ducts → If increase >30% → Inspect duct stress

FAQ

Q: When should I shut down a vibrating fan? A: Per ISO 10816-3, immediate shutdown if >0.18in/s (rigid base) or >0.28in/s (isolated base).

Q: Can I adjust isolators myself? A: Consult professionals - incorrect adjustments may trigger resonance.

Q: When's the best time to fix vibration issues? A: Conduct initial vibration tests within 24 hours post-installation.

Professional Solutions

Cooltron offers global technical support including:

On-site diagnostics: Spectrum analyzers, laser alignment tools

Custom installation plans: Facility-specific isolation system design

Remote AR guidance: Real-time troubleshooting via augmented reality

Want to learn more about centrifugal fan maintenance? Contact our engineers now: [email protected]

0 notes

Text

Upgrade your ventilation system with a premium Centrifugal Fan from Perkins Blowers. Engineered for superior airflow, efficiency, and durability, our fans are perfect for industrial, commercial, and HVAC applications. Built with high-quality materials, they ensure reliable performance and energy savings. Order now for optimal air movement solutions! https://perkinsblowers.co/centrifugal-fans

0 notes

Text

The Siemens 2CF7402-1NA91-1EE6 Centrifugal Blower Cooling Fan is a high-performance industrial cooling solution designed for efficient airflow and temperature control. Built for durability and reliability, this fan ensures optimal cooling in electrical enclosures, automation systems, and industrial machinery. It operates with low noise, high efficiency, and long-lasting performance, making it ideal for demanding environments. With precision engineering and Siemens’ trusted quality, this centrifugal blower enhances equipment longevity and prevents overheating. Perfect for industrial automation, HVAC systems, and electronic cooling, it offers seamless integration and energy-efficient operation.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Automation#manufacturing#Siemens#Cooling Fan#Centrifugal Blower#2Cf7402-1Na91-1Ee6

0 notes