#axial ventilator

Explore tagged Tumblr posts

Text

Ventilation by Exhaust Fans

An exhaust fan is a mechanical ventilation device that helps to draw out stale and impure air from your home and bring in fresh air, thereby improving the quality of indoor air. Exhaust fans are typically ducted to the exteriors of your house, through which bad indoor air can effectively be removed from your living space.

Exhaust fans are classified into various types, mainly depending on the type of mount and the location where you need to install the fans. The different types are:

Ceiling Mounted Exhaust Fans: As the name suggests, ceiling exhaust fans are those which are installed in the ceiling. Such fans expel stale air from your home upwards through the roof. The fan is connected to ducting, which is exhausted outside the home via an external vent, like a roof cap or soffit exhaust vent.

Inline Exhaust Fans: Unlike ceiling exhaust fans that are installed directly into the ceiling, inline exhaust fans are typically mounted in-between ducting, hence the name inline fan. For instance, if you wanted to ventilate an area that did not have clearance or space for a ceiling mount fan, you would make use of inline exhaust fans to ventilate such areas. The exhaust fan would be placed in between the ductwork and the stale air would travel through the ducts and ultimately be expelled from your home. Since inline fans are not mounted directly to the ceiling, they are very quiet. When installing an inline fan, to reduce noise, we recommend using an insulated flex duct that is at least eight feet long from the intake port on the ceiling to the inline fan. Inline exhaust fans are ideal for exhausting areas or rooms where you cannot, or do not wish to install the exhaust fan directly. Since these types of exhaust fans are mounted in remote areas, they are also referred to as remote mounted exhaust fans. Inline exhaust fans can either be single-port (exhausting from a single area) or multi-port (exhausting from multiple areas).

Wall Mounted Exhaust Fans: These exhaust fans are installed on walls. Since they are installed on exterior walls of the home and not on interior walls, the stale air has a direct route to the outside of your home and thus no duct work is required in installing these exhaust fans.

Combination Exhaust Fans: Exhaust fans are also available as combination units. You have the choice of a fan-light combination where the exhaust fan provides illumination as well, or heat-fan-light combination wherein you get a heater, light and ventilating fan all in a single device.

Exterior Remote Mounted Exhaust Fans: While most other exhaust fans are installed inside your home and push stale air out, exterior remote mounted fans are installed outside your home and pull out stale indoor air instead of pushing it out. The main benefit of these exhaust fans is that regardless of however noisy they are, most of the noise remains outside your home.

Kitchen Range Exhaust Fans: These fans are mounted inside the range hood over your kitchen stove. Such fans not only help to rid your kitchen of stale air but also help to expel bad odors and reduce moisture levels in your cooking area.

These several types of exhaust fans can be used for complete ventilation of your bilding including intermittent local ventilation for baths, kitchens, dryer rooms; continuous whole building ventilation, and for exhausting hard-to-air spaces such as crawl spaces, attics, and basements.

Canada Blower exhaust fans are very effective at ventilating your home and other living spaces. Without proper ventilation, the air inside your home can get filled with harmful contaminants and disease causing pathogens.

Pollutants such as pesticides, harmful gases, smoke, pet dander, lead, asbestos, dust mites, paint fumes, grease etc get released into indoor air due to daily activities such as cooking, smoking, burning fuel, bathing, renovating etc. In addition to these pollutants, activities such as bathing, cooking, and washing also release excess moisture in the air and make indoor air extremely humid. If not ventilated adequately, these added pollutants and increased moisture levels can decrease the quality of indoor air greatly, thereby leading to various problems such as:

Health problems including asthma, allergies, nose bleeds, skin rashes, headaches, nausea, and other breathing disorders. In fact, according to the Environmental Protection Agency, a large percentage of the over 20 million annual asthma cases in the US alone can be attributed to bad indoor air quality.

Split, warped and rotted furniture due to excess humidity.

Cracked and peeling paint on the walls.

Formation of fungus, mold spores, and mildew, which in turn lead to severe health problems.

Thus, by using exhaust fans to ventilate your building efficiently and completely, thereby improving indoor air quality, you can avoid of all these problems ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net.

When sizing a Canada Blower exhaust fan that does not open directly to the outside but is ducted, it is important to ensure that the exhaust fan has the capability to move stale air throughout the duct and ultimately to the outside. Here, we first need to understand what static pressure and equivalent duct length is.

Inside every duct, there is a constant pressure being exerted at any point from all directions. When an exhaust fan moves air through the duct, the air counters resistance from this pressure which is known as static pressure. Thus, an exhaust fan has to have the ability to overcome the static pressure in a duct so as to effectively duct stale air to the outside of your home. This can be done by calculating the equivalent duct length of any duct.

#Canada Blower#fan#blower#ventilator#Chicago Blower#pressure blower#high temperature ventilator#centrifugal fan#axial ventilator#scroll cage blower#blower wheel#ventilator blade#fan impeller#radial ventialtor#propeller ventilator#vaneaxial blower#tubeaxial blower#inline fan

2 notes

·

View notes

Photo

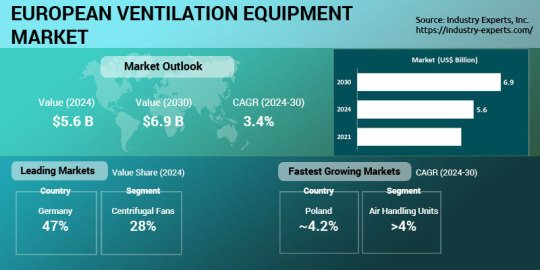

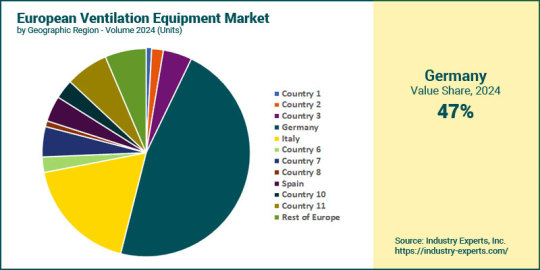

(via European Ventilation Equipment Market Size, Outlook 2024-2030)

#european ventilation equipment#ventilation equipment#european ventilation equipment market#axial fans centrifugal fans cross flow fans domestic exhaust fans

0 notes

Text

Round 2 - Chordata - Reptilia

(Sources - 1, 2, 3, 4)

Reptilia is a class of tetrapods that includes Rhynchocephalia (an order that dates back to the Middle Triassic, but is today only represented by one species: the Tuatara), Squamata (lizards and snakes), Testudines (turtles), and Archosauria (crocodilians and birds).

Reptiles have four limbs (two of which evolved into wings in birds and some of which were lost in snakes and some lizards). Most species lay eggs, though some squamates give live birth. Reptile eggs are surrounded by membranes for protection and transport, which adapt them to reproduction on dry land. Rhynchocephalians, squamates, and turtles have a three-chambered heart, while archosaurs have a four-chambered heart. Non-avian reptiles all exhibit some form of cold-bloodedness, and have limited physiological means of keeping a constant body temperature, often relying on external sources of heat. Many reptiles have lungs that are ventilated almost exclusively by the axial musculature: the same musculature that is used during locomotion. Because of this, most squamates are forced to hold their breath while running. Crocodilians, birds, monitor lizards, and iguanas have a muscular diaphragm that is analogous to the mammalian diaphragm, freeing space for the lungs to expand. How turtles and tortoises breathe has been the subject of much study, with varied results indicating they have found a variety of solutions to this problem. Reptilian skin is covered in a horny epidermis, making it watertight and enabling reptiles to live on dry land, in contrast to amphibians. This skin can be protected by scales, scutes, or feathers (which are modified scales). Reptiles shed their skin through a process called ecdysis which occurs continuously throughout their lifetime. Meanwhile birds moult their feathers, usually once or twice a year and not all at once. Reptiles usually have excellent vision, allowing them to detect shapes and motions at long distances. Birds, crocodiles and turtles have three types of photoreceptor, which give them sharp color vision and enables them to see ultraviolet light. Rhynchocephalians and many squamates also have a photosensory organ on the top of their heads called the parietal eye, which cannot form images, but is sensitive to changes in light and dark and can detect movement. Some snakes have extra sets of sensory organs in the form of heat-sensitive pits. Most reptiles possess a nictitating membrane, a translucent third eyelid which is drawn over the eye from the inner corner. In crocodilians, it protects the eyeball surface while allowing for vision underwater. However, many squamates lack eyelids, which are instead replaced by a transparent scale. This is called the brille, and it protects the eyes from dust and dirt. Living reptiles range in size from the Jaragua Dwarf Gecko (Sphaerodactylus ariasae) which can grow up to 17 mm (0.7 in) to the Saltwater Crocodile (Crocodylus porosus) which can reach over 6 m (19.7 ft) in length and weigh over 1,000 kg (2,200 lb).

The earliest known proto-reptiles originated from the Carboniferous period, with the earliest known eureptile ("true reptile") being Hylonomus from the Late Carboniferous. As stated above, Rhynchocephalians first appeared in the Middle Triassic. Megachirella, a stem-squamate, lived in the Middle Triassic as well, though more modern squamates, like Cryptovaranoides, are not seen until the Late Triassic. Turtles are not seen until the Late Jurassic, though stem-group turtles are found from the Middle Jurassic. Pseudosuchians date back to the Early Triassic and dinosaurs to the Late Triassic. However, crocodilians (the last remaining group of pseudosuchians) and birds (the last remaining group of dinosaurs) are both more recent, originating in the Cretaceous.

Propaganda under the cut:

For centuries, reptiles and amphibians were treated as the same class of animals, with the words even used interchangeably. It wasn’t until the beginning of the 19th century that it was understood that reptiles and amphibians were very different groups of animal. However, reptiles and amphibians are still studied under the same branch: Herpetology.

Since herbivorous reptiles do not have chewing teeth like mammals, many species swallow rocks and pebbles (called gastroliths or “gizzard stones” in birds) to aid in digestion: The rocks are washed around in the stomach, helping to grind up plant matter. Saltwater Crocodiles also use gastroliths as ballast, stabilizing them in the water or helping them to dive.

Some reptiles are capable of reproducing via parthenogenesis, in which the embryo develops directly from an egg without need for fertilization. The New Mexico Whiptail (Aspidoscelis neomexicanus) is most famous for this, being an all-female species. Other all-female or almost all-female species include the Mourning Gecko (Lepidodactylus lugubris), Indo-pacific Gecko (Hemidactylus garnotii), some other Whiptails (Cnemidophorus), Caucasian Rock Lizards (Darevskia), and the Brahminy Blindsnake (Indotyphlops braminus). While not the primary means of reproduction, parthenogenesis has also been observed occurring in Komodo Dragons (Varanus komodoensis), Argus Monitors (Varanus panoptes), boas, pythons, filesnakes, gartersnakes, pit vipers, Domestic Turkeys (Meleagris gallopavo domesticus), Domestic Chickens (Gallus domesticus), Domestic Pigeons (Columba livia domestica), a California Condor (Gymnogyps californianus), and one American Crocodile (Crocodylus acutus). This most often happens in human care when the reptile does not have access to a male, but it has been observed occurring in the wild as well.

While most birds are well-known for being caring parents, some non-avian reptiles also parent their young. Crocodilians make large nests for their eggs, guard the nests, and then carry the babies in their mouths to the water once they hatch. Male Gharials (Gavialis gangeticus) will guard the nests of communal hatching sites, even taking interest in the juveniles and carrying them around on their back. Pythons incubate their eggs by coiling around them, “shivering” to generate heat. Many rattlesnakes, which give live birth, will stay with their young until their first shed.

Meanwhile, Megapodes are a family of birds that build large mounds to incubate their eggs and then leave them, taking the sea turtle approach. Their chicks eventually dig themselves out of the mounds and are able to run, pursue prey and, in some species, fly on the day they hatch. The Maleo (Macrocephalon maleo) is a megapode which buries its eggs in volcanic soil or sandy beaches, allowing the sun or geothermal energy to incubate its eggs.

Some birds, particularly corvids and parrots, are intelligent to the level of young humans, being able to use tools, solve puzzles, do math, plan for the future, and make decisions as a group.

There’s like a million other things I could say here, but I’d hopefully like to save some for if this class makes it to the next round!

81 notes

·

View notes

Text

TWIN LOBE ROOTS AIRBLOWERS

S.V.ENGINEERS

About Us: S.V. Engineers

www.svblowers.in

Welcome to S.V. Engineers, where every journey begins with a vision and every success story starts with dedication. Established in 2009 in the vibrant city of Chennai, Tamil Nadu, S.V. Engineers embarked on its entrepreneurial voyage under the dynamic leadership of A. Sankar, a visionary at the tender age of 23. With divine grace, the blessings of elders, and the unwavering support of friends and family, what started in a modest space spanning below 100 sq.ft blossomed into a thriving enterprise.

In its nascent stages, S.V. Engineers focused on the meticulous servicing of air blowers and pumps, catering exclusively to the Chennai market. However, fueled by ambition and a commitment to excellence, within three years, the company witnessed exponential growth. A pivotal turning point was reached when S.V. Engineers diversified its offerings to include sales of a myriad of esteemed brands encompassing air blowers (Everest, Kay, Ingersoll Rand) and pumps and motors (Kirloskar, CG, CRI).

The driving forces behind S.V. Engineers' meteoric rise are rooted in Sankar's indefatigable work ethic, unwavering positivity, and lofty aspirations for his business. With each passing day, the company's footprint extended beyond Chennai, encompassing the entirety of Tamil Nadu, Kerala, Andhra Pradesh, Telangana, Karnataka, Puducherry, and Goa.

Our Services

At S.V. Engineers, we specialize in the sales and service of industrial air and water application products. Our comprehensive range of offerings includes:

Industrial Air Blowers: From twin lobe roots air blowers to centrifugal blowers, inlet blowers, axial fans, cabinet & circular inline fan blowers, fresh air ventilation blowers, and exhaust blowers, we cater to various industrial applications with precision and reliability.

Industrial Water & Wastewater Plant Equipments: We provide sales and service for all types of water pumps, STP & ETP sludge filter presses, oil skimmers, and aeration air blowers, ensuring the smooth operation of water treatment facilities.

Our Clientele

S.V. Engineers takes pride in its esteemed clientele, comprising leading companies across South India. Our commitment to excellence and customer satisfaction has garnered us a reputation as a trusted partner in the industrial sector.

Present Day: 2024

Fast forward to the present day, and S.V. Engineers operates from a spacious 1000 sq.ft facility located in Velapanchavadi, Chennai. Despite the growth and expansion, our core values remain unchanged – integrity, quality, and customer-centricity.

Join us at S.V. Engineers as we continue to redefine standards and push the boundaries of excellence in the industrial sector. Experience the difference with S.V. Engineers, where innovation meets reliability, and every solution is crafted with care.

#airblowers#aeration system#twin lobe roots blowers#stp blowers#etp blowers#sales & service#tamilnadu chennai#ring blowers#side channel blowers#centrifugal blowers#id fan blowers#inline & inlet bllowers

2 notes

·

View notes

Text

Leading Brands in BLDC Exhaust Fan Technology

Introducing Intellifan: The Pioneering BLDC Exhaust Fan Manufacturer

Intellifan happens to be one of the most talked-about names in the industry related to designing, developing, and manufacturing superior-quality Brushless DC BLDC exhaust fans. Innovation and customer satisfaction are at the heart of this brand, and that is what has made Intellifan stand out as one of the leading BLDC exhaust fan manufacturers for different industries and applications.

The Need for Efficient Exhaust Fans

In today's fast-paced industrial landscape, efficient ventilation systems play a crucial role in maintaining a healthy and safe working environment. Exhaust fans are an essential component of these systems, responsible for removing heat, fumes, and pollutants from the air. However, traditional exhaust fans often fall short in terms of energy efficiency, noise levels, and reliability. This is where Intellifan's BLDC exhaust fans come into the picture, offering a superior alternative to conventional exhaust fan technology.

BLDC exhaust fans

Advantages of the BLDC Technology

Intellifan's BLDC exhaust fans are touted to set new standards in performance, energy efficiency, and reliability. Some key advantages of the technology will be:

Higher Energy Efficiency: BLDC motors use significantly lesser power compared to conventional induction motors. This guarantees huge savings on energy and much reduced operating costs. Quieter Operation: The BLDC fans run at considerably lower noise levels, which makes for a more comfortable working environment and disturbances all minimized or nil. More Reliability: BLDC motors are built to be much more robust, long-lasting, and maintenance-free. Improved Airflow: Intellifan-designed BLDC exhaust fans are intended for superior airflow in the right direction towards proper ventilation and removal of heat. Intellifan Range of BLDC Exhaust Fan Range

Intellifan offers a whole range of BLDC exhaust fans to cope with all sorts of industrial applications falling under different needs and requirements. Our product umbrella includes:

Axial Fans: Axial fans find perfect applications in general ventilation due to their design for high airflow and low pressure. Centrifugal Fans: These are suitable in high-pressure applications. These ensure effective airflow, thus finding application in dust collection systems. Mixed Flow Fans: These fans combine the benefits of both axial and centrifugal fans. They offer a high flow with moderate pressure. Key Features and Benefits

The BLDC exhaust fans by Intellifan come with the following major features and benefits:

Advanced Motor Technology: Our BLDC motors are built with high-quality components, ensuring reliable operation and extended lifespan. Aerodynamically Optimized Design: Intellifan's fans are designed to provide maximum airflow while minimizing energy consumption. Easy Installation and Maintenance: Our fans are designed for easy installation and maintenance, reducing downtime and increasing productivity. Customization Options: Intellifan offers customization options to meet specific industry requirements and application needs. Industry Applications

IntelliFan BLDC exhaust fans can be applied in broad industries such as:

Industrial Manufacturing: Efficient ventilation and extraction of heat are key in the context of industrial manufacturing.

Heating, Ventilation, and Air Conditioning Systems: IntelliFan fans are highly applicable to HVAC systems.

Agricultural Purposes: Our fans apply in agriculture for ventilation and cooling livestock and plants. Commercial and Residential Buildings: Intellifan's fans are used both in commercial and residential buildings to ensure proper ventilation and air circulation.

Why Choose Intellifan?

When it comes time to choose a reliable BLDC exhaust fan manufacturer, Intellifan makes a strong case against the competition. Here are just a few reasons why:

Proven Track Record: Intellifan has a proven track record of high-quality products with exceptional customer service. Only at INTELLIFAN: Because of our commitment to innovation, our products are ahead of the curve with the latest technologies and features for customers. Customer Options Available: For Meeting Industry-Specific Needs and Application Requirements Competitive Pricing: The products offered by Intellifan are competitively priced and offer the customer an economical solution for their ventilation needs.

Conclusion

Intellifan is the pioneering and leading manufacturer of BLDC exhaust fans, true to its commitment of offering quality products and outstanding customer service. Our determination to become innovative, energy-efficient, and reliable has earned us the leading name in the industry. From industrial and commercial to residential, the need for efficient ventilation finds its best solution in Intellifan.

visit:- https://www.bldcfan.in/bldc-exhaust-fan/ Address: 13, Prakash Industrial Estate, Sahibabad Industrial Area Site 4, Sahibabad, Ghaziabad, Uttar Pradesh 201005

3 notes

·

View notes

Text

Glass fiber reinforced plastic negative pressure fan

The FRP negative pressure fan is a new type of ventilation equipment made of anti-corrosion FRP material, which belongs to the axial flow fan, the outer frame of the fan is made of anti-corrosion FRP material. The FRP negative pressure fan is suitable for almost all places that need cooling or ventilation, especially for places with acid and alkali corrosion, high temperature or odour workshops, such as chemical, petroleum, metallurgy, mining, machinery, etc.

0 notes

Text

Cooltron: Best Axial Fans for Efficient Cooling & Ventilation in the USA

Meta Description: Cooltron offers high-performance, energy-efficient axial fans for diverse industrial needs across the USA. Durable, customizable & quiet operation. Contact us for tailored solutions!

Axial fans are a crucial component in heating, ventilation, and air conditioning (HVAC) systems, known for their efficiency in moving large volumes of air with minimal energy consumption. Among the top manufacturers of axial fans, Cooltron stands out for its high-performance products tailored to meet diverse industrial needs. With a strong presence in the U.S., Cooltron's axial fans are designed to serve various applications across all states, from California to New York, and down to Florida, covering counties and cities like Los Angeles, New York City, and Miami.

Features of Cooltron Axial Fans

Cooltron's axial fans are engineered with precision to deliver superior airflow while maintaining low noise levels, making them ideal for environments where quiet operation is essential. These fans are built with durable materials, ensuring longevity and ease of maintenance. Whether it's for cooling systems in data centers, ventilation in commercial buildings, or exhaust systems in industrial settings, Cooltron's axial fans are versatile and efficient.

High-Speed and Energy Efficiency

Cooltron's high-speed axial fans, like the 230V AC model, are housed in die-cast aluminum with thermoplastic blades, providing a robust structure for continuous operation. These fans are designed to maximize airflow while being energy-efficient, making them a cost-effective choice for businesses looking to reduce their energy footprint. With features like long-life dual ball bearings, these fans can run for up to 67,000 hours, ensuring minimal downtime and maintenance costs.

Customization and Compliance

Cooltron offers customization options to meet specific ISO standards by adjusting parameters such as fan speed, noise levels, and material composition. This flexibility ensures that their fans comply with regulatory requirements while delivering increased output, making them suitable for demanding environments like automotive and server applications.

Applications Across the U.S.

Cooltron's axial fans are widely used across various industries in the U.S., including:

Data Centers: In states like California and Texas, where tech hubs are prevalent, Cooltron fans help regulate temperatures to prevent equipment overheating.

Commercial Buildings: In cities like New York City and Chicago, these fans are installed in ducts to ventilate large spaces efficiently.

Industrial Settings: In states like Michigan and Ohio, Cooltron fans are used in exhaust systems to improve air quality and safety.

Why Choose Cooltron?

Cooltron's commitment to quality, reliability, and customer satisfaction makes it a preferred choice among axial fan manufacturers. With years of expertise in designing and manufacturing industrial cooling products, Cooltron ensures that its fans meet the stringent standards required by diverse applications. Whether you're in urban areas like Los Angeles or rural counties in Montana, Cooltron's axial fans are designed to provide efficient airflow solutions tailored to your specific needs.

Cooltron offers reliable and efficient axial fans designed to meet industrial needs across the U.S. Whether you're upgrading your HVAC system in a commercial building or need reliable cooling solutions for industrial equipment, Cooltron's axial fans are the perfect choice. Visit our website at https://www.cooltron.com/ or contact us at [email protected] to learn more today!

0 notes

Text

Efficient cooling solution: A complete analysis of Motexo axial fans

In today's highly automated and equipment-intensive production environment, effective heat management is essential to ensure the stable operation of equipment and extend its service life. As a leading cooling solution provider in the industry, Motexo's axial fans have become the preferred cooling partner for many industries with their excellent performance, diverse product lines, and customized services. This article will explore the technical characteristics, product series, and customization capabilities of Motexo axial fans in-depth, revealing their outstanding performance in heat dissipation.

1. Wide range of size coverage to meet diverse needs

Motexo axial fans have an extensive range of sizes, ranging from compact 200mm to large 2000mm. This comprehensive product line ensures that small electronic devices and large industrial machinery can find a suitable cooling solution. More importantly, these fans are designed for applications with power less than 120kW, so Motexo can provide efficient and economical cooling solutions even in high-load working environments. With such size diversity, Motexo has successfully covered most of the market's ventilation and cooling needs, demonstrating its products' broad applicability and flexibility.

2. Four unique fans to cope with various working conditions

In response to complex and changing working conditions, Motexo has carefully designed four types of axial flow fans, each with its own unique design advantages to adapt to different heat dissipation challenges:

1. **Wing-shaped fan**: The wing-shaped blades designed using aerodynamic principles can effectively increase air volume and pressure and are suitable for occasions requiring a large amount of air circulation.

2. **Incremental arc fan**: This fan's blades adopt a progressive arc design, which can provide smooth airflow while making low noise and is very suitable for noise-sensitive environments.

3. **Sickle fan**: Its unique sickle-shaped blade design enhances wind output and is particularly suitable for application scenarios that require strong ventilation.

4. **Reversible fan**: The bidirectional rotation function allows the wind direction to be adjusted according to actual needs, improving installation flexibility and convenience of use.

The design of these four fans covers almost all possible ventilation and cooling scenarios, reflecting Motexo's deep understanding and precise grasp of market demand.

3. Customized services to meet specific needs

In addition to the standardized product series, Motexo provides highly flexible, customized services. Customers can provide drawings or detailed instructions to customize fan blades, covers, and other key components according to their specific needs. This customization is reflected not only in the size but also in the choice of materials. Motexo supports the use of a variety of materials to manufacture blades, including aluminum alloy (AL), polyamide (PAG), and high-performance engineering plastics (PACAS). Each material has unique performance advantages, such as lightweight and high strength, corrosion resistance, or excellent heat resistance, ensuring the fan can achieve optimal performance in a specific environment.

In summary, Motexo axial fans have become leaders in heat dissipation with their wide range of sizes, targeted fan type design, deep understanding, and rapid response to customer needs. Whether a standard product or a customized solution, Motexo can provide customers with efficient, reliable, and economical options to ensure that various types of equipment operate at the optimal temperature, extend equipment life, and improve production efficiency. In the future, with the continuous advancement of technology and changes in market demand, Motexo will continue to lead the innovation of heat dissipation technology and provide more excellent heat dissipation solutions for global customers.

0 notes

Text

Air Handling Blower

Industrial aeration involves moving air through either a solid or fluid medium bed and is used for various purposes. Depending on specific material being aerated, Canada Blower fans are utilized for moisture control in applications such as grain bin storage, and also provide oxygen and control moisture/temperature in composting applications. Due to varying environmental conditions, fans used in aeration systems often require special construction such as fiberglass, alloys and specialty coatings. The control and containment of air containing a biological hazard is crucial for maintaining a safe environment. An air handling system designed to move such material must be designed to ensure contaminated air does not escape. This can be accomplished with an induced draft fan that will maintain a negative pressure, so that any leaks in a system draw outside atmosphere in, as opposed to allowing the contaminated air out. Biomass and Incineration are two new methods of generating power that utilize renewable biological fuels and refuse as their main fuel source. The process of converting these fuels into an energy source requires the use of specialized boiler system. Issues such as dust loading and corrosion can become major concerns if your system does not utilize the proper fan for exhausting particulate and gas emissions. That is why selecting the right fan is crucial for optimizing the performance and longevity of your overall system. Canada Blower offers a wide range of underfire combustion air fans, overfire air fans and induced draft fans needed to stand up to the harsh operating environments.

Canada Blower is a leading supplier of the main system fans located on the clean side of the industrial process. Canada Blower fans are often selected for this particular application because of their ability to cover a wide performance range and various operating conditions. Forming fans play an integral role for forming products in the nonwoven industry, such as diapers. These fans create the negative pressure in the forming chamber, giving the product its shape. We typically provide our model RBW radial bladed fan with a backplate for this application. The RBW fan is capable of producing high static pressures at medium to low airflows.

Air washers balance the required humidity of the plant air by humidifying the air during the dry seasons and dehumidifying the air when conditions are more humid. This is accomplished by using re-circulated heated or chilled water that is sprayed into the air. Canada Blower fans are used to draw air through these air washer systems and typically provide adjustable pitch axial fans in the range of 2.5" to 4" static pressure. Regardless of the size of your operation and system requirements, Canada Blower is capable of manufacturing virtually any size fan or blower to meet your exact specifications. Air strippers are used on drum filters for removing material build up on the filter. The vacuum nozzles on the filter remove the fiber / particulate which are then disposed of or used for reclaiming the material. The fans used in this particular application require higher pressure at a relatively low airflow along with a radial blade design for handling the material. Because of these factors Canada Blower model ORB ventilator incorporates radial blades with a backplate to prevent long stingy material from collecting around the blower shaft.

Flue gas recirculation is a highly effective technique used for lowering Nitrogen Oxide (NOx) emissions from burners. This is particularly crucial, as NOx is a significant pervasive pollutant that produces a negative array of health and environmental by-products. NOx emission levels can be greatly reduced in industrial boilers by reticulating used flue gases back into the system. This process lowers the peak combustion temperature and drops the percentage of oxygen in the combustion air / gas mixture, delaying the formation of NOx caused by high flame temperatures. Canada Blower offers a wide range of centrifugal blowers specifically designed to be used with FGR systems ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net.

Forced Draft fans purpose is to provide a positive pressure to a system. This basic concept is used in a wide variety of industries but the term FD Fans is most often found in the boiler industry. Fans for boilers force ambient air into the boiler, typically through a preheater to increase overall boiler efficiency. Inlet or outlet dampers are used to control and maintain the system pressure. Typical fan arrangements are 3SI or 3DI which utilize a wheel center hung on the shaft with integral inlet boxes.

1 note

·

View note

Photo

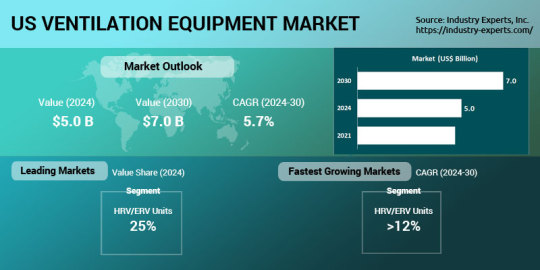

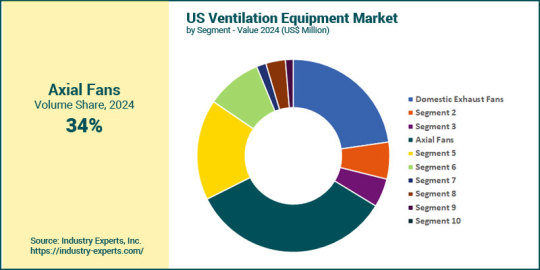

(via Ventilation Equipment Market | Axial Fans, Centrifugal Fans) The market for United States Ventilation Equipment by product segment analyzed in this report include Axial Fans, Centrifugal Fans, Centrifugal Blowers, Tangential/Cross Flow Fans, Domestic Exhaust Fans, Power Roof Ventilators, Range Hoods, Industrial Propeller Fans, Air Handling Units (AHUs) for Ventilation, and Heat Recovery/Energy Recovery Ventilation Units. Shipment value of the United States ventilation equipment is projected to grow by a CAGR of 5.7% over the forecast period, reaching US$7 billion by 2030, attributed mainly to high growth in sales of high valued HRV/ERV Units.

#US Ventilation Equipment Market#ventilation equipment market#Axial Fans#centrifugal fans#centrifugal blowers#Tangential/Cross Flow Fans#Domestic Exhaust Fans#power roof ventilators#range hoods#Industrial Propeller Fans#air handling units#heat recovery ventilation

0 notes

Text

Axial Flow Fan Supplier in Jamshedpur

Axialair Corporation is a trusted Manufacturer and Supplier of Axial Flow Fan in Jamshedpur, India. We are Based in Ahmedabad, Gujarat, India. Axialair Corporation’s Axial Flow Fans are designed to provide efficient and reliable airflow for a wide range of industrial, commercial, and residential applications. These fans work by drawing air through the fan and pushing it in a straight line, making them ideal for environments that require high airflow with low resistance. We engineer our axial flow fans for superior efficiency, reliability, and longevity, making them ideal for high-volume airflow environments. Industries widely use these fans in situations requiring high airflow and low to medium pressure, such as ventilation, cooling, and material handling systems. Features: Durable Construction: Made from corrosion-resistant materials such as galvanized steel or stainless steel, ensuring long-lasting durability even in challenging environments. Energy-Efficient Motors: The energy-saving motors equip the fans to reduce power consumption while maintaining optimal airflow. Quiet Operation: Advanced design technology reduces noise levels, making these fans ideal for use in noise-sensitive environments like offices or residential buildings. Flexible Installation Options: Axial Flow Fans are available in multiple sizes and mounting configurations to suit a variety of installation requirements. Weatherproof Design: We design Axial Flow Fans for outdoor use and equip them with weather-resistant housing to ensure reliable performance in harsh conditions. Application: Industrial Facilities. Ventilation Systems. Warehouse Ventilation. Agricultural Facilities. Laboratories and Clean Rooms. Tunnels and Underground Facilities. Residential Buildings. Restaurants and Kitchens. FAQs: How often should I maintain my Axial Flow Fan? You should perform regular maintenance, such as cleaning the fan blades and inspecting the motor, every 6 to 12 months for optimal performance. Can Axial Flow Fans be used in hazardous environments? Axialair designs explosion-proof models for use in hazardous environments, such as chemical plants or factories with flammable gases. What is the lifespan of an Axial Flow Fan? With proper maintenance and care, Axial Flow Fans typically have a long lifespan, ranging from 10 to 15 years, depending on the model and usage conditions. Axialair Corporation offers Axial Flow Fan Supplier in Jamshedpur, Jharkhand, India Including Tata Steel Industrial Area, Adityapur Industrial Area, Gamharia Industrial Area, Jamshedpur Industrial Area, Ranchi, Bokaro, Jamshedpur, Dhanbad, Giridih, Hazaribagh, Ramgarh, Hazaribagh, Chirkunda, Mango, Chaibasa, Koderma, Sahibganj, Jhumri Telaiya, Jamtara, Dumka, Gumia, Madhupur, Phusro, Chakradharpur. Contact us today for more information or to request a quote. Read the full article

#AdityapurIndustrialArea#AxialFlowFan#AxialFlowFanSupplierinAhmedabad#AxialFlowFanSupplierinGujarat#AxialFlowFanSupplierinIndia#AxialFlowFanSupplierinJamshedpur#AxialFlowFanSupplierinJharkhand#Bokaro#Chaibasa#Chakradharpur#Chirkunda#Dhanbad#Dumka#ExporterofAxialFlowFan#GamhariaIndustrialArea#Giridih#Gumia#Hazaribagh#India#Jamshedpur#JamshedpurIndustrialArea#Jamtara#Jharkhand#JhumriTelaiya#Koderma#Madhupur#Mango#ManufacturerofAxialFlowFan#Phusro#Ramgarh

0 notes

Text

Centrifugal Fan Blower Manufacturers

In industries where proper ventilation and airflow management are crucial, centrifugal fan blowers play a pivotal role. These powerful machines help regulate air circulation, remove dust, and enhance air quality across various applications. As a leading centrifugal fan blower manufacturer, Ventilair India is committed to providing innovative and high-performance solutions that cater to different industrial requirements.

What is a Centrifugal Fan Blower?

A centrifugal fan blower is a mechanical device designed to move air or gas using centrifugal force. The fan consists of an impeller that rotates within a casing, drawing air into the center and then pushing it outward at high velocity. These fans are widely used in industries where efficient ventilation, cooling, and air handling are required.

Types of Centrifugal Fan Blowers

Centrifugal fan blowers come in various designs based on the application requirements. Some common types include:

Forward Curved Blowers: Known for their compact size and high efficiency, these are commonly used in HVAC systems.

Backward Curved Blowers: Designed for high-pressure applications, these fans are energy-efficient and durable.

Radial Blade Blowers: Used in industries requiring dust-laden airflow or high-static pressure applications.

Mixed Flow Blowers: A combination of axial and centrifugal designs, providing a balance between efficiency and performance.

Multi-Vane Blowers: Ideal for applications requiring uniform airflow with moderate pressure.

Website: https://www.ventilair.in/centrifugal-fan-blower-manufacturers/

0 notes

Text

Centrifugal Vacuum Pumps in Industrial Applications: Types, Benefits, and Efficiency

Centrifugal vacuum pumps are integral components in various industrial applications, renowned for their efficiency and reliability in fluid movement and gas compression. These pumps operate on the principle of centrifugal force, converting mechanical energy into hydraulic energy to facilitate the transfer of fluids or gases. This article delves into the types of centrifugal vacuum pumps, their benefits, efficiency considerations, and the pivotal role of centrifugal blowers in industrial settings.

Types of Centrifugal Vacuum Pumps

Centrifugal vacuum pumps are categorized based on their design and operational features. The primary types include:

Single-Stage Centrifugal Pumps: These pumps have one impeller and are suitable for applications requiring low to moderate pressure increases. They are commonly used in water supply systems, irrigation, and low-pressure industrial processes.

Multi-Stage Centrifugal Pumps: Featuring multiple impellers mounted on a single shaft, multi-stage pumps can achieve higher pressures, making them ideal for applications such as boiler feedwater systems, high-pressure cleaning, and certain chemical processing tasks.

Axial Flow Pumps: In these pumps, the fluid flows parallel to the pump shaft. They are designed for high flow rates with low-pressure applications, such as flood dewatering and circulation of large volumes of water.

Radial Flow Pumps: Here, the fluid moves perpendicular to the pump shaft. Radial flow pumps are suitable for applications requiring high pressure with low flow rates, such as in hydraulic systems and certain chemical processes.

Mixed Flow Pumps: Combining features of both axial and radial flow pumps, mixed flow pumps handle medium flow rates and pressures, commonly used in sewage treatment plants and industrial water supply systems.

Benefits of Centrifugal Vacuum Pumps

The widespread adoption of centrifugal vacuum pumps in industrial applications is attributed to several key benefits:

Simplicity and Compact Design: Centrifugal pumps have a straightforward design with fewer moving parts, leading to ease of maintenance and reduced operational complexities.

High Efficiency: These pumps are capable of handling large volumes of fluid with relatively low energy consumption, making them energy-efficient solutions for many industries.

Versatility: Centrifugal vacuum pumps can handle a wide range of fluids, including water, chemicals, and slurries, across various industrial processes.

Continuous Operation: They provide a steady and consistent flow, which is essential for processes requiring uninterrupted fluid movement.

Low Maintenance Requirements: Due to their simple construction and fewer moving components, these pumps typically require less maintenance, resulting in lower downtime and operational costs.

Efficiency Considerations

The efficiency of centrifugal vacuum pumps is influenced by several factors:

Proper Sizing and Selection: Selecting a pump that matches the specific requirements of the application ensures optimal performance and energy efficiency.

Impeller Design: The shape and size of the impeller significantly affect the pump's efficiency. Advanced impeller designs can reduce energy consumption and improve performance.

Operating Conditions: Maintaining the pump within its designed operating parameters, such as flow rate and pressure, prevents energy losses and mechanical stress.

Regular Maintenance: Routine inspection and maintenance of components like seals, bearings, and impellers help sustain efficiency and prolong the pump's lifespan.

Centrifugal Blowers in Industrial Applications

Centrifugal blowers, often working in tandem with centrifugal vacuum pumps, play a crucial role in various industrial processes. They are designed to move air or gases and are essential in applications requiring ventilation, aeration, and cooling.

Key Applications of Centrifugal Blowers:

Ventilation Systems: Centrifugal blowers are used to supply fresh air and exhaust stale or contaminated air in industrial facilities, ensuring a safe and comfortable working environment.

Drying Processes: In industries such as paper manufacturing and food processing, blowers facilitate the removal of moisture from products by providing a consistent airflow.

Cooling Systems: They are employed to dissipate heat from machinery and processes, preventing overheating and maintaining optimal operating temperatures.

Air Pollution Control: Centrifugal blowers assist in controlling air quality by directing polluted air through filtration systems, thereby reducing emissions and environmental impact.

Advantages of Centrifugal Blowers:

High Efficiency: Centrifugal blowers are designed to deliver a high volume of air at low pressures efficiently, making them suitable for various industrial applications.

Robust Construction: Built to withstand harsh industrial environments, these blowers offer durability and long service life.

Versatility: They can handle different types of gases and operate under various conditions, making them adaptable to multiple industrial needs.

Low Noise Operation: Modern centrifugal blowers are engineered to minimize noise levels, contributing to a quieter and safer workplace.

Conclusion

Centrifugal vacuum pumps and blowers are indispensable in the industrial sector, offering efficient solutions for fluid and air handling needs. Their diverse types and designs cater to a wide range of applications, from low-pressure fluid movement to high-pressure industrial processes. The benefits of simplicity, efficiency, versatility, and low maintenance make them preferred choices in various industries. Understanding the specific requirements of each application and selecting the appropriate pump or blower type is crucial for optimizing performance and achieving operational excellence.

0 notes

Text

Gardtec, CAB901 120V UL-Certified Axial AC Ventilation Fan

Enhance Your Indoor Air Quality with the Gardtec CAB901 120V UL-Certified Axial AC Ventilation Fan In today's world, maintaining good indoor air quality is essential for health and comfort. The Gardtec CAB901 120V UL-Certified Axial AC Ventilation Fan offers an effective solution for enhancing air circulation in various environments, from homes to commercial spaces. With its robust design and reliable performance, this fan is engineered to meet the demands of both residential and industrial applications.

Key Features UL-Certified Safety: The CAB901 is UL-certified, ensuring it meets rigorous safety standards. This certification provides peace of mind, knowing that you’re using a product designed with safety and reliability in mind.

Efficient Airflow: Featuring an axial design, the Gardtec CAB901 delivers powerful airflow to ventilate spaces effectively. Its high-efficiency motor ensures optimal performance while minimizing energy consumption, making it an eco-friendly choice.

Versatile Installation: This fan is designed for easy installation in a variety of settings. Whether you need it for an attic, workshop, or commercial area, its compact size allows for flexible placement without compromising on power.

Durable Construction: Built to last, the CAB901 features a rugged construction that can withstand harsh conditions. The fan’s materials are resistant to corrosion, ensuring long-term durability and performance.

Quiet Operation: Noise can be a significant concern with ventilation systems. The CAB901 operates quietly, allowing for effective air circulation without disruptive sounds, making it suitable for both work and living environments.

Applications The Gardtec CAB901 is perfect for a variety of applications, including:

Home Ventilation: Improve air quality in kitchens, bathrooms, and living spaces by enhancing airflow and reducing humidity. Commercial Use: Ideal for warehouses, workshops, and retail spaces where air circulation is crucial for comfort and safety. Industrial Settings: Suitable for factories or processing plants, ensuring that fumes and heat are effectively expelled. Benefits of Using the CAB901 Ventilation Fan Improved Indoor Air Quality: Regular air circulation helps reduce indoor pollutants, allergens, and moisture, creating a healthier environment.

Energy Efficiency: With its high-efficiency motor, the CAB901 helps reduce energy costs while providing powerful ventilation.

Enhanced Comfort: By maintaining optimal temperatures and reducing humidity, this fan contributes to a more comfortable indoor experience.

Cost-Effective Solution: Investing in a quality ventilation fan like the CAB901 can lead to long-term savings on energy bills and maintenance costs.

Conclusion The Gardtec CAB901 120V UL-Certified Axial AC Ventilation Fan is a reliable and efficient solution for improving indoor air quality across a range of environments. With its combination of safety, durability, and performance, this fan is a valuable addition to any space where air circulation is a priority. Elevate your indoor air quality and create a more comfortable living or working environment with the Gardtec CAB901.

#CAB901#VentilationFan#ULCertified#AxialFan#IndoorAirQuality#AirCirculation#EnergyEfficient#HomeImprovement#CommercialVentilation#QuietOperation#DurableFan#EcoFriendly#Gardtec

0 notes

Link

$287.55 $169.50 150KL - Axial extract Fan 150dia Wall/Ceiling 81L/sFID - Domestic Fans - VE150K https://nzdepot.co.nz/product/150kl-axial-extract-fan-150dia-wall-ceiling-81l-sfid-domestic-fans-ve150k/?feed_id=196755&_unique_id=67b3dbbbd77fd Continuous or periodic exhaust ventilation of bathroom, showers, kitchens and other utility spaces. Ventilation shaft mounting or duct connection Low to medium air flow for short distances at low air resistance Classic design and aesthetic look The casing and impeller are made of high-quality durable ABS plastic, UV resistant The clever impeller design makes for high fan efficiency and long service life Insect screen Reliable and low-watt electric motor Designed for continuous operation and requires no maintenance Equipped with overheating protection All fans are single phase, 3 phase readily available HVAC, Fans, Domestic Fans, VE150K, 150KL – Axial extract Fan […] #

0 notes

Text

Rückschlagventile – Zuverlässig & Vielseitig

Rückschlagventile – Zuverlässig & Vielseitig Rückschlagventile verhindern den Rückfluss von Flüssigkeiten oder Gasen und sind in vielen Bereichen unverzichtbar. Sie sind in verschiedenen Größen (DN8 bis DN200) und mit unterschiedlichen Anschlüssen (Flansch, Gewinde, Zwischenflansch) erhältlich. Die Ventile entsprechen den DIN- und ANSI-Normen und sind für vielseitige Anwendungen geeignet.

Hochwertige Materialien & Sichere Dichtungen Gefertigt aus Edelstahl, Messing, Grauguss, Chromstahl, verzinktem Stahl oder Bronze, bieten diese Ventile eine hohe Beständigkeit. Dichtungen aus NBR, EPDM, Viton (FPM/FKM), PTFE oder Metall sorgen für eine zuverlässige Abdichtung und lange Lebensdauer.

Zuverlässige Modelle & GESTRA-Qualität Dank der Zusammenarbeit mit dem renommierten Hersteller GESTRA sind zuverlässige Modelle verfügbar, darunter: ✔ RV108 & RV110 ✔ GESTRA RK76, RK44 & RK86

Muffen-Rückschlagventile – Ideal für Luft, Gas & Wasser Diese Ventile sind kompakt und in Größen von DN8 bis DN100 erhältlich. Sie bestehen aus Edelstahl oder Messing und haben Anschlüsse nach ISO228/1 und NPT. Sie sind korrosionsbeständig und halten Temperaturen von -20 °C bis +150 °C stand. Erhältliche Modelle: RV101 & RV102.

Arten von Rückschlagventilen: 🔹 Rückschlagklappen 🔹 Kugel-Rückflussverhinderer 🔹 GESTRA Rückschlagventile 🔹 Axial-Rückschlagventile 🔹 Fußventile 🔹 Doppel-Rückschlagventile

📌 Jetzt entdecken: Rückschlagventile ansehen ✅

1 note

·

View note