#Cartesianrobotic

Explore tagged Tumblr posts

Text

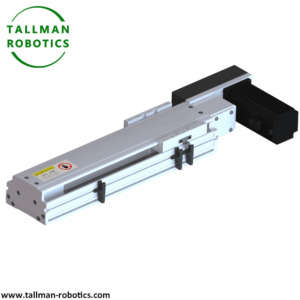

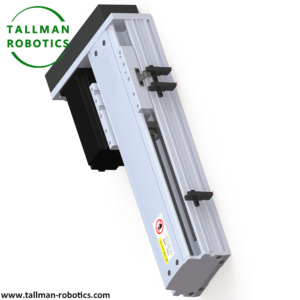

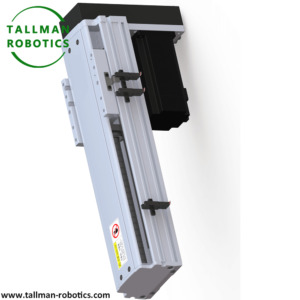

Linear Actuators Robots

Linear Actuators Robots are a pivotal technology in modern robotics due to their versatility, precision, and scalability. They have a broad range of applications in various fields. Here's an overview of how Linear Actuators Robots are integrated into robotic systems and their benefits: Classification and Mechanisms: Types: Linear Actuators Robots can be driven by different mechanisms including screw type, belt drives, and linear motors. Each mechanism offers unique advantages; for instance, screw-based actuators driven by stepping motors are highly suitable for precise positioning but may be underpowered for certain applications requiring servo motors. Motion and Force: These actuators provide both horizontal and vertical motion. They can handle travel distances up to 500 feet and speeds up to 600 inches per second, and manage loads up to 10,000 pounds, making them suitable for a variety of industrial applications. Applications: Manufacturing Automation: Linear Actuators Robots are prominently used in automation for repetitive, tedious, or dangerous tasks. They help in streamlining processes and maintaining high precision and consistency in manufacturing, greatly reducing production costs. Prosthetics: The introduction of micro linear actuators has revolutionized prosthetics, enabling more natural and powerful motions in prosthetic hands. These tiny actuators offer significant strength and precision, essential for driving individual fingers directly. Drones and Aerospace: In drones, actuators are used for functions such as camera gimbals, retractable landing gear, and arms for manipulating objects. They are also incorporated into aerospace applications, such as the International Space Station, demonstrating their reliability and precision in high-stakes environments. In conclusion, Linear Actuators Robots are vital components in the development of robotic systems, offering a broad spectrum of applications from industrial automation to advanced prosthetics and space exploration. Their adaptability, precision, and robustness make them indispensable in advancing robotics technology into the future. Here, we introduce our Screw drive linear modules by model TMS45 semi-closed type for general environment.

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#ActuatorsinCartesianRobot#AutomationandRoboticswithElectricLinearActuator#Cartesianrobotic#Electriclinearactuators#IndustrialRobotslinearactuators#inearActuators#LinearActuator#Linearactuatorrobots#LinearActuatorsforRobotics#LinearMotionandActuatorsforSurgicalRobotics#Linearmotorsingleaxisrobots#LinearMotors&Actuators#Linearrobots#MicroLinearActuators#MultiStationBeltLinearActuator2AxisRobot#PrecisionLinearActuators#RobotActuators#RobotLinearActuators#RoboticArmwithLinearActuators#roboticslinearactuator#SingleAxisRobotLinearActuators#SingleAxisRobots#XYActuator(SingleRail)

0 notes

Text

TOYO Robotics at SEMICON India 2024: Leading the Future of Semiconductor Automation

youtube

TOYO Robotics is proud to showcase our cutting-edge automation solutions at SEMICON India 2024. We connected with industry leaders and demonstrated how our innovations are driving the future of semiconductor manufacturing.

Thank you to all who visited our booth and supported our vision! Please do visit our website www.toyorobotics.co to know more about our product.

#semiconindia#toyorobotics#electricactuator#desktoprobot#cartesianrobot#electricactuatormanufacturer#linearmotor#Youtube

0 notes

Text

YouTube'da "02 Plastik kalıp çalışma short videosu" videosunu izleyin

1 note

·

View note

Text

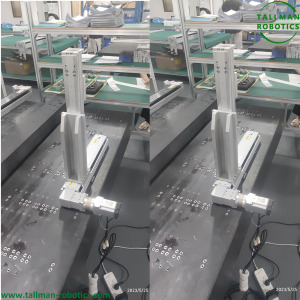

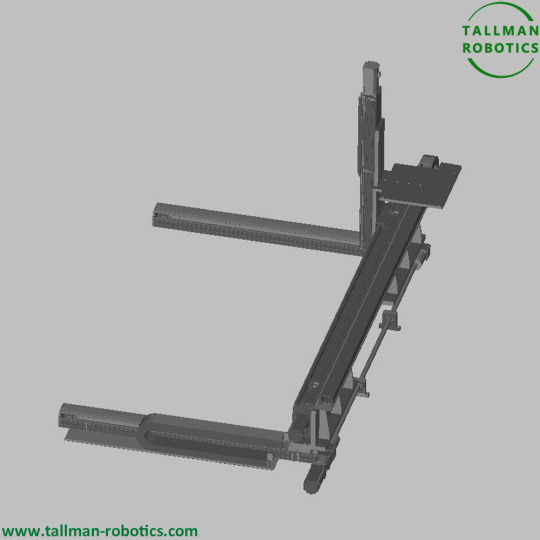

YZ Linear Robot Will Be Delivered to South Africa

A YZ linear robot, also known as a cartesian or gantry robot, moves objects or tools along the vertical (Z-axis) and horizontal (Y-axis) axes. This type of robotic system offers several advantages and applications in various industries due to its precise motion control, high-speed operation, and efficient performance.

https://www.youtube.com/embed/nnG45cxeRvo First, Let’s discuss Key features of YZ linear Actuators: 1. High precision: YZ linear robots are equipped with advanced linear guide systems and encoders, allowing them to achieve precise positioning and repeatability. They can provide accurate and consistent vertical and horizontal motion control, essential for tasks requiring exact positioning. 2. High-speed operation: The linear motion systems in YZ linear robots can be composed of high-performance motors and drives, resulting in fast movements along the Y and Z axes. This speed can be critical in applications where productivity and throughput are important, such as assembly lines and automated testing stations. 3. Scalable and customizable: YZ linear robots can be designed with specified stroke lengths and payload capacities to accommodate various application requirements. This modularity makes them suitable for a wide range of industries and tasks. 4. Easy integration: With the ability to adapt to various workspaces and operations, YZ linear modules can be easily integrated into existing production lines and facilities. They can work in tandem with other robotic systems, such as X-axis linear robots, rotary robots, or even collaborative robots. Secondly, Let’s discuss Applications of YZ linear Actuators: 1. Assembly and pick-and-place: YZ linear robots are ideal for assembly line operations and pick-and-place tasks, such as placing components on printed circuit boards or assembling delicate products. 2. Material handling: These robots can be used for loading and unloading materials in warehouses or transferring products between different stations in a manufacturing plant. 3. Cutting, welding, and gluing: YZ linear robots can carry cutting tools, welding torches, or glue dispensers to perform precise and controlled operations in automated manufacturing processes. 4. Inspection and testing: Equipped with cameras or other testing instruments, YZ linear robots can inspect products for quality control and perform non-destructive testing. 5. Research and laboratory work: In laboratories, YZ linear robots can be utilized for various tasks, such as specimen handling, test tube transfer, or accurate pipetting. In summary, YZ linear Actuators are versatile machines that can bring significant improvements to manufacturing, assembly, and testing processes in various industries. Their precise motion control, high-speed operation, and customizable features make them an essential tool for automation and increase productivity. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#2-axisgantryrobots#CartesianGantryRobots#CartesianRobot#ModularCartesianRobotsSystems#Roboticandpositioningsystemsat#Versatilemulti-axissystems#XYZgantrysystems

0 notes

Text

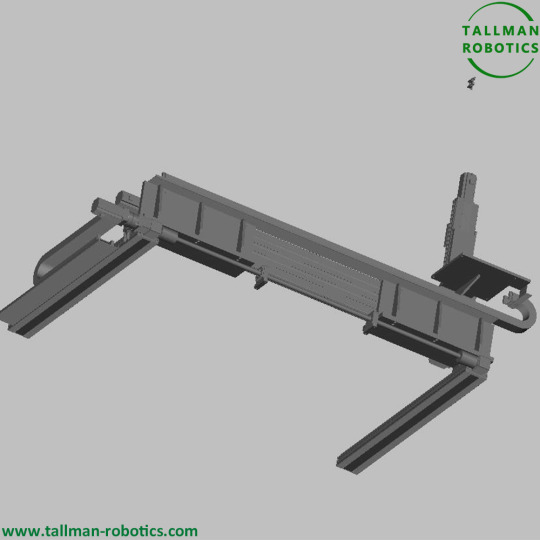

XYZ Cartesian Robots Will Be Ready for Delivery to Germany

XYZ Cartesian Robots from Tallman Robotics Limited will be delivered to Germany.

XYZ Cartesian Robots are automated machines that are used in industry to carry out repetitive tasks. XYZ have three axes of movement and can be programmed to carry out precise, repetitive motions. They are widely used in production, assembly and packaging in many industries. XYZ Gantry Robots,which are motorized robots used for industrial automation and material handling applications. They are usually mounted on a linear rail system and can move, lift, and manipulate loads in a three-dimensional space. Gantry Robots are especially well-suited to applications that require high payloads and repeatable accuracy. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#Cartesianrobotsystem#CartesianRobotSystems#Cartesianrobots#GantryStages#GantrySystems#IndustrialRobots#ModularCartesianRobotsSystems#MultiAxisCartesianRobots#XYGantryStages#XY-ZCartesianRobots#XYZGantry

0 notes

Text

YouTube'da "02 Plastik kalıp çalışma short videosu" videosunu izleyin

1 note

·

View note

Text

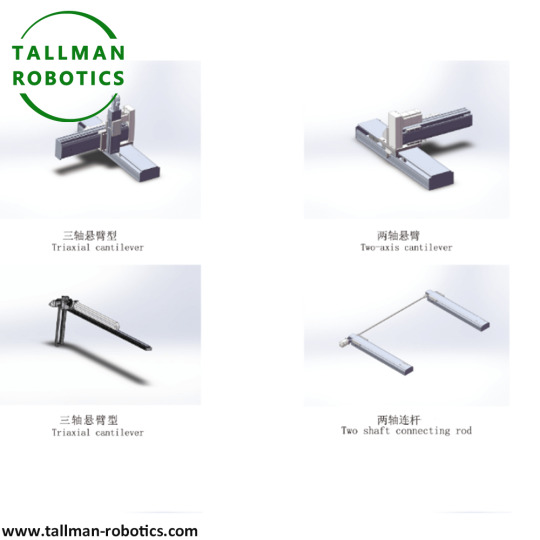

Multi Axis Cartesian Robots

Multi Axis Cartesian Robots refers to the combined application range of XYZ axis cantilever rectangular coordinate manipulator (with or without auxiliary rail). You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

Combination of XYZ axis cantilever rectangular coordinate manipulator of multi axis cartesian robots: Y-axis base is fixed, and X/Z axis moves with Y-axis slide, and the working range is XYZ plane; Z-axis sliding seat is fixed on X-axis sliding seat, and Z-axis body moves up and down; Applicable to XYZ three-dimensional workpiece handling, transfer, walking track and other applications. It is one of the simplest structures for left-right, up and down, forward and backward moving transportation and grasping. Compared with the gantry structure, it is much cheaper. This structure is stable and better. If the effective travel of X axis is too long, it is recommended to build a gantry structure with auxiliary guide rail, auxiliary axis or complete gantry structure. Read the full article

#Cartesianmulti-axissystems#cartesianrobot#CartesianRobotSystems#DoubleHeadGantryRobot#MultiAxisCartesianRobots#Multi-AxisRobotics#PalletizingRobotSystem#TwoGantryRobots#XYCartesianGantrySystems

0 notes

Text

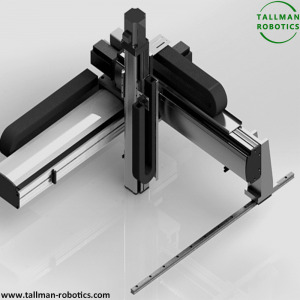

Multi Axis Robots

Multi Axis Robots in our ranges refere to XYZ Three-axis Cantilever Manipulator or Multi axis robotic arm.You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

The Y-axis base is fixed, the Z-axis body is fixed, and the slider moves up and down. The XYZ axis moves with the Y-axis slider to achieve XYZ space movement, in this case, it can be understood as Multi axis robotic arm or Multi Axis Robots. The most commonly used combination structure is suitable for the handling, taking and placing, positioning and other functions of workpieces. Transmission mode: standard type: ball screw transmission (synchronous belt transmission is optional) Maximum load: according to the actual model selection/customized specifications. The most commonly used combination structure is suitable for the handling, taking and placing, positioning and other functions of light loaded workpieces. The cross sliding platform module is a combination of two groups of directly selected sliding platforms in the X and Y directions, which is usually called a right angle robot, a coordinate axis sliding platform, and an XY axis sliding platform. In industry, the X axis is often represented in the horizontal direction, and the other axis is the Y axis. When the midpoint of the X axis coincides with the Y axis, it looks like the Chinese character "cross" in appearance, and the name of the cross slide is derived from this. The working principle of the cross sliding platform module is to fix one group of linear sliding platforms on the sliding blocks of another group of sliding platforms. For example, fix the X axis on the sliding table of the Y axis, so that the slider on the X axis is the moving object, and the Y axis can control the Y direction movement of the slider. Read the full article

#AutomatedGantries#Cartesianmulti-axissystems#CartesianRobot/OrthogonalRobot#Industrialrobots#LinearRobotics#MultiAxesApplicationRobots#Multi-Axis-IndustrialAutomatedRoboticArm#Multi-AxisSystems#RoboticAutomationSolutions

0 notes