#Carbon Steel Valves

Explore tagged Tumblr posts

Text

TIL the DMC-12 of Back to the Future fame had a plastic chassis. What the fuck.

#twinkie talks#my engineering sensibilities were OFFENDED#worse than when I learned our ford ranger hs an ALUMINUM ALLOY HEAD on a CARBON STEEL BLOCK?!#who the fuck approved that???#We only had to have the block replaced because the spark plugs wouldnt FUCKING stay in#and eventually a valve bent and kerfuckled the whole damn thing#yes yes aluminum alloys his aluminum alloys that#IT DOESNT HAVE THE SAME CHARACTERISTICS AS CARBON STEEL ESPECIALLY FROM A HEAT STANDPOINT#THAT SHIT IS GONNA FUCKING WARP#WHICH IS WHAT IT DID#METALLURGY!!!!! AUGGH!!!!!

3 notes

·

View notes

Text

Swing Check Valves in Ahmedabad Gujarat: A Comprehensive Guide

Swing Check Valve in Ahmedabad – In this guide, we explore Swing Check Valves in Gujarat, covering prominent manufacturers, dealers, and types like Carbon Steel Swing Check Valves.

Google Map:--> https://maps.app.goo.gl/pmF6ogWW6EPkpfYq7

Swing Check Valve Manufacturer from Ahmedabad, Swing Check Valve in Ahmedabad, Swing Check Valve in Gujarat, Swing Check Valves in Ahmedabad, Swing Check Valves in Gujarat, Swing Check Valve, Top Swing Check Valve Dealers in Ahmedabad, Popular Swing Check Valve Dealers in Ahmedabad, Carbon Steel Swing Check Valve, Top Swing Check Valve Manufacturers in Ahmedabad, Popular Swing Check Valve Manufacturers in Ahmedabad, www.goldtechnocasting.com/carbon-steel-swing-check-valve-in-ahmedabad.php, Gold Techno Casting

#Swing Check Valve Manufacturer from Ahmedabad#Swing Check Valve in Ahmedabad#Swing Check Valve in Gujarat#Swing Check Valves in Ahmedabad#Swing Check Valves in Gujarat#Swing Check Valve#Top Swing Check Valve Dealers in Ahmedabad#Popular Swing Check Valve Dealers in Ahmedabad#Carbon Steel Swing Check Valve#Top Swing Check Valve Manufacturers in Ahmedabad#Popular Swing Check Valve Manufacturers in Ahmedabad#www.goldtechnocasting.com/carbon-steel-swing-check-valve-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

Exploring the Craft: The Art of Carbon Steel Pipe Manufacturing

Once the molten steel reaches the optimal composition, it is poured into molds to form billets or blooms, which serve as the starting point for Carbon Steel Pipe production. These solidified forms are then meticulously shaped and elongated through a series of processes such as hot rolling, extrusion, or forging, depending on the desired specifications.

0 notes

Text

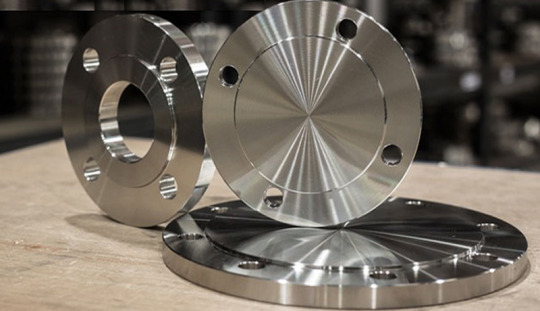

Comprehensive Selection of Carbon Steel Flanges for Industrial Piping Solutions

Explore a diverse range of high-quality Carbon Steel Flanges at SWBM Fittings. Our extensive product category features a variety of flanges, meticulously crafted from robust carbon steel. These flanges are designed to meet the demands of industrial piping applications, ensuring durability, reliability, and optimal performance.

#carbon steel pipe suppliers#cnaf gaskets in dubai#sms food grade pipe fittings#sms food-grade pipe fittings#toho bronze valves suppliers in dubai#marine valves#dubai#construction#pipe fittings#jis marine valves#Carbon Steel Flanges#Steel Flanges#Flanges#Flange#UAE#Dubai#dubailife

0 notes

Text

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering

#DrugFreeSociety#metalgasket

Metallic Gaskets are used for sealing higher temperature and pressure applications, where non-asbestos materials will fail. Typical applications are for heat exchangers, compressors, condensers, pumps, and valves.

Metal gaskets are manufactured from a material such as Soft iron, Low Carbon steel, Stainless Steel, Monel, and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets

here are 3 main classifications of gasket: metallic, semi-metallic and non-metallic.

Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...

Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.

Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces, particularly metal surfaces, have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.

A gasket is a seal that is manufactured to fit between two or more surfaces, such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.

Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel, Copper, Cast Steel, Monel, Inconel, Brass, Bronze, 17-4, among many others. They also can be combined with various rubber products.

Gaskets are normally made from a flat material, a sheet such as paper, rubber, silicone, metal, cork, felt, neoprene, nitrile rubber, fiberglass, polytetrafluoroethylene (otherwise known as PTFE or Teflon) or a plastic polymer (such as polychlorotrifluoroethylene).

A combination of cork and rubber, for example neoprene or nitrile, yields a gasket resistant to solvents, oils, and fuels. Some of the materials used in the formulations and grades include: Cork & Neoprene Blend. Cork & Viton Blend.

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#DrugFreeSociety#metalgasket#Metallic Gaskets are used for sealing higher temperature and pressure applications#where non-asbestos materials will fail. Typical applications are for heat exchangers#compressors#condensers#pumps#and valves.#Metal gaskets are manufactured from a material such as Soft iron#Low Carbon steel#Stainless Steel#Monel#and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets#here are 3 main classifications of gasket: metallic#semi-metallic and non-metallic.#Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...#Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.#Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces#particularly metal surfaces#have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.#A gasket is a seal that is manufactured to fit between two or more surfaces#such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.#Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel#Copper

0 notes

Text

Carbon steel threaded valve. A valve is a mechanical device or a piece of equipment that is used to control, regulate, or direct the flow of fluids, such as gases and water, by partially blocking, closing, or opening various channels. There are many different applications and sectors that use this type of fitting. The most sought-after items utilized by many industries globally are carbon steel valves, which are created from a variety of materials.

0 notes

Text

MS Seamless Pipe at Lowest Price From Best Supplier

Mild Steel (MS) seamless pipes play a crucial role across a variety of industries, owing to their durability, strength, and flexibility. These pipes are widely used in applications such as construction, oil and gas pipelines, structural and mechanical components, and more. If you're seeking MS seamless pipes at the lowest price, Udhhyog is your ideal partner for high-quality, cost-effective industrial steel products.

What are MS Seamless Pipes?

MS seamless pipes are made from mild steel, a low-carbon steel that offers excellent workability and strength. Unlike welded pipes, seamless pipes are produced by extruding the metal to form a hollow tube, ensuring uniformity in structure without any welded seams. This process gives seamless pipes enhanced strength, which makes them ideal for heavy-duty industrial applications.

Key Characteristics of MS Seamless Pipes:

High Strength and Durability: Seamless pipes are known for their ability to withstand high pressure, temperature, and external forces without breaking or leaking.

Uniform Structure: The absence of a weld line provides a consistent thickness and smooth finish, which leads to improved performance.

Corrosion Resistance: Mild steel seamless pipes can be treated with coatings that provide additional protection against corrosion.

Versatility: MS seamless pipes are used in a wide range of industries, from construction and infrastructure projects to power plants and manufacturing facilities.

Why Choose Udhhyog for MS Seamless Pipes?

When it comes to MS seamless pipes, Udhhyog stands out as a trusted supplier, offering premium-quality products at highly competitive prices. Here’s why Udhhyog should be your go-to source for these critical industrial materials:

1. Top-Notch Product Quality

At Udhhyog, quality is never compromised. Our MS seamless pipes are manufactured to meet the highest industrial standards, ensuring exceptional performance and durability. Whether you need pipes for construction, oil and gas applications, or industrial manufacturing, Udhhyog's MS seamless pipes are designed to deliver optimal results in any environment.

2. Lowest Prices in the Market

One of Udhhyog’s key strengths is its ability to offer MS seamless pipes at the lowest prices. We understand that affordability is essential for businesses, especially MSMEs, and our competitive pricing strategy ensures that you get top-quality materials without overextending your budget.

3. Streamlined Procurement Process

At Udhhyog, we believe in simplifying the procurement process for our clients. Through our technology-driven platform, you can browse a wide selection of steel products, including MS seamless pipes, and make purchases with ease. We provide real-time pricing, inventory updates, and flexible payment options, including credit facilities for MSMEs, making the entire process seamless and efficient.

4. A Wide Range of Products

While MS seamless pipes are a key product offering, Udhhyog also specializes in a broad array of steel materials, such as flanges, valves, pipe fittings, and more. This means you can source all your industrial needs from a single, trusted supplier. With Udhhyog, you save time, money, and the hassle of dealing with multiple vendors.

5. Tailored Solutions for MSMEs

As a dedicated B2B platform, Udhhyog understands the unique challenges faced by MSMEs. To help these businesses succeed, we offer tailored solutions, including credit-based procurement and flexible payment plans. This allows smaller companies to access the high-quality materials they need without financial strain.

6. Nationwide Delivery

Wherever your business is located in India, Udhhyog has a robust distribution network that ensures timely delivery of your MS seamless pipes. Whether you're based in a major city or a more remote industrial area, Udhhyog guarantees fast and reliable delivery across the country.

Applications of MS Seamless Pipes

MS seamless pipes are widely used in various industries due to their strength and flexibility. Some of the primary applications include:

Construction and Infrastructure: MS seamless pipes are commonly used in scaffolding, structural frames, and foundation reinforcements for buildings and bridges.

Oil and Gas: Their ability to withstand high pressure and harsh environments makes seamless pipes essential for oil and gas pipelines and drilling operations.

Mechanical and Automotive: These pipes are used in manufacturing machinery, automotive components, and hydraulic systems due to their high strength and resilience.

Power Generation: Seamless pipes are employed in power plants, where high-pressure and high-temperature steam and water need to be transported through reliable piping systems.

Water Treatment and Plumbing: MS seamless pipes are often used in water distribution systems, sewage pipelines, and municipal plumbing due to their durability and corrosion resistance.

Industrial Manufacturing: These pipes are used in manufacturing plants for transporting gases, liquids, and other materials, as well as in the production of mechanical components.

Why Udhhyog is Your Ideal MS Seamless Pipe Supplier

At Udhhyog, customer satisfaction is at the forefront of our business. Our team works closely with clients to understand their requirements and provide the best possible solutions. Whether you’re a small enterprise or a large industrial company, we offer high-quality MS seamless pipes tailored to your needs.

By leveraging advanced technology and maintaining strong relationships with manufacturers, Udhhyog is able to offer superior products at prices that meet the demands of businesses of all sizes. Our online platform makes the purchasing process simple, fast, and transparent, ensuring you get the right products delivered on time, every time.

For all your industrial needs, including MS seamless pipes, trust Udhhyog for a seamless procurement experience. Visit Udhhyog and explore our range of industrial steel products at unbeatable prices today!

#SeamlessPipeSupplier#MildSteelPipes#IndustrialPipes#SteelSuppliers#SteelIndustry#ConstructionMaterials#OilAndGasPipes#PipingSolutions#PipeFittings#SteelProcurement#MSPipe#Udhhyog#B2BSteel#AffordableSteel

2 notes

·

View notes

Text

The Leader C.S Gate Valve Class-800 S/W is a high-performance valve designed for demanding applications. Built to Class-800 specifications, this valve is made from carbon steel and offers robust construction, durability, and reliable operation under high pressure. Ideal for use in various industrial settings, it ensures efficient control of flow with minimal leakage.

2 notes

·

View notes

Text

The Atam CS Butterfly Valve with Stainless Steel Disc Class-125 is a high-performance valve built for durability and corrosion resistance. Featuring a carbon steel (CS) body and stainless steel disc, it ensures efficient flow control in demanding environments. Ideal for use in industrial applications, it offers reliability and long-lasting performance.

#AtamButterflyValve#CSButterflyValve#StainlessSteelDisc#Class125Valve#FlowControl#IndustrialValves#DurableValves#Udhhyog

4 notes

·

View notes

Text

I'm doing a run with a single scientist named Prime who wants to make a clone army of herself. I started her with *most* of the tech necessary to start cloning but I still had to do a lot of research to get accelerated growth vat learning so my clones would be competent at their appropriate tasks right out of the vat. Rn im building the cloning vats (this map has NO DAMN STEEL i think this is the first time i had to buy steel out of necessity) but I already set up this super cool nutrient paste network that feeds into a tap for colonists, a valve that when opened will feed into a machine that automatically produces chemfuel, (just as efficient as a biofuel refinery but takes no labor to function) and will feed into the growth vats for clone and a gene extractor that will automatically extract useful genes from any xenohuman prisoners i get while making escape impossible! This combined with raiding ancient biotechnology labs will let's me divide my clones into castes hyperspecialized for their job.

Eventually I will switch to the cloning from Altered Carbon mod, which requires lots of neutroamine instead of nutrient paste which I'll get from meat from a goeto toad farm.

This version of cloning is faster, let's me grant additional buffs, and let's me transfer and COPY the minds of my colonists, making every clone a true extention of Prime Herself instead of an imitation.

Once I'm done with this playthrough I want to do a vampire run and use xenogenes to make some real messed up thralls, I heard taukai are actually pretty powerful so I'll give my thralls cancer to make them work harder.

2 notes

·

View notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Swing Check Valve in Ahmedabad Gujarat - High Quality Solutions

Discover top-grade Swing Check Valve in Ahmedabad Gujarat. Ensure reliable flow control with our durable and efficient valves. Learn more about our offerings!

Google Map:--> https://maps.app.goo.gl/NNBcNyCLAcYruZ4a6

Swing Check Valve Manufacturer from Ahmedabad, Swing Check Valve in Ahmedabad, Swing Check Valve in Gujarat, Swing Check Valves in Ahmedabad, Swing Check Valves in Gujarat, Swing Check Valve, Top Swing Check Valve Dealers in Ahmedabad, Popular Swing Check Valve Dealers in Ahmedabad, Carbon Steel Swing Check Valve, Top Swing Check Valve Manufacturers in Ahmedabad, Popular Swing Check Valve Manufacturers in Ahmedabad, www.goldtechnocasting.com/carbon-steel-swing-check-valve-in-ahmedabad.php, Gold Techno Casting

#Swing Check Valve Manufacturer from Ahmedabad#Swing Check Valve in Ahmedabad#Swing Check Valve in Gujarat#Swing Check Valves in Ahmedabad#Swing Check Valves in Gujarat#Swing Check Valve#Top Swing Check Valve Dealers in Ahmedabad#Popular Swing Check Valve Dealers in Ahmedabad#Carbon Steel Swing Check Valve#Top Swing Check Valve Manufacturers in Ahmedabad#Popular Swing Check Valve Manufacturers in Ahmedabad#www.goldtechnocasting.com/carbon-steel-swing-check-valve-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

Utilising Carbon Steel Pipe Fittings for Reliable Connections in Industrial Projects

Carbon steel pipe fittings are a reliable choice for many industrial projects due to their ability to withstand pressure, temperature changes and corrosion while being easy to connect to joints and valves.

They have excellent shock and vibration resistance, making them ideal for transporting water or other fluids beneath high roadways.

Quality Carbon steel Pipe Fittings for Reliable Connections in Industrial Projects

When selecting pipe fittings for an industrial project, ensure they are made from top-quality materials - especially carbon steel pipes and fittings.

Carbon steel boasts superior strength to other metals and is generally more durable. Furthermore, it has greater rust and corrosion resistance than some steel types.

Selecting the suitable material is essential when selecting a pipe, as each grade has its characteristics and is tailored for specific uses. Knowing what chemicals or temperatures your pipe must withstand will help determine which steel grade works best for your project.

It is wise to select carbon steel pipe fittings treated for durability and resistance to environmental wear and tear. This could include painting, galvanization or other protective coatings, which could significantly extend their lifespan in the long run.

Durability

Carbon steel pipe fittings are highly reliable and long-lasting in industrial projects. They can withstand extreme temperatures, pressures, and vibrations without corroding or cracking.

They make an ideal transport option for liquids and gases in various industries, from construction to electric power generation. Furthermore, their excellent corrosion resistance makes them suitable for corrosive environments.

However, ensuring the carbon steel pipe fittings you select are made from quality materials is essential. Select them based on specific requirements for your application and guarantee they meet an API or ASTM standard rating.

Additionally, ensure your pipe fittings have been tested for reliability in any environment and can withstand the pressures, temperatures and other environmental conditions they will be exposed to. Doing this helps avoid unnecessary disruptions or even complete system failure when needed.

Cost

If your industrial piping system is exposed to harsh weather conditions and water or chemical corrosion, you must create durable connections that resist rusting, corrosion and leaks. Carbon steel pipe fitting solutions offer a cost-effective way to achieve this goal.

These pipes are more cost-effective than stainless steel or copper yet still offer superior resistance to various environmental elements like high temperatures, chemicals and corrosives.

When installing or replacing the pipe, fittings can make the process smoother. There are various types of fittings, such as elbows, tees, reducers and couplings in multiple styles to meet your requirements.

Conclusion

Our carbon steel pipe fittings offer reliable connections to withstand the strain, no matter the application- from industrial plants to high-pressure pipelines. You have your pick of elbows, equal tees, reducer bushings and more.

Our carbon steel pipe fittings are manufactured with up to 2 per cent carbon content for extra strength and resilience in your piping system. They're perfect for transporting air, water, oil, and steam in low-pressure industrial projects.

4 notes

·

View notes

Text

What Are the Different Types of Carbon Steel Flanges and Their Uses?

When it comes to the world of pipes and fittings, flanges are essential components that often go unnoticed. In this blog, we'll explore the different types of carbon steel flanges and their versatile uses in various industries.

#carbon steel pipe suppliers#pipe fittings#sms food grade pipe fittings#toho bronze valves suppliers in dubai#dubai#construction#marine valves#cnaf gaskets in dubai#sms food-grade pipe fittings#jis marine valves

0 notes

Text

youtube

Bliss Flow Systems proudly represents Basket Strainer, Basket Strainer Supplier in India, Basket Strainer Distributor in India And We are supplier & Distributor of Safety Relief Valve, Rupture Pin Valve, Choke Valve, Rupture Disc, Flame Arrester, Solenoid Valve, Oil Water Analyser in India. Duplex Strainer, and Fabricated Carbon Steel, Stainless Steel, Alloy Steel. Supplied to India, Middle East, Singapore and Malaysia. Get Contact Detail +91 44 79614177.

2 notes

·

View notes

Text

Understanding the Benefits of 321H Stainless Steel Round Bar

If you are looking for a reliable, durable, and corrosion-resistant stainless steel round bar, then the 321H stainless steel round bar is a perfect choice. This type of alloy is composed of 18% chromium, 8% nickel, and 0.08% carbon and is ideal for engineering projects that require high strength at elevated temperatures. Let's look at the benefits of 321H stainless steel round bars.

High Corrosion Resistance

One of the main advantages of using 321H Stainless Steel Round Bars is its superior corrosion resistance compared to other metal alloys. The chromium content in this alloy helps it resist oxidation and other forms of corrosion at elevated temperatures up to 900°C (1650°F). This mixture makes it an ideal material for use in industries operating under high-temperature conditions, such as petrochemical or power generation plants.

Strength and Durability

This alloy's combination of chromium and nickel makes it incredibly strong yet still malleable enough to be used in various engineering applications. It also has excellent creep strength, which means it can withstand extended periods under extreme pressure without becoming deformed or damaged. This property suits it for applications where parts must withstand prolonged exposure to high temperatures, such as engine components, valves, and turbine blades.

Heat Resistance

The heat resistance properties of 321H stainless steel round bars make them ideal for applications that require exposure to extreme heat or corrosive elements, such as jet engines or chemical processing tanks. The 8% nickel content protects against oxidation and other forms of corrosion under these conditions, making this alloy resistant up to 925°C (1700°F).

Conclusion

321H stainless steel round bar offers many advantages over traditional metal alloys, especially when working with extreme heat or corrosive elements. Its superior corrosion, strength, durability, and heat resistance make it an ideal choice for demanding engineering projects requiring high-performance materials capable of withstanding extreme environments. Whether you need parts for a petrochemical plant or a turbine blade component, 321H stainless steel will ensure your project operates safely and efficiently in any environment.

2 notes

·

View notes