#Carbon Molecular sieve nitrogen generation

Explore tagged Tumblr posts

Text

Why Use Carbon Molecular Sieves For Gas Separation?

Want to know what is Carbon Molecular Sieve & Uses of Carbon Molecular Sieves in Different Gas? here, all you need to know Carbon Molecular sieve specifications. CMS is a highly versatile and effective absorbent material. Western Carbon & Chemicals is a leading Carbon Molecular sieves supplier. Visit us!

#Carbon Molecular sieve specification#Carbon Molecular sieves manufacturers in India#Carbon Molecular sieve nitrogen generation#compressed air#Molecular sieve manufacturers in India#Carbon Molecular sieves supplier

0 notes

Text

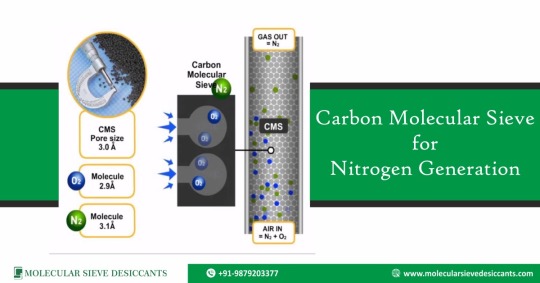

Efficient Nitrogen Generation with Carbon Molecular Sieve | CMS for PSA Process

Experience reliable Nitrogen generation with Carbon Molecular Sieve, efficiently separating Oxygen from compressed air for continuous flow of pure Nitrogen. Learn more about PSA process with CMS technology. Order from the top supplier for reliable and high-quality CMS products today.

For more information

contact us +91 9879203377,

Email us - [email protected]

Website - https://www.molecularsievedesiccants.com/carbon-molecular-sieve

#carbon molecular sieves#CMS#molecular sieves#carbon molecular sieves manufacturers#carbon adsorbent#PSA process for Nitrogen Generation#Nitrogen Generation Process with Carbon Molecular Sieve

0 notes

Text

Efficient PSA Nitrogen Plants by Trimech India

Trimech India specializes in designing and manufacturing PSA nitrogen plants that deliver high-purity nitrogen efficiently and cost-effectively. Our PSA nitrogen generator employs advanced twin-tower technology with Carbon Molecular Sieve (CMS) to separate nitrogen from atmospheric air. With capacities ranging from 5 NM3 to 1000 NM3/Hr, these compact, low-maintenance systems eliminate the need for N2 cylinders, making them ideal for industries like pharmaceuticals, food processing, and electronics. Backed by robust after-sales service, including user training and warranty support, Trimech India ensures reliability and customer satisfaction. Choose us for a sustainable and economical nitrogen generation solution!

0 notes

Text

Designing tiny filters to solve big problems

New Post has been published on https://thedigitalinsider.com/designing-tiny-filters-to-solve-big-problems/

Designing tiny filters to solve big problems

For many industrial processes, the typical way to separate gases, liquids, or ions is with heat, using slight differences in boiling points to purify mixtures. These thermal processes account for roughly 10 percent of the energy use in the United States.

MIT chemical engineer Zachary Smith wants to reduce costs and carbon footprints by replacing these energy-intensive processes with highly efficient filters that can separate gases, liquids, and ions at room temperature.

In his lab at MIT, Smith is designing membranes with tiny pores that can filter tiny molecules based on their size. These membranes could be useful for purifying biogas, capturing carbon dioxide from power plant emissions, or generating hydrogen fuel.

“We’re taking materials that have unique capabilities for separating molecules and ions with precision, and applying them to applications where the current processes are not efficient, and where there’s an enormous carbon footprint,” says Smith, an associate professor of chemical engineering.

Smith and several former students have founded a company called Osmoses that is working toward developing these materials for large-scale use in gas purification. Removing the need for high temperatures in these widespread industrial processes could have a significant impact on energy consumption, potentially reducing it by as much as 90 percent.

“I would love to see a world where we could eliminate thermal separations, and where heat is no longer a problem in creating the things that we need and producing the energy that we need,” Smith says.

Hooked on research

As a high school student, Smith was drawn to engineering but didn’t have many engineering role models. Both of his parents were physicians, and they always encouraged him to work hard in school.

“I grew up without knowing many engineers, and certainly no chemical engineers. But I knew that I really liked seeing how the world worked. I was always fascinated by chemistry and seeing how mathematics helped to explain this area of science,” recalls Smith, who grew up near Harrisburg, Pennsylvania. “Chemical engineering seemed to have all those things built into it, but I really had no idea what it was.”

At Penn State University, Smith worked with a professor named Henry “Hank” Foley on a research project designing carbon-based materials to create a “molecular sieve” for gas separation. Through a time-consuming and iterative layering process, he created a sieve that could purify oxygen and nitrogen from air.

“I kept adding more and more coatings of a special material that I could subsequently carbonize, and eventually I started to get selectivity. In the end, I had made a membrane that could sieve molecules that only differed by 0.18 angstrom in size,” he says. “I got hooked on research at that point, and that’s what led me to do more things in the area of membranes.”

After graduating from college in 2008, Smith pursued graduate studies in chemical engineering at the University of Texas at Austin. There, he continued developing membranes for gas separation, this time using a different class of materials — polymers. By controlling polymer structure, he was able to create films with pores that filter out specific molecules, such as carbon dioxide or other gases.

“Polymers are a type of material that you can actually form into big devices that can integrate into world-class chemical plants. So, it was exciting to see that there was a scalable class of materials that could have a real impact on addressing questions related to CO2 and other energy-efficient separations,” Smith says.

After finishing his PhD, he decided he wanted to learn more chemistry, which led him to a postdoctoral fellowship at the University of California at Berkeley.

“I wanted to learn how to make my own molecules and materials. I wanted to run my own reactions and do it in a more systematic way,” he says.

At Berkeley, he learned how make compounds called metal-organic frameworks (MOFs) — cage-like molecules that have potential applications in gas separation and many other fields. He also realized that while he enjoyed chemistry, he was definitely a chemical engineer at heart.

“I learned a ton when I was there, but I also learned a lot about myself,” he says. “As much as I love chemistry, work with chemists, and advise chemists in my own group, I’m definitely a chemical engineer, really focused on the process and application.”

Solving global problems

While interviewing for faculty jobs, Smith found himself drawn to MIT because of the mindset of the people he met.

“I began to realize not only how talented the faculty and the students were, but the way they thought was very different than other places I had been,” he says. “It wasn’t just about doing something that would move their field a little bit forward. They were actually creating new fields. There was something inspirational about the type of people that ended up at MIT who wanted to solve global problems.”

In his lab at MIT, Smith is now tackling some of those global problems, including water purification, critical element recovery, renewable energy, battery development, and carbon sequestration.

In a close collaboration with Yan Xia, a professor at Stanford University, Smith recently developed gas separation membranes that incorporate a novel type of polymer known as “ladder polymers,” which are currently being scaled for deployment at his startup. Historically, using polymers for gas separation has been limited by a tradeoff between permeability and selectivity — that is, membranes that permit a faster flow of gases through the membrane tend to be less selective, allowing impurities to get through.

Using ladder polymers, which consist of double strands connected by rung-like bonds, the researchers were able to create gas separation membranes that are both highly permeable and very selective. The boost in permeability — a 100- to 1,000-fold improvement over earlier materials — could enable membranes to replace some of the high-energy techniques now used to separate gases, Smith says.

“This allows you to envision large-scale industrial problems solved with miniaturized devices,” he says. “If you can really shrink down the system, then the solutions we’re developing in the lab could easily be applied to big industries like the chemicals industry.”

These developments and others have been part of a number of advancements made by collaborators, students, postdocs, and researchers who are part of Smith’s team.

“I have a great research team of talented and hard-working students and postdocs, and I get to teach on topics that have been instrumental in my own professional career,” Smith says. “MIT has been a playground to explore and learn new things. I am excited for what my team will discover next, and grateful for an opportunity to help solve many important global problems.”

#000#air#applications#battery#biogas#boiling#california#carbon#Carbon dioxide#carbon footprint#Carbon sequestration#career#chemical#Chemical engineering#chemicals#chemistry#Cleaner industry#climate change#CO2#coatings#Collaboration#college#deployment#development#Developments#devices#double#Emissions#energy#energy consumption

0 notes

Text

How energy-efficient are compressed air nitrogen gas generators?

Compressed air nitrogen gas generators are essential for industries requiring a steady and reliable supply of nitrogen. Their energy efficiency is a crucial factor, especially for businesses seeking cost-effective and sustainable solutions. By generating nitrogen on-site, these systems eliminate the need for nitrogen delivery, reduce energy consumption in logistics, and enhance operational efficiency. Here’s a deeper look into their energy efficiency and contributing factors.

Energy Efficiency in Nitrogen Generators

Compressed air nitrogen gas generator typically operate using Pressure Swing Adsorption (PSA) or membrane separation technology. Both processes rely on compressed air as the feed source to produce nitrogen gas, and the energy efficiency of the generator is closely tied to how effectively this compressed air is utilized.

Optimized Air Utilization advanced nitrogen gas generators are designed to maximize the conversion of compressed air into nitrogen. PSA systems, for example, use adsorbent materials like carbon molecular sieves to separate nitrogen from oxygen efficiently. In well-designed systems, up to 80-90% of the compressed air can be converted into usable nitrogen, ensuring minimal wastage.

Energy Savings Compared to Cylinder Supply Producing nitrogen On site medical oxygen generators eliminates the energy-intensive processes associated with traditional nitrogen supply methods. In cylinder or liquid nitrogen delivery, energy is consumed during compression, liquefaction, and transportation. In contrast, on-site generators streamline the process, reducing the overall energy footprint.

Variable Purity Options Compressed air nitrogen gas generators allow users to customize nitrogen purity levels (typically ranging from 95% to 99.999%). Lower purity requirements demand less energy, making the system more efficient for applications that do not need ultra-pure nitrogen.

Reduced Energy Losses Modern nitrogen generators incorporate energy-efficient components, such as low-pressure drop filters and advanced air compressors, to minimize energy losses. Some systems also integrate energy recovery mechanisms to further improve overall efficiency.

Factors Influencing Energy Efficiency

Several factors impact the energy efficiency of compressed air nitrogen gas generators:

Quality of the Air Compressor The air compressor is the primary energy-consuming component in the system. Energy-efficient compressors, such as variable speed drive (VSD) compressors, adjust their output based on demand, reducing energy consumption during low-load periods.

System Design Proper system design, including optimized piping and effective air filtration, ensures minimal pressure drops and maximizes efficiency. Poor design can lead to energy losses and higher operating costs.

Maintenance Practices Regular maintenance, such as replacing filters, cleaning adsorbent beds, and checking for leaks, keeps the generator operating at peak efficiency. Neglecting maintenance can reduce system performance and increase energy consumption.

Environmental Conditions Ambient temperature, humidity, and altitude can influence the efficiency of a nitrogen generator. High humidity, for example, requires additional energy for air drying before compression, affecting the system’s overall energy efficiency.

Environmental and Economic Benefits

The energy efficiency of compressed air nitrogen gas generators translates directly into reduced operational costs and environmental benefits. Lower energy consumption means lower utility bills, while minimizing the carbon footprint of nitrogen production supports sustainability goals. Furthermore, the independence from delivery trucks and packaged nitrogen reduces reliance on fossil fuels, aligning with global environmental standards.

Conclusion

Compressed air nitrogen gas generators are an energy-efficient solution for industries requiring consistent nitrogen supply. By optimizing air utilization, leveraging advanced technology, and adhering to proper maintenance practices, these systems ensure a balance between cost savings and environmental responsibility. For businesses in manufacturing, food processing, pharmaceuticals, and beyond, investing in energy-efficient nitrogen generators can deliver long-term value and sustainability.

0 notes

Text

0 notes

Text

Understanding the Role of Molecular Sieve Oxygen Generator in Gas Separation

In industrial and medical applications, the molecular sieve oxygen generator (MSOG) plays a pivotal role in separating oxygen from air using advanced adsorption techniques. These generators utilize molecular sieves, specifically designed to selectively adsorb nitrogen molecules while allowing oxygen to pass through, thus producing high-purity oxygen gas.

Molecular sieve oxygen generators operate on the principle of pressure swing adsorption (PSA), where compressed air is passed through a bed of molecular sieves. These sieves, typically made of zeolite materials, have uniform pore sizes that trap nitrogen molecules, leaving behind oxygen-enriched gas for various applications.

The MSOG process begins with the compression of ambient air, which is then directed into the PSA unit. Inside the unit, the air passes through multiple layers of molecular sieves, where nitrogen molecules are adsorbed onto the surface of the sieves due to their larger size and higher affinity compared to oxygen molecules. This selective adsorption process allows the oxygen to pass through, resulting in a higher concentration of oxygen in the outgoing stream.

The efficiency of Molecular Sieve Oxygen Generators lies in their ability to continuously regenerate the molecular sieves. This regeneration process involves depressurizing the adsorption bed, which releases the trapped nitrogen molecules and prepares the sieves for the next cycle of oxygen production. This cyclic process ensures a steady supply of high-purity oxygen gas suitable for medical treatments, industrial processes, and specialized applications like underwater welding and cutting.

Applications of Molecular Sieve Oxygen Generators

Medical Use: In healthcare settings, MSOGs provide a reliable source of medical-grade oxygen for patients requiring respiratory support, anesthesia, and emergency treatments. The high purity of oxygen produced ensures safety and efficacy in medical applications.

Industrial Processes: Industries utilize molecular sieve oxygen generators for various applications such as metal fabrication, glass manufacturing, and wastewater treatment. Oxygen-enriched air enhances combustion processes, improves efficiency in chemical reactions, and supports environmental control measures.

Aquaculture and Environmental Remediation: MSOGs contribute to aquaculture by enriching water bodies with oxygen, which is crucial for fish farming and maintaining aquatic ecosystems. They also aid in environmental remediation efforts by supporting oxidation processes that neutralize pollutants in soil and water.

Military and Aerospace: In military and aerospace applications, molecular sieve oxygen generators provide oxygen supply solutions for aircraft, submarines, and enclosed environments where conventional oxygen cylinders may not be feasible.

Emergency Response: During disasters and emergencies, MSOGs serve as essential equipment for providing oxygen to victims and responders in remote or inaccessible locations, ensuring rapid medical assistance and support.

Benefits of Molecular Sieve Oxygen Generators

Cost-Effective: Compared to traditional methods of oxygen supply, MSOGs offer lower operational costs and reduced reliance on external oxygen suppliers.

Continuous Operation: The cyclic adsorption and regeneration process allows for uninterrupted production of oxygen, meeting continuous demand without downtime.

Compact and Portable: Modern molecular sieve oxygen generators are designed to be compact and portable, making them suitable for mobile medical units, disaster response teams, and remote industrial sites.

Environmental Friendly: The production of oxygen through PSA technology is energy-efficient and environmentally friendly, minimizing carbon footprint and resource consumption.

In conclusion, molecular sieve oxygen generators represent a significant advancement in gas separation technology, offering reliable, high-purity oxygen for diverse applications ranging from medical treatments to industrial processes and environmental management. Their efficiency, reliability, and versatility make them indispensable in modern healthcare, industry, and emergency response scenarios, ensuring safe and sustainable oxygen supply solutions.

1 note

·

View note

Text

What is a PSA Nitrogen Gas Plant?

A PSA Nitrogen Gas Plant(Pressure Swing Adsorption) is an industrial system that generates nitrogen gas using the pressure swing adsorption process. Here are some key points to know about PSA nitrogen gas plants:

Principle: PSA technology uses two beds of carbon molecular sieves to separate nitrogen from atmospheric air.

Process: Air is compressed and passed through one bed, adsorbing oxygen and moisture, while nitrogen is released. The process then switches to the second bed, regenerating the first bed.

Benefits: PSA nitrogen gas plants offer a reliable, cost-effective, and energy-efficient way to produce high-purity nitrogen gas.

Applications: PSA nitrogen plants are used in various industries, including:

Food packaging and processing

Laser cutting and welding

Pharmaceutical manufacturing

Chemical processing

Laboratory research

Capacity: PSA plants come in various sizes, ranging from small units to large industrial systems.

Purity: PSA plants can produce nitrogen gas with purity levels up to 99.999%.

Advantages: On-site nitrogen generation, reduced reliance on cylinders, and low operating costs make PSA plants an attractive option.

For More Information –

. Contact Us - 8126173604

. Email Id - [email protected]

. Address - 493, Devlok Colony, Swarg Ashram Road, Hapur - 245101, Uttar Pradesh, India

#PSA Nitrogen Gas plant#PSA Nitrogen Gas Manufacturer#PSA Nitrogen Gas Supplier#PSA Nitrogen Gas Exporter

0 notes

Text

The Role of Nitrogen in 3D Metal Printing

In the rapidly evolving world of additive manufacturing, particularly 3D metal printing, the choice of gases used during the process can significantly impact the quality and efficiency of printed products. Among these gases, nitrogen plays a crucial role. This blog explores the benefits of using PSA Nitrogen Generator in 3D metal printing, highlighting how they enhance the printing process and improve the final product quality.

Understanding 3D Metal Printing

3D metal printing also referred to as metal AM or direct metal laser sintering, is the process of creating metal parts using a digital 3D model where the metal components are printed in a layer-by-layer format. This method is especially popular in aerospace, automotive, and healthcare industries because it can create intricate shapes that are otherwise difficult to manufacture using conventional processes. Central to the process are the shielding gases that maintain the atmosphere free from oxygen, which would otherwise compromise the quality of the metal used in the process.

The Importance of Nitrogen in 3D Metal Printing

Nitrogen, an inert gas, is commonly used in 3D metal printing for several reasons:

1. Oxidation Prevention: When it comes to printing, they use metal powder or filament that undergoes high temperatures. Nitrogen has the property of rendering an atmosphere non-reactive and thereby shields the metal from oxygen. This is important for supporting the microarchitectural structure and quality of the printed part.

2. Cost-Effectiveness: The cost of nitrogen, compared with other inert gases such as argon, is relatively cheaper. This makes it a popular option, especially if large amounts of gas are needed, as might be the case with industrial applications.

3. Availability: Nitrogen is relatively cheap, easily availed since it is found in large quantities in the air and the use of nitrogen generators makes its production easier.

Benefits of Using Nitrogen Generator in 3D Printing

Nitrogen generators offer several advantages for 3D metal printing operations:

1. Continuous Supply: Nitrogen generator ensure a continuous and reliable supply of nitrogen. This is crucial for uninterrupted printing operations, especially for large-scale industrial applications.

2. Cost Savings: By generating nitrogen on-site, companies can reduce the costs associated with purchasing and transporting gas cylinders. This also eliminates rental fees for gas storage tanks.

3. Purity Control: On-site nitrogen generators allow for control over the purity levels of the gas. This is essential in 3D printing, where even slight impurities can affect the quality of the final product.

4. Environmental Benefits: Generating nitrogen on-site reduces the carbon footprint associated with the transportation and handling of gas cylinders. It also minimizes the waste associated with empty gas cylinders.

5. Safety and Convenience: On-site generation reduces the risks associated with storing and handling high-pressure gas cylinders. It also simplifies logistics, as there's no need to manage deliveries and storage of large gas quantities.

How Nitrogen Generators Work

Nitrogen generator typically use one of two technologies: Pressure Swing Adsorption (PSA) or Membrane Separation.

- PSA Technology: This method involves passing compressed air through a vessel containing a carbon molecular sieve. The sieve adsorbs oxygen, allowing nitrogen to pass through. The result is high-purity nitrogen suitable for 3D printing applications.

- Membrane Separation: In this method, compressed air is passed through a membrane that selectively permeates oxygen, leaving behind nitrogen. This method is simpler and often used for applications requiring lower nitrogen purity.

Get in touch with Absstem!

Get in touch with Absstem today for reliable and cost-effective nitrogen generators, ensuring a continuous supply of high-purity nitrogen for your 3D printing needs. Contact us now!

Conclusion

It is thus paramount to understand how to use nitrogen in 3D metal printing to come up with parts made of metal with precision. Printing requires an inert environment; the nitrogen generators provide this efficiently and economically without any side effect to the environment. By using nitrogen production in-house, 3D printing organizations can remove worries regarding the availability of supplies and ways, decrease total costs, and enhance the results of using 3D printing techniques. Therefore, nitrogen generators’ application in supporting such cutting-edge technology as additive manufacturing will continue to rise in the future due to increased use of the technology.

0 notes

Text

oxygen generator for hospital

oxygen generator for hospital

Medical Oxygen Generators: A Lifeline in Modern Healthcare

In the realm of healthcare, oxygen therapy is a cornerstone treatment for patients with respiratory conditions, critical illnesses, and during surgical procedures. Medical oxygen generators have emerged as vital devices that ensure a steady, reliable supply of oxygen. These generators, also known as oxygen concentrators, have revolutionized patient care by offering an efficient and cost-effective solution to traditional oxygen supply methods.

Understanding Medical Oxygen Generators

Medical oxygen generators are devices designed to extract oxygen from ambient air and deliver it in a concentrated form. Ambient air comprises approximately 21% oxygen, 78% nitrogen, and 1% other gases. Oxygen generators use a process called Pressure Swing Adsorption (PSA) or, less commonly, membrane technology to separate oxygen from nitrogen and other gases. The result is a high concentration of oxygen, typically around 90-95%, which is then delivered to patients in need.

How They Work

1. **Air Intake**: The generator draws in ambient air.

2. **Filtration**: The air passes through filters to remove dust, bacteria, and other particulates.

3. **Compression**: The filtered air is compressed and directed into one of two molecular sieve beds.

4. **Oxygen Concentration**: The molecular sieve beds contain a material called Zeolite that absorbs nitrogen when under pressure, allowing oxygen to pass through.

5. **Delivery**: The concentrated oxygen is then collected in a storage tank and delivered to the patient through a mask or nasal cannula.

6. **Regeneration**: The generator switches to the second sieve bed, allowing the first to release the trapped nitrogen and regenerate for the next cycle.

Advantages of Medical Oxygen Generators

1. **Continuous Supply**: Unlike traditional oxygen tanks that need frequent refilling, oxygen generators provide a continuous supply of oxygen as long as they have access to power and air.

2. **Cost-Effective**: Over time, oxygen generators can be more cost-effective than purchasing and refilling oxygen cylinders.

3. **Portability**: Modern portable oxygen concentrators allow patients to maintain their mobility and independence, improving their quality of life.

4. **Safety**: Eliminating the need for high-pressure oxygen cylinders reduces the risk of accidents associated with handling and storage.

5. **Environmental Impact**: Reduced reliance on oxygen cylinders means fewer resources are spent on manufacturing, transporting, and disposing of these cylinders, leading to a smaller carbon footprint.

Applications in Healthcare

- **Chronic Obstructive Pulmonary Disease (COPD)**: Patients with COPD often require long-term oxygen therapy to manage their symptoms and improve their quality of life.

- **Surgery and Recovery**: Oxygen generators are essential in surgical settings to ensure patients receive adequate oxygen during and after procedures.

- **Emergency Medicine**: In emergency rooms and ambulances, oxygen generators provide critical support to patients experiencing acute respiratory distress.

- **Home Healthcare**: Many patients require oxygen therapy at home, and portable oxygen concentrators have made this more feasible and convenient.

Challenges and Considerations

While medical oxygen generators offer numerous benefits, there are challenges and considerations to keep in mind:

- **Initial Cost**: The upfront cost of purchasing an oxygen generator can be significant, although it pays off over time.

- **Power Dependency**: These devices require a constant power source, which can be a limitation in areas with unreliable electricity.

- **Maintenance**: Regular maintenance is necessary to ensure the device functions correctly and safely.

- **Training**: Healthcare providers and patients need proper training to use oxygen generators effectively.

The Future of Medical Oxygen Generators

The development of medical oxygen generators is advancing rapidly, with ongoing improvements in efficiency, portability, and ease of use. Innovations such as battery-operated portable units and smarter, automated systems are making oxygen therapy more accessible and user-friendly. As technology continues to evolve, we can expect these devices to become even more integral to patient care, providing a lifeline to those in need.

Conclusion

Medical oxygen generators have transformed the landscape of oxygen therapy, offering a reliable, cost-effective, and safe solution for patients across various healthcare settings. As we continue to innovate and improve these devices, they will undoubtedly play an even more crucial role in ensuring patients receive the life-sustaining oxygen they need, whenever and wherever they need it.

0 notes

Text

Next-Level Efficiency: The Rise of Mobile Nitrogen Generators in the Netherlands

Streamlining Operations with Mobile PSA Nitrogen Generators

In an era where flexibility and efficiency are paramount, industries across the Netherlands are increasingly turning to innovative solutions like mobile nitrogen generators to meet their operational needs. This move towards mobile systems highlights a significant shift in how industries approach resource management and process optimization. Mobile PSA nitrogen generators represent the forefront of this innovation, offering unmatched versatility and efficiency. This article explores the advantages and applications of these mobile systems in various sectors.

The Advantages of Going Mobile

The introduction of mobile nitrogen generators in the Netherlands has revolutionized the way businesses manage their nitrogen supply. Unlike stationary units, these mobile solutions offer the flexibility to be used across different sites or moved within a large facility, depending on the immediate needs. This mobility is particularly beneficial for industries like oil and gas, where operations are often remote and change locations based on exploratory results.

Mobile PSA nitrogen generators use Pressure Swing Adsorption (PSA) technology to produce high-purity nitrogen directly on-site. This technology is not only effective but also space-efficient, making it ideal for mobile applications. The PSA process involves molecular sieves that adsorb impurities at high pressure, then swing to low pressure to release nitrogen at desired purity levels—efficiently delivering continuous flow nitrogen on demand.

Cost Efficiency and Environmental Impact

One of the key benefits of mobile nitrogen generators is their cost-effectiveness. By generating nitrogen on-the-go, companies can significantly reduce the logistical costs associated with nitrogen delivery in cylinders or tanks. This reduction in transport not only cuts costs but also lowers the carbon footprint of operations, aligning with global sustainability goals.

Moreover, mobile PSA nitrogen generators minimize the risk of nitrogen loss that can occur during cylinder exchange and transport, ensuring more efficient use of resources. This efficiency is not only economically advantageous but also environmentally responsible, providing industries with a powerful tool to meet both their financial and ecological targets.

Versatility Across Industries

The versatility of mobile nitrogen generators extends across various sectors. In the construction industry, for instance, nitrogen is used to ensure the stability and safety of pneumatic systems. Mobile nitrogen generators can be easily transported to construction sites, providing a reliable nitrogen supply for machinery and equipment maintenance.

In the event sector, where setting up temporary installations like beer taps and food preservation systems often requires nitrogen, mobile PSA nitrogen generators offer a quick and reliable solution. These generators can be set up temporarily for events and removed once the need subsides, showcasing their adaptability and ease of use.

Innovative Features and Customization

Today's mobile nitrogen generators are equipped with advanced features that enhance their usability and performance. Many models include touchscreen controls, remote monitoring capabilities, and automated systems that adjust nitrogen purity and flow rate according to real-time demand. Additionally, manufacturers offer customization options to cater to specific industry needs, whether it involves adjusting the generator's size, mobility, or output specifications.

Conclusion: Besseling Group Leading the Way

As industries throughout the Netherlands embrace more agile and cost-effective solutions, the role of mobile nitrogen generators becomes increasingly essential. Leading this shift is Besseling Group, whose expertise in manufacturing state-of-the-art mobile PSA nitrogen generators ensures that businesses can achieve optimal efficiency and productivity. With a focus on innovation, customer satisfaction, and environmental responsibility, Besseling Group continues to support industries in their journey towards more dynamic and sustainable operations.

0 notes

Text

Generate High-Quality Nitrogen with Carbon Molecular Sieve - PSA Process

Efficiently generate nitrogen gas with the help of Carbon Molecular Sieve (CMS) through the Pressure Swing Adsorption (PSA) process. Purify compressed air by adsorbing oxygen molecules, resulting in a continuous flow of pure nitrogen for various industrial and commercial applications.

For more information

contact us +91 9879203377,

Email us - [email protected]

Website - https://www.molecularsievedesiccants.com/carbon-molecular-sieve

#carbon molecular sieves#CMS#molecular sieves#carbon molecular sieves manufacturers#carbon adsorbent#PSA process for Nitrogen Generation#Nitrogen Generation Process with Carbon Molecular Sieve

0 notes

Text

Nitrogen Gas Plant Manufacturers in India

PSA Nitrogen Gas Plant Manufacturer in India, the workhorse of countless industrial processes, plays a vital role in applications ranging from food preservation to creating cutting-edge electronics. For businesses requiring a steady.

Cost-effective nitrogen supply, Pressure Swing Adsorption (PSA) Nitrogen Gas Plants SA Nitrogen Gas Plant manufacturers offer a compelling solution. This blog delves into the world of Indian PSA Nitrogen Plant Manufacturer in Gujarat, with a special focus on Inertech Projects Pvt Ltd, a trusted name in the industry.

What is a PSA Nitrogen Gas Plant?

A Pressure Swing Adsorption (PSA) Nitrogen Gas Plant Supplier in India is a system that separates nitrogen gas from compressed air. This separation is achieved through a process called pressure swing adsorption (PSA), where a carbon molecular sieve (CMS) selectively adsorbs other gases like oxygen and carbon dioxide, allowing pure nitrogen to pass through.

Benefits of PSA Nitrogen Gas Plants:

Cost Savings: Eliminates the need for purchasing and transporting nitrogen cylinders or liquid nitrogen, leading to significant cost reductions.

Convenience: Ensures a continuous and reliable on-site supply of nitrogen gas, eliminating the risk of running out during critical operations.

Flexibility: PSA plants can be customized to meet specific nitrogen purity and flow rate requirements, catering to diverse industrial applications.

Environmentally Friendly: Reduces carbon footprint by eliminating the need for nitrogen transportation and associated emissions.

Why Choose a PSA Nitrogen Gas Plant Manufacturer in India?

India's growing industrial sector has fueled the demand for reliable and cost-effective nitrogen generation solutions and Nitrogen Gas Plant Manufacturers in India. Here's why choosing a domestic PSA Nitrogen Gas Plant manufacturer can be advantageous:

Cost Competitiveness: Indian manufacturers often offer competitive pricing compared to international counterparts.

Shorter Lead Times: Reduced geographical distance translates to faster delivery and installation times.

After-Sales Support: Easier access to local after-sales support and maintenance services.

Understanding of Local Regulations: Indian manufacturers are well-versed in domestic regulations and safety standards pertaining to pressure vessels and gas handling equipment.

Finding the Right PSA Nitrogen Gas Plant Manufacturer & Supplier

Selecting the ideal PSA Nitrogen Gas Plant manufacturer and supplier requires careful consideration. Here are some key factors to evaluate:

Manufacturer Reputation: Research the manufacturer's experience, track record, and customer testimonials.

Product Range and Customization Options: Ensure they offer a variety of plant capacities and can customize the system to meet your specific needs.

Quality Certifications: Verify compliance with relevant quality standards like ISO 9001 for quality management systems.

After-Sales Service: Evaluate the availability and responsiveness of their after-sales service network.

Warranty: Compare warranty terms offered by different manufacturers.

Features and Specifications of PSA Nitrogen Gas Plants

PSA Nitrogen Gas Plants come in various configurations with distinct features and specifications. Here's a breakdown of some key aspects to consider:

Capacity: Measured in Standard Cubic Meters per Hour (SCM/Hr), it determines the amount of nitrogen gas the plant can produce in an hour.

Purity: Expressed as a percentage (%), it indicates the concentration of nitrogen in the generated gas. Typical purity levels range from 95% to 99.999%.

Feed Air Pressure: The required pressure of compressed air fed into the PSA system.

Power Consumption: The amount of electricity needed to operate the plant.

Control System: The level of automation and control offered by the system.

Footprint: The physical space required for installation.

Additionally, consider these aspects:

Turnkey Solutions: Whether the manufacturer offers complete solutions encompassing design, manufacturing, installation, and commissioning.

Safety Features: The safety measures incorporated into the plant design to ensure safe operation.

Environmental Considerations: The plant's impact on the environment, including noise levels and waste disposal.

By carefully considering these factors, you can choose a PSA Nitrogen Gas Plant manufacturer and supplier that best meets your specific requirements and budget.

Choosing the ideal PSA Nitrogen Gas Plant Manufacturer, Supplier, Dealer, Wholesaler, Distributor, Exporter, and Trader requires a discerning eye. Here are some key aspects to evaluate before making a decision, beyond the qualities offered by Inertech Projects Pvt Ltd:

Inertech Projects Pvt Ltd stands out as a prominent manufacturer of PSA Nitrogen Gas Plants in India. Renowned for their quality, reliability, and customer focus, Inertech offers a comprehensive range of PSA plants to cater to diverse industrial needs. Here's what sets them apart.

Conclusion

PSA Nitrogen Gas Plants offer a cost-effective and reliable solution for on-site nitrogen generation. Choosing a reputable Indian manufacturer provides several advantages. By thoroughly evaluating potential partners and understanding the features and specifications, you can ensure a successful implementation of a PSA Nitrogen Gas Plant that fulfills your industrial nitrogen needs.

#PSA Nitrogen Gas Plant Manufacturer in India#Nitrogen Gas Plant Manufacturers in India#Nitrogen Gas Plant Supplier in India#Nitrogen Plant Manufacturer in Gujarat

0 notes

Text

Carbon Molecular Sieve Nitrogen Generation | Medaad.com

Create a reliable nitrogen supply with Medaad.com's Carbon Molecular Sieve Nitrogen Generation! Our USP ensures superior quality, reliability and cost-effectiveness so you can trust us to provide the best nitrogen for your needs.

Carbon Molecular Sieve Nitrogen Generation

0 notes

Text

The Technology Behind PSA Medical Oxygen Generator: How Do They Work?

In today's world, access to medical-grade oxygen is more crucial than ever, especially in global health crises. Pressure Swing Adsorption (PSA) technology has revolutionized medical oxygen production, offering a reliable and efficient solution to meet the escalating demand. This comprehensive guide delves into the intricate workings of PSA Medical Oxygen Generators, shedding light on their functionality, benefits, and significance in the healthcare landscape.

PSA Medical Oxygen Generators are advanced systems designed to extract oxygen from ambient air, purify it to medical-grade standards, and deliver it for various healthcare applications. This innovative technology operates on the adsorption principle, utilizing specialized molecular sieves to separate oxygen molecules from other gases in the air.

At the heart of a PSA Medical Oxygen Generator lies a bed of adsorbent material, typically zeolite or activated carbon, housed within a pressure vessel. The process begins with the compression of ambient air, which is then directed into the adsorption chamber. The adsorbent material selectively captures nitrogen and other impurities within this chamber, allowing purified oxygen to pass through.

The adsorption process occurs in cycles, commonly known as "pressure swing adsorption." During adsorption, the adsorbent material retains nitrogen and other gases under high pressure, while oxygen is collected as the product gas. Subsequently, the pressure in the chamber is reduced, causing the adsorbent material to release the captured gases, which are then vented out of the system. This cyclical process ensures a continuous supply of medical-grade oxygen without needing external storage or replenishment.

Advantages of PSA Medical Oxygen Generators:

On-Site Production: One of the most significant advantages of PSA Medical Oxygen Generators is their ability to produce oxygen on-site, eliminating the logistical challenges associated with transportation and storage. This ensures a reliable and uninterrupted oxygen supply, particularly in remote or underserved areas.

Cost-Efficiency: on site Medical oxygen manufacturers offer substantial cost savings over time by eliminating the need for traditional oxygen cylinders or bulk liquid oxygen supplies. Healthcare facilities can significantly reduce operational expenses associated with procurement, storage, and transportation, making it a financially viable solution in the long run.

Enhanced Safety: With on-site production and minimal handling requirements, PSA Medical Oxygen Generators enhance safety standards within healthcare facilities. The risk of accidents or mishaps during oxygen storage, handling, and transportation is significantly mitigated, ensuring the well-being of patients and healthcare professionals alike.

Environmental Sustainability: Unlike traditional oxygen production methods that rely on energy-intensive processes, PSA Medical Oxygen Generators operate efficiently and consume minimal resources. By leveraging ambient air as the source of oxygen, these systems promote environmental sustainability by reducing carbon emissions and energy consumption.

Applications and Impact in Healthcare:

PSA Medical Oxygen Generators find widespread applications across various healthcare settings, including hospitals, clinics, emergency medical services, and homecare environments. These systems cater to diverse medical needs, including respiratory therapy, anaesthesia, intensive care, and surgical procedures.

The impact of PSA Medical Oxygen Generators extends far beyond conventional healthcare settings, particularly in regions facing resource constraints or emergencies. During crises such as pandemics or natural disasters, these systems are critical in augmenting healthcare infrastucture and ensuring timely access to life-saving oxygen therapy.

Key Considerations for Healthcare Facilities:

When considering the implementation of PSA Medical Oxygen Generators, healthcare facilities should prioritize several factors to optimize performance and reliability:

Capacity and Scalability: Assessing the oxygen demand and scalability requirements is essential to selecting a PSA Medical Oxygen Generator that aligns with the facility's needs and anticipated growth.

Compliance and Certification: Ensure the chosen system complies with regulatory standards and certifications governing medical oxygen production and delivery, including ISO 13485 and FDA guidelines.

Maintenance and Service Support: Establish a comprehensive maintenance schedule and access to prompt service support to ensure the continuous operation and performance of the PSA Medical Oxygen Generator.

Training and Education: To maximize efficiency and minimize risks, provide adequate training to healthcare personnel involved in the operation, maintenance, and safety protocols associated with PSA Medical Oxygen Generators.

Conclusion:

In modern healthcare, PSA Medical Oxygen Generators are a testament to innovation and ingenuity, offering a sustainable and reliable solution to meet the growing demand for medical-grade oxygen. As trusted medical oxygen plant manufacturers, Trident Pneumatics remains committed to advancing healthcare infrastructure worldwide through cutting-edge technologies and unwavering dedication to quality and safety. Embracing the transformative potential of PSA Medical Oxygen Generators; we pave the way for a healthier and more resilient future, where access to life-saving oxygen therapy knows no bounds.

0 notes

Text

0 notes