#carbon molecular sieves manufacturers

Explore tagged Tumblr posts

Text

Efficient Nitrogen Generation with Carbon Molecular Sieve | CMS for PSA Process

Experience reliable Nitrogen generation with Carbon Molecular Sieve, efficiently separating Oxygen from compressed air for continuous flow of pure Nitrogen. Learn more about PSA process with CMS technology. Order from the top supplier for reliable and high-quality CMS products today.

For more information

contact us +91 9879203377,

Email us - [email protected]

Website - https://www.molecularsievedesiccants.com/carbon-molecular-sieve

#carbon molecular sieves#CMS#molecular sieves#carbon molecular sieves manufacturers#carbon adsorbent

0 notes

Text

For carbon molecular sieves needs, the carbon molecular sieves manufacturer in UK has got you covered! Western Carbon is a leading carbon molecular sieves manufacturer that provides a range of carbon molecular sieves suppliers in UK by employing cutting-edge technology at our Hi-Tech manufacturing unit

#carbon molecular sieves supplier in UK#carbon molecular sieves manufacturer in UK#carbon molecular sieves manufacturers in UK#carbon molecular sieves suppliers in UK

0 notes

Text

Efficient PSA Nitrogen Plants by Trimech India

Trimech India specializes in designing and manufacturing PSA nitrogen plants that deliver high-purity nitrogen efficiently and cost-effectively. Our PSA nitrogen generator employs advanced twin-tower technology with Carbon Molecular Sieve (CMS) to separate nitrogen from atmospheric air. With capacities ranging from 5 NM3 to 1000 NM3/Hr, these compact, low-maintenance systems eliminate the need for N2 cylinders, making them ideal for industries like pharmaceuticals, food processing, and electronics. Backed by robust after-sales service, including user training and warranty support, Trimech India ensures reliability and customer satisfaction. Choose us for a sustainable and economical nitrogen generation solution!

0 notes

Text

PSA Oxygen Generators for Healthcare & Industry

Oxygen is one of the most critical products that has been consumed in healthcare and industry. In order to keep up with increasing demands for reliable and cost-effective oxygen solutions, PSA oxygen gas generators have emerged as an important technology. PSA medical oxygen systems allow on-site production of oxygen while providing a consistent supply instead of relying on regular bottled oxygen deliveries. Here we are going to discuss the importance of PSA medical oxygen systems and their uses in the health and industrial sectors.

Understanding PSA Technology

Modern oxygen generators that work on an on-site basis have pressure swing adsorption at the core. By applying the PSA technology in air, it separates this medium with the help of specifically designed molecular sieves to differentiate between gases. Molecular sieves separate oxygen efficiently hence ensuring reliable and cost-efficient medical and industrial oxygen generators.

Health Care Application of PSA Oxygen Generator

Medical Oxygen Improves Patient Care

In healthcare facilities, the availability of oxygen becomes a matter of life and death. PSA medical oxygen generators offer a consistent supply of high-purity oxygen which is necessary for the treatment of patients with respiratory problems during surgeries and emergency care. The generators enable the hospitals and clinics to perform their functions without the suppliers.

Cost-Effective Hospital Solutions

The on-site oxygen generator in hospitals has reduced the cost of transporting and storing oxygen cylinders. Oxygen is produced on demand in these systems, eliminating shortages and providing a sustainable alternative for healthcare institutions.

Portable Oxygen Solutions for Remote Areas

Sourcing medical oxygen proves to be difficult for remote and rural health care stations. Oxygen generators for healthcare offer a bridge between the medical world and such stations with portable and easy-to-set-up systems. Such systems ensure that the most distant facilities can still offer excellent care to their patients.

Industrial Applications of PSA Oxygen Generators

Meeting Industrial Oxygen Demands

Industrial oxygen applications in processes, such as metal fabrication, chemical processing, and water treatment, depend much on oxygen. With PSA technology-equipped industrial oxygen generators, businesses are assured of uninterrupted flows for the necessary volumes required to sustain production.

Improved manufacturing productivity

For manufacturers, continuous supply of oxygen is a vital requirement for welding, cutting, and combustion. With PSA oxygen gas generators, productivity is improved since there is a reliable and cost-effective supply of oxygen directly at the site.

Environmental Benefits of PSA Oxygen Systems

Companies can decrease their carbon footprint by implementing industrial oxygen generators. There are no transportation-related emissions from these systems, and less waste is generated compared to other methods of oxygen delivery.

Advantages of On-Site Oxygen Generation

Continuous Supply of Oxygen

One of the biggest pluses of on-site oxygen generators is the uninterrupted flow of oxygen. In case one applies it to health or industrially, then one cannot afford to stop his machinery operation by ascribing it to lack of oxygen.

Increased Safety End

Large quantities of oxygen can be stored in cylinders, which is a safety risk. PSA medical oxygen generators produce oxygen as needed, reducing the chances of accidents caused by cylinder leaks or improper handling.

Cost Savings Over Time

The investment cost in PSA oxygen gas generators may be high in the initial stages, but long-term savings are considerable. These systems are economically viable as they save on transportation, storage, and operating costs for businesses and healthcare facilities.

Sustainability and Reliability

Reducing Dependence on External Suppliers

One of the significant advantages of oxygen generators in healthcare and industry is their independence from external supply chains. This ensures a reliable source of oxygen, even in times of supply chain disruption or emergencies.

Lower Environmental Impact

The production of oxygen on-site by industrial oxygen generators reduces the environmental impact that is associated with frequent transportation of oxygen cylinders. It supports the global efforts to make more sustainable industrial and healthcare practices.

Choosing the Right PSA Oxygen Generator

Key Considerations for Healthcare Facilities

When choosing an oxygen generator for healthcare, capacity, purity levels, and ease of maintenance should be the key considerations. Hospitals and clinics must ensure that the chosen system meets their specific oxygen requirements.

Tailoring Solutions for Industrial Needs

The oxygen requirements of various industries vary with their activities. PSA oxygen gas generators come in different sizes and arrangements, which allows for customized solutions to meet the particular needs of an industry.

Future Outlook of PSA Oxygen Generators

Technological Developments

PSA technology is constantly evolving with promises of greater efficiency and reliability. Future PSA medical oxygen systems may be equipped with more sophisticated monitoring capabilities, making them more efficient and easier to use.

Expanding Access in Emerging Markets

As global demand for oxygen increases, on-site oxygen generators continue to become more accessible within emerging markets. These systems are critical in improving healthcare infrastructure while supporting industrial development in unserved regions.

Conclusion

PSA oxygen gas generators are revolutionizing the way oxygen is made available to the healthcare and industrial sectors. The facility of producing high-purity oxygen on-site ensures reliability, cost-efficiency, and sustainability. Whether for health purposes as an oxygen generator or as an industrial oxygen generator, these systems are setting out on the path toward becoming a more self-reliant and environmentally friendly world. It is the next best step in adopting not just a smart decision but a step toward more improved operation efficiency and care of the patient and industry alike.

0 notes

Text

Looking For Top Molecular Sieves Supplier in Tanzania?

For Molecular Sieves needs, the Molecular Sieves manufacturer in Tanzania has got you covered! Western Carbon is a leading Molecular Sieves manufacturer that provides a range of Molecular Sieves suppliers in Tanzania products like Extruded carbon, Molecular Sieves, Impregnated carbon, etc. Call us.

#molecular sieves manufacturer#molecular sieves suppliers#molecular sieves supplier in tanzania#molecular sieves manufacturer in tanzania#molecular sieves manufacturers in tanzania#molecular sieves suppliers in tanzania

0 notes

Text

Unlocking the Power of Zeolite Molecular Sieve: A Comprehensive Guide

Zeolite molecular sieves have revolutionized a wide range of industries by providing an efficient way to purify, separate, and dehydrate gases and liquids. This unique material boasts incredible adsorption capabilities, making it an essential component in industries like petrochemicals, pharmaceuticals, and environmental protection. In this blog, we’ll dive deep into what a zeolite molecular sieve is, how it works, and the diverse range of applications that benefit from its extraordinary properties.

What is a Zeolite Molecular Sieve?

A zeolite molecular sieve is a type of crystalline aluminosilicate that contains a three-dimensional, porous structure. These tiny, uniform pores have the unique ability to selectively adsorb molecules based on their size, shape, and polarity. This makes zeolite molecular sieves particularly effective in separating or capturing specific gases, liquids, or even impurities.

The name "molecular sieve" comes from this ability to "sieve" molecules based on their dimensions. The precise pore size within the zeolite framework allows it to exclude larger molecules while adsorbing smaller, targeted ones. This selective adsorption process is what makes zeolite molecular sieves so valuable in a wide range of industrial applications.

How Zeolite Molecular Sieves Work

Zeolite molecular sieves work via a process called adsorption, where molecules adhere to the surface of the sieve’s internal pores. Each sieve is designed to capture specific molecules, such as water, carbon dioxide, or various gases, depending on the application.

What makes zeolite molecular sieves especially powerful is their precise and uniform pore structure, which allows for the efficient removal of moisture, gases, or other contaminants. This means that they can separate, purify, or dry substances with incredible accuracy.

Key Features of Zeolite Molecular Sieves:

Precise Molecular Adsorption: Zeolite sieves adsorb molecules based on size, ensuring accurate separation.

Thermal and Chemical Stability: Zeolite molecular sieves are highly durable, withstanding harsh environments.

Reusability: These sieves can be regenerated for long-term use, making them a cost-effective solution.

Wide Range of Pore Sizes: Zeolite molecular sieves come in different grades (3A, 4A, 5A, etc.) to cater to various molecular sizes.

Applications of Zeolite Molecular Sieves

1. Gas Dehydration

In industries such as petrochemicals, natural gas processing, and air separation, moisture removal is critical. Zeolite molecular sieves are widely used to dry gases by adsorbing water vapor, ensuring high-quality and safe operations. Whether it's hydrogen, nitrogen, or oxygen, zeolite sieves play a vital role in gas drying applications by offering superior moisture control.

2. Air Purification

Zeolite molecular sieves are commonly used in air separation processes to remove carbon dioxide, moisture, and other impurities from the air. Their precision allows for the production of high-purity oxygen and nitrogen, which are critical for medical, industrial, and scientific applications.

3. Liquid Purification and Separation

The capability of zeolite molecular sieves extends to liquid purification as well. From ethanol dehydration to the purification of industrial solvents, zeolite sieves ensure that contaminants and water are efficiently removed. This results in higher-quality products and improves overall efficiency in manufacturing processes.

4. Environmental Protection

Zeolite molecular sieves have a crucial role in environmental applications, particularly in reducing air pollution. They are used in filters to capture harmful gases like volatile organic compounds (VOCs) and sulfur oxides (SOx). These sieves help industries meet regulatory standards for clean air and reduce harmful emissions.

5. Petrochemical and Refinery Processes

In the petrochemical industry, zeolite molecular sieves are critical for processes such as catalytic cracking and gas sweetening. Their ability to remove impurities like hydrogen sulfide (H2S) and carbon dioxide (CO2) ensures higher quality in refined products and boosts efficiency in refinery operations.

Types of Zeolite Molecular Sieves

Zeolite molecular sieves come in several varieties, each designed to adsorb specific molecules. The pore size is determined by the type of zeolite used, allowing for precise molecular separation.

3A Zeolite Molecular Sieve: Ideal for adsorbing water from liquids and gases, commonly used in ethanol dehydration and natural gas drying.

4A Zeolite Molecular Sieve: Known for removing water and certain gases like carbon dioxide, this sieve is widely used in air and gas purification.

5A Zeolite Molecular Sieve: Capable of adsorbing larger molecules such as hydrocarbons, commonly employed in separating natural gas and refining processes.

13X Zeolite Molecular Sieve: Designed for removing both water and CO2, this molecular sieve is often used in air separation and medical oxygen concentrators.

Advantages of Zeolite Molecular Sieves

Zeolite molecular sieves offer several benefits that make them stand out from other adsorbents like silica gel or activated alumina. Their high selectivity and ability to operate under extreme conditions make them ideal for challenging industrial environments.

Key Advantages:

Selective Adsorption: Zeolite molecular sieves excel at targeting specific molecules, ensuring the highest levels of purity.

Thermal Durability: Capable of withstanding extreme temperatures without losing effectiveness.

High Adsorption Capacity: Zeolite molecular sieves can hold large amounts of moisture or gases, improving efficiency in operations.

Reusability: These sieves can be regenerated through heating, providing a cost-effective, long-term solution.

Regeneration of Zeolite Molecular Sieves

One of the main benefits of zeolite molecular sieves is their ability to be regenerated. After adsorbing gases or moisture, these sieves can be heated to release the trapped molecules, restoring their adsorption capacity. This process can be repeated multiple times, making zeolite molecular sieves a highly sustainable option for industrial use.

Regeneration is usually performed by applying heat or reducing pressure, which allows the adsorbed molecules to desorb from the zeolite structure. Once the sieve is regenerated, it can continue performing with high efficiency, reducing the need for frequent replacements and minimizing operational costs.

The versatility and efficiency of zeolite molecular sieves have made them indispensable in a wide range of industries. From gas drying to liquid purification, these highly selective adsorbents ensure superior results by capturing moisture and impurities with precision. Their durability, reusability, and ability to operate in extreme conditions make them a go-to solution for industries looking to optimize performance and improve the quality of their products.

Whether you’re in the petrochemical, environmental, or medical field, investing in zeolite molecular sieves will offer you a reliable and efficient way to purify, separate, and dry gases and liquids. With a broad spectrum of applications, zeolite molecular sieves are key to maximizing operational efficiency while maintaining a clean, high-quality output.

0 notes

Text

0 notes

Text

What is a PSA Nitrogen Gas Plant?

A PSA Nitrogen Gas Plant(Pressure Swing Adsorption) is an industrial system that generates nitrogen gas using the pressure swing adsorption process. Here are some key points to know about PSA nitrogen gas plants:

Principle: PSA technology uses two beds of carbon molecular sieves to separate nitrogen from atmospheric air.

Process: Air is compressed and passed through one bed, adsorbing oxygen and moisture, while nitrogen is released. The process then switches to the second bed, regenerating the first bed.

Benefits: PSA nitrogen gas plants offer a reliable, cost-effective, and energy-efficient way to produce high-purity nitrogen gas.

Applications: PSA nitrogen plants are used in various industries, including:

Food packaging and processing

Laser cutting and welding

Pharmaceutical manufacturing

Chemical processing

Laboratory research

Capacity: PSA plants come in various sizes, ranging from small units to large industrial systems.

Purity: PSA plants can produce nitrogen gas with purity levels up to 99.999%.

Advantages: On-site nitrogen generation, reduced reliance on cylinders, and low operating costs make PSA plants an attractive option.

For More Information –

. Contact Us - 8126173604

. Email Id - [email protected]

. Address - 493, Devlok Colony, Swarg Ashram Road, Hapur - 245101, Uttar Pradesh, India

#PSA Nitrogen Gas plant#PSA Nitrogen Gas Manufacturer#PSA Nitrogen Gas Supplier#PSA Nitrogen Gas Exporter

0 notes

Text

oxygen generator for hospital

oxygen generator for hospital

Medical Oxygen Generators: A Lifeline in Modern Healthcare

In the realm of healthcare, oxygen therapy is a cornerstone treatment for patients with respiratory conditions, critical illnesses, and during surgical procedures. Medical oxygen generators have emerged as vital devices that ensure a steady, reliable supply of oxygen. These generators, also known as oxygen concentrators, have revolutionized patient care by offering an efficient and cost-effective solution to traditional oxygen supply methods.

Understanding Medical Oxygen Generators

Medical oxygen generators are devices designed to extract oxygen from ambient air and deliver it in a concentrated form. Ambient air comprises approximately 21% oxygen, 78% nitrogen, and 1% other gases. Oxygen generators use a process called Pressure Swing Adsorption (PSA) or, less commonly, membrane technology to separate oxygen from nitrogen and other gases. The result is a high concentration of oxygen, typically around 90-95%, which is then delivered to patients in need.

How They Work

1. **Air Intake**: The generator draws in ambient air.

2. **Filtration**: The air passes through filters to remove dust, bacteria, and other particulates.

3. **Compression**: The filtered air is compressed and directed into one of two molecular sieve beds.

4. **Oxygen Concentration**: The molecular sieve beds contain a material called Zeolite that absorbs nitrogen when under pressure, allowing oxygen to pass through.

5. **Delivery**: The concentrated oxygen is then collected in a storage tank and delivered to the patient through a mask or nasal cannula.

6. **Regeneration**: The generator switches to the second sieve bed, allowing the first to release the trapped nitrogen and regenerate for the next cycle.

Advantages of Medical Oxygen Generators

1. **Continuous Supply**: Unlike traditional oxygen tanks that need frequent refilling, oxygen generators provide a continuous supply of oxygen as long as they have access to power and air.

2. **Cost-Effective**: Over time, oxygen generators can be more cost-effective than purchasing and refilling oxygen cylinders.

3. **Portability**: Modern portable oxygen concentrators allow patients to maintain their mobility and independence, improving their quality of life.

4. **Safety**: Eliminating the need for high-pressure oxygen cylinders reduces the risk of accidents associated with handling and storage.

5. **Environmental Impact**: Reduced reliance on oxygen cylinders means fewer resources are spent on manufacturing, transporting, and disposing of these cylinders, leading to a smaller carbon footprint.

Applications in Healthcare

- **Chronic Obstructive Pulmonary Disease (COPD)**: Patients with COPD often require long-term oxygen therapy to manage their symptoms and improve their quality of life.

- **Surgery and Recovery**: Oxygen generators are essential in surgical settings to ensure patients receive adequate oxygen during and after procedures.

- **Emergency Medicine**: In emergency rooms and ambulances, oxygen generators provide critical support to patients experiencing acute respiratory distress.

- **Home Healthcare**: Many patients require oxygen therapy at home, and portable oxygen concentrators have made this more feasible and convenient.

Challenges and Considerations

While medical oxygen generators offer numerous benefits, there are challenges and considerations to keep in mind:

- **Initial Cost**: The upfront cost of purchasing an oxygen generator can be significant, although it pays off over time.

- **Power Dependency**: These devices require a constant power source, which can be a limitation in areas with unreliable electricity.

- **Maintenance**: Regular maintenance is necessary to ensure the device functions correctly and safely.

- **Training**: Healthcare providers and patients need proper training to use oxygen generators effectively.

The Future of Medical Oxygen Generators

The development of medical oxygen generators is advancing rapidly, with ongoing improvements in efficiency, portability, and ease of use. Innovations such as battery-operated portable units and smarter, automated systems are making oxygen therapy more accessible and user-friendly. As technology continues to evolve, we can expect these devices to become even more integral to patient care, providing a lifeline to those in need.

Conclusion

Medical oxygen generators have transformed the landscape of oxygen therapy, offering a reliable, cost-effective, and safe solution for patients across various healthcare settings. As we continue to innovate and improve these devices, they will undoubtedly play an even more crucial role in ensuring patients receive the life-sustaining oxygen they need, whenever and wherever they need it.

0 notes

Text

Global Top 24 Companies Accounted for 43% of total Porous Carbon market (QYResearch, 2021)

Porous carbons are an important class of porous materials that have grown rapidly in recent years. They have the advantages of a tunable pore structure, good physical and chemical stability, a variable specific surface, and the possibility of easy functionalization.

Porous carbon materials have versatile applications in different areas of science and technology. In modern times, there are different varieties of porous carbons, including activated carbon, soft and hard templated mesoporous carbons, activated carbon fibers or porous nanocarbons. So far, among all types of nanoporous materials, porous carbons have the largest applications in different sectors of the scientific, technological, and industrial sectors.

The Porous Carbon industry can be broken down into several segments, Activated Carbon, Activated Carbon Fiber, Carbon Molecular Sieves, Others, etc.

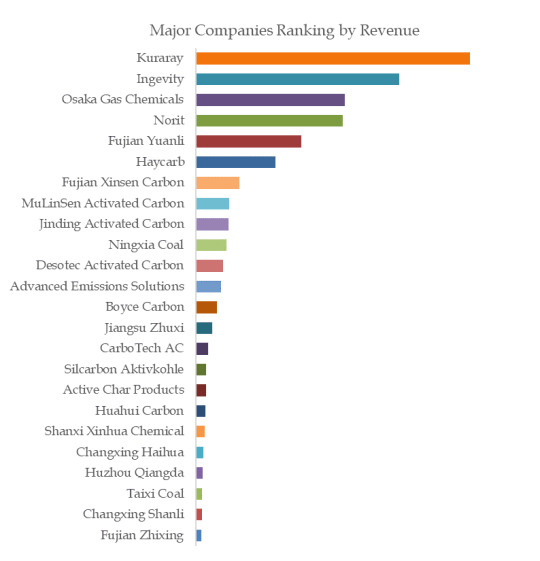

Across the world, the major players cover Kuraray, Osaka Gas Chemicals, Fujian Yuanli, Norit, Ingevity, Haycarb, Jinding Activated Carbon, Ningxia Coal, Advanced Emissions Solutions, Fujian Xinsen Carbon, etc.

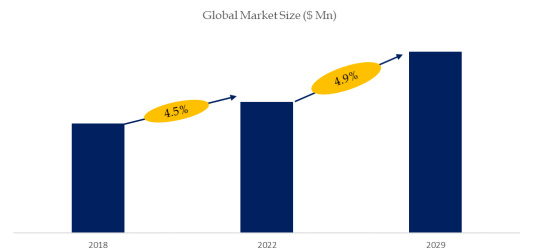

According to the new market research report “Global Porous Carbon Market Report 2023-2029”, published by QYResearch, the global Porous Carbon market size is projected to reach USD 6.35 billion by 2029, at a CAGR of 4.9% during the forecast period.

Figure. Global Porous Carbon Market Size (US$ Million), 2018-2029

Figure. Global Porous Carbon Top 24 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Porous Carbon include Kuraray, Ingevity, Osaka Gas Chemicals, Norit, Fujian Yuanli, Haycarb, Fujian Xinsen Carbon, MuLinSen Activated Carbon, Jinding Activated Carbon, Ningxia Coal, etc. In 2022, the global top 10 players had a share approximately 43.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Efficient Nitrogen Generation with Carbon Molecular Sieve | CMS for PSA Process

Experience reliable Nitrogen generation with Carbon Molecular Sieve, efficiently separating Oxygen from compressed air for continuous flow of pure Nitrogen. Learn more about PSA process with CMS technology. Order from the top supplier for reliable and high-quality CMS products today.

For more information

contact us +91 9879203377,

Email us - [email protected]

Website - https://www.molecularsievedesiccants.com/carbon-molecular-sieve

#carbon molecular sieves#CMS#molecular sieves#carbon molecular sieves manufacturers#carbon adsorbent#PSA process for Nitrogen Generation#Nitrogen Generation Process with Carbon Molecular Sieve

0 notes

Text

For carbon molecular sieves needs, the carbon molecular sieves manufacturer in India has got you covered! Western Carbon is a leading carbon molecular sieves manufacturer that provides a range of carbon molecular sieves suppliers in India by employing cutting-edge technology at our Hi-Tech manufacturing unit

#carbon molecular sieves supplier in india#carbon molecular sieves manufacturer in india#carbon molecular sieves manufacturers in india#carbon molecular sieves suppliers in india

0 notes

Text

Ethylene: From Cracking Open the Basics to Shaping Our World

From the plastic bottles you use every day to the antifreeze in your car and even the soft fabric of your pajamas, a surprising common thread exists: Ethylene. This essential molecule, with the chemical formula C2H4, forms the backbone of countless products we use every day. In this blog, we'll uncover the secrets of Ethylene, how it's made, and its surprising impact on our modern world. We'll even explore some of the exciting ways it might be used in the future. Get ready to dive into the world of the most significant industrial organic compound around!

Introduction

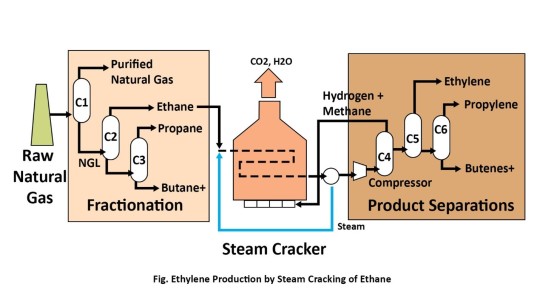

Ethylene, a colorless gas with a hint of fruitiness, is a major player in the industrial world. Through a process called steam cracking, manufacturers turn ethane and naphtha (petroleum liquids) into valuable chemicals, including ethylene. This process involves intense heat (around 750°C) to break down the hydrocarbons. Ethylene itself is flammable, but it's the foundation for numerous essential chemicals. From polyethylene (the plastic in many everyday items) to ethylene oxide (used in antifreeze) and even ingredients for PVC and polystyrene, ethylene is a versatile building block. Interestingly, this same gas also helps speed up fruit ripening in large-scale agriculture. Polyethylene production currently dominates ethylene use, but its applications extend to refrigeration and even fuel gas for industrial cutting and welding.

Manufacturing Processes

Ethylene, a very common organic compound, is essential for the petrochemical industry. Made from various oil-based materials in factories that use high-temperature steam, it serves as the starting point for many other important chemicals.

Cracking and quenching

Cracking and quenching are fundamental processes in ethylene production. Initially, an ethane-propane blend undergoes high-temperature cracking in furnaces, yielding ethylene, propylene, and additional byproducts. To halt undesirable reactions and byproduct formation, the resultant stream is swiftly cooled in a water-based quench. Downstream, a decanter removes heavies, condensed dilution steam, tar, and coke, ensuring product purity. The cracked gas is then guided to compression and separation stages, enabling the isolation of ethylene and propylene for further refinement and utilization. These sequential steps are integral to the efficient production of ethylene, a cornerstone chemical in numerous industrial applications.

Compression and drying

Compression and drying are crucial stages in gas processing. The cracked gas undergoes compression across five stages, ensuring optimal pressure levels for subsequent processing. Following the third compression stage, caustic soda and water washes in a caustic scrubber effectively eliminate carbon dioxide and sulfur impurities from the cracked gas stream. Subsequently, the compressed gas is cooled and subjected to molecular sieves for drying, effectively removing residual water content. This meticulous drying process ensures the purity and quality of the gas, preparing it for further refinement and utilization in various industrial applications.

Separation

• After drying, the cracked gas goes through a special chamber (cold box) to remove hydrogen and other small, light hydrocarbons. This process is designed to take out these unwanted elements without losing much of the valuable ethylene.

• At this stage, the condensed substances from the cooling process are directed into a sequence of separation columns. Initially, in the first column known as the demethanizer, methane is separated at the top and utilized further within the cold box, while the lower portion is directed into a second column, the deethanizer.

• The upper portion of the deethanizer, primarily containing ethylene and ethane, is sent through an acetylene converter before undergoing fractionation in the C2-splitter. Within this column, lighter components are removed from the overheads and returned to the compression system, while ethylene suitable for polymer-grade applications is extracted as a side stream. Ethane from the bottom of the C2-splitter is recycled back to the cracking furnaces.

• The lower portion of the deethanizer is channeled into a depropanizer, which separates out C3 (propylene fractionation tower/distillation tower) components in the overheads. This overhead stream is subjected to catalytic hydrotreatment to remove methyl acetylene and propadiene before being directed to the C3-splitter. Within this column, lighter components are extracted from the overheads and recycled to the compressors, while propylene suitable for polymer-grade applications is extracted as a side stream. Propane from the bottom of the C3-splitter is recycled back to the cracking furnaces, while a C4+ stream is obtained from the bottom of the depropanizer.

Technologies used by Major Players

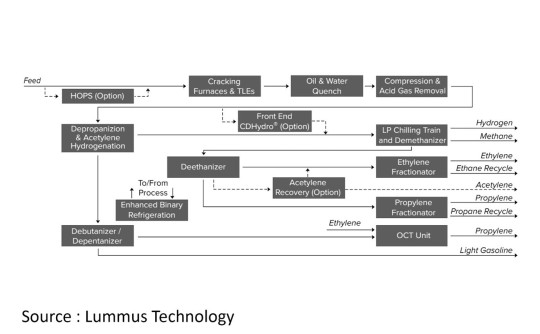

Lummus Technology

• The raw materials utilized in the production of ethylene by Lummus Technologies encompass a variety of hydrocarbons, such as ethane, propane, butane, naphtha, kerosene, diesel, gasoils, or hydrocracked vacuum gasoils.

• Initially, a mixture of fresh feed and recycled ethane and propane undergoes thermal cracking with steam in pyrolysis furnaces. The resulting gas is progressively cooled through steam generation and direct contact with oil and/or water.

• Subsequently, the effluent undergoes compression in a three-stage centrifugal compressor, followed by the removal of acid gases using amine solution and/or caustic soda. Dehydration of the gases is achieved using a molecular sieve. Product recovery is carried out under cryogenic conditions in refrigerated fractionation systems.

• Acetylene compounds undergo hydrogenation in catalyst systems, and hydrogen is purified through Pressure Swing Adsorption (PSA) or methanation.

• Polymer-grade ethylene and propylene are obtained via highly integrated super-fractionation towers aimed at minimizing energy consumption. Simultaneously, mixed C4 products and pyrolysis gasoline are coproduced and recovered. The C4s can serve as feed for an OCT or CPT unit, facilitating the production of propylene, butene-1, or hexene-1. A unified mixed refrigeration system fulfills all refrigeration needs. Essential utilities like steam, cooling water, and fuel are fully integrated to optimize overall efficiency.

• An additional feature involves potentially integrating a gas turbine generator with the pyrolysis furnaces to generate electrical power and extra super-high-pressure steam. The hot exhaust gases from the turbine are directed back to the furnaces to provide hot combustion air.

Applications of Ethylene

Ethylene, a crucial building block in chemical manufacturing, plays a pivotal role in the production of various essential compounds. One prominent application is in the synthesis of Polyethylene, a versatile plastic widely used in packaging, construction, and other industries. Additionally, Ethylene Oxide, valued for its role as a sterilizing agent and in the manufacture of ethylene glycol, finds extensive use in the medical and automotive sectors. Ethylene Dichloride serves as a precursor in the production of vinyl chloride, a key ingredient in the manufacturing of PVC pipes and other products. Ethylene Benzene is utilized in the synthesis of styrene, employed in the production of plastics, rubber, and resins. These and other derivatives highlight the diverse applications of ethylene across various industrial sectors.

1. Polyethylene

Polyethylene, a ubiquitous plastic, finds extensive application in diverse industries. Its versatility makes it a preferred choice for food packaging, ensuring the preservation and safety of food products. Additionally, it is utilized in the production of bottles, providing lightweight and durable containers for beverages, household products, and personal care items. Polyethylene's flexibility and strength make it ideal for manufacturing bags, facilitating storage, transportation, and disposal of goods. Its widespread use in these applications underscores its importance in modern society, contributing to convenience, efficiency, and safety in various aspects of daily life.

2. Ethylene dichloride (EDC)

Ethylene dichloride (EDC), recognized for its lead scavenging properties, is a common additive in leaded fuels, effectively reducing engine knocking and enhancing combustion efficiency. Beyond its role in fuel formulations, EDC has found diverse industrial applications. It served as an extraction solvent, facilitating the separation of desired compounds in various processes. Moreover, its solvency properties made it suitable for textile cleaning and metal degreasing applications. EDC's inclusion in certain adhesives contributed to their adhesive strength and durability.

3. Ethylene Benzene

Ethylbenzene serves as a fundamental precursor in the synthesis of styrene and synthetic polymers, playing a pivotal role in various industrial processes. Widely recognized as a solvent, it facilitates the dissolution of substances in applications ranging from paints and inks to carpet glues and varnishes. Additionally, ethylbenzene finds utility as a constituent of asphalt and naphtha, contributing to their formulation and performance characteristics. Its presence in synthetic rubber and fuels underscores its versatility across multiple sectors. Moreover, ethylbenzene is incorporated into tobacco products and insecticides, adding to its diverse range of applications. It also serves as a component in automotive and aviation fuels, enhancing their combustion properties.

4. Food & Beverages

Ethylene provided in cylinders are employed to regulate the ripening of fruits, particularly bananas, with a concentration of a few ppm being utilized in warehouse atmospheres.

Market Outlook

The driving force behind the global Ethylene market is its use in making Polyethylene plastic. No wonder it's everywhere, from food packaging and grocery bags to toys, cable insulation, and even household items like squeeze bottles. There are different types of Polyethylene, with two major players being LDPE (Low-Density) and HDPE (High-Density). Interestingly, HDPE goes a step further – it's also used to create other plastics like PET (Polyethylene Terephthalate), commonly found in water bottles, food containers, and packaging. But Ethylene's uses extend beyond plastics. It's also a key ingredient in producing Ethylene Oxide, a precursor for chemicals like ethanol amines and monoethylene glycol, further boosting the demand for Ethylene.

Ethylene Major Global Players

Significant players in the Global Ethylene market are Sinopec, LyondellBasell, DowDupont, Exxon Mobil Corporation, INEOS, Chevron Phillips, Braskem, Zhejiang Petrochemical, PTT Global Chemical, Formosa Plastics Group (Formosa Petrochemical Corp.), PetroChina, Arabian Petrochemical Company, Yeochun NCC Co. Ltd., Royal Dutch Shell, Kavian Petrochemical, and Others.

Conclusion:

Ethylene is a colorless gas with a distinctive fruity odor. Widely utilized in agriculture, ethylene expedites the ripening of fruits such as tomatoes, bananas, and mangoes. Moreover, ethylene serves as a vital precursor in chemical synthesis, contributing to the production of Polyethylene, Ethylene Oxide, Ethylene Dichloride, and Ethylene Benzene. Additionally, it finds application as a refrigerant in petrochemical industries and as a fuel gas for welding and cutting processes. The global ethylene market is forecasted to witness substantial growth, primarily driven by increasing demand for ethylene as a feedstock in chemical manufacturing, particularly for Polyethylene, renowned for its durability, flexibility, and lightweight nature, essential for food and beverage packaging and various other industries. This anticipated market expansion reflects the continuous evolution of ethylene-based products and their pivotal role in meeting diverse industrial needs, paving the way for innovation and growth opportunities in the chemical sector.

0 notes

Text

Next-Level Efficiency: The Rise of Mobile Nitrogen Generators in the Netherlands

Streamlining Operations with Mobile PSA Nitrogen Generators

In an era where flexibility and efficiency are paramount, industries across the Netherlands are increasingly turning to innovative solutions like mobile nitrogen generators to meet their operational needs. This move towards mobile systems highlights a significant shift in how industries approach resource management and process optimization. Mobile PSA nitrogen generators represent the forefront of this innovation, offering unmatched versatility and efficiency. This article explores the advantages and applications of these mobile systems in various sectors.

The Advantages of Going Mobile

The introduction of mobile nitrogen generators in the Netherlands has revolutionized the way businesses manage their nitrogen supply. Unlike stationary units, these mobile solutions offer the flexibility to be used across different sites or moved within a large facility, depending on the immediate needs. This mobility is particularly beneficial for industries like oil and gas, where operations are often remote and change locations based on exploratory results.

Mobile PSA nitrogen generators use Pressure Swing Adsorption (PSA) technology to produce high-purity nitrogen directly on-site. This technology is not only effective but also space-efficient, making it ideal for mobile applications. The PSA process involves molecular sieves that adsorb impurities at high pressure, then swing to low pressure to release nitrogen at desired purity levels—efficiently delivering continuous flow nitrogen on demand.

Cost Efficiency and Environmental Impact

One of the key benefits of mobile nitrogen generators is their cost-effectiveness. By generating nitrogen on-the-go, companies can significantly reduce the logistical costs associated with nitrogen delivery in cylinders or tanks. This reduction in transport not only cuts costs but also lowers the carbon footprint of operations, aligning with global sustainability goals.

Moreover, mobile PSA nitrogen generators minimize the risk of nitrogen loss that can occur during cylinder exchange and transport, ensuring more efficient use of resources. This efficiency is not only economically advantageous but also environmentally responsible, providing industries with a powerful tool to meet both their financial and ecological targets.

Versatility Across Industries

The versatility of mobile nitrogen generators extends across various sectors. In the construction industry, for instance, nitrogen is used to ensure the stability and safety of pneumatic systems. Mobile nitrogen generators can be easily transported to construction sites, providing a reliable nitrogen supply for machinery and equipment maintenance.

In the event sector, where setting up temporary installations like beer taps and food preservation systems often requires nitrogen, mobile PSA nitrogen generators offer a quick and reliable solution. These generators can be set up temporarily for events and removed once the need subsides, showcasing their adaptability and ease of use.

Innovative Features and Customization

Today's mobile nitrogen generators are equipped with advanced features that enhance their usability and performance. Many models include touchscreen controls, remote monitoring capabilities, and automated systems that adjust nitrogen purity and flow rate according to real-time demand. Additionally, manufacturers offer customization options to cater to specific industry needs, whether it involves adjusting the generator's size, mobility, or output specifications.

Conclusion: Besseling Group Leading the Way

As industries throughout the Netherlands embrace more agile and cost-effective solutions, the role of mobile nitrogen generators becomes increasingly essential. Leading this shift is Besseling Group, whose expertise in manufacturing state-of-the-art mobile PSA nitrogen generators ensures that businesses can achieve optimal efficiency and productivity. With a focus on innovation, customer satisfaction, and environmental responsibility, Besseling Group continues to support industries in their journey towards more dynamic and sustainable operations.

0 notes

Text

The Role of Nitrogen in 3D Metal Printing

In the rapidly evolving world of additive manufacturing, particularly 3D metal printing, the choice of gases used during the process can significantly impact the quality and efficiency of printed products. Among these gases, nitrogen plays a crucial role. This blog explores the benefits of using PSA Nitrogen Generator in 3D metal printing, highlighting how they enhance the printing process and improve the final product quality.

Understanding 3D Metal Printing

3D metal printing also referred to as metal AM or direct metal laser sintering, is the process of creating metal parts using a digital 3D model where the metal components are printed in a layer-by-layer format. This method is especially popular in aerospace, automotive, and healthcare industries because it can create intricate shapes that are otherwise difficult to manufacture using conventional processes. Central to the process are the shielding gases that maintain the atmosphere free from oxygen, which would otherwise compromise the quality of the metal used in the process.

The Importance of Nitrogen in 3D Metal Printing

Nitrogen, an inert gas, is commonly used in 3D metal printing for several reasons:

1. Oxidation Prevention: When it comes to printing, they use metal powder or filament that undergoes high temperatures. Nitrogen has the property of rendering an atmosphere non-reactive and thereby shields the metal from oxygen. This is important for supporting the microarchitectural structure and quality of the printed part.

2. Cost-Effectiveness: The cost of nitrogen, compared with other inert gases such as argon, is relatively cheaper. This makes it a popular option, especially if large amounts of gas are needed, as might be the case with industrial applications.

3. Availability: Nitrogen is relatively cheap, easily availed since it is found in large quantities in the air and the use of nitrogen generators makes its production easier.

Benefits of Using Nitrogen Generator in 3D Printing

Nitrogen generators offer several advantages for 3D metal printing operations:

1. Continuous Supply: Nitrogen generator ensure a continuous and reliable supply of nitrogen. This is crucial for uninterrupted printing operations, especially for large-scale industrial applications.

2. Cost Savings: By generating nitrogen on-site, companies can reduce the costs associated with purchasing and transporting gas cylinders. This also eliminates rental fees for gas storage tanks.

3. Purity Control: On-site nitrogen generators allow for control over the purity levels of the gas. This is essential in 3D printing, where even slight impurities can affect the quality of the final product.

4. Environmental Benefits: Generating nitrogen on-site reduces the carbon footprint associated with the transportation and handling of gas cylinders. It also minimizes the waste associated with empty gas cylinders.

5. Safety and Convenience: On-site generation reduces the risks associated with storing and handling high-pressure gas cylinders. It also simplifies logistics, as there's no need to manage deliveries and storage of large gas quantities.

How Nitrogen Generators Work

Nitrogen generator typically use one of two technologies: Pressure Swing Adsorption (PSA) or Membrane Separation.

- PSA Technology: This method involves passing compressed air through a vessel containing a carbon molecular sieve. The sieve adsorbs oxygen, allowing nitrogen to pass through. The result is high-purity nitrogen suitable for 3D printing applications.

- Membrane Separation: In this method, compressed air is passed through a membrane that selectively permeates oxygen, leaving behind nitrogen. This method is simpler and often used for applications requiring lower nitrogen purity.

Get in touch with Absstem!

Get in touch with Absstem today for reliable and cost-effective nitrogen generators, ensuring a continuous supply of high-purity nitrogen for your 3D printing needs. Contact us now!

Conclusion

It is thus paramount to understand how to use nitrogen in 3D metal printing to come up with parts made of metal with precision. Printing requires an inert environment; the nitrogen generators provide this efficiently and economically without any side effect to the environment. By using nitrogen production in-house, 3D printing organizations can remove worries regarding the availability of supplies and ways, decrease total costs, and enhance the results of using 3D printing techniques. Therefore, nitrogen generators’ application in supporting such cutting-edge technology as additive manufacturing will continue to rise in the future due to increased use of the technology.

0 notes

Text

Choose the Right Garnet Abrasive for Your Waterjet Cutting

Abrasive waterjet cutting, a precise and efficient cold-cutting process, is operated through waterjet equipment. Various types of garnets, each with its unique properties, are available in different sizes for abrasive cutting applications. When the right type and size of garnet are used in the high-pressure waterjet stream, it produces a remarkably smooth cutting surface with no heat-affected zones or slag.

This precision is crucial for your waterjet cutting application. With various types, grades, and sizes of garnet available, the garnet you choose depends on the intended application. Consider the thickness of the material, its composition, the speed of the cut, and the cut finish requirements. It is crucial to get the right garnet, but which garnet is right for waterjet cutting applications? Let's find out!

What is Garnet Abrasive?

Garnet is a hard silica mineral found in the metamorphic rocks. It is a naturally occurring crystallized aluminum or calcium silicate mineral. It is found in deposits from almandite and andradite quarried in the USA, India, China, South Africa, and Australia. The garnet abrasive used for waterjet cutting are pieces between 60 mesh viz 250 micrometers and 200 mesh viz 74 micrometers. The pieces bigger than 60 mesh viz 250 micrometers are used for sandblasting.

Western Carbon & Chemicals is the largest garnet manufacturer in India. We offer garnet in different grades, namely WCC-Garnet 20-40 mesh, WCC-Garnet 30-60 mesh, WCC-Garnet 80 mesh, and WCC-Garnet 120 mesh. The garnet crystal ranges from 6-8 on the moh scales that determine hardness.

Types of Garnet

River or Alluvial Garnet: River garnet resembles pinkish sand. It is naturally crushed and formed over the years as the beaches and rivers break down into minerals. Abrasive garnet is found in abundance on the Australian and Indian coasts.

Rock Garnet: The rock garnet has a dark brown to red colour found on the coats of Western India, the USA, and China. The rock garnet crystals are mined, crushed, and purified. It has sharp edges and offers a more aggressive cut than other types of garnet.

Factors to Look for When Choosing Garnet Abrasive for Waterjet Cutting

Mesh Size: Mesh size or grade is the size rating of a single piece of garnet. The most common abrasive garnet size for waterjet cutting is from 50 to 120 mesh. When choosing the grade 80 mesh, it is the most common one; for more aggressive and denser materials like stainless steel, choose from 40 to 60 mesh. To improve cutting, go for a higher mesh between 100 to 120 mesh. Review the nozzle of the waterjet and orifice combination to enhance water flow.

Particle Size Consistency: For waterjet cutting applications, consistent size particles are essential. Oversized particles can clog the orifice or damage the equipment. Go for double sifted garnet, as it ensures quality and consistency in particle sizes for accurate cutting.

Purity: Higher purity means top-quality garnet. It offers accurate cutting and reduces the chances of rejection.

Finding the Right Garnet Abrasive for Waterjet Cutting Applications

To maximize the performance of the waterjet cutting system, you need to choose the right garnet abrasive in terms of purity, grade, mesh size, and type. Western Carbon & Chemicals is a leading garnet exporter in China. We provide a variety of garnet grades to suit your specific applications. We offer customization in terms of mesh size, hardness, grade, and purity. Contact us to discuss your requirements.

Also View:- What Are The Common Uses Of Molecular Sieves?

#garnet exporter in China#garnet manufacturer in India#garnet exporter#garnet manufacturer#Garnet Abrasive for Waterjet Cutting#Garnet Abrasive for Waterjet Cutting Applications#Types of Garnet#What is Garnet Abrasive

0 notes