#Capsule Filler Machine

Explore tagged Tumblr posts

Text

Capsule Pill Maker

Our range of Capsule Making Machines and filling equipment is designed to provide precision and ease in the creation of high-quality vitamin capsules, supplements, and other nutritional products. Whether you're filling size 00 capsules or any other size, our machines are built for optimal performance and versatility.

Capsule Making Machine for 00 Capsules: This capsule making machine is perfect for filling size 00 capsules with powders, herbs, or other substances. Ideal for small-scale or DIY production, it ensures fast, clean, and accurate filling. Check it out here: Capsule Making Machine for 00 Capsules.

Capsule Pill Maker: This pill capsule maker is perfect for those who want to create their own capsules at home or in small batches. With its manual operation, it’s easy to use and offers flexibility in filling various capsule sizes. Learn more here: Capsule Pill Maker.

Pill Capsule Filler: The pill capsule filler provides a cost-effective way to fill multiple capsules quickly and efficiently. It’s perfect for making vitamin or nootropic pills. View the details here: Pill Capsule Filler.

Capsule Filling Equipment: This capsule filling equipment is ideal for both beginners and small-scale manufacturers. It offers a simple, manual method to fill capsules with precision. It's designed to accommodate various capsule sizes, including size 00, 0, and others. Explore it here: Capsule Filling Equipment.

Capsule Machine Filler: The capsule machine filler is designed for high efficiency, making it ideal for those who need to fill many capsules quickly. It’s easy to assemble, clean, and use, ensuring minimal downtime between batches. Learn more here: Capsule Machine Filler.

Capsule Filler Kit: For those looking for a complete capsule filler kit, this package includes everything needed to fill capsules with your desired materials. It’s a great choice for DIY enthusiasts or small businesses just starting out. Check it out here: Capsule Filler Kit.

Capsule Filler Machine: Our capsule filler machine is an excellent choice for efficient, high-quality production. With a capacity to fill up to 100 capsules at once, it’s perfect for both small and medium-scale production of vitamins and other dietary supplements. Learn more here: Capsule Filler Machine.

These manual capsule filling machines offer easy operation, high productivity, and reliable results. Whether you're making gelatin capsules, vegan pills, or pullulan capsules, our machines help ensure that every batch is filled precisely and efficiently. Perfect for supplement creators, herbalists, and DIY enthusiasts alike.

0 notes

Text

Manual Capsule Filler

Manual Capsule Filler (300 holes capsule filler) including capsule filler with loader uses to fill powder, pellets and granules into capsules. Machine is having 300 holes with orientation of 25 x 12 rows. All contact parts made from Stainless Steel 304 materials. Machine designed with utmost care to handle all capsule sizes ranging from 00 to 5 with different machine and format parts. Assembly has been done in such a way that it can be easily dismantle for cleaning operations. Though all the operations are manual, the machine calls for precision machined components and assembled with highly skilled personnel. Machine having wide usage in R&D laboratories, Research Institutions, Herbal & Nutraceutical preparations, Unani & Ayurvedic medicines, Pilot batch productions etc.

Capsule Filler Machine is widely uses in Research Laboratories, Academic Institution, Herbal/Ayurvedic preparation and medium to small scale manufacturing industries. Our range consist of 100 holes capsule filling machine, 300 holes capsule filler with option of automatic capsule loader to load trays of capsule filling machines.

0 notes

Text

Unlocking Efficiency with Capsule Filling & Weigher Machines

In today’s fast-paced pharmaceutical and nutraceutical industries, precision and efficiency are paramount. Capsule filling and weigher machines have emerged as essential tools in achieving these goals. These advanced machines streamline the encapsulation process, ensuring consistent and accurate dosage with minimal human intervention.

Capsule-filling machines automate the task of inserting powders or granules into capsules, dramatically increasing production speed while maintaining high standards of quality. These machines are designed to handle various capsule sizes and formulations, making them versatile for different products.

On the other hand, weigher machines complement the filling process by providing precise measurements of the capsule contents. They ensure that each capsule meets the specified weight requirements, which is crucial for regulatory compliance and product efficacy. Modern weigher machines offer high-speed performance and integration with other systems, such as automated filling lines, enhancing overall productivity.

Investing in advanced capsule filling and weigher machines not only boosts operational efficiency but also improves product consistency. As industries strive for higher standards and greater output, these machines are proving indispensable in achieving excellence in production. Embracing this technology can lead to significant advancements in both quality and efficiency.

0 notes

Text

Lodha Pharma's Capsule Filling Machine is an innovative product intended to fulfill the wide range of pharmaceutical company requirements. This machine, designed for accuracy and efficiency, fills capsules precisely and consistently with a variety of powders, granules, or pellets. It is a dependable option for high-volume production applications because to its sophisticated technology and sturdy design. Check this page at https://www.lodhapharma.com/high-speed-capsule-filling-machine.php for further details.

0 notes

Text

Lodha Machines is the largest manufacturer and exporter of pharmaceutical machinery in Gujarat, India. Offers the best solutions for medicine filling and packaging machines in the pharmaceutical industry. We take pride in providing the highest quality pharma machines, ensuring efficiency, reliability, and compliance with industry standards. We are committed to providing the best quality pharmaceutical machinery, which is designed with precision and meets strong quality control demands. We are also manufacturers of various types of pharmaceutical machinery like Washing & Air jet Cleaning Machines, Autoclaves and Sterilizers, Ampoule Filler Sealer, Liquid Filling Machine, Powder Filling Machine. If you require visit our site: https://www.lodhamachines.com/ or Contact us: +919687731331

#pharmaceutical machinery#capsule filling machine price#pharmaceutical machinery manufacturer#capsule filling machine manufacturer#tablet making machine manufacturer#pharma machine Manufacturer#Washing & Air jet Cleaning Machines#Autoclaves and Sterilizers#Ampoule Filler Sealer#Liquid Filling Machine#Powder Filling Machine

0 notes

Text

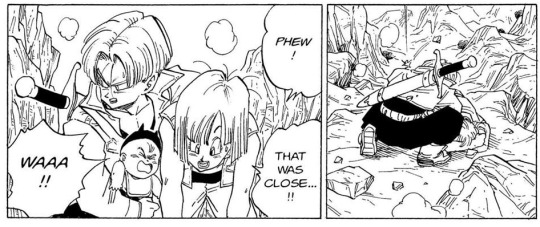

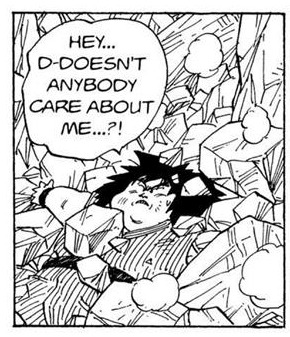

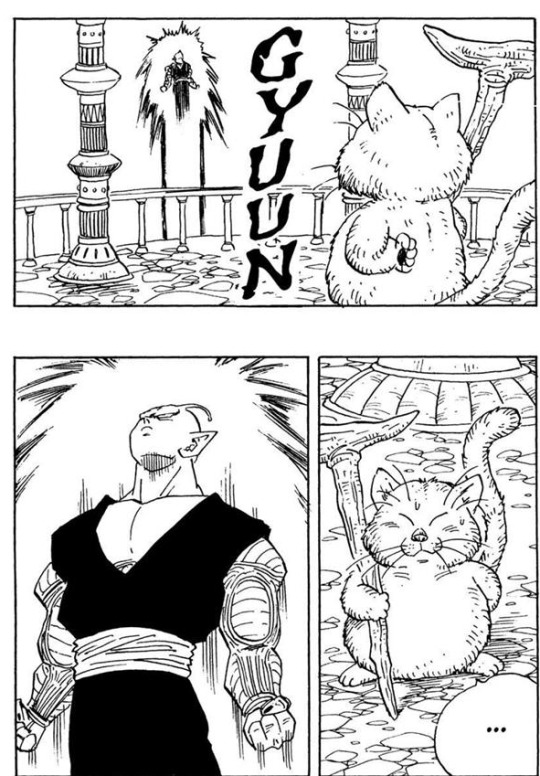

Fun Fact (stealing the format from @tobiasdrake): Yajirobe going to Capsule Corp in the Cell Saga is anime filler!

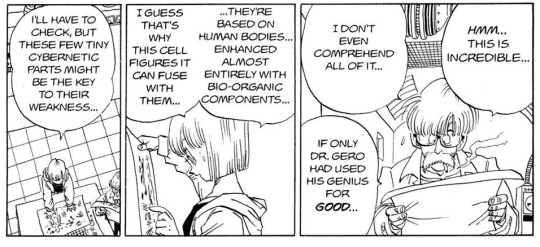

In the anime and manga, Bulma takes Yajirobe and Trunks via hover-car to the battlefield to see the Androids, then gets shot down by Dr. Gero and saved by Trunks.

Well, Yajirobe didn't get saved by Trunks, he survived just by tanking the explosion. Yajirobe still trained with Kami, he's still really strong.

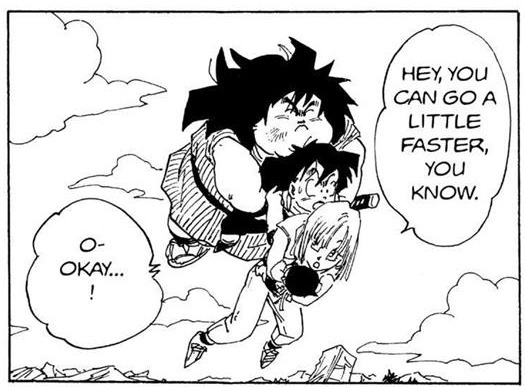

Anyway, after Bulma exposits that she knows where Dr. Gero's lab is to re-orient the plot, Gohan has to take her, Trunks, and Yajirobe home.

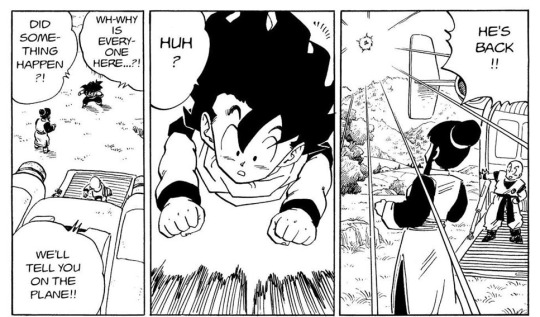

Which he does. Kind of. See, the manga never showed him taking them home. In the manga, the next time we see Gohan is when he arrives at his own house alone while everyone else is evacuating Goku.

The anime decided to flesh this out by randomly deciding that Gohan must have dropped off ALL THREE at Capsule Corp, including Yajirobe. Anime Gohan sure is inconsiderate.

Guess Toei really liked "Yajirobe deals with Bulma and baby Trunks" jokes. TFS got a lot of great mileage out of it.

And it's true that in the manga, we don't see Yajirobe on the lookout when Piccolo flies past to meet with Kami, we just see Korin alone.

Except that scene takes place in chapter 161 of Z, while Gohan returning home takes place in chapter 162, one chapter later. So it's possible at this point that Gohan returned Yajirobe off-panel after Piccolo arrived.

Later, the manga does have a few scenes of Bulma at Capsule Corp, one when she's calling Trunks about the duplicate time machine.

And a follow-up.

And then another scene where she and Briefs are analyzing the blueprints.

And a follow-up.

Notice how Yajirobe is absent from all these scenes? Yeah, the anime added him into them. The next time Yajirobe appears in the manga is when Goku is asking Korin (the God of Martial Arts) to rate his Power Level compared to Cell.

Though given Gohan's line about meeting Korin and Goku commenting on Yajirobe making it back, it seems like Manga Gohan didn't drop Yajirobe off directly at Korin tower.

That exchange would justify why the anime felt like they had room to put Yajirobe at Capsule Corp for comedic filler shenanigans, except I'm pretty sure the anime put Yajirobe at Capsule Corp before this scene in the manga happened.

As far as the manga goes, it looks to me like Gohan dropped him off nearby and Yajirobe hiked the rest of the way. This scene is only two days after Gohan was told to take him home, so he couldn't have been that far.

23 notes

·

View notes

Text

Spheronizer Technology: Enhancing Drug Formulation with Sugar and Film Coating

In the ever-evolving world of pharmaceuticals, the pursuit of improved drug delivery and enhanced patient compliance is ongoing. Spheronizer technology has emerged as a valuable tool in this endeavour, enabling the creation of sophisticated drug formulations with enhanced properties.

What is a Spheronizer?

A spheronizer, also known as a spheronizer machine, is a specialized piece of equipment used in the pharmaceutical industry to transform powders into uniform, spherical particles. These particles, often referred to as pellets or granules, offer significant advantages over irregular-shaped powders in drug formulation.

The Spheronization Process

Spheronization often includes many critical steps:

Powder Preparation: The active pharmaceutical ingredient (API) is blended with various excipients, such as binders, fillers, and disintegrants, to create a homogenous powder mixture suitable for spheronization. This step ensures that the API is evenly distributed throughout the final product.

Extrusion: The powder mixture is then passed through an extruder to form cylindrical extrudates. This step helps to increase the density and improve the flow properties of the material, making it easier to handle and process in the subsequent spheronization step.

Spheronization: The extrudates are fed into the spheronizer machine, which is essentially a rotating cylinder with a textured plate. The centrifugal force and friction generated within the spheronizer cause the extrudates to break down and form spherical particles. The finished pellets' size and shape can be modified by modifying the rotation speed, plate texture, and processing time.

Drying: The wet spherical particles are then dried using various techniques, such as fluid bed drying or tray drying, to remove excess moisture and achieve the desired moisture content. This procedure is critical for ensuring the stability and shelf life of the finished product.

Coating (Optional): The dried pellets can be further processed with sugar coating or film coating to enhance their properties. Sugar coating can mask unpleasant tastes, improve swallowability, and enhance the appearance of the medication. Film coating can be used to control drug release, protect the API from degradation, and improve the handling and storage of the product.

Benefits of Spheronizer Technology in Drug Formulation

Improved Flowability: Spherical particles exhibit superior flow properties compared to irregular powders. This ensures consistent filling of capsules and tablets, leading to accurate dosing and improved product quality.

Enhanced Dissolution: The increased surface area of spherical particles can enhance the dissolution rate of the API, leading to improved bioavailability and therapeutic efficacy.

Controlled Release: By applying specialized coatings, such as sugar coating or film coating, drug release can be modified to achieve desired profiles, such as sustained release or targeted delivery. This can improve the effectiveness of the medication and reduce the frequency of dosing.

Taste Masking: Sugar coating can effectively mask the unpleasant taste of some APIs, making the medication more palatable for patients, particularly children. This can help with patient compliance and adherence to treatment regimens.

Improved Stability: Spheronization can enhance the stability of drugs by protecting them from degradation due to moisture, light, or oxidation. This can extend the shelf life of the medication and ensure its efficacy over time.

Reduced Dust Generation: The formation of spherical particles minimizes dust generation during manufacturing, improving workplace safety and reducing the risk of cross-contamination.

Conclusion

Spheronizer technology, coupled with sugar coating and film coating techniques, has revolutionized the way pharmaceutical scientists approach drug formulation. By harnessing the unique properties of spherical particles, they can create innovative drug delivery systems that are more effective, patient-friendly, and cost-efficient.

0 notes

Text

“Shriram College: The Leader In Pharmacy Education In India”

Shriram Pharmacy College, Bankner, has earned its place as one of the top institutions in India dedicated to pharmacy education and research. It is renowned for its commitment to academic excellence, state-of-the-art infrastructure, and industry-relevant training programs. The college plays a significant role in shaping the future of the pharmaceutical industry by equipping students with the skills needed to address modern challenges in drug manufacturing, production, quality control, and regulatory compliance.

This blog will explore the key aspects of Shriram Pharmacy College’s programs and how they contribute to the evolving field of pharmaceutical education. We will also delve into how the college ensures students are prepared to meet the industry’s high standards in drug manufacturing, quality control, automation, and environmental sustainability.

## Engineer Drug Manufacturing Processes Effectively

At Shriram Pharmacy College, students are provided with a comprehensive understanding of drug manufacturing processes. Through a blend of theoretical knowledge and practical exposure, the college ensures that its students are proficient in the intricacies of drug formulation and manufacturing.

From raw material procurement to final product delivery, the college’s curriculum focuses on optimizing drug manufacturing processes for better efficiency and quality. Students are trained in advanced techniques to improve yield, reduce costs, and enhance product consistency. Moreover, they are encouraged to stay updated with the latest research and technological advancements that drive innovations in drug manufacturing.

## Enhance Pharmaceutical Production Equipment Efficiency

Efficiency in pharmaceutical production equipment is crucial for the smooth operation of any manufacturing plant. At Shriram Pharmacy College, students gain an in-depth understanding of the various types of pharmaceutical production equipment used in the industry, such as tablet presses, capsule fillers, mixers, and granulators.

The curriculum emphasizes the importance of regular maintenance, troubleshooting, and optimization techniques to ensure that production equipment functions at peak efficiency. Students learn how to monitor equipment performance and identify areas for improvement, thereby minimizing downtime, reducing operational costs, and ensuring consistent product quality.

## Guarantee Adherence To Regulatory Requirements

Regulatory compliance is a cornerstone of the pharmaceutical industry. Shriram Pharmacy College places significant emphasis on teaching students about the regulatory frameworks that govern drug manufacturing and distribution in India and internationally.

Students are educated on the guidelines set by bodies such as the Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the Central Drugs Standard Control Organization (CDSCO). The college ensures that students are well-versed in Good Manufacturing Practices (GMP), Good Laboratory Practices (GLP), and other regulatory standards necessary for ensuring the safety, efficacy, and quality of pharmaceutical products.

## Create Streamlined Pharmaceutical Manufacturing Techniques

As the demand for cost-effective pharmaceutical solutions increases, Shriram Pharmacy College equips students with the tools to create streamlined and efficient manufacturing techniques. Through the curriculum, students are introduced to process optimization methodologies like Lean Manufacturing and Six Sigma, which are widely adopted in the industry to reduce waste and enhance operational efficiency.

The college also teaches students how to integrate newer technologies like Artificial Intelligence (AI) and machine learning into the manufacturing process, facilitating real-time monitoring, predictive maintenance, and production optimization.

## Integrate Automation Into Pharmaceutical Operations

Automation is transforming the pharmaceutical industry by increasing efficiency, reducing human error, and improving safety. Shriram Pharmacy College is at the forefront of this shift by incorporating automation into its training programs.

Students learn how automated systems can be integrated into various stages of pharmaceutical operations, including manufacturing, packaging, and quality control. They are trained to design, implement, and maintain automated solutions that ensure consistency, precision, and speed in production processes. This knowledge prepares students for careers in an increasingly automated pharmaceutical landscape, where human involvement is minimized, but oversight and control remain paramount.

## Pioneer Packaging And Labeling Advancements

Packaging and labeling are essential components of pharmaceutical manufacturing, as they ensure product integrity and provide essential information to consumers. Shriram Pharmacy College places a strong emphasis on educating students about the latest advancements in packaging and labeling technologies.

Students are introduced to innovations such as smart packaging, tamper-evident seals, and RFID-enabled labels. They also learn the importance of compliance with regulatory requirements for packaging and labeling, including the accurate display of drug information, dosage instructions, and expiration dates. By focusing on these aspects, the college ensures that students understand the critical role packaging and labeling play in ensuring both safety and consumer trust.

## Enhance Production Quality Control Measures

Quality control (QC) is paramount in the pharmaceutical industry. Shriram Pharmacy College ensures that students are equipped with the necessary skills to enhance production quality control measures at every stage of the drug manufacturing process.

The college provides comprehensive training in QC techniques, including the analysis of raw materials, in-process testing, and final product validation. Students are taught to use sophisticated laboratory instruments and software to monitor and test product quality, ensuring it meets regulatory standards. By focusing on improving QC processes, the college helps students become skilled professionals capable of ensuring the highest standards of pharmaceutical product quality.

## Assess Environmental Impact Of Operations

In today’s environmentally conscious world, pharmaceutical companies are under increasing pressure to minimize their environmental footprint. Shriram Pharmacy College includes sustainability as a key component of its curriculum, teaching students how to assess and reduce the environmental impact of pharmaceutical operations.

Students learn how to design eco-friendly manufacturing processes, reduce waste, and optimize energy consumption. They are also educated on sustainable sourcing practices, waste management protocols, and green chemistry techniques. By fostering an understanding of environmental sustainability, the college ensures that future pharmacy professionals can contribute to making the pharmaceutical industry more eco-friendly.

/media/703e96b75a9549241280177463387020

## Frequently Asked Questions (FAQ)

**1. What makes Shriram Pharmacy College different from other pharmacy colleges in India?**

Shriram Pharmacy College stands out for its state-of-the-art infrastructure, comprehensive curriculum, and industry-relevant training. The college focuses on both theoretical learning and practical exposure, ensuring students are well-prepared for the challenges of the pharmaceutical industry. Additionally, it integrates emerging technologies and modern manufacturing practices into its programs, equipping students with cutting-edge knowledge that sets them apart in the competitive job market.

**2. Does Shriram Pharmacy College provide placements to its students?**

Yes, Shriram Pharmacy College has a dedicated placement cell that works actively to place students in top pharmaceutical companies. The college has a strong network with leading industry players and offers career counseling, interview preparation, and internship opportunities. Many students from Shriram Pharmacy College have secured positions in renowned companies, owing to the college’s excellent reputation and industry connections.

**3. How does Shriram Pharmacy College ensure that its students are industry-ready?**

Shriram Pharmacy College ensures that students are industry-ready by offering a curriculum designed in collaboration with industry experts. Students participate in internships, workshops, and real-time projects to gain practical experience. The college also invites professionals from the pharmaceutical industry for guest lectures, providing students with insights into current trends and challenges in the sector.

**4. Are there any research opportunities at Shriram Pharmacy College?**

Yes, Shriram Pharmacy College encourages students and faculty to engage in research activities. The college has well-equipped laboratories and research facilities that support projects in areas such as drug development, quality control, and pharmaceutical technologies. Students are also encouraged to participate in research conferences and contribute to academic publications.

**5. What career options are available to graduates of Shriram Pharmacy College?**

Graduates of Shriram Pharmacy College have a wide range of career options available to them in the pharmaceutical sector. They can work in pharmaceutical manufacturing, quality control, regulatory affairs, research and development, and marketing. Additionally, students can pursue higher education or take on roles in hospitals, drug safety, and clinical research organizations.

## Conclusion

Shriram Pharmacy College, Bankner, continues to be a leader in pharmacy education in India by combining academic rigor with practical industry exposure. The college offers students unparalleled opportunities to excel in the pharmaceutical industry by focusing on key areas such as drug manufacturing, quality control, regulatory compliance, and automation. By fostering innovation, sustainability, and efficiency, Shriram Pharmacy College is shaping the next generation of pharmacy professionals who will drive the future of the pharmaceutical industry. Whether it’s through cutting-edge research, industry collaborations, or state-of-the-art facilities, Shriram Pharmacy College ensures that its students are well-equipped to meet the demands of the ever-evolving pharmaceutical world.

Like, Share, Subscribe for updates from Shri Ram Pharmacy College!

Thank you for visiting Shri Ram Pharmacy College’s YouTube channel! If you enjoyed our content, please take a moment to **Like**, **Share**, and **Subscribe** to stay updated with our latest videos, including insightful lectures, industry updates, and student success stories. By subscribing, you’ll be a part of our growing community dedicated to excellence in pharmacy education. Don’t forget to visit our official website at [www.shrirampharmacycollege.com] for more information on our programs, admissions, and campus life. We appreciate your support and look forward to connecting with you soon!

0 notes

Text

Top Benefits of Talc Powder in Industry and How to Choose the Right Supplier

Talc powder is an essential ingredient in a wide array of industrial applications due to its unique properties. As one of the softest minerals known to man, talc powder is utilized in various industries, including cosmetics, pharmaceuticals, plastics, ceramics, paint, and more. This versatile mineral has significant importance, especially for manufacturers and suppliers seeking the highest quality talc powder for their products. In this article, we’ll explore what talc powder is, its applications, and how to find the right supplier to meet your business needs.

What is Talc Powder?

Talc is a naturally occurring mineral primarily composed of magnesium, silicon, and oxygen. It is renowned for its softness and has a unique greasy or soapy feel. Due to its properties such as heat resistance, electrical insulation, and chemical inertness, talc powder has been used for centuries in a variety of industries.

Talc powder is typically produced through a process of mining, crushing, and grinding the talc rocks. The resulting powder is fine and smooth, making it an ideal additive for many products. Its characteristics, such as its ability to absorb moisture, enhance texture, and act as a lubricant, make it indispensable in both industrial and consumer goods.

Key Industrial Applications of Talc Powder

Talc powder is widely used across several industries due to its versatile nature. Let’s take a closer look at some of its most common applications:

Cosmetics and Personal Care: Talc powder is a key ingredient in many personal care products like baby powder, body powder, and deodorants. Its moisture-absorbing properties make it ideal for preventing skin irritation and keeping the skin dry. Talc is also used in the formulation of makeup products such as foundations, eye shadows, and blushes, giving them a smooth texture and long-lasting finish.

Pharmaceuticals: In the pharmaceutical industry, talc powder serves as an excipient in the production of tablets and capsules. It helps in the lubrication of tablet machines and enhances the smoothness of pills, making them easier to swallow. Talc is also used as a bulking agent in certain pharmaceutical formulations.

Plastics and Rubber: Talc powder is frequently added to plastics and rubber compounds to improve their strength and stiffness. By acting as a reinforcing agent, talc helps reduce friction and enhances the material’s durability. It is often used in the manufacture of automotive parts, electrical components, and household goods.

Ceramics: In ceramics, talc powder is used to improve the texture and workability of clay. It also contributes to the durability and finish of ceramic products such as tiles, sanitary ware, and cookware.

Paints and Coatings: Talc’s ability to improve the smoothness and consistency of paints makes it a valuable ingredient in the coatings industry. It also enhances the performance of paints by providing opacity, durability, and resistance to corrosion and weathering.

Paper and Pulp: Talc powder is used as a filler in paper manufacturing. It enhances the paper's printability and opacity while improving its surface smoothness. Additionally, talc helps in the control of viscosity and moisture levels during the papermaking process.

Food Industry: Although less common, talc is also used in the food industry as an anti-caking agent in powdered foods like spices, flour, and sugar. Its function is to prevent clumping, allowing for smoother processing and handling.

Choosing the Right Supplier of Talc Powder

When looking for a reliable supplier of talc powder, it’s essential to consider several factors. The quality of talc is critical to ensuring that the final product performs well in its intended application. Here are some important aspects to keep in mind:

Purity and Quality: High-quality talc powder should be free from impurities, such as asbestos, which can be harmful to human health. It’s essential to source talc from a supplier that adheres to strict quality control standards and conducts thorough testing of the material.

Variety and Customization: Different industries may require talc powder with specific characteristics, such as particle size, color, and chemical composition. A reliable supplier should be able to provide a range of talc products tailored to meet the unique needs of your industry.

Reputation and Experience: An experienced supplier with a strong reputation in the market is likely to provide high-quality products consistently. Look for a supplier that has years of experience in sourcing and delivering talc powder to various industries.

Timely Delivery and Customer Service: Efficient delivery and responsive customer service are essential when working with a talc powder supplier. Delays in receiving materials can disrupt your production process, so it’s important to choose a supplier who can meet your deadlines.

Pratibha Refractory Minerals, a well-established name in the industry, is a leading supplier of talc powder. They offer high-quality talc powder for various industrial applications, ensuring that their customers receive reliable and consistent products.

Conclusion

Talc powder plays a crucial role in a wide range of industries, and choosing the right supplier is key to ensuring that your products meet the highest standards. Whether you are in the cosmetics, pharmaceuticals, or manufacturing sector, sourcing quality talc powder can significantly improve the performance and quality of your products. By working with a reputable supplier, you can ensure that your business remains competitive and successful in a fast-evolving market.

0 notes

Text

0 notes

Text

0 notes

Text

Automatic Capsule Filler Machine

youtube

Automatic Capsule Filler Machine is suitable for filling powder/pellets in hard gelatin capsules. It adopts indexing motion and multi-position tamping method to complete capsule orientation, separation, filling, closing and ejection etc. With help of different size parts, machine is suitable for size #00, #0, #1, #2, #3 & #4 capsules. The production speed can be controlled by means of a VFD (Variable Frequency Drive). Machine is designed in accordance with cGMP standards. All product contact parts are made of Stainless Steel 316 & machine covered by Stainless Steel 304. Advantage of the machine is advanced design, study structure, precise dosing, and safe and reliable, high filling rate etc.Machine having wide usage in R&D laboratories, Research Institutions, Herbal & Nutraceutical preparations, Unani &Ayurvedic medicines, Pilot batch productions etc.

We can provide line equipments naming Capsule Sorter Elevator, Capsule Conveying System, Capsule Polishing Machine, Dust Extractor, Damage Capsule Sorter and Empty Capsule Ejector to make complete Automatic Capsule Filling Line.

0 notes

Text

Choosing the Right Pharmaceutical Machine Manufacturer: Key Considerations and Industry Trends

Introduction

The pharmaceutical industry relies on precision and quality in every aspect of production, from drug formulation to packaging. A trusted pharmaceutical machine manufacturer plays a vital role in providing the high-quality, reliable equipment needed to meet stringent regulatory standards and optimize production processes. With advancements in automation and compliance requirements becoming more rigorous, selecting the right manufacturing partner is crucial for pharmaceutical companies looking to stay competitive.

The Role of a Pharmaceutical Machine Manufacturer

Pharmaceutical machine manufacturers supply specialized equipment for various stages of drug production, including mixing, filling, coating, and packaging. Their expertise enables pharmaceutical companies to enhance productivity, achieve consistent quality, and ensure regulatory compliance. A pharmaceutical machine manufacturer typically provides:

Mixing and Blending Equipment: Critical for creating uniform pharmaceutical formulations.

Filling Machines: These ensure accurate filling and minimize waste, essential for liquid or powder forms.

Tablet Presses and Capsule Fillers: Used for solid dosage production, ensuring consistent weight and dosage.

Coating Machines: Provides coating for tablets to improve stability, mask taste, or control release.

Inspection and Packaging Equipment: Ensures final products meet quality standards and remain safe for consumers.

Each type of machinery is designed with precision and strict compliance in mind, helping pharmaceutical companies maintain high standards in their production lines.

Key Considerations When Choosing a Pharmaceutical Machine Manufacturer

Selecting the right pharmaceutical machine manufacturer requires careful evaluation of multiple factors. Here are some key considerations:

Quality and Compliance: Regulatory requirements in the pharmaceutical industry are stringent. Manufacturers should have the necessary certifications, such as ISO 9001 and Good Manufacturing Practice (GMP) compliance. Equipment should meet or exceed FDA or WHO standards for quality.

Customization and Flexibility: Each pharmaceutical process has unique requirements, so look for a manufacturer that offers customized solutions to fit specific production needs. This includes flexible machine configurations to support different products, dosage forms, and batch sizes.

After-Sales Support and Maintenance: Reliable technical support and maintenance services are essential for uninterrupted operations. Choose a pharmaceutical machine manufacturer that provides ongoing support, training, and quick troubleshooting assistance.

Technology and Innovation: The pharmaceutical industry is constantly evolving. Select a manufacturer that invests in R&D and adopts new technologies, such as automation, Internet of Things (IoT), and AI, to enhance efficiency and accuracy.

Cost Efficiency and ROI: While high-quality machinery can be an investment, it should also offer long-term value. A reputable pharmaceutical machine manufacturer provides cost-effective equipment that balances quality with competitive pricing, ensuring a return on investment through improved productivity and minimized downtime.

Emerging Trends in Pharmaceutical Machinery

In recent years, pharmaceutical manufacturing has witnessed significant innovations driven by technological advances and changing industry demands. Leading pharmaceutical machine manufacturers are embracing these trends:

Automation and Robotics: Automation reduces human error, enhances precision, and speeds up production processes. Robotics is being used for repetitive tasks like filling, sealing, and labeling, improving both efficiency and safety.

IoT and Smart Machines: IoT integration enables real-time monitoring of machine performance, maintenance scheduling, and remote troubleshooting. Smart machines equipped with IoT sensors offer predictive maintenance, ensuring continuous and smooth operations.

Single-Use Technologies: For biopharmaceutical applications, single-use systems reduce cross-contamination risks and simplify cleaning processes. Many manufacturers now offer single-use mixers, filters, and bioreactors that streamline production, especially for small-batch or high-potency drugs.

3D Printing in Pharmaceutical Machinery: Although still emerging, 3D printing is paving the way for customized, on-demand machinery components. This flexibility enables manufacturers to produce equipment parts tailored to specific processes, reducing lead times and production costs.

Environmental Sustainability: With a growing focus on sustainability, machine manufacturers are innovating eco-friendly designs. Energy-efficient machines, biodegradable packaging solutions, and waste reduction practices are becoming standard in the industry.

Why Partnering with the Right Pharmaceutical Machine Manufacturer Matters

A trusted pharmaceutical machine manufacturer provides more than just machinery; they are a partner in helping pharmaceutical companies achieve operational excellence. High-quality equipment not only streamlines production but also enhances safety and ensures compliance, which is paramount in an industry with strict regulations.

Collaborating with an experienced manufacturer enables pharmaceutical companies to:

Enhance Product Quality: High-precision machines reduce variability and enhance the quality and safety of end products.

Increase Productivity: Advanced, reliable machinery optimizes throughput, reducing bottlenecks and minimizing downtime.

Achieve Compliance: Reputable manufacturers provide equipment designed to meet GMP, FDA, and WHO guidelines, essential for regulatory compliance.

Reduce Costs: High-efficiency machines lower operational costs and reduce wastage, improving profitability in the long run.

Conclusion

Choosing the right pharmaceutical machine manufacturer is a strategic decision that affects quality, efficiency, and regulatory compliance. By partnering with a reputable manufacturer that offers high-quality equipment, advanced technology, and reliable support, pharmaceutical companies can streamline production processes and gain a competitive edge in a demanding industry. As trends continue to evolve, it’s essential to work with a manufacturer that can adapt to new technologies and help businesses stay ahead in an ever-changing market.

0 notes

Text

TESTOSIL: FEEL THE BOOST, TRANSFORM YOUR LIFE! 💪✨

Feeling sluggish? Struggling to keep up with the younger crowd?

You’re not alone.

Many of us worry about energy dips and performance issues as we age.

That’s where Testosil comes in, offering a potential boost when you need it most.

With Testosil for sale, it's time to compare its benefits against others like Testosil vs Prime Male.

Ready to see if this could be your game-changer? Let's jump into the details!

👉 BUY TESTOSIL FOR UNMATCHED TESTOSTERONE SUPPORT

Testosil

When it comes to boosting testosterone levels, I know how confusing things can get.

You might be wondering if there's a product out there that actually works.

Let’s break down what Testosil is all about.

What Is Testosil?

Testosil is marketed as a testosterone booster designed to help men enhance their physical performance and vitality.

It claims to support muscle growth, increase energy levels, and improve overall mood.

I’ve seen plenty of guys rave about its effects on various forums and social media platforms.

But what’s the real deal?

Let’s look at the testosil ingredients that make this product tick.

Key Testosil Ingredients

The magic lies in the blend of ingredients packed into each capsule.

Here are some key components:

D-Aspartic Acid: This amino acid plays a role in hormone production. Some studies suggest it may help boost testosterone levels.

Fenugreek Extract: Known for its potential to enhance libido and promote healthy testosterone levels.

Zinc: Essential for hormone production, zinc deficiency can lead to lower testosterone levels.

Vitamin D: Often linked with improved mood and energy, adequate vitamin D is crucial for maintaining testosterone levels.

These ingredients work together like a well-oiled machine.

They’re not just random herbs thrown into a bottle; they’re selected based on research and effectiveness.

Testosil Side Effects

Now, let's talk about something important – testosil side effects.

Every supplement has its pros and cons, right?

Some users have reported mild side effects such as:

Upset stomach

Headaches

Changes in sleep patterns

Most of these issues seem manageable but keep an eye on how your body reacts when you start taking it.

If you're ever unsure or feel something's off, consulting with a healthcare professional is always smart.

Is Testosil Safe?

So, is testosil safe?

From what I gather, most users don’t experience severe adverse reactions when taking it as directed.

It's generally regarded as safe for healthy adults.

However, if you have any pre-existing health conditions or are on medication, it's better to consult with your doctor first.

Safety first!

The Benefits of Testosil

What really sets this product apart are the potential testosil benefits that many users rave about:

Increased Energy Levels: Many folks report feeling more energetic throughout the day.

Enhanced Muscle Growth: If you're hitting the gym hard, you might notice gains more quickly than before.

Improved Mood: A boost in testosterone can lead to better mood stability and reduced irritability.

Better Libido: Let’s face it; who doesn’t want that?

Take John from Texas, 35 years old:

“After using Testosil for three months, I noticed my workouts were way more productive! My energy skyrocketed.”

And then there’s Mike from California, 42 years old:

“Not only did my strength improve at the gym but my confidence shot up too! It feels great.”

These testimonials highlight how effective this supplement can be for real people dealing with everyday challenges related to low testosterone levels.

Why Choose Testosil?

There are tons of products claiming to do similar things out there but let me tell you why I think Testosil stands tall above others:

Its ingredient list isn’t filled with fillers or mystery compounds.

Real user experiences show positive results without extreme side effects.

It targets multiple areas—energy, muscle growth, mood—all in one go!

If you're looking for a reliable way to boost your testosterone naturally without resorting to harsh chemicals or treatments, give Testosil a shot!

In short,

This isn’t just another supplement; it could be the game-changer you've been searching for.

Ready to take control of your vitality?

👉 BUY TESTOSIL TO TRANSFORM YOUR WORKOUTS

Testosil For Sale

When you're on the hunt for something that can genuinely boost your performance, you want to know where to find it.

I get it.

You’ve heard about Testosil, and now you’re wondering where to snag your own bottle.

Let’s break this down.

Where To Buy Testosil

Finding the right place to buy Testosil is crucial.

You want a reliable source that guarantees quality and authenticity.

The best option?

Head straight to their official website.

It’s the most straightforward way to ensure you’re getting the real deal without any shady business.

Plus, buying directly from the source often means better deals and exclusive offers.

Testosil Price: What You Can Expect

Now, let’s talk money.

The price of Testosil can vary depending on promotions or bundles they offer.

Typically, you’ll find it priced competitively compared to other supplements in its category.

Here’s a quick breakdown of what I’ve seen:

Single Bottle: Around £39.99

Two Bottles: Approximately £69.98 (a nice little saving)

Three Bottles: About £99.97 (the best value if you're serious)

Keep an eye out for seasonal discounts or special promotions on their site too!

These can help you snag a great deal without compromising on quality.

Snagging A Testosil Discount Code

Who doesn’t love a good discount?

If you’re looking for ways to save on your purchase, keep an eye out for Testosil discount codes floating around online.

They often run promotions that give you a percentage off your order or free shipping when you buy multiple bottles.

Signing up for their newsletter is also a smart move.

You might just score an exclusive code sent straight to your inbox!

Imagine getting that boost in performance while saving some cash at the same time—win-win!

Why Choose Testosil Over Other Options?

You might be thinking, “Why should I go with Testosil?”

Good question!

What sets it apart?

For starters, it’s formulated with natural ingredients designed specifically for enhancing testosterone levels safely and effectively.

Many users report noticeable improvements in energy levels, mood stability, and even muscle growth after consistent use.

Take John, 35 years old. He shared,

“I was feeling sluggish and unmotivated until I tried Testosil. Within weeks, my energy skyrocketed! It feels like I'm back in my twenties.”

Then there’s Sarah, 42:

“After starting Testosil, not only did my workouts improve but so did my overall mood! I can’t recommend it enough!”

These testimonials aren’t just fluff; they reflect genuine experiences from real people who decided to take action and boost their confidence through supplementation.

Final Thoughts

So here we are—ready to make a decision?

When searching for Testosil for sale, remember:

Buy from their official website.

Look out for promotional offers.

Keep an eye open for discount codes that could save you money.

This isn’t just about buying another supplement; it's about investing in yourself and reclaiming your vitality.

Don’t wait around while others take charge of their health—make your move today!

👉 BUY TESTOSIL FOR A LIFETIME GUARANTEE

Testosil Vs Prime Male

When it comes to boosting testosterone, two names pop up a lot: Testosil and Prime Male.

I get it. You want to know which one packs more punch.

Let’s break this down.

Ingredients Matter

Both products claim to help with testosterone levels, but what’s inside matters.

Testosil focuses on natural ingredients like:

D-Aspartic Acid

Fenugreek Extract

Zinc

These are known for their potential in supporting testosterone production.

On the flip side, Prime Male boasts its own blend, including:

D-Aspartic Acid

Vitamin D

Nettle Root Extract

Both have D-Aspartic Acid, but the other ingredients differ.

This could affect how each product works for you.

Benefits Breakdown

What can you really expect from each?

With Testosil, users often rave about increased energy levels and better workouts.

Here’s what one user said:

“I’m 35 and felt sluggish all the time. After using Testosil for a month, my energy shot up! I’m hitting the gym harder than ever.” — Mark, 35

Now let’s look at Prime Male. It promises similar benefits but also claims to enhance mood and mental clarity.

One user mentioned:

“I’ve noticed not just physical changes but also a boost in my focus throughout the day.” — John, 42

So both products have their perks. It boils down to what you need most—energy or overall well-being.

Price Point Comparison

Money always plays a role in decisions, right?

Testosil generally sits at a lower price point compared to Prime Male.

If you’re watching your budget but still want results, that could be a game-changer.

But remember: cheaper doesn’t always mean lesser quality.

User Experiences

Real experiences can guide us better than any marketing spiel.

Many folks report significant gains with both products.

For instance:

“Testosil helped me regain my confidence and strength after months of feeling low.” — Tom, 38

And then there’s feedback on Prime Male, which often highlights its mood-enhancing effects:

“I feel more motivated and energetic since starting Prime Male.” — Sarah, 40

Both have their champions!

Safety First

Safety is non-negotiable when choosing supplements.

Both brands claim to use safe ingredients with minimal side effects.

However, personal reactions can vary widely based on individual health conditions or allergies.

Always consult your doctor before trying something new!

Testosil Vs Nugenix: A Quick Look

Now if we throw in another player—Nugenix—the conversation gets even spicier!

While Nugenix has solid reviews too, its formula differs significantly from both Testosil and Prime Male.

It tends to focus heavily on libido enhancement rather than overall testosterone support.

So if that’s your main goal? Nugenix might be worth considering alongside these two heavyweights.

In short:

Testosil: Great for energy and workout performance.

Prime Male: Good for mood enhancement along with physical benefits.

Nugenix: More focused on libido improvement.

Final Thoughts

At the end of the day, it comes down to personal preference and goals.

I’d suggest trying out one first before jumping into another if you're unsure which fits best for your lifestyle.

Remember: everyone reacts differently!

So whether you lean towards Testosil, go for Prime Male, or even consider adding in some insights from the comparison with Nugenix, make sure it aligns with what you're looking for in terms of results!

👉 BUY TESTOSIL AND FEEL THE DIFFERENCE NOW

FAQ

What is Testosil?

Testosil is a testosterone booster designed to help increase testosterone levels in men. It aims to support muscle growth, enhance energy levels, and improve overall vitality.

What are the ingredients in Testosil?

Testosil typically includes a blend of natural ingredients like D-Aspartic Acid, Fenugreek Extract, and Zinc. These components are known for their potential to support testosterone production and overall male health.

Are there any side effects associated with Testosil?

While many users report positive experiences, some might encounter mild side effects such as headaches or digestive issues. It's always smart to monitor how your body reacts when trying a new supplement.

Is Testosil safe to use?

Yes, Testosil is generally considered safe for most people when used as directed. Still, it's wise to consult with a healthcare professional before starting any new supplement, especially if you have pre-existing health conditions.

What benefits can I expect from taking Testosil?

Users often notice increased energy levels, improved mood, enhanced libido, and better muscle recovery. Many find it helps them feel more confident and motivated in their fitness journey.

Where can I buy Testosil?

You can find Testosil available for purchase on various online platforms. Always check official websites or reputable retailers to ensure you're getting the genuine product.

Are there any discounts available for Testosil?

Occasionally, promotions or discount codes may be offered through the official website or trusted retailers. Keep an eye out for special offers that could save you some cash!

How does Testosil compare to Prime Male?

Both supplements aim to boost testosterone but may differ in their ingredient formulations and target audience. Personal preference and individual responses will often guide which one works best for you.

Is Testosil better than Nugenix?

It really depends on what you're looking for. Nugenix has its own set of benefits and formulation that some users prefer. Trying both might give you a clearer picture of which suits your needs better.

How long does it take to see results from Testosil?

Many users report noticing changes within a few weeks of consistent use. Everyone's body reacts differently, so patience is key while monitoring your progress!

👉 BUY TESTOSIL AND BOOST YOUR ENERGY TODAY

0 notes

Text

Equipment Used in the Pharmaceutical Industry

The pharmaceutical industry relies on a vast range of specialized equipment to ensure that the production processes for medicines, vaccines, and other health products are safe, efficient, and compliant with regulatory standards. From raw material handling to the packaging of the final product, equipment plays a crucial role in ensuring quality and sterility. This article explores the essential equipment used in pharmaceutical manufacturing, highlighting the importance of each category and its application in the production process.

1. Mixing and Blending Equipment

Mixers and blenders are critical in combining raw materials and active pharmaceutical ingredients (APIs) into homogeneous mixtures. This equipment ensures that the components are evenly distributed, which is vital for dosage consistency in tablets, capsules, and other pharmaceutical forms. Different types of mixing equipment are used depending on the properties of the ingredients:

Ribbon Blenders: Used for dry powder mixing, commonly in tablet production.

High-Shear Mixers: Ideal for wet granulation processes where liquid binding agents are added to powders.

2. Granulation Equipment

Granulation is a key step in the production of tablets. This process converts fine powders into larger, free-flowing granules, making it easier to compress them into solid dosage forms. The two main types of granulation processes are wet granulation and dry granulation. Equipment used for this purpose includes:

Fluid Bed Granulators: Used in wet granulation to spray binder solutions onto powder particles.

Roller Compactors: Used in dry granulation, where powders are compacted between rollers to form granules without adding liquids.

3. Tableting and Encapsulation Machines

Tableting and encapsulation are the processes of converting granules into solid dosage forms. Specialized machines are required to compress powders into tablets or encapsulate them in capsules:

Tablet Presses: These machines compress powders or granules into tablets of uniform size and weight. Single-punch or rotary tablet presses are commonly used, depending on production scale.

Capsule Fillers: Capsule filling machines automatically fill empty gelatin or HPMC capsules with powders, granules, or liquid formulations, ensuring precise dosage in each capsule.

4. Coating Machines

Pharmaceutical tablets often require coatings for several reasons, such as improving taste, protecting the active ingredients, or controlling drug release. Coating machines apply a thin layer of polymer or sugar-based coating onto the tablet's surface. The most common equipment used for this purpose includes:

Pan Coaters: These machines rotate tablets in a pan while spraying the coating solution.

Fluidized Bed Coaters: Used for applying coatings to particles or small tablets by suspending them in an air stream while applying the coating material.

5. Sterilization Equipment

In pharmaceutical production, sterility is paramount, especially in the manufacturing of injectable drugs, vaccines, and other sterile products. Sterilization equipment ensures that any microbial contamination is eliminated. The common sterilization methods and equipment include:

Autoclaves: Use steam under pressure to sterilize equipment and pharmaceutical products. They are widely used for sterilizing surgical instruments, glassware, and some types of media.

Dry Heat Sterilizers: Ideal for sterilizing equipment that can withstand high temperatures but not moisture, such as glass bottles and metal equipment.

Gamma Irradiation: Used for sterilizing pharmaceutical products that are sensitive to heat or moisture.

6. Filtration Systems

Filtration is critical in ensuring that liquids and gases used in pharmaceutical manufacturing are free from particulates, bacteria, and other contaminants. Filtration systems are essential in the production of injectable drugs, vaccines, and sterile products:

Membrane Filters: Used to remove bacteria and particulates from liquid formulations. These filters are commonly used in the preparation of sterile solutions.

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are used in cleanrooms and HVAC systems to ensure the air is free from particulates and microorganisms.

7. Water Purification Systems

Water is a fundamental ingredient in the pharmaceutical industry, used in various forms, such as Purified Water (PW), Water for Injection (WFI), and Ultra-Pure Water (UPW). Water purification systems ensure that the water used in pharmaceutical production meets strict purity standards:

Reverse Osmosis (RO) Systems: Remove dissolved solids, bacteria, and organic impurities from water.

Electrodeionization (EDI) Systems: Used for the continuous production of ultra-pure water by removing ionic contaminants.

Water for Injection (WFI) Systems: Produce highly purified, sterile water used in the production of injectables and other sterile pharmaceutical products.

8. Packaging Equipment

Pharmaceutical packaging must ensure the product’s safety, integrity, and compliance with regulatory requirements. The packaging process also protects the product from contamination, tampering, and environmental factors. Common types of packaging equipment include:

Blister Packaging Machines: Used for packaging tablets and capsules in pre-formed cavities made of plastic or aluminum.

Bottle Filling Machines: Automatically fill liquid pharmaceuticals into bottles or vials, ensuring precise measurement and sealing.

Labeling Machines: Apply labels to pharmaceutical containers, ensuring that they contain the correct product information and batch details.

9. Quality Control Equipment

Pharmaceutical production requires stringent quality control to ensure that products meet regulatory standards. Quality control equipment is used for testing various attributes of the product, such as potency, purity, dissolution rate, and more:

HPLC (High-Performance Liquid Chromatography): Used to analyze the chemical composition of drugs and ensure that they contain the correct concentrations of active ingredients.

Dissolution Testers: Measure the rate at which tablets or capsules dissolve in liquids, ensuring that they meet specified release profiles.

Spectrophotometers: Analyze the absorbance of light in drug samples, helping to identify impurities or verify the concentration of active ingredients.

10. Cleanroom Equipment

Pharmaceutical manufacturing often takes place in cleanrooms, which are controlled environments designed to minimize contamination from airborne particles. Cleanroom equipment includes:

Air Showers: Used at the entrances to cleanrooms to blow off dust and contaminants from personnel before entering the sterile environment.

Laminar Flow Hoods: Ensure a sterile working environment by providing a stream of filtered air over work surfaces, minimizing the risk of contamination.

Conclusion

The pharmaceutical industry relies on a wide variety of specialized equipment to ensure the safe, efficient, and compliant production of medicines and other health products. From mixing and granulation to sterilization, packaging, and quality control, every stage of pharmaceutical manufacturing is supported by advanced technologies designed to maintain product integrity and meet the highest purity standards. With the demand for pharmaceuticals constantly increasing, the role of equipment in ensuring product safety, quality, and regulatory compliance cannot be overstated.

SWJAL PROCESS Pvt. Ltd. offers high-quality pharmaceutical equipment to ensure safe, efficient, and compliant production processes across the pharmaceutical industry.

0 notes

Text

Pharmaceutical Machinery Manufacturers & Exporters - Lodha International LLP

Lodha International LLP is a premier manufacturer and exporter of pharmaceutical machinery, offering a varies range of top-quality products. Their offerings include liquid filling machines, powder filling machines, capsule filling machines, tablet section machines, cream and ointment filling machines, ampoule filler sealers, and more. With extensive experience and a global reach, Lodha International LLP is recognized as a leading and trusted provider in the industry. Located in Gujarat, they are dedicated to supplying high-quality equipment, exceptional support, and reliable service. Their product range covers complete packaging lines and processing equipment for production, quality control, and formulation labs across the pharmaceutical, dietary supplements, food, cosmetic, and chemical industries. Providing to both small-scale operations and large production batches, they maintain high standards and quality in every product. As a top producer of pharmaceutical equipment in India, Lodha International LLP offers competitive pricing without sacrificing quality. For those in search of a dependable supplier of pharmaceutical machinery, Lodha International LLP is the ideal choice for complete manufacturing solutions. For more info Please Visit: www.lodhapharma.com

0 notes