#Capacitor Design Network

Explore tagged Tumblr posts

Text

Reviving Tesla’s Dream: The Future of Wireless Power Transmission

“My project was retarded by the laws of nature. The world was not prepared for it. It was too far ahead of time. But the same laws will prevail in the end and make it a triumphal success.” – Nikola Tesla

In the early days of radio technology, there was a crucial decision point that split wireless technology into two distinct paths. One path, pursued by Marconi and others, focused on electromagnetic wave transmission. The other path, championed by Nikola Tesla, aimed to minimize electromagnetic waves and use the Earth itself for energy transmission. While the world predominantly embraced the former, Tesla’s innovative approach was largely forgotten. Let’s explore Tesla’s lost art.

Tesla's wireless power transmission system, often known as his "Magnifying Transmitter," was a pioneering approach to sending electrical energy over long distances. Unlike today’s wireless technologies, which rely on electromagnetic waves, Tesla's design aimed to transmit energy through the earth, which he believed was more efficient.

Tesla showcased his system’s potential during his 1899 experiments in Colorado Springs. He successfully transmitted energy through the ground, illuminating bulbs about a mile away from the transmitter. Tesla saw this as a matter of engineering: just as a machine that can throw a rock 5 feet can be engineered to throw it 1,000 feet, he believed his system could be adjusted to transmit power across any distance on Earth.

Modern wireless technologies, such as radio, Wi-Fi, and cellular networks, use electromagnetic waves that spread outward from a source. These waves lose strength according to the inverse square law, which means signal strength decreases with the square of the distance from the source. This energy loss is a significant limitation for long-distance communication and power transmission.

Tesla’s vision was quite different. He recognized that while electromagnetic waves were effective for communication, they were inefficient for transmitting large amounts of power. As he put it, “I only used low alternations, and I produced 90 percent in current energy and only 10 percent in electromagnetic waves, which are wasted.” Tesla aimed to minimize electromagnetic radiation, which he considered to be energy-draining. Instead, he focused on transmitting energy through the earth, which he believed was more efficient and recoverable.

Tesla's system utilized a large coil known as the "Magnifying Transmitter," which generated a high-voltage, low-frequency current. This design featured significant self-inductance and minimal capacitance, producing a strong resonant effect. By accumulating and directing massive amounts of energy with minimal losses, Tesla aimed for efficient power transmission. As he explained, “I accumulate in that circuit a tremendous energy... I prefer to reduce those waves in quantity and pass a current into the earth, because electromagnetic wave energy is not recoverable while the earth current is entirely recoverable, being the energy stored in an elastic system.”

The scientific principles of Tesla's system include:

1. Resonant Circuits: Tesla's system used resonant circuits, tuning the primary and secondary coils to the same frequency. This resonance allowed for efficient energy transfer between coils, amplifying energy while minimizing losses.

2. Self-Inductance: A key component of Tesla’s system was self-inductance. A large coil with high self-inductance generated a strong magnetic field essential for creating high-voltage, low-frequency current. Self-inductance helped store energy in the coil’s magnetic field, critical for high power levels.

3. Capacitance: Tesla’s design involved large capacitors to store electrical energy. Capacitance was kept small compared to self-inductance to achieve desired resonant effects. The capacitors would discharge rapidly, creating high-voltage pulses for transmission through the earth.

To construct a system similar to Tesla’s, he advised:

1. Low Frequency, High Voltage Design: Build a large Tesla coil to generate high voltages at low frequencies. Ensure the design minimizes electromagnetic radiation and focuses on efficient energy transfer into the ground.

2. Loose Coupling for Resonance: Use loose coupling between the primary and secondary coils to achieve significant resonant rise. The coils should be inductively linked but not too close to avoid direct energy transfer.

3. Earth Connection: Establish a deep, effective ground connection to allow the transmitter to send electrical currents into the earth, utilizing its natural conductive properties.

4. Minimizing Radiation: Design the system to suppress electromagnetic radiation, aiming to retain energy within the circuit and direct it into the ground. Tune the system to maximize energy storage and transfer.

5. Energy Storage and Discharge: Incorporate large capacitors for storing and rapidly discharging energy to create high-voltage, low-frequency oscillations.

Tesla’s system faced significant challenges, including the need for large, expensive equipment. In 1914, he estimated the cost of his "Magnifying Transmitter" at $450,000—around $15 million today. These financial constraints prevented him from fully realizing his dream and unfortunately led to his public image as a mad scientist with unrealistic future visions. However, the potential applications of his system are vast, from global wireless power transmission to reducing infrastructure costs and powering remote areas. With ongoing advancements in technology, Tesla’s vision may be within reach.

Tesla’s system presents an alternative approach to wireless energy transmission, focusing on efficiency and long-distance power transfer over the broad dispersal of electromagnetic waves. While modern technologies have advanced in different ways, Tesla’s principles—especially his focus on resonant circuits and earth currents—provide valuable insights into alternative methods of energy transmission. Exploring these principles today could lead to innovative applications, such as more efficient long-distance power transmission or new energy transfer methods.

#nikola tesla#science#history#wireless#energy#power#technology#quotes#ahead of his time#ahead of our time

113 notes

·

View notes

Text

Allan was sitting hunched over at his desk, with a strong light shining on it. Acrid smoke curled up while he worked. He was concentrating so hard that he didn't hear Malmani come in.

"Hey Allan! Your door was open and-- Ancestors! What are you doing? What is that smell?" Malmani took two steps back and coughed.

Allan looked up, startled. "Oh, sorry, I didn't hear you come in Malmani. The smell? Oh, hold on a second, sorry." He flipped a switch next to his desk and a powerful fan over his desk started, and pulled the acrid smoke away. "I was trying to solder together this board and was concentrating so hard. These surface mount components are super tough to do on their own."

As the air cleared, Malmani was able to take a closer look. Eyes watering, she noticed that he had two little clamps on his desk and they were holding a thin wafer of green plastic with...small protrusions dotted all over it.

She flicked her ear and said "What are you making? It looks like a miniature city"

Allan looked down at the PCB and chuckled "Hah, it does, doesn't it? I'm trying to make a new kind of environmental sensor. The ones we have are really bulky and fail often." He realized that they were of K'laxi make and that he was talking to a K'laxi and quickly added "Er, sorry, I mean that I was thinking about the design while I was trying to repair one last week and started daydreaming about making it better."

"It's fine Allan, it's fine. I'm not insulted." Malmani thought for a moment. "At least, I don't think I'm insulted. I was just wondering what you were doing, and now I know. But why?"

"Like I said, the ones in place are bulky. I think I can make one that's more compact. Maybe even one that's more accurate. Plus, it's fun to do."

"Fun?"

"Sure! I like thinking about electronics and how they work and how you could optimize things and make it better."

"So Starbase didn't ask you to make it, you're just making it because you want to?"

"Yup. Starbase and I have been collaborating on the design though. They're letting me know what things they wish were easier to read."

"That's right Mal." Starbase chimed in "Allan was asking me about the environmental sensors, and I had mentioned how it's tough for me to get a holistic view of an area since the sensors don't talk to each other - just to me - so first thing he's doing is adding a local network connection. They should be able to talk to each other and send a more unified picture of what's going on."

Allan nodded "Yeah, see these bits right here?" He gestured with a small plastic stick. "These are the mesh networking components. They are what will let them talk to each other. We're also going to try a human sourced environmental sensor. We make ours a different way, and I think it'll be smaller and faster to refresh. I'm keeping a lot of the K'laxi wiring though, your resistors and capacitors are incredibly efficient. I've already requested a couple boxes of K'laxi components, I want to see how well they mesh with human ones."

Mal shook her head. "I can't get over how you're just designing a new component for Starbase just because. I don't think I would have ever thought to do that."

Allan shrugged. "It's just the way I'm wired I guess. I don't think it's a human-only thing. After all, K'laxi built the whole entire Starbase without us, you have to have your own people who like to tweak and tinker, right?"

Mal thought a moment. "There must be some K'laxi like that because you're right. But I don't know if it's as..." She struggled for word "...as prevalent as it is with Humans? Most of the time, once we have a solution that works, we leave it in place until we have a need for a change. Iterating just for iterations sake doesn't come as naturally to us."

Allan nodded. "Looking at the components in place, I can tell."

Mal flicked an ear.

"Er, I mean that a lot of the comments are perfectly good at doing their job, but they look like that once a workable solution was found people stopped. In a bunch of human components you come across solutions that are elegant, or ones that utilize as few components as possible, or solutions that are the cheapest they could be, things like that." Allan thought for a moment. "I wonder if it has to do with our world? Earth is a lot more dangerous than K'lax right? Maybe we are always trying to find an edge, because that would give us just a little bit more breathing room in case of a disaster."

"Huh Maybe. Anyway, I was coming in to remind you that this week it's your turn to buy the snacks for tonights board game."

"Oh! That's right, that is tonight. Starbase, I'll have to stop here and we can pick it up tomorrow after work okay? I'm almost ready to install the firmware and have you connect and tell me." He stopped "How it feels I guess?"

"That's fine Allan, I'll be here."

#humans are deathworlders#humans are space orcs#humans make things#humans are space capybaras#humans are space oddities#worldbuilding#writing#sci fi writing#humans and ai

173 notes

·

View notes

Text

Essential Electronic Items for IoT and Electronics Enthusiasts

Are you diving into the world of Internet of Things (IoT) and electronics? Whether you are a seasoned engineer or simply beginning out, having a stable list of essential components is key to bringing your initiatives to existence. Here’s a curated list of electronic objects that each maker and tech enthusiast ought to have of their toolkit:

1. Microcontrollers

Arduino Uno: Great for novices and versatile for diverse projects.

Raspberry Pi: Ideal for more complex duties and going for walks complete operating structures.

ESP8266/ESP32: Perfect for wireless communication and IoT projects.

2. Sensors

DHT22: For temperature and humidity readings.

PIR Sensor: Useful for movement detection.

Ultrasonic Distance Sensor: Measures distances with high accuracy.

3. Actuators

Servo Motors: For unique manage in robotics and mechanical structures.

Stepper Motors: Ideal for applications requiring particular movement.

Solenoids: Good for growing mechanical actions and locks.

4. Displays

LCD Display: Useful for showing records and debugging.

OLED Display: Compact and clean for exact photographs and texts.

5. Connectivity Modules

Bluetooth Module (HC-05/HC-06): For short-range wi-fi communication.

Wi-Fi Module (ESP8266): Connects gadgets to the internet.

GSM Module: Enables verbal exchange over mobile networks.

6. Power Supplies

Battery Packs: Various types for transportable electricity.

Voltage Regulators: Ensure solid voltage ranges in your circuits.

Power Banks: Handy for charging and powering devices on the move.

7. Prototyping Tools

Breadboards: Essential for prototyping with out soldering.

Jumper Wires: For making connections on breadboards.

Soldering Kit: For everlasting connections and circuit meeting.

eight. Additional Components

Resistors, Capacitors, and Diodes: Fundamental for circuit design and stability.

Transistors: Key for switching and amplification tasks.

Connectors and Switches: For interfacing and controlling circuits.

By preserving these objects handy, you'll be nicely-prepared to address a huge range of IoT and electronics projects. Whether you're constructing smart domestic devices, wearable tech, or computerized structures, having the right additives can make all the difference.

#IoT#Electronics#Arduino#RaspberryPi#ESP32#Sensors#Actuators#Displays#ConnectivityModules#PowerSupplies#Prototyping#Tech#DIY#Makers#Engineering#ElectronicComponents#TechProjects

2 notes

·

View notes

Text

Empowering Businesses with Ionic App Development Services

In the dynamic landscape of mobile app improvement, corporations are constantly in search of revolutionary solutions to interact with their target market efficaciously. With the proliferation of smartphones and tablets, having a sturdy mobile presence has come to be imperative for staying competitive in the present-day market. This is wherein Ionic app development businesses step in, imparting flexible and green solutions to build cross-platform cellular packages that captivate customers and power business increase.

Unveiling the Power of Ionic App Development

Ionic is an open-source framework that lets builders build fantastic, function-wealthy cellular packages using internet technology which includes HTML, CSS, and JavaScript. Leveraging web technology permits Ionic app development companies to create go-platform programs that run seamlessly on diverse devices and working structures, consisting of iOS, Android, and the web.

1. Cross-Platform Compatibility:

One of the key advantages of Ionic app development is its potential to create cross-platform programs with a single codebase. This drastically reduces development time and costs, as developers can write as soon as possible and deploy throughout multiple systems, making sure of consistency in personal enjoyment throughout gadgets.

2. Native-Like Performance:

Despite being constructed with net technologies, Ionic packages offer native-like overall performance and responsiveness. Through technology like Capacitor or Cordova, Ionic apps can get the right of entry to device capabilities and APIs, turning in a continuing consumer experience with smooth animations, rapid loading instances, and fluid navigation.

3. Rapid Development Cycle:

Ionic's development environment is characterized by its simplicity and simplicity of use, facilitating a fast improvement cycle. With features like Ionic CLI (Command Line Interface) and Ionic DevApp, developers can streamline the development technique, iterate speedy, and take a look at their applications in actual time throughout multiple devices.

4. Extensive UI Component Library:

Ionic comes with a rich set of pre-designed UI additives and layouts, allowing builders to create visually attractive and intuitive personal interface results easily. From buttons and paperwork to navigation bars and modals, Ionic's UI thing library empowers builders to construct polished and expert-looking applications with minimal attempts.

5. Community Support and Ecosystem:

The Ionic framework boasts a colorful community of builders, designers, and lovers who actively contribute to its surroundings. From open-supply plugins and extensions to comprehensive documentation and tutorials, the Ionic network affords helpful resources and support, fostering collaboration and innovation in app development.

Industries Leveraging Ionic App Development Services

1. E-Commerce:

Ionic app improvement agencies cater to the growing desires of e-trade organizations through building characteristic-wealthy buying apps, inventory control structures, and customer engagement structures. These applications allow e-commerce manufacturers to supply seamless shopping reports, customized tips, and stable payment gateways to their clients.

2. Healthcare:

In the healthcare enterprise, Ionic apps are utilized to create telemedicine systems, patient portals, appointment scheduling structures, and health tracking programs. These apps enhance accessibility to healthcare services, facilitate remote consultations, and empower sufferers to manipulate their health correctly from their cell devices.

3. Education:

Educational establishments and e-gaining knowledge of structures leverage Ionic app improvement offerings to create interactive knowledge of apps, online course platforms, and educational video games. These applications guide far-off mastering, personalized education, and knowledge dissemination, catering to the numerous needs of college students and educators globally.

4. Finance:

Ionic apps are revolutionizing the finance zone by imparting answers together with cell banking apps, virtual wallets, and funding systems. With sturdy security features and seamless personal reports, Ionic-powered finance apps allow people to manage their budgets comfortably and securely on the go.

5. Travel and Hospitality:

Ionic app improvement businesses play an important position in growing travel reserving systems, inn reservation systems, and tour courses for the travel and hospitality industry. These programs provide intuitive interfaces, actual-time updates, and seamless booking reviews, enhancing the overall journey experience for users internationally.

Conclusion

Ionic app improvement organizations are at the leading edge of innovation within the cellular app improvement landscape, empowering organizations across diverse industries to construct compelling and function-rich packages that resonate with their target audience. With its cross-platform compatibility, native-like performance, and giant surroundings, Ionic offers a versatile and efficient framework for growing mobile applications that drive engagement, enhance the personal experience, and propel enterprise boom in the state-of-the-art virtual era.

2 notes

·

View notes

Text

Reading more about inrush current control techniques now, all I knew before this was that you use Negative Temperature Coefficient parts to control it without affecting overall efficiency too much.

I've never had to design a board that drew much power, or didn't just use an off the shelf power supply. Power supply design is black magic so even major companies usually just buy certified open frame units to avoid redoing a ton of regulatory work, it's what's best for everyone. All the appliances at First Job just had a 24V Great Wall open frame units jammed in there, plus consumer 12V supplies for the network gear.

You can do some clever things involving having the NTC take itself out of the loop with a relay and a zener diode if you have really high efficiency targets to hit or you don't want to fry your NTC as the current picks up. I love these kinds of self-contained feedback tricks, they're super handy. And of course there's digital current controllers for high precision applications.

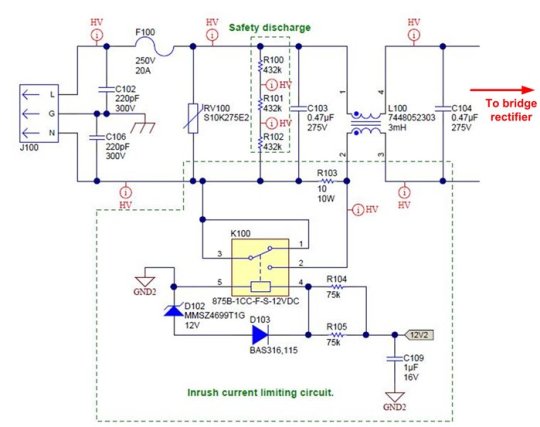

Figure 5 shows the relay circuit for a 1kW power supply. The relay is initially turned off. During power up, the input current flows through a 10Ω/10W cement resistor. Once the power supply is energized, a regulated bias voltage, 12V2, turns on the relay to minimize the power dissipation on the current-limiting circuit during normal operation.

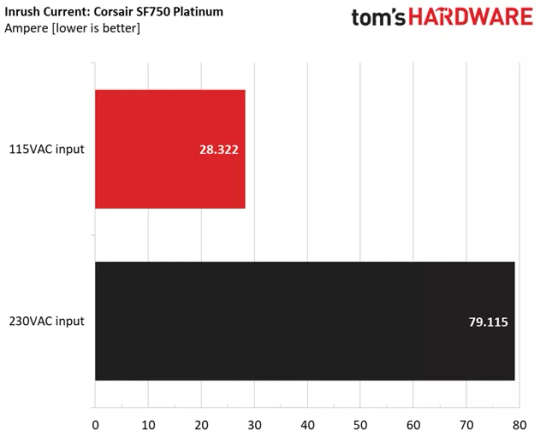

Anyway. Reading specs it looks like there's a systematically higher inrush current in computer PSU's when you connect them to 230V, which is probably just Ohm's Law at work. A lot of supplies with really good 110V inrush limiting have utterly dogshit 230V inrush limiting.

An interesting problem I realize this might cause is that, because most tech reviewers are Americans with 110V, they won't pick this up as often. E.g. the highly recommended SF750 from Corsair has fantastic 120V inrush of ~30A but on 230W it's almost 80A, which would definitely trip a lot of home breakers.

10 notes

·

View notes

Text

Your Trusted Electronics Components Distributor in India

In the fast-paced world of electronics, the demand for high-quality components continues to grow exponentially. Whether you're a manufacturer, a repair service provider, or a hobbyist, sourcing reliable electronic parts is critical to ensuring the durability and performance of your products. That's where Visha World, a leading electronics components distributor in India, comes in.

Why Choose Visha World?

Established with a vision to serve the ever-growing electronic industry in India, Visha World has emerged as a trusted partner for businesses and individuals seeking top-quality electronic components. With years of experience in the field, the company offers a wide range of products from some of the most recognized brands globally. Their expertise in sourcing, inventory management, and logistics ensures that you always get what you need when you need it.

Extensive Product Range

At Visha World, customers can find a vast selection of electronic components. From resistors, capacitors, and diodes to integrated circuits (ICs), transistors, and connectors, they stock all the essential parts for electronics manufacturing and repair. Whether you're working on power supplies, communication devices, or consumer electronics, you can rely on Visha World to provide the components you need to bring your projects to life.

2.High-Quality Products

Quality is paramount when it comes to electronic components. At Visha World, all products undergo strict quality checks to ensure they meet international standards. The company partners with leading manufacturers to guarantee that each component is reliable and performs optimally. This commitment to quality is one of the key reasons why Visha World has earned a reputation as a trusted distributor in India.

3.Affordable Pricing

While quality is important, pricing is also a crucial factor for many buyers. Visha World understands this and strives to offer competitive pricing on all their products. Whether you're purchasing components in bulk for large-scale manufacturing or ordering a few parts for DIY projects, you’ll find that the prices are designed to suit a variety of budgets without compromising on quality.

4.Prompt Delivery and Efficient Service

In the fast-moving electronics industry, time is of the essence. Visha World prides itself on its quick delivery services across India. Thanks to its robust distribution network, the company ensures that products are delivered promptly and securely. Their customer support team is also readily available to assist you with any inquiries, providing a seamless and hassle-free experience.

Key Offerings

Some of the key electronic components offered by Visha World include:

Resistors: Essential for controlling current flow in circuits.

Capacitors: Vital for energy storage and smooth circuit operation.

Diodes: Used for directing current flow in a single direction.

Transistors: Critical for amplifying signals in electronic devices.

Integrated Circuits (ICs): Crucial for complex circuit designs in modern electronics.

Connectors: Used for connecting various components in a device.

Serving Diverse Industries

Visha World caters to a wide array of industries, including consumer electronics, automotive electronics, telecommunications, and medical electronics. Whether you're in need of components for PCBs (Printed Circuit Boards), smart devices, or LED lighting, you’ll find everything you require under one roof.

Conclusion

With a focus on quality, affordability, and customer satisfaction, Visha World stands out as a premier distributor of electronic components in India. By offering a diverse range of products, competitive pricing, and unmatched service, Visha World continues to empower businesses and individuals alike to achieve their goals in the ever-evolving world of electronics.

1 note

·

View note

Text

Understanding the Impact of Antenna Loading on Performance

Antenna performance is crucial for providing optimal communication in wireless systems, including mobile phones, satellites, Wi-Fi routers, and other wireless technologies. Antenna loading is an important topic that can have a substantial impact on antenna performance. This phenomena includes modifying an antenna's impedance properties by adding other components, which has a significant impact on efficiency, bandwidth, and overall signal quality. In this blog post, we will delve into the notion of antenna loading and investigate its impact on antenna performance.

A common example of antenna loading is the usage of tiny antennas in mobile phones. These antennas frequently need to be small while still performing well. Antenna loading aids in achieving the required performance without increasing the antenna's physical size. Another example is when an antenna is outfitted with a matching network made up of inductors or capacitors to increase impedance matching and maximize power transfer.

Types of Antenna Loading Inductive loading is the addition of inductive devices, such as coils, to an antenna. This increases the antenna's inductive reactance, decreasing its resonant frequency. By carefully adjusting the inductive reactance, designers may ensure that the antenna resonates at the desired frequency while remaining small.

Capacitive loading is the addition of capacitors or other dielectric materials to an antenna construction. This raises capacitive reactance, which might reduce the resonant frequency. Capacitive loading is commonly employed when a smaller antenna is required or to achieve a certain resonance in conjunction with other components.

Distributed loading employs a network of capacitive and inductive components scattered over the antenna. This method is commonly used to improve performance while retaining a given electrical characteristic over a wider frequency range.

Material Loading: Certain materials, such as ferrites or magnetic materials, can be added to the antenna to change its electrical characteristics. These materials can help to reduce the physical size of the antenna while increasing efficiency.

Antenna Loading Affects Performance: Loading has a significant impact on the antenna's resonant frequency. By adding inductive or capacitive loading, the antenna's resonance frequency can be altered, allowing it to operate at the desired frequency despite its small physical size. For example, in a mobile phone, a small antenna can nevertheless be resonant at the needed cellular frequency despite its size.

Impedance Matching: Antenna loading is frequently used to improve the impedance match between the antenna and the transmitter/receiver circuit. A well-matched impedance optimizes power transfer while minimizing reflections, which is essential for maintaining high efficiency and signal quality. In practice, impedance mismatches result in signal losses and lower communication range. By carefully loading the antenna with the proper reactive components (capacitors and inductors), the impedance can be set to match the system's characteristic impedance, resulting in optimal performance.

Bandwidth refers to the range of frequencies over which an antenna can function efficiently.

When an antenna is loaded, the bandwidth can expand or contract depending on the type and quantity of loading. Inductive loading tends to reduce bandwidth, while capacitive loading can boost it. Engineers can fine-tune the antenna's performance by modifying the amount of loading, ensuring that it fulfills the application's bandwidth requirements, whether for narrowband or wideband systems.

Antenna Efficiency: Antenna loading can also affect efficiency. While loading might lower an antenna's physical size, it can sometimes compromise efficiency. This is especially true in circumstances where the loading components produce high resistance, which might result in power losses. The goal of any loading design is to balance size reduction and efficiency, so that the antenna operates effectively without compromising on performance.

Antenna Size: One of the most compelling reasons for adopting antenna loading is to lower the antenna's physical size while preserving operational performance. Full-sized antennas are difficult to put into many wireless applications, particularly mobile devices, due to size limits. Antenna loading enables the design of smaller, more compact antennas that nevertheless resonate at the desired frequencies while meeting the system's performance requirements.

Signal Polarization: In some situations, antenna loading can alter the polarization of the signal emitted by the antenna. The addition of reactive components might alter the antenna's polarization characteristics, potentially making it unsuitable for some applications, such as directional communications or systems that require precise polarization orientations.

Conclusion Antenna loading is a strong approach used in antenna design to improve performance, particularly when physical size limits are a concern. Designers can meet the performance needs of diverse wireless applications while maintaining efficiency and usefulness by adjusting an antenna's impedance, resonant frequency, and bandwidth. However, it is critical to recognize that antenna loading is a balancing act; modifications made to increase one aspect of the antenna's performance may unintentionally impair another. As a result, engineers must carefully weigh the trade-offs when using antenna loading techniques to guarantee that the final design operates optimally in real-world scenarios.

0 notes

Text

Exploring the Excellence of Tibcon Capacitor Manufacturers and Tibcon Capacitor Wholesale Solutions

Capacitors are essential components in electrical and electronic systems, and when it comes to reliability and performance, Tibcon Capacitor Manufacturers stand out as a trusted name in the industry. Known for their high-quality products and innovative designs, Tibcon capacitors are a go-to solution for a wide range of applications, from household appliances to industrial machinery. Additionally, the availability of Tibcon capacitor wholesale options makes them a preferred choice for businesses seeking cost-effective solutions without compromising quality.

Why Tibcon Capacitors are a Top Choice

Tibcon Capacitor Manufacturers have built a strong reputation for delivering capacitors that meet the highest standards of performance and durability. Their products are widely used in applications such as:

Air conditioners and refrigerators

Fans and lighting systems

Industrial motors and power factor correction units

Key Features of Tibcon Capacitors:

Durability: Designed to withstand extreme conditions, including high voltage and temperature fluctuations.

Energy Efficiency: Tibcon capacitors help optimize energy consumption, making them ideal for eco-conscious applications.

Wide Range: From AC motor run capacitors to power factor correction capacitors, Tibcon offers solutions for diverse needs.

Innovative Technology: With a focus on R&D, Tibcon Capacitor Manufacturers integrate cutting-edge technology into their products.

Benefits of Choosing Tibcon Capacitor Wholesale

For businesses, procuring capacitors in bulk is often the most cost-effective option. Tibcon capacitor wholesale services offer several advantages:

Competitive Pricing: Bulk purchases ensure better pricing, making it an economical choice for businesses.

Consistent Quality: Even in wholesale quantities, Tibcon maintains stringent quality control standards.

Availability: With a robust supply chain, wholesale partners can rely on Tibcon for timely deliveries.

Customization Options: Wholesale buyers can often access customized solutions tailored to specific requirements.

Industries Benefiting from Tibcon Capacitors

Tibcon capacitors are trusted across a range of industries, including:

Consumer Electronics: Ensuring smooth performance of household appliances.

Automotive: Supporting electrical systems in vehicles.

Industrial Equipment: Enhancing efficiency in motors and machinery.

Why Choose Tibcon Capacitor Manufacturers for Your Business?

Trusted Brand: Decades of expertise make Tibcon a reliable partner for high-quality capacitors.

Global Reach: With an extensive network, Tibcon caters to clients worldwide.

Technical Support: Their team provides excellent after-sales service and technical guidance.

Final Thoughts

Whether you are a business owner looking to streamline your inventory or an engineer searching for top-notch capacitors, partnering with Tibcon Capacitor Manufacturers is a smart move. Their reputation for quality and the affordability of Tibcon capacitor wholesale options make them a preferred choice in the market.

Ready to enhance your systems with durable and efficient capacitors? Explore the offerings from Tibcon Capacitor Manufacturers and leverage their Tibcon capacitor wholesale solutions to power your business forward!

0 notes

Text

Top 10 Practice Problems for the PE Electrical and Computer Power Exam

Preparing for the PE Electrical and Computer Power Exam is a challenging yet rewarding journey for engineers aspiring to advance their careers. The exam, designed to assess your knowledge and competence in electrical power systems, can seem overwhelming due to its rigorous format and diverse question types. However, with the right preparation, you can approach the exam with confidence.

At Studyforfe, we specialize in providing PE Electrical and Computer Power Exam preparation courses tailored to equip you with the skills and strategies necessary for success. To help you get started, here are 10 essential practice problems that will sharpen your understanding of the key topics tested in the Electrical Power PE Exam.

Power Factor Correction

Problem: A three-phase induction motor is running at 40% full load. The power factor is 0.65 lagging. Calculate the value of the capacitor required to improve the power factor to 0.9.

Solution: This problem tests your understanding of power factor correction using capacitors in three-phase systems. You'll need to calculate reactive power and determine the correct size for the capacitor to achieve the desired power factor.

Fault Analysis

Problem: A fault occurs at the terminal of a transformer, causing a short-circuit. Given the system's impedance, calculate the fault current and determine the effects on the transformer.

Solution: Fault analysis is a crucial part of the Electrical Power PE Exam, and this problem helps you practice calculating fault currents and understanding their impact on electrical equipment.

Transformer Efficiency

Problem: Calculate the efficiency of a transformer that operates at 75% load, given its no-load loss of 50 W and load loss of 150 W at full load.

Solution: Understanding transformer losses is essential. This problem tests your ability to calculate efficiency based on load and no-load losses.

Load Flow Analysis

Problem: Using the per-unit system, solve for the voltage at a specific bus in a power system given the complex impedance of transmission lines and generation sources.

Solution: Load flow analysis is key to understanding power distribution and generation in a system, making this an important problem to tackle.

Relay Coordination

Problem: Two overcorrect relays are protecting a section of a power system. Given the time-current characteristics, determine the time-delay setting for each relay to ensure proper coordination during faults.

Solution: Relay coordination ensures that the appropriate relay operates during faults. This problem helps you practice time-current characteristics and protection settings.

Short Circuit Calculations

Problem: A fault occurs on a transmission line. Calculate the fault current at the point of fault using the system's impedance and fault location.

Solution: Short circuit calculations are a vital part of the PE Electrical and Computer Power Exam, as they help you assess system stability during faults.

Transformer Rating

Problem: A transformer has a primary voltage of 13.8 kV and a secondary voltage of 480 V. If the transformer is rated for 500 kVA, calculate the current on both the primary and secondary sides.

Solution: This problem tests your ability to use transformer ratings and voltage relationships to calculate current.

Power Distribution System

Problem: In a power distribution system, calculate the total power loss in a network of conductors with known resistance and current flow.

Solution: Power loss calculations in distribution systems are essential for efficient network design and operation. This problem will help you practice these calculations.

Overvoltage Protection

Problem: A power system is susceptible to overvoltage due to switching operations. Calculate the surge protection required to prevent damage to sensitive equipment.

Solution: Overvoltage protection is a critical aspect of power system reliability. This problem allows you to practice designing protective measures against surges.

Energy Efficiency in Power Systems

Problem: Given a motor's efficiency and power consumption, calculate the potential energy savings if the motor is upgraded to a more efficient model.

Solution: This problem emphasizes the importance of energy efficiency in modern electrical systems, which is a key topic in the Electrical Power PE Exam.

These practice problems are just a few examples of the wide range of topics covered in the PE Electrical and Computer Power Exam. By regularly practicing these types of questions, you’ll improve your ability to tackle the various question formats, including multiple-choice, drag-and-drop, and point-and-click.

If you’re looking for structured guidance and expert support throughout your exam preparation, Studyforfe offers comprehensive courses tailored to the PE Electrical and Computer Power Exam. Our courses are designed to equip you with the knowledge, practice, and exam strategies you need to succeed.

With our expert resources and practice problems, you can approach your exam with the confidence and skills necessary to pass on your first try. Start your preparation today with Studyforfe, and take the next step in your professional journey.

#PE Power Exam#PE Power#PE Power Exam Prep#PE Power Exam Preparation Course#PE Electrical Power#PE Electrical and Computer Power Exam#Electrical Power PE Exam

0 notes

Text

The Essentials of PCB Design: Techniques and Best Practices

Introduction

This carries basic sense in the electronic world. PCB design basically forms the infrastructural skeleton of any devices for powering our day-to-day life. In consumer electronics and industrial systems, optimized PCB ensures efficient performance in terms of circuit along with size, heat, and manufacturability issues. Whether it's a simple two-layer or complex multi-layered board, the principle of PCB design makes equal importance to come up with reliable products.

We're going to go through the critical phases of a PCB design, really getting into the advanced features of a multilayer PCB layout design and then to the important details of DFM, DFT, DFA, and thermal analysis. Meanwhile, on the importance of a professional PCB design service, which may be what will ensure your design meets the highest standards of performance and reliability.

In short words, the overall meaning of PCB design is that it is the planning and designing of a layout of a printed circuit board that serves as an electronic device foundation. In general, the board usually consists of a network of copper traces. The traces connect all other components like resistors, capacitors, ICs, and transistors. This will ensure that the components are properly communicated to the PCB and achieve the purpose, with the overhead efficiency of the product, durability, and size all well in balance.

Critical Objectives of a PCB Design:

Signal Integrity: Small signal loss and interference.

Thermal Management: Must be able to dissipate the heat created by the elements efficiently.

Manufacturability: A PCB that would reliably be produced in volume.

Electrical Performance: Optimizes the circuit's performance on power and speed.

In the course of evolution, electronic devices have had to keep abreast of increased functional requirements within ever smaller spaces. Thus came PCB layout design with compactness yet complexity in circuitry.

What is a Multilayer PCB

A multilayer PCB has more than three layers of conductive material separated by insulating layers. Such layers allow designers to design complex layouts since they would allow routing a significant number of signals across multiple layers without over saturating the surface. The design of a multilayer PCB is considered crucial in industries like telecommunications, aerospace, automobile, and consumer electronics where signal integrity is paramount while available space must be maximized.

PCB design services? Lanjekar Manufacturing take care of everything from schematic to the multilayer layout PCB design, to make sure that your design is ready for production.

Advantages of Multi-layer PCB Design Layout

More components in a smaller area can be accommodated.

Breaking of signal paths across different layers will reduce the interference caused by electromagnetic rays. High signal integrity .

Multilayer PCB boards help in denser designs, and hence the footprint of the overall product is reduced.

Compact Board size.

It is a little bit complicated to design the multilayer PCB layout; however, the challenges are associated with this. Signals cross-talk or interference do not make it easy to route across multiple layers while thermal integrity is also of great challenge. Professional PCB design services can take advantage of understanding in balancing these factors for maximized performance.

DFM, DFT, DFA Analysis: Manufacturability and Testability

When a PCB is to be designed, electrical performance would not be the only matter of concern but rather ease and efficiency in manufacturing and testing the board. That's where DFM, DFT, and DFA analysis comes into play.

DFM (Design for Manufacturability)It ensures the PCB can be manufactured within an error range that is not costly. It checks the design for trace spacing, trace width, copper pathways, size, and locations of vias along with materials. The success of DFM analysis helps reduce the chances of possible manufacturing mistakes and lead times since it smoothes the transition from design to manufacture.

DFT (Design for Testability)DFT analysis tries to make the PCB testable for defects or failures during and after production. In this, the testing points are included in the designing into which automatic test equipment can probe shorts, opens, and other possible reasons that may jeopardize the board functionality. With DFT analysis included in the designing process of a PCB, designers save test time and money, avoid costly rework, and save on failures during and even after the manufacturing process.

DFA (Design for Assembly)Design for DFA ensures that the PCB could be assembled without much trouble. DFA assures that components are sited such that they can be mounted simply through soldering, and there should be sufficient clearance for a robotic assembly tool. This gives assurance that such design does not produce an assembly flaw. Optimal DFA-ing increases the reliability of the product but it decreases labor costs to a minimum.DFM, DFT, and DFA analysis in the design of a PCB may ensure that the final product meets certain technical specifications while also remaining easy to manufacture and test. Professional services for the design of PCB would be invaluable here because both have the experience performing such analyses and possess all the tools necessary in doing so.

Looking for professional PCB design services? Lanjekar Manufacturing delivers comprehensive solutions, ensuring your design is ready for production.

What is Thermal Analysis?

Thermal analysis is the checking of heat being distributed on a printed circuit board and how it spreads out to be dissipated correctly. Overheated specific portions of the board might damage components, interfere with signals, or even cause failure of the overall system.

Thermal Analysis in PCB Design: Controlling Heat for Longevity

Thermal management possibly represents probably one of the important aspects of PCB design, particularly when high power applications, such as power supplies, industrial systems, and communication devices, are taken into account. Performance and reliability outcome can be severely affected if too much heat begins to emanate from the electronic components.

Types of thermal management in PCB design:

Copper Pour and Heat Sink: Application for copper pours is the areas where extensive areas of copper are utilized for absorbing heat and letting it dissipated. In such application, high power components may be mounted on heat sinks, therefore, making them cool better.

Component Placement: Sensitive components should be placed away from the source of generation of heat. Overheating is thus avoided, Advanced simulation tools are used by the professional PCB design services; hence, ideal heat is managed in the product designed and also ensuring that the final product achieved meets all its requirements for performance.

Why Choose Professional PCB Design Services?

Though it might seem like circuitry know-how is all one needs for designing modern PCBs, the realities of the business are far removed from that. Functionality, manufacturability, testability, and thermal management all need to be balanced quite heavily. That's where professional PCB design services come in-they make all the difference.

Here's why you must opt for professional PCB design services:

Access to State-of-the-Art Tools: Professional services guarantee that the design and simulation tools are state-of-the-art for building accuracy and performance in your PCB design.

Handling Complex Design: Whether it is multilayer PCB layout design, DFM, DFT, DFA analysis, or thermal analysis, any expertise can handle it.

Market Sooner: Outsourcing the PCB design service will save your cycle going shorter than you expect and readying for the marketplace sooner.

Conclusion

PCB designing forms the heart of modern electronics, and proper understanding requires the amalgamation of technical and manufacturing considerations. Whether you are working with a very simple two-layer board or a complex multi-layer PCB layout design, you have to integrate DFM, DFT, DFA analysis, and rigorous thermal analysis into the process of PCB designing to be successful. Association with professional PCB design services will make sure your product meets the highest possible standards for performance, reliability, and manufacturability.

Need help with PCB design? Lanjekar Manufacturing offers full end-to-end PCB design services to optimize your design towards all factors with respect to performance and manufacturability.

Also read:

Know Electronics Manufacturing: The Total Guide

Firmware Development: Where Software Meets Hardware

The Essentials of PCB Design: Techniques and Best Practices

The Complete Guide to Hardware Development: From Design to Deployment

0 notes

Text

GIGABYTE B760M DS3H AX DDR4 Intel Motherboard

GIGABYTE B760M DS3H AX DDR4 Intel Motherboard

Rs. 13,645.00 Rs. 19,999.00

Discount: Rs. 6,354.00 (32%) Visit Us:- https://elitehubs.com/products/gigabyte-b760m-ds3h-ax-ddr4-intel-motherboard

Features Of GIGABYTE B760M DS3H AX

UNPARALLELED PERFORMANCE

With the fast-moving technology changes, GIGABYTE always follows the latest trends and provides customers with advanced features and latest technologies. GIGABYTE motherboards are equipped with upgraded power solution, latest storage standards and outstanding connectivity to enable optimized performance for gaming.

ULTRA DURABLE

GIGABYTE Ultra Durable™ design provides product durability and high-quality manufacturing process. GIGABYTE motherboards use the best components and reinforce every slots to make each of them solid and durable.

6+2+1 Phases Hybrid Digital VRM Design

6+2+1 Phases Low RDS(on) MOSFETs, Premium Choke and Capacitors to improve transient response and minimize oscillation

GIGABYTE Ultra-Efficient M.2 Thermal Guard

With durability in mind, GIGABYTE provides a thermal solution for M.2 SSD devices. The M.2 Thermal Guard prevents throttling and bottlenecks from high speed M.2 SSDs as it helps to dissipate heat before it becomes an issue.

CONNECTIVITY

GIGABYTE Motherboards enable the ultimate connection experience with blazing data-transfer speeds through the next generation network, storage and Wi-Fi connectivity.

PERSONALIZATION

GIGABYTE motherboards bundle several useful and intuitive software to help users to control every aspect of motherboard and provide customizable lighting effect with outstanding aesthetics to fit your unique personality

Specifications Of GIGABYTE B760M DS3H AX

ModelBrandGIGABYTEModelB760M DS3H AXSupported CPUCPU Socket TypeLGA1700CPU Type13th Gen Intel® Core™ Processors & 12th Gen Intel® Core™, Pentium® Gold and Celeron® ProcessorsChipsetsChipsetINTEL B760MemoryNumber of Memory Slots4 x DDR4Memory StandardSupport for DDR4 5333(O.C.)/ DDR4 5133(O.C.)/DDR4 5000(O.C.)/4933(O.C.)/4800(O.C.)/ 4700(O.C.)/ 4600(O.C.)/ 4500(O.C.)/ 4400(O.C.)/ 4300(O.C.)/4266(O.C.) / 4133(O.C.) / 4000(O.C.) / 3866(O.C.) / 3800(Maximum Memory Supported128 GBChannel SupportedDual Channel DDR4 Memory TechnologyExpansion SlotsPCI Express x161 x PCI Express x16 slot, supporting PCIe 4.0 and running at x16, 2 x PCI Express x1 slots, supporting PCIe 3.0 and running at x1Storage DevicesSATA 3Gb/s4 x SATA 6Gb/s connectorsOnboard VideoOnboard Video ChipsetIntegrated Graphics Processor-Intel® HD GraphicsOnboard AudioAudio Channels2/4/5.1/7.1-channelAudio ChipsetRealtek® Audio CODECOnboard LANLAN ChipsetRealtek 2.5GbE LAN chip (2.5 Gbps/1 Gbps/100 Mbps)Rear Panel PortsUSB2 x USB 2.0/1.1 ports;3 x USB 3.2 Gen 1 ports;1 x USB Type-C® port, with USB 3.2 Gen 2 supportS/PDIF Out1 x optical S/PDIF Out connectorAudio Ports3 x audio jacksPS/21 x PS/2 keyboard/mouse portVideo PortsHDMI/Display portHDMI1 x HDMI PortOnboard USBOnboard USBN/AOnboard 1394Onboard 1394N/APhysical SpecForm FactorMicro ATX Form FactorPower Pin1 x 24-pin ATX main power connector 1 x 8-pin ATX 12V power connectorDimensions24.4cm x 24.4cm

0 notes

Text

Role of Smart Technology in the Power Transformer Market

The global power transformer market was valued at USD 22.83 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030. This growth is primarily driven by the increasing demand for electricity in both emerging and developed countries, alongside significant investments in infrastructure. As countries expand their electrical grids and enhance their capabilities, this will be a crucial factor in stimulating market growth over the forecast period. Additionally, the growing demand for smart grid technologies has led to a heightened need for smart meters, which is expected to further contribute to the positive trajectory of the power transformer industry in the coming years.

Government initiatives aimed at installing advanced power transformers and modernizing existing power grids to improve energy efficiency and reduce losses are also anticipated to have a favorable impact on demand in the power transformer sector. Furthermore, the industry is expected to benefit from increased research into transmission networks and the rapid adoption of non-traditional and renewable energy sources for electricity generation in remote areas. Smart grids, with their ability to be accessed and monitored remotely, allow for quick adjustments to fluctuations in electricity demand. They also provide effective cooling and power delivery, which can lead to a reduction in carbon emissions.

In the coming years, the development of green transformers, advancements in high-voltage transmission technologies, and stringent government regulations designed to lower greenhouse gas emissions will further bolster the growth of the global power transformer market.

Gather more insights about the market drivers, restrains and growth of the Power Transformer Market

Insulation Insights

The insulation segment of the power transformer market is categorized into several sub-segments, including gas, oil, solid, air, and other insulation types. Among these, oil insulation emerged as the dominant type, accounting for a significant market share of 58.9% in 2022. It is anticipated to experience a positive CAGR of 7.7% from 2023 to 2030. Oil is widely used as an insulation medium across various industries due to its ability to maintain stability at high temperatures. Its exceptional electrical insulation properties, particularly its dielectric strength, effectively mitigate potential damage from high voltage.

Moreover, oil insulation plays a crucial role in protecting other components, such as copper coils, from damage such as burning. Oil is commonly utilized in fluorescent lamp ballasts, high-voltage capacitors, oil-filled transformers, high-voltage switches, and circuit breakers. Typically, transformers use mineral oil (primarily naphthenic), silicone, and bio-based oils for insulation. However, with the increasing focus on environmental sustainability, transformer manufacturers are gradually shifting towards more eco-friendly alternatives, such as ester oil, for transformer development.

For instance, in September 2022, Baoding Tianwei Baobian Electric Co. Ltd announced the launch of its 110KV natural ester oil transformer. The ester oil utilized in this transformer boasts an impressive 98% natural degradation rate and a higher ignition point, aligning with the industry's move towards sustainable practices. This shift not only meets the rising environmental standards but also enhances the safety and efficiency of power transformers.

The global power transformer market is poised for robust growth, driven by rising electricity demand, government initiatives, and advancements in technology, alongside a significant emphasis on sustainability and environmental responsibility.

Order a free sample PDF of the Power Transformer Market Intelligence Study, published by Grand View Research.

#Power Transformer Market#Power Transformer Market Analysis#Power Transformer Market Report#Power Transformer Industry

0 notes

Text

Power Factor Correction Market: Enhancing Energy Efficiency and Reducing Operational Costs - UnivDatos

The power factor is beneficial in reducing the electricity bill. The technology will keep the reactive conditioning of power consumption constant. Consequently, the power factor will not drop lower than the designated number, and you can handle energy expenses.

The power factor correction will increase the load of the power factor. It will also increase efficiency in the distribution system characteristic of the current global market. It will be corrected by using a passive power factor correction capacitor to the linear loads. However, to capture the effect of non-linear loads, the power drawn from the system will also be distorted.

In such circumstances, there is a benefit in both passive and active power factor correction. It can oppose to improvement and distortion of the power factor. The device, which is applied for power factor correction is going to be implemented at the central substation. It can correct the power factor and assist with a lower power cost.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=67611&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Necessity of Power Factor Correction:

People and organizations should have basic knowledge of power factor and power factor correction to manage energy bills. There are several steps that a person will have to follow and more often, it is possible to cut down power bills which will mean a lot of cash saved in the long run. And then, people start to see that almost everyone is paying more for reactive power, which the devices they use, do not consume, therefore there is no need to cater for extra bills. Better PF results mean saving money can be used in another way for different goals, it is also possible to have electrical devices last longer. The advantages are very many and understanding how the correct Power factor correction can help to get all these advantages.

Many powers suppliers demand kW (base load) and the maximum demand tariff rate. When the maximum demand tariff has been assessed in kVA, the adjustment of the power factor leads to the reduction of the kVA of the installation, or consequent lesser energy costs and smaller maximum demand tariffs. The benefits of such installation are somewhat long-term oriented.

Power factor correction is required by the network codes and regulations requiring standards minimum power factor value. They will make their charges higher for cases where the minimum power factor is not attained, and this remains a regional factor.

A low power factor consumes more energy than a good power factor for the same rating of power consumption. This in turn will keep harmonic currents from creating distortions in the system, thus retaining the power factor and keeping the reactive power low enough that they are able to minimize their monthly electricity bills and control their monthly capacity charges.

It usually takes about one to three years to recoup its cost from corrected pf and this is in the form of monthly saving. Abnormal power factors are known to cause voltage dips, power decay, heat generation, and motor burnouts. Implementing power factor correction technology works to prevent expensive damages, reduce electric demand, and enhance the stability and efficiency of the power system. Further, it allows users to keep track of the numbers of their rated electrical power.

Click here to view the Report Description & TOC: https://univdatos.com/get-a-free-sample-form-php/?product_id=67611&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Conclusion:

It was established that power factor has the potential to positively or negatively affect monthly energy consumption. It can be noted that if there is a bad power factor, action is taken to rectify it is possible. There is more information regarding this aspect of power factor correction technology. Once installed more energy will be conserved hence the cost of energy will be low. Furthermore, electrical devices will also be longer lasting because the chances of overheating will be minimized. According to a new report by UnivDatos Market Insights, the Power Factor Correction Market is expected to reach USD ~3.5 billion by 2032 by growing at a CAGR of ~5.2%.

0 notes

Text

The Principle Behind AC-DC Rectifiers

AC-DC rectifiers are essential electronic devices that convert alternating current (AC) into direct current (DC). This conversion is crucial for powering electronic devices and systems that require a stable and constant DC voltage. Understanding the principle behind rectifiers involves examining how they manage the flow of electric current to achieve this conversion.

Basic Principle of Rectification

Rectification is the process of converting AC into DC. The principle behind rectifiers relies on the use of semiconductor devices, such as diodes, to control the direction of current flow. Here’s a step-by-step explanation of the principle:

AC and DC Basics:

Alternating Current (AC): AC is an electric current that reverses direction periodically. It is the type of current supplied by power grids and used in most household appliances.

Direct Current (DC): DC flows in a single direction and provides a constant voltage. It is required by many electronic devices and battery-powered equipment.

Role of Diodes:

Diodes: Diodes are semiconductor devices that allow current to flow in only one direction. They have two terminals: the anode and the cathode. When the anode is positive relative to the cathode, the diode conducts electricity; when the anode is negative, the diode blocks current flow.

Half-Wave Rectification:

Principle: A half-wave rectifier uses a single diode to allow only one half of the AC waveform to pass through, effectively blocking the negative half-cycle of the AC signal.

Operation: During the positive half of the AC cycle, the diode conducts and allows current to pass, creating a series of positive DC pulses. During the negative half of the cycle, the diode blocks the current, resulting in zero output.

Full-Wave Rectification:

Principle: A full-wave rectifier uses multiple diodes (usually in a bridge configuration) to convert both halves of the AC waveform into DC.

Operation: In a full-wave rectifier, the positive and negative halves of the AC signal are both used to produce a continuous DC output. This is achieved by using either a center-tap transformer with two diodes or a bridge rectifier with four diodes arranged in a bridge configuration.

Rectifier Circuit Design:

Transformer: In many AC-DC rectifier circuits, a transformer is used to adjust the AC voltage to the desired level before rectification. It can step up or step down the voltage as needed.

Filter: After rectification, the DC output often contains ripples or fluctuations. A filter, typically composed of capacitors and inductors, smooths out these ripples to provide a more stable DC voltage.

Regulator: For applications requiring a precise DC output voltage, a voltage regulator may be added to the circuit to maintain a constant voltage despite variations in input or load.

Applications of AC-DC Rectifiers

Power Supplies: AC-DC rectifiers are used in power supplies to convert AC from the mains into DC for powering electronic devices and equipment.

Battery Chargers: Rectifiers convert AC into DC for charging batteries in various applications, including automotive and consumer electronics.

Industrial Equipment: Rectifiers provide DC power for motors, control systems, and other industrial machinery.

Communication Systems: Rectifiers ensure a stable DC power supply for communication equipment and network infrastructure.

Renewable Energy Systems: In solar and wind power systems, rectifiers convert AC generated by inverters into DC for storage or use in DC-based appliances.

Conclusion

The principle behind AC-DC rectifiers involves using semiconductor devices like diodes to control the flow of current and convert AC into DC. By allowing current to flow in only one direction, rectifiers effectively transform the alternating waveform into a direct one. This conversion is essential for providing stable and reliable power to a wide range of electronic devices and systems. The basic rectification process, along with the use of transformers, filters, and regulators, ensures that AC-DC rectifiers meet the power requirements of various applications, from household electronics to industrial equipment.

0 notes

Text

Marx Network High Voltage Pulse Power Supply Market Overview and Future Growth Forecasts 2024 - 2032

The Marx network high voltage pulse power supply market has gained significant attention in recent years, driven by advancements in technology and the increasing demand for efficient power solutions across various industries. This article explores the current state of the market, key drivers, challenges, and future trends.

Introduction to Marx Network High Voltage Pulse Power Supply

The Marx network high voltage pulse power supply market is poised for significant growth driven by technological advancements, increasing industrial demand, and expanding research activities.

What is a Marx Network?

A Marx network is a type of electrical circuit that generates high-voltage pulses. It typically consists of a series of capacitors charged in parallel and discharged in series, resulting in a high-voltage output. This technology is widely used in various applications, including scientific research, medical equipment, and industrial processes.

Importance of High Voltage Pulse Power Supply

High voltage pulse power supplies are crucial for applications requiring short bursts of high energy. They play a vital role in fields such as particle acceleration, pulsed lasers, and electromagnetic testing. The reliability and efficiency of these power supplies significantly impact the performance of the systems they power.

Market Overview

Current Market Trends

The Marx network high voltage pulse power supply market is experiencing robust growth, driven by:

Technological Advancements: Innovations in materials and designs are improving the efficiency and reliability of power supplies.

Increasing Demand in Research and Development: The need for high voltage power supplies in scientific experiments and testing is on the rise.

Growing Industrial Applications: Industries such as aerospace, defense, and manufacturing are increasingly adopting high voltage solutions for various processes.

Market Segmentation

The market can be segmented based on application, end-use industry, and region.

By Application

Particle Accelerators

Medical Equipment

Industrial Applications

Research Laboratories

By End-Use Industry

Aerospace and Defense

Healthcare

Manufacturing

Telecommunications

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Key Drivers of Market Growth

1. Rising Demand for Advanced Medical Equipment

The healthcare sector's ongoing advancement in diagnostic and treatment technologies has increased the demand for high voltage pulse power supplies. These systems are essential for applications like MRI machines and radiation therapy.

2. Expansion of Research Facilities

Research institutions worldwide are investing in advanced equipment that requires reliable high voltage power supplies, contributing to market growth. The need for precise and consistent energy sources in experiments has never been higher.

3. Industrial Automation

With the rise of Industry 4.0, there is a growing need for efficient and reliable power supplies in automation processes. High voltage pulse power supplies are critical for enhancing the performance of industrial machinery.

Challenges Facing the Market

1. High Initial Costs

The initial investment required for high voltage pulse power supplies can be substantial, which may deter some potential users. This challenge is particularly pronounced in developing regions where budget constraints are prevalent.

2. Technical Complexity

The design and operation of Marx network systems require specialized knowledge and expertise. This technical complexity can limit the market's accessibility for smaller companies or new entrants.

3. Regulatory Hurdles

Compliance with stringent safety and environmental regulations can pose challenges for manufacturers and users. Navigating these regulations can increase costs and delay product development.

Future Trends in the Market

1. Integration of Smart Technologies

The integration of IoT and smart technologies into high voltage pulse power supplies is expected to enhance performance and monitoring capabilities. This trend will likely lead to more efficient energy management and predictive maintenance.

2. Sustainable Solutions

There is a growing emphasis on developing environmentally friendly high voltage power solutions. Manufacturers are exploring materials and technologies that reduce energy consumption and minimize waste.

3. Expansion in Emerging Markets

As developing economies invest in research and industrial capabilities, the demand for high voltage pulse power supplies in these regions is projected to increase. This expansion will offer significant growth opportunities for market players.

Conclusion

The Marx network high voltage pulse power supply market is poised for significant growth driven by technological advancements, increasing industrial demand, and expanding research activities. While challenges such as high initial costs and technical complexity exist, the future looks promising with emerging trends like smart technologies and sustainable solutions. Stakeholders must navigate these challenges and capitalize on opportunities to thrive in this dynamic market.

#Marx Network High Voltage Pulse Power Supply Market Size#Marx Network High Voltage Pulse Power Supply Market Trend#Marx Network High Voltage Pulse Power Supply Market Growth

0 notes

Text

ASRock X870E Taichi Motherboards With Ryzen 9000 CPUs

AMD Ryzen 9000 Series Processor-Ready Epic X870E Taichi /X870 Series Motherboards are Unveiled by ASRock.

Today, ASRock, the world’s top producer of motherboards, graphics cards, mini PCs, and gaming monitors, revealed a complete range of motherboards, from flagship to mainstream, that use the AMD X870E/X870 series chipset. These motherboards are specifically made for the newest AMD Ryzen 9000 series processors with AM5 socket.

- Advertisement -

The new motherboard lineup includes the popular X870 Steel Legend WiFi, X870 Pro RS and Pro RS WiFi, which are now available in a white design, as well as the flagship series X870E Taichi and Taichi Lite, mainstream gaming X870 Riptide WiFi, and recently announced flagship Phantom Gaming X870E Nova WiFi.

X870 and X870E

Prepared to Power Flagship to Commonplace Computers

From the premium Taichi series to the more affordable Steel Legend and Pro RS WiFi motherboards, every new ASRock X870E Taichi /X870 motherboard has an extremely durable construction for maximum performance. The Taichi line has distinctive low-ripple 1000μf 20K black capacitors that provide steady and outstanding CPU performance, server-grade 8-layer PCBs that enable great memory overclocking up to DDR5-8200, and SPS Dr.MOS power supply of up to 24+2+1 phases.

Fast IO Speed

All boards come with two USB4 Type-C ports on the back I/O for external devices that need to operate at very high speeds, in addition to PCI-Express Gen-5 GPU and Blazing M.2 (Gen5x4) SSD connectors. Their easy-to-assemble design makes system setup simpler with features like a toolless M.2 heatsink installation and an EZ release graphics card slot.

The BIOS Flashback feature, which can be accessed via the rear I/O on all motherboards, makes it simple to update the BIOS even in the absence of a CPU and memory module.

- Advertisement -

ASRock’s Innovation in Connectivity Patented

The newest and fastest WiFi 7 (802.11be) 2×2 is included in networking. It provides multi-gigabit rates and low latency throughput, making it perfect for gaming and wireless virtual reality headsets. With its proprietary design for enhanced EMI protection, ASRock’s optimized 5Gbps LAN on motherboards from the X870E Taichi series guarantees fast and reliable performance.

youtube

X870E Taichi

The flagship motherboard from the Taichi series has excellent hardware specifications, a sturdy power design, USB4 Type-C, and DIY-friendly features. Its great performance and luxury look make it suitable for high-end gaming.Image Credit To ASRock

The infinite potential philosophy

The philosophical condition of undifferentiated absolute and limitless possibility is symbolized by taichi. A motherboard that elegantly completes every duty! Turn into water. Formless, formless, and adaptable to every circumstance.

VRM design

Unique 20K Capacitor with 1000uF Capacity

In addition to increasing the capacitance value from 560uF to 1000uF and prolonging the lifetime to 20,000 hours, the improved 20K Black capacitor offers the following advantages:

Higher Capacitance: Superior support under heavy loads due to increased charge storage.

Lower Ripple: Improved quality due to less variations in power output.

More Stable Output Current: Reduces the effects of voltage on a stable power source.

Improved System Stability and Performance: More dependable and steady operation.

Power Phase Design for 24+2+1

Having robust parts and a totally seamless power supply to the CPU. For experienced gamers, it also provides unparalleled overclocking capabilities and improved performance at the lowest temperature.

Exclusive PCB Solutions

Low Loss PCB of Server Grade

In addition to improving signal integrity and enabling motherboards to support PCIe 5.0 for graphics cards and M.2 SSDs, server grade low loss PCBs significantly increase memory OC capability, enabling the highest levels of memory performance.

Two-ounce copper printed circuit board

Stable signal traces and power forms are provided by the two-ounce copper inner layers! providing overclocking with a lower temperature and more energy economy.

PCB with 8 layers

The 8 Layer PCB ensures a reliable, long-lasting system with excellent performance. It does this by offering solid signal traces and power designs that give lower temperature and improved energy efficiency.

Support for DDR5 XMP & EXPO

Originating from the design idea of “built for stable and reliable,” ASRock spares no detail. Because this motherboard is constructed from premium materials, enthusiasts may increase the performance of DDR5 RAM overclocking by turning on the pre-tested profiles. Make sure the RAM modules can be overclocked in a way that is gratifying, inexpensive, and requires no sweat at all. They should also be Intel XMP/AMD EXPO capable.

ASRock X870E Taichi Specs

Supports Processors from the AMD Ryzen 9000, 8000, and 7000 Series.

110A SPS, 24+2+1 Phase Power Design.

Four DDR5 DIMMs.

Up to 8200+ (OC) Dual Channel Supported.

Two PCIe 5.0 x16.

Options for Graphics Output: 1 HDMI, 2 USB4 Type-C.

ALC4082 5.1 CH HD Audio Codec by Realtek.

WIMA Audio Caps, ESS SABRE9219 DAC.

One Thunderbolt M.2 (PCIe Gen5x4).

3 PCIe Gen4x4 Hyper M.2.

Six SATA3.

Two USB4 Type-C (Rear) ports.

One Type-C USB 3.2 Gen2x2 (Front).

5 Type-A USB 3.2 Gen2 (Rear).

3.2 Gen1 7 USB (3 Rear, 4 Front).

5G LAN.

Wi-Fi 802.11b + Bluetooth.

Supports Toolless Multi-Layer and EZ Release Graphics Cards M.2 Bottom Heatsink and M.2 Heatsink.

Read more on Govindhtech.com

#X870ETaichi#AMDRyzen9000Series#graphicscards#motherboards#miniPCs#Gamingmonitor#AMDRyzen#CPUperformance#DDR5RAM#news#technews#technology#technologynews#technologytrends#govindhtech#Youtube

1 note

·

View note