#CNC router programming

Explore tagged Tumblr posts

Text

CNC Programming 2D 3D Designs In Aspire Vectric , Vcarve Pro

#vectorartwork#vectortracing#vector#vectorart#cnc stalking#vectorlogo#carving#cncrouter#cnn arabic#cnco#cnc programming#CNC router programming

1 note

·

View note

Text

Rotary CNC Router Machine

At GK Laser Enterprises, we pride ourselves on delivering cutting-edge solutions to meet the evolving needs of the manufacturing and fabrication industries. One such innovation that has gained popularity for its versatility and precision is the Rotary CNC Router Machine. As a leader in CNC technologies, we offer a range of advanced CNC machines, and today we dive deep into how a rotary CNC router machine can revolutionize your operations.

What is a Rotary CNC Router Machine? A Rotary CNC Router Machine is a computer-controlled cutting machine that uses rotary tools to carve, cut, or engrave materials in three dimensions. The term “rotary” refers to its ability to rotate the material around an axis while it works, providing access to all sides of the material. This capability enables intricate detailing, sculpting, and shaping of cylindrical or irregularly shaped materials.

Unlike traditional CNC routers that work on flat surfaces, rotary CNC routers can handle 3D shapes, making them ideal for creating complex, multi-faceted designs.

How Does a Rotary CNC Router Machine Work? The Rotary CNC Router works by rotating the material, typically using a rotary axis attachment, while the cutting tool precisely follows the programmed paths. Here’s a breakdown of the process:

Material Preparation: A workpiece, such as wood, metal, or plastic, is mounted on the rotary axis, which allows it to rotate. Programming: A computer-aided design (CAD) program creates a digital blueprint of the desired outcome. This is then converted into machine-readable code using computer-aided manufacturing (CAM) software. Cutting Process: The router uses its rotary axis to rotate the material while the cutting tool moves along the X, Y, and Z axes to carve, cut, or engrave the material into the desired shape. Finishing: Once the operation is complete, the workpiece is inspected and may require minimal finishing, thanks to the machine’s precision.

Key Features of a Rotary CNC Router Machine High Precision and Accuracy: Rotary CNC routers are known for their precision in handling complex designs, offering high accuracy even in detailed cuts and engravings. Versatility: Whether you’re working with wood, metal, plastic, or composites, the rotary CNC router can handle a wide range of materials. This versatility makes it invaluable for industries such as furniture design, sculpture, and sign-making. 3D Carving and Engraving: With the ability to rotate the material, rotary CNC routers are ideal for creating 3D objects like sculptures, chair legs, moldings, and even complex cylindrical designs. Automation and Efficiency: The CNC aspect automates the cutting process, ensuring uniformity in production and reducing the need for manual labor. This enhances efficiency and speeds up production time.

Why Choose a Rotary CNC Router Machine for Your Business? If your business requires precision, complexity, and scalability, a rotary CNC router is a wise investment. At GK Laser Enterprises, we emphasize the value it can bring to industries like:

Furniture Manufacturing: Intricate 3D carvings and details for chair legs, columns, and sculptures can be easily achieved using rotary CNC routers. Sign Making and Woodworking: From large signs to ornate wood designs, rotary CNC routers deliver exceptional precision that elevates your craftsmanship. Sculpture and Artwork Creation: Artists and designers benefit from the ability to craft complex shapes and details, providing unmatched creativity. Metal and Plastic Fabrication: Industrial manufacturers who work with metals and plastics can create custom parts, components, and molds with great precision.

Benefits of Using a Rotary CNC Router Machine Enhanced Productivity: With automated processes, your business can take on more projects with faster turnaround times, maximizing profitability. Cost Efficiency: Despite the upfront investment, the long-term savings on labor, material waste, and improved product quality make it a highly cost-effective solution. Precision and Consistency: The automation ensures that each piece you produce is identical in quality and detail, improving overall consistency. Flexibility: Whether you’re producing one-of-a-kind custom pieces or bulk products, the rotary CNC router offers the flexibility to handle both with ease. Lower Material Waste: Precision machining ensures that there is minimal waste, reducing the cost of raw materials and promoting sustainable practices.

Why Buy From GK Laser Enterprises? At GK Laser Enterprises, we provide high-quality rotary CNC router machines tailored to meet the unique needs of businesses across industries. With our deep industry expertise, we ensure that you get the most suitable machine for your applications, ensuring optimal performance and cost-efficiency.

We also offer:

Comprehensive Training and Support: Our team will provide full training on how to operate and maintain your CNC router machine. Maintenance Services: Regular servicing to keep your machine running smoothly, ensuring minimal downtime and maximum output. Custom Solutions: We understand that every business has different requirements, so we provide customized solutions that best fit your needs.

Conclusion The Rotary CNC Router Machine offers unparalleled precision and flexibility, making it an essential tool for businesses involved in woodworking, metalworking, and creative design. At GK Laser Enterprises, we’re committed to providing top-tier CNC solutions that enhance productivity and reduce costs. By investing in a rotary CNC router, your business can stay ahead of the competition while delivering superior quality products. Contact us today to learn more about our CNC machines and how they can benefit your operations!

2 notes

·

View notes

Text

CNC is Computer Numerical Control. These are various machining tools that are guided by a computer, and they have been around since about the middle of last century. I first saw one of these when I was in elementary school and I visited my mom’s friend Bill’s machine shop. He manufactured metal parts for various industrial purposes, and parts for his son’s Formula One race car (I used to love hanging out in the pits at these races at Riverside raceway).

When I went to Sheridan Lumber the first time and was given a flyer for a shop that has a CNC router, I had the idea to make curves where there were previously right angles on the original Device.

The thick maple/mahogany wood sandwiches (that had the crazy number of clamps) are what these shapes will be cut out of. I’ll also be making some small mahogany cylinders where they were previously PVC (the Linear Motion Transfer Cylinders).

I thought we would be doing the cutting today, but Manuel needs time to get all the information into the CAD program. This is a bit more of a complicated project then they usually do there, which is just cutting shapes out of thin sheets of wood for things like wall designs and other interior home type stuff.

When he's ready, I'll go in for the actual cutting, which I am excited to see happen.

4 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

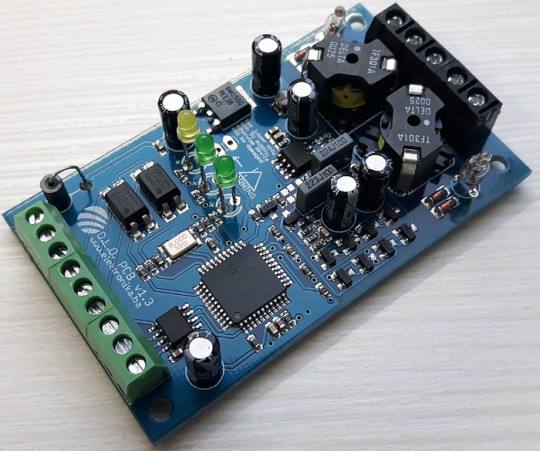

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

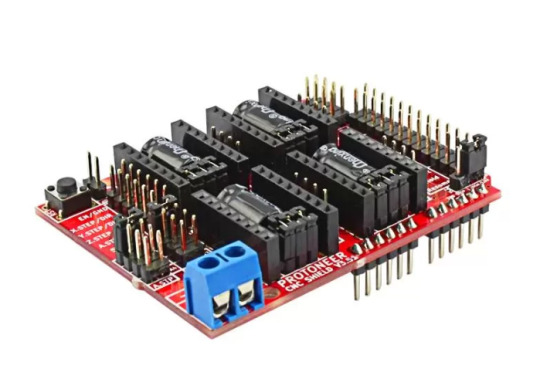

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

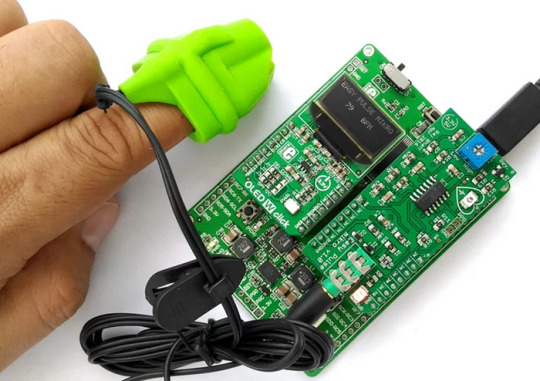

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

CNC Wood Router Machine Supplier in Gujarat

Success Technologies is a Manufacturer, and Supplier of CNC Wood Router Machine in Gujarat, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. We offer a wide range of Mini Tabletop CNC Router, CNC Engraving & Router Machine 2D/3D, CNC Rotary Wood Router Machine, CNC Engraving & Router Machine, 4 Axis CNC Router, CNC Router with Wood Turning Lathe, CNC Router for Door Lock Hole and Hinge. CNC Router with Saw Blades, CNC Router Double Head with Drilling Head, For Sewing Machine Wooden Table Top Making Industries, ATC CNC Router With Automatic Tool Changer, CNC Machine for Horizontal Wood Processing, CNC Router Machine with CCD Camera Customized, CNC Router Machine, CNC Router for Pattern Industries. A CNC wood router machine is a computerized cutting machine used to carve, cut, engrave, and shape wood with high precision. Unlike traditional hand routers, CNC wood routers are automated and controlled by a computer program, making them ideal for complex and repeatable designs. These machines can also be used on a wide variety of materials, including MDF, acrylic, aluminum, and plastic, but they are most commonly used for woodworking projects. Applications of CNC Wood Router Machine: Furniture Manufacturing Cabinet Making Sign Making and Engraving Architectural Woodworking Prototype Manufacturing Custom Woodworking Projects How difficult is it to operate a CNC wood router machine? Operating a CNC wood router is relatively easy, especially with modern software that is intuitive and user-friendly. However, learning to program and operate the machine may require some training. Many manufacturers provide tutorials and support. What types of software do CNC wood routers use? CNC wood routers typically use CAD (Computer-Aided Design) software to create designs and CAM (Computer-Aided Manufacturing) software to convert the design into machine-readable instructions. Common software includes AutoCAD, VCarve Pro, and Fusion 360. Success Technologies is CNC Wood Router Machine Supplier in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#CNCWoodRouterMachineSupplier#CNCWoodRouterMachineSupplierinGujarat#CNCWoodRouterMachineSupplierinIndia#Deesa#Exporter#ExporterofCNCWoodRouterMachine#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofCNCWoodRouterMachineinGujarat#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#Porbandar

0 notes

Text

First shift Senior Router and CNC Programmer Machinist -Pay to $35 per hour

First shift Senior Router and CNC Programmer Machinist Two plus years of router programming experience or CNC programming experience as well as one plus years of experience in a lead role is required to be considered Pay up to $35 per hour Must be a United States citizen or Green Card holder No remote Full-time Permanent W-2 employee Full benefits No relocation Located in the Okauchee, Wisconsin��

0 notes

Text

Elevate Your Craftsmanship with Omni CNC! 🚀

In today's fast-paced manufacturing environment, the demand for precision and efficiency is at an all-time high. CNC (Computer Numerical Control) router machines have emerged as vital tools for various industries, from woodworking and metalworking to sign-making and prototyping.

If you're looking to invest in a CNC router machine, Omni CNC is your go-to source for high-quality, reliable machines that can elevate your craftsmanship to new heights! 🛠️

What is a CNC Router Machine? 🤔

A CNC router machine is a computer-controlled cutting tool used to carve and shape materials with precision. Unlike traditional routers, CNC routers can automatically execute complex designs and patterns based on digital files. This level of automation not only improves accuracy but also enhances productivity, making it an essential asset for both small shops and large manufacturing facilities.

Benefits of Using CNC Router Machines 🌟

Precision and Accuracy: CNC routers deliver exceptional accuracy, allowing you to create intricate designs with ease. Whether you're cutting wood, plastic, or metal, the precision of CNC technology ensures that every cut is flawless.

Increased Efficiency: With the ability to operate continuously and execute multiple tasks without manual intervention, CNC routers significantly increase productivity. This efficiency translates to reduced production time and costs.

Versatility: CNC routers can handle a wide variety of materials, including wood, acrylic, aluminum, and composite materials. This versatility makes them ideal for various applications, from custom furniture to intricate signage.

Ease of Use: Modern CNC routers come equipped with user-friendly software that simplifies the design and programming process. Even those new to CNC technology can quickly learn to operate these machines.

Consistency: Once programmed, CNC routers can reproduce the same design multiple times with perfect consistency. This feature is particularly valuable for businesses that require uniformity in their products.

Types of CNC Router Machines Available at Omni CNC 🏭

At Omni CNC, we offer a diverse range of CNC router machines to cater to various needs and budgets. Here’s a closer look at some of our popular models:

1. Desktop CNC Routers

Perfect for hobbyists and small workshops, our desktop CNC routers are compact yet powerful. They are ideal for intricate designs, small-scale projects, and prototyping.

2. Standard CNC Routers

Our standard CNC routers are versatile machines suitable for woodworking, plastics, and soft metals. These routers come with larger work areas, making them perfect for furniture makers and sign manufacturers.

3. Heavy-Duty CNC Routers

Designed for industrial applications, our heavy-duty CNC routers can handle large materials and complex tasks. These machines are equipped with robust components to ensure durability and reliability in high-volume production settings.

4. Customized CNC Routers

At Omni CNC, we understand that every business has unique requirements. That’s why we offer customized CNC router solutions tailored to your specific needs. From specialized tooling to unique sizes, we can create a machine that fits your operation perfectly.

Features to Look for in a CNC Router Machine 🔍

When selecting a CNC router machine, consider the following features to ensure you make an informed decision:

1. Spindle Power

The spindle power affects the machine's ability to cut through various materials. Higher power spindles can handle tougher materials and deliver faster cutting speeds.

2. Work Area Size

Choose a CNC router with a work area that accommodates the size of the projects you plan to undertake. A larger work area can increase versatility and efficiency.

3. Software Compatibility

Ensure that the CNC router is compatible with user-friendly design software. This compatibility will simplify the programming process and make it easier to create intricate designs.

4. Construction Quality

Look for machines made from high-quality materials, such as aluminum or steel, for enhanced durability and stability. A sturdy construction will contribute to better cutting accuracy and longevity.

5. Customer Support

Reliable customer support is crucial when investing in CNC machinery. At Omni CNC, we offer exceptional support, including setup assistance, training, and ongoing maintenance.

Why Choose Omni CNC? 🤝

Quality Assurance: We prioritize quality and only offer machines that meet stringent industry standards. Our CNC routers are built to last and perform at the highest level.

Expertise: With years of experience in the CNC industry, our team is knowledgeable and passionate about helping you find the right machine for your needs.

Competitive Pricing: At Omni CNC, we offer competitive pricing without compromising on quality. Our goal is to provide you with the best value for your investment.

Comprehensive Support: We provide extensive support throughout your purchasing journey and beyond. From installation to troubleshooting, we’re here to help you every step of the way.

Customer-Centric Approach: Your satisfaction is our priority. We take the time to understand your needs and provide tailored solutions that meet your requirements.

Conclusion 🌈

Investing in a CNC router machine can transform your business, allowing you to create high-quality products with precision and efficiency. At Omni CNC, we offer a wide range of CNC router machines for sale to suit various applications and budgets. Explore our selection today and discover how our machines can elevate your craftsmanship!

For more information on our CNC router machines or to request a quote, contact us at Omni CNC! 📞✉️

Contact Us:

OMNI CNC Technology Co.,Ltd

📍Business Address : No.27 Taiping Zhuang Industrial Park, Jinan, Shandong, China 250000

📞 Phone: 86 531 85938856

🌐 Website: No. 1 CNC Cutting Machine Manufacturer in China | OMNICNC

💼E-mail: [email protected]

🕘 Hours of Operation: 8:30-17:30

Let Omni CNC be your partner in innovation and precision!

0 notes

Text

Kitchen Cabinet Door Making CNC Router Machine for Sale

CNC router machines are highly versatile and can be programmed to create a wide range of cabinet door styles, from simple and traditional to intricate and custom designs. They offer precision, consistency, and efficiency in the manufacturing process, which can be especially valuable when producing a large number of cabinet doors.A CNC router machine is a computer-controlled cutting machine that is commonly used in woodworking and cabinetry among other applications.

Cabinets Making CNC Router Description

The closet, wardrobe, cabinets, and other wooden furniture manufacturing are the most popular applications for computerized wood carving machine. Our Nesting CNC Router, ATC CNC Router, Multi-Spindles CNC Cutting Router are perfect CNC Routers for woodworking projects. Why use a wood CNC router?

Traditional woodworking workers can‘t meet the growing needs of the woodworking industry in terms of processing speed or accuracy. Wood CNC machines have the advantages of efficient use, mass production, fast speed, and high efficiency, which greatly help the manufacturers of furniture and cabinets. Moreover, The manufacturers of wooden furniture and cabinets can customize wood CNC machines according to their own economic conditions, production processes, and other actual needs. The flexibility of woodworking engraving machines brings great benefits to wood furniture manufacturers.

CNC Router Cabinet Making Machine For Sale

This CNC router cabinet making machine is a high-efficiency machine, it is controlled by Syntec CNC controller, this machine with 9kw(12HP) spindle is powerful enough for high speed cutting.And the carousel type tool magazine is driven by a servo motor, which support fast tool change and high precision tool change.

The opening machine can make maximum use of the working time of the opening machine, high processing efficiency, convenient feeding and unloading, and can avoid the droop of the drag chain. The cabinet making CNC router is suitable for kitchen cabinet making, cabinet door making, corner cabinet making, decorative cabinet making, home cabinet making, wall cabinet making, wood cabinet making, base cabinet making and other custom cabinet making in bathroom, garage, living room, and office.

This CNC router cabinets machine is with an optional Italian drilling bank for fast hole drilling. Now,The ATC CNC Nesting machine is a special equipment for customized panel furniture cutting, drilling and groove milling. It is suitable for auxiliary processing of wardrobe, cabinet, computer desk, panel furniture, office furniture, wooden speaker, wooden kitchenware, etc. Because of its automatic processing and production, time-saving, cost saving and other advantages, it is trusted by the majority of furniture manufacturing enterprises.

Cabinets Making CNC Router Applications

Woodworking Industry: Cabinet making CNC router is ideally suitable for furniture decorations, musical instruments, wooden crafts, solid wood furniture, MDF door, wood composite door, cabinet making, kitchen cabinet doors, windows, tables, etc.

Decoration Industry: Art model, wall art, screen relief engraving and cutting, decoration processing, gifts wrapping, waved plate, electrical cabinets panels, sports equipment, and other industrial wood works.

Kitchen Cabinet Door Making CNC Features

1. The 12-tool linear automatic tool magazine reduces tool changing time and improve work efficiency.

2. Its new-type heavy duty machine structure ensures strong loading capacity and stable operation.

3. Optional LNC or SYNTEC control system has strong compatibility and is easy to operate and control. It is also equipped with a handwheel to facilitate the control of movement for the CNC router.

4. The whole vacuum table is divided into 7 zones with each zone controlled by a control valve. The strong adsorption force prevents sliding or moving of the wooden panel during operation.

5. Auxiliary feeding rollers make it more convenient to load wooden boards and reduce human labor.

What is a Nesting CNC Machine?

The nesting CNC machine is a computer numerical control equipment specially designed for the production of panel furniture line. It is also known as CNC nesting machine for sale, furniture making machine, CNC router nesting near me, nesting CNC router for furniture, furniture manufacturing machine, cabinet CNC machine, kitchen cabinet door making machine, CNC machine for cabinet making, cabinet door machine for sale, etc.

Nesting CNC machine is mainly used to cut various wooden works. Generally, through the design of intelligent software, the nesting CNC routers can automatically optimize the typesetting design and generate the effect map. Besides, the nesting machine can also perform operations such as modification intuitively, and automatically generate various paths. Therefore, it can save sheets and improve sheet utilization. The nesting CNC machine is widely used in the furniture industry such as cabinet doors, wardrobe doors, solid wood doors, paint-free doors, solid wood composite doors, and suite doors. If you are a manufacturer of furniture production lines, this nesting CNC machine is definitely one of your indispensable CNC equipment.

Nesting CNC Routers VS. Wood CNC Routers

Both nesting CNC machine wood cutter and CNC woodworking engraving machine belong to wood machining equipment. They can both be used for wood CNC cutting and engraving. And from the working principle to the appearance of the CNC machine, the CNC wood engraving machine is similar to the wood nesting CNC machine. How ever, here are many differences. What are the differences between wood nesting machine for sale and wood CNC engraver for sale? It is also a big concern that many businesses have when choosing CNC routers. Next, I will make a clear explain.

Processing field Generally speaking, the main function of CNC wood router machine is CNC engraving. While the nesting CNC machine is mainly used to cut a board into different sizes. CNC nesting router machine is a special equipment for custom-made board furniture with multiple functions such as cutting, punching, carving, grooving, edge milling, and engraving.

Machine bed structure The bed structure and accessories used by the nesting machine are much higher than those of the CNC wood carving machine. Therefore, furniture CNC wood nesting machine can adapt to long-term cutting work with very fast processing speed. Although ordinary woodworking engraving machine or multi-process CNC engraver for sale can cut material, its bed structure and mechanical parts determine that it cannot carry out cutting work for a long time. Otherwise, it will cause deformation of the bed and lower mechanical precision.

Positioning cylinder Ordinary CNC engraving machines do not have positioning cylinders. However, the panel furniture needs to be punched and slotted on the front and back, the lack of positioning cylinders will lead to errors in the hole spacing. In order to ensure good processing accuracy, nesting machines are generally equipped with positioning cylinders. .

Spindle configuration Traditional wood engraving machines basically have only one spindle to cut and engrave. And there is no way to realize automatic tool changing. If you want to process complex processes, you need to manually change the tool, which wastes a lot of manpower and time. The CNC nesting cutting machine can switch between multiple cutter heads to realize the automatic tool change of three or four cutter heads, and even the carousel tool magazine. It can process both the front and back of the cabinet to punch holes.

Automation degree The nesting machine for CNC furniture can cooperate with automatic CNC systems such as feeding, unloading, and labeling to truly realize automatic production. And one person can complete the operation. At the same time, the nesting CNC machine has more detection and fault-tolerant mechanisms. In addition, the operation of such a nesting CNC equipment is very simple. Even an ordinary worker can complete the operation after simple training.

Control system The nesting CNC machine near me can continuously increase the utilization rate of the plate by cooperating with a number of designs and layout optimization software. And then it can realize automatic order unpacking and cutting. Besides, the operation method can be improved by simple CNC analysis. But our ordinary CNC woodworking engraving machine cannot complete it in time.

Dust removal effect The dust removal function of the nesting machine is much stronger than that of the CNC engraver machine, and the dust removal effect is better. To put it simply, the nesting CNC machine that the woodworking engraving machine can do can do, but the CNC engraving machine that the nesting machine can do cannot. So if you just do some hollow carving and relief cutting of door panels, you can choose woodworking engraving machine. But if you plan to make panel furniture involves cabinet body and cabinet door, please choose the best CNC nesting machine for sale.

0 notes

Text

What is the Working Principle of CNC?

The working principle of CNC (Computer Numerical Control) involves using computers to control machine tools such as lathes, mills, routers, and grinders. CNC machines are programmed with precise instructions (G-code) that dictate the movements of the machine's cutting tools. This results in highly accurate and repeatable processes. CNC technology automates complex machining tasks that would otherwise require manual intervention, ensuring precision and efficiency in production.

Learn about CNC processes at Kuber Auto Pressing.

0 notes

Text

CNC router programming

#vectorartwork#vectortracing#vector#vectorart#cnc stalking#vectorlogo#carving#cncrouter#cnn arabic#cnco#cnc programming#CNC router programming

0 notes

Text

Benefits of a CNC Milling Machine

Benefits of a CNC Milling Machine

A cnc milling machine uses a mechanical process to cut materials and create products. Engineers design 3D products using CAD software, then input the program into the milling machine through a computer interface. While soft materials like wood and foam can be cut on a router, stronger metals such as titanium and steel require milling machines. Regardless of the material, these machines produce parts with accuracy and consistency.

1. Customization

A CNC milling machine is a powerful tool that can be used to create a wide range of products. From basic parts for everyday use to complex

components for medical and aerospace applications, it can be used to machine materials like wood, plastics, or metals. Each product gets a unique computer program that manages the movement and functioning of the multi-point cutting tools that cut away material to craft the final part or product. The program, written in an international standard language called G-code, is fed into the machine through a controller board to initiate the machining process. After the machine reads the coding, it installs the appropriate machining material and begins cutting the workpiece to its desired size. This can be done through a variety of methods including rotating the cutter, moving the workpiece in various directions, or a combination of these techniques.

2. Precision

Precision is a critical aspect of CNC milling that can help your shop save time and money. This is because more accurate cutting prevents you from having to redo a part, which reduces the overall project timeline. This is where Bates Machine & Mfg. really shines. These machines are also able to maximize geometric tolerances when working with tight angles that manual tools cannot replicate. This can be beneficial for many applications, including aerospace and medical products. Precision CNC milling can also help you cut down on wastage, which is another cost-saving benefit. This can be especially important for high-volume orders where every part needs to meet certain standards. For example, if you are manufacturing medical devices, your company will require strict dimensional tolerances to ensure patient safety. A precision CNC machine will be able to maintain these standards even as the tools wear down.

3. Speed

With a CNC milling machine, you can create components in high volumes with an unprecedented level of consistency. This is thanks to the fact that cnc machines reduce human error during machining. Whether you’re producing a prototype or a final product, every part will match the specifications laid out in your CAD or CAM file. This helps you save on labor costs, maximize materials, and produce accurate results. To get the most out of your cnc mill, you’ll need to know how to select your speeds and feeds. These are the key factors that influence your machinists' tool life, machining speed, and surface finish quality. Feed and speed calculations have been scientifically studied since the 1890s. The results of this research have been documented in terms of a number of formulas.

4. Efficiency

There are multiple efficiency options available to manufacturers with CNC milling machines. Because they operate autonomously and without the need for human operators, these machines cut down on wasted material. This also helps to reduce the risk of errors that can occur with manual operations. Additionally, these machines work on a repeatable basis using software programs that use fixed tools along specified routes. This can help to reduce production times, making them a great option for completing large scale projects in a shorter timeframe. It’s also important to keep the machine in top condition to maximize efficiency. This can be done by setting reasonable daily goals and regularly checking for any issues that may arise. These simple tips can help to ensure that the milling process is running smoothly, maximizing machining time and efficiency.

5. Cost

The cost of a CNC machine project depends on several factors. The first is the design and digitalization process which includes hiring a designer to create a product and turning it into a CAD file that the machine can understand. Another factor is the geometry of your part, which determines how many axes the machine needs to work on. Simple geometries can use a three-axis mill, which is affordable and has high accuracy. For more complex geometry, a 5-axis machine is needed. This type of machine requires more expertise and knowledge to operate and can cost more. It's important to consider all these factors when planning your CNC machine project. A knowledgeable manufacturer can help you minimize the costs by choosing the right design, material and production volume. Read the full article

0 notes

Text

Getting Started with CNC Machining

CNC machining, while complex, can be a rewarding skill to learn. Here's a basic outline of the steps involved:

1. Understanding CNC Basics

How CNC machines work: Familiarize yourself with the different types of CNC machines (mills, lathes, routers, etc.) and their capabilities.

G-code and M-code: Learn the basic syntax of these programming languages used to control CNC machines.

Safety protocols: Understand the safety measures required when operating a CNC machine.

2. Mastering CAD/CAM Software

CAD (Computer-Aided Design): Create 2D or 3D models of the parts you want to machine using software like AutoCAD, SolidWorks, or Fusion 360.

CAM (Computer-Aided Manufacturing): Convert your CAD design into machine code (G-code) using CAM software like Mastercam, Fusion 360, or CAMWorks. This process involves defining toolpaths, speeds, and feeds.

3. Choosing and Setting Up Your CNC Machine

Machine selection: Consider factors like workspace, budget, and the types of materials you plan to work with when choosing a CNC machine.

Machine setup: Learn how to install and calibrate your CNC machine, including setting up the controller, workholding systems, and tool changers.

4. Material Selection and Preparation

Material compatibility: Choose materials suitable for CNC machining, considering factors like machinability, strength, and cost.

Material preparation: Prepare the material by cutting it to size and securing it properly on the machine bed.

5. Tool Selection and Setup

Tool types: Select the right cutting tools based on the material, machining operation, and desired surface finish.

Tool setup: Install the cutting tools in the machine's tool holder or turret, ensuring correct alignment and tightness.

6. Machining Process

G-code input: Transfer the generated G-code to the CNC machine's controller.

Machine operation: Start the machining process and monitor the machine's performance.

Toolpath verification: Use simulation tools to check the toolpath before starting the actual machining process.

7. Post-Machining Processes

Deburring: Remove sharp edges and burrs from the machined parts.

Finishing: Apply surface treatments like polishing or coating if required.

0 notes

Text

Stone CNC Router Machine

In the world of stone fabrication, precision, efficiency, and versatility are key. At GK Laser Enterprises, we understand that our clients need advanced technology to stay ahead in the competitive market. That's why we're proud to introduce our Stone CNC Router Machines – a game-changer in the stone-cutting industry.

What is a Stone CNC Router Machine? A Stone CNC (Computer Numerical Control) Router Machine is a state-of-the-art tool used for cutting, carving, engraving, and shaping stone materials. Unlike traditional methods, which rely heavily on manual labor and hand tools, CNC routers utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) to perform intricate tasks with unmatched precision and efficiency.

How Does It Work? The magic of a Stone CNC Router Machine lies in its advanced software and robust hardware. Here's a step-by-step overview of how it operates:

Design Creation: The process begins with creating a digital design using CAD software. This design is a precise blueprint of the desired outcome, whether it's a detailed engraving or a complex cut.

Programming: The CAD design is then converted into a CAM file, which contains the instructions for the CNC machine. This file is uploaded to the CNC router's computer.

Setup: The stone material is securely placed on the machine's worktable. The CNC router is equipped with various cutting tools, which are selected based on the type of stone and the specific task.

Execution: Once everything is set, the machine executes the programmed instructions with high-speed precision. The router's spindle moves along the X, Y, and Z axes, following the design's path and performing cuts, carvings, or engravings.

Finishing: After the machining process is complete, the stone piece may require some finishing touches, such as polishing or additional detailing, to achieve the desired look.

Why Choose a Stone CNC Router Machine?

Unmatched Precision One of the most significant advantages of Stone CNC Router Machines is their ability to achieve unparalleled precision. Whether you're working on intricate patterns, detailed engravings, or complex shapes, the accuracy of CNC technology ensures that each piece is crafted to perfection. This level of precision is nearly impossible to achieve with manual methods.

Increased Efficiency Time is money in any industry, and stone fabrication is no exception. Stone CNC Router Machines significantly reduce the time required for cutting and shaping stone materials. Automated processes mean faster turnaround times, allowing you to complete projects more quickly and take on more clients.

Versatility Stone CNC Router Machines are incredibly versatile. They can work with a wide range of stone materials, including granite, marble, limestone, and more. This versatility opens up a world of possibilities for creating customized stone products, from countertops and flooring to intricate sculptures and architectural elements.

Cost-Effectiveness While the initial investment in a Stone CNC Router Machine may seem substantial, the long-term benefits far outweigh the costs. Reduced labor expenses, faster project completion, and minimal material wastage all contribute to significant cost savings over time. Additionally, the machine's precision minimizes the risk of errors, further reducing expenses.

Applications of Stone CNC Router Machines Stone CNC Router Machines have revolutionized various industries by offering precise and efficient solutions for stone fabrication. Some of the key applications include:

Countertops and Flooring The demand for customized stone countertops and flooring is on the rise. Stone CNC Router Machines allow for the creation of unique designs, precise cutouts for sinks and fixtures, and seamless edges, making them a favorite choice for kitchen and bathroom installations.

Architectural Elements From intricate moldings and columns to decorative facades and wall panels, Stone CNC Router Machines bring architectural visions to life. Their ability to produce detailed and complex designs makes them indispensable in the construction and interior design industries.

Sculptures and Artworks Artists and sculptors have embraced Stone CNC Router Machines for their ability to translate digital designs into tangible masterpieces. The precision and versatility of CNC technology enable the creation of detailed sculptures, engravings, and artistic installations.

Memorials and Gravestones The memorial industry relies on Stone CNC Router Machines to create personalized gravestones and monuments. The ability to engrave intricate designs, text, and images ensures that each memorial piece is a unique and lasting tribute.

Why Choose GK Laser Enterprises? At GK Laser Enterprises, we are committed to providing our clients with the best tools and technology for their stone fabrication needs. Our Stone CNC Router Machines are designed to deliver exceptional performance, reliability, and precision. Here are some reasons to choose us:

Cutting-Edge Technology: Our CNC routers are equipped with the latest advancements in CNC technology, ensuring top-notch performance and precision. Custom Solutions: We understand that every project is unique. That's why we offer customizable CNC router solutions to meet your specific requirements. Expert Support: Our team of experts is always ready to provide support, from installation and training to maintenance and troubleshooting. Quality Assurance: We stand behind the quality of our machines, offering warranties and comprehensive service packages for peace of mind.

Conclusion The Stone CNC Router Machine is a revolutionary tool that has transformed the stone fabrication industry. With its precision, efficiency, and versatility, it offers countless benefits for businesses in various sectors. At GK Laser Enterprises, we are proud to provide top-of-the-line Stone CNC Router Machines that empower our clients to achieve their creative and operational goals. Discover the power of precision with our CNC routers and take your stone fabrication projects to the next level. Contact us to learn more about how our advanced Stone CNC Router Machines can enhance your business and meet your specific needs.

0 notes

Text

CNC Router Machine Supplier in Gujarat

Success Technologies is a Manufacturer, and Supplier of CNC Router Machine in Gujarat, India Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. Success Technologies Is a Manufacturer, Exporter, and Supplier of CNC Wood Router Machine, CNC Stone Router Machine, CNC Metal Engraving Machine, Co2 Laser Machine, Fiber Laser Metal Cutting Machine, CNC Lathe Machine, Welding Machine, Channel Letter Bending Machine, Fiber Laser Marking Machine, Printer. A CNC (Computer Numerical Control) router machine cuts, carves, and engraves materials like wood, plastic, metal, and composites. By using computer-controlled software, CNC routers offer high precision and repeatability, making them essential in various industries, including woodworking, sign making, and manufacturing. Types of CNC Router Machines 3-Axis CNC Routers 4-Axis CNC Routers 5-Axis CNC Routers Gantry-Style CNC Routers Bed-Style CNC Routers Process of CNC Router Machines Design and Programming: The desired design or pattern is created using CAD software and converted into G-code instructions for the CNC machine. Material Setup: The material to be cut or routed is securely clamped onto the machine's worktable. Tool Selection: We select the appropriate cutting tool (e.g., router bit, saw blade) based on the material and desired cut. Machine Operation: The CNC machine follows the G-code instructions to move the cutting tool across the material, creating the desired shape or pattern. Finishing: We remove the finished workpiece from the machine and may perform additional finishing processes, such as sanding or painting. Success Technologies is a CNC Router Machine Supplier in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#CNCRouterMachine#CNCRouterMachineSupplier#CNCRouterMachineSupplierinGujarat#CNCRouterMachineSupplierinIndia#Deesa#Exporter#ExporterofCNCRouterMachine#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofCNCRouterMachine#ManufacturerofCNCRouterMachineinAhmedabad#Mehsana#Morbi#Nadiad#Navsari#Palanpur

0 notes

Text

CNC Machining: The Backbone of Modern Manufacturing

New Post has been published on https://www.cncmachinings.com/blog/cnc-machining-the-backbone-of-modern-manufacturing/

CNC Machining: The Backbone of Modern Manufacturing

In the ever-evolving landscape of manufacturing, Computer Numerical Control (CNC) machining stands as a cornerstone technology. By integrating computer technology with traditional machining processes, CNC machining has revolutionized the way industries produce high-precision parts and components. This article delves into the intricacies of CNC machining, its applications, advantages, and the future trajectory of this pivotal manufacturing process.

What is CNC Machining?

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. This process can control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

The process begins with creating a computer-aided design (CAD) model of the part to be manufactured. This model is then translated into a CNC program, typically using computer-aided manufacturing (CAM) software. The program generates a series of instructions, known as G-code, which guide the CNC machine’s actions.

Key Components of CNC Machines

Controller: The brain of the CNC machine, responsible for interpreting G-code and controlling the movement and operation of the machine. Spindle: The part that rotates the cutting tool or the workpiece, crucial for various machining processes like drilling, milling, and turning. Cutting Tools: These vary based on the material and type of cut required, including end mills, drills, and lathes. Work Table: The surface on which the workpiece is secured during machining. Drive System: Comprising motors and screws, it translates the controller’s commands into precise movements.

Applications of CNC Machining

CNC machining is utilized across a plethora of industries due to its versatility and precision. Some prominent applications include:

Aerospace: Manufacturing complex components with tight tolerances for aircraft and spacecraft. Automotive: Producing high-precision parts such as engine components and transmission systems. Medical Devices: Crafting intricate parts for medical equipment, including surgical instruments and prosthetics. Electronics: Creating precise components for consumer electronics, such as circuit boards and enclosures.

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve incredibly tight tolerances, ensuring each part is manufactured to exact specifications. Repeatability: Once a CNC program is perfected, it can be used to produce identical parts consistently, ensuring high quality and uniformity. Efficiency: CNC machines can operate 24/7 with minimal human intervention, significantly increasing production rates. Versatility: Capable of machining a wide range of materials, including metals, plastics, wood, and composites. Complexity: Able to produce complex geometries that would be difficult or impossible with manual machining.

The Future of CNC Machining

As technology advances, so too does the potential of CNC machining. Emerging trends and innovations are set to further enhance its capabilities:

Integration with IoT: The Internet of Things (IoT) will enable CNC machines to communicate with other machines and systems, leading to smarter, more interconnected factories. Artificial Intelligence: AI can optimize machining processes, improve tool life, and predict maintenance needs, thereby reducing downtime and costs. Hybrid Manufacturing: Combining CNC machining with additive manufacturing (3D printing) to leverage the strengths of both technologies for more efficient production. Advanced Materials: Continued development of new materials, such as advanced composites and alloys, will expand the applications and capabilities of CNC machining.

Conclusion

CNC machining is undeniably a bedrock of modern manufacturing, providing unmatched precision, efficiency, and versatility. Its integration with advanced technologies promises even greater innovations, making it an indispensable tool for industries worldwide. As we look to the future, CNC machining will undoubtedly continue to drive the evolution of manufacturing, enabling the production of increasingly sophisticated and high-quality products.

0 notes

Text

Discover the Versatility of CNC Router Machines with Omni-CNC.com

In today’s fast-paced manufacturing and crafting world, precision, efficiency, and versatility are paramount. CNC router machines have revolutionized the way businesses and hobbyists approach cutting, shaping, and engraving various materials. At Omni-CNC.com, we offer a wide range of high-quality CNC router machines for sale, designed to meet the needs of diverse industries and applications. Whether you are in woodworking, metalworking, signage, or prototyping, our CNC routers provide the perfect solution. Let's delve into the benefits and applications of CNC router machines and why Omni-CNC.com is your go-to source for these cutting-edge tools.

The Power of CNC Router Machines 🛠️

CNC (Computer Numerical Control) router machines are automated cutting tools that follow programmed instructions to create precise and intricate designs. They offer numerous advantages over traditional manual methods, including:

Precision and Accuracy 🎯: CNC routers can achieve a level of precision that is difficult to replicate with manual tools. They can cut, engrave, and shape materials with incredible accuracy, ensuring high-quality results every time.

Efficiency and Speed ⚡: Automated operation allows CNC routers to complete tasks much faster than manual methods. This efficiency translates to increased productivity and reduced production times.

Versatility 🌟: CNC routers can work with a variety of materials, including wood, plastic, metal, foam, and composites. This versatility makes them suitable for a wide range of applications.

Consistency 🔄: Once a design is programmed, CNC routers can replicate it precisely, ensuring consistency across multiple pieces. This is particularly beneficial for batch production.

Complex Designs 🔍: CNC technology enables the creation of complex and intricate designs that would be challenging or impossible to achieve manually.

Applications of CNC Router Machines 🌍

The versatility of CNC router machines makes them invaluable across various industries. Some common applications include:

Why Choose Omni-CNC.com for Your CNC Router Needs? 🌟

At Omni-CNC.com, we are committed to providing top-of-the-line CNC router machines that meet the highest standards of quality and performance. Here’s why you should choose us:

High-Quality Products 💎: Our CNC router machines are built with precision engineering and high-quality materials to ensure durability and reliability.

Advanced Technology 🚀: We incorporate the latest advancements in CNC technology to provide machines that are efficient, accurate, and easy to use.

Custom Solutions 🛠️: We understand that every customer has unique needs. Our team can help you find the perfect CNC router machine and customize it to suit your specific requirements.

Expert Support 🧑💼: Our knowledgeable and experienced team is available to provide technical support, training, and guidance, ensuring you get the most out of your CNC router machine.

Competitive Pricing 💰: We offer high-quality CNC router machines at competitive prices, providing excellent value for your investment.

Choosing the Right CNC Router Machine 🤔

Selecting the right CNC router machine depends on your specific needs and applications. Here are some factors to consider:

Work Area Size 📏: Determine the size of the materials you will be working with and choose a machine with an appropriate work area.

Material Compatibility 🧱: Ensure the CNC router machine can handle the materials you plan to use, whether it’s wood, metal, plastic, or composites.

Power and Speed ⚙️: Consider the power and speed of the machine, which will affect its ability to cut through different materials efficiently.

Software Compatibility 💻: Check that the CNC router machine is compatible with the design software you use, ensuring seamless integration and operation.

Budget 💸: Set a budget and explore options that offer the best balance of features, performance, and cost within your price range.

📞 Contact Us

Ready to elevate your manufacturing or crafting capabilities with a CNC router machine? Contact us today to learn more about our products and how we can assist you in finding the perfect CNC router machine for your needs. Our team at Omni-CNC.com is here to help you every step of the way.

📞 Phone: 86 531 85938856 💻 Website: www.omni-cnc.com 📧 Email: [email protected]

Transform your projects with the precision and versatility of CNC router machines from Omni-CNC.com. Get in touch with us today to start your journey towards enhanced productivity and creativity! 🚀🛠️

0 notes