#CNC hardening machine tool

Explore tagged Tumblr posts

Text

#induction heating machine#induction heating equipment#induction forging furnace#induction hardening machine#CNC hardening machine tool

0 notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

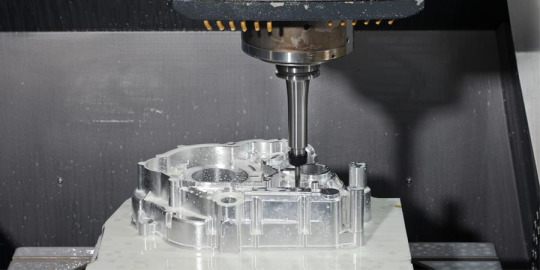

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

Upgrade Your CNC Machine with High-Performance Carbide Insert Tooling

In CNC machining, carbide milling inserts play a crucial role in enhancing cutting speed, efficiency, and overall performance. With their high resistance to wear and heat, these inserts are ideal for working with tough materials like hardened steel and titanium.

Carbide inserts provide exceptional edge retention, ensuring a consistent quality of work even under high machining loads. By incorporating CNC carbide tools and CNC insert tooling into your operations, you can achieve greater precision and reduce operational costs over time.

0 notes

Text

Thread-Rolling Tools Perfected with Solid Carbide Drill Bits for Hardened Steel

In modern CNC machining, thread milling tools are favored for their flexibility, ability to thread both internal and external features, and their performance across a wide range of materials. One major element that boosts their precision and cost-efficiency is the use of carbide milling inserts.

At Sharpedge Tech, our thread milling tools are designed to seamlessly integrate with various carbide insert geometries—offering manufacturers excellent chip control, thread consistency, and tool longevity. Carbide milling inserts allow easy indexability and quick replacement, reducing overall downtime and maintaining quality output throughout the batch.

To complement these inserts, we recommend using lathe carbide inserts in pre-threading operations to prepare the surface. This ensures a smoother start and reduces vibrations that could affect thread accuracy.

When tool holding stability is crucial, pairing your setup with zero point clamping systems enhances positioning accuracy and repeatability—especially in high-speed or multi-tool environments. For harder metals or alloys, solid carbide tools can be used for roughing, leaving the finishing threads to the precision of milling inserts. And when tool edge retention is critical, maintenance with a carbide tool grinder ensures your inserts stay sharp and geometry-consistent.

With this robust setup—featuring thread milling tools and carbide milling inserts—you can achieve fast, accurate, and versatile threading across multiple materials and applications.

0 notes

Text

Best Shaft Mounted Gearbox supplier in Ahmedabad, India

Introduction

In the world of industrial automation and mechanical power transmission, selecting the right gearbox is essential to ensure smooth operations, reliability, and longevity of machinery. One of the most commonly used gearboxes in heavy-duty applications is the Shaft Mounted Gearbox (SMGB). These gearboxes are widely preferred for their compact design, direct mounting, and ability to handle high loads with minimal maintenance.

Located in the heart of Gujarat's industrial corridor, Nisuka Industries has established itself as a leading Shaft Mounted Gearbox Manufacturer in Ahmedabad, India. With decades of experience, state-of-the-art infrastructure, and a commitment to quality, we provide a wide range of shaft mounted gearboxes suitable for various industries including mining, cement, material handling, and more.

What is a Shaft Mounted Gearbox?

A Shaft Mounted Gearbox (SMSR) is a type of speed reducer that is directly mounted onto the driven shaft of the machine. Unlike traditional gearboxes that require base mounting and alignment couplings, shaft mounted gearboxes offer a simpler and more space-saving solution.

At Nisuka Industries, our gearboxes are engineered to provide:

High torque output

Durability in demanding conditions

Minimal maintenance needs

Compact and efficient design

Our SMSR gearboxes are perfect for conveyor systems, crushing machines, screening plants, and other high-load applications.

Why Nisuka Industries?

Being a Shaft Mounted Gearbox Manufacturer in India, we combine local expertise with international quality standards. Here’s what sets us apart:

1. Advanced Manufacturing Facility

We are equipped with modern CNC machines, precision gear cutting tools, and in-house heat treatment processes to ensure every component meets the highest accuracy and durability standards.

2. Customized Solutions

Our design team works closely with clients to deliver tailor-made gearboxes. Whether you need special ratios, specific shaft sizes, or unique mounting arrangements, we can build it.

3. Stringent Quality Control

We follow ISO-compliant quality practices and conduct multiple quality checks throughout the production cycle including gear testing, load testing, and vibration analysis.

4. Pan-India Reach

Thanks to our strategic location in Ahmedabad, we serve industries across India with fast delivery and dedicated customer support.

Applications of Shaft Mounted Gearboxes

Shaft mounted gearboxes are used in industries where high load and high torque are required with low speed. Common applications include:

Belt conveyors

Aggregate crushers

Sand and gravel washing plants

Cement and fertilizer plants

Quarry and mining operations

Material handling systems

Our gearboxes are designed to handle dusty, abrasive, and high-impact working environments with ease.

Proud Conveyor Gearbox Manufacturer in India

In addition to our SMSR offerings, Nisuka Industries is also recognized as a conveyor gearbox manufacturer in India. We manufacture gearboxes specifically designed for conveyor applications that demand continuous operation, minimal vibration, and energy efficiency.

Our conveyor gearboxes are integrated with:

Heavy-duty bearings

High-quality oil seals

Gear teeth hardened for extended life

Backstop units for inclined conveyors

Whether you operate a packaging plant or a large-scale mining facility, our conveyor gearboxes are built to deliver consistent performance and reduce maintenance time.

Supporting Components: Conveyor Belt Tensioners

Smooth conveyor operations depend on more than just the gearbox. That’s why we also supply reliable conveyor belt tensioner manufacturer in India. These tensioners are essential in maintaining the correct belt tension, preventing slippage, reducing wear, and improving energy efficiency.

Our belt tensioners are:

Corrosion-resistant

Easy to install and adjust

Compatible with all standard conveyor systems

Ideal for high-vibration environments

By offering a complete mechanical power transmission package—including shaft mounted gearboxes, conveyor gearboxes, and belt tensioners—we help our clients streamline their operations from end to end.

Industries We Serve

Our gearboxes and components are trusted across various industries such as:

Mining and Quarrying

Cement and Asphalt Plants

Fertilizer and Chemical Plants

Steel and Power Plants

Food and Beverage Processing

Recycling and Waste Management

Each product is built to handle specific operational challenges while ensuring maximum uptime and performance.

Customer-Centric Approach

At Nisuka Industries, our relationship with the client goes beyond just selling a product. We provide:

Pre-sales consultation and gearbox selection

Custom engineering support

On-site installation guidance

After-sales service and spare parts availability

Technical documentation and maintenance support

Our goal is to ensure that every customer experiences enhanced productivity and operational peace of mind when using our gearboxes.

Conclusion

When it comes to power transmission and industrial automation, you need more than just a product—you need a partner you can trust. Nisuka Industries has proudly earned the trust of clients across India as a reliable Shaft Mounted Gearbox Manufacturer in Ahmedabad, India. From conveyor gearboxes to shaft-mounted units and even conveyor belt tensioners in India, we provide complete mechanical solutions under one roof.

Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry. If you’re seeking durable, efficient, and cost-effective gearbox systems for your industrial needs, look no further than Nisuka Industries.

#Shaft Mounted Gearbox supplier in Ahmedabad#Shaft Mounted Gearbox exporter in Ahmedabad#Shaft Mounted Gearbox manufacturer in Ahmedabad

0 notes

Text

Reducing Setup Time and Downtime with 5C Expanding Collets

In today’s fast-paced manufacturing world, time is money—literally. One of the most critical aspects of machining and turning operations is minimizing setup time and reducing downtime to maintain productivity and efficiency.

Enter 5C expanding collets—a smart, reliable solution that can drastically cut time spent during changeovers and part holding. Whether you're a high-volume production shop or a small-batch job shop, using 5C collets can give you a significant competitive edge.

What Are 5C Expanding Collets?

5C expanding collets are specialized work holding devices designed for internal gripping of workpieces. Unlike traditional collets that clamp from the outside, these collets expand to grip the internal bore of a part.

This makes them ideal for hollow components, precision sleeves, and parts with a central cavity. Designed to fit 5C spindles or fixtures, they’re a versatile addition to any machine shop’s tooling lineup.

A trusted collets manufacturer typically engineers these collets using hardened steel to ensure durability, repeatability, and precise cantering.

High concentricity and strong gripping force are key features that make them ideal for CNC lathes, grinding machines, and even milling applications.

How 5C Expanding Collets Reduce Setup Time

1. Quick Changeover

With traditional work holding solutions, switching between different part sizes often means readjusting or replacing the chuck or jaw system, which can take several minutes or even hours.

5C collets allow for quick changeovers with minimal adjustment, drastically cutting down setup time.

2. Minimal Tooling Adjustments

Unlike traditional fixtures that require custom tooling for each part, 5C expanding collets are designed to accommodate a variety of part sizes within their expansion range.

This reduces the need for custom jigs or fixtures and allows the operator to move quickly from one job to the next.

3. Standardized Fixturing

Most modern machining centres are already compatible with the 5C collet system. This universal compatibility means that operators don’t have to waste time adapting machines or creating specialized mounts, further reducing downtime during setup.

Decreasing Downtime with Reliable Work holding

Downtime doesn't just come from setups—it often results from unreliable gripping, frequent part slippage, or tool crashes due to improper clamping. Here’s how 5C collets can help:

1. Secure Internal Grip

Expanding collets grip the internal diameter of the part, distributing force evenly and reducing the chance of deformation. This ensures better machining stability and fewer rejections due to poor tolerances.

2. Consistent Repeatability

Top-quality collets manufacturers design their 5C expanding collets with high precision, ensuring repeatable clamping force and concentricity. This consistency leads to fewer inspection failures and reduced rework, directly minimizing unplanned downtime.

3. Less Wear and Tear

Because 5C collets grip parts uniformly, they cause less wear on both the workpiece and the tooling. Lower tool wear means fewer tool changes and longer intervals between maintenance—keeping machines running longer without interruptions.

Ideal Applications for 5C Expanding Collets

These collets are particularly useful in:

Precision turning of tube-shaped components

Grinding operations requiring internal support

Milling or drilling of hollow parts

Machining sleeves, bushings, and bearing races

Whether you're a collets manufacturer or an end-user in aerospace, automotive, or medical manufacturing, the benefits of switching to expanding collets are universal.

Choosing the Right Collets Manufacturer

The performance of your 5C collets depends heavily on the quality and precision of the product. When choosing a supplier, look for the following:

Proven track record in precision machining solutions

Use of high-grade steel and heat treatment processes

Compatibility with standard 5C spindles

Customization options for special applications

After-sales support and availability of spare parts

Investing in collets from a reputable collets manufacturer ensures your operations remain smooth, efficient, and productive.

Conclusion

In a manufacturing landscape where every second counts, upgrading to 5C expanding collets is a smart move for shops aiming to reduce setup time and eliminate costly downtime.

Their quick-change capability, internal gripping precision, and durability make them an essential component in modern machining setups.

If you’re ready to enhance your work holding efficiency and precision, consider working with a trusted collets manufacturer who can provide customized 5C solutions tailored to your specific needs.

The right collet system doesn’t just hold your part—it holds the key to your shop’s productivity.

0 notes

Text

Why CNC EDM Wire Cut Machines Are Revolutionizing Precision Manufacturing

In today’s competitive industrial landscape, precision and efficiency are the keys to success. Among the various cutting technologies available, the CNC EDM wire cut machine stands out as a game-changer in tool and die manufacturing, aerospace, automotive, and electronics industries. If you're involved in any kind of metal cutting or precision machining, investing in a high-quality CNC EDM wire cut machine is no longer optional—it's essential.

What is a CNC EDM Wire Cut Machine?

CNC EDM (Electrical Discharge Machining) wire cut machines use electrical discharges (sparks) to erode material from a workpiece with incredible accuracy. The process involves a thin wire acting as the electrode, cutting through metal without direct contact. This non-contact process is ideal for machining hard metals and producing intricate shapes that conventional cutting tools can't handle.

Benefits of Using CNC EDM Wire Cut Machines

1. Exceptional Precision

One of the biggest advantages of CNC EDM wire cutting is its ability to produce parts with ultra-tight tolerances. Accuracy down to ±1 micron can be achieved, making it ideal for high-precision components in aerospace, defense, and medical equipment.

2. Smooth Surface Finish

Unlike traditional machining, wire EDM leaves a fine finish that often eliminates the need for secondary finishing processes. This can significantly reduce production time and costs.

3. Cuts Hardened Materials

EDM can machine hardened tool steel, tungsten carbide, titanium, and exotic alloys that traditional tools struggle with. This makes it invaluable for tool and die industries.

4. Complex Geometries

From sharp corners to narrow slots, a CNC EDM wire cut machine can create intricate shapes with ease, thanks to the flexibility of wire movement and precision control.

Applications Across Industries

Tool and Die Making: Producing dies, punches, and molds.

Automotive Industry: Manufacturing complex engine and transmission components.

Medical Devices: Crafting intricate surgical instruments and implants.

Aerospace Engineering: Machining lightweight, high-strength alloys for components.

Electronics: Creating fine-pitched connector dies and lead frames.

Features to Look for When Buying

When choosing a CNC EDM wire cut machine, consider the following:

Axis Control: Machines with multiple axis movement offer more flexibility.

Cutting Speed: A balance between speed and precision is key.

Wire Diameter Compatibility: Determines the detail and size of cuts.

Automation & CNC Programming: Reduces labor and increases productivity.

Cooling & Flushing Systems: Helps maintain accuracy and wire longevity.

Maintenance and Cost Efficiency

Modern EDM wire cut machines are designed for long service life with minimal maintenance. Consumables like wire and dielectric fluid must be replaced periodically, but the absence of direct contact reduces tool wear significantly.

Conclusion

The CNC EDM wire cut machine has become an indispensable tool for precision manufacturing. Its ability to cut hard materials, create complex shapes, and deliver superior finishes makes it a must-have for any high-tech workshop. Whether you’re a small tool room or a large-scale manufacturer, adopting EDM technology can take your production quality to the next level.

0 notes

Text

The Critical Role of High-Precision Wire Machines in Modern Manufacturing

In an era where manufacturing demands extreme accuracy, efficiency, and scalability, high-precision wire machines have become indispensable. These advanced systems—including wire EDM (Electrical Discharge Machining), CNC wire bending machines, and laser wire cutting systems—are revolutionizing production across industries.

Here’s an in-depth look at why these machines are essential for modern manufacturing:

Wire Machinery Manufacturers

1. Unparalleled Precision for Complex Components

High-precision wire machines achieve micron-level accuracy, making them ideal for industries where even the slightest deviation can lead to product failure.

Wire EDM can cut intricate shapes in hardened metals with tolerances as tight as ±0.0001 inches (±0.0025 mm).

CNC wire forming machines produce consistent, repeatable bends for medical devices, springs, and electrical contacts.

Laser wire cutting ensures clean, burr-free cuts for delicate applications like aerospace and electronics.

This level of precision is critical for industries such as: ✔ Medical devices (surgical tools, implants) ✔ Aerospace (turbine blades, fuel system components) ✔ Automotive (fuel injectors, transmission parts) ✔ Electronics (micro connectors, sensor components)

2. Material Versatility & Reduced Waste

Unlike traditional machining, high-precision wire machines work with a wide range of materials, including:

Exotic alloys (Inconel, titanium)

Hardened steels (tool steels, stainless steel)

Delicate materials (copper, brass, tungsten)

Since these machines use non-contact cutting methods (like EDM and laser), they minimize material distortion and waste, leading to cost savings and sustainable manufacturing practices.

3. Faster Production & Lower Labor Costs

Automation in high-precision wire machines reduces dependency on manual labor while increasing throughput.

Wire EDM can run unattended for hours, cutting multiple parts simultaneously.

CNC wire benders produce thousands of identical components with zero variation.

Automated feeding systems ensure continuous production with minimal downtime.

This efficiency is crucial for high-volume manufacturing while maintaining strict quality control.

Wire Machinery Manufacturers

4. Enabling Miniaturization & Advanced Designs

As products become smaller and more complex (e.g., microelectronics, medical implants), traditional machining struggles to keep up.

High-precision wire machines excel in: ✔ Micro-machining (creating tiny, intricate parts) ✔ Prototyping (fast, accurate iterations for R&D) ✔ Complex geometries (undercuts, sharp internal corners)

Without these machines, manufacturing cutting-edge technology would be slower, costlier, and less reliable.

5. Cost-Effective Long-Term Investment

While high-precision wire machines require an upfront investment, they pay off quickly by: ✅ Reducing scrap rates (less material waste) ✅ Lowering rework costs (fewer defective parts) ✅ Extending tool life (non-contact processes wear out tools slower) ✅ Improving ROI (faster production = higher profits)

6. Future-Proofing Manufacturing with Smart Technology

The latest high-precision wire machines integrate IoT, AI, and real-time monitoring, enabling:

Predictive maintenance (reducing unexpected downtime)

Adaptive machining (auto-adjusting for material variations)

Data-driven optimization (improving cycle times and accuracy)

This positions manufacturers to stay competitive in Industry 4.0 and beyond.

Conclusion: A Must-Have for Competitive Manufacturing

High-precision wire machines are no longer a luxury—they are a strategic necessity for any manufacturer aiming to: ✔ Produce flawless, high-tolerance parts ✔ Reduce costs and waste ✔ Speed up production cycles ✔ Stay ahead in tech-driven industries

Wire Machinery Manufacturers

Companies that invest in these advanced systems gain a significant competitive edge, ensuring long-term success in an increasingly demanding market.

0 notes

Text

Efficient Trapezoidal Screw Production Solutions: Techniques & Technologies

Trapezoidal screws, often used in linear motion systems and mechanical actuators, are critical components in a wide range of industries—from automotive to aerospace and industrial machinery. Known for their robust design and efficiency in converting rotary motion into linear motion, the demand for high-quality trapezoidal screws has significantly grown. As a result, manufacturers are constantly seeking optimized and scalable trapezoidal screw production solutions.

This article covers everything you need to know about producing trapezoidal screws, including materials, machining technologies, threading techniques, quality assurance, and automation trends in 2025.

1. What is a Trapezoidal Screw?

A trapezoidal screw is a type of lead screw with a trapezoid-shaped thread profile, typically conforming to standards like ISO or DIN. Unlike square threads, trapezoidal threads offer better load distribution and are easier to machine, making them ideal for high-load, low-speed applications.

Common Applications:

CNC machine beds

Linear actuators

Presses and lifting devices

Industrial automation systems

2. Choosing the Right Materials

Material selection is crucial for durability, precision, and resistance to wear. Common materials include:

Carbon Steel: Cost-effective and strong, often used with surface hardening.

Stainless Steel: Excellent corrosion resistance, preferred for medical and food-grade applications.

Bronze or Brass: Common for nuts paired with steel screws to reduce friction and galling.

Plastic or Polymer Composites: For low-load, high-speed applications, especially where lubrication is a concern.

Key Considerations:

Operating temperature

Load requirements

Corrosive environments

Maintenance cycles

3. Production Methods and Machining Solutions

a. Turning and Thread Cutting

Traditional lathes and modern CNC turning centers are used for cutting the trapezoidal thread profile.

Single-point threading on CNC lathes ensures precision but is time-intensive.

Thread rolling is a faster, deformation-based process ideal for high-volume production.

b. Thread Milling

Thread milling offers flexibility, especially for internal threads or difficult-to-machine materials. It reduces tool wear and produces cleaner finishes.

c. Grinding and Finishing

Post-threading, precision grinding improves surface quality and dimensional tolerance. Centerless and cylindrical grinding methods are popular for finishing the screw shaft.

4. Thread Standards and Tolerances

Global standards such as ISO 2904, DIN 103, and ANSI/ASME B1.5 define dimensions, tolerances, and profiles for trapezoidal screws. Precision is key, especially in applications where backlash or misalignment can impact performance.

Pitch accuracy and lead deviation must be tightly controlled.

Use of coordinate measuring machines (CMMs) and thread gauges ensures compliance.

5. Heat Treatment and Surface Coatings

To enhance durability and wear resistance, manufacturers often apply:

Case hardening or nitriding

Black oxide coating for mild corrosion resistance

Zinc or nickel plating

Teflon or PTFE coating for smooth motion

Each treatment is selected based on environmental conditions and expected wear cycles.

6. Quality Control and Inspection

Precision is everything. Key quality assurance practices include:

Microscopic inspection of threads

Surface roughness measurement

Load and torque testing

Dimensional accuracy checks with optical comparators

Modern facilities integrate inline sensors and AI-driven quality monitoring systems to flag defects in real-time.

7. Automation in Trapezoidal Screw Production

In 2025, smart manufacturing is transforming screw production. Here’s how:

a. CNC Automation

Automated lathes and thread milling machines minimize human error and increase consistency.

b. Robotic Handling

Collaborative robots (cobots) are used for part loading/unloading, inspection, and material movement.

c. MES Integration

Manufacturing Execution Systems (MES) streamline production planning, track progress, and optimize workflows.

d. Digital Twin Technology

Simulations of production lines and tool paths reduce setup time and improve first-pass yield.

8. Custom Screw Design Capabilities

Many industries require non-standard trapezoidal screws with customized:

Lengths

Thread profiles

Shaft features (flats, keyways, undercuts)

Nut assemblies (anti-backlash, split nuts)

Modern CAD/CAM software enables rapid prototyping and seamless CNC code generation, allowing quick design-to-production cycles.

9. Cost-Saving Strategies

To stay competitive, manufacturers implement the following strategies:

Batch production for economies of scale

Tool wear monitoring to avoid defects

Lean manufacturing principles to reduce waste

Local sourcing of raw materials to minimize delays and cost

10. Sustainability and Environmental Practices

Eco-conscious manufacturing is gaining ground. Companies are:

Using recyclable materials

Recycling cutting fluids and coolants

Installing energy-efficient CNC machines

Adopting green certifications like ISO 14001

Conclusion

The production of trapezoidal screws involves a blend of precision engineering, material science, and modern manufacturing technology. As industries demand more efficient, customizable, and high-performance lead screws, manufacturers must adopt advanced production methods and digital tools to stay ahead.

Whether you’re an established manufacturer or entering the lead screw industry, investing in optimized trapezoidal screw production solutions is key to meeting market expectations in 2025 and beyond.

0 notes

Text

Transform Production with Elite CNC Lathe Machines for Sale

In precision-driven industries, CNC lathe machines for sale are the linchpin of efficiency, accuracy, and scalability. For automotive suppliers, aerospace manufacturers, and engineering firms, upgrading to advanced CNC lathe technology isn’t just an investment—it’s a strategic leap toward dominating competitive markets. The High-Speed Drilling And Tapping Center Series Lathe Machine T600-21T redefines industrial machining, blending cutting-edge automation with robust engineering to tackle the most demanding production challenges.

Why CNC Lathe Machines Are Critical for Industrial Excellence CNC lathe machines eliminate human error, reduce waste, and slash cycle times through automated precision. Outdated equipment risks costly delays, rework, and inconsistent quality. For TOB clients, the T600-21T delivers:

High-Speed Machining: Spindle speeds up to 4,000 RPM handle steel, titanium, and composites with surgical precision.

Multi-Tool Versatility: Turret systems enable seamless transitions between drilling, tapping, and threading operations.

Vibration-Dampening Bed: The reinforced structure ensures stability during high-torque tasks, maintaining ±0.003mm tolerances.

Automated Feed Control: Optimizes tool paths to reduce material waste by 30% and accelerate production.

Unmatched Engineering for High-Stakes Applications

Precision Components: Hardened steel cross slide and carriage guarantee durability in 24/7 operations.

Tailstock Flexibility: Supports long workpieces for complex geometries in shafts, pins, and hydraulic fittings.

Smart Speed Adaptation: Adjustable spindle settings cater to materials from aluminum to hardened alloys.

Industry 4.0 Integration: Real-time monitoring and predictive maintenance compatibility for smarter workflows.

Applications Driving ROI Across Sectors

Aerospace: Crafting turbine blades, landing gear, and engine components.

Automotive: Machining transmission systems, brake rotors, and custom fasteners.

Medical Devices: Producing implants, surgical tools, and diagnostic equipment.

Energy Sector: Fabricating valves, pump connectors, and pipeline parts.

Tailored Solutions for Your Production Line Beyond standard models, we offer customization for spindle configurations, control interfaces, or specialized tooling. Whether you need high-volume throughput or prototype agility, the T600-21T adapts to your workflow, ensuring seamless integration into existing systems.

Why Partner with Us?

Decades of Expertise: Proven track record in CNC lathe innovation and industrial solutions.

End-to-End Support: Installation, training, and maintenance services to maximize uptime.

Custom-Built Flexibility: Modify machines to meet regional standards, niche applications, or unique specs.

Upgrade to Unrivaled Precision Today Don’t let inefficiencies hold back your growth. The T600-21T CNC Lathe Machine combines speed, durability, and intelligence to future-proof your operations. Contact us to schedule a demo, request a quote, or discuss bulk-order incentives—and position your business as a leader in precision manufacturing.

Elevate Efficiency with CNC Lathe Machines for Sale—Connect Now!

0 notes

Text

Enhance Your Shop’s Capabilities with Premium CNC Carbide Tools

Machining hardened steel requires tools that can handle extreme stress, and PCBN tools (polycrystalline cubic boron nitride) are specifically designed for such conditions. Their hardness rivals that of diamonds, making them ideal for finishing hardened steels and superalloys.

Solid carbide drill bits for hardened steel offer a combination of heat resistance, hardness, and cutting edge stability. These are essential for accurate hole making in dies, molds, and hardened components.

By integrating CNC carbide tools into your workflow, you ensure consistent performance and high material removal rates, making them a must-have in modern machining environments.

0 notes

Text

Milling Tools with Carbide Burr Bits for Metal: From Rough Cuts to Refined Edges

Solid carbide tools are the go-to solution for industries that demand strength, durability, and accuracy—especially in high-speed and high-volume CNC environments. Among the most effective pairings in machining setups is the integration of carbide tip drill bits for initiating precision drilling prior to profiling, slotting, or finishing.

At Sharpedge Tech, our experience shows that using carbide tip drill bits helps establish clean, accurate pilot holes that align perfectly with follow-up operations involving solid carbide end mills or reamers. These bits offer unmatched hardness and are especially effective on materials like hardened steel, titanium, and composites.

For best performance, we recommend mounting them using ER collet chucks, which ensure concentricity and grip stability—essential for high-accuracy drilling. Coupling this with grinding wheels designed for carbide tooling helps maintain edge sharpness over extended use.

In complex component geometries, carbide milling inserts further enhance versatility, allowing users to switch between roughing and finishing within the same setup. To handle holding challenges, zero point clamping systems reduce changeover time and improve repeatability, especially in multi-axis CNC environments. Finally, for operators concerned with surface quality, pairing carbide burr bits with these tools allows for quick post-machining edge cleanup—ensuring every component is both functional and aesthetically precise.

When solid carbide tools work alongside carbide tip drill bits, the result is a streamlined, high-precision workflow built for speed, strength, and sustainability.

0 notes

Text

Hard Turning: Precision Machining for High-Performance Manufacturing

Hard turning is an advanced machining process that has revolutionized precision engineering. Unlike traditional grinding, hard turning enables manufacturers to achieve exceptional surface finishes, tight tolerances, and high efficiency in metalworking operations. This process is particularly valuable for industries requiring high-performance components, such as automotive, aerospace, and industrial machinery.

Advantages of Hard Turning

Enhanced Efficiency: Hard turning eliminates the need for multiple grinding operations, reducing cycle times and increasing production throughput.

Cost-Effective Solution: By using a single setup, hard turning minimizes tooling costs and labor expenses compared to conventional grinding techniques.

Superior Surface Finishes: With the right cutting tools and machine precision, hard turning can achieve surface finishes comparable to grinding.

Versatility in Material Processing: Hard turning is effective for machining hardened steel, alloy materials, and other difficult-to-cut metals.

CMbE: Your Partner in Precision Engineering

CarnaudMetalBox Engineering (CMbE) is a leader in manufacturing solutions, offering high-precision machining tools and technology tailored for hard turning applications. With a deep understanding of metal forming and machining, CMbE provides:

Advanced CNC Machines: Designed for precision and durability, ensuring optimal hard turning performance.

Custom Tooling Solutions: Engineered to meet specific material and tolerance requirements.

Industry Expertise: Decades of experience in supporting manufacturers with cutting-edge machining solutions.

Conclusion

Hard turning has become an essential process in modern manufacturing, delivering efficiency, precision, and cost savings. With CMbE’s expertise and innovative solutions, manufacturers can enhance their machining capabilities and maintain a competitive edge in precision engineering. Explore CMbE’s industry-leading technology to optimize your hard turning operations today.

0 notes

Text

How To Make The Most Of 304 Stainless Steel Round Bar?

304 stainless steel round bar is one of the most broadly occupied materials in an assortment of businesses because of its flexibility, erosion resistance, and amazing formability. Its combination of chromium and nickel substances makes it perfect for applications where toughness and style are vital. A 304 stainless steel circular bar, in particular, is regularly utilized in fabricating, developing, and designing components that require quality, accuracy, and resistance to natural components. This article explores how to form the foremost 304 stainless steel circular bars, counting key contemplations and applications.

1. Get the Material’s Properties

304 stainless steel is known for its great resistance to erosion, especially in situations uncovered to nourishment, water, and chemicals. Hastelloy fasteners manufacturers also offer great weldability and can be effortlessly manufactured utilizing common machining procedures. These properties make it the best choice for an assortment of applications, such as latches, shafts, bolts, and components within the nourishment handling, car, and marine businesses.

2. Exactness Machining

Three hundred four stainless steel circular bars are frequently chosen for their capacity to resist overwhelming loads and mechanical push. To maximize the material’s potential, it’s critical to utilize accurate machining procedures. CNC (computer numerical control) turning and processing is ideal for forming stainless steel threaded rod circular bars into exact components like shafts, gears, and pins. Legitimate tooling, such as carbide or high-speed steel cutters, ought to be utilized to attain smooth surfaces and tight resiliences. One challenge with machining 304 stainless steel is its work-hardening propensity. It’s vital to utilize ideal speeds and bolsters to maintain a strategic distance from the over-the-top warm era and instrument wear.

3. Welding and Joining

304 stainless steel screws can be welded using strategies such as TIG (Tungsten Inactive Gas) or MIG (Metal Idle Gas) welding. These procedures are well-suited for joining stainless steel since they minimize warm mutilation and give solid, clean welds. It is fundamental to utilize suitable filler materials that coordinate the composition of 304 stainless steel to preserve the material’s quality and erosion resistance at the joint.

Sometimes, recently welded, the surfaces ought to be altogether cleaned to evacuate any contaminants such as oil or rust. Post-weld warm treatment is regularly superfluous for stainless steel hex bolts, but in certain high-stress applications, it may well be required to diminish leftover push and progress the by-and-large quality of the weld.

4. Erosion Resistance in Particular Situations

304 stainless steel is profoundly safe from erosion, but it can be vulnerable to pitting and hole erosion in chloride-rich situations, such as marine or coastal regions. In the event that your venture includes a presentation to these conditions, consider employing a safer combination, such as 316 stainless steel round bar, or joining extra defensive coatings to improve its life span.

5. Applications of 304 Stainless Steel Circular Bar

The flexibility of 304 stainless steel circular bars creates them appropriate for a wide range of applications. Common employments incorporate:

- Clasp and Bolts:

304 stainless steel round bars are commonly utilized to make bolts, nuts, and screws due to their quality and erosion resistance.

- Shafts and Axles:

In apparatus and car applications, 304 stainless steel is utilized for shafts and axles that require resistance to wear and natural stretch.

- Auxiliary Components:

The material is frequently utilized in auxiliary back bars and other engineering components, particularly in applications where appearance and resistance to erosion are imperative.

Wrapping It Up

To create the foremost 304 stainless steel circular bars, understanding the material’s properties and selecting the correct handling strategies are key. Whether you’re machining exact parts, welding basic components, or guaranteeing erosion resistance in requesting situations, 304 stainless steel’s toughness and versatility offer incalculable conceivable outcomes. By following the best practices in creation, you’ll guarantee that your 304 stainless steel components will perform successfully and stand the test of time in an assortment of businesses

0 notes

Text

How to Choose the Best VMC Machine Components for High-Precision Manufacturing

How to Choose the Best VMC Machine Components for High-Precision Manufacturing

When it comes to high-precision manufacturing, Vertical Machining Centers (VMC machines) are the backbone of industrial production. Whether you're working in automotive, aerospace, or precision tooling, the efficiency of your VMC machine depends on the quality of its components.But with so many VMC machining parts available, how do you choose the right components that ensure accuracy, durability, and optimal performance? In this guide, we’ll explore the essential VMC machine components, how they work, and what factors you should consider when selecting the best parts for high-precision manufacturing. What is a VMC Machine and How Does It Work? A VMC machine (Vertical Machining Center) is a computer-controlled milling machine featuring a vertical spindle orientation. It is widely utilized in machining operations for drilling, cutting, and milling metal and non-metallic materials with high precision.Why Are VMC Machines Essential for Precision Manufacturing?Automation & Efficiency – Reduces human error and speeds up production. Multi-Axis Control – Ensures complex shaping and cutting with high accuracy. Consistency & Repeatability – Delivers uniform quality across all parts.

Key VMC Machine Components and Their Roles Understanding the main components of a VMC machine helps you choose the best VMC machining parts for smooth operation and enhanced productivity. Component Function Spindle Rotates cutting tools and performs machining operations. Tool Holder Holds cutting tools securely for precision machining. Worktable Supports the workpiece and provides stability. Ball Screws & Linear Guides Ensure smooth movement and accurate positioning of machine parts. Coolant System It prevents overheating and improves tool life. CNC Controller Controls machine movements and ensures automation. Let’s dive deeper into how to select the best VMC components for high-precision applications.

1. Choosing the Right Spindle for Your VMC Machine

Why It Matters?The spindle is the heart of a VMC machine, determining speed, torque, and precision. A high-quality spindle ensures:Better surface finish Faster material removal rates Reduced vibration & wear Speed & Power: Higher RPM for fine-detail work, higher torque for heavy cuts. Cooling System: Spindles with oil or air cooling last longer and perform better. Bearings: High-quality ceramic or hybrid bearings improve durability.

2. Selecting the Best Tool Holders for Precision Machining

Why It Matters?A poor-quality tool holder can lead to vibrations, misalignment, and reduced accuracy.What to Look For?Taper Type: Choose between BT, CAT, or HSK tool holders based on machine compatibility. Balanced Design: Reduces vibrations, ensuring smoother cutting. Material: Hardened steel or coated holders enhance lifespan.

3. Worktable Considerations: Stability and Load Capacity

Why It Matters?A stable VMC worktable is crucial for maintaining precision and repeatability.What to Look For?Material Strength: Cast iron tables absorb vibrations better than aluminum. Size Compatibility: Ensure the table fits your standard workpiece dimensions. Clamping Mechanism: Secure clamping improves accuracy in multi-step operations.

4. Linear Guides and Ball Screws for Motion Control

Why It Matters?These components dictate machine movement accuracy and smoothness.What to Look For?High-precision ball screws ensure accurate positioning. Low-friction linear guides improve speed and efficiency. Anti-backlash designs prevent inconsistencies in cutting.

5. CNC Controller: The Brain of Your VMC Machine

Why It Matters?A powerful CNC controller enhances automation, reducing human intervention and improving precision.What to Look For?User-friendly Interface for easy programming. Multi-axis support for complex part machining. Advanced Error Detection to prevent machining failures.

How do you choose the right VMC components manufacturer?

Key Factors to Consider:Quality & Certifications – Look for manufacturers with ISO or AS9100 certifications. Compatibility – Ensure the components fit your VMC machine model. Customer Support – Choose a supplier who offers post-purchase support. Customization Options – Some industries require specialized VMC parts for better performance.

Final Thoughts: Maximizing Performance with the Right VMC Components

Selecting high-quality VMC machine components ensures better precision, longer tool life, and increased production efficiency. Whether you're upgrading spindles, tool holders, or CNC controllers, investing in the right parts will improve your manufacturing accuracy and machine longevity.Need help choosing the best VMC components for your operation? Contact us today for expert recommendations and premium-quality VMC machining parts!

FAQs

What are the most essential components of a VMC machine? The spindle, tool holder, worktable, ball screws, and CNC controller are the most critical components affecting precision machining, speed machining, and efficiency. How often should I replace VMC machine components? Spindle & bearings: Every 3-5 years (depending on use). Tool holders: Replace if worn or causing runout. Ball screws & linear guides: Inspect every 6-12 months for wear. What are the best materials for VMC machine components? Hardened steel or ceramic bearings for spindles. Coated tool holders for extended durability. Cast iron worktables for better vibration control. Read the full article

0 notes

Text

Precision in Every Spark: Why CNC EDM Die Sinking Machines Are Shaping the Future of Tooling

In today’s fast-paced manufacturing industry, the demand for high-precision components and intricate tooling is ever-increasing. As traditional machining methods struggle to meet the needs of complex geometries and tough materials, a new hero emerges—the CNC EDM Die Sinking Machine. Known for its ability to machine hard metals with extreme accuracy, this technology is rapidly becoming a cornerstone in mold and die-making industries around the world.

In this blog, we’ll explore what a CNC EDM Die Sinking Machine is, how it works, and why it’s a smart investment for manufacturers seeking precision, efficiency, and reliability.

What is a CNC EDM Die Sinking Machine?

EDM stands for Electrical Discharge Machining, a non-traditional process that uses electrical sparks to erode material from a workpiece. Unlike traditional cutting tools, EDM doesn’t involve physical contact. Instead, it uses a controlled electrical discharge between an electrode and the workpiece, both submerged in a dielectric fluid.

The CNC EDM Die Sinking Machine, also known as a sinker EDM or ram EDM, is a specialized variant of this process. It uses pre-shaped electrodes to “sink” cavities or intricate shapes into metal components, making it especially useful in the creation of molds, dies, and precision parts.

With the integration of Computer Numerical Control (CNC), these machines offer unmatched accuracy, repeatability, and automation.

How Does It Work?

The CNC EDM die sinking process involves:

Electrode Creation: A copper or graphite electrode is shaped according to the desired cavity or feature.

Workpiece Setup: The workpiece, usually made of hard metal like tool steel, is placed in the dielectric tank.

Machining: Controlled electrical discharges remove metal from the workpiece to form the required shape.

Flushing: The dielectric fluid helps remove debris and cools the machining area.

CNC Control: All operations are automated and optimized via a CNC program for high consistency.

This method allows manufacturers to create highly detailed, complex, and precise shapes that would be difficult—or even impossible—with traditional machining.

Key Benefits of Using a CNC EDM Die Sinking Machine

🎯 Precision and Accuracy

With tolerance levels as tight as ±2 microns, CNC EDM Die Sinking Machines deliver precise results essential for mold and die manufacturing, aerospace parts, medical tools, and more.

⚙️ Ability to Machine Hard Materials

Materials like titanium, hardened steel, carbide, and Inconel can be effortlessly machined without tool wear or thermal damage.

🔁 Repeatability

Thanks to CNC automation, complex parts can be produced repeatedly with consistent quality and finish.

🌀 Complex Geometries

Intricate cavities, fine details, undercuts, and sharp internal corners are easy to create—something nearly impossible with conventional milling.

🧼 Smooth Surface Finish

EDM machines provide a naturally smooth finish, often eliminating the need for secondary polishing processes.

Applications Across Industries

A CNC EDM Die Sinking Machine is a go-to solution for multiple industries that demand intricate, high-strength, and precise components:

Tool & Die Manufacturing: For injection molds, stamping dies, and casting tools.

Aerospace & Defense: For high-stress parts made from exotic alloys.

Automotive Industry: Precision engine components and mold tooling.

Medical Equipment: Surgical instruments and implants with tight tolerances.

Electronics: Micro molds and connectors.

Choosing the Right CNC EDM Die Sinking Machine

When investing in a CNC EDM machine, consider the following factors:

✅ Machine Size & Work Area: Choose a model that suits your workpiece size and production volume.

✅ Electrode Compatibility: Ensure it supports your preferred electrode material (graphite or copper).

✅ Control System: Look for intuitive software with advanced machining strategies and automation.

✅ Build Quality: A rigid frame and reliable components ensure stability and durability.

✅ After-Sales Support: Partner with a supplier that offers maintenance, training, and spare parts.

Future of EDM: Smart, Automated, and Connected

With Industry 4.0 taking hold, modern CNC EDM Die Sinking Machines are integrating IoT capabilities, real-time monitoring, and data-driven optimization. Predictive maintenance, automation compatibility, and AI-driven cutting strategies are helping businesses reduce downtime and boost productivity.

As the demand for complex, high-performance parts grows, EDM technology continues to evolve—offering solutions that traditional machining cannot match.

0 notes