#CNC engraving machine for copper

Explore tagged Tumblr posts

Text

Unveiling N-Gravetek's Precision: CNC Engraving Machines for Copper Masterpieces

In the realm of craftsmanship and artistry, precision is paramount. Whether you are an artisan, a jeweler, or a manufacturer, the ability to engrave intricate designs on copper can be a game-changer. N-Gravetek, a trailblazing brand in the world of CNC engraving machines, has taken this art to new heights with their specialized CNC engraving machines designed specifically for copper. In this article, we delve into the world of copper engraving and explore how N-Gravetek's machines are transforming the industry.

The Allure of Copper Engraving

Copper has held a special place in human culture for centuries. Its malleability, conductivity, and timeless beauty have made it a preferred material for art, jewelry, and intricate designs. Copper engraving, in particular, has been used to create stunning masterpieces, from ornate jewelry pieces to intricate printing plates for fine art prints.

However, copper engraving is not without its challenges. Achieving precise and detailed engravings on copper can be a painstaking process that requires skill, patience, and the right tools. This is where N-Gravetek's CNC engraving machines come into play.

The N-Gravetek Difference

N-Gravetek has been a pioneer in the CNC engraving machine industry, consistently pushing the boundaries of what is possible in terms of precision and craftsmanship. Their CNC engraving machines are renowned for their ability to create intricate designs on various materials, and their machines tailored for copper are no exception.

Key Features of N-Gravetek's CNC Engraving Machines for Copper:

High Precision: N-Gravetek's machines are engineered to provide unparalleled precision. They can engrave intricate patterns and designs on copper with remarkable accuracy, ensuring that every detail is captured flawlessly.

Versatility: These machines are not limited to copper alone. They can work with a wide range of materials, allowing artisans and manufacturers to explore various creative possibilities.

User-Friendly Interface: Navigating the world of CNC engraving can be intimidating, especially for newcomers. N-Gravetek's machines feature an intuitive interface that simplifies the engraving process, making it accessible to users of all skill levels.

Customization: N-Gravetek understands that every project is unique. Their CNC engraving machines allow for easy customization, so you can bring your specific vision to life.

Durability: Built to withstand the rigors of continuous use, N-Gravetek's machines are known for their durability and reliability. They are designed to be workhorses in any engraving workshop.

Real-World Applications

N-Gravetek's CNC engraving machine for copper have found applications in various industries:

1. Jewelry Manufacturing

Jewelers rely on the precision of N-Gravetek's machines to create intricate designs and patterns on copper jewelry pieces. From personalized rings to intricate pendants, these machines allow jewelers to turn their clients' visions into reality.

2. Fine Art

Artists and printmakers use N-Gravetek's CNC engraving machines to craft copper printing plates for fine art prints. The precision and detail these machines offer are essential for reproducing artwork with the utmost fidelity.

3. Industrial Manufacturing

In the realm of industrial manufacturing, N-Gravetek's machines play a crucial role in engraving serial numbers, logos, and designs on copper components. The precision of these machines ensures the quality and consistency of the final product.

The Future of Copper Engraving

As technology continues to advance, so does the world of engraving. N-Gravetek's CNC engraving machines for copper are at the forefront of this transformation, empowering artisans, manufacturers, and artists to explore new creative horizons.

In conclusion, N-Gravetek's CNC engraving machine for copper are more than just tools; they are enablers of creativity and precision. Whether you're crafting exquisite jewelry, producing fine art prints, or adding a touch of elegance to your industrial products, N-Gravetek's machines are poised to become your trusted companions in the world of copper engraving. With N-Gravetek, the future of copper engraving looks brighter than ever before.

0 notes

Text

Low Volume Manufacturing of CNC Machining

CNC machining low volume manufacturing or small batch manufacturing is the process of producing small batches using computer numerical control (CNC) machines.

Why Choose Low Volume Manufacturing? When the development of new products are in the testing stage, 1-2 samples are not enough to test, and can not meet the conditions of mold opening, or the number of products customized itself is not much, customers often choose precision CNC machining of small quantities. During new product development, small batch production can shorten the R&D and production cycle, and do FMEA to predict the risk before mass production, which is conducive to test market sales, and can also quickly adapt to changes in customer orders and market demand, to achieve inventory minimization and production system flexibility.

What Are The Advantages & Features of CNC Low Volume Manufacturing? 1.High precision Products of CNC machining low volume manufacturing with a high precision of +/-0.01mm, finish up to Ra1.6, suitable for oxidation, sandblasting, painting and powder coating, electroplating, polishing, silkscreen, laser engraving and other surface treatment. 2.High flexibility CNC small batch production is highly flexible and can respond quickly to market changes and customer needs, especially suitable for customized products and prototype development. 3.No MOQ CNC machining is flexible for the quantity, 1~1000 pieces can be processed, we have various types of CNC machining machines (3-axis, 4-axis, 5-axis, imported machines) to meet the customer's customized product needs. 4.Rich selection of materials A wide range of materials can be CNC machined, including metal and plastic materials. Commonly customized materials for small batch production are: aluminium alloy, stainless steel, titanium alloy, magnesium alloy, zinc alloy, nickel alloy, copper, steel and so on. 5.Higher production time and cost Small batch manufacturing usually involves more model changeovers and programme setups, which increases production lead time and results in lower productivity. Higher unit costs due to lower production quantities and fixed costs such as depreciation of equipment and maintenance costs that cannot be spread effectively.

Applications for CNC Low Volume Manufacturing 1.Customized products For parts or products that need to be customized, CNC small batch manufacturing allows for a quick response to customer needs. 2.Prototyping During the product development phase, CNC low volume manufacturing allows for rapid prototyping to help designers validate designs and make adjustments. 3.Small batch production For products that are not in high demand, CNC low volume manufacturing can provide flexible production methods and reduce costs. In short, small batch manufacturing is suitable for customized products, R&D trials, medical devices and other areas where uniqueness and flexibility are important.

Matters Needing Attention for CNC Low Volume Manufacturing 1.CNC machining of small batches has two main purposes, one is the product itself has a low demand for customization. The other is the small batch trial production before large-scale production, which can avoid economic losses in large-scale production due to flow design errors and product design problems. Regardless of the type of product you have, it is important to choose the right manufacturer and determine the number of units to be produced in advance before producing small batches. 2.In addition, it is equally important to pay attention to the quality of the product. Generally, these pre-produced products are not put on the market, but are mainly used as trial products to examine whether the actual production matches the design expectations. If the difference is relatively large, it is necessary to make changes to the original design or even overturn the whole design and re-plan it. Therefore, in the small batch trial production must not try to save trouble, the use of materials are best in the actual production will be used.

In summary, CNC low volume manufacturing or small batch manufacturing offers significant advantages in terms of customized products, prototyping and production of small quantities, but there are challenges in terms of cost control and production efficiency.

#design#business#autos#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#low volume manufacturing#small batch#small batch manufacturing#small batch production#low volume production#cnc processing#cnc manufacturing#cnc precision machining

1 note

·

View note

Text

Customized Hot Sale OEM Car Pressurized Chain Case

Product Name:Die-casting moulds and parts

Material:Stainless Steel , Brass , Copper , Aluminum alloy .

Technics:High-speed CNC, EDM, wire cutting, closing device, drilling, engraving machine and mold department.

Application:Auto parts series, fishing gear series, electric chain saw series, water pump die casting series, electric and pneumatic series, etc.

Size:Customize by Ningheng

Certification:ISO9001 ,TS16949

Brand:Ningheng

0 notes

Text

Highflyer: Leading the Way in Metal Sign Board Manufacturing in Bangalore

Introduction to Highflyer's Expertise

In the bustling city of Bangalore, where businesses strive to stand out, Highflyer has emerged as a beacon of excellence in the signage industry. As premier Metal Sign Board Makers Bangalore, Highflyer combines cutting-edge technology with artisanal craftsmanship to create signage solutions that captivate and communicate. With a reputation built on quality, innovation, and customer satisfaction, Highflyer has become the go-to choice for businesses seeking impactful metal signage.

The Highflyer Difference: Quality and Innovation

What sets Highflyer apart in the competitive landscape of Metal Sign Board Makers in Bangalore is their unwavering commitment to quality and innovation. Utilizing state-of-the-art manufacturing processes, including CNC cutting, laser engraving, and precision welding, Highflyer ensures that each metal signboard is a testament to excellence. Their use of premium-grade metals, coupled with advanced finishing techniques, results in signage that not only looks stunning but also withstands the test of time and elements.

Customization: Tailoring Metal Signs to Brand Identities

Understanding that each business has unique signage needs, Highflyer offers an extensive range of customization options. As versatile Metal Signage Manufacturers in Bangalore, they work closely with clients to bring their visions to life. From sleek, modern designs to ornate, traditional styles, Highflyer's team of skilled designers and craftsmen can create metal sign boards that perfectly align with a brand's identity and marketing objectives. This bespoke approach ensures that every sign is not just a product, but a powerful branding tool.

Materials Matter: The Highflyer Metal Selection

Highflyer's success as a Metal Sign Board Manufacturer in Bangalore is largely due to its meticulous material selection. While specializing in stainless steel for its durability and aesthetic appeal, Highflyer also works with a variety of other metals including aluminium, brass, and copper. Each material is chosen for its unique properties, allowing Highflyer to recommend the best option based on the client's specific needs, budget, and the sign's intended location. This expertise in material selection ensures longevity and visual impact for every sign board produced.

Advanced Manufacturing Techniques

Highflyer's facility is equipped with the latest in metal fabrication technology, positioning them at the forefront of Metal Sign Board Makers Bangalore. Their use of CNC machines allows for precision cutting and shaping of metal, ensuring exact dimensions and clean edges. Laser engraving technology enables intricate designs and text to be etched onto metal surfaces with remarkable detail. Additionally, their advanced welding and joining techniques ensure structural integrity, making their signboards as durable as they are attractive.

Finishing Touches: Elevating Metal Signage

The finishing process is where Highflyer truly shines among Metal Signage Manufacturers in Bangalore. Offering a wide range of finishes including brushed, polished, painted, and powder-coated options, Highflyer can achieve any desired look. Their electroplating capabilities allow for the application of decorative and protective metallic coatings, enhancing both the appearance and durability of the sign boards. These finishing options not only protect the metal from corrosion but also add a layer of sophistication to the final product.

Illuminated Metal Signs: Lighting Bangalore's Businesses

Recognizing the impact of illuminated signage, Highflyer has mastered the art of integrating lighting solutions into their metal sign boards. As innovative Metal Sign Board Makers in Bangalore, they offer a range of illumination options including LED backlighting, halo lighting, and front-lit designs. These illuminated metal signs ensure visibility at all hours, making them particularly effective for businesses operating in the evening or low-light areas. Highflyer's expertise in this area has made it a favourite among hotels, restaurants, and retail outlets across Bangalore.

Sustainability in Metal Sign Manufacturing

In an era of increasing environmental awareness, Highflyer stands out among Metal Sign Board Makers Bangalore for their commitment to sustainability. They implement eco-friendly practices throughout their manufacturing process, from using recyclable metals to employing energy-efficient machinery. Highflyer also focuses on minimizing waste and utilizing environmentally safe finishing products. This dedication to sustainability not only reduces their environmental footprint but also appeals to environmentally conscious clients.

Quality Assurance and Durability Testing

Highflyer's reputation as a reliable Metal Signage Manufacturer in Bangalore is built on its rigorous quality assurance processes. Each signboard undergoes thorough inspection and testing before leaving the facility. This includes checks for structural integrity, finish quality, and in the case of illuminated signs, electrical safety. Highflyer also conducts durability tests, simulating various weather conditions to ensure their signs can withstand Bangalore's diverse climate. This commitment to quality gives clients confidence in the longevity and performance of their investment.

Installation and After-Sales Support

Highflyer's service doesn't end with manufacturing. As a comprehensive Metal Sign Board Manufacturer in Bangalore, they offer professional installation services, ensuring that each sign is securely and correctly mounted. Their team of experienced installers is well-versed in handling various installation challenges, from simple storefront mounts to complex high-rise installations. Furthermore, Highflyer provides robust after-sales support, offering maintenance tips and repair services to keep the signs looking their best for years to come.

Innovative Designs: Pushing the Boundaries of Metal Signage

Always at the forefront of innovation, Highflyer continuously explores new design possibilities in metal signage. As creative Metal Sign Board Makers Bangalore, they experiment with 3D effects, mixed material compositions, and interactive elements. This drive for innovation has resulted in unique creations like textured metal signs, kinetic sign elements, and even smart signage incorporating digital displays. By pushing the boundaries of what's possible with metal signage, Highflyer helps businesses in Bangalore create truly memorable brand experiences.

FAQs (Frequently Asked Questions)

What types of metals does Highflyer use for their signboards?

Highflyer primarily uses stainless steel but also works with aluminium, brass, and copper, selecting the best material based on client needs and sign location.

Does Highflyer offer illuminated metal sign options?

Yes, Highflyer provides various illumination options including LED backlighting, halo lighting, and front-lit designs for enhanced visibility.

How does Highflyer ensure the quality and durability of their metal signboards?

They conduct rigorous quality assurance processes, including structural integrity checks, finish quality inspections, and durability tests simulating various weather conditions.

Can Highflyer create custom designs for metal signboards?

Absolutely. Highflyer offers extensive customization options, working closely with clients to create bespoke designs that align with brand identities and marketing objectives.

Does Highflyer provide installation services for their metal signboards?

Yes, Highflyer offers professional installation services and after-sales support, ensuring proper mounting and ongoing maintenance of their sign boards.

Conclusion: Highflyer's Mark on Bangalore's Skyline

In conclusion, Highflyer has established itself as more than just Metal Sign Board Makers Bangalore; they are partners in building brand visibility and identity. Through their combination of skilled craftsmanship, advanced technology, and customer-centric approach, Highflyer continues to shape the visual landscape of Bangalore's business community. As they look to the future, Highflyer remains committed to innovation, quality, and sustainability, ensuring they will continue to be the premier choice for businesses seeking exceptional metal signage solutions in Bangalore and beyond.

https://blog.highflyersigns.com/elevating-your-brand-with-quality-metal-sign-boards-highflyer/

#metalsignboardmakersbangalore, #metalsignagemanufacturerinbangalore, #metalsignboardmanufacturerinbangalore, #metalsignageboardmanufacturerinbangalore, #metalsignletterssignboardmanufacturerinbangalore,

#metalsignboardmakersbangalore#metalsignagemanufacturerinbangalore#metalsignboardmanufacturerinbangalore#metalsignageboardmanufacturerinbangalore#metalsignletterssignboardmanufacturerinbangalore

0 notes

Text

Fiber Optic Laser Cutting Machine

In the world of manufacturing and fabrication, precision cutting plays a crucial role in achieving high-quality results. Traditional cutting methods often come with limitations, such as slower cutting speeds, heat distortion, and limited material compatibility. However, with the advent of fiber optic laser cutting machines, these limitations are being overcome.

Fiber Optic Laser Cutting Machine

A Fiber Optic Laser Cutting Machine is a highly advanced tool used in industrial manufacturing for cutting a wide range of materials with precision and efficiency.Fiber optic laser cutting machines utilize the power of lasers to cut through various materials with exceptional precision. These machines employ a fiber optic laser beam that is guided through a series of mirrors and lenses to focus the laser energy onto the material being cut. The intense heat generated by the laser beam melts or vaporizes the material, creating a clean and precise cut.

Fiber Optic Laser Cutting Machine Key Components:

Fiber Laser Source: The core component that generates the laser beam. It’s known for its high efficiency and power density.

Laser Cutting Head: Contains the focusing lens and nozzle, directing the laser beam onto the material.

CNC Controller: The computer system that controls the movements of the cutting head and worktable, ensuring precise cutting according to the programmed design.

Worktable: The surface on which the material to be cut is placed. It often includes a clamping mechanism to hold the material in place.

Cooling System: Keeps the laser source and other components at optimal temperatures to prevent overheating.

Protective Enclosure: A safety feature that protects operators from exposure to the high-power laser beam and collects fumes and particles generated during cutting.

Advantages:

High Precision: Capable of cutting complex shapes with tight tolerances.

Speed: Faster cutting speeds compared to traditional methods, especially for thin materials.

Quality: Produces clean cuts with minimal burrs and reduced heat-affected zones.

Efficiency: High power efficiency and lower operating costs due to reduced energy consumption.

Versatility: Can cut a wide variety of materials, including metals (steel, aluminum, copper), plastics, and composites.

Automation: Easily integrated with automated systems for mass production.

Applications of Fiber Optic Laser Cutting Machines

Fiber optic laser cutting machines find applications in various industries, including:

Automotive: Cutting metal components for carparts, such as chassis, body panels, and engine components.

Aerospace: Precision cutting of aircraft parts, including turbine blades, fuselage components, and brackets.

Electronics: Cutting intricate patterns on circuit boards, creating precise openings for electronic components.

Signage: Cutting and engraving letters, logos, and designs on various materials, such as acrylic, wood, and metal.

Furniture: Creating intricate designs on wooden furniture pieces, cutting precise joints and patterns.

Jewelry: Cutting and shaping precious metals, such as gold and silver, to create intricate jewelry pieces.

Textiles: Cutting fabrics for apparel, upholstery, and other textile products with precision and speed.

Q1: Are fiber optic laser cutting machines safe to use?

A1: Yes, fiber optic laser cutting machines are safe to use when operated correctly. They come with safety features, such as enclosed cutting areas, interlock systems, and protective eyewear. It is essential to follow the manufacturer’s guidelines and receive proper training to ensure safe operation.

Q2: Can fiber optic laser cutting machines cut reflective materials?

A2: Yes, fiber optic laser cutting machines can cut reflective materials, such as stainless steel and aluminum. The machines are equipped with special optics and laser parameters to handle reflective surfaces effectively.

Q3: How do fiber optic laser cutting machines compare to other cutting methods?

A3: Fiber optic laser cutting machines offer several advantages over traditional cutting methods. They provide higher precision, faster cutting speeds, minimal heat distortion, and versatility in cutting various materials. Additionally, they can be integrated into automated production lines for increased efficiency.

Q4: What maintenance is required for fiber optic laser cutting machines?

A4: Fiber optic laser cutting machines require regular maintenance to ensure optimal performance. This includes cleaning the optics, checking and replacing consumables (such as nozzles and lenses), and inspecting the machine’s mechanical components. It is recommended to follow the manufacturer’s maintenance schedule and guidelines.

Q5: Can fiber optic laser cutting machines be used for 3D cutting?

A5: Yes, fiber optic laser cutting machines can be used for 3D cutting. With the use of advanced software and robotic systems, these machines can cut complex 3D shapes and contours with precision. This capability opens up new possibilities for various industries, including automotive, aerospace, and architecture.

0 notes

Text

Elevate Your Fabrication Shop with CNC Plasma and Router Tables

In the ever-evolving world of fabrication and manufacturing, having the right tools is essential for achieving precision, efficiency, and versatility. CNC Plasma Tables, CNC Router Tables, and the specialized CNC 4x4 Plasma Table are powerful additions to any workshop, each offering unique capabilities that cater to different material types and project requirements. This blog will explore the benefits and applications of these advanced machines, helping you understand how they can enhance your fabrication processes.

CNC Plasma Table: Precision Cutting for Metals

What is a CNC Plasma Table?

A CNC Plasma Table uses a plasma torch to cut through electrically conductive materials like steel, aluminum, brass, and copper. With CNC (Computer Numerical Control) technology, these tables offer precise control over the cutting process, ensuring high accuracy and repeatability.

Benefits of CNC Plasma Tables:

High Precision: Ideal for detailed and complex metalwork, providing clean, sharp cuts.

Speed: Operates at high speeds, significantly reducing cutting time compared to traditional methods.

Versatility: Suitable for various metals, making it useful in industries such as automotive, aerospace, and metal fabrication.

Cost-Effective: Efficient use of materials and reduced waste lead to cost savings over time.

Applications:

Custom Metal Fabrication: Create intricate metal parts and components.

Signage: Produce detailed and durable metal signs.

Automotive and Aerospace: Manufacture precise parts for vehicles and aircraft.

CNC Router Table: Versatile Cutting for Various Materials

What is a CNC Router Table?

A CNC Router Table is designed to cut, carve, and engrave various materials, including wood, plastic, foam, and soft metals. Like the CNC Plasma Table, it uses computer controls to achieve high precision and intricate designs.

Benefits of CNC Router Tables:

Material Versatility: Capable of working with a wide range of materials.

Detail and Precision: Suitable for creating highly detailed and intricate designs.

Ease of Use: User-friendly interfaces make it accessible for various skill levels.

Customization: Perfect for custom projects, allowing for personalized creations.

Applications:

Woodworking: Produce detailed carvings, furniture parts, and decorative elements.

Signage: Create intricate wooden or plastic signs.

Prototyping: Develop accurate prototypes for product design and testing.

Artistic Projects: Craft detailed pieces for art installations or custom decor.

CNC 4x4 Plasma Table: Compact Powerhouse

What is a CNC 4x4 Plasma Table?

A CNC 4x4 Plasma Table is a compact version of the standard CNC Plasma Table, offering similar capabilities in a smaller footprint. This makes it ideal for workshops with limited space.

Benefits of CNC 4x4 Plasma Tables:

Space Efficiency: Compact size fits into smaller workshops without sacrificing cutting capabilities.

High Precision: Delivers the same level of precision as larger models, perfect for detailed metalwork.

Cost-Effective: More affordable than larger tables, making it accessible for small to medium-sized businesses.

Versatility: Suitable for a variety of metal cutting projects.

Applications:

Small Workshops: Ideal for businesses with limited space.

Custom Metalwork: Perfect for creating detailed metal parts and components.

Educational Settings: Used in schools and training centers to teach CNC cutting techniques.

Conclusion

Investing in CNC Plasma Tables, CNC Router Tables, and CNC 4x4 Plasma Tables can transform your fabrication shop, providing you with the tools needed to tackle a wide range of projects with precision and efficiency. Whether cutting metals, carving wood, or creating detailed prototypes, these advanced machines offer the versatility and performance required to meet the demands of modern manufacturing. Choosing the right CNC table for your specific needs can enhance your workshop's capabilities and take your projects to the next level.

#cnc plasma tables#cnc plasma table#stv#stvcnc#router table#cnc plasma cutters#cnc router table#plasma table#cnc plasma table kit

0 notes

Text

Forging Ahead: The Evolving Art of Metalworking

Metalworking is a dynamic craft that has been essential to human development since the dawn of civilization. From the creation of simple tools to the complex components used in modern machinery, metalworking involves a variety of techniques and materials that transform raw metal into functional and decorative items. This craft not only demands strength and endurance but also a high degree of precision and artistry, making it a vital skill in both traditional and contemporary industries.

Understanding the Basics: Tools and Techniques

Metalworking encompasses a wide range of activities, including forging, casting, welding, and machining. Each method requires specific tools and expertise. Forging, for example, involves heating the metal until it becomes malleable and then shaping it with hammers and anvils. Casting, on the other hand, involves pouring molten metal into molds to achieve desired shapes. Welding is used to join metal pieces together, while machining shapes metal pieces with the help of lathes, mills, and drills.

For beginners, understanding the properties of different metals—such as steel, aluminum, and copper—is crucial. Each metal behaves differently under stress and heat, influencing the choice of tools and methods used. Additionally, mastering safety practices is essential to prevent injuries from hot metals, sharp edges, and the powerful machinery often used in metalworking.

Safety Protocols: Protecting the Artisan

Metalworking can be hazardous, making safety a top priority in any metal shop. Proper attire, including gloves, goggles, and protective clothing, is mandatory to guard against burns, cuts, and other injuries. Ventilation is also critical, especially in processes that produce fumes, such as welding or metal casting. Regular maintenance of equipment ensures that machines function correctly and safely, reducing the risk of accidents.

Artistic Metalworking: From Utility to Beauty

While many metalworking projects focus on functionality, such as creating parts for machines or buildings, there is also a significant artistic component to this craft. Artistic metalworking is seen in sculptures, jewelry, and decorative items. Techniques such as engraving, etching, and patination are used to add intricate details and finishes to metal surfaces, allowing for personal expression and creativity. Metal's versatility makes it an excellent medium for artists who wish to explore different textures, forms, and patinas.

The Green Forge: Sustainable Practices in Metalworking

Sustainability in metalworking is gaining traction as environmental concerns become more prominent. This includes using recycled materials, optimizing processes to reduce waste, and employing energy-efficient machinery. Metalworkers are increasingly aware of the lifecycle of the materials they use, from sourcing to disposal, and strive to minimize their environmental footprint. By repurposing scrap metal or using less toxic methods and materials, they contribute to a more sustainable practice.

Technological Innovations: Shaping the Future of Metalworking

Technology has transformed traditional metalworking methods, introducing precision and efficiency that were previously unattainable. Computer Numerical Control (CNC) machines, for instance, allow for highly accurate cutting and shaping of metal parts, essential in industries like aerospace and automotive manufacturing. Additionally, technologies such as 3D metal printing are revolutionizing the field by enabling the creation of complex metal structures directly from digital designs, opening up new possibilities for customization and innovation.

Building a Community: The Collaborative Spirit of Metalworkers

Metalworking, much like other crafts, thrives in a community setting where knowledge, skills, and ideas can be shared. Workshops, classes, and online forums provide spaces for both novice and experienced metalworkers to learn from each other and collaborate on projects. These communities not only help preserve traditional techniques but also foster innovation as diverse experiences and perspectives come together to solve problems and create new works.

Crafting Durability and Beauty

Metalworking is an enduring craft that combines the ruggedness of industrial manufacturing with the finesse of artistic sculpture. It plays a crucial role in both our everyday lives and in the advancement of technology. As metalworkers continue to adapt and innovate, they not only carry forward a rich heritage of craftsmanship but also contribute to the development of new techniques and sustainable practices. Whether through the strength of a forged steel beam or the delicate beauty of a cast bronze statue, metalworking remains a profound testament to human creativity and ingenuity.

0 notes

Text

CNC Laser Cutting, CNC Laser Cutting Services, India 2023, 2024

CNC laser cutting has emerged as a revolutionary technology that has transformed various industries, offering precision, versatility, and efficiency in the process of cutting and engraving materials.

With its ability to create intricate designs and complex shapes with utmost accuracy, CNC laser cutting has become a go-to method in manufacturing, prototyping, and various creative applications. This blog post aims to provide a comprehensive understanding of CNC laser cutting, exploring its principles, applications, benefits, and the overall process involved.

Table of Contents:

Understanding CNC Laser Cutting

CNC laser cutting is a revolutionary technology that has transformed the manufacturing industry. It offers precision and efficiency like never before, making it a popular choice for various applications. Understanding how CNC laser cutting works can provide valuable insights into its benefits and applications. CNC, which stands for Computer Numerical Control, refers to the automation of machine tools through the use of computerized systems. In the case of laser cutting, a high-powered laser beam is directed by a CNC-controlled system to cut through various materials with extreme precision. The laser beam melts, burns, or vaporizes the material, creating intricate and accurate cuts. One of the primary advantages of CNC laser cutting is its versatility. It can cut through a wide range of materials, including metals, plastics, wood, and even fabrics. This flexibility makes it suitable for various industries, from automotive and aerospace to electronics and signage. Precision is another key benefit of CNC laser cutting. The laser beam is controlled by a computer program, ensuring consistent and accurate cuts every time. This eliminates human errors and reduces material waste, resulting in cost savings for manufacturers.

Moreover, CNC laser cutting enables complex designs and shapes to be created effortlessly. Intricate patterns, holes, and engravings can be achieved with ease, allowing for customization and creativity in manufacturing processes. The efficiency of CNC laser cutting is also noteworthy. It is a non-contact process, meaning there is no physical force exerted on the material, minimizing the risk of damage or deformation. Additionally, the speed of laser cutting is considerably faster compared to traditional methods, resulting in higher production rates. In conclusion, CNC laser cutting is a game-changer in the manufacturing industry. Its precision, versatility, efficiency, and ability to create complex designs make it an invaluable tool for various applications. Embracing this technology can lead to enhanced productivity, cost savings, and the realization of intricate and customized products.

Applications of CNC Laser Cutting

CNC laser cutting has revolutionized the manufacturing industry with its precise and efficient cutting capabilities. This technology uses a high-powered laser beam to cut through a wide range of materials with incredible accuracy. From metal fabrication to signage production, CNC laser cutting finds applications in various industries. One of the primary applications of CNC laser cutting is in metal fabrication. It allows manufacturers to create intricate and precise cuts on metals such as steel, aluminum, and copper. This is especially useful in industries like automotive, aerospace, and electronics, where precision is crucial for the production of complex components. Another popular application is in the production of signage. CNC laser cutting enables the creation of detailed and customized signage designs from various materials like acrylic, wood, and metal. The precise cutting capabilities of the laser ensure clean edges and sharp details, resulting in visually appealing signage. CNC laser cutting is also widely used in the field of prototyping and rapid manufacturing.

It allows for quick and accurate production of prototypes and small-scale production runs. This is particularly beneficial for industries like product design and development, where fast iteration and validation are essential. Additionally, CNC laser cutting finds applications in the field of art and design. Artists and designers can use this technology to create intricate patterns, engravings, and sculptures on a variety of materials. The precision and versatility of laser cutting open up endless creative possibilities. In summary, CNC laser cutting has become an indispensable tool in various industries. Its precise cutting capabilities, versatility, and efficiency make it ideal for metal fabrication, signage production, prototyping, and artistic endeavors. As technology continues to advance, we can expect even more innovative applications for CNC laser cutting in the future.

Advantages of CNC Laser Cutting

CNC laser cutting is a revolutionary technology that has transformed the manufacturing industry. It utilizes a high-powered laser beam to cut through various materials with precision and accuracy. This process offers numerous advantages, making it a popular choice for industries ranging from automotive to aerospace. Here are some key advantages of CNC laser cutting. Firstly, CNC laser cutting provides exceptional precision. The laser beam is controlled by a computer program, ensuring accurate and consistent cuts. This level of precision allows for intricate designs and complex shapes, making it ideal for intricate components and delicate materials. Secondly, CNC laser cutting is highly versatile. It can cut through a wide range of materials, including metals, plastics, wood, and even fabrics. This versatility makes it a valuable tool for various industries, as it can handle different materials and meet diverse manufacturing needs. Additionally, CNC laser cutting offers excellent speed and efficiency.

The laser beam can cut through materials quickly, reducing production time and increasing productivity. Moreover, it eliminates the need for additional machining processes, saving both time and costs. Furthermore, CNC laser cutting is a non-contact process, which means there is minimal physical contact between the laser and the material being cut. This reduces the risk of material damage, distortion, or contamination, ensuring high-quality cuts and preserving the integrity of the material. Lastly, CNC laser cutting is highly automated. Once the design is programmed into the system, the machine can operate autonomously, requiring minimal human intervention. This automation improves efficiency, reduces labor costs, and allows for uninterrupted production. In conclusion, CNC laser cutting offers numerous advantages, including precision, versatility, speed, non-contact cutting, and automation. These benefits make it an indispensable tool in modern manufacturing, enabling companies to achieve higher productivity, superior quality, and cost-effectiveness in their production processes.

Factors to Consider when Implementing CNC Laser Cutting

When it comes to implementing CNC laser cutting technology, there are several important factors that need to be considered. CNC laser cutting offers numerous benefits, including precision, efficiency, and versatility. However, to maximize these advantages, it is crucial to carefully consider the following factors:

Material Compatibility: Different materials have varying properties, and not all are suitable for laser cutting. Factors such as thickness, reflectivity, and conductivity must be taken into account to ensure the laser can effectively cut through the material without causing damage or producing poor-quality cuts.

Laser Power and Beam Quality: The power and quality of the laser beam directly impact the cutting speed and quality. Higher power lasers can cut through thicker materials, while beam quality determines the precision of cuts. Choosing the right combination of power and beam quality is vital for achieving desired results.

Machine Accuracy and Stability: CNC laser cutting machines need to be highly accurate and stable to ensure consistent and precise cuts. Factors such as machine rigidity, positioning accuracy, and repeatability should be evaluated when selecting a machine to guarantee reliable performance.

Cutting Speed and Productivity: The cutting speed of a CNC laser machine affects productivity. Finding the right balance between cutting speed and quality is essential. Higher cutting speeds may sacrifice precision, while slower speeds may decrease productivity.

Software and Programming: The software used to program and control the CNC laser machine plays a crucial role. User-friendly software with advanced features simplifies the programming process and optimizes cutting paths, resulting in efficient operation and reduced material waste.

Safety Measures: Laser cutting involves high-power lasers and potentially hazardous fumes and particles. Implementing appropriate safety measures, such as exhaust systems, protective enclosures, and operator training, is essential to ensure a safe working environment.

By carefully considering these factors, businesses can effectively implement CNC laser cutting technology and unlock its full potential. It is crucial to thoroughly assess the requirements and choose the right equipment, materials, and processes to achieve optimal results and maximize efficiency and productivity.

Section 1: Understanding CNC Laser Cutting

In this section, we will delve into the basics of CNC laser cutting, including its components and how the technology operates. We will explore the various types of lasers used, such as CO2 and fiber lasers, and provide insights into the different cutting techniques employed.

Section 2: Applications of CNC Laser Cutting

CNC laser cutting finds its applications across a wide range of industries. In this section, we will discuss how CNC laser cutting is utilized in metal fabrication, automotive manufacturing, aerospace and defense, electronics, architecture, medical industries, and art. We will highlight specific examples to demonstrate the versatility and benefits of this technology.

Section 3: Advantages of CNC Laser Cutting

The advantages of CNC laser cutting are manifold. In this section, we will explore the precision and accuracy it offers, the ability to work with a variety of materials, the efficiency and speed of the process, reduced material waste, the capability to create complex designs, safety measures, and the cost-effectiveness of CNC laser cutting.

Section 4: Factors to Consider when Implementing CNC Laser Cutting

Implementing CNC laser cutting requires careful consideration of various factors. This section will provide guidance on material selection, laser power and beam quality, machine maintenance and upkeep, safety precautions and operator training, budgetary considerations, project complexity and size, and future scalability. By addressing these factors, organizations can optimize their CNC laser cutting operations.

Conclusion :

CNC laser cutting has revolutionized the manufacturing, creative, and medical industries, offering unmatched precision, versatility, and efficiency. By harnessing the power of laser technology, CNC laser cutting systems have become invaluable tools for cutting and engraving various materials with exceptional accuracy.

With a wide range of applications and numerous benefits, including precision, versatility, efficiency, and cost-effectiveness, CNC laser cutting continues to push the boundaries of innovation. As the technology evolves, its potential for future advancements and integration into various industries appears limitless. Embracing CNC laser cutting not only unlocks new possibilities but also paves the way for sustainable and environmentally friendly manufacturing practices.

#metal gates#metal railings balusters#metal modular wall paneling#metal modular 3d wall paneling#architecture#decor#home#interiors#kitchen#furniture manufacturer#metal fabrication#metal fabricaters#interior decorating#exterior#exterior design#cnc laser cutting#cnc cutting

1 note

·

View note

Text

Learn about SPINDLE MOTOR

Spindle

Changzhou Troy Machinery & Electric Co., Ltd. was established in 1998 and has since become a market leader in High-speed spindle motor design, production, and distribution.

We continually invest in new, cutting-edge production and testing equipment to make sure that our products are of the greatest calibre. Because of our cutting-edge technology and reliable quality, we have gained the trust of customers both domestically and internationally. Our “WHD” brand name is gaining popularity.

CNC spindle, engraving machines, drilling machines, edge banding machines, and other related devices frequently use products from our STZ, STF, STM, STL, and STX family. In addition, we may create unique spindle motors based on the demands of our clients. In order to uphold our company’s core philosophy of putting the customer first, we have shipped our products to many different nations throughout the world, including the United States, Russia, Europe, India, Brazil, and Iran.

To twist and wind thread from a pile of flax or wool carried on a distaff, a spindle is a narrow, rounded rod with tapered ends.

CNC Spindle motor

The geometrical tolerances of the workpiece surface are usually subjected to high demands when grinding. Hence, specifications for a minimum position change of the grinding discs due to external forces and bending moments are often included in the construction of grinding machine spindles.

Spindle ATC — Automatic Tool Change Spindler Motor Many tools can be used automatically by the motor. WHD offers water-cooled 5.5 kW ATC spindles, water-cooled 7.5 kW spindles, and air-cooled 9.0 kW spindles. With over 20 years of manufacturing and selling spindle motors, WHD offers High-Speed Air-Cooled Spindle motors for CNC engraving and CNC wood routing.WHD spindle motors have been delivered, among other locations, to the US, Europe, Brazil, India, and Russia.

ATC — Automatic Tool Change Spindle motor

Automated Tool Change Spindle Motor is referred to as ATC. The ATC Spindle Motor has a number of automatic tools. There are three alternatives provided by WHD: a water-cooled 5.5 kW ATC spindle, a water-cooled 7.5 kW ATC spindle, and an air-cooled 9.0 kW ATC spindle. With over 20 years of manufacturing and selling spindle motors, WHD offers High-Speed Air-Cooled Spindle motors for CNC engraving and CNC wood routing. WHD spindle motors have been delivered, among other locations, to the US, Europe, Brazil, India, and Russia. Woodworking, acrylic plastic, and light metal engravings like copper and aluminium are some of its applications.

0 notes

Text

Looking for precise and efficient ways to create stunning CNC Machines for silver Jewellery or CNC Machines for copper jewelry? Explore our collection of CNC engraving machine for silver and CNC engraving machine copper jewelry today

#CNC Machines for silver Jewellery#CNC Machines for copper Jewellery#CNC engraving machine for silver#CNC engraving machine for copper

0 notes

Text

Genmitsu 3020-PRO MAX CNC Router Machine for Metal Carving and More

- Brand: Genmitsu Features - Bigger and also much better with an all brand-new additional rigid and also beefy design including an increased Z Height of 72mm double steel X axis overview rails, all aluminum pin holder as well as 300W spindle. All these upgrades make metal carving less complicated, perfect for a limitless selection of boring, as well as sculpting operations on different metals, like brass, copper and also 6061 aluminum, and so on. - Updated straight guide structure and 4040 Y axis profiles highly boost the etching accuracy and also handling strength, getting rid of Z axis wobble concerns that a lot of various other desktop CNC machines have. - : The Upgraded Genmitsu Rotary Roller requires no assembly, and you can conveniently adjust the roller distance without devices called for. - : High Quality Machined Rollers make the brand-new rotating more consistent with better inscription accuracy as well as fewer missed out on motor steps. The polyurethane finish of the rollers offer an improved grip as well as get rid of slipping of the item you are engraving. - : 5mm - 160mm; Length: 10mm-- 195mm. Flexible Roller Distance: 19mm - 76mm (16 various distances, each one 9.5 mm additionally than the last). Read the full article

0 notes

Text

Factory Direct Sales Customized Car Pedal

Product Name:Die-casting moulds and parts

Material:Stainless Steel , Brass , Copper , Aluminum alloy .

Technics:High-speed CNC, EDM, wire cutting, closing device, drilling, engraving machine and mold department.

Application:Auto parts series, fishing gear series, electric chain saw series, water pump die casting series, electric and pneumatic series, etc.

Size:Customize by Ningheng

Certification:ISO9001 ,TS16949

Brand:Ningheng

0 notes

Text

Create amazing copper products with Copper CNC cutting

Copper CNC cutting is a process where a computer-controlled machine is used to cut or engrave copper. Copper CNC cutting can be done for various purposes, including creating electrical components, decorative objects, or even sculptures. If you need & you want an instant solution, then here is it!

0 notes

Text

3015 Pipe and Sheet Laser Cutting Machine 2000w 3000w 4000w

Pipe and Sheet Laser Cutting Machine

A 3015 Pipe and Sheet Laser Cutting Machine is a type of laser cutter designed to cut both flat sheets and pipes or tubes. the size of the working area, with 3000mm x 1500mm being a common size for the cutting bed.The 3015 pipe and sheet laser cutting machine is equipped with a specialized rotary device that allows for the cutting of both flat sheets and cylindrical pipes or tubes. This versatility makes it suitable for a wide range of applications in industries such as metal fabrication, automotive, aerospace, and more.

The machine can efficiently cut flat sheets of various materials, including metals like steel, stainless steel, aluminum, and non-metals like acrylic, wood, and plastics. It provides precise and clean cuts, allowing for complex shapes and intricate designs to be achieved.

These machines often come with advanced software programs that allow for easy importation and manipulation of design files. The software can optimize cutting paths, reduce material waste, and increase efficiency. Additionally, some machines can be integrated into automated production lines for enhanced productivity.Laser cutting machines offer exceptional precision and accuracy, resulting in clean and smooth cuts without the need for additional finishing processes. This level of precision ensures tight tolerances and enables the production of high-quality parts and components.

Laser cutting machines can perform both cutting and engraving operations. Cutting involves the laser beam melting, burning, or vaporizing the material along a predefined path to create a clean, precise cut. Engraving, on the other hand, involves etching or marking the material’s surface with the laser beam to create text, logos, or intricate designs.Laser cutting is a non-contact process, which minimizes material waste compared to traditional cutting methods. The precision of laser cutting allows for tight nesting of parts, maximizing material usage and reducing costs.

The 3015 pipe and sheet laser cutting machine operates at high speeds, allowing for efficient production and quick turnaround times. It can handle complex cutting patterns and contours, optimizing productivity for both sheet and pipe cutting operations.

What Is a Laser Cutting Machine ?

The fiber laser cutting machine for sale, also known as the metal laser cutting machine or metal laser cutter, is the laser machine adopting fiber laser source to cut steel, carbon steel, stainless steel, copper, brass, aluminum, iron, galvanized steel, titanium and various alloys. It has wide applications in metal part, equipment, ship, and automotive manufacturing, advertising signs, sheet metal structure, kitchenware, metal furniture, custom metal fabrication, and other fields.

The fiber laser cutter, based on functions, falls into the laser cutting machine for metal sheet, fiber laser tube cutting machine, and sheet and tube laser cutting machine. Each model of the fiber laser machine has multiple specifications and configurations.

Based on the fiber laser power, we provide 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W fiber laser cutting machine and other high power laser cutting machines to realize your metal cutting designs, ideas, and plans.

In addition, there are multiple worktable sizes available for the laser sheet cutting machine. For example, 1530 fiber laser cutting machine, 1540 laser sheet cutting machine, 2040 CNC fiber laser cutter, 1560 sheet metal laser cutter, 2040 fiber laser cutting machine , 2060 fiber laser cutter, etc. Feel free to contact us if you want to know more about the fiber laser cutting system or the laser cutting service.

Advantages of CNC fiber laser cutter?

1. Good beam quality. The waveguide structure of the fiber laser determines that it is easy to obtain a single transverse mode output. Besides, it is unlikely to be affected by external factors, which can achieve high brightness laser output.

2. High efficiency. The overall electro-optical efficiency of commercial fiber lasers is as high as 25%, which is conducive to cost reduction, energy-saving, and environmental protection.

3. Good heat dissipation. The CNC fiber laser uses thin rare earth element doped fibers as the gain medium, which has a very large surface area to volume ratio. This is conducive to heat dissipation. The water-cooling method for high-power fiber laser can avoid the loss of quality and efficiency caused by the heat effect.

4. Compact structure and high reliability. Since the fiber laser uses fine and flexible fiber as the gain medium, it helps to compress the size and save cost.

5. Maintenance free. There is no optical lens in the resonant cavity of the CNC fiber laser. So it has the advantages of adjustment-free, maintenance-free, and high stability, which is incomparable to traditional lasers.

Application of the fiber laser cutting machine

Fiber laser cutting machines can cut many kinds of metal plates and tubes. It is mainly suitable for cutting stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, aluminized zinc plate, pickled plate, copper, silver, gold, and other metal plates and tubes.

The fiber laser cutting machine has wide application fields. For example, thin metal sheet processing, advertising signs, electric cabinets, mechanical parts, kitchenware, automobile, equipment, crafts, arts, electronic boards, medical equipment, instruments, tools, etc.

Why choose the fiber laser cutting machine?

High cutting accuracy.The positioning accuracy of the metal laser cutter reaches 0.03 mm, and the repeated positioning accuracy reaches 0.02 mm.

Narrow slit. The width of the slit is generally 0.10-0.20 mm.

Smooth cutting surface. There is no burr on the cutting surface, and the roughness of the cut surface is generally controlled within Ra6.5.

Fast cutting speed. The cutting speed of a fiber laser cutter can reach 60m/min. And the maximum running speed of a fiber laser metal sheet cutting machine can reach 140m/min.

Good cutting quality: Adopting non-contact cutting, there is basically no thermal deformation and damage of the workpiece. Besides, the cutting surface generally requires no further processing.

Flexible operation. The fiber laser cutting machine has good flexibility to cut any patterns. It can also cut various regular and irregular-shaped tubes and steel bars.

Long service life. A top-rated fiber laser has high photoelectric conversion rate and stable performance. The service life of the major parts of a fiber laser cutting machine could reach 100,000 hours.

Less maintenance. The laser of laser metal cutters for sale is transmitted by optical fibers instead of optical lenses. So there is no need to adjust the optical path and replace lenses frequently, which reduces many maintenance costs.

Strong adaptability. The laser cutting machine for metal sheet is capable of handling any harsh working environment. It also has strong adaptability to dust, vibration, impact, humidity, and temperature.

0 notes

Text

Maximizing Your Workshop’s Potential with CNC Plasma and Router Tables

In the world of fabrication and manufacturing, precision and efficiency are essential. Two of the most powerful tools available to achieve these goals are the CNC Plasma Table and the CNC Router Table. These machines can significantly enhance your workshop's capabilities, allowing for more intricate designs, faster production times, and improved overall quality. In this blog, we'll explore the benefits and applications of CNC Plasma Tables and CNC Router Tables, and how they can elevate your projects.

Understanding CNC Plasma Tables

A CNC Plasma Table uses a plasma torch to cut through electrically conductive materials like steel, aluminum, brass, and copper. The CNC technology allows for precise control over the cutting process, ensuring accuracy and consistency.

Advantages of CNC Plasma Tables:

Precision Cutting: CNC Plasma Tables offer high precision and can produce intricate designs with ease.

Speed: These tables cut faster than traditional methods, increasing your production efficiency.

Versatility: Capable of cutting a wide range of metals, making them ideal for various industries including automotive, construction, and metal fabrication.

Applications of CNC Plasma Tables:

Custom Metal Fabrication: Create custom parts and components with complex shapes and designs.

Sign Making: Produce detailed and durable metal signs.

Artistic Projects: Craft metal art pieces with precision and creativity.

Exploring CNC Router Tables

CNC Router Tables are designed to cut, carve, and engrave a variety of materials, including wood, plastic, and soft metals. Like the CNC Plasma Table, the CNC Router Table uses computer controls to achieve high precision and intricate designs.

Advantages of CNC Router Tables:

Versatility: CNC Router Tables can work with a wide range of materials, making them suitable for many different types of projects.

Detail and Precision: Capable of creating highly detailed and intricate designs.

Automation: The automated nature of these machines reduces manual labor and increases consistency.

Applications of CNC Router Tables:

Woodworking: Create detailed carvings, furniture parts, and decorative elements.

Prototyping: Produce accurate prototypes for design validation and testing.

Signage: Craft detailed wooden or plastic signs for businesses and events.

Choosing the Right CNC Table for Your Workshop

Deciding between a CNC Plasma Table and a CNC Router Table depends on the materials you work with and the nature of your projects. If you primarily work with metals and need to produce intricate designs quickly, a CNC Plasma Table is an excellent choice. On the other hand, if your projects involve a variety of materials, including wood and plastic, and require detailed carving and engraving, a CNC Router Table would be more suitable.

Conclusion

Investing in a CNC Plasma Table or a CNC Router Table can transform your workshop, providing you with the tools needed to take on more complex and varied projects. These machines offer precision, efficiency, and versatility, making them invaluable assets in modern fabrication and manufacturing. By understanding their unique advantages and applications, you can choose the right CNC table to meet your specific needs and elevate the quality and scope of your work. Whether you’re cutting metal or carving wood, these powerful tools will help you achieve your goals with greater ease and accuracy.

#plasma table#stvcnc#cnc router table#cnc plasma cutters#cnc plasma tables#router table#cnc plasma table kit#stv#cnc plasma table

0 notes

Note

Heey, sorry if you already got this question a bunch of times, but which machine would you recommend for people who want to learn metal engraving?

Hey, no worries at all. So, it's a common misconception that hand engraving is done with a rotory machine, like a dremel to take away part of the metal kinda like how a cnc milling machine would.

I use things called gravers (also sometimes called scourpers). They look kinda like wood chisels but real small, and come in a variety of shapes.

When starting I'd recommend googleing a local jewellers suppliers and getting yourself a No. 2 flat graver in steel (youll occasionally see it marked as HSS which stands for High Speed Steel) and a wooden handle like the pictures below.

The steel graver bit should cost somewhere between $6-15 and the handle should be somewhere between $3-6. Just need one of each starting off.

DO NOT CHEAP OUT ON THE STEEL BIT OF THE GRAVER!!!

I've seen the cheap ones shatter. And when they do you'll seriously injure your hands. DO. NOT. CHEAP. OUT. ON. THE. STEEL.

You'll also potentially need a hand vice or at least some way to hold what you're working on. A very basic hand engraving vice looks like this:

They run anywhere from $25-35.

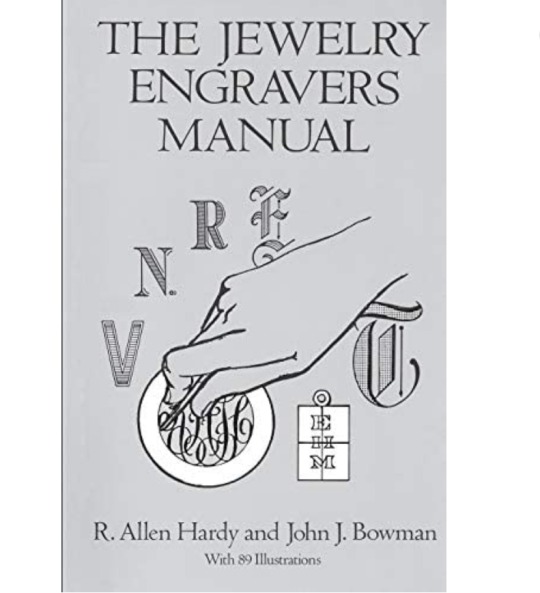

And grab a copy of this book:

It's from way back in the day so it's out of copyright. Don't pay for it, just get a pdf copy. The writing is kinda old fashioned and hard to follow but the information is still as relevant today as it was back then. Again, great book, don't pay for it. The person who wrote it and their kids are dead and only amazon or whatever will get the money.

With those you can get started. The information you need is in the book. You don't need the fancy ball vice like in the book and you don't need to bend the graver like it says in the book, just put the steel lengthwise in a vice with maybe an inch sticking out, and use a hammer to drive the wooden handle on to it by hitting the wood. Don't leave it sticking miles out cuz it could shatter when you hit the wooden bit with the hammer.

Start with copper or silver, other metals are too hard or expensive. Silver is nicer than copper.

MOST IMPORTANTLY YOU DON'T NEED TO BUY ANYTHING 'GRS' BRANDED.

They sell pneumatically assisted gravers, they're good but astonishingly expensive and the price doesn't match the quality. (if you ever do go work up to pneumatically assisted gravers you should go with Steve Lindsay stuff).

I use pneumatic assisted gravers so I don't destroy my elbow and shoulder by engraving all day, I've tried both GRS and Lindsay gravers and the Lindsay stuff is far better, both are about the same expense. At the professional level your equipment can be up in the $5-15k range cuz you're using microscopes, special vices/work holding, gravers made of special metals etc. However you can get started for about $40

136 notes

·

View notes