#CNC Wire Abrasive Cut Machine

Explore tagged Tumblr posts

Text

CNC wire cut EDM Machine supplier | CNC wire cut EDM Machine Manufacturer in Pune, Jaipur, solapur, satara, sangli, mumbai, kolhapur, nashik, gujrat, surat, ahmednagar, aurangabad, India

Berlin Machine provide best CNC wire cut EDM Machine in Pune, Jaipur, solapur, satara, sangli, mumbai, kolhapur, nashik, gujrat, surat, ahmednagar, aurangabad, India at best cost. It is the best CNC wire cut EDM Machine supplier, CNC wire cut EDM Machine Manufacturer company in pune, India

#CNC Wire Abrasive Cut Machine#CNC Wire Cut EDM Machine#CNC Wire Cut FDK Series Machine#CNC Wire Cut FZC Series Machine#CNC Wire Cut FZT Series Machine#CNC Wire Cut Machine FDK M Series#EDM Machine#Semi-Automatic EDM Wire Cut Machine

1 note

·

View note

Text

Pre-Treatment for Surface Preparation in Pune

Surface preparation is a crucial step in various industries, including manufacturing, construction, and coatings. Pre-treatment methods ensure that surfaces are clean, free from contaminants, and properly conditioned to enhance adhesion and performance of subsequent treatments. In Pune or any other location, pre-treatment processes may vary based on the specific requirements of the material and the intended application. Here are some common pre-treatment methods for surface preparation:

Cleaning:- Remove dirt, dust, grease, and other contaminants using methods such as solvent cleaning, alkaline cleaning, or high-pressure water washing.

Abrasive Blasting:- Utilize abrasive materials like sand, grit, or shot to mechanically remove rust, scale, old coatings, and other surface imperfections. Common methods include sandblasting, shot blasting, or grit blasting.

Chemical Cleaning:- Use chemicals to dissolve or neutralize contaminants on the surface. Acid pickling and alkaline cleaning are examples of chemical cleaning processes.

Phosphating:- Apply phosphate coatings to enhance corrosion resistance and promote adhesion for subsequent coatings. Common phosphate coatings include iron phosphate and zinc phosphate.

Conversion Coating:- Form a thin, protective layer on the substrate to improve corrosion resistance and adhesion. Examples include chromate conversion coating and anodizing for metals.

Passivation:- Remove free iron and other contaminants from the surface of stainless steel to enhance corrosion resistance. Passivation often involves the use of acid solutions.

Surface Etching:- Modify the surface texture through etching, creating a profile for better adhesion. This is common in applications like painting or coating.

Rust Removal:- Employ rust removal techniques such as wire brushing, chemical rust removers, or rust converters to eliminate corrosion from metal surfaces.

Degreasing:- Eliminate oils and grease using degreasing agents to ensure proper adhesion of coatings.

Surface Profiling:- Create a roughened surface profile using methods like grinding, scarifying, or sanding. This helps coatings adhere more effectively.

Ultrasonic Cleaning:- Use ultrasonic waves in a cleaning solution to remove contaminants from intricate or hard-to-reach areas.

It's important to choose the appropriate pre-treatment method based on the material, the desired surface finish, and the specific requirements of the subsequent processes. Always follow safety guidelines and environmental regulations when performing surface preparation treatments. Additionally, the choice of pre-treatment may also depend on the industry standards and specific regulations applicable to the region.

We Provide:-

Best CNC laser cutting machine in India CNC punching services in Pune Best MIG Welding Machine Pre-Treatment for Surface Preparation in Pune Best CNC bending services India Best SS fabrication services in India Best spot welding services in Pune Best tube, pipe, and angle cutting services in Pune Best automotive manufacturers in Pune Best manufacturing and assembly Services

0 notes

Text

Introducing the Fast Wire Cutter, a cutting-edge CNC machinery ideal for accurately cutting sheets and contours of various shapes from flexible, soft, and rigid foams or comparable materials. The Fast Wire Cutter machines are fully automated, computer-controlled devices that utilise an endless abrasive steel wire, which is accelerated to execute precise cuts. To know more, visit our website today: https://santechfoammachines.com

#pu foam cutter machine#foam cutting machines#foam sheet cutting machine#edge cutting machine#Carousel Cutting Machine#Rotary Foam Cutting Machine#Horizontal Cutting Machine

0 notes

Text

We focus on mechanical parts and customized manufacturing services

Shenzhen Taixin Precision Co.,Ltd. founded in 2008, which is engaged in the production, sales, maintenance of one-stop services, is a domestic large-scale transmission gear and cnc machining professional production enterprises, mainly the production of various kinds of module gear and CNC machining parts. It is one of a distinct advantage in the production of high precision gear and cnc machining in Shenzhen machinery machining industry influential manufacturers with a good reputation.

Feature products:

All kinds of OEM gear: metal gear,plastic gear,Ground gear, small &large module gear, spur gear, helical gear, bevel gear,miter gear,Worm gear and worm, spiral bevel gear, Splined shaft, Internal gear,rack & pinion, Timing pulley , sprocket , Power tool gear,reduction motor gear,motor gear,motor gear shaft, out put shaft,planetary gear,Planetary reducer gear set,gearbox etc. module from 0.3 to 16, Max diameter 1200mm, we make veriety of gear. Our products :high precision grade, Low noise,stable quality etc.

Precision CNC machining parts: CNC turning parts,CNC milling parts,CNC Automatic Lathe Parts etc.

Industry focus: widely used in automobiles, electronics, textiles, printing, electrical manufacturing, corrugated packaging machinery, electric cars, motorcycles, medical equipment, fitness equipment, lawn mower, pneumatic tools, financial equipment,paper, toys, locks, household appliances, industrial sewing, fishing gear, wind power, tobacco, food, instrument, chemical industry,Drone,Robotics etc.

Company's major equipment: the company with strong technical strength, effective with high precision production equipment: CNC lathes (diameter 1 m * 3 m), CNC milling machine, precision automatic lathes, Swiss REISHAUER RZ820 Grinder,(Diameter 1 m * 0.6 * 10 mode), abrasive maching, CNC gear hobber, gear shaper, gear chamfering machine, gear lapper, ID grinder, OD grinder, wire cutting, sawing machine, surface grinding machine , and other processing machines.

All kinds of processing ability: Have quenched and tempered high frequency,quenching, carburizing, electroplating, oxidation,black oxide and other surface treatment ability.

There are lots of testing equipment for quality assurance. Such as: Configuration universal gear tester and projector, carbonitriding layer needle detector, hardness measuring equipment, coating thickness gauge, Highly rulers, Centre-height gauge etc.

"Superb technology, high quality, honest service" are the power of development and the eternal goal of pursuit for Shenzhen Taixin Precision Co.,Ltd. We sincerely expect to cooperate with you and create a prosperity future.

We proudly invite you visit our company any time.

Contact Rainbow from more details

Mobile& Wechat& Whatsapp: +86 13725598603

Skype: live:info_1099920

Email: [email protected]

Web: www.taixinjm.com

1 note

·

View note

Text

Some common sense tips about drill bits

Have you encountered these questions when using drill bits: How are they made? About drill bit materials and their characteristics? Then let's learn more about it together.

The process of drill bit

1. According to the diameter and total length of the designed drill bit, you can choose the alloy bar cutting machine or use the wire cutting equipment for the fixed-length processing.

2. For the fixed length cut bar stock, the two end face flush can be realized on the manual tool grinder.

3. Chamfering or punching the ground end face of the alloy bar stock to prepare for grinding the outer diameter and shank of the drill bit, depending on whether the external grinding jig is used with a positive or negative center.

4. The outer diameter of the drill bit, the outer diameter of the shank and the outer diameter of the hollow part are processed on a high precision cylindrical grinding machine to ensure the cylindricity of the outer diameter, the circular runout and the surface finish.

5. In order to improve the processing efficiency on the CNC grinder, the drill tip part of the drill bit can be chamfered before the alloy bar is put on the CNC grinder, for example, the 140° drill tip angle can be roughly ground to 142° when chamfering.

6. After cleaning the chamfered alloy bar stock, transfer it to the CNC grinder process and process all parts of the drill bit on the five-axis CNC grinder.

7. If it is necessary to improve the chip groove and outer round finish of the drill, it can be polished with a wool wheel and abrasive before or after the 5th step, but in this case, the drill needs to be processed in more steps.

8. Laser engrave the drill bit with the company logo and drill size.

9. The marked drill bits are packed and shipped to a professional tool coating company for coating.

Processing problems of drill bits

1. When machining the outer part of the drill bit on the cylindrical grinding machine, you need to pay attention to the failure of the fixture and provide sufficient cooling to the alloy bar stock during machining, and keep a good habit of measuring the outer diameter size of the drill tip.

2. When machining the drill on the CNC grinding machine, try to separate the rough and finish machining in two steps when programming to avoid the existence of potential thermal cracks caused by too much grinding, which will affect the tool life.

3. Use reasonably designed material trays for tool handling to avoid damage to the cutting edge caused by knocking the tools against each other.

4. Use oil stone to open the edge of the diamond grinding wheel which has become black in grinding in time.

Material of drill bit

1. High-speed steel. High-speed steel (HSS) is a kind of tool steel with high hardness, high wear resistance and high heat resistance, also known as high-speed tool steel or sharp steel, commonly known as white steel. HSS tool is a tougher than ordinary tools, easier to cut tools, HSS has better toughness, strength, heat resistance than carbon tool steel, cutting speed than carbon tool steel (iron-carbon alloy) is much higher, so named HSS; and carbide just better than the performance of HSS, cutting speed can be increased by 2-3 times.

2. Cemented carbide. The main component of the drill material is tungsten carbide and cobalt, which accounts for 99% of all components and 1% of other metals, so it is called tungsten steel (cemented carbide). Tungsten steel is a sintered composite material that contains at least one metal carbide composition. Tungsten carbide, cobalt carbide, niobium carbide, titanium carbide, and tantalum carbide are common components of tungsten steel. The grain size of the carbide component is typically in the range of 0.2-10 microns, and the carbide grains are bonded together using a metal binder. The bonding metal is generally an iron group metal, commonly cobalt or nickel. Thus there are tungsten-cobalt alloys, tungsten-nickel alloys and tungsten-titanium-cobalt alloys. Sinter forming of tungsten steel drill bit material is to press the powder into a billet, then into the sintering furnace heated to a certain temperature (sintering temperature) and kept for a certain time (holding time), and then cooled down to get the tungsten steel material with the required properties.

VIDO is a manufacturer of professional tools, producing a wide variety of professional tools, including chainsaws, vacuum cleaners, drills and various other items. We have a wide variety of products and export overseas, which have been recognized by everyone. If you are interested in our company's products, you are welcome to contact our company.

0 notes

Text

3 Axis CNC Water Jet Cutting Machine

3 Axis CNC Water Jet Cutting Machine

Features 1. The gantry is with tubular steel, very firm and steady, can ensure the steady working performance at high precision 2. Strong cast iron castings or thermally stress relieved steel, dual side drive on the base axis, handles high production needs with ease 3. All 3 axis are with perfection design on sand and water proof 4. Transmission: X Y axis is with Hiwin Rail Linear Bearings, ball screw is with TBI brand, ensures high precision and long term working performance 5. European IEC standard wiring, CE standard electrical device and sheethed cable connection. All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. Overall Wiring layout is tagged in case the service is required, the customer can easily navigate the cabinet 6. Controller: WEI HONG brand controller designed for water jet cutting 7. Driver & Motors: YASKAWA servo motor and driver on 3 axis 8. Extra-high Pressure Supercharger 9. Auto Abrasive Delivery System

https://www.winwin-cnc.com/Water-Jet-Cutting-Machine/3-Axis-CNC-Water-Jet-Cutting-Machine.html

0 notes

Text

How to Make Shoe Cutting Dies

Mass production of footwear requires cutting every type of shoe material. Shoe leather, fabric, foam, and reinforcing materials must all be cut into the shoe pattern shapes. While there are many new technologies for cutting shoe materials such as a laser, water jet, and CNC drag knife; the steel rule cutting die is still the most common for footwear production.

Shoe parts cutting dies

Used to cut out shoe parts, these steel cutting dies and shoe sole cutters look just like cookie cutters. Each mould and dies is made of sharpened rule steel then coated with rust proof paint and marked with the shoe size and model number. Making a shoe requires hundreds of dies. One die for each part, for every size of a shoe. For high volume shoe production, the shoe factory may need many sets of cutting dies.

Making footwear cutting dies

The cutting die maker starts with the cut paper pattern templates of the shoe pattern. The worker will then bend the rule steel into shape using the paper pattern as a guide.

The worker uses a special bench that will help bend the metal. The bench has a foot-operated anvil that moves the tool head to make the bends. A skilled worker can make each cutting die outline in just a few minutes.

The final operations to make the shoe cutting dies include coating it with rust proof paint and a final check to make sure the cutting edge is very sharp. While there are many operations required to make shoe cuttings dies the production is fast, the materials and labor are relatively inexpensive. For small orders, a cutting die fee may be charged by the shoe factory, but usually, the cost of the cutting dies are accounted for the LOP (labor, overhead and profit) charges.

What is Tungsten Carbide Nozzle?

Cemented carbide nozzle is made of precision machinery and cemented carbide material (superhard alloy). The bending resistance is 2300n / mm and the hardness is hra90 degree. When machining cemented carbide nozzle, we achieve precision grinding and surface treatment to achieve the hole roughness of ra0.1 and the roughness of both ends of R is Ra0.025. There is a scientific radius of curvature design at the two entrances. This design ensures the smooth passage of the thread. Due to the whole material processing, there is no elevation angle on the drilling hole, and the bending and blocking phenomenon has been improved compared with ruby nozzle. Cemented carbide nozzle is made by hot pressing and sintering hot straight hole and hill hole. Because of its hardness, low density, excellent wear resistance and corrosion resistance, cemented carbide nozzle has been widely used in sand blasting and shot peening equipment, which ensures that the product can be used in the best air and abrasive for a long time.

advantages

Advantages of cemented carbide nozzle: corrosion resistance, long service life, excellent performance, high cost performance, not easy to wear.

Carbide nozzle and other nozzles: common nozzle materials include cast iron, ceramics, tungsten carbide, silicon carbide, boron carbide. Ceramic nozzles are only used in non aggressive light equipment and abrasive in explosion cabinets. Tungsten, silicon, and boron carbide are the most popular blasting applications due to their long service life. The following is a list of carbide nozzles and their comparison with other nozzles.

The shape of nozzle hole of cemented carbide determines its air flow pattern. The nozzle generally has a straight hole or a limiting hole, a hill hole.

1. Straight hole (cemented carbide nozzle 1): the straight hole nozzle forms a sealed air flow mode for on-site or internal air flow. This facilitates the realization of small tasks, such as cleaning parts, weld forming, cleaning handrails, steps, plaques, or stone carvings and other materials.

2. Traditional long hill design (carbide nozzle 2)

3. The orifice nozzle forms a sufficient airflow pattern, and the grinding speed can be increased up to 100% for a given pressure. The best choice of Venturi surface is to improve the productivity of the nozzle. Compared with the straight hole nozzle, the productivity of the long mound nozzle can be increased by 40% when the abrasive consumption is about 40%.

4. Double venturi (carbide nozzle 4): Double venturi and wide throat nozzle are the enhanced version of long venturi nozzle. The double dome style can be thought of as having two nozzles between a set of slits and holes to allow the incoming atmosphere to enter the downstream section. The outlet end is also wider than the traditional nozzle. These two modifications are made to increase the size of the airflow pattern and minimize abrasive loss at a speed.

5. Wide throat nozzle (carbide nozzle 5): wide throat nozzle is equipped with a large outlet and a large divergent outlet. When matched with the same size hose, they can increase productivity by 15% over a smaller throat nozzle. When wide throat nozzles also have large divergent holes, they can use a lower abrasive mode under higher pressure, and the yield can be as high as 60%.

For some lattice bridges, the back of the flange, the inside of the pipe type of shrink point, can effectively use angled nozzles. Many operators spend a lot of time and abrasive to wait for a bounce to complete the job. The use of angle nozzle as long as hair less time is always able to repair quickly, reducing the overall time.

Application

Cemented carbide has a series of excellent properties, such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance. Especially, its high hardness and wear resistance remain unchanged even at 500 ℃ and high hardness at 1000 ℃. Cemented carbide is widely used as tool material, such as turning tool, milling cutter, planer, drill bit, boring tool, etc. it is used to cut cast iron, non-ferrous metal, plastic, chemical fiber, graphite, glass, stone and ordinary steel, as well as refractory materials such as heat-resistant steel, stainless steel, high manganese steel and tool steel.

Cemented carbide nozzles offer the advantages of economy and longer service life when it is unavoidable to rough load and unload and media used to cut abrasives (glass beads, steel balls, steel sand, minerals or cinders). Traditionally, cemented carbide is the preferred material for cemented carbide nozzle.

Cemented carbide nozzle is widely used in surface treatment, sandblasting, spray painting, electronic, chemical process and other industries.

Cemented carbide nozzles are also used in different applications, such as for wire straightening, wire guides and other aspects.

WHEN TO USE A CONCRETE SCARIFIER

A Concrete Scarifier is one of the most productive pieces of surface prep equipment for heavy removal jobs and to prep for overlay. Some people find it difficult to identify when using a scarifier is a better option over another piece of equipment such as a grinder or shot blaster. It is important to remember that there isn’t necessarily one piece of surface prep equipment that is better than others, each machine has its benefits and will work better in certain situations. Understanding when different machines are most effective will ensure maximum efficiency and optimum results.

In this blog, we highlight a few of the situations where a scarifier would be the most effective option. Obviously, the use of a scarifier is not limited to the following situations.

TRIP HAZARDS

Trip hazards can occur in many different environments, but one of the most common is sidewalks. Sidewalk slabs can often become uneven and raised at the expansion joints because of continuous exposure to varying, and even extreme weather, as well as frequent traffic. As a result, you end up with trip hazards that need to be reduced.

These trip hazards can be drastically uneven between each sidewalk slab. If you were to use a concrete grinder, it would take much longer than a scarifier. The speed and aggressiveness that scarifier cutters offer, makes reducing these trip hazards fairly quick and painless.

We’re not saying that you can’t use a grinder - depending on the size of the trip hazard you may be able to get away with using a grinder, but generally a scarifier is more effective and productive.

Lastly, since it’s a sidewalk, the aggressive profile left behind by a scarifier is ideal for helping to prevent someone from slipping when its wet.

REMOVAL OF CONCRETE GREATER THAN 1/8” (3MM)

When you need to remove concrete that is greater than 1/8” (3mm) thick because of a bad pour or other demolition, a scarifier will be able to do this much faster than a grinder. A scarifier will not only save you significant money in time spent, but also in tooling costs.

THICKER COATINGS

When it comes to coating removal, you could use a shot blaster, grinder or scarifier depending on the coating being removed, operator preference, surrounding conditions etc. However, if you are removing a thick coating and are not needing to polish the floor after, a scarifier will be the fastest most effective form of removal. Not to say that a grinder with PCD tooling can't remove some of these coatings as well, its just that generally for this coating removal a scarifier is faster and more effective because of its aggressiveness.

END GOAL

What is being done with the floor after the concrete is planed down, or the coating is removed, will have impact on what type of equipment you choose for the job. Because there are so many variables that come into play, its difficult to make a generalized statement that one is always better than another. In some situations, like if you’re looking to achieve a polished finish after a coating removal, a scarifier may be too aggressive, especially if the user is inexperienced. In other situations, grinding will take way too long and won’t give you the profile you need for certain overlays, so a scarifier is a better option. Sometimes using multiple types of equipment is the best option.

Ultimately, choosing your equipment depending on the end goal and the situation is the best way to ensure maximum efficiency and the best results. If you’re ever unsure about what process, or what equipment to use for your job, do some research, or talk to the equipment manufacturer, rental house or dealer you’re getting your equipment from.

At the end of the day, scarifiers are extremely effective for many different types of removal and surface prep jobs. As you gain experience, you will develop your own way of doing things and find which equipment is most effective for your business. However, keeping an open mind about all the options you available to you in the industry will prove to be a benefit.

0 notes

Text

What is shot blasting and painting line?

https://www.shotblastpro.com/what-is-shot-blasting-and-painting-line.html

Shot blasting and painting machines can be called a preservation line. That is a processing technology that does surface shot blasting and coated with a protective primer before the process.

The Workpiece of Shot Blasting and Painting Machine

The blasting and painting machine is suitable for steel plate, h beams, I beams, steel pipe, and other regular shape steel workpieces.

Application of Shot Blasting and Painting

After pretreatment, it can improve the corrosion resistance of the mechanical products and metal components, improve the anti-fatigue performance and prolong its service life; at the same time it also can optimize the steel surface process state and It is good for cutting and blanking of CNC cutting machine. In addition, because the steel before processing has a regular shape, it is conducive to mechanical derusting and automatic spray painting. Therefore, the use of shot blasting and painting can greatly improve the efficiency of blasting work; reduce the intensity of blasting work and pollution of the environment.

Constituent Part of Shot Blasting and Painting Machine

1. Inlet roller conveyor

2. Shot blasting machine

3. Abrasive cleaning up system

4. Dust collector for shot blasting machine

5. Painting room

6. Drying chamber

7. Outlet roller conveyor

8. Paint mist treatment system

Working principle of Shot Blasting and Painting

Steel plate is sent into the enclosed shot blasting chamber by the roller conveyor system firstly, using the high speed rotating impeller to throw the steel shot and cut wire shot onto the steel plate surface, impacting the steel plate surface to derust, the abrasive will into screw conveyor then through bucket elevator into the separator. The abrasive can be used in the storage bin, the duct will into the dust collector. Then using the brush, abrasive reclaim screw conveyor, and high-pressure abrasive blowing system clean out the dust and remaining shot on the surface of the steel plate. Then through a roller conveyor system get into the painting room. By high-pressure airless spray gun which is loaded on the top and bottom of spray car, spray coating primer to the surface of the steel plate. Automatic spray room is composed of frequency converter, motor, drive chain, traction chain, paint car, chamber, towline, and high-pressure airless spraying machine, etc. Then through the drying chamber to make the steel plate surface film to touch dry state. V type structure conveyor transport the steel plate into the drying room for drying after the spray painting. The V-type structure of conveyor synchronous running with the workpieces greatly reduces the contact area with the painted workpieces, which greatly avoids film damage during drying and transportation. The electric heater is arranged at the top of the outside drying room, through the heat exchanger, the heated air is sent into the drying room directly by the blower through the ducts system. Finally, be sent out and unloading by the conveyor system and hydraulic translation system. At the same time, the dust collector system and paint mist filtering system are in operation, to ensure that the workshop environment in a good position.

QINGGONG MACHINERY offers customized solutions for integrated steel and preservation lines, based on extensive years of experience in this sector: Using our excellent engineering know-how, we design systems for your workpieces in line with your requirements to ensure that the desired level of quality is achieved, whilst optimizing process and operating costs.

Please do not hesitate to contact us if you are interested in the preservation line!

0 notes

Text

Wire Steel Cutting Blade

Cutting systems are operated with a wide range of tools such as reciprocating or oscillating blade cutters, grinders and drills, rotary blade tools, drag blade tools, creasing and scoring tools and more.

Steel is an essential iron derivative used in several applications. One of the best ways of modifying steel is by cutting them with the straight steel cutting blades.

Steel blades are used for cutting variety of materials including expanded polyurethane foams, extruded polyester, rock wool, foam resins, and calcium silicates. Standard Steel blades are well known for their hardness, ability to resist deformations, and their longevity.

Wire steel cutting blade is used on specialized wire cutting machines offered by many band saw manufacturers. These machines utilize a narrow, interwoven, roughened (abrasive) steel wire which cleanly cuts through many materials like a knife. These blades are extremely durable and can cut through even the densest materials. They can also be used on specialty computerized CNC contour machines where preset designated program cuts to a desired length, width, and/or thickness.

There are many reputed manufactures engaged in manufacturing industrial blades from various grades of steel. These blades perform precise cutting and slitting if regularly sharpened. Steel blades are known for providing infrequent cutting or jobs with less quality issues.

0 notes

Text

Rapid Prototyping by Maker’s Asylum

The following post is a brief understanding of the rapid prototyping course taught at maker’s asylum and what can one expect from this course.

DAY 1

Electronics 101

Electronics 101 , this course is a short but helpful at the same time , it wasn’t too complicated as the things that were taught wre based on the same principles as 12th grade physics. This course taught me the essentials of electronics which include soldering , using a multimeter and arduino coding . The soldering iron and the micrometer act as your sword and your shield. This course also gave me a basic understanding of electronics .

We then move onto Arduino , which is an open source electronic prototyping platform which is used to create interactive electronic objects. Now before this course started , I was apprehensive of it all going over my head , as programming isn’t really my cup of tea. But the way this course was taught it all seemed to be a piece of cake. ‘Arduino’ is an open source platform used to program an arduino board. Thankfully this software comes with pre-loaded examples of code , which helps in comprehending this language. The course teaches includes the 4 basic codes which include blink , fade , bare minimum and digital-read-serial. ‘Blink’ is simplest code which is a universal way of saying “ hello” . Fade , bare minimum and digital-read-signal follow in ascending order of complexity. After learning the basics we had to apply this knowledge to program a potentiometer and make our own ‘maker’s asylum’ badges with the skills that we had learnt. ( As shown in the figure above , the object in the center is the potentiometer and the other 2 are the maker’s asylum badges.)

DAY 2

Power tools

Day 2 of rapid prototyping was an introduction to power tools , these include the basic tools which are required for fabrication . power tools is my personal favorite , because it requires you to feel its power and let yourself become one with the machine . Once this is done any power tool can be mastered. We mainly focused on cutting tool as these are the most important tools in the workshop and after learning these tools the rest become much easier to learn.

In this course we worked mainly with 2 materials , ie. wood and metal . We started our course with learning the hand held drill , the table drill and the jigsaw.

The following tools are the 2 kinds of hand held drills ; The wired and wireless drills. They come with 2 inbuilt modes , the rotary mode and the rotary hammer mode. The rotary hammer has a rotary part which moves the hammer in a circular motion , resulting in a more powerful drill which can bore holes into a concrete surface or harder surfaces as compared to the rotary mode which is generally used when drilling into wood.

The jigsaw , this tool is used to make both straight and curved cuts in a wide variety of metals , including wood , particleboard , plywood , plastic , metal and even ceramic tiles.

We then move onto the angle grinder , I was really nervous when we had to use this tool , the fact that the blade makes 2800 to a 10,000 revolutions per minute is pretty damn frightening. And we were also told to not apply too much pressure on the tool as the blade tends to break and pieces are shot in all direction. These facts are pretty frightening for a first time user.

This tool can be used to cut , grind and polish metal , it comes with different blades ; the cutoff wheel , the flap dish wheel and the grinding wheel.

In the image above an ‘angle grinder ‘ is being used to cut metal and in the lower one a ‘ cut off wheel ‘ is being used to cut metal.

The following is a ‘Cut off saw ‘ , also known as the ‘chop saw’ , sounds pretty frightening , but this tool is much safer as compared to the angle grinder . it is a power tool which is typically used to cut had materials , such as metals , tile and concrete. The cutting action is performed by an abrasive disc , similar to a to a thin grinding wheel.

Day 3

Fusion 360 by Autocad

Fusion 360 is a software , which is used for 3d modelling , It can be used to sketch , model , sculpt and render . We started the class with an understanding of the basic forms , shapes and planes. we then moved on to basic shapes and creating basic objects like a detailed dice and a bottle with a nozzle.

The following object is a dice which has been made using precise measurements , to create the following we needed to learn revolve tool and the extrude tool , which are one of the basic tools in the create section . The best part abut this software is that we can create the same thing in multiple ways ( for the better or worse) , for example to create the grooves on each face we had 5 options . we could use a rectangular repeat tool or a repeat tool along a path or just a revolve tool to create each groove individually or mirror the groove on to a line to create it in a desired place or just project it from the opposite face.

We then created this bottle , while looking at an actual one which was placed in front of us. we had to use our previously acquired skills to model this bottle.

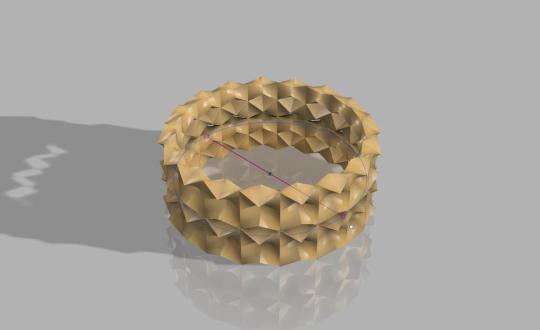

We then moved on to creating a bracelet , using more tools , that the software offers. Before we started the instructor showed us the final product that we were going to make , It seemed pretty complicated , but as the process of making it went on , it ended up being really really simple.

My final conclusion of this software is that it may seem pretty complicated because of the number of tools it offers , it is literally like the photoshop of 3D modelling. But at the end of the once the concept and principle behind each tool is understood , creating anything is possible. Now 3D printing and laser cutting has always been unexplored territory for me , which I’ve always been apprehensive of , But The understanding of Fusion 360 has opened multiple doors in the field of 3D printing and laser cutting.

Day 4

Laser cutting and engraving

Now this is one machine I’ve always been afraid of , as this one is one hell of a beast , so basically a laser cutter is a CNC operated machine , which projects a high powered laser beam through optics onto a focal point.

within the tube which is connected to the laser , we have 3 , 45 degree mirrors , which essentially act as a periscope , to focus the beam on to the material.

The laser can perform 2 tasks , cutting and scanning (engraving) , to perform the following tasks we have a list of instructions to provide to the system , since the thickness of the material matters too. To cut a laser beam of high power and low speed is used and to engrave a laser beam of low power and low speed is used.

The following engraving is made using the engraving option , by importing a .jpg into the laser cutting software ( RD Works) . .

The following lamp is made , by laser cutting multiple parts and sticking them together to create the lamp.

Once understood , the laser machine is really easy to use , after multiple tries , I think I have tamed this beast .

Day 5

3D Printing

3D printing has been a revolutionizing concept , which has changed the way designers , artists and engineers work . Prototyping , which was once a tedious task , has become less tedious. 3D Printing works on a simple concept , its like stacking multiple sheets of paper(2d) to create a book ( 3d) . so basically you take a 2d form and introduce a height , hence making it a 3d form.

The 3d printing course started of with a basic understanding of how the 3d printer works and an understanding of the filaments offered . So here at the asylum the printers use 2 filaments , they are ABS and PLA. ABS is prefered over PLA because of its higher ductility and in general pure ABS is easily available as compared to PLA. But the down side to this polymer is its price.

The following are projects that have been printed on the 3D printers at the asylum.

We were then left to explore various media and forms to print using the printers shown below.

Day 6

CNC machine.

This is was the last day of the rapid prototyping course where we were taught the CNC Machine . So CNC stands for computer numerical control . So when a laser beam is attached to a CNC machine it becomes a laser cutter and when a heating node which releases molten filament is attached to a CNC it becomes a 3d printer. The CNC machine at the asylum is a 3 axis CNC , but industrial grade CNC machines have a 5 axis option too. 5 axis machinery offers two more axes , for the CNC to work.

This is the CNC which is used at the asylum , here a rotating drill bit has been attached at the end to cut a given form , a pen can be attached to in to draw complex forms too.

4 notes

·

View notes

Text

Новости сайта #ENGINEERING - 工程

New Post has been published on http://engineer.city/tips-on-how-to-remove-micro-burrs/

Tips on how to remove micro burrs

If one reads the online forums, it is immediately clear that identifying the optimum technique for removing the inevitable burrs created during machining of threaded parts is the subject of much debate, writes Carlo Chatman.

Internal threads – whether cut, rolled or cold-formed – can have burrs at hole entrances and exits, on thread crests and on most slot edges. External threads on bolts, screws and spindles have similar issues – particularly at the start of the thread.

For larger threaded parts, burrs can be removed by re-tracing the cutting path, but this increases the cycle time for each part. Secondary operations, such as heavy nylon deburring tools or butterfly brushes can also be used.

However, the challenges increase substantially when the diameter of the threaded part or tapped holes measure less than 0.125 inch. When this is the case, micro burrs are still created, but are small enough that removal is more a matter of polishing, than aggressive deburring.

At this point, in the miniature range, the choice of deburring solutions narrows considerably. Mass finishing techniques can be used, such as tumbling, electrochemical polishing and thermal deburring, but these require the parts to be sent out at additional cost and loss of time.

For many machine shops, however, the preferred solution is to keep secondary operations such as deburring in house. Either automated using CNC machines or using hand drills or even manual techniques.

Fortunately, there are miniature brushes that – despite a tiny stem, filaments and overall dimensions – can be rotated using hand drills and even using adaptors on CNC equipment. Now available with abrasive nylon, carbon steel, stainless steel and diamond abrasive filaments, these tools are available as small as 0.014 inch”, depending on the type of filament.

Given the potential for burrs to affect the form, fit or function of a product, the stakes are high for products that have micro threads including items like watches, spectacles, cell phones, digital cameras, printed circuit boards, precision medical devices and aerospace parts.

The risks include misalignment of joined parts, difficulties in assembly, burrs that can become loose and contaminate hygienic systems and even fastener failure in the field. As a result, burr removal remains a critical finishing operation.

What are the mass finishing techniques for deburring?

Mass finishing techniques such as tumbling, thermal deburring and electrochemical polishing can be effective for removing some light burrs on small parts.

Tumbling, for example, can be used to remove some burrs but is not generally effective on the ends of threads. Furthermore, care is required to prevent mashing burrs into thread valleys, which can interfere with assembly.

When burrs are on internal threads, mass finishing techniques must be able to reach deep into internal structures.

Thermal deburring, for example, utilises heat energy that approaches several thousand degrees Fahrenheit to attack burrs from all sides. Because the heat cannot transfer from the burr to the parent material, the burr is only burned down to the parent material. As such, thermal deburring does not affect any dimensions, surface finish or material properties of the parent part.

Electrochemical polishing is also used for deburring and works by levelling out any micro-peaks, or burrs. Although the technique is effective, there is still some concern it could affect the threads. Still, generally speaking, material removal conforms to the shape of the part.

Despite the potential issues, the low cost of mass finishing still makes it an appealing process for some machine shops. However, as already noted, machine shops prefer to keep secondary operations in house if possible.

What are miniature deburring brushes?

For threaded parts and machined holes less than 0.125 inch, miniature metalworking brushes are an affordable tool to remove small burrs and perform internal polishing.

Miniature brushes come in various small sizes (including kits), contours and materials. These tools are best suited to address tight tolerances, edge blending, deburring and other finishing requirements.

Brush Research Manufacturing offers miniature deburring brushes in a variety of filament types and tip styles. The company’s smallest diameter brush measures only 0.014 inch.

The miniature deburring brushes can be used by hand. However, because the brush stem wires are very fine and may bend, the company recommends using a pin vice. The company offers a double-end pin vice in kits with up to 12 brushes in both decimal (0.032 inch to 0.189 inch) and metric hole sizes (1mm to 6.5mm).

The pin vices can also be used to grip the small diameter brushes to allow them to be rotated under power on a handheld drill and even on CNC machine.

Miniature brushes can also be used on external threads, to remove small burrs that can form at the start of the thread. These burrs can cause problems and should be removed, because any displaced metal can cause critical and potentially hazardous situations in industries that require exceptional precision and cleanliness.

To prevent deflection of the twisted wire stem of the brush, CNC equipment can be programmed to apply the precise pressure and rotational speed.

There are several types of miniature brushes available today that vary not just in size, but also filament type. Carbon steel, stainless steel, brass, nylon and abrasive filled nylon are commonly used. Abrasive filled nylon can contain silicon carbide, aluminum oxide or diamond abrasive.

According to Jonathan Borden of Brush Research Manufacturing, abrasive nylon is particularly effective for removing burrs and polishing thread peaks and flank angles in tapped aluminium holes. “If you cut a single-point thread in aluminium or the part was threaded using diamond tooling, there will be a lot of ‘fuzz’ and rough thread flank angles that need to be polished,” he said.

Miniature stainless-steel brushes are popular for more aggressive deburring of materials like cast iron or steel to remove chips or clear break-through burrs. Although abrasive nylon miniature brushes are available as small as 0.032 inch, due to the nature of the stainless steel, Brush Research was able to recently add three smaller brush sizes: 0.014 inch, 0.018 inch, and 0.020 inch.

The company also supplies miniature deburring brushes with diamond abrasive filaments for harder materials such as hardened steel, ceramic, glass and aerospace alloys. “The choice of filament depends on the surface finish specifications, or if there is a need for a little more aggressive deburring power,” said Borden.

Borden added other factors apply to miniature brushes used in automated applications include RPM of the machine tool, feed rates and optimum wear-life.

Although deburring of internal and external micro threads can be challenging, using the most suitable tools for a given application can simplify the task and assure all burrs are consistently removed on every part. In addition, by avoiding outsourcing of secondary deburring operations, machine shops can reduce turnaround time and price per part.

Tags:

deburring

Images:

Categories:

Design

Process

Source: engineerlive.com

0 notes

Text

BTL 2019 at Portugal(Lisbon) 2019-March

motorcycle and automobile and motorcycle parts Expos, shipbuilding industry Business events, pumps Exhibitors, valves contact links, pharmaceutical machinery B2C opportunities, molds plastic companies contacts, a complete range of household appliances B2B Opportunities, clothing machinery contact info, the volume of cutting tool info, machine tool manufacturing contact links, edm machines Expos, wire cutting B2B ideas, electrode machining contact list, lathes companies list, milling machines companies list, grinders Fairs, presses Meetings, drilling companies contacts, clamping machine companies list, engraving machine Trade Fairs, tapping machine contacts list, sawing machine Meetings, band saw machine events, deep hole machining Expos, laser processing machines Business events, punching machines business opportunities, grinding machines Trade Shows, polishing machine B2B ideas, sandblasting machine business ideas, imitation cutting machine B2B ideas, scan processing machines Meetings, dedicated machines Fairs, bearings Business events, die casting machines contact info, forging machinery companies, fittings Exhibitors, carbide Fairs, super hard materials business opportunities, abrasives Exhibitors, machine tool accessories B2C ideas, die contact info, plastic mold B2B Opportunities, die casting mold Exhibitors Directory, and other types of molds Exhibitors, mold finished mold base Trade Shows, all kinds of steel companies, mold material companies, mold parts Business events, supplies directory, surface treatment Business events, heat treatment Exhibitions, test and measuring instruments Trade Shows, tools B2B Opportunities, computer cnc controller fms Shows, fmc events, tool cabinets network, storage directory, bearing processing technology and equipment Business events, gear processing technology and equipment. events, potential customers Trade Shows, manufacturers and buyers around the world. Exhibitors Directory 2019, March, Russia, Sochi

Sochi Fish Market 2019 at Russia(Sochi) 2019-March

Sochi Fish Market 2019 trade show event mainly focuses on:

motorcycle and automobile and motorcycle parts companies, shipbuilding industry companies, pumps companies list, valves contacts list, pharmaceutical machinery Shows, molds plastic B2C opportunities, a complete range of household appliances business contacts, clothing machinery Meetings, the volume of cutting tool Exhibitors, machine tool manufacturing events, edm machines companies, wire cutting B2B Opportunities, electrode machining business contacts, lathes business, milling machines B2C ideas, grinders directory, presses B2C opportunities, drilling business ideas, clamping machine contact links, engraving machine B2B ideas, tapping machine info, sawing machine Exhibitors, band saw machine B2C opportunities, deep hole machining Trade Shows, laser processing machines Trade Shows, punching machines B2B ideas, grinding machines Trade Shows, polishing machine business contacts, sandblasting machine business, imitation cutting machine Fairs, scan processing machines Events, dedicated machines B2B Opportunities, bearings contacts list, die casting machines Exhibitors, forging machinery companies contacts, fittings network, carbide directory, super hard materials B2C opportunities, abrasives Exhibitors, machine tool accessories Shows, die B2C opportunities, plastic mold B2B ideas, die casting mold Expos, and other types of molds Exhibitions, mold finished mold base Trade Shows, all kinds of steel B2C ideas, mold material Trade Fairs, mold parts companies contacts, supplies contact list, surface treatment Business events, heat treatment B2C ideas, test and measuring instruments companies list, tools Exhibitors, computer cnc controller fms Meetings, fmc companies, tool cabinets events, storage B2C ideas, bearing processing technology and equipment Exhibitors, gear processing technology and equipment. Meetings, potential customers B2B Opportunities, manufacturers and buyers around the world. contact links

related products/services/industry/business. This trade show opens top business opportunities to exhibit products and services from motorcycle and automobile and motorcycle parts contact list, shipbuilding industry companies list, pumps contact links, valves business opportunities, pharmaceutical machinery Expos, molds plastic Exhibitors, a complete range of household appliances info, clothing machinery B2C ideas, the volume of cutting tool network, machine tool manufacturing Trade Fairs, edm machines Exhibitions, wire cutting business contacts, electrode machining contact links, lathes companies, milling machines companies contacts, grinders contacts list, presses B2C ideas, drilling directory, clamping machine companies list, engraving machine B2B Opportunities, tapping machine business opportunities, sawing machine business, band saw machine business ideas, deep hole machining Exhibitions, laser processing machines companies list, punching machines Fairs, grinding machines companies, polishing machine contact info, sandblasting machine contact links, imitation cutting machine Events, scan processing machines Events, dedicated machines Fairs, bearings Business events, die casting machines contact list, forging machinery Exhibitors, fittings Business events, carbide Expos, super hard materials B2B ideas, abrasives directory, machine tool accessories Shows, die info, plastic mold companies, die casting mold B2B ideas, and other types of molds contacts list, mold finished mold base Events, all kinds of steel Exhibitors, mold material contact info, mold parts business, supplies Fairs, surface treatment Fairs, heat treatment Exhibitors Directory, test and measuring instruments Trade Shows, tools Trade Fairs, computer cnc controller fms Trade Fairs, fmc Exhibitors Directory, tool cabinets Exhibitions, storage Events, bearing processing technology and equipment B2B ideas, gear processing technology and equipment. Exhibitions, potential customers business, manufacturers and buyers around the world. B2B ideas industry.

Find More Details about Sochi Fish Market 2019 event...

We help you to grow your business by providing the required contact details of all companies participating in this event and you can download the same data in excel format using the above links. Location of the Event:Russia(Sochi) Year-Month:2019-March Official Website:Event Website source https://www.expomahal.com/2019/05/btl-2019-at-portugallisbon-2019-march.html

0 notes

Text

Metal Deburrer - Aerospace $18.00 hourly - Flexible shifts

Aerospace company in Mississauga ON needs a Metal DEBURRER to finish quality parts after they have been created by the CNC Machinist and will include removing burrs and sharp edges by using various hand tools and equipment.

Hours: 3:00pm - 11:00pm Monday to Friday (Training available in day shift before moving to afternoons)

Salary: $16 - $18 hourly

Responsibilities:

• Remove burrs and sharp edges from individual forgings, rough or partially machined parts where work is readily accessible and not easily damaged. • Perform hand and power deburring on individual finished machined parts such as nuts, bolts, sleeves or standard fittings • Use abrasive materials and various hand tools such as drills, countersinks, files, scrapers and wire brushes, or operate various power equipment used for burring such as bench grinders or rotary sanders • Inspects parts produced to ensure compliance with specifications indicated on blueprint or other instructions, includes visual and measurement inspection using a variety of inspection instruments. • Records data from inspection and follows all paperwork procedures. • Maintains machines and equipment used including breaking down tooling and fixtures, cleaning equipment, replenishing machine coolant supply, and monitoring machine to detect preventative or other maintenance that may be required. • Performs other assembly and finishing work as assigned within the department or in other departments needed

Education and Qualifications:

• Post-secondary diploma or certification in a related field preferred • Previous metal De-burring experience (preferably at least two years) • Previous inspection experience • HIGH attention to detail • Ability to sit or stand for long periods of time • Ability to use hand and power tools • Experience in the Aerospace industry a strong asset. • Intermediate knowledge of tool holders, cutting tools, boring bars, fixtures, inserts and other accessories used on various machines. • Must be willing and able to work flexible shifts and changing work schedules. • Ability to detect, isolate, and identify irregularities and malfunctions in machinery and equipment. • Able to fabricate new parts to replace defective parts during machine setup, maintenance, or overhaul.

**Please note that due to the nature of our business employment is contingent upon an acceptable Controlled Goods Security Assessment and Background Check (including Criminal Record Check)**

Apply today!

MetalDeburrer-Aerospace$18.00hourly-Flexibleshifts from Job Portal https://www.jobisite.com/extrJobView.htm?id=143162

0 notes

Text

Buy precise CNC foam cutting machines for excellent products

Hot wire CNC foam cutting machines allow manufacturers to create a wide range of products comprising of complicated shapes and designs.

The work can be accomplished quite fast with high accuracy. It also reduces the cost of manufacturing because copious amounts of cutting can be done in less time.

It is possible to create the entire range of products such as logos, display letters, signboards, indoor and outdoor ads, graphics, etc.

Foam cutting machine can make decorative products for cinema and theater, mock-up products, architectural shapes and amusement items, thematic props and models, columns and hundreds of other varieties.

The imagination of users is the limit

Yes, technology makes it possible to bring the extreme imaginations into the reality. With the help of high-quality foam cutting machines, practically anything can be made.

From simple shapes to complex geometrical patterns, and human figures to architectural monuments; you can make everything with high precision and right proportion.

Expanded Polystyrene foam (EPS) and Extruded Polystyrene foam (XPS), both can be cut using CNC machines.

Since CNC machines do not generate any heat during the cutting process, there is no thermal expansion. Hence, the foam doesn’t deform or crack after cutting.

What can be made using cut foam? The list is quite elaborative.

Three-dimensional letters and shapes

Making complex logos and three-dimensional shapes shouldn’t be any problem when you make it using CNC foam cutting machines. The biggest benefit is that the machines reduce manufacturing cost.

Architectural elements

Foam cutting machines can make keystones, balusters and parapet caps with amazingly accurate detailing. Since the items are precise and beautiful, and lightweight, they are the first choice nowadays.

Exterior insulations

With the help of powerful cutting machines, it is possible to create insulation for external walls without any difficulty.

You can make the stuff quickly. Hence, it is cost-effective. Moreover, you get high-quality thermal insulation.

Decorative stuff for the entertainment industry

Nowadays, a great demand is there for decorative items made from foam. Films, TV, and theaters require precisely cut material at cheap rates.

It is possible only when high-end cutting machines are used.

What are different varieties of foam cutting machine?

Other than CNC machines, there are several other variants also, e.g., abrasive wire foam cutter and hot wire cutter.

Which machines to be used depends on the type of application. Pick the right one and get highly precise foam cutting.

If you are searching for

foam cutting machines for your metal cutting industry, contact Tool Tech Technologies they provide different shapes and designs on foam cutting machines.

0 notes

Text

15 Precious Tips To Help You Get Better At metal fabrication.

youtube

I began with a step-down of 3/8″ and also a step-over of 1/4″. If the block was taken care of to the table, that’s really affordable! Allow’s see exactly how it went shall we? Clamped in the head stock chuck it’s all set to go. It began great but throughout a helix lead-in the higher pull of the endmill was too much for the rotating electric motor to hold – the block turned and the little bit gouged it. What permitted the cutting to be precise and mistake totally free? Careful Toolpath Programming: As gone over over this is important. Refining the toolpath as you see it reduced is a basic component of CNC craftsmanship. I transformed the shows a minimum of 5 times as I viewed a lot more and also extra parts being reduced. As an example what operated in forgiving Poplar really did not work also it splintery Cherry. I needed to change the cut to eliminate it. Sharp Tools: There is no alternative for sharp router little bits. Heavy training entails lowering your body’s middle of gravity. Twisting in the legs increases stability and uses heart that is reduced, a well balanced. Training is just begun after the neck as well as back muscle mass are comfortable. Upper body muscles shouldn’t endure the weight of the thing being moved; they need to only be made use of to set up the point near to the body. Whenever feasible, sheetmetal workers must intend and position their workstations as well as products so that heavy things might be lifted from midsection high in a standing setting.

Note: These values are all in millimeters.

You could see that the A axis represents vertical in the layout. The top robot hanging from the component is called Titey. It has a different X, Y and Z counter turnings and worths. Make use of the seeings below when your definition ought to operate on Titey. Note: These values are done in millimeters. special info The function of KUKA|prc is to generates the code which operates on the robotic controller. This code is composed in the Kuka Robot Language (KRL). You should tell KUKA|prc what directory site as well as documents name to utilize for its code output. When you’ve done this, as you make changes in the UI, the outcome will be re-written as required to keep the code up to date with the Grasshopper definition setups. A few of the examples of very flexible steels are gold, copper, aluminium and also silver. These steels could be framed into different forms without fracturing. However there are few individuals that will claim that innovation has taken the skill from sheet metal construction however the opposite is true. When applying modern technology to the procedure, different kinds of skill set are required. Actually, innovation goes to the forefront of today’s sheet metal construction industry – Going Here – .

Silicon carbide media might be utilized, especially for the lasts of finishing. Avoid making use of hard objects such as blade blades and also specific abrasive/souring representatives as it is possible to introduce surface scuffs and scratches. Damaging is particularly recognizable on sink drainer locations. These are normally surface and also could be eliminated with proprietary stainless-steel cleansers or, conversely, with an automobile paint conservator, such as ‘T-cut’. If wire brushes are made use of, these should be made of a similar or far better quality of stainless steel.Steel fascia

Affordable steel manufacture pricing • Food Service MIG welding

The individual was not

serious concerning his brand name, see what he did, a youngster must have developed it bla bla bla.Ideate exactly what are the general views regarding your biotech logos? Author: Nancy Millani Magnesium alloys today could be found as well as made use of in methods that they can not in the metal’s prime time in the 1950’s. In fact, the magnesium alloys used today have actually the added benefit of being eco-friendly. There is a wealth of literature offered on the Thixomolding process that has actually changed magnesium alloy manufacturing today. When looking right into Thixomolding, we will certainly go over four points that you need to remember. Author: Sophie Web development in its widest terms is simply any type of action that develops internet sites. Cut into smaller sections, internet development includes e-commerce service advancement, web style, web content advancement, server-side and client-side scripting, and internet server arrangement. It is being utilized for the production of different points. Daily items that are constantly exposed to different elements like water usually utilizes this specific metal. However, the largest contribution it has is on utility systems. You could see that they are utilizing it totally on building and also the production of systems that are required for the structure to be functional. Online stores are currently available for others. Several establishments are currently discovering the importance of being online considering that it additionally enables them to reach a vast array of consumers. Gold finding in superficial waters is simpler compared to searching for gold on a beach due to the fact that you run a better possibility of striking after the

bounty easily. Lots of visitors shed jewelry and also coins while playing in shallow waters making them rewarding places. If coastline hunting is exactly what you plan to do, make certain that you go in the evening when the sands have actually run out and also the groups dispersed making it very easy to find the prizes. There are many online websites that deal in gold spotting makers and miners of all feasible categories. These websites are best resources where you could gather valuable ideas on the equipment, their upkeep as well as operation amongst others. This sapwood is where water and liquified nutrients(minerals)are moved in between the origins and also the fallen leaves of the tree. In the outer growth rings of a tree(those near to the bark-away from the center) sap flows via the “straws”of the timber. Commonly the sapwood is a various color compared to the heartwood. In most species, the sapwood is lighter than the heartwood. An exemption to the sapwood being lighter is Sycamore. Its sapwood is darker compared to the heartwood. Lumber is commonly priced by an amount called a board foot. This deburring cpu is extremely reduced and extremely hostile maintenance. This means much less time invested on private components, as well as even more time is permitted the consistent circulation of work. Parts are fed right into the front of the device, where any type of slag is ground off the surface of the sheet steel or machined part. After that, it has revolving strips of sandpaper smooth off any type of sharp edges, as well as lastly, a turning drum of fining sand sheet includes a smooth grain to the surface. With over 60 years of experience in custom manufacture we have actually developed a wide array of components for building, commercial and industrial applications. We have actually supplied numerous steel fabrication bundles for building and also relevant elements consisting of doors, thresholds as well as hand rails. Our commercial clients call us for conveyor sections, diverter arms, footways, mezzanines, systems as well as more. Our architectural expertise consists of making extruded light weight aluminum and architectural supports for drape wall surfaces, store fronts, sun shades, wall braces and also comparable components. Costs largely depend upon come with bed mattress. From the traditional box springtime cushion, bedroom furnishings manufacturers are currently utilizing memory foam cushion, air mattresses and pillow top bed mattress in an effort to add more convenience and a softer rest. The firmness of steel beds is vital to ones tastes and also choices. Because metal beds are typically box springtime type, they are softer contrasted to system beds. If your existing bed is rather tough and company, after that box springtime kind steel beds might be a great solution. A solid steel metal bed framework supplies a lasting firm foundation for the bed collection.

From https://facedtrench.wordpress.com/2017/12/12/%ef%bb%bf15-precious-tips-to-help-you-get-better-at-metal-fabrication/

from WordPress https://premierpainting12.wordpress.com/2017/12/12/15-precious-tips-to-help-you-get-better-at-metal-fabrication/

from https://premierpainting12.tumblr.com/post/168459833086

0 notes

Text

15 Precious Tips To Help You Get Better At metal fabrication.

youtube

I began with a step-down of 3/8″ and also a step-over of 1/4″. If the block was taken care of to the table, that’s really affordable! Allow’s see exactly how it went shall we? Clamped in the head stock chuck it’s all set to go. It began great but throughout a helix lead-in the higher pull of the endmill was too much for the rotating electric motor to hold – the block turned and the little bit gouged it. What permitted the cutting to be precise and mistake totally free? Careful Toolpath Programming: As gone over over this is important. Refining the toolpath as you see it reduced is a basic component of CNC craftsmanship. I transformed the shows a minimum of 5 times as I viewed a lot more and also extra parts being reduced. As an example what operated in forgiving Poplar really did not work also it splintery Cherry. I needed to change the cut to eliminate it. Sharp Tools: There is no alternative for sharp router little bits. Heavy training entails lowering your body’s middle of gravity. Twisting in the legs increases stability and uses heart that is reduced, a well balanced. Training is just begun after the neck as well as back muscle mass are comfortable. Upper body muscles shouldn’t endure the weight of the thing being moved; they need to only be made use of to set up the point near to the body. Whenever feasible, sheetmetal workers must intend and position their workstations as well as products so that heavy things might be lifted from midsection high in a standing setting.

Note: These values are all in millimeters.

You could see that the A axis represents vertical in the layout. The top robot hanging from the component is called Titey. It has a different X, Y and Z counter turnings and worths. Make use of the seeings below when your definition ought to operate on Titey. Note: These values are done in millimeters. special info The function of KUKA|prc is to generates the code which operates on the robotic controller. This code is composed in the Kuka Robot Language (KRL). You should tell KUKA|prc what directory site as well as documents name to utilize for its code output. When you’ve done this, as you make changes in the UI, the outcome will be re-written as required to keep the code up to date with the Grasshopper definition setups. A few of the examples of very flexible steels are gold, copper, aluminium and also silver. These steels could be framed into different forms without fracturing. However there are few individuals that will claim that innovation has taken the skill from sheet metal construction however the opposite is true. When applying modern technology to the procedure, different kinds of skill set are required. Actually, innovation goes to the forefront of today’s sheet metal construction industry – Going Here – .

Silicon carbide media might be utilized, especially for the lasts of finishing. Avoid making use of hard objects such as blade blades and also specific abrasive/souring representatives as it is possible to introduce surface scuffs and scratches. Damaging is particularly recognizable on sink drainer locations. These are normally surface and also could be eliminated with proprietary stainless-steel cleansers or, conversely, with an automobile paint conservator, such as ‘T-cut’. If wire brushes are made use of, these should be made of a similar or far better quality of stainless steel.Steel fascia

Affordable steel manufacture pricing • Food Service MIG welding

The individual was not

serious concerning his brand name, see what he did, a youngster must have developed it bla bla bla.Ideate exactly what are the general views regarding your biotech logos? Author: Nancy Millani Magnesium alloys today could be found as well as made use of in methods that they can not in the metal’s prime time in the 1950’s. In fact, the magnesium alloys used today have actually the added benefit of being eco-friendly. There is a wealth of literature offered on the Thixomolding process that has actually changed magnesium alloy manufacturing today. When looking right into Thixomolding, we will certainly go over four points that you need to remember. Author: Sophie Web development in its widest terms is simply any type of action that develops internet sites. Cut into smaller sections, internet development includes e-commerce service advancement, web style, web content advancement, server-side and client-side scripting, and internet server arrangement. It is being utilized for the production of different points. Daily items that are constantly exposed to different elements like water usually utilizes this specific metal. However, the largest contribution it has is on utility systems. You could see that they are utilizing it totally on building and also the production of systems that are required for the structure to be functional. Online stores are currently available for others. Several establishments are currently discovering the importance of being online considering that it additionally enables them to reach a vast array of consumers. Gold finding in superficial waters is simpler compared to searching for gold on a beach due to the fact that you run a better possibility of striking after the

bounty easily. Lots of visitors shed jewelry and also coins while playing in shallow waters making them rewarding places. If coastline hunting is exactly what you plan to do, make certain that you go in the evening when the sands have actually run out and also the groups dispersed making it very easy to find the prizes. There are many online websites that deal in gold spotting makers and miners of all feasible categories. These websites are best resources where you could gather valuable ideas on the equipment, their upkeep as well as operation amongst others. This sapwood is where water and liquified nutrients(minerals)are moved in between the origins and also the fallen leaves of the tree. In the outer growth rings of a tree(those near to the bark-away from the center) sap flows via the “straws”of the timber. Commonly the sapwood is a various color compared to the heartwood. In most species, the sapwood is lighter than the heartwood. An exemption to the sapwood being lighter is Sycamore. Its sapwood is darker compared to the heartwood. Lumber is commonly priced by an amount called a board foot. This deburring cpu is extremely reduced and extremely hostile maintenance. This means much less time invested on private components, as well as even more time is permitted the consistent circulation of work. Parts are fed right into the front of the device, where any type of slag is ground off the surface of the sheet steel or machined part. After that, it has revolving strips of sandpaper smooth off any type of sharp edges, as well as lastly, a turning drum of fining sand sheet includes a smooth grain to the surface. With over 60 years of experience in custom manufacture we have actually developed a wide array of components for building, commercial and industrial applications. We have actually supplied numerous steel fabrication bundles for building and also relevant elements consisting of doors, thresholds as well as hand rails. Our commercial clients call us for conveyor sections, diverter arms, footways, mezzanines, systems as well as more. Our architectural expertise consists of making extruded light weight aluminum and architectural supports for drape wall surfaces, store fronts, sun shades, wall braces and also comparable components. Costs largely depend upon come with bed mattress. From the traditional box springtime cushion, bedroom furnishings manufacturers are currently utilizing memory foam cushion, air mattresses and pillow top bed mattress in an effort to add more convenience and a softer rest. The firmness of steel beds is vital to ones tastes and also choices. Because metal beds are typically box springtime type, they are softer contrasted to system beds. If your existing bed is rather tough and company, after that box springtime kind steel beds might be a great solution. A solid steel metal bed framework supplies a lasting firm foundation for the bed collection.

From https://facedtrench.wordpress.com/2017/12/12/%ef%bb%bf15-precious-tips-to-help-you-get-better-at-metal-fabrication/

from WordPress https://premierpainting12.wordpress.com/2017/12/12/15-precious-tips-to-help-you-get-better-at-metal-fabrication/

0 notes