#Boiler Repairs Doncaster

Explore tagged Tumblr posts

Text

a thought occurred to me (that i shall now tell to you, my friend Callisto, who i am currently writing to in my discord DMs) If Henry's a 4-6-0, i think it makes a lot more thermodynamic sense than if he's a 4-6-2.

imagine if you wanted to make a more powerful Atlantic. (without sacrificing speed) ultimately you're going to need either more cylinders, or larger cylinders or both. but more tractive effort means less factor of adhesion. no use getting more tractive effort if you're slipping. So you add the extra drive wheel in place of the trailing wheel. this design now has three, larger cylinders. More tractive effort, and a relatively similar footprint. You will need a conjugated valve gear or at the very least three sets of walschearts valve gears, rather than internal stephenson valve gear. But the frames and boiler can be nearly unmodified. unfortunately after some analysis you, Sir Nigel Gresley, realize it's never going to work. There's just not enough fire grate area and you use steam faster than you can build it. You're going to need to start from scratch with a new boiler. That second plan is the first version of the A0 prototype, Gordon, which as we know is thought to have been refined into more or less mechanically identical to the production A1 class. but the first plans, discarded, were built as Henry. Henry should have same tractive effort and top speed, or nearly so, as Gordon, but without the boiler volume or fire grate area to match.

in theory running him as if he had indeed been an Atlantic--just as fast but with a shorter, lighter train--should have worked. But that's when we get into the other mechanical issues that resulted from being a… "bastard." I wouldn't be surprised if, at least before repairs were undertaken, Henry's boiler had to be de-rated to a lower pressure to avoid leaks (or worse). Lower pressure means not just less power, but less efficiency too. the Ivatt Atlantics and the Gresley A1 Pacifics had similar boiler pressures of 170 and 180 PSI respectively. (the A3s were uprated to 220 PSI; but Gordon probably never was since i believe his post rebuild boiler is his original boiler.)

Cylinders Two, outside (Majority), Four (2 outside + 2 inside) on No. 3292 Compound & 3279

WHAT

a C1 Atlantic was fitted with four cylinders????

No. 292, built at Doncaster in 1904 (but not entering service until 1905), was a four-cylinder compound. The high-pressure cylinders, having a diameter of 13 in (330 mm) and a stroke of 20 in (510 mm), were outside the frames, driving the rear coupled wheels; and the low-pressure cylinders, 16 by 26 in (410 by 660 mm) were inside, driving the front coupled axle. The valves were arranged so that the locomotive could work either as a compound or as a four-cylinder simple. The boiler pressure was 200 lbf/in2 (1,400 kPa), but whilst the boiler was under repair, the locomotive used a 175 lbf/in2 (1,210 kPa) boiler from 1910 to 1912. This locomotive was withdrawn in 1927 and scrapped in 1928.[9]

No. 1300, another four-cylinder compound, was an experimental locomotive which differed greatly from all of the others. It was built by Vulcan Foundry in 1905, largely to their own design although to Ivatt's specifications. The boiler had a narrow firebox, a diameter of 5 ft 3 in (1.60 m) and a pressure of 200 lbf/in2 (1,400 kPa). As with No. 292, the high-pressure cylinders were outside, driving the rear coupled wheels, whilst the low-pressure cylinders were inside, driving the front coupled axle; but their dimensions were 14 by 26 in (360 by 660 mm) and 23 by 26 in (580 by 660 mm) respectively. The engine worked as a two-cylinder simple on starting, changing over to compound expansion automatically. A superheater was fitted in 1914, and the engine was rebuilt as a two-cylinder simple in 1917; the new cylinders were outside, 20 by 26 in (510 by 660 mm) of the type used on class H3, driving the leading coupled wheels. It was withdrawn in 1924.[10] the cylinder diameters varied wildly on the C1s too

a compound loco would have superior efficiency. a simple loco with four cylinders on the other hand would chew through steam twice as fast. idk… idk… a 4-6-0 Henry with an atlantic boiler might not be possible

i mean the whole point of an atlantic is it's a 4-4-0 with a bigger firebox there were small boiler atlantics like this that could accomodate a third driver

but the outline of this engine is definitely more like James than Henry god and like. even this engine, with a much smaller firebox and boiler than the large boiler C1s, still has the same cylinder dimensions as them and only slightly smaller than the pacifics. giving Henry a big wide firebox matches the illustrations, it matches the tvs model, but… it's also explicitly the problem with Henry. so like. it's difficult to really figure out a realistic answer to what's wrong with Henry's design that would be fixed by better coal.

37 notes

·

View notes

Text

Time Doesn't Heal All Wounds Part 1

Narrator: It was a beautiful spring day in England. The Flying Scotsman or Scott as most called him, was up for auction after his previous owner went bankrupt. This is the 3rd time in his preservation that this happened. After securing the necessary funds to make a bid, the National Railway Museum (NRM) had won the right to buy him.

(We cut to the auction).

Auctioneer: Sold to the representatives of the NRM for £2.3 million. As a reminder, they will be getting not only the locomotive, but also his spare boiler, cylinders and a Mark 1 supporting coach.

(The representatives smile as they walked up to Scott).

Andrew: Hello, Flying Scotsman. My name is Andrew J. Scott. I'm the director of the museum, it's an honor to have you with us.

Scott: The pleasure's all mine, sir. I've heard a lot about the museum from my dear cousins. It's been a long time since I've last seen them.

Andrew: Well, I'm sure you would like to see them. But first, we have to see how you run and determine if you're able to pull trains.

Scott: I understand, sir. Will we be able to leave now?

Andrew: Yes, I have a crew ready to get you in full steam. I'll see you in York. Good day, Scotsman.

Scott: Thank you, sir.

(Andrew left as Scott's new crew members arrived).

Gary: Hello, old boy. My name is Gary, I'm your new driver, and this is George, your fireman.

George: Nice to meet you, Scotsman.

Scott: Nice to meet you fellows too. You can just call me Scott.

Gary: Right, well then Scott let's get you in steam. We need to make sure you're able to be displayed for this year's Railfest.

Scott: Ok, Gary.

(The two men climbed into Scott's cab and got him in steam).

Narrator: Once he was in steam, Scott began to leave for York. Then he started to feel awful.

Scott (moaning): Oh, Gary. I'm not feeling very well.

Gary: Hmm, your pressure is dropping. What do you think is happening?

Scott (moaning): I don't know. I don't think I'm going to make it to York. I have to stop.

George: There's a siding just up ahead. We'll stop there, so we can notify the station in Doncaster.

Narrator: They arrived at the siding just in time. Scott had broken down. His boiler tubes were starting to leak.

Gary: My god, I haven't seen anything like this. How are feeling, Scott?

Scott: I don't feel well at all. I feel like something's leaking out. Can you see anything from inside my cab?

George: Sorry old boy, you won't be able to start up again at this rate. Your boiler tubes are starting to leak. We'll have to tow you to York. Just rest for now while we wait for help to arrive.

(Scott nodded as his closed his eyes and eventually fell asleep).

Narrator: While Scott was asleep, he was towed to the repair yards. It was a long journey but they were able to get him to York.

(We cut to the repair yards as Scott wakes up).

Scott: Oh. What happened?

Gary: I'm not quite sure yet. The engineers are still trying to figure it out. We didn't want to put you under until we heard what you had to say. Do you know what else is bothering you?

(Scott thought for a moment).

Scott: I'm not sure. I just feel old and worn out.

Gary: Well, I guess you'll be grateful to have some rest. We'll do the best we can to help.

Scott: I will let the engineers do what they need to do.

(The engineers began to pour the anesthetic).

Scott (feeling drowsy): Thank you, everyone.

Gary: You're welcome old boy. Now you just get some rest.

(Scott closed his eyes and fell asleep).

Narrator: The engineers worked on the Flying Scotsman for weeks. It wasn't until June, that they were able to wake him up.

(Scott begins to open his eyes and sees Gary and George).

Scott (tiredly): Hello.

Gary: Scott, how do you feel?

Scott: Really tired.

George: The engineers kept you asleep for almost a month. You needed your boiler to be completely washed out. There was a lot of boiler sludge that had to be removed. I also heard that a lot of your stay nuts had signs of overheating so those had to be replaced along with the leaky boiler tubes.

(Scott was beginning to doze off).

Gary: I think we just need to let him rest. If his stays had signs of overheating, then he must have been run ragged. He needs as much rest as he can. We still don't even know how he'll run during Railfest.

George: He'll start light duties during charter trains as the Scarborough Spa Express (SSE). Who knows, maybe that was all that was wrong and he'll be running good as new.

(They leave Scott to rest).

Narrator: Throughout the summer of 2004, Scott and his crew spent their time in and out of the works. Originally, 121 tubes were replaced, but then three days after Scott started work as the SSE, he broke down. A crosshead bearing was damaged so that was replaced. Then after five days, he broke down again. Pipework in his oil pump were defective so that had to be repaired. There were also concerns about previous repairs to the crack in his right hand cylinder. It was now September, and Scott had to be taken to the NRM's workshop for more repairs. His cousin Mallard was there.

(Scott and Mallard are both in their human form. While Scott could be described a large, overweight man; Mallard would be described as a man who used to be an NFL QB. No longer star material but still relatively fit. Mallard glares at Scott while he's lying on the couch).

Mallard: You know this is pathetic, right? To think the supposed pride of the LNER has been reduced to a has been engine on their last set of wheels.

Scott: Did you have something to say to me, Mallard? Or did you just come all this way to laugh in my face?

Mallard: I came here to tell that you that you're an embarrassment to the Gresley name. You go flouncing about and cause your owners nothing but financial problems. We all know that your 100 mph record means nothing anymore. There were plenty of other engines that were more useful than you. Quite frankly, I don't understand why you were saved to begin with.

Scott (sadly): I don't know why I was saved either. Not that it matters now. I've been in and out of the works for the past four months. This time, there's so much work to be done, that I don't know when I'll wake up once I'm put under.

Mallard: The NRM should just cut their losses and scrap the whole thing and build a new engine from scratch. They'll lose less money that way.

(Gary and George walk in).

Gary: That's enough, Mallard. If you're not here to be repaired, then leave so you don't get in anyone's way.

Mallard: Well then.

(He leaves as the two men walk up to Scott who tries to curl up on the couch).

George: Don't listen to him, Scott. The NRM would've never bought you if they didn't think you were worth it.

Scott: I know. I just want these repairs done, so I can go back to the engine I once was.

Gary: Don't worry, old boy. We'll do our best to help you.

Scott: What did they say was wrong with me this time?

George: Inner firebox, that cracked cylinder, the air brakes. You know how it is.

(Scott sighs).

Scott: How long will they make me sleep this time, gentlemen?

Gary: I'm not sure, but we'll be here when you wake up.

Scott: And I can't thank you two enough for that.

George: Come on old boy. Let's get you back to your engine. You need to go back under.

Scott: I understand. I'm nothing but thankful for the both of you being here.

Narrator: With the help of George and Gary, Scott makes it back to his engine.

Gary: Steady there. Just dream good dreams and don't let Mallard's words bother you.

Scott: I won't. Thank you. Both of you.

(The engineers walk in and began to pour the anesthetic again).

Scott: I just hope I won't develop a tolerance to this stuff.

(Scott falls asleep after a few minutes).

Tagging: @bluy1206, @werbitssft, @klein-sodor-bahn, and @theyellowroseofsodor.

26 notes

·

View notes

Text

Been on an A1/A3 kick as of late, and 'Grande Parade' has drawn my interest

The original 2744 was built in 1928, entering service in August. She had 9 and a bit years of incident-free service until the Castlecary Rail Disaster, 10th December 1937. Going light on the details of the event for the purposes of this post, but the damage to 2744 was sufficient for Doncaster to just build a whole new engine.

Ouch.

The replacement (scroll to Works Visits or Summary for the mention) fared rather better, lasting through to BR days racking up 25 years and 7 months of service.

See also: The locomotive was recovered and taken to Cowlairs Works where it took some time to restore it to a condition in which it could be towed to Doncaster. The January 1938 Railway Observer reported that work had begun on the erection of a replacement locomotive at Doncaster, although the remains of the original were still at Cowlairs. From an accounting perspective this was a “repair” of the original but in practice it was a completely new locomotive assembled largely from stock components. The locomotive emerged from Doncaster Works on 14th April 1938 carrying a boiler that had last seen use on A3 2544 “Lemberg” whilst the tender had last been attached to A1 2579 “Dick Turpin”. The June 1938 Railway Observer states that new motion, stamped “2744”, had been provided and that the works plate fitted to the replacement locomotive, proclaimed it to be Doncaster 1694 of 1928.

The original locomotive reached Doncaster on 2nd April 1938 where it was dismantled with anything reusable going into the pool of spare parts. The boiler was overhauled and subsequently emerged fitted to A3 2749 “Flamingo” during its next works visit whilst the tender eventually emerged from the works attached to A3 2752 “Spion Kop”. (Also a bit of a scroll there so just copied the relevant bit)

Considering what the RWS interpretation of that would be, cause like. Henry.

I've got my own headcanon for henhouse, but this is rather different as it's literally stated to be a replacement. They started a new one before the original was brought back.

Just kinda wondering there as to whether you could say something of the 1928 engine went across, what with the Works Plates being the same and all, or if the on-paper-repair-but-actually-brand-new thing would put it in the more literal variant of the "Two Henry's" thing.

In the latter case, how would the other A1s & A3s take it? How would the new engine themself handle it?

Discuss

#LNER A1/A3#rws oc: grande parade#LNER 2744 Grande Parade#also just wanna note here her number's the reverse of Scotsman's#just a neat thing i noticed#there's potential for a lot of angst here isn't there#messed around with this post a few times in drafts#so sorry if it doesn't exactly flow#but i found some new info when it was basically a whole other post#kinda like the engine in question heh

5 notes

·

View notes

Text

The Importance of Regular Boiler Servicing in Doncaster: Trust NE Gas Services for Reliable Heating

Regular boiler servicing plays a crucial role in ensuring the efficient and reliable heating of your home in Doncaster. As a homeowner, it is essential to prioritize the maintenance of your boiler to avoid unexpected breakdowns and maximize its lifespan. At NE Gas Services, we understand the significance of regular boiler servicing and the impact it has on your comfort and safety.

Ensuring Optimal Performance: Regular boiler servicing conducted by NE Gas Services ensures that your heating system operates at its optimal performance. Our experienced technicians thoroughly inspect and clean the boiler, identifying any potential issues that could hinder its efficiency. By addressing these issues promptly, we ensure that your boiler functions effectively, providing consistent heat throughout your home.

Enhancing Energy Efficiency: A well-maintained boiler operates with greater energy efficiency, leading to reduced energy consumption and lower utility bills. During our servicing, NE Gas Services checks and adjusts the boiler's settings, ensuring that it operates at its maximum efficiency level. This not only saves you money but also contributes to a greener environment by reducing your carbon footprint.

Extending the Lifespan of Your Boiler: Regular maintenance and servicing by NE Gas Services can significantly extend the lifespan of your boiler. By addressing any minor issues early on, we prevent them from escalating into major problems that could result in costly repairs or even the need for a complete replacement. Our expert technicians are trained to identify and resolve potential issues, keeping your boiler running smoothly for years to come.

Ensuring Safety: Safety is paramount when it comes to boiler operation. Regular servicing helps identify and rectify any safety concerns, such as gas leaks or carbon monoxide emissions. At NE Gas Services, we prioritize your safety and conduct thorough inspections to ensure that your boiler meets all safety standards and regulations. Trust us to keep your home and loved ones protected. Regular boiler servicing is a crucial investment in maintaining the efficiency, longevity, and safety of your heating system. When it comes to reliable heating solutions in Doncaster, trust NE Gas Services to provide top-notch boiler servicing. Contact us today to schedule your boiler servicing and experience the peace of mind that comes with a well-maintained heating system provided by professionals who genuinely care about your comfort and safety.

0 notes

Text

It gets worse! The decision was consciously made to keep the working pressure at 250psi to up the output for the larger bore A3 cylinders. BR used A4 boilers (pressure regulated down by adjusting the safety valves!) during the '50s to replace life expired A3 boilers because they were easier to come by. Doncaster couldn't justify building two different types in postwar austerity years so A3 production ceased.

my foreman did some work on FS' old boiler (which was, I believe, taken by hosking as a spare for bittern) and said what an absolute state it was in. And this coming from an experienced boilersmith who's turned out several boilers which were totally fucked, including those in scrapyard condition.

He hates FS and I think it's entirely because of how much it sucked working on that boiler.

Also sections of the frames were beyond repair and had to be newly forged and welded in place. From having to have this done on our engine, it requires specialist welds that not many engineers can do, and also costs a LOT.

Flying Scotsman in 2004 - A Comedy of Errors and Owners:

Ok - so this is something I've been sitting on for a while now, but I feel like with 'The World Famous Engine' now being uploaded to Ao3, now is the right time to cover this rather insane topic. See, we all know the story of Flying Scotsman and the NRM: the NRM bought the engine for the nation, and then sent it into the Works for 1 years' worth of work in 2006... One year of work that ended up spiralling into ten years and £4.2 million.

But behind that story is a rather more shocking story, and one that really needs more recognition to help people understand just how absolutely shockingly Flying Scotsman had been treated before that overhaul.

Sir William McAlpine:

Our story most likely begins under Alan Peglar, but I have a rather sneaking suspicion it actually gets interesting under McAlpine. Sir William McAlpine bought 4472 Flying Scotsman in 1972 to save the engine after Alan Peglar went bankrupt in San Francisco, leaving the engine on a US Military Base.

He brought Scotsman and had the engine restored at Derby Works in England, and then successfully owned and ran the engine for another 23 years, making him the longest-lasting and most successful of all Scotsman's owners.

Pretty good achievement!

But, during this era, Flying Scotsman visited Australia, broke the record for the longest non-stop run by a steam locomotive, pulled the Royal Train, ran on a multitude of heritage railways and mainline excursions, got an overhaul three times - including one at Barrow-in-Furness (story idea, anyone?). This is not where the worst of the issues arose from, but it does give you a good idea of the kind of work this engine was being tasked with.

And then in 1995, it was involved in an accident at Llangollen Railway. When put back into steam, smoke emerged from a crack separating the boiler and the front cab. It was deemed a total failure and immediately withdrawn from service immediately - and that's what did McAlpine in. He sold the engine off to cover some debts, and Tony Marchington

What do I think went wrong here? I have a feeling that Scotsman was run pretty haggard in Australia (which, fair - it's not always a very nice country to machines) and when refitted to his BR livery, several... shortcuts were made to get the engine back in service. All the same, this isn't where the trouble came from.

Tony Marchington:

And here's where things went south. Fast. Flying Scotsman was bought, went through a three-year long overhaul worth £1 million and then was set to work. Thing is, that overhaul had a number of red flags surrounding it - perhaps most notable being the fitting of an A4 boiler working at 250psi. Now, for those unaware - the original A1 class ran at 180psi, and the upgraded A3 class ran at 225psi. The engine was being run at a pressure it was extremely unfit to operate with.

It would be a bit like fitting a massive V12 motor to a Honda Accord. Yes, the car will move extremely fast and look impressive and move for a while, but every other piece of that car will deteriorate rapidly due to the pressure it's all under. Now transfer that to a steam locomotive - one where to reach that pressure, the firebox is under a lot of strain.

Flying Scotsman failed a lot during the Marchington era, and it's not surprising why. The poor engine was literally falling to pieces - as one NRM staffmember noted: "On our first inspection, the rear drivers had been removed to deal with bearing problems. The visiting NRM team was most unimpressed with the quality of work being done on the bearings. Other examples of poor workmanship (of which I cannot remember the detail) were evident on inspection.”

Please note, the bearings and valves had all recently been replaced.

Also note, Tony Marchington was under pressure from the shareholders of Flying Scotsman PLC - a company he set up - to make money, and so many of the fitters working on the engine may have been given far, far too many constraints in time and budget to properly overhaul the engine, in essence needing to just 'do the bare minimum to get it back in service'...

And this is the condition the NRM bought 4472 Flying Scotsman in.

The National Railway Museum:

All of the above is an indication of the condition that Flying Scotsman was in when bought in 2004 - but that only tells about half of the story. The other half is a bunch of issues surrounding the purchase, certification and understanding of just how bad things were. And make no mistake, the NRM is not blameless in this circus - it just managed to inherit a bad situation and then fumble with it until they sat down and figured out what had happened.

Let's take a moment to look at the AEAT report that the NRM got, then compare it to reality:

The AEAT report stated that:

"Whilst it was not possible to complete a thorough examination of the locomotive, or to witness it in steam, the condition of the locomotive has been monitored regularly as part of the VAB audit process. Taking this into consideration, it is considered that the general mechanical condition is satisfactory for continued operation, subject to effective maintenance, until the next General Overhaul in 2006. The scope of mechanical overhaul is not anticipated to be extensive but will involve strip down of the motion and axleboxes to gauge wear and remedial action. The cylinders all require re-lining and boring to nominal diameter."

The reality of the condition of the engine was far from this rather rosy portrayal given by AEAT. For starters, the engine was not properly examined, and several areas of testing were 'not possibly to be checked adequately' for a variety of reasons, including:

the locomotive was being prepared for a test run

equipment failure

4472 Flying Scotsman not being in steam

Anyone notice something off? Why exactly can the company not see how the engine is when in steam if the engine is being prepared for a test run?

Furthermore, AEAT had been the VAB (Vehicle Acceptance Body) for Flying Scotsman for 14 years by this point and finding a huge number of faults at this point very much would have raised questions about their work. More probably, the company had grown accustomed to the engine working, and simply assumed everything was satisfactory unless demonstratable to the contrary. Like the NRM admitted:

"[T]he previous owner’s VAB may not have been the best choice of inspector."

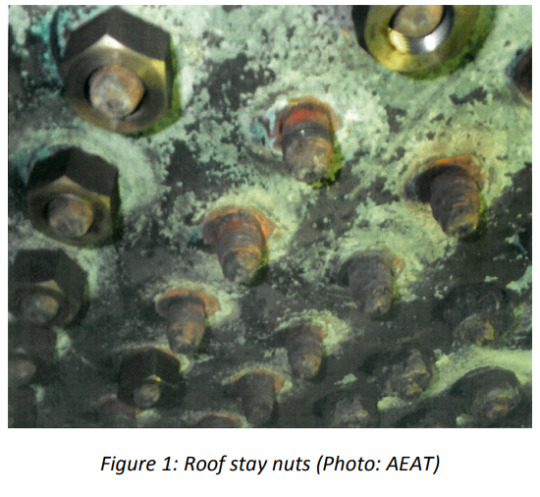

Thing is, AEAT included pictures in their report, but most of these were of the air brake compressor, locomotive air brake, tender air brake cylinders, TPWS antenna selection switch and the TPWS antenna mounting arrangements, which while critical to obtaining permission to operate on Network Rail, don't say much about the actual condition of the engine. And the photos that were of the actual mechanical parts of the engine were... telling.

The Stay Nuts in the firebox are rusting, melting and missing. And that wasn't the only major issue with the engine - several of which were extremely dangerous:

the Robinson superheater header doors had been seal welded;

other inspection doors had also been seal welded;

Repairs to defective studs on the superheater header were needed;

the smokebox door locking mechanism was broken;

the firebox stays needed caulking;

the boiler mountings and pipework in the cab was considered dangerous;

the air brake reservoirs were overdue re-certification;

two tender springs needed replacing;

Re-metalling one crosshead was needed, which resulted in having to remove the bogie, and led to the discovery that the piston rods were incorrectly fitted to the crossheads and required extensive repairs in order to make them fit properly;

Removal of the 'belly' access door in the bottom of the boiler barrel in order to remove a build-up of some 6 inches of sludge;

one of the tender wheel tyres was flat;

the air pump needed repairs;

the vital axlebox oil pads which were long overdue for replacement;

the tender handbrake just didn't work and needed repairs;

121 boiler tubes needed replacement (2004);

the boiler itself needed replacement (2006);

Foundation ring heavily corroded and cracked;

a large number of latent fractures throughout the whole of the locomotive's frame assembly;

the valves and bearings were faulty or broken;

there was a serious crack in the right-hand cylinder;

the entire firebox itself was in desperate need of replacement;

the boiler washout plugs had been fitted with domestic gas plugs;

the wheels are all in need of re-turning;

the frame hornblocks are all cracked;

one of the driving wheels was bent;

the frame stretchers were all cracked and beyond repair;

The centre-cylinder motion bracket also had cracks;

The frames were wrongly aligned;

And the frame's horn ties were scrap, and needed to be remade.

That is thirty separate issues that the NRM discovered between 2004 and 2012 restoring the Flying Scotsman. The Flying Scotsman needed such a complete overhaul to be restored that some people argued that it would cheaper to just build an entirely new engine.

A completely new version of this engine:

And remember, AEAT certified this engine to run on the mainline. The Flying Scotsman had turned into a literal moving death trap under its various owners, and I am not surprised it cost the NRM £4.2 million to rebuild Flying Scotsman.

In summary, 4472 Flying Scotsman was about as sick as an engine could get when it arrived at the NRM. The amount of work required to fix the poor engine was extensive - and some may argue unjustified. Personally, I disagree. Yes, Flying Scotsman cost a ridiculous amount of money to save and rebuild - but this is not an engine who would ever accept living on a plinth in a museum. This is an engine with a fascinating history filled with trials, tribulations and triumphs; and in my opinion the Flying Scotsman's place is on the mainline. Will there be a day when the old engine has to be withdrawn and placed in the NRM? Probably - it's the oldest mainline certified engine in the UK already, and it's not getting any younger. But by that same token, Flying Scotsman went through a massive, extensive overhaul to ensure that generations to come could see the majestic A3 doing what it always did best, and there's something truly inspiring about that.

A big thank you to the NRM for saving Flying Scotsman, and an even bigger 'what the hell?' to the people who almost destroyed it by being careless.

The pictures used in this post do not belong to me. All pictures belong to their owners. If you wish to read the NRM Flying Scotsman report yourself, this is the URL, and a hyperlink to its archived form on the Wayback Machine:

#railway stuff peep peep#in fact very few people in the heritage engineering world have anything nice to say about flying Scotsman#that engine is the pariah of functional steam#showed up to the shed one day in a FS beanie#holy shit did i get hazed

138 notes

·

View notes

Link

#boiler repair Doncaster#boiler maintenance#boiler installation#boiler repair#emergency plumber Doncaster#plumbing services Doncaster#24 hour plumber repair#plumbers around me#plumbers in my area#plumber near me#local plumber#24 hour emergency Doncaster#urgent plumber Doncaster#plumbing#plumber#need a plumber#plumber services

0 notes

Text

Siblings Reunited, Part 2

As the months flew by, the engines raced back and forth, hauling trains of whatever was requested by the workmen in the Steamworks during the restoration of the A3 Pacific purchased from Doncaster Works, later identified as former LNER No. 2560, Pretty Polly. As she was repaired, over time she got stronger and stronger, no longer falling into the realm of unconsciousness, and looking more and more like an actual engine every day. Gordon had noticed the strange uptick of freight going to the Steamworks recently, however no matter how much he asked, he could never get a straight answer out of anybody. His frustration only grew as he continued to try and find out what was going on. "Henry, what on earth is going on with you lot recently? You have been running at all hours of the day AND night, pulling trains to the steamworks!" Henrys eyes widened in shock as he looked at Gordon. "Well.. you see.. Uh.." Henry racked his smokebox for an excuse that was just dumb enough to work. "They.. Havent told us what theyre doing either! They just tell us what they need, we take it to them, and thats that!" Gordons eyes narrowed at his friend as they sat in the station. "Then why havent they asked me?" "They.. Uh.. They realize youre awfully busy with the express, and.. That you have a certain dislike of pulling freight.. So.." Henry hoped that Gordon couldnt see the nervousness in his eyes as they sat in silence for what seemed like forever. Thankfully, the express engine heaved a sigh and looked away. "Thats probably the straightest answer ive gotten out of any of you since all this nonsense began." He huffed, pulling out of the station with his express. Henry let out a breath he didnt know he was holding in as he watched Gordon leave. "That was close.." He groaned. "Too true." Came a new voice. Henry jumped as his eyes panned over to the other line, where Edward had silently pulled in. "Edward, you scared me!" Henry smiled. "any word on how her repairs are going?" He asked, looking to the 4-4-0. "Last i heard, she looks like an actual engine now!" Edward grinned. "Shes still unable to properly communicate with us, but once we get her back up to operational condition, we'll be in business!" Henry and Edward shared excited looks. "Thats wonderful! Do they have an estimated time of completion? August is coming up on us awfully fast.." The big green engine asked, his internal worry shining through his voice as his smile quickly turned into a worried frown. "They cant say for sure.. Theyre working practically 24/7 trying to get everything done on time.. Polly was in terrible condition when she arrived, you know!" Edward sighed, his own worries linking with Henrys. "Dont worry, Edward. If we keep going like we are now, we'll get done in no time. We've made remarkable progress in just a few months already." Henry gave his friend a gentle smile. "We'll pull through. Even if its by the paint on our boilers, we'll get done in time."

#greendon2022#ttte#ttte edward#ttte gordon#ttte henry#ttte pretty polly#edward the blue engine#gordon the big engine#henry the green engine#Part 2 of Siblings Reunited is here!!#Again i apologize if this doesnt fully qualify as 'Greendon2022' material.#But it does focus on Gordons birthday so i guess it counts?#Kinda sorta?

10 notes

·

View notes

Text

Guest Engine Spotlight - Green Arrow

LNER Class V2 #4771

The first of the once numerous V2 class, a close cousin to the famous A1 and A3 Pacifics. The V2s had smaller driving wheels and shorter boilers. Initially built for fast goods trains but were upgraded to Express Mixed Traffic due to their their reliable performance, and 184 were made from 1936 to 1944.

The first V2 Engine was named Green Arrow, the same name as the Fast Freight service it ran with the following four V2s. Only 7 other engines of this class received names.

The V2 engines were well regarded; in prime condition they could almost match Pacifics in speed and they came in highly useful during World War 2, still manufactured in spite of the limitations of the times. They were capable of pulling trains of 20 carriages weighing over 700 tons and beyond. Unfortunately, the toll taken on both engines and the rails themselves caused incidents after the war, and attempts to improve the engines were ultimately aborted with the emerging diesel locomotives of the 1960′s.

Sadly, only the original Green Arrow was preserved, having been withdrawn from service in 1962 (four years before the very last V2s were withdrawn and promptly scrapped) and managed to avoid being written off as scrap at any point, instead housed in various locations with the intent to display as an exhibit. Today, Green Arrow is standing as a static exhibit in Doncaster Museum on a 3-year loan from the National Rail Museum. While Green Arrow needs repairs to be able to go back on the rails, it looks hopeful that it will receive them sooner or later.

In the Railway Series, Green Arrow appears in Thomas and the Great Railway Show. Green Arrow is presented with an agreeable personality and quickly befriends Thomas. As one of the residents of the National Railway Museum, he is chosen to pull passenger trains as part of the show. He and Thomas would later double head a passenger train in the last chapter of that book, and the two of them manage to avoid an accident where the rails ahead were damaged.

Further Reading / Information and Picture Sources:

https://en.wikipedia.org/wiki/LNER_Class_V2 https://en.wikipedia.org/wiki/LNER_Class_V2_4771_Green_Arrow https://ttte.fandom.com/wiki/Green_Arrow https://drawingdatabase.com/lner-class-v2-4771-green-arrow/ https://www.lner.info/locos/V/v2.php

#irl Engines#The Railway Series#TTTE Lore#This is TTTE#TTTE#Thomas the Tank Engine#Green Arrow V2#LNER V2#Green Arrow Locomotive#Green Arrow Engine#Green Arrow#TTTE Green Arrow#TTTE Thomas

18 notes

·

View notes

Text

The Night Shift

@flashfictionfridayofficial

So this is my first Flash Fiction Friday since opening my new writing sideblog. Fittingly this is my longest entry yet at a whopping 760 words, much longer than my usual offerings. This is also the first time I've written a story in my Mechamorph Extended Universe on tumblr (more information available in my pinned post) so hopefully the technical terms and machine talk aren't too overwhelming (can you tell trains are one of my special interests?).

Anyway, enough waffling. Here's my entry for FFF#118, found below the cut. All feedback and questions very welcome: Ask about my characters! Tell me about my bad grammar and huge sentences! etc.

Warnings: War mention, Bodily Harm/Injury, Burns

“Alright Madison we’re ahead of schedule, nice work. Let’s keep that steam pressure up.” From the footplate the thundering of Madison’s valve gear drowned out the sounds of the early night, mixed with the cacophony of other mechanical sounds that formed a familiar soundtrack. Hugo had one arm out of the driver’s window as dark grey smoke poured along the engine’s boiler and rushed past the cab. A mechanised stoker slowly turned over underneath the cab floor, the unseen screw forcing coal from the cab into Madison’s roaring fire. The radiant heat washed over Hugo’s legs, staving off the cold of the French evening. He was glad that he didn’t have to feed that enormous furnace that propelled them through the night, the few times the mechanical stoker had failed he hadn’t enjoyed the task and that hadn’t even been running at speed. She was a hungry girl; and judging by the sight-glass, a thirsty one too.

Madison ran fast and free. The P1 was one of only two examples to be built; an immensely powerful freight locomotive although she was starting to show her age. Running 100 wagon trains to and from the coalfields since 1926 had been strenuous work and her boiler ached. But this was war, and a single freight locomotive wasn’t worth the steel needed to repair them. What was worth something was the long line of trucks behind her loaded with munitions destined for the Maginot Line. With German forces creeping ever closer to the fortifications it was expected that a bitter and drawn-out defence was going to break out soon.

“You’re losing some pressure in the booster. Are your pipes alright?” Hugo gently tapped one of the many gauges in front of him that informed him how his mechanical partner was getting along.

“Does it matter what I say? Both of us know that the REC would rather throw me under the cutter’s torch than repair my leaky pipes. I’ve got plenty of steam in me so just let me run alright. Believe it or not I know how to do that.” A green light nestled within the cluster of steam gauges and controls lit up as a voice filled the cab, punctuated by an impetuous blast of steam from the cylinder drain cocks.

“No need to get defensive, I’m just doing my job as your engineer.” Hugo rolled his eyes at the snarky mechamorph. He knew she wasn’t too upset, just focused on the work at hand. He swung open the firebox doors to check on the fire’s condition but before he could take a good look a sharp crack rang out. A detonator? But the track was all clea-

Hugo’s train of thought was broken off by an explosion beneath Madison. Hot coals flew through the air as the cab was propelled upwards away from the rails, sounds of shearing metal filled the air as the steam pipes connecting Madison’s boiler to the booster engine underneath her tender fractured. Scalding steam was violently vented into the cab, catching Hugo square in the unprotected face and causing him to instantly recoil in pain. He quickly passed out, crumpling on the footplate red faced but not from embarrassment.

“Over yonder hills where foundry flames fly. Where coal fields lay under the red sky. That’s where a being of steel find rest. That’s the home we’ve come to know best. That’s what we always said at Doncaster.” Madison struggled down the line, her inside valve gear was ruined restricting her to two cylinders rather than three. Repeating the little ditty to nobody in particular, forcing herself to stay moving. Her booster engine had been obliterated by the explosion along with her trailing axle which painfully clattered along the sleepers. Her boiler had buckled upward, and all of her glass fittings were shattered, but thankfully she hadn’t exploded… yet. If she could just make it to the hills there was a station, they could call for help. She wished she could reconfigure and walk but if anything, it would just damage her more. She wished she could just stop in a siding and wait to be found the next day, but she couldn’t. For Hugo’s sake. For the sake of the 20-year-old conscript, he was just a child really. A kid playing with trains who had been forced to take his toys to war, he never even trained with a rifle. All he knew was keeping Madison clean and running, she owed it to him to keep him running too.

“C’mon Hugo we’re almost there, there’ll be help for you over yonder hills. Stay with me.”

4 notes

·

View notes

Text

When it comes to boiler repair, boiler replacement, or boiler installation, TNA Plumbing & Heating is equipped with all the expertise you would come to expect from a professional company that holds the experience we do.

We seek to provide a professional all-around service in every circumstance, from the moment we meet, throughout the customer process, and even after your boiler has been installed, repaired or replaced. As dedicated plumbers we strive for excellence with every customer we deal with ensuring the quality of service and 100% customer satisfaction every time.

We know that finding a reliable heating engineer or emergency plumber can sometimes be difficult, but we can assure you that with our experience and passion for improving the water and heating quality in your homes, you won't find more reliable, professional, and dedicated plumbers than ourselves.

We understand that the water and heating control in your homes is extremely important, in terms of the way you live your life on a day-to-day basis, and because of this, we seek to provide an ultra-quick response to all emergency call-outs in Doncaster and across South Yorkshire. Your satisfaction is paramount to us as a business, and our aim is to help you as fast as we can, and as efficiently as possible.

Our plumbing services are recognised all over South Yorkshire for being reliable and above all else, efficient. If you live in Doncaster, South Yorkshire, or the surrounding areas, make sure you give us a call today and speak to a professional plumber. TNA Plumbing & Heating also offers power flushing Services, so make sure you call us today or visit us online to find out more. As a Doncaster-based company, TNA Plumbing & Heating looks to achieve incredibly high standards every time.

From the moment we step into your home we remain professional and look to establish the root of the problem as quickly as possible. Once we have diagnosed the problem with your plumbing or heating, we will do everything in our power to ensure the problem is fixed in the most efficient manner, something we have a great track record for, and something we feel we can be very proud of.

Web Site: https://tnaplumbingandheating.co.uk/

Address: Norwich Rd, Doncaster, Yorkshire DN2 4QD

Phone Number: 07860 635025

Contact Email: [email protected]

Business Hours: Monday - Sunday: Open 24 hours

1 note

·

View note

Text

Best Boiler Installer In Doncaster

The best boiler installer in Doncaster? Are you asking or informing? If that was a question, the answer would have to be Vulcan Plumbing Heating or VPH in short. Hands down. Why such a claim? We will explain why.

We all know what chills we feel in the winter when it is all snow and ice all over the place. Boilers literally save lives in the cold times. But that is common. You did not need us to know that. But what if we say that not only we use the best in class boiler in your home but also we provide warranty? You know that it means you will never be alone with a broken boiler. We will always be there for you trying to keep you warm and safe. Lord have mercy, but a broken boiler in the winter stings harder than a broken heart. Jokes apart. What we are trying to say is that we are reportedly the best boiler installer in Doncaster.

Boilers are life saving and we know how it matters. With all the experience we have gathered, the success stories, the difficulties, the improvisations, it makes us one of the best heating services in Doncaster.

Why Should We Choose The Best? Others Deserve A Chance:

Now, it is true that everyone deserves a chance. And it is also true that winter is no game even for an adult. In the winter, the boilers are much in use. Rightfully so, we get to service boilers mostly in the winter period. Now, not all boilers are in the condition of being fixed even after the warranty. Thanks to a ton of carelessness throughout the whole year, some of the boilers come to us in a state of beyond repair. That led us to introducing boiler replacements in Doncaster. Why are we the best? Best in class product, warranty, boiler replacements and routinely scheduled checks. Need anything else? We are very much all ears for you. Our careful customer care service attends and tries to solve every problem regarding a boiler. Have a free consultation with us, book an appointment, let us have a look at the site. We will need to find the right boiler within the right budget.

Do not be worried about a boiler if you are staying in Doncaster. You already have found the best boiler installation service. As a replacement, you can worry about your fireplace. We do not cover that. Sorry.

#best boiler installer in Doncaster#best heating services in Doncaster#boiler replacements in Doncaster#boiler replacements#the best boiler installation service

1 note

·

View note

Text

Burnr Ltd

A warm welcome to Burnr Ltd, your local gas engineer in Doncaster. Burnr Ltd is a family run company specialising in the installation, servicing and repair of boilers in Doncaster and surrounding areas. We also carry out landlord gas safety inspections, power flushing, gas hob installation, cooker installationand plumbing.

Website: https://www.gasengineerindoncaster.co.uk/

Address: Unit 5, 245 Station Rd, Hatfield, Doncaster, DN7 4DY

Phone Number: 01302 965662

Business Hours: Mon - Fri: 09:30 AM – 05:00 PM

1 note

·

View note

Link

We are providing all aspects of plumbing and heating services in Doncaster and all surrounding towns and villages. Our team are well educated and highly experienced to gives you satisfied services. We aim to provide a quality service first time every time.

0 notes

Text

Importance of Boiler Safety & Maintenance

Boiler explosions have disastrous effects. Boilers that were poorly designed, improperly installed, or improperly sited as well as those that were not properly operated or maintained could all be factor in boiler explosion. Signum FM is a leading famous Doncaster-based company with many years of experience in offering a comprehensive range of commercial boiler repair services. Check out this infographic to know about the importance of boiler safety & maintenance. https://bit.ly/3GM7voO

0 notes

Text

Testimonials- Gas Boiler Repair, Gas Central Heating Installer Sheffield

Know client's testimonial of Warmshires Ltd in Worksop, Nottingham for reliable heating & plumbing services throughout Retford, Sheffield, Doncaster, Lincolnshire & Newark areas.

#Gas Boiler Repair Doncaster#Gas Central Heating Installer Sheffield#Bathrooms installations Lincolnshire

0 notes

Text

Why You Need to Hire A Certified Gas Plumber Melbourne

Only authorized specialists should be allowed to manage boilers, hot water systems, fireplaces and everything related to gas powered installations. It is dangerous and risky to undertake any project on your own, without proper training and experience in the field. A Gas Plumber Melbourne can provide this service without hesitation, offering high-quality work and guaranteed satisfaction. When plumbing issues arise, no one is more qualified and better prepared than a Gas Plumber Melbourne.

Why Hire a Gas Plumber Melbourne Service?

We depend and use gas daily, and it has become a necessity, an important part of our lives. When you do not manage it correctly, accidents can occur, and they can easily become fatal. To avoid the risk of a fire, explosion and such, it is crucial to hire a Gas Plumber Melbourne when it comes to installing and maintaining gas appliances. There are many risks implied when gas leaks from pipes, when appliances are not working properly or when they are not fixed correctly. A registered and certified gas plumber Melbourne knows how to manage such situations correctly and how to find solutions.

Unauthorized individuals should not manage gas installations and repairs. This is the reason for hiring a safe Gas Plumber Melbourne. Such a professional is highly familiar with safety regulations and standards that must be met. When you want an inspection for your peace of mind and even when you are renovating a house and want to know everything is working properly, hire the services of a professional gas plumber Melbourne who has an impeccable reputation in this field. You can even receive advice from engineers on what installations to choose from the beginning, what boilers, hot water systems, how you can reduce heating bills and such.

Choosing the Best Gas Plumber Melbourne

Many considerations need to be kept in mind when it comes to choosing the right Gas Plumber, the most important one is verifying if the person is registered. You can request this information before hiring him. Because you need to collaborate only with experienced and specialized companies Melbourne 24 Hour Plumbing ensures that your work is carried out professionally and no unpleasant situations occur afterward. Considering the amount of time and money you are investing in the process, you must make the right decisions.

Just like you take your time in choosing proper installations, fittings, designs, and furniture, the same level of attention should be given to the gas plumber Melbourne, if not even more.

Services of a Gas Plumber Melbourne

Melbourne 24 Hour Plumbing is usually demanded when there is tap repair or replacement, pump installation and repairs, burst water pipes, kitchen sink fitting, bathroom remodeling, cold and hot water system installations and repairs, toilet repairs, and many other plumbing issues.

If you find yourself in an emergency gas situation, call the services of a plumbing expert right away to attend to your problem. It always helps to have the contact numbers of a qualified gas plumber Melbourne at hand. You never know when problems will occur and in those stressful situations, people don’t usually have a lot of time at their disposal. The sooner you get in touch with Melbourne 24 Hour Plumbing the better, as situations must be handled as soon as they appear.

Melbourne 24 Hour Plumbing is your local plumber Melbourne specialist. If you have an issue with a blocked drain Melbourne or hot water system Melbourne, then you need a 24 hour plumber Melbourne or an emergency plumber Melbourne to service you. You might also reach out to a gas plumber Melbourne to help you. It’s important that you have a plumber Melbourne,Melbourne plumber, plumbing Melbourne, plumbers Melbourne you can trust. Drain Camera Melbourne and Carbon Monoxide Testing Melbourne are other service we offer to our clients.Emergency Plumbing Melbourne is important to your home system. Do you have a Burst Pipe Melbourne? Our public holiday plumber is available 24/7.

We service many suburbs including:

Plumber Prahran, Plumber South Yarra, Plumber Toorak, Plumber Carlton, Plumber Brunswick,Plumber Brighton, Plumber Camberwell, Plumber St Kilda, Plumber Malvern, Plumber Elwood,Plumber Caulfield, Plumber Cranbourne, Plumber Doncaster, Plumber Frankston, Plumber Williams Town, Plumber Port Melbourne, Plumber Carrum Downs, Plumber Glen Iris, Plumber Hampton, Plumber Mordialloc, Plumber Box Hill, Plumber Middle Park, Plumber Richmond,Plumber Burwood, Plumber South Melbourne, Plumber Hampton, Plumber Albert Park, Plumber Elsternwick, Plumber Ivanhoe, Plumber Templestowe, Plumber Essendon, Plumber Pascoe Vale, Plumber Thornbury, Plumber Coburg Plumber Rye, Plumber Portsea, Plumber Sorrento,Plumber Rosebud, Plumber Mornington, Plumber Dromana, Plumber Mount Eliza, plumber Kew, Plumber Chelsea, Plumber CBD, plumber Carnegie, plumber Cheltenham, Plumber Bon Beach, Plumber Mentone, Plumber Seaford, Plumber Carrum, Plumber Safety Beach, Plumber Karingal, Plumber Langwarrin, Plumber Skye, Plumber Sandhurst, Plumber Balnarring Plumber Mount Martha, Plumber Pearcedale, Plumber Baxter, Plumber Clyde, Plumber Clyde North,Plumber Lynbrook, Plumber Lyndhurst, Plumber Fitzroy, Plumber Armadale, Plumber Hawthorn,Plumber Caulfield East, Plumber Caulfield South, Plumber Caulfield North, Plumber Officer,Plumber Hampton Park, Plumber Beaconsfield, Plumber Berwick, Plumber Narre Warren,Plumber Hallam, Plumber Endeavour Hills, Plumber Yallambie, Plumber Westmeadows,Plumber West Melbourne, Plumber Watsonia, Plumber Viewbank, Plumber Tullamarine,Plumber Southbank, Plumber Rosanna, Plumber Ripponlea, Plumber Reservoir, Plumber Princes Hill, Plumber Preston, Plumber Northcote, Plumber North Melbourne, Plumber Montmorency, Plumber Meadow Heights, Plumber Macleod, Plumber Lower Plenty, Plumber Kingsbury, Plumber Kensington, Plumber Wheelers Hill, Plumber Waterways, Plumber Travancore, Plumber Surrey Hills, Plumber Strathmore, Plumber Springvale, Plumber Sandringham, Plumber Patterson Lakes, Plumber Oakleigh, Plumber Oak Park, Plumber Notting Hill, Plumber Noble Park, Plumber Niddrie, Plumber Murrumbeena, Plumber Moorabbin,Plumber Moonee Vale, Plumber Moonee Ponds, Plumber Mont Albert, Plumber McKinnon,Plumber Keilor, Plumber Jolimont, Plumber Jacana, Plumber Highett, Plumber Heidelberg,Plumber Heatherton, Plumber Abbotsford, Plumber Aberfeldie, Plumber Airport West, Plumber Alphington, Plumber Ascot Vale, Plumber Ashburton, Plumber Attwood, Plumber Avondale Heights, Plumber Balaclava, Plumber Balwyn, Plumber Hadfield, Plumber Gowanbrae, Plumber Glenroy, Plumber Glen Huntly, Plumber Gladstone Park, Plumber Gardenvale, Plumber Garden City, Plumber Flemington, Plumber Fishermans Bend, Plumber Fawkner, Plumber Fairfield,Plumber Edithvale, Plumber East Melbourne, Plumber Eaglemont, Plumber Donvale, Plumber Yarraville, Plumber Wantirna, Plumber Vermont, Plumber Spotswood, Plumber Seddon,Plumber Scoresby, Plumber Rowville, Plumber Ringwood, Plumber Park Orchards, Plumber Nunawading, Plumber Newport, Plumber Mulgrave, Plumber Mount Waverly, Plumber Mitcham,Plumber Lysterfield, Plumber Kooyong, Plumber Knoxfield, Plumber Kingsville, Plumber Huntingdale, Plumber Hughesdale, Plumber Glen Waverley, Plumber Forest Hill, Plumber Footscray, Plumber Ferntree Gully, Plumber Docklands, Plumber Deepdene, Plumber Dandenong, Plumber Croydon, Plumber Cremorne, Plumber Collingwood, Plumber Canterbury,Plumber Cambellfield, Plumber Burnley, Plumber Bundoora, Plumber Bulleen, Plumber Broadmeadows, Plumber Braeside, Plumber Boronia, Plumber Blackburn, Plumber Blackrock, Plumber Bellfield, Plumber Beaumaris, Plumber Beacon Cove, Plumber Bayswater, Plumber Bangholme, Plumber Ashwood and all over Melbourne.

#emergency plumbing melbourne#Blocked Drain Melbourne#Melbourne Plumbers#melbourne plumbing#Melbourne Plumber#melbourne plumbing melbourne#plumbers melbourne#plumbing melbourne#gas plumber melbourne#Roof Plumber Melbourne#Local Plumber Melbourne#Leaking Tap Melbourne#Burst Pipe Melbourne#Public Holiday Plumber#drain camera Melbourne#carbon monoxide testing melbourne#emergency plumber melbourne#24 hour plumber melbourne#hot water system melbourne#blocked drain melbourne hot water system melbourne#blocked toilet Melbourne

0 notes