#Biomass Plant Manufacturer

Explore tagged Tumblr posts

Text

Manufacturer of Biomass Processing Plant for Sustainable Energy

Kerone a leading manufacturer in the field of biomass processing and production plants, our company stands at the forefront of sustainable and eco-friendly solutions for energy generation. Specializing in the design, fabrication, and implementation of innovative biomass processing facilities, we have established our self as a pioneers in harnessing the potential of organic materials for renewable energy production. With a commitment to environmental responsibility, Kerone employs advanced technologies to efficiently convert biomass, such as agricultural residues, forestry waste, and organic byproducts, into clean and renewable energy sources. Our plants are characterized by a seamless integration of advanced machinery and automation, ensuring optimal efficiency and minimal environmental impact. As a forward-thinking organization, we prioritize research and development, constantly innovating to enhance the performance and sustainability of their biomass processing systems. With a global footprint, Kerone plays a crucial role in promoting a greener future by providing reliable and scalable solutions that contribute to the transition towards a more sustainable and circular economy. If you want to buy Industrial heating, drying and coating equipments online from India, you are viewing the perfect advertisement… Contact us today for all your industrial needs. Website : https://kerone.com/ P.H: +91-22-48255071 / 72 Email-Id : [email protected],[email protected]

0 notes

Text

Biomass Briquetting Machines and Briquetting Plants | Briquette machines manufacturer

The Biomass Briquette Machine is a revolutionary solution in the renewable energy sector. It offers a more economical alternative to traditional fuels due to its unique characteristics. With low moisture content, low ash content, and high density, Biomass Briquettes provide efficient and clean burning, resulting in reduced fuel consumption and minimal emissions.

Contact Details Call : +91 991 520 0537 https://lehrafuel.com/biomass-briquetting-machine/

#lehra fuel#biomass briquetting plant#briquette machine manufacturer#Biomass Brequetting Machine#Biomass Plant Manufacturer#Biomass energy#Lehra Fuel#Briquetting Machine#Briquetting Plant

0 notes

Text

The Role of Biomass Handling Systems in Sustainable Energy Solutions

Biomass handling systems are crucial in sustainable energy solutions, enabling efficient collection, processing, and transport of biomass materials. These systems enhance energy production, reduce waste, and lower carbon emissions, contributing significantly to the development of renewable energy and a cleaner, more sustainable environment. For more information click on the given link: https://methodsindia.com/from-waste-to-wealth-bagasse-handling-systems-changing-the-game/

#Biomass Handling Systems#Bagasse Dryers#Bulk Reception Unit (Bru)#Cross Country Conveyors#Sugar Elevators#Mineral Beneficiation Plant Manufacturers in India

0 notes

Text

How to Start Biomass Briquettes Business

Biomass briquettes are solid biofuels made from compressed organic matter like agricultural, forestry, or industrial waste. In recent years, the demand for alternative energy sources has surged globally, with a growing emphasis on sustainable and eco-friendly solutions. So, biomass briquettes, have emerged as a promising substitute for traditional fuels like coal and wood. Biomass briquettes are…

View On WordPress

#biomass briquette machine#biomass briquette plant#biomass briquettes#biomass briquettes business#biomass briquettes business in india#biomass briquettes business plan#biomass briquettes manufacturing business#biomass briquettes production process#how to start biomass briquettes business#new business idea#sawdust briquette machine#small business ideas#start biomass briquettes business

0 notes

Text

Explore the eco-friendly world of Jay Khodiyar Biomass Briquetting Plant in India. Our advanced technology transforms agricultural and forestry waste into high-quality briquettes, promoting sustainability and profitability. Dive into the benefits and setup processes of our innovative briquetting solutions and join the green revolution today!

#Biomass Briquetting Plant#Eco-Friendly Fuel Alternatives#Agricultural Waste Recycling#Biomass Briquetting Technology#Sustainable Biofuel Production#Biomass Energy Equipment#Biomass to Briquettes Process#Waste to Energy Systems#Briquetting Plant Manufacturer#Biomass Pellet Machine#Biomass Briquetting Benefits#Cost-Effective Heating Solutions#Green Energy Briquettes#Biomass Briquetting Press

0 notes

Text

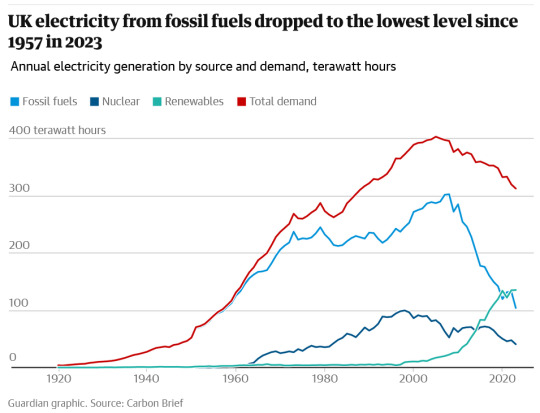

"The amount of electricity generated by the UK’s gas and coal power plants fell by 20% last year, with consumption of fossil fuels at its lowest level since 1957.

Not since Harold Macmillan was the UK prime minister and the Beatles’ John Lennon and Paul McCartney met for the first time has the UK used less coal and gas.

The UK’s gas power plants last year generated 31% of the UK’s electricity, or 98 terawatt hours (TWh), according to a report by the industry journal Carbon Brief, while the UK’s last remaining coal plant produced enough electricity to meet just 1% of the UK’s power demand or 4TWh.

Fossil fuels were squeezed out of the electricity system by a surge in renewable energy generation combined with higher electricity imports from France and Norway and a long-term trend of falling demand.

Higher power imports last year were driven by an increase in nuclear power from France and hydropower from Norway in 2023. This marked a reversal from 2022 when a string of nuclear outages in France helped make the UK a net exporter of electricity for the first time.

Carbon Brief found that gas and coal power plants made up just over a third of the UK’s electricity supplies in 2023, while renewable energy provided the single largest source of power to the grid at a record 42%.

It was the third year this decade that renewable energy sources, including wind, solar, hydro and biomass power, outperformed fossil fuels [in the UK], according to the analysis. Renewables and Britain’s nuclear reactors, which generated 13% of electricity supplies last year, helped low-carbon electricity make up 55% of the UK’s electricity in 2023.

[Note: "Third year this decade" refers to the UK specifically, not global; there are several countries that already run on 100% renewable energy, and more above 90% renewable. Also, though, there have only been four years this decade so far! So three out of four is pretty good!]

Dan McGrail, the chief executive of RenewableUK, said the data shows “the central role that wind, solar and other clean power sources are consistently playing in Britain’s energy transition”.

“We’re working closely with the government to accelerate the pace at which we build new projects and new supply chains in the face of intense global competition, as everyone is trying to replicate our success,” McGrail said.

Electricity from fossil fuels was two-thirds lower in 2023 compared with its peak in 2008, according to Carbon Brief. It found that coal has dropped by 97% and gas by 43% in the last 15 years.

Coal power is expected to fall further in 2024 after the planned shutdown of Britain’s last remaining coal plant in September. The Ratcliffe on Soar coal plant, owned by the German utility Uniper, is scheduled to shut before next winter after generating power for over 55 years.

Renewable energy has increased sixfold since 2008 as the UK has constructed more wind and solar farms, and the large Drax coal plant has converted some of its generating units to burn biomass pellets.

Electricity demand has tumbled by 22% since its peak in 2005, according to the data, as part of a long-term trend driven by more energy efficient homes and appliances as well as a decline in the UK’s manufacturing sector.

Demand for electricity is expected to double as the UK aims to cut emissions to net zero by 2050 because the plan relies heavily on replacing fossil fuel transport and heating with electric alternatives.

In recent weeks [aka at the end of 2023], offshore wind developers have given the green light to another four large windfarms in UK waters, including the world’s largest offshore windfarm at Hornsea 3, which will be built off the North Yorkshire coast by Denmark’s Ørsted."

-via The Guardian, January 2, 2024

#uk#united kingdom#england#scotland#wales#northern ireland#electricity#renewables#renewable energy#climate change#sustainability#hope posting#green energy#fossil fuels#oil#coal#solar power#wind power#environment#climate action#global warming#air pollution#climate crisis#good news#hope

393 notes

·

View notes

Text

Researchers at Hokkaido University have taken a significant step forward in the drive to make recyclable yet stable plastics from plant materials. This is a key requirement to reduce the burden of plastic pollution in the environment. They developed a convenient and versatile method to make a variety of polymers from chemicals derived from plant cellulose; crucially, these polymers can be fully recycled. The method was published in the journal ACS Macro Letters. Cellulose is one of the most abundant components of biomass derived from plants, being a key part of the tough cell walls surrounding all plant cells. It can be readily obtained from plant wastes, such as straw and sawdust, therefore, using it as a feedstock for polymer manufacture should not reduce the availability of agricultural land for food production.

Continue Reading.

94 notes

·

View notes

Text

Researchers discover new route to recyclable polymers from plants

Researchers at Hokkaido University have taken a significant step forward in the drive to make recyclable yet stable plastics from plant materials. This is a key requirement to reduce the burden of plastic pollution in the environment. They developed a convenient and versatile method to make a variety of polymers from chemicals derived from plant cellulose; crucially, these polymers can be fully recycled. The method was published in the journal ACS Macro Letters. Cellulose is one of the most abundant components of biomass derived from plants, being a key part of the tough cell walls surrounding all plant cells. It can be readily obtained from plant wastes, such as straw and sawdust, therefore, using it as a feedstock for polymer manufacture should not reduce the availability of agricultural land for food production.

Read more.

20 notes

·

View notes

Text

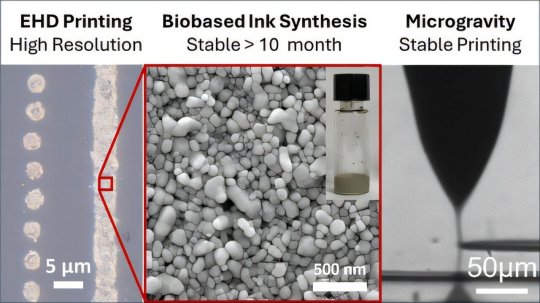

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

2 notes

·

View notes

Text

2 notes

·

View notes

Text

Cellulase Enzyme Manufacturer

Pharmabiz.World: Leading the Way in Cellulase Enzyme Production

In an era where industries are increasingly focused on sustainability, efficiency, and cost-effectiveness, the importance of enzymes in various applications cannot be overstated. Among the many enzymes that have gained significant attention, cellulase stands out for its diverse range of uses. Pharmabiz.World (PBW), a global leader in the production of cellulase enzymes, is at the forefront of this innovative field, driving both environmental and industrial transformation with its high-quality enzyme solutions.

What is Cellulase and Why is it Important?

Cellulase is a group of enzymes that break down cellulose, a complex carbohydrate found in the cell walls of plants. This enzyme is essential in processes such as the conversion of plant biomass into simpler sugars, which can then be used in biofuels, food production, textile processing, and more. The ability to break down cellulose efficiently makes cellulase a key enzyme in industries focused on bioconversion and waste reduction.

In industries such as paper and pulp, textiles, biofuels, and agriculture, cellulase plays a crucial role by enhancing production yields, reducing environmental impact, and lowering energy consumption. At Pharmabiz.World, the company takes pride in producing enzymes that help businesses across these sectors achieve their goals more efficiently and sustainably.

PBW's Commitment to Innovation

Pharmabiz.World (PBW) is committed to the continuous advancement of enzyme technology, specifically cellulase. The company invests heavily in research and development to ensure their products meet the highest standards of performance and sustainability. By working with cutting-edge biotechnology, PBW has developed a cellulase enzyme that not only delivers superior performance but also meets the growing demand for eco-friendly, sustainable solutions.

PBW's cellulase enzymes are designed to break down complex cellulose structures, making it easier to extract valuable components like sugars and fibers from plant materials. Whether it's in the production of biofuels, improving the digestibility of animal feed, or enhancing the efficiency of textile manufacturing, PBW’s cellulase enzymes offer a competitive advantage to businesses seeking more sustainable and efficient processes.

Industries Benefiting from PBW’s Cellulase Enzyme Solutions

1. Biofuel Production: The biofuels industry is one of the major beneficiaries of cellulase enzymes. PBW’s cellulase is utilized in the conversion of agricultural residues and other plant-based materials into fermentable sugars, which can then be transformed into bioethanol or other forms of renewable energy. By enhancing the breakdown of cellulose, PBW’s enzymes make the process of biofuel production more efficient, reducing costs and increasing output.

2. Textile Industry: Cellulase enzymes have revolutionized the textile industry by offering an eco-friendly alternative to traditional chemical treatments. PBW’s cellulase enzymes are used in fabric finishing processes, such as biopolishing and stonewashing, to improve the quality of textiles, reduce pilling, and increase durability—all while minimizing water and chemical usage.

3. Animal Feed: In agriculture, cellulase is used to enhance the digestibility of animal feed, particularly for livestock consuming fibrous plant materials. PBW’s cellulase improves the breakdown of plant fibers in animal digestive systems, leading to better nutrient absorption, growth rates, and feed efficiency.

4. Food & Beverage: In the food and beverage industry, cellulase is used to improve processes such as fruit juice extraction, wine clarification, and bread-making. PBW’s enzymes help businesses achieve higher yields, reduce production time, and enhance product quality—all while maintaining the integrity of natural flavors and textures.

5. Paper and Pulp: The paper and pulp industry benefits from PBW’s cellulase enzymes in several ways. By breaking down the lignocellulose structure in wood, cellulase can reduce the need for harsh chemicals in paper processing, leading to a more environmentally friendly and cost-effective production method.

The PBW Advantage: High-Quality, Customized Solutions

Pharmabiz.World understands that every industry and application has its unique challenges. This is why the company offers tailor-made cellulase solutions designed to meet the specific needs of their clients. PBW’s cellulase enzymes are formulated to deliver maximum efficiency, even in the most challenging conditions, such as extreme temperatures or high levels of acidity.

The company’s commitment to quality is reflected in its rigorous testing protocols and compliance with international standards. PBW’s enzymes are produced in state-of-the-art facilities, ensuring that every batch meets the highest standards for purity, potency, and consistency.

Sustainable Practices for a Greener Future

At PBW, sustainability is a core value. The company not only produces enzymes that enhance the efficiency of industrial processes but also ensures that its manufacturing practices minimize environmental impact. By reducing waste, conserving resources, and lowering carbon emissions, PBW is helping industries move toward greener practices without sacrificing performance.

Epilogue

Pharmabiz.World is proud to be a global leader in the production of cellulase enzymes, providing industries with the tools they need to succeed in a world increasingly focused on sustainability and innovation. Whether it's improving energy efficiency in biofuel production, enhancing fabric quality in textiles, or boosting livestock productivity in agriculture, PBW’s cellulase enzymes are designed to deliver exceptional performance.

With a commitment to research, sustainability, and customer-centric solutions, Pharmabiz.World continues to set the standard for enzyme production. For industries seeking high-performance, eco-friendly enzyme solutions, PBW is the partner of choice for driving efficiency, reducing environmental impact, and supporting the future of innovation.

Visit our website: https://pharmabiz.world/acid-cellulase | Email Us Your Requirements: [email protected] OR Call / WhatsApp Now for Order: 01169310523.

0 notes

Text

Biomass Briquetting Plant | Biomass Briquetting Machine | Biomass Briquetting manufacturing

A biomass plant, also known as a biomass power plant or bioenergy plant, is a facility that generates electricity or heat by burning biomass materials. Biomass refers to organic materials derived from plants and animals, such as wood, crop residues, agricultural waste, dedicated energy crops, and organic industrial and municipal waste.

Turn your waste into value with our effective Biomass Briquetting Machine. To know more about the process of briquetting contact us. Call Now!

0 notes

Text

Cost of Biomass Plant

In the quest for sustainable energy solutions, biomass plants have emerged as a viable option for converting organic materials into renewable energy. However, one of the most common questions surrounding this technology is the cost involved in setting up a biomass plant. For businesses and individuals considering this eco-friendly energy source, understanding the factors that influence the cost is crucial. In this article, we’ll explore the various aspects that determine the cost of a biomass plant, with insights into how one of the leading biomass plant manufacturers, play a pivotal role in delivering cost-effective and efficient solutions.

Key Factors Influencing the Cost of a Biomass Plant

Size and Capacity of the PlantThe size and capacity of the biomass plant are among the primary factors that influence the overall cost. Larger plants capable of processing more biomass and generating higher energy output naturally require more substantial investments. The capital cost increases with the scale, including expenses for land, machinery, and infrastructure.

Type of Biomass UsedThe type of biomass used as feedstock significantly impacts both the operational cost and efficiency of the plant. Common types of biomass include wood chips, agricultural residues, and organic waste. Some feedstocks may be more expensive to procure or may require additional preprocessing, thereby increasing the total cost. Maha Shiv Shakti Engineers assists clients in selecting the most suitable and cost-effective biomass feedstocks, ensuring that the plant operates efficiently and economically.

Technology and EquipmentThe technology employed in a biomass plant is another critical factor that affects costs. Advanced technologies, such as gasification and anaerobic digestion, can offer higher efficiency but may come with higher upfront costs. The choice of equipment, including boilers, turbines, and control systems, also plays a crucial role in determining the total investment required.

Location and LogisticsThe location of the biomass plant influences both the initial setup cost and ongoing operational expenses. Proximity to biomass sources can reduce transportation costs, while the availability of infrastructure like roads, water, and electricity can affect the installation cost. Additionally, local regulations and environmental compliance requirements can add to the cost. With a focus on strategic planning, Maha Shiv Shakti Engineers helps clients select optimal locations that minimize logistical costs and maximize efficiency.

Regulatory and Compliance CostsComplying with environmental regulations is essential for any biomass plant. The costs associated with obtaining permits, conducting environmental impact assessments, and adhering to emission standards can vary widely depending on the region. Failure to comply can result in fines or additional expenses for retrofitting the plant.

Operational and Maintenance CostsThe long-term success of a biomass plant depends on its operational efficiency and maintenance. Regular maintenance is essential to prevent breakdowns and ensure the plant operates at optimal capacity. The cost of skilled labor, spare parts, and consumables must be factored into the overall budget. As one of the leading biomass plant manufacturers, Maha Shiv Shakti Engineers offers comprehensive maintenance services, helping clients reduce downtime and extend the lifespan of their plants.

The Role of Biomass Plant Manufacturers

Choosing the right biomass plant manufacturer is crucial to managing costs effectively. A reputable manufacturer like Maha Shiv Shakti Engineers not only provides high-quality equipment but also offers end-to-end solutions, from initial consultation and design to installation and maintenance. Their expertise in the field enables them to deliver cost-effective solutions tailored to the specific needs of each client, ensuring that the investment in a biomass plant yields the best possible returns.

Conclusion

The cost of setting up a biomass plant is influenced by various factors, including the size and capacity of the plant, the type of biomass used, the technology employed, location, and regulatory requirements. By working with experienced biomass plant manufacturers like Maha Shiv Shakti Engineers, businesses can navigate these complexities and develop efficient, cost-effective biomass plants that contribute to a sustainable energy future. Whether you’re looking to reduce energy costs or transition to renewable energy, a well-planned biomass plant can be a valuable investment.

0 notes

Text

Optimizing Biomass Handling Systems for Efficient Energy Production - Methods India

Biomass handling systems in India encompass a range of traditional and modern methods designed to efficiently manage, process, and utilize biomass resources for energy production and other applications. In India, biomass is a crucial component of the renewable energy mix, and the handling systems employed are tailored to the diverse types of biomass available, including agricultural residues, forestry waste, and urban organic waste.For More Information Click this link - https://methodsindia.com/how-to-use-natures-energy-a-guide-to-biomass-handling-system/

#Biomass Handling Systems#Bagasse Dryers#Bulk Reception Unit (Bru)#Cross Country Conveyors#Sugar Elevators#Mineral Beneficiation Plant Manufacturers in India

0 notes

Text

Cement Industry, From Carbon-Intensive to Carbon-Neutral

As the world steps up its efforts to combat climate change, industries contributing significantly to global greenhouse gas (GHG) emissions, unlike cement, face immense pressure to transition toward sustainability. Responsible for about 8% of global CO2 emissions, the cement industry is at the forefront of this transformation. While cement production remains essential for modern infrastructure, the challenge now is to find greener ways of producing it. As a response, the sector is embarking on a Net Zero pathway, aiming for a 25% reduction in CO2 emissions by 2030 and a full decarbonization by 2050, driven by technological innovations, use of alternative raw materials, and circular economy principles. This path is reshaping the cement industry, making it more sustainable while continuing to meet global infrastructure demands.

One of the most effective strategies has been the adoption of alternative raw materials. Traditionally, cement production relies heavily on limestone, contributing significantly to emissions. However, by integrating clinker substitutes such as fly ash, Ground Granulated Blast Furnace Slag(GGBFS), and calcined clay, the industry has reduced its CO2 footprint. These materials, sourced from industrial waste like coal power plants and steel production, fit within the framework of the circular economy. Not only do they help minimize new resource consumption, but they also reduce the overall environmental impact of cement manufacturing. This shift toward alternative materials is particularly visible in the ready-mix concrete (RMC) sector. Here, eco-friendly materials like fly ash and GGBFS are increasingly being adopted, ensuring that these solutions align with the industry’s sustainability objectives without compromising on performance.

Through these innovations, companies are leading the charge toward a greener future while maintaining high-quality standards.

Energy consumption has long been a significant challenge for the cement industry, with production being highly energy-intensive. Traditionally reliant on fossil fuels such as coal, the industry is now rapidly transitioning to renewable energy sources like solar and wind. Additionally, alternative fuels such as biomass, municipal waste, and used tires are gaining traction, further reducing dependence on fossil fuels and lowering overall emissions. Within the broader concrete production sector, similar strides are being made to incorporate renewable energy into operations. These changes highlight the cement industry’s ongoing efforts to reduce its environmental impact while maintaining operational efficiency.

Energy optimization is another critical area of focus. Technologies such as waste heat recovery systems, which convert excess heat from the production process into electricity, have proven highly effective. Moreover, the adoption of pre-calciners and pre-heaters has drastically improved the thermal efficiency of clinker production, cutting down on energy consumption during the most energy-intensive phase of cement manufacturing. These technological innovations are driving significant improvements in energy efficiency, not just in cement production but across the construction materials industry as a whole.

The transport of cement and related materials also accounts for a significant share of industry emissions. Diesel-powered trucks are still widely used, but the shift toward greener options, such as rail and waterway transportation, is gaining momentum. Some manufacturers are also investing in more eco-friendly vehicle fleets powered by compressed natural gas (CNG) and electric engines, further reducing emissions within the supply chain. Water conservation is emerging as another important focus area for the cement sector. Cement production has traditionally been a water intensive process, but with growing concerns around water scarcity, manufacturers are adopting technologies like rainwater harvesting, air-cooled condensers, and water recycling systems to reduce usage and promote sustainability across their operations.

Another area showing promise is digitalization. Through advanced data analytics and automation, manufacturers can monitor real-time data on energy usage, emissions, and resource consumption. This allows for quick, efficient adjustments to production processes, optimizing efficiency and minimizing waste. The construction sector, particularly ready-Mix concrete plays a critical role in supporting the cement industry’s sustainability efforts.

By integrating advanced technologies and adopting green strategies, these companies contribute to the overall industry’s Net Zero ambitions and a sustainable future. While the road to reducing cement industry emissions presents numerous challenges, the opportunities for innovation and collaboration are immense. With ongoing technological advancements, policy support, and a commitment from across the sector, the cement industry is well-positioned to lead the journey toward a Net Zero future.

Visit our site to know more : https://www.aparnaenterprisesltd.com/

0 notes