#Biomass Boilers

Explore tagged Tumblr posts

Text

#Heat Pump technology#heat exchangers#heating and cooling systems#air source heat pumps#ground source heat pump#Biomass Boilers#partnered with Viessmann#Viessmann products#reduce energy bills

0 notes

Link

According to a research report “Biomass Power Generation Market by Technology (Combustion, Gasification, Anaerobic Digestion, Pyrolysis), Feedstock (Agricultural Waste, Forest Waste, Animal Waste, Municipal Waste), Fuel (Solid, Liquid, Gaseous) and Region – Global Forecast to 2028″ published by MarketsandMarkets, the global biomass power generation market is projected to reach USD 105.7 billion by 2028 from an estimated USD 91.3 billion in 2023, at a CAGR of 3.0% during the forecast period.

0 notes

Text

2 notes

·

View notes

Text

Isotex Global Customer Testimonial | Sintex Industries

Isotex Global yields positive results for a textiles industries.

Sintex industries ltd., shares his experience with Isotex Corporation Pvt Ltd. and highlights its features of steam boiler - biomass briquettes.

Our customer testimonial for Isotex global at sintex industries.

#customer testimonial#sintex industries#textile industry#isotex boiler#steam boiler#biomass boiler#isotex global

0 notes

Text

A biomass boiler is a type of heating system that uses organic materials derived from plants, animal waste, forestry residues, or dedicated energy crops as its fuel source. It is a renewable energy system because the organic materials used in biomass boilers can be replenished through natural processes, making them more sustainable when compared with fossil fuel-based boilers.

0 notes

Text

Biomass Boiler Market Size, Share and Global Trend By Feedstock (Woody biomass, Forest residue, Agriculture, Biogas & Energy Crop, Urban Residue), By Type (Fully Automated Biomass Boiler, Semi-Automated Biomass Boiler, Combined Heat and Power System), By Application (Heating, Power Generation), By End-user (Residential, Commercial, Industrial), and Geography Forecast till 2022-2029

0 notes

Text

Biomass Boiler Market Size, Share and Global Trend By Feedstock (Woody biomass, Forest residue, Agriculture, Biogas & Energy Crop, Urban Residue), By Type (Fully Automated Biomass Boiler, Semi-Automated Biomass Boiler, Combined Heat and Power System), By Application (Heating, Power Generation), By End-user (Residential, Commercial, Industrial), and Geography Forecast till 2022-2029

0 notes

Text

Biomass Boiler Market Trends From 2017: Uncovering Lucrative Business Opportunities to 2024

The report titled “Biomass Boiler Market: Global Demand Analysis & Opportunity Outlook 2024” delivers detailed overview of the biomass boiler market in terms of market segmentation by feedstock type, by product type, by end-user, by application, and by region. The biomass boiler market has been segmented by end-user into residential, commercial and industrial sector, out of which, the commercial sector has dominated the biomass boiler market with largest market share in previous years and is anticipated to continue its dominance over the forecast period which can be attributed to the growing commercial markets while keeping in mind the reduction of carbon footprint. Further, the woody biomass segment is anticipated to expand at a robust growth and gain significant market share due to its constant demand in overall feedstock market. In terms of region, Europe accounted for the highest market share in 2016 and is expected to retain its dominance over the forecast period where U.K and Europe are witnessing the demand for biomass boilers. Stringent government regulations to control greenhouse gas emissions are anticipated to drive the growth of Europe biomass boiler market by the end of 2024. Rising awareness among the population to adopt energy saving solutions for emission control is the major reason behind North America to hold the second largest Biomass Boiler Market after Europe.

The global market of biomass boiler is anticipated to reach market valuation of USD 10.8 Billion by the end of 2024 by expanding at a compound annual growth rate of 17.9% over the period 2017-2024. Rising awareness about the ecological risks and increasing government regulations are some of the major factors that are estimated to benefit the expansion of biomass boiler market with noteworthy revenue over the forecast period.

Download Sample PDF of This Report Here @ https://www.researchnester.com/sample-request-413 Eco-Friendly Energy Generation to Fuel the Market Growth Rise in greenhouse gas emission has led the government agencies of many regions to enforce boiler standards and regulations to promote the use of the biomass energy resources. In addition to that, rising usage of manure as biomass fuel to generate electricity is believed to propel the growth of the biomass boiler market across the globe.

However, large size of boiler as compared to the ordinary ones coupled with lack of awareness regarding biomass boiler are some of the factors to hinder the growth of the biomass boiler market.

Further, for the in-depth analysis, the report encompasses the industry growth drivers, restraints, supply and demand risk, market attractiveness, BPS analysis and Porter’s five force model.

This report also provides the existing competitive scenario of some of the key players of the biomass boilermarket which includes company profiling ofETA Heiztechnik GmbH, Alstom SA, Hurst Boiler & Welding Co., Advanced Recycling Equipment, Baxi Group, JernforsenEnergi System AB, Garioni Naval SpA, Foster Wheeler AG, Ecovision Systems Ltd. and Lambion Energy Solutions GmbH.

The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the biomass boiler market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

About Research Nester Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision so as to avoid future uncertainties.

Contact Us AJ Daniel Email: [email protected] U.S. Phone: [+1 646 586 9123] U.K. Phone: [+44 203 608 591]

0 notes

Photo

Efficient Heating with an Oil Fired Steam Boiler

Thermodyne is a leading manufacturer of industrial steam boilers, hot water generators, and thermic fluid heaters. Their products are designed to provide efficient and reliable heating solutions for a variety of industries, including food and beverage, pharmaceuticals, chemicals, and steam boilers are designed to use a variety of fuels, including oil, gas, and solid fuels like biomass. They offer a range of steam boilers, from small-capacity boilers for process industry applications to large-capacity boilers for power generation. Their hot water generators are designed to provide hot water for industrial processes and heating applications. They are available in both coil-type and shell-type designs and can be customized to meet specific requirements. For more information contact us at https://www.thermodyneboilers.com/oil-fired-boilers/

0 notes

Text

Home Boiler Systems | Solares Energies

Home Boiler Systems | Solares Energies

Are you interested in an Energy Efficient Electric Boiler or Biomass Boiler, or would you like to replace a combi boiler? If yes, then we can help.

youtube

0 notes

Text

#Large Scale Heating Installation#heating and cooling systems#domestic hot water solutions#large scale heating#large-scale heat network#large ground source heat pumps#biomass boilers#heating and hot water solutions#commercial heating and cooling#industrial heating solutions#Clean Renewable Energy#Portsmouth#East Sussex#Essex#Hampshire#Hertfordshire#North Wales#Surrey#West Sussex#Bournemouth#Brighton

0 notes

Note

As a Guy who Fixes Machines for a living, but unfortunately doesn't have Much experience with engines, *but* has read a Ton about them: please tell me about steam engines and/or their Repair Quirks and Logistics. Infodump Away :chinhands:

I'm going to be honest with you - this is one of the most flattering asks I've ever received in my 14+ years on this website.

Steam locomotives seem pretty overwhelming at first because, as you'd expect, there's a lot of moving parts, and they're actually huge. Like many large animals, people often don't realize how big they can actually get until they're in the presence of one. The one I drove, Strasburg #90, weighs in at 212,000 lbs - and she's smaller than a lot of the active steam locomotives operating today. 106 tons is nothing to sneeze at, and she's still considered smaller.

You probably don't need this in layman's terms, but I'm going to try to keep the explanations easy to understand in case anyone who doesn't work with machines reads this.

How do the beasts run?

Continuing the metaphor of these things basically being really large animals, you have to feed and water them. Early steam locomotives ran on wood, but as time went on the most common fuels became coal and oil, and today some can even run clean on vegetable oil or torrefied biomass. The fact that they need to be fed and watered fairly regularly is why there's always at least two people in the locomotive cab - you've got an engineer driving and a fireman keeping the beast fed and monitoring the water levels in the boiler.

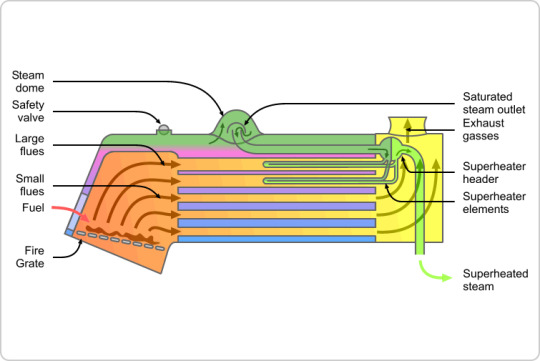

This is a diagram of a fire tube boiler from Wikipedia. Steam locomotives generally use this type of boiler, which gives them their familiar shape. The fuel is thrown into the firebox on the left of the diagram, and the heat from the fire flows up to the tubes in the boiler. The water in the boiler becomes steam (specifically what's called "wet steam" because it's saturated). The steam rises to the highest point in the boiler, the steam dome at the top. From here, the steam is sent down into a superheater, which dries it out and produces superheated steam, and that's what's directed down to the cylinders to get everything moving. The smokestack on the right of the diagram is where the exhaust gasses are released, giving off that plume of smoke everyone expects to see.

Now that the steam is at the cylinders, the pistons can start pumping and moving the driving rods on the driving wheels (the big ones). Here's an animated gif of that process, again from Wikipedia.

At this point, it's basically like any other engine with pistons - the pistons get pumping and the machine starts operating. This whole section of the locomotive is referred to as the running gear, and includes the valve gear, connecting rods, brake gear, wheelsets, axleboxes, and springing.

Essentially, it's a steam engine with wheels that is capable of pulling incredible amounts of weight if everything is done correctly. Your average steam locomotive is still stronger than your average diesel or electric locomotive is. Depending on what you needed your steam locomotive to do, the size of the driving wheels would differ - locomotives built for high speed tend to have really large drive wheels, whilst locomotives designed to go slower but pull more weight have smaller drivers for better adhesion and traction.

Maintenance?

As expected, since they have a lot of moving parts, steam locomotives need a lot of active maintenance. They're checked frequently, have mandated annual inspections, and are required by the Federal Railroad Administration in the United States to have a more thorough inspection every 1,472 days of active service - so it's basically 15 years or 1,472 days of operation, whichever comes first. 90, the locomotive I drove at Strasburg, is currently undergoing her 1,472-day inspection as I write this post and she'll hopefully be back in operation for her 100th birthday next year.

One of the things that's unique about steam locomotive maintenance is that the boiler regularly has to be cleaned out, which is why the boilerplate on the front has hinges - that thing's a door! This job was more dangerous historically because boilers were often insulated with asbestos, but pretty much anything operating today has had any asbestos removed or wasn't built with it in the first place. This website has a really good explanation of the process of cleaning out and fixing up a locomotive boiler for a 1,472 day inspection, complete with photos!

In terms of steam locomotive shops, I'm biased towards Strasburg because I grew up going there all the time, but they really do perform incredible work. Late last year, one of their locomotives, #475, had a run-in with a crane left on the track due to a misthrown switch, and her smokebox took some damage. Fortunately, the damage was minor, and they were able to get her repaired in a mere 96 hours.

She now looks like this:

They opted to braze weld her and didn't smooth it out as a reminder to crews to stay vigilant, so she now has some really cool battle scars.

I'm not as well-versed in repair since I don't have hands-on experience with it (yet), but once I can start volunteering I'll hopefully have some more stuff to talk about since I'm hoping to learn to work with these machines more closely! (And drive. Drive all the time. Drive forever.)

40 notes

·

View notes

Text

1 note

·

View note

Text

Biomass boilers are being integrated into broader energy management systems that optimize energy consumption across multiple sources and loads. These systems use real-time data and analytics to optimize the operation of the biomass boiler based on heat demand, load profiles, and other factors, ensuring efficient energy usage. According to the International Energy Agency (IEA), the growth of renewable capacity is forecast to accelerate in the next five years, accounting for almost 95% of the increase in global power capacity through 2026. All these factors drive the growth of the biomass boiler market forecast in the coming period.

0 notes

Text

Biomass Boiler Market Size, Share and Global Trend By Feedstock (Woody biomass, Forest residue, Agriculture, Biogas & Energy Crop, Urban Residue), By Type (Fully Automated Biomass Boiler, Semi-Automated Biomass Boiler, Combined Heat and Power System), By Application (Heating, Power Generation), By End-user (Residential, Commercial, Industrial), and Geography Forecast till 2022-2029

0 notes

Text

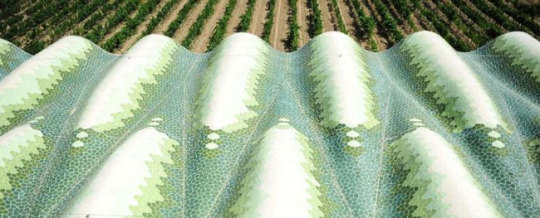

The Mastinell winery (photos 2, 3 and 4) has a hotel where each room is located like a wine bottle stacked up for fermentation (photo 1).

This luxury hotel is located among the vineyards in Penedès, an area of Catalonia known around the world for its protected denomination of origin wine and cava (sparkling wine). The hotel is connected to the winery and focuses on offering plenty of activities related to enotourism (tourism about wine) and 5-star food based on local seasonal products.

The building was designed by the architect Josep Lluís Juanpere and Escamis (GCA Arquitectes) who won the Gold Medal in the 2011 Shanghai International Interior Design Festival. It's a sustainable building with cross ventilation, which reuses rainwater and creates its energy with a biomass boiler.

Photo sources: Shutterstock, Sobremesa, and Catalan wine in a nutshell!.

#vilafranca del penedès#catalunya#arquitectura#wine#enotourism#enology#winery#travel#architecture#modern architecture#boutique hotel#hotel#luxury#penedès#exteriors#interior#interiors#adventure#sustainability#sustainable architecture

74 notes

·

View notes