#Best Sewage Treatment Plants Manufacturer

Explore tagged Tumblr posts

Text

Are you Looking for Sewage Treatment Plant Manufacturing Company in India?

A Sewage Treatment Plant (STP) is a facility designed to clean and purify wastewater, also known as sewage, before it is released back into the environment. Through a series of physical, chemical, and biological processes, STPs remove harmful contaminants, pathogens, and pollutants from sewage, making it safe for discharge into water bodies or reuse for various purposes such as irrigation or industrial processes. STPs play a critical role in protecting public health, preserving water quality, and safeguarding the environment.

Sewage treatment plants offer a multitude of advantages that contribute to public health, environmental protection, and sustainable development.

Advantages of STP (Sewage Treatment Plant)

Protection of Public Health: One of the primary advantages of sewage treatment plants is the protection of public health. By removing harmful pathogens, bacteria, and contaminants from wastewater, these facilities help prevent the spread of waterborne diseases such as cholera, typhoid, and gastroenteritis. Treated effluent can be safely discharged into water bodies or reused without posing significant health risks to humans or animals.

Environmental Protection: Sewage treatment plants play a crucial role in safeguarding the environment by preventing pollution of water bodies. Untreated sewage contains a variety of pollutants, including organic matter, nutrients (such as nitrogen and phosphorus), heavy metals, and toxins. When discharged into rivers, lakes, or oceans, these pollutants can degrade water quality, harm aquatic life, and disrupt ecosystems. Treatment plants remove or reduce these contaminants, minimizing their impact on the environment and preserving natural habitats.

Improvement of Water Quality: By treating wastewater to remove pollutants, sewage treatment plants contribute to the improvement of water quality in receiving waters. Clean water is essential for supporting aquatic ecosystems, recreational activities, and various uses such as irrigation and industrial processes. Treated effluent that meets regulatory standards can be safely discharged into water bodies, enhancing overall water quality and reducing the risk of contamination.

Resource Recovery: Sewage treatment plants facilitate the recovery and reuse of valuable resources from wastewater. For example, the organic matter removed during treatment can be converted into biosolids through processes such as anaerobic digestion or composting. These biosolids can then be used as fertilizer in agriculture, closing the nutrient loop and reducing the need for synthetic fertilizers. Additionally, treated wastewater can be recycled for irrigation, industrial cooling, or even potable water supply through advanced treatment processes like reverse osmosis or ultraviolet disinfection.

Mitigation of Odors and Nuisances: Proper treatment of sewage helps mitigate the unpleasant odors and nuisances associated with untreated wastewater. By removing organic matter and pathogens, treatment plants reduce the risk of foul odors, insect breeding, and aesthetic degradation in surrounding areas. This enhances the quality of life for nearby residents and reduces complaints related to odor pollution.

Compliance with Regulations: Sewage treatment plants ensure compliance with environmental regulations and standards governing wastewater discharge. Regulatory agencies establish limits on pollutant concentrations in effluent to protect water quality and public health. By treating wastewater to meet these standards, treatment plants help industries, municipalities, and communities avoid fines, legal penalties, and reputational damage associated with non-compliance.

In summary, sewage treatment plants offer a wide range of advantages, including protection of public health, environmental preservation, resource recovery, and regulatory compliance. Investing in wastewater treatment infrastructure is essential for promoting sustainable development and ensuring a cleaner, healthier future for generations to come.

Best Sewage Treatment Plants Manufacturer in India

If you are looking for a Sewage Treatment Plants Manufacturer in India, look no further than TR Aqua Private Limited, TR Aqua Private Limited is a leading manufacturer and supplier of Sewage Treatment Plants in India.

For more details, please contact us!

Website — https://www.traqua.in/

Contact No. — +91–9971440474

Email — [email protected]

#Sewage Treatment Plants Manufacturer#Best Sewage Treatment Plants Manufacturer#stp plant#stp plant manufacturer#stp plant manufacturer in India#Sewage Treatment Plant Manufacturer in India#Sewage Treatment Plant supplier#Sewage Treatment Plant supplier in India#tr aqua private limited

1 note

·

View note

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

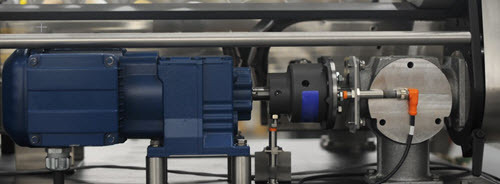

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Are you Looking for STP Plant Manufacturer And Supplier In Chennai?

Ravi Enviro Industries Private Limited is the best STP plant manufacturer in Chennai. We offer effective & reliable STP plants to meet unique needs. Backed with advanced technology, our STP plants are low maintenance, long-term efficient, sustainable & best investment. REIPL is renowned as the finest STP plant manufacturers in Chennai. Contact us to discuss your WTP needs.

#STP plant manufacturers in Chennai#Sewage treatment plant suppliers in Chennai#best STP plant manufacturer in Chennai#STP manufacturers in Chennai#STP plant suppliers in Chennai

0 notes

Text

Reasons For Increasing Demand For Sewage Treatment Plant

The increasing need for proper waste management has led to high demands for sewage treatment plants and their vendors. Thus, more and more sustainable approaches to wastewater management appear essential as urbanization and industrialization processes progress intensively. There can be varying reasons for the growth of demand for the best products that reach you from top Sewage Treatment Plant Vendors.

Here are some main factors that have led to the increasing need for sewage treatment plants.

Urban Expansion and Population Growth

With cities expanding rapidly, the volume of wastewater generated has surged. Municipalities and industries increasingly rely on sewage treatment plant manufacturers to develop efficient systems for treating and recycling wastewater, ensuring public health and environmental safety.

High-Quality Standards for Environment

National governments worldwide are implementing measures to enhance legislation that discourages the pollution of water bodies. These regulations require industries and residential complexes to install sewage treatment plants to comply with wastewater discharge regulations. Working with reliable vendors to provide sewage treatment plants puts compliance and sustainability into perspective.

Water Scarcity and Recycling Needs

Water is a scarce resource all over the world and wastewater recycling was developed as a realistic solution. Sewage treatment systems have remarkable features that facilitate the reinsertion of water through treated Sewage for irrigation, some industrial applications, and recharging of groundwater.

Technological Advancements

The new generation of sewage treatment plants now uses technologies such as membrane bioreactors, UV disinfection, and smart control from the Internet of Things. These innovations enhance efficiency, reduce operation costs, and make wastewater management more attractive to industries and residential areas.

Growing Awareness of Environmental Impact

Recipients and purveyors are beginning to realize their impacts on the natural environment. This increased awareness has prompted people to seek sewage treatment plants in various developments deemed sustainable proactively.

Conclusion

The number of new sewage treatment plants remains high due to the growth in urban centers and the increase in sewage discharge regulation and wastewater recycling. Since GRS Royston has to deal with an important environmental factor in its operations, the company needs to work with a reputable manufacturer to receive the necessary and efficient technology. Well, guess what? These systems are no longer luxuries—they are necessities for a world that wants to be sustainable.

youtube

#sewage water treatment provider#sewage treatment plant provider#sewage treatment plant vendors#sewage treatment plant manufacturer#best sewage treatment plant manufacturers#sewage water treatment manufacturers#Youtube

1 note

·

View note

Text

Cost-Effective Wastewater Solutions: Advantages of Packaged Sewage Treatment Plants

Efficient wastewater management is essential for residential, commercial, and industrial spaces. Packaged sewage treatment plants are compact, self-contained systems designed to treat wastewater effectively. These plants are an excellent choice for areas with limited space or remote locations, offering a simple yet efficient solution to manage sewage and meet environmental compliance standards.

What Are Packaged Sewage Treatment Plants?

A packaged sewage treatment plant is a pre-fabricated system that treats sewage in a single, integrated unit. Unlike traditional systems, these plants require minimal space and are easy to install. With features like modular design and low operational costs, they are gaining popularity in diverse industries. Additionally, Packaged STP systems are highly efficient and can handle varying sewage loads, making them ideal for dynamic requirements.

Advantages of Packaged Sewage Treatment Plants

Compact Design: Their compact size makes them perfect for urban areas or sites with space constraints.

Easy Installation: These systems are delivered pre-assembled and ready for operation, reducing installation time and costs.

Low Maintenance: With advanced technology, packaged sewage treatment plants require minimal supervision and maintenance.

Environmentally Friendly: They treat wastewater to meet regulatory standards, ensuring eco-friendly disposal or reuse of water.

Cost-Effective: These systems provide a long-term solution with lower investment and operational costs compared to traditional setups.

Applications of Packaged Sewage Treatment Plants

Residential complexes

Hotels and resorts

Industrial facilities

Hospitals and schools

By investing in Packaged STP, businesses and communities can ensure sustainable wastewater management while reducing environmental impact. Whether it’s treating wastewater from a small residential area or a large industrial setup, packaged sewage treatment plants are versatile and highly reliable solutions. Embracing packaged sewage treatment plants is a step toward efficient and eco-friendly wastewater management, helping communities and industries meet their sustainability goals.

#domestic sewage treatment plant#Top STP Manufacturer#Sewage treatment plant manufacurer#best sewage treatment plant

0 notes

Text

#sewage treatment plant manufacturer#sewage treatment plant manufacturers in india#stp plant manufacturer#sewage treatment plant manufacturer in delhi#best sewage treatment plant manufacturer

0 notes

Text

#stp plant#best stp plant manufacturer#stp plant manufacturer in India#Best STP plant manufacturer in India#STP plant manufacturer in Ghaziabad#sewage treatment plant manufacturer in Ghaziabad#Best STP plant manufacturer in Ghaziabad

1 note

·

View note

Text

Water Treatment plant manufacturer in India

#water treatment plant#sewage treatment plant#water treatment#mineral water plant#water treatment plant manufacturer in india#water treatment plants#water treatment plant manufacturer in kolkata#water treatment plant manufacturer in west bengal#effluent treatment plant manufacturer in india#wastewater treatment plant manufacturers in india#wastewater treatment plant#packaged drinking water plant#best effluent treatment plant manufacturers in india

1 note

·

View note

Text

#We are best manufacturer and Service Provider of ETP & STP Equipment#Bio Gas | Water | Sewage | Wastewater Treatment Plant#Industrial | Solid Waste Management Services in Pune#Maharashtra#India

0 notes

Text

Commonly Asked Questions About Activated Carbon Filter

Looking for information on activated carbon filters? Check out our commonly asked questions blog post! Learn about how activated carbon filters work and what they can remove from your water.

#Activated carbon filters#best activated carbon filter#activated carbon filter solutions#sewage treatment plants#activated carbon filter manufacturers

0 notes

Text

What are the Advantages of SBR STP Plants?

Advantages of SBR STP Plants:

1. Flexibility and Efficiency

Adaptive Capacity: SBR plants can handle varying inflow rates and loads effectively due to their batch processing nature.

High Treatment Efficiency: They achieve high removal rates for organic matter, nutrients (like nitrogen and phosphorus), and pathogens, meeting stringent environmental standards.

2. Space and Cost Savings

Compact Design: SBR systems can be designed to fit into smaller spaces compared to traditional continuous flow systems, making them suitable for urban and space-constrained environments.

Operational Cost Savings: They often require lower energy inputs and chemical usage, contributing to overall cost savings over the plant’s lifecycle.

3. Operational Control and Automation

Controlled Process: SBR plants can be automated to a high degree, allowing for precise control over treatment parameters and optimizing resource utilization.

Monitoring and Optimization: Advanced sensors and control systems can monitor water quality parameters in real-time, ensuring consistent performance.

4. Environmental Sustainability

Reduced Footprint: By efficiently treating wastewater, SBR STP plants contribute to reducing pollution in water bodies and safeguarding public health.

Reuse Potential: Treated effluent from SBR plants can often be reused for non-potable purposes like irrigation, industrial processes, or groundwater recharge, conserving freshwater resources.

The SBR process is a form of activated sludge treatment where sewage is treated in batches rather than continuously. This sequential approach allows for greater control over the treatment process and can adapt to fluctuations in influent flow and composition. Here’s how it typically works:

Sequential Process: The treatment cycle in an SBR plant consists of sequential phases such as filling, reacting, settling, and decanting. Each phase is carefully timed and managed to optimize treatment efficiency.

Biological Treatment: During the reacting phase, microorganisms break down organic matter in the sewage, reducing pollutants and contaminants through biological processes. This step is crucial for achieving high-quality effluent standards.

Settling and Decanting: After the reaction phase, the mixture settles, allowing the solid waste (sludge) to settle to the bottom. The clarified water (effluent) is then decanted from the top, ready for further treatment or discharge.

Applications and Future Prospects

SBR STP plants are widely applicable across various sectors, including residential complexes, commercial buildings, industrial facilities, and municipalities. As environmental regulations become stricter worldwide, there is a growing demand for advanced wastewater treatment technologies like SBR to ensure compliance and sustainability.

Looking forward, ongoing research and development aim to further enhance the efficiency, scalability, and cost-effectiveness of SBR technology. Innovations in sensor technology, automation, and biological treatment processes promise to make SBR STP plants even more robust and adaptable to future challenges.

Conclusion

In conclusion, SBR STP plants represent a significant advancement in wastewater treatment technology, offering a sustainable and efficient solution for managing sewage and industrial effluents. With their ability to provide high-quality treated water, operational flexibility, and environmental benefits, SBR STP plants are poised to play a crucial role in shaping the future of water management and conservation.

Contact Information:

For inquiries or to explore TR AQUA Private Limited’s range of SBR STP Plants, interested parties can reach out through the following channels:

Call: +91–9971440474

Email: [email protected]

Address: A-171, Dilshad Colony, Delhi-110095, India

#sewage treatment plant manufacturer#sbr stp plant#sbr stp plant manufacturer in India#sbr stp plant supplier in India#Best sbr stp plant manufacturer in India#Top sbr stp plant manufacturer in India

0 notes

Text

Best Manufacturers of Water Treatment Systems in India

Introduction:

In the realm of water treatment plant manufacturing, the success of any project hinges not only on advanced technology and equipment but also on an efficient and competent workforce. Staffing plays a crucial role in ensuring the smooth operation, quality control, and overall productivity of water treatment plants in India, a country grappling with water scarcity and pollution challenges, water treatment plant manufacturers face unique staffing considerations. This blog aims to explore the key aspects of staffing for water treatment plant manufacturers in India, with a specific focus on the keyword Water Treatment Plant Manufacturers in India.

Understanding the Workforce Requirements:

Manufacturing water treatment plants requires a diverse range of skills and expertise. While some positions may be specialized, others demand a broader skill set. As a water treatment plant manufacturer in India, it is essential to identify the specific roles and responsibilities required in your organization. These may include design engineers, project managers, technicians, operators, quality control specialists, and administrative staff.

Recruitment Strategies:

To attract and hire talented professionals in the water treatment industry, it is crucial to implement effective recruitment strategies. Here are a few tips:

a. Online Presence: Build a strong online presence through a professional website and social media platforms. Highlight your organization's values, projects, and career opportunities to engage potential candidates.

b. Industry Networks: Leverage industry-specific networks, forums, and job portals to connect with experienced professionals in water treatment plant manufacturing.

c. Collaborate with Educational Institutions: Establish partnerships with technical and engineering institutes to tap into fresh talent and create internship programs that provide hands-on experience.

d. Referrals: Encourage your existing employees to refer qualified candidates. Offering incentives can boost employee engagement in the recruitment process.

Training and Skill Development:

Given the specialized nature of water treatment plant manufacturing, providing ongoing training and skill development programs is crucial. Invest in training initiatives that enhance the technical knowledge and expertise of your workforce. Stay updated with the latest advancements in water treatment technologies and encourage employees to participate in relevant workshops, seminars, and certifications.

Compliance with Regulations and Standards:

Water treatment plant manufacturers in India must comply with various regulations and standards set by governmental bodies and environmental agencies. Ensure your staff members are well-versed in these regulations and provide them with the necessary training to maintain compliance. Emphasize the importance of safety protocols and the responsible handling of chemicals and hazardous substances.

Retention and Employee Satisfaction:

Retaining skilled employees is vital for the long-term success of your organization. Foster a positive work culture by promoting open communication, recognizing employee achievements, and providing growth opportunities. Offer competitive compensation packages, benefits, and incentives to attract and retain top talent in the water treatment industry.

Conclusion:

Staffing is a critical aspect of water treatment plant manufacturing in India. By understanding the specific workforce requirements, implementing effective recruitment strategies, providing continuous training, ensuring compliance, and focusing on employee retention, water treatment plant manufacturers can build a skilled and dedicated workforce capable of delivering high-quality products and services. As the demand for water treatment solutions continues to grow in India, investing in staffing considerations will undoubtedly contribute to the success and sustainability of your organization in the long run.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Water Treatment Companies in India#Best Water Treatment Companies

1 note

·

View note

Text

Are You Searching for STP Plant Manufacturer And Supplier In Bangalore?

If you are looking for Sewage treatment plant suppliers in Bangalore for your unique wastewater treatment requirements, Ravi Enviro Industries Private Limited has got you covered! Our expertise in STP plants to treat specific Sewage positions us as the best STP plant manufacturer in Bangalore.

#STP plant manufacturers in Bangalore#Sewage treatment plant suppliers in Bangalore#best STP plant manufacturer in Bangalore#STP manufacturers in Bangalore#STP plant suppliers in Bangalore

0 notes

Text

4 Things You Must Check When Finding A Sewage Water Treatment Provider!

Choosing the right treatment provider for sewage water is paramount to effectively and sustainably managing wastewater. Maintaining a decent sewage is a priority for everyone. Here, obtaining the best materials for sewage water treatment becomes essential. You must look for the services of the best Sewage Water Treatment Provider that manufactures and supplies the finest tools and equipment.

When you look for the best Sewage Treatment Plant Provider, you must be very watchful to find out the strengths of the top Sewage Treatment Plant Provider. Here are a few of the things you must check!

Experience and Expertise:

Check how much experience the provider has in the industry and expertise in the sewage water treatment field. Select a sewer water treatment provider with experience in undertaking various projects for sewage treatment. A proficient service provider will know exactly what to do in designing efficient treatment solutions according to your needs.

Compliance with Regulations:

Regulatory compliance is essential for any sewage treatment plant provider. Ensure that the provider adheres to local, state, and national regulations regarding wastewater treatment. Compliance guarantees that the treatment processes meet environmental standards and helps avoid legal complications. Ask the provider for certifications and references to verify their adherence to regulatory requirements.

Technological Developments:

Technological advancements have greatly improved the sewage treatment process. When choosing a sewage treatment plant, consider whether it offers the latest technologies and innovations. Modern technology, including advanced filtration methods, automated monitoring systems, and others, has improved sewage treatment efficiency and effectiveness and resulted in better environmental impacts.

Support and Service of the Customer:

Efficient customer support is important when dealing with sewage treatment systems. Assess the service provider of the customer service in responsiveness, availability, and seriousness to answer questions and resolve their issues. A good sewage water treatment provider should provide consistent maintenance, timely troubleshooting for your treatment plant, as well as extensive support throughout its use.

In a nutshell, getting the right sewage water treatment company requires checking on their experience, regulatory compliance, new technologies, and customer service. You will be ensuring that your sewage treatment will be carried out efficiently and effectively in the long run. If you invest in a respectable sewage treatment plant provider, you will be able to maintain environmental standards and continue with long-term solutions for wastewater management.

youtube

#sewage water treatment provider#sewage treatment plant provider#sewage treatment plant vendors#sewage treatment plant manufacturer#best sewage treatment plant manufacturers#sewage water treatment manufacturers#Youtube

0 notes

Text

Netsol Water: Leader in Sewage Treatment Plant Manufacturers in Delhi

Water pollution is turning into a global crisis, as industries and urban centers produce massive amounts of wastewater each day. In populous areas like Delhi, the challenge of an effective sewage treatment has never come at such a crucial juncture. Netsol Water is one of the best Sewage Treatment Plant Manufacturers in Delhi, providing best solutions for waste waste management.

Untreated water is one of the major threats to public health, ecosystems, and the environment. It ruins the freshness of fresh-water sources, poses a threat to aquatic life and may unleash a waterborne diseases upsurge. And so comes companies like Netsol Water, breathing hope and practical solutions.

Netsol Water: A Brief Overview

With a mission to come out strongly with this vision in solving the needs of India pertaining to water treatment, Netsol Water has picked up the pace in this multiple-choice game-like environment of Delhi. The firm offers systems for designing, manufacturing, and installing the most sewage treatment plants (STPs) specifically designed according to the diversified needs of various industries.

What's special about Netsol Water?

Customized Solutions: Netsol Water knows that no two places are alike when it comes to sewage treatment. They thus ensure that solutions put in place specifically target the problem at hand and also meet the local regulatory compliances, based on their work with clients.

Latest Technology: By being on the forefront of water treatment technology, Netsol Water ensures efficiency, cost-effectiveness, and environmental friendliness of plants.

Comprehensive Services: Netsol Water offers complete services right from consultancy to installation and then next-line maintenance, thus making it a one-stop shop for all types of sewage treatment requirements.

Commitment towards Sustainability: Netsol Water doesn't treat water; it does water management sustainably with industries.

Science behind Netsol Water's Sewage Treatment Plants

Need of the Multistage Process Netsol Water STPs efficiently employ a multi-stage process so that polluted wastewater becomes usable clean water. A basic description of how such plants function would include the following:

Preliminary Treatment: It removes big debris and waste by screening and grit removal.

Primary Treatment: Sedimentation tanks allow suspended solids to settle, thereby reducing the overall pollutant load.

Secondary Treatment: Organic matter is broken down through biological processes that work through activated sludge or other microorganisms.

Tertiary Treatment: Final filtration and disinfection take away any remaining impurities and pathogens.

Sludge Management: Byproducts from the treatment process are managed safely and are frequently reused for beneficial purposes.

This multi-stage approach ensures that the water leaving Netsol Water's STPs meets or exceeds regulation standards; such water can be safely discharged or reused.

Netsol Water Changing Industries

Netsol Water caters to the diversified sectors, so its versatility can be seen in the diversified sectors that it caters to. Some of these sectors are as follows:

Textile and Dye Industries: Wastewater produced by this section of industries is heavily polluted. So they easily require the specialist treatment solutions of Netsol Water.

Pharmaceutical Companies: Sewage produced from drug manufacturing should be handled with care. To this, Netsol Water provides precision.

Food and Beverage Producers: From dairy plants to breweries, Netsol Water helps these businesses handle their organic-rich wastewater effectively.

Chemical Sector: Netsol Water's advanced technologies overcome the intricate chemical Sewages.

Automotive Industry: Netsol Water provides the automotive manufacturing and servicing industries with overall wastewater treatment solutions.

Environmental Impact of Netsol Water Delhi

Being one of the top Sewage Treatment Plant Manufacturer in Delhi, Netsol Water has been significantly contributing towards Delhi's environment. With effective wastewater treatment solutions, Netsol Water is assisting in all the ways:

Clean up pollution in the Yamuna River, which is Delhi's primary source of water

Reduce contamination and consequently boost the quality of groundwater

Improve public health by reducing probable waterborne diseases

Support the sustainable goals for the development of Delhi

Innovations and Future Outlook

Netsol Water does not boast of resting on its oars. The company keeps abreast of emerging challenges in water treatment with continuous innovations. A few areas of focus are:

Energy Efficiency: Developing treatment processes that consume less energy, thereby reducing the carbon footprint of STPs.

Water Reuse Technologies: Enhanced techniques to make treated water suitable for various industrial and agriculture applications.

Smart Monitoring Systems: Implementing IoT-based solutions for real-time monitoring and optimization of treatment plants.

Modular Designs: Creating scalable modular designs of STPs which can easily expand or change as and when the need arises.

Why Netsol Water?

For the sewage treatment requirements of any business firm at Delhi, Netsol Water offers:

Specialized Consultation: Professional experts to calculate exact requirements.

Tailor-made Design: Space-suitable, budget-suitable, and requirement-suitable STPs.

Installation Process: No Disruption in Its Services.

Comprehensive Training: Your manpower operates and maintains the STP

Ongoing Support: Maintenance and Troubleshooting services are provided to ensure the continuity of the plant.

Conclusion: A Greener Future with Netsol Water

In the middle of the ongoing rapid growth phase of the city, Delhi cannot afford to have anything short of industry-level wastewater management. Netsol Water stands at the forefront of this critical industry: With innovative, reliable, and sustainable solutions for sewage treatment. Netsol Water is top on Sewage Treatment Plant Manufacturer in Delhi, offering solutions for waste waster.

Therefore, by opting for Netsol Water, a Delhi based company would be abiding by the rules of the land while creating an environment for the generations to come that will be cleaner and healthier. And with such companies like Netsol Water, we do have hope for the future because the right technology combined with the right commitment can significantly assist in conquering the obstacles presented in front of us by water pollution and creating a more sustainable world.

Whether a small businessman or industrial giant, if you are based in Delhi and battling against wastewater issues, there is hope for you, perhaps in the form of Netsol Water, transforming those battles into opportunities for environmental stewardship.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#sewage#stp#stps#delhi

3 notes

·

View notes