#Best ERP software for Pharma industry

Explore tagged Tumblr posts

Text

Discover the Future of Pharma with Zillancer’s ERP Solutions

Zillancer brings you specialized Pharma ERP solutions that transform your business by optimizing supply chains, enhancing productivity, and ensuring regulatory compliance. Let us guide your pharmaceutical company to new heights of efficiency and innovation.

#Pharmaceutical ERP#Pharma ERP Solution#ERP Pharma Software#ERP Software Pharma#ERP for Pharma Industry#ERP for Pharmaceuticals#ERP for Pharma Companies#Pharmaceutical ERP Solution#ERP for Pharmaceutical Industry#ERP Software for Pharma#Pharmaceutical ERP Systems#Best Pharma ERP Software#Pharmaceutical ERP Software#ERP System for Pharma Company#ERP Software for Pharma Industry#Pharmaceutical Manufacturing ERP#ERP for Pharmaceutical Companies#ERP Solution for Pharmaceutical Industry#ERP Systems for Pharmaceutical Manufacturing

0 notes

Text

Why is ERP important for the pharmaceutical industry?

In an era where precision, efficiency, and compliance drive success, the pharmaceutical industry faces unique challenges. From stringent regulatory requirements to managing complex supply chains, the need for streamlined operations is more critical than ever. This is where ERP solutions for the pharmaceutical industry in Mumbai and across India play a pivotal role, transforming the way businesses operate and ensuring they remain competitive.

What Is a Pharmaceutical ERP System?

A Pharmaceutical ERP system is a comprehensive software solution designed specifically to meet the needs of the pharmaceutical sector. It integrates various business processes such as production planning, inventory management, quality control, regulatory compliance, and sales into a single platform. By centralizing data, the system offers real-time visibility and control over operations, ensuring that pharmaceutical companies can efficiently manage their resources and maintain compliance with industry regulations.

Challenges in the Pharma Industry

The pharmaceutical industry encounters numerous challenges that can hinder operational efficiency and profitability. Here are some of the key challenges:

Stringent Regulatory Compliance: Adhering to local and international regulations, such as GMP (Good Manufacturing Practices) and FDA guidelines, is essential but complex. Non-compliance can lead to significant penalties and reputational damage.

Inventory Management: Maintaining an optimal inventory of raw materials and finished products is challenging, especially given the perishable nature of many pharmaceutical goods.

Quality Assurance: Ensuring the quality of products at every stage of the production process is crucial. Any deviation can result in recalls and financial losses.

Supply Chain Complexity: Managing a multi-tiered supply chain, including procurement, manufacturing, and distribution, requires robust coordination and real-time visibility.

Data Accuracy and Security: Handling sensitive data like clinical trial results and patient information demands a secure and reliable system.

The Role of the Best Pharmaceutical ERP Solutions Provider in India

To overcome these challenges, partnering with the best ERP software for businesses in Mumbai and India becomes essential. Here’s how these solutions can help:

Industry-Specific Expertise: They understand the unique challenges and regulatory requirements of the pharmaceutical industry.

Customized Solutions: They can tailor ERP systems to meet the specific needs of individual pharmaceutical companies.

Implementation and Support: They provide comprehensive implementation services, training, and ongoing support.

For pharmaceutical companies in India, partnering with a local provider can offer several advantages, including better understanding of local regulations and market dynamics. For businesses looking for ERP solutions in the region, there are many providers offering ERP solutions for the pharmaceutical industry in Mumbai and ERP solutions for pharmaceutical companies in India. It's essential to research and select a provider with a proven track record and expertise in the pharmaceutical sector. For businesses looking for general solutions, there are also options for Best ERP software for businesses in Mumbai.

By implementing a robust pharmaceutical ERP system, companies can streamline operations, improve compliance, enhance quality control, and gain a competitive edge in the market.

Why Choose ERP Solutions for Pharmaceutical Companies in India?

Implementing ERP solutions for pharmaceutical companies in India offers numerous benefits. It not only helps businesses stay compliant and efficient but also provides a competitive edge. For companies based in Mumbai, leveraging the best ERP software for businesses in Mumbai ensures tailored solutions that address local and global challenges effectively.

In conclusion, ERP systems are indispensable for the pharmaceutical industry, offering the tools needed to tackle its unique challenges. By choosing the right ERP solutions provider, pharmaceutical companies can optimize their operations, ensure compliance, and drive sustainable growth.

0 notes

Text

pharma erp software

CBO ERP Limited is proud to introduce the Control Business Online Software to pharmaceutical companies. It is the fastest and most efficient way to manage each and every aspect of your business. The Pharma Manufacturing ERP Software uses an easy to understand interface so that many will be able to use it with minimal training. The six modules that our product can help pharmaceutical companies manage are manufacturing, distribution, finance, online net reporting, mobile & tablet as well as Online HR payroll.

0 notes

Text

Erp for pharma industry: For Enhancing Efficiency and Smoothening Operations

With increasing costs and the burden of dealing with patients' information, pharmaceutical manufacturers are always on the lookout for different ways to be efficient. One such solution that is nowadays adopted more and more is best erp for pharmaceutical industry.

Enterprise Resource Planning has multi-dimensional roles for pharmaceutical operations. In real practice, pharma ERP software is a suite of integrated applications delivered as software service, which helps centralize and integrate data coming from business processes that entail manufacturing, vendor cost management, accounting systems, supply chain visibility, raw material management, procurement, inventory management, and compliance management pharma erp.

In a pharmaceutical company talking about Mej ERP AI is provide best pharmaceutical services for all users so i suggest you please freely register Mej ERP AI, an ERP system controls all critical functions and delicate operations of manufacturing drugs. They optimize manufacturing right from the pre-formulation management to raw materials and formulation. A well-designed ERP can also handle clinical trial arrangements, expiry management, batch tracking, and quality assurance while ensuring stringent regulations are followed across countries. ERP systems break down data silos, enhance data accessibility, improve patient care, streamline operations, and reduce costs erp for pharma industry.

ERP Replacement Drives Growth

A biopharm company that anticipated fast growth needed a new ERP system for optimized management. Ultra Consultants helped find a solution tailored to meet the requirements of an ERP.

What is ERP, and how does it work in Pharmaceutical Companies?

The erp for pharmaceutical serves as the glue binding together data from various departments within the pharma company, helping to make better decisions and to integrate information. The ERP system of a pharmaceutical or medical device company will give a broad view of production, quality management, administrative processes, and financial management.

It is observed that most pharmaceutical companies' information systems are partitioned into specialized subsystems with no interoperable capability. It creates complexity, inefficiencies, and increased costs. In answer to these challenges, the pharma erp software bestows one umbrella under which all data and relevant processes are integrated with seamless operations, added collaboration, and improvisation to the patient.

Challenges in Pharmaceutical Industry

There are several factors pharmaceutical erp software that hamper the productivity and growth of the pharmaceutical manufacturing sector. Some of these are mentioned below:

Changing Government Regulations

Government regulations in the software for pharma industry are dynamic. Compliance is essential to the safety of products, market access, and the safety of consumers. Among the drug and healthcare reforms to the quality standards and practices at an international level, the regulatory environments of pharma companies in operation are faced with a lot of complexities. There is a danger of losing products in the market, regulatory actions, fines, and reputational damage to companies in case they do not comply.

Supply Chain Disruptions

The erp software for pharmaceutical industry chain is very complex with numerous suppliers and distributors. Disruption of such supply chains has great effects on the health of patients, public trust, and business performance. Companies must be able to manage a plethora of uncertainties, from the supply of raw materials and transportation challenges to unplanned events—be it natural disasters or pandemics. Coordination and visibility are both key.

Quality Control

Quality control in the pharmaceutical industry is very stringent. It additionally expects manufacturers to achieve robust standards so that products can ensure safety, efficacy, and compliance. Involving extensive testing, inspections, and documentation, quality control could become very hard to handle through manual operation or by using an old system.

Inventory Management

Pharma companies handle inventory items in many diverse kinds with special storage and handling requirements. Effective inventory control or management will thus ensure that the inconvenience of stockouts is avoided, waste is reduced to a minimum, and delivery time is within schedule. On the other hand, manual inventory processes are time-consuming, prone to error, and inefficient, increasing costs and causing operational problems.

Shortage of Skilled Labor

The pharmaceutical industry requires a highly skilled workforce to drive innovation, compliance, and great product quality. Therefore, there is an acute shortage of skilled labor, making it difficult to attract and retain the best talent. Manufacturers have to invest in training and human resource optimization to maximize output.

How ERP Software Helps Pharma Companies Overcome Challenges

Such pharmaceutical manufacturing software can help companies overcome these challenges and optimize their operations. Here's how ERP software can help your pharma company:

Regulatory Compliance Management

The ERP system offers a single platform to deal with and monitor regulatory compliance. Besides, it automatically looks after adherence to quality standards, traces the changing landscape of regulatory requirements, and ensures easy documentation and reporting. ERP software automates the compliance process and diminishes the risk of non-compliance, making auditing easier and less time-consuming.

Efficient Inventory Management.

A pharma ERP system automatically simplifies inventory management, as it gives visibility in real time regarding stock level, expiration, and batch number. It allows one to forecast demand accurately and automatically replenish while optimizing storage and distribution. Generally, ERP software results in very few outages of stock, low carrying cost, and improved total inventory control.

An ERP system in pharmaceutical manufacturing integrates various functions and processes like formulation management, production planning, and quality control. This eliminates manual activities and provides errorless outputs, thereby enhancing the efficiency of operations. The manufacturing capabilities are tuned well, to optimize and scale, and efficiently handle the productions needs using the ERP software system.

Improved Quality Control

An ERP system is, therefore, of great importance in quality control by capturing and analyzing data at every stage of the manufacturing process. This will involve real-time monitoring of quality parameters, automation of quality control processes, and deviation management.ERP software assists in maintaining detailed and accurate records of quality as well as tracking nonconformities through maintianace of compliance in that dimension.

Optimal Supply chain management

A good ERP system offers visibility and control across the pharmaceutical chain, making procurement, inventory, order fulfillment, and real-time collaboration with the suppliers and distributors efficient. On top of that, it facilitates track-and-trace features that optimize procurement, makes demands better, and improves tracing of both forward and backward goods. Financial Management and Cost Control

An enterprise resource planning system assimilates and streamlines financial data while automating the accounting process. It thereby accurately generates each and every report. It allows for the best financial planning, computation, and budgeting. Consequently, it results in informed decision-making and effective control over costs. The ERP system optimizes the financial management process, including improving accounts payables, better availing of receivables, and improving general financial effectiveness.

Benefits of ERP Software to the Pharma Industry

Here are a few benefits that are brought to the industry by pharma ERP software:

Effective Inventory Management

Phama ERP software ensures real-time inventory tracking, optimal stock levels, and reduced wastage or stockouts. The software provides greater traceability for the manufacturer to monitor batches, track raw materials, and guarantee compliance with regulatory bodies. This is, in fact, the visibility that can greatly reduce the potential risks of recall of a product and enhance the inventory management function.

Pharma ERP software provides automated solutions helping the company meet the regulations. It measures, tracks documentation, and supports audits. By using the ERP, companies

can assure their way through the complex maze of regulations confidently.

Streamlined Manufacturing

ERPs streamlined manufacturing, which lets the division become more operationally efficient, minimizing errors and removing production rocks. It gives efficient, optimal production capabilities and forecasts scalability and has control over uncertainties with the supply chain.

Better Quality management

ERP software incorporates quality control processes, thus boosting product traceability and thus minimizing errors, and ensuring good product consistency. ERP software supports the tracking of compliance; this will quickly manage non-compliances and keeps up very detailed records.

Better Financial Management

The ERP software consolidates financial data as it automatically keeps an operational account system and generates robust financial reporting in real-time. It eliminates manual data entry and reconciliation which was prone to error and slow.

This enhances financial planning, cost analysis and budgeting mainly because of the reports easily available

Optimal Supply Chain Management

The ERP software must be embedded with end-to-end visibility and control from the supply chain, for procurement to inventory management and order fulfillment. It further helps the firm in demand forecasting, reducing lead time and enhancing efficiency in the supply chain.

Different types of ERP Systems for Pharma Companies

There are different available types and features of the on-premise ERP systems for the pharma companies in the marketplace:

On-Premise ERP Systems

On-Premise ERP Systems: Installed and maintained at the user firm's physical location, this provides the user full control over both the data and infrastructure. Suitable for big companies, including those that employ their own IT team. Cloud-Based ERP Systems: Usually hosted on the third-party vendor's infrastructure, which provides more flexibility, scalability, and is even cheaper than the on-premise ones mentioned earlier. These are fit for small to mid-range businesses searching for ease of quick installation and non-complicated access to data. Hybrid ERP Systems: These combine on-premise and cloud capabilities in order to give the user the flexibility of on-premise customization with the.

Execution of ERP software in a pharmaceutical industry

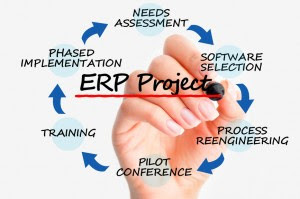

Execution of the ERP software requires a lot of planning, customization, and in the handling of change. Important steps involved are thus:

Business needs evaluation

To determine a point of pain, specific to be addressed and functions to be included in the ERP system.

Select the right pharma ERP solution

Choose an ERP that fulfills the needs specific to the pharmaceutical industry.

Customize and configure the ERP

Tailor the ERP in close collaboration with the vendor of ERP.

Data migration and training

Plan data migration and provide appropriate training to your employees in a more comprehensive way.

Change Management

Execute proper change management policy for a smooth transition.

Continuous Improvement

Keep updating and fine-tuning the ERP system regularly to churn at their best.

Conclusion

The pharmaceutical industry is changing tremendously with growing complexities, changing regulations, and customer demands. An ERP system can help your company meet and streamline operations in dealing with needs. A pharma ERP solution will help to streamline inventory management, compliance with the regulatory body, and improve the quality of controlled products and states in the supply chain. All this can make your business operationally excellent, productive, and delivering quality medications and medical devices around the world.

0 notes

Text

AARTI Pharmalabs Job Vacancies in Vapi, Gujarat: Opportunities for Pharma Professionals Best Opportunity for Pharma Professionals at RAARTI Pharmalabs RAARTI Pharmalabs is offering exciting career opportunities for pharma professionals at its facility in Vapi, Gujarat. We are currently hiring for various roles in engineering stores, quality assurance, quality control, process engineering, and production. Read on for detailed job descriptions and qualifications. Open Positions 1. Sr. Executive - Engineering Stores Qualification: Any Graduate + Diploma / MBA in Material Management or SCM Experience: 1-6 years, preferably in API / Intermediates, Bulk Drug Industry Location: Vapi, Gujarat Responsibilities: Maintain minimum and maximum engineering stock levels. Keep accurate records of all engineering material transactions. Coordinate with the Purchase Department and vendors to ensure timely availability of engineering items. Prepare MIS for engineering stores functions, including aging reports, stock reports, and WBS cost reports. Utilize SAP software for stores functions, particularly the MM Module or similar ERP systems. Prepare material issue entries, PR/POs for engineering material movements within and outside the plant. Conduct periodic stock taking and manage stock audits. Prepare RGP and NRGP for various engineering goods and maintain registers. Operate and maintain spare storage systems effectively. Ensure timely closure of engineering invoices with the accounts department. Prepare Capex, Opex, and service POs as needed. Maintain inventory records, process material orders, and handle receiving, inspecting, and storing supplies. Coordinate with other departments to ensure smooth store functions. 2. Sr. Executive / Executive - Quality Assurance (QA) Qualification: M.Sc. in Chemistry Experience: 4-7 years, preferably in API / Intermediates, Bulk Drug Industry Location: Vapi, Gujarat Responsibilities: Issue quality system-related documents, such as batch production records, analytical records, SOPs, logbooks, and formats. Prepare and update lists of equipment, instruments, and quality system documents. Coordinate with production and quality control for validations. Review quality system-related documents. Store compiled/filled documents and update relevant registers. Prepare Continuous Process Verification Reports and Annual Product Quality Reviews. Conduct IPQA rounds to ensure GMP compliance. 3. Sr. Executive / Executive - Quality Control (QC) Qualification: B.Sc. / M.Sc. in Chemistry or B.Pharm Experience: 4-8 years, preferably in API / Intermediates, Bulk Drug Industry Location: Vapi, Gujarat Responsibilities: Work in HPLC / GC sections with a minimum of 2-3 years of experience. Knowledge of Good Laboratory Practices (GLP) and handling QMS elements like incidents, OOS, and Out of Calibration. Experience with Chromeleon Software is an added advantage. 4. Sr. Executive / Executive - Process Engineering Qualification: BE/B.Tech in Chemical Engineering Experience: 1-6 years, preferably in API / Intermediates, Bulk Drug Industry Location: Vapi, Gujarat Responsibilities: Provide technical support for process optimization, batch cycle time reduction, product yield improvement, capacity constraint analysis, solvent recovery, and energy-saving initiatives. Monitor and optimize production costs and minimize losses. Focus on capacity enhancement, process improvement, and solvent recovery. Conduct basic and detailed engineering activities like energy and mass balance, PFD, P&ID, equipment sizing, and project management. Introduce new technologies aligned with best manufacturing practices. Calculate heat and mass balance and utility requirements for processes. Compile experimental observations for tech transfer reports. Execute and validate new processes by working closely with R&D, production, and other cross-functional teams. Plan and execute process engineering initiatives and validate batches for existing products.

5. Sr. Executive / Executive - Production Qualification: BE/B.Tech in Chemical Engineering or M.Sc. in Chemistry Experience: 1-6 years, preferably in API / Intermediates, Bulk Drug Industry Location: Vapi, Gujarat Responsibilities: Ensure timely production according to the production plan. Understand and execute real-time multi-product processes efficiently. Handle online BMR/BPR filling, distillation processes, and various equipment. Train assistants on handling hazardous chemicals. Execute unit operations and processes while coordinating with engineering, QA/QC, warehouse, and EHS teams. Maintain cGMP standards and manage online documentation. Ensure awareness of HAZOP, PSSR, near-miss reporting, and unsafe acts/conditions. Minimize deviations and handle change control and DMS software. Maintain neat and clean working areas. Improve solvent recovery, reduce cycle time, and increase yield output. How to Apply All interested candidates can apply by sending their resumes to [email protected] or calling +91-9075017122. Company Address: RAARTI Pharmalabs Plot No. C-22/1 & 2, Phase-1, GIDC, Vapi, Dist. Valsad, Gujarat 396195 [caption id="attachment_62019" align="aligncenter" width="930"] Aarti pharmalabs Recruitment Drive[/caption]

0 notes

Text

How SAP Business One is beneficial for the Pharma Industry in the healthcare sector

The pharmaceutical industry is a vital player in the healthcare sector, which keeps millions around the world in good shape. As medical science and technology keep evolving at a breakneck pace, the need for effective management solutions within the pharmaceutical sector is increasing. These circumstances have helped new specialized software, such as SAP Business One, to win another niche. This ERP offers a range of solutions specifically adapted to the needs of the healthcare industry.

The pharmaceutical industry includes various activities, ranging from drug development to production and release to the public. As of 2020. The global strategic report projects that the global market value was $1.2 trillion and is forecasted to grow at about 6% CAGR in 2021-2026.

Pain Points of the Pharma Industry:

Despite the importance of the healthcare industry, it faces numerous challenges which undermine its performance. Thus, the industry’s main pain points include the following:

Regulatory compliance: The pharmaceutical industry is subject to numerous regulatory requirements, which results in cumbersome compliance.

Supply chain management: The pharmaceutical supply chain is complex and involves multiple stakeholders and steps. As a result, the optimal level of efficiency is rarely achieved.

Inventory management: Ensuring the right level of inventory that would not compromise product quality and would be sufficient to comply with expiration dates remains a persistent issue.

Data hiring management: The range of information pharmaceutical companies work with is wide, and patient information and clinical test results and regulatory documents should be in its successful form.

SAP Business One ERP implementation ways to benefit pharma industry:

SAP Business One’s robust yet seemingly all-encompassing response to the issues with which the pharma industry is faced seems not only feasible but also crucial at the very least.

Integrating regulatory requirements in the systems workflow process allows affirming your business adherence to industry standards is safe and managing regulatory compliance is maintained.

Supply Chain Optimization: The ERP system helps to maintain procurement and distribution transparency across the supply chain. It is useful for determining bottlenecks and contamination in the process to increase manufacturing and reduce expenses.

Inventory Control: This system allows for batch traceability, leading to a reduction in stock waste and stock out. Shelf-life manufacturing traceability is achieved via regulatory channels.

Centralized Data Management: With centralized data storage and integration, ERP Systems such as SAP Business One introduce powerful data analytics. This will give all stakeholders more informed decisions, and they will be achieved through data accuracy and convenience.

As a conclusion, one might say that SAP Business One in the pharmaceutical industry is a breakthrough system offering to solve any needs and issues with the help of a comprehensive suite of ERP solutions. The decreased burden of regulatory conformity, the following supply chain management, and the expanded data inventory enable pharmaceutical organizations to stay abreast of the health and welfare sector out of their league. The necessity and request for efficient health and welfare industry control frameworks are continually increasing, and SAP Business One is the immediate leader in this capacity, transferring technological innovation and transformation throughout culture.

Book a free demo with SoftCore Solutions, the Best SAP B1 ERP partner in Hyderabad

0 notes

Text

ERP for Plastic Manufacturing Industry

safal erp for plastic manufacturing industry is the best .SAFAL have worked a lot with client into plastics industry like FIBC, Woven Sack, Non Woven, as well as manufacturers which are into technical textiles like geosynthetics material, technical fabric, fiberglass fabric, PTFE membrane, etc. Our customer consists of manufacturers of auto plastic components like plastic mold components like auto parts, pharma containers, consumer items, packaging parts, computer peripherals, electric parts. Using our Plastic ERP software for molding industry, we have mapped major processes that involve injection molding, extrusion and vacuum forming.

#erpforplasticmanufacturingindustry#erpforplasticmanufacturingindustryfree#besterpforplasticmanufacturingindustry

0 notes

Text

Datanote Erp: a Versatile Erp Software Which Suits Best to Diverse Industries

The impact of the ongoing pandemic can be seen in all industries. Companies want to recover it as soon as possible. They can not get the time back but can speed up the process to minimize the gap. And the best thing industries are doing is adopting ERP software that suits their business best and gives a better result.

In this series, DataNote has come with versatile ERP software that serves several industries and enables them to a faster and better organised.

Engineering Industry

Made from our extensive experience, DataNote ERP meets the specific requirements of the parts & machine manufacturing industry and takes care of all the production needs from inventory management to distribution.

Food & Beverages Industry

Modules of DataNote ERP make sure that food & beverage industries are complying with all the rules and regulations while maintaining the service standard. It saves the cost of restaurants and increases revenue.

Metal Processing

Metal processing industries have various plants and processes. DataNote ERP accurately manages department-wise inventory, operations, sales, profit, quality checks and everything. DataNote ERP is an all-in-one comprehensive solution that can cater for the needs of the metals processing industry.

Plastic & Rubber Industry

DataNote ERP effectively manages one of the fastest-growing industries which is full of tedious tasks by streamlining all the data and converting them into a simple one. It saves time while managing the quality of the final product on the other hand.

Garment & Textile industry

In the Garment & Textile industry, the competition is increasing and margins and timelines are being reduced. So DataNote ERP is designed in such a way that it controls the cost and optimizes the resources.

Chemical & Pharma Industry

DataNote ERP software for Chemical & Pharma manufacturing effectively helps meet the regulatory requirements without compromising the stated quality standards. DataNote ERP syncs inventory, orders, and customers for impactful process cycles.

Solar & Electronics Industry

The Solar & Electronic Industry is changing rapidly as conventional energy is becoming the first choice. DataNote ERP ensures visibility over work orders, supply chain, installation, and service which boost productivity and minimizes costs.

Casting & Forging Industry

With in-depth research and practical knowledge of our industry expert, DataNote ERP software came into existence. It helps the companies to retrieve, manage and analyze data in real-time for better monitoring and control.

Building Material

Designed with extensive experience, DataNote ERP streamlines vendor management, customer service, product delivery, and inventory management to gain a significant advantage in the market. DataNote ERP ensures maximum productivity in a short time.

Trading Industry

Whether it's packing and shipping goods on a small scale to processing and distributing global orders, DataNote ERP offers an end-to-end solution that controls and organizes every aspect of the trading business.

Cosmetic & FMCG Industry

Cosmetic & FMCG Industry is the most competitive industry full of challenges, particularly in the areas of Inventory and Cost Management. Well-organized ERP of DataNote helps companies get rid of paper-based manual processes that hinder productivity.

This Blog is Already Published in ERP software that suits their business

Contact No: +91 97370 45567

Email: [email protected]

0 notes

Text

Are you looking for Best ERP solutions for your company or organization ? Udyogsoftware is one of the leading Best ERP software in india for various industries like chemical , pharma , manufacturing etc . For more details, get a demo today

1 note

·

View note

Text

Best Pharma ERP In India

Uveous Technologies is one of the best dynamic and top leading software company which provides Best Pharma ERP in India. The organization was established to create world-class ERP programming and answers for different Industries to empower them to deal with their organizations adequately and contend in quickly changing worldwide economy.

It is a full-included ERP that spreads Pharmaceutical industry procedure and gives full help to assembling, dispersion, monetary, and consistence needs. Continuous data and comprehensive perspective on the business helps in settling on proactive educated choice to outlive the challenge.

This ERP software for Pharma distribution system is very useful and have lots of benefits likes Batch Control & Traceability, In-depth Bi-directional Traceability, Production Management, On-Demand Reports, also have Roles & Authorization and Product Costing.

Uveous Technologies has been developed to group the specific business and regulatory needs of ERP for pharmaceutical industry. This based on CGMP Guidelines and develop, manage, size, track and secure your formulas/recipes. Consolidates batch information and manages multi-staged production controlling costs and overheads. Its forecasts, plans, schedules and manages inventory to avoid wastage and also Supports complete Sales & Procurement cycles with quality checks at needed stages.

#Best ERP software for Pharma industry#Inventory management software for Pharma#ERP for Pharmaceutical in India#Pharma ERP in Nepal#Pharmaceutical ERP System in Nepal#erp for pharmaceutical industry#ERP software for Pharma distribution system#Pharmaceutical ERP in Himanchal Pradesh#erp for pharmaceutical companies#Pharma ERP Software Company in Nepal#best pharma erp

0 notes

Text

Revolutionize Pharmaceutical Operations with Zillancer's ERP Solutions!

In the pharmaceutical industry, efficiency is key.

Zillancer offers cutting-edge Pharmaceutical ERP solutions designed to streamline your processes, ensuring compliance, reducing costs, and improving overall performance. Learn how our experts can tailor ERP systems to meet your pharmaceutical needs.

#Pharmaceutical ERP#Pharma ERP Solution#ERP Pharma Software#ERP Software Pharma#ERP for Pharma Industry#ERP for Pharmaceuticals#ERP for Pharma Companies#Pharmaceutical ERP Solution#ERP for Pharmaceutical Industry#ERP Software for Pharma#Pharmaceutical ERP Systems#Best Pharma ERP Software#Zillancer

1 note

·

View note

Text

ERP For Pharma

Enterprise Resource Planning (ERP) for Pharma Industry

The pharmaceutical industry is a complex and highly regulated industry, with a wide range of processes, systems, and data that need to be managed effectively. The pharma industry has many stakeholders, including manufacturers, wholesalers, distributors, healthcare providers, and patients, all of whom need accurate, up-to-date information. To meet these demands, an effective and efficient ERP system is essential.

ERP systems are designed to integrate all aspects of an organization's operations into one comprehensive system. This integration helps streamline processes and improve efficiency, while also reducing costs. In the pharma industry, an ERP system can help manage everything from supply chain management, to finance, to manufacturing, to quality control.

One of the key benefits of ERP For Pharma companies is improved supply chain management. ERP systems can provide real-time visibility into the entire supply chain, from the manufacturer to the customer. This allows companies to better manage their inventory, reducing waste and increasing efficiency. Additionally, ERP systems can help companies monitor their suppliers and ensure that they are meeting quality and regulatory requirements.

Another key benefit of ERP for pharma companies is improved financial management. ERP systems can help companies track their financial performance, including sales, expenses, and profits. This information can then be used to make informed business decisions, such as where to allocate resources, what products to focus on, and how to improve operations.

ERP systems can also help companies manage their manufacturing processes. In the pharma industry, this includes everything from tracking raw materials to managing production schedules, to ensure that finished products meet regulatory requirements. An ERP system can help companies streamline their manufacturing processes, reducing waste, and improving efficiency.

One of the biggest challenges facing the pharma industry is the need to comply with complex regulatory requirements. ERP systems can help companies meet these requirements by automating many of the processes involved, such as tracking the movement of products, ensuring that products are properly stored, and tracking quality control procedures. This helps companies to avoid costly penalties for non-compliance and maintain their reputation for quality and safety.

Finally, ERP systems can help companies improve their customer service. By integrating all aspects of the business into one system, companies can provide real-time information to their customers, including order status, delivery times, and product information. This helps companies to build strong relationships with their customers and improve customer satisfaction.

Enterprise Resource Planning (ERP) systems for the pharmaceutical industry typically include the following features:

Supply Chain Management: Manages the entire supply chain process from procurement to distribution.

Regulatory Compliance: Helps companies to meet FDA and other regulatory requirements.

Quality Management: Helps companies to manage their quality control processes and maintain product quality standards.

Clinical Trials Management: Supports the management of clinical trials and the collection of data.

Sales and Distribution: Manages sales and distribution processes, including order management, pricing, and customer service.

Financial Management: Automates and streamlines financial processes, such as accounting, budgeting, and financial reporting.

Manufacturing and Production: Supports the management of the production process, including planning, scheduling, and cost control.

Inventory Management: Helps to manage inventory levels and ensure that the right products are available at the right time.

Human Resource Management: Supports the management of human resources processes, including payroll, benefits administration, and time and attendance tracking.

Conclusion: ERP systems offer many benefits to pharma companies. From improved supply chain management and financial management to improved manufacturing processes and regulatory compliance, ERP systems can help companies streamline their operations, reduce costs, and improve efficiency. By investing in an ERP system, pharma companies can better manage their operations and stay ahead of their competition.

#ERP for pharma#pharma erp software#ERP for Ayurvedic#ERP Software for Ayurvedic & Pharma#Best Pharma ERP Software#pharmaceutical erp systems#best erp for pharmaceutical industry

0 notes

Text

Pharmacy Software India

At CBO ERP LIMITED, we pride ourselves on crafting software fine-tuned to these specific needs for Pharmaceutical Software Solutions. The Pharma Software Solutions is our product that not only fulfills unique requirements but also boosts efficiency, ultimately elevating the return on investment for businesses. We understand that the Pharmacy Software Indian industry is an extremely competitive industry. So we work hard and provide the best products. https://www.cboerp.com/latest-news.php

0 notes

Link

If you have a pharma industry then you are facing several problems such as drug formulation, inventory management, securing the data, etc. Pick Absolute pharma manufacturing ERP software for a one-stop solution.

For more information, visit https://bit.ly/3REIQ9r

#manufacturing erp#manufacturing erp software#production erp#manufacturing software#Best Manufacturing ERP Software in india#Top ERP Software for Manufacturing Business#manufacturing erp software india#best erp software for manufacturing industry#erp software#erp solutions#enterprise resource planning software#erp application#erp software management#erp modules#erp development#erp solutions company#pharma ERP software

1 note

·

View note

Text

Lighthouse ERP for pharmaceutical and ayurveda industry completely transforms the way industry functions bring positive changes in workflow.

#ERP for pharma#pharma erp software#ERP for Ayurvedic#ERP Software for Ayurvedic & Pharma#Best Pharma ERP Software#pharmaceutical erp systems#best erp for pharmaceutical industry

0 notes