#Bay Area Diesel Fuel Supplier

Explore tagged Tumblr posts

Text

Vehicle Stops - Are Your Diesel Fuel Prices Correct? | Bay Area Diesel Fuel Supplier

No, when we speak about right diesel fuel costs at truck quits this isn't mosting likely to be another write-up regarding anyone direct. This write-up has to do with truck stop cost mistakes and also gas card procedure mistakes.

Bay Area Diesel Fuel Supplier Oh, you believed they didn't make mistakes. Well think again. Although they all discuss their great systems as well as all of this terrific info, let's really take a look. We will not talk about any company straight or calling out any direct company As well as please at no factor are we claiming they are attempting to pull one over on fleets. We are simply mentioning that mistakes occur as well as if you don't understand it, you should. These are all quality vehicle quit companies as well as fuel card companies. A lot of these vehicle quits and also gas card offers systems are not as up to date for 2013 as you might assume. Advertising their item, they can do that real well yet real and also real possibly do not equivalent each other. For them to make fleet gas price adjustments in their systems is difficult for a variety of reasons. Maybe old modern technology, or poor customer care or simply pure blunders. Yes, the old "glitch, system errors, wrong information, data back-up, and so on" have you ever heard this? Excellent if you have because that indicates you really knew your gas information and also asked the inquiries. Even when these" problems" take place legitimately, unless you point it out, do not anticipate your truck stop or fuel card service provider to point it out. The majority of the moment they do not also understand it takes place till it is mentioned to them. Give thanks to goodness, your gas monitoring system gets on top of this. Might you envision just how negative your fleet monitoring program would look or your gasoline costs would be if you really did not have this things down?? You could be spending a great deal even more cash than you should be, yet we understand everybody watches this details really close. Individuals discovered and also solved over 350 fuel pricing issues. That is virtually 40 per week. Okay, one mistake what does that expense your fleet monitoring spending plan? Let's say you were intended to get price plus 3. Rather your offer diminished the table at 1 vehicle quit as well as you're paying complete retail. Your gasoline purchases there per month are 5,000 gallons at a distinction of.28 cents per gallon contrasted to your expense plus 3 to retail. That error just cost you an extra $1,400 for the month in gasoline or over $16,800 a year. That is 1 error at one area, with one truck quit that is just purchasing 5,000 gallons a month. As a company YTD, we have actually captured (consisting of mobile fueling) blunders over $400,000. As a Fleet Supervisor, Director of Transport, VP of Strategic Sourcing, blunders can truly include in your profit/loss. That is a really little sample of what we see.

0 notes

Text

Benefits of Working With a Diesel Delivery Service

With a diesel delivery service, you can rely on a reliable and consistent supplier of fuel for your fleet. Your provider knows your exact needs, and can ensure that your diesel deliveries are timely and within budget. What's more, your rates are consistent and reliable, regardless of time of year or market fluctuations. These benefits provide peace of mind for facility managers and allow them to plan ahead for their fleet's fuel needs. If you probably want to get more enlightened on this topic, then click on this related post: https://en.wikipedia.org/wiki/Fuel-management_systems.

Diesel delivery services are available for businesses throughout the Bay Area. They specialize in providing on-site fuel for generators, heavy machinery, mobile fuel tanks, and truck fleets. With a tanker able to deliver up to 9,000 gallons of diesel per tank, they cater to business owners with fleets of trucks and vans.

In addition to providing fuel for the fleet, the fuel delivery service can deliver DEF for modern diesels. Its diverse range of DEF options includes pallets of jugs, 55-gallon drums, and bulk fuel totes. Diesel fuel is a necessary component of modern diesels. When used in these vehicles, it is vital to use DEF, which is supplied by Fuel Logic. You can get more information about diesel delivery services on this page.

The cost of fuel is rising, and diesel delivery services can help you save money on your fuel costs. Bulk purchases can help you reduce operational costs, and having diesel available when you need it will streamline refueling. Additionally, there are other benefits to working with a diesel delivery service. With the right company, you can refuel your generators, trucks, and other equipment at a fraction of the cost. Follow this link to get in touch with the best fuel management service providers.

Off-road diesel is specifically designed for off-road vehicles. It is dyed red and is different from taxed clear diesel. It is used for off-road purposes, and therefore isn't taxed. However, violators can face heavy fines. Off-road diesel delivery services from SOS Xtreme Comfort will comply with state and federal laws and provide you with off-road diesel for your vehicles at bulk prices.

The current tight supply of diesel in the world is threatening to put the price of fuel at a high. While prices are still affordable in Europe, other parts of the world could be in trouble. The situation in Africa and Latin America has yet to be fully analysed, but it is safe to assume that the market is heading towards a stock-out.

0 notes

Link

Gas and Diesel Delivery Services in Las Vegas NV | Towing Services of Las Vegas

More information is at: http://towinglasvegas.org/gas-and-diesel-delivery-service-near-me/

Are you searching for a gas station or a tow service till the nearest fuel station? Towing Services of Las Vegas provides high quality diesel gas and fuel delivery directly to your trucks’ fuel tanks, at your business when your fleet is parked, or to your equipment directly on the job-site. The efficiency of our custom designed delivery trucks fueling your fleet of trucks or equipment provides a seamless and nearly invisible service. Just call us or leave a message for Costs? Free Estimate.

REQUEST FREE QUOTE!

GAS AND FUEL DELIVERY SERVICE

Towing Services of Las Vegas understands that timely customer service, fuel quality and price are important factors to consider when choosing a bulk fuel supplier. With over 20 years of experience in the fuel industry, We has created a knowledgeable team dedicated to providing your business with industry leading service and quality with a competitive price. And our service of Gas and Fuel Delivery can never let you down in times needed.

Choosing us gets an advantage from day one. Our expansive nationwide network of fuel terminals allows us to deliver to Las Vegas NV and nearby areas with unmatched speed and reliability. Our unmatched customer service allows us to constantly grow, easily expanding our remote location delivery network. Our expertise, nationwide network of strategic partners and regional operation hubs make sure customers’ complete fueling needs are fulfilled.

Most importantly, We are committed to providing our clients with personalized, round-the-clock customer service. The experts at our nationwide offices are available for consultation day or night and are rigorously trained to ensure that gas and fuel delivery gets to its destination on time and without issue. It’s no wonder why our clients include a multitude of lots of international companies across numerous and diverse industries. No matter what your petroleum needs are, Towing Services of Las Vegas will work tirelessly to ensure that they’re fulfilled quickly, cost-effectively and without hassle. Get in touch with one of our knowledgeable customer service representatives today to learn more about our service called Gas and Fuel Delivery services and make one for you too.

CALL US FOR:-

§ 5th wheel towing service near me

§ 5th wheel Transport Company near me

§ 5th wheel moving service

§ 5th wheel RV hauling rates

§ How to move a fifth wheel trailer without a truck

§ Cost to move a fifth wheel

§ 5th wheel transport cost

§ 5th wheel RV towing

BEST GAS AND FUEL DELIVERY SERVICES IN LAS VEGAS

TOWING SERVICES OF LAS VEGAS

REQUEST MORE INFORMATION HERE!

CONTACT US:

Towing Services of Las Vegas

Best Towing, Tow Truck, Roadside Assistance, And Mobile Roadside Services in Las Vegas, Nevada

CALL (702) 560-5869 TOWING SERVICE

CALL (702) 560 2682 MOBILE MECHANIC 1

CALL (702) 560 5357 MOBILE MECHANIC 2

CALL (702) 560-5948 MOBILE MECHANIC 3

CALL (702) 560-5945 ROADSIDE ASSISTANCE

Open 7 days 24 Hours

Located in Las Vegas, NV!

WEBSITE:

towinglasvegas.org

lvmobilemechanic.com

mobileautotruckrepairlasvegasnv.com

mobilemechaniclasvegas.org

roadsideassistancelasvegas.org

Service area:

10 Cities within 30 miles of Las Vegas, NV

Blue Diamond, NV | Boulder City, NV | Henderson, NV | Indian Springs, NV | Jean, NV | Nellis AFB, NV | North Las Vegas, NV | Overton, NV | Sloan, NV | The Lakes, NV | Arden, Nevada | Calico Basin, Nevada | Callville Bay, Nevada | Citibank, Nevada | City Center, Nevada | Clark Co Courthouse, Nevada | Cold Creek, Nevada | Corn Creek, Nevada | Embarq Telphone, Nevada | Enterprise, Nevada | Las Vegas Brm, Nevada | Lv Valley Water Co, Nevada | McCarran Airport, Nevada | Mgm Properties, Nevada | Mount Charleston, Nevada | Mountain Sprg, Nevada | Mountain Springs, Nevada | Mt Charleston, Nevada | Nevada Power, Nevada | Old Nevada, Nevada | Sloan, Nevada | Sw Gas Co | The Lakes | Univ Nv Las Vegas

the zip codes in Clark County, NV and the city/neighborhood in which the zip code is in: 89002 (Henderson), 89005 (Boulder City), 89011 (Henderson), 89012 (Henderson), 89014 (Henderson), 89015 (Henderson), 89016 (Henderson), 89030 (North Las Vegas), 89031 (North Las Vegas), 89032 (North Las Vegas), 89044 (Henderson), 89052 (Boulder City), 89074 (Henderson), 89081 (North Las Vegas), 89084 (North Las Vegas), 89085 (North Las Vegas), 89086 (North Las Vegas), 89087 (North Las Vegas), 89101 (Las Vegas), 89102 (Las Vegas), 89103 (Las Vegas), 89104 (Las Vegas), 89106 (Las Vegas), 89107 (Las Vegas), 89108 (Las Vegas), 89109 (Las Vegas), 89110 (Las Vegas), 89113 (Las Vegas), 89115 (Las Vegas), 89117 (Las Vegas), 89118 (Las Vegas), 89119 (Las Vegas), 89120 (Las Vegas), 89121 (Las Vegas), 89122 (Las Vegas), 89123 (Las Vegas), 89124 (Las Vegas), 89128 (Las Vegas), 89129 (Las Vegas), 89130 (Las Vegas), 89131 (Las Vegas), 89134 (Las Vegas), 89135 (Las Vegas), 89138 (Las Vegas), 89139 (Las Vegas), 89141 (Las Vegas), 89142 (Las Vegas), 89143 (Las Vegas), 89144 (Las Vegas), 89145 (Las Vegas), 89146 (Las Vegas), 89147 (Las Vegas), 89148 (Las Vegas), 89149 (Las Vegas), 89156 (Las Vegas), 89158 (Las Vegas), 89161 (Las Vegas), 89166 (Las Vegas), 89169 (Las Vegas), 89178 (Las Vegas), 89179 (Las Vegas), 89183 (Las Vegas).

0 notes

Text

The Future Of Work Now: Diesel Oil Analysis At The MBTA

New Post has been published on https://perfectirishgifts.com/the-future-of-work-now-diesel-oil-analysis-at-the-mbta/

The Future Of Work Now: Diesel Oil Analysis At The MBTA

One of the most frequently-used phrases at business events these days is “the future of work.” It’s increasingly clear that artificial intelligence and other new technologies will bring substantial changes in work tasks and business processes. But while these changes are predicted for the future, they’re already present in many organizations for many different jobs. The job and incumbents described below are an example of this phenomenon.

Dashboard of MBTA oil analysis

The Massachusetts Bay Transportation Authority—known locally as the MBTA or the “T”—is a government agency that provides subway and commuter rail services to the Greater Boston metropolitan area. Its subway is the oldest in the United States, and its commuter rail system consolidated many private rail systems that began as early as 1830. Today the MBTA unites 78 communities in Eastern Massachusetts and Rhode Island, and serves (at least in pre-COVID days) about 1.3 million riders a day.

The MBTA commuter rail system, which carries about 120,000 riders on an average day, has been challenged in the past by high levels of service breakdowns. In 2017, for example—a difficult winter weather year—the system had the highest number of mechanical failures of any commuter rail system in the US, several of which cover many more miles and run more trains than the MBTA. Both Keolis, the private contractor that runs the MBTA, and MBTA executives came under heavy criticism.

Most of the breakdowns involved the aging fleet of diesel electric locomotives, and after 2017 the MBTA embarked upon a program to overhaul and upgrade legacy locomotives. One aspect of that program was an effort to use artificial intelligence—machine learning in particular—to identify impending maintenance problems before they lead to breakdowns.

Ryan Coholan and Diesel Locomotive Oil

Ryan Coholan is the Chief Railroad Officer of the MBTA. He’s a 28-year veteran of the railroad business, and bemoans the reliance that the industry—and his own organization—still has on obsolete technologies like fax machines. But he’s a big believer in data and the analysis of it, and thought that there were opportunities to use them to improve the MBTA’s commuter rail performance.

The most important data for a diesel electric locomotive is arguably about the condition of its oil. The MBTA had always taken regular oil samples from diesel engines, and they were given a quick look by one person. But if they weren’t extreme, they were filed away. Analyses of the samples typically look at elements within the oil such as copper, iron, lead, aluminum, calcium, and sodium. When there were engine failures in the past, the last oil sample would be pulled to look for out-of-range values. But there was no systematic analysis of how sample values related to maintenance problems.

However, there was another way to look at oil data, as Coholan wrote in an article:

“What we had to do was understand that the humble oil sample was actually a molecular ‘blackbox’ recorder that had a powerful story to tell, measured in parts per million (ppm).”

Coholan had a friend of a friend, Mike Jensen, who runs an industrial data and analytics consulting firm called 4Atmos Technologies, LLC and had done some past work in oil analytics. When they talked Jensen suggested that a machine learning model might be helpful in predicting engine breakdowns. Coholan confirmed that the MBTA had the necessary data for training a model, including many years of oil sample data (400 samples from 90 locomotives proved to be enough) and outcomes data in terms of engine failures. The discussion led to an official pilot project. However, pulling the data together and building a training dataset wasn’t easy, and it took about a year and a half.

Once trained, however, the model seemed to work quite well. It could predict a high likelihood of an engine problem in the next 15 days. And the elements found in the oil sample could predict the specific problem that was likely to occur. For example, if there was water in the oil, that meant that the water jumper to cool the cylinder head was probably leaking. Fuel in oil meant an injector was likely to be leaking. Metal in the oil could usually be tied to problems in a particular engine component. Iron in the oil, for example, meant that a turbocharger was likely to fail. The model could predict three days ahead of time a probable failure of a turbocharger.

Mike Jensen’s analysis found that just looking for out-of-range values in oil samples wasn’t a useful approach to predicting engine problems. He wrote about the finding in an article:

“We discovered that more than 75% of our failure signatures had combinations of values that were all below their prescribed thresholds. Instead of looking at each element individually we combined elements in clusters to help identify high probability candidates.”

Institutionalizing Oil Analysis and Prediction

The positive early results confirmed the value of doing oil analysis on a regular basis and using it to predict mechanical failures. The project was formalized and became known as “Project Velocity.” When the model identified a particular oil/failure combination it was called an “agent.” Even individual types of failures were named after the mechanics or mechanical team that explained the finding in the data; one recurrent problem became known as the “Sullivan failure,” for example.

Now the oil analysis takes place every ten days—it was formerly every 30 days—and is embedded in the day to day work of the Mechanical Operations department, which oversees Keolis’ maintenance work. The MBTA has its own Oil Lab doing the oil analysis, and it’s become a desirable place to work—“I have people who fight to go into the lab,” Coholan said.

The person who won that fight is Jim Zoino, a Mechanical Maintenance Systems Specialist at the MBTA who is primarily responsible for testing oil samples and reporting what to do about them. Zoino has a background in IT technical support at large banks, but he’s worked at the transportation authority since 2011. When the Oil Lab opened, he volunteered to run the oil samples—usually 8 to 10 a day—and create reports on them, and now it’s the primary aspect of his job.

The primary tool for analyzing the oil is a mass spectrometer, which sends an electric charge through the oil, vaporizes it, and measures the wavelength of the resulting light. It can then determine the chemical composition of the oil sample. The Project Velocity software reads the chemical composition data and compares it to other oil samples across different types of locomotives in the MBTA fleet to determine whether particular elements are out of the normal range. A high iron PPM finding on one type of locomotive might be no problem, but on another type might indicate a pending turbocharger failure.

Initially, Zoino knew very little about locomotive oil. He would give the data to Mike Jensen, who would interpret the results and send a report on what—if anything—was likely to be wrong with the locomotive. Over time, however, Zoino learned how to interpret the data and the implications of high concentrations of calcium, zinc, copper, and so forth. Now, unless there is something highly unusual in the spectrometer results, he produces the report himself. It goes to several people in the MBTA, the operations and maintenance contractor Keolis, and the contractors who rebuilt locomotives.

Zoino said that there was initially not much interest or cooperation from other MBTA executives or Keolis when Mike Jensen began to report the oil analysis findings. The MBTA wasn’t familiar with mass spectrometry, machine learning, or predictive maintenance, so its managers were skeptical. And the analysis meant more work for Keolis, so its managers weren’t enthusiastic either. But after a couple of years of the program, Zoinos commented,

“We’re turning the ship around, making great strides. The project is maturing. Keolis now comes to us and asks us to analyze samples. They’re penalized for maintenance failures, so they have an incentive to pay attention to the data.”

The Value of Project Velocity

This predictive maintenance model, of course, had many benefits to the MBTA. If a failure was predicted, the MBTA would instruct Keolis maintenance personnel to fix it quickly. Preventing a failure before it occurred saved substantial time and money. If a failure happened while the vehicle was operating on the rails, it could strand and inconvenience 1300 passengers. Coholan said that the dollar value of a “good catch” prediction was in the millions of dollars; he said, “The ROI is massive, massive.”

The success of the program prompted a $40M investment in rehabbing legacy locomotives by the MBTA. The company that overhauled the legacy fleet was very interested in the oil analytics program—particularly when it became apparent that components on some of the locomotives they rebuilt were failing too early. The MBTA was able to extend the warranties on those locomotives at no extra cost because of the data from Project Velocity. The program also led to changes in maintenance practices and intervals. As a result of the oil model, the overhauls, and the new practices, the MBTA has dramatically increased the mean miles between locomotive failures, and the on-time performance of the commuter rail system is higher than ever.

Ryan Coholan only wonders why the MBTA, his locomotive suppliers, and maintenance companies waited so long to do this type of analysis:

“We all knew that lubricating oil is the blood of the locomotive diesel engine. And we were watching life around us become more data-driven all the time. We had lots of data around passengers, delays, and so forth, but there was nothing focused on helping the locomotives perform better. It was very satisfying to finally discover something.”

From CIO Network in Perfectirishgifts

0 notes

Link

Best Commercial Truck Repair Service and Cost in Las Vegas NV |Mobile Auto Truck Repair Las Vegas

More information is at: http://mobileautotruckrepairlasvegasnv.com/commercial-truck-repair/

Commercial Truck Repair Service near Las Vegas NV: Are you looking for the Best Commercial Truck Repair Service near Las Vegas NV? MOBILE AUTO TRUCK REPAIR LAS VEGAS, we understand the importance of fast, reliable commercial truck repair, maintenance and inspection to ensure maximum uptime for your fleet/business. Cost? Free estimates! Send us a message or call us today. Best Commercial Truck Repair Service around Las Vegas NV. We serve Las Vegas NV and other areas. Get a Free Quote Now!

Best Commercial Truck Repair Service In Las Vegas Nv

LAS VEGAS COMMERCIAL TRUCK REPAIR

Commercial Truck Service

Commercial Truck Repair Service near Las Vegas NV: Your truck isn’t doing you any good if it’s off the road. An idled truck is a truck that’s not pulling its own weight, and can have a significant impact on your customer satisfaction and your bottom line. At MOBILE AUTO TRUCK REPAIR LAS VEGAS, we understand the importance of fast, reliable commercial truck repair, maintenance and inspection to ensure maximum uptime for your fleet/business. We have more than 90 years’ experience as a commercial truck repair shop, and can be counted on to provide you with the best service on trucks from Mack, Volvo, Hino & Isuzu or any other brand.

If you’re looking for a commercial truck service center, MOBILE AUTO TRUCK REPAIR LAS VEGAS has all of your needs covered. With seven locations to serve you in Pennsylvania and New Jersey, including in the heart of the Philadelphia metro area, we make your truck repair easy and convenient. We offer many great services, including:

● Factory-authorized service for Volvo, Mack, UD, Hino, GMC, Isuzu, Fuso, Cummins, Eaton, Meritor, and Alison

● Service for all makes and models

● Breakdown services

● Emergency truck repair

● Diesel engine repair and service

● 24 hour towing and roadside service

● DOT and state inspections, NJ diesel emission inspection

● Contract maintenance

● Accident repair and restoration

● ASIST fleet management

● Advanced cloud-based diagnostics

● Dedicated team focused on aftermarket solutions

Commercial Truck Repair Service near Las Vegas NV: We employ highly trained technicians in all of our semi-truck repair shops, half of which are certified master technicians. They are factory authorized to work on any type of truck, including popular brands like Volvo, Mack, UD, Hino, GMC, Isuzu, Cummins, Eaton, Meritor and Alison. Our technicians are continually training to stay ahead of the advancements in our industry through factory-authorized courses and hands on training. Our diesel truck service centers have all the latest technology and equipment to inspect, diagnose and repair modern commercial diesel truck engines. We currently have 100+ commercial truck service bays in operation, with shifts working 24/7, backed by extensive tooling and our comprehensive parts inventory.

To offer you fast commercial truck repairs, we also carry a stock of more than $10 million in parts. This means we have your commercial truck parts handy when we need them, and can get them installed quickly. For more obscure parts and models, we have a wide network of factory and aftermarket suppliers we can call on. We do everything we can to offer the best support to Keep Customers on the Road. Your satisfaction is the best testimonial for our business, and we’ll work hard to keep you satisfied.

Contact MOBILE AUTO TRUCK REPAIR LAS VEGAS today and we’ll point you to our closest commercial truck repair shop. We’ll give you the friendly, expert service you deserve, and make sure your fleet is inspected, maintained and repaired by our team of professional commercial truck mechanics. We look forward to becoming your trusted partner for all your commercial truck and engine service needs.

We employ a small, hardworking, team of highly skilled and experienced mechanics on our 24 hour mobile truck repair team. With over 50 years of experience between them, you can rest assured that any of your medium or heavy duty truck needs are in qualified and supremely capable hands.

When you call us for 24 hour mobile truck repair, you’ll get a company that responds with a sense of urgency and an eagerness to help. We know downtime costs you money, so we respond fast, make quick accurate assessments and get to work.

All of our trucks are fully equipped and stocked with an array of parts in order to avoid any needless part or equipment runs. We want to get you back on the road as quickly and safely as possible.

Our Mobile Truck Repair Services Include:

● Engine Repairs

● Transmission and Clutch Repairs

● Tire Repairs, Changes & Replacements

● Battery Jump Starts

● Lockouts

● Electronic Diagnostics

● Welding

COSTLY BEASTS

Commercial Truck Repair Services in Las Vegas NV: Besides the upfront cost to purchase a diesel truck, do you know the depth and breadth of other costs involved? Wouldn’t it be great if buying a more expensive truck also meant a low cost of ownership? Unfortunately, the opposite is true. · A more expensive vehicle always means a higher insurance premium so you need to make sure you factor this into your monthly budget. Diesel fuel is typically more expensive, although, since it is much more efficient it requires less fuel than its gassy counterpart. · Maintenance and repairs are always higher with diesel trucks which also means that your truck will cost you more time having it serviced.

MOUNTAINOUS MAINTENANCE

With the superior performance of the diesel engine also comes the need for superior maintenance. Diesel owners must understand that maintenance is absolutely critical to keeping your engine healthy in the younger years, performing well in the middle years, and still running in the geriatric years. It is not uncommon for a diesel engine to triple or quadruple the life expectancy of a gas engine but it is likely impossible if maintenance is minimal or forgotten.

PEAK PROBLEMS

Commercial Truck Repair Services in Las Vegas NV: There are several foreseeable problems with a diesel engine that can be limited with scheduled routine maintenance and a few extra powerful services that can reverse the damage naturally occurring in diesel engines. The cost of services to combat the following problems varies widely depending on many factors including make/model, brands of products chosen and capacity of different systems. Therefore I am only able to list a ballpark range you will need to drill this down based on your particular diesel truck and preferences.

A diesel engine is chock full of power and therefore the engine runs extremely hot. Consequently, the coolant is one of the most important needs of the diesel engine. It should be continually monitored because it has a tendency to become more acidic as it ages. If the acid level becomes too high it can cause other parts of the cooling system to rot which will ultimately lead to expensive repairs. It is imperative that you take time to not only check it but to have it flushed as a preventative measure between 50K-100K miles and no more than every 5 years for most makes but it truly depends on the coolant chemistry and severity of use. Coolant flushes for a diesel truck start at around $180.

Dirt is an enemy of your diesel engine components. When dirt and grime are present and enter the system, performance will be compromised and the life of the engine will be significantly shorter. The best way to combat the enemy is to keep it clean oil, clean air, clean fuel. Failing to do these services regularly will lead to significant engine problems and expensive repairs?

FREQUENTLY ASKED QUESTIONS ON 24 HOUR TRUCK REPAIR

Commercial Truck Repair Services in Las Vegas NV: Commercial trucks, semi-trucks, and tractor-trailers can get damaged in a snap. Those large and heavy machines are hard to maintain in a working condition because of their large size. We, at MOBILE AUTO TRUCK REPAIR LAS VEGAS, have learned to perform various truck repair jobs and our clients depend on the honesty and integrity of our relationship. What more can we tell you about us?

What tasks do you specialize in?

Our well-trained and informed technicians can fix trucks, cars, and semi-trucks. Roadside assistance is an additional service for all our customers in Las Vegas NV. You can contact us for speedy mobile tire change and trailer repair.

How long will the repair take? When will I get my truck back?

Truck Repair we understand that every day your truck is out of commission is costing you money. We make every effort to repair work trucks as quickly as possible. The best thing to do is to give us a call and tell us the problem. We can usually adjust our work schedule to quickly service or repair your truck. If we are too busy to handle your repair request immediately we can help you find someone who can.

Our highly trained mechanics have experience working with all types of light & medium duty trucks.

● Dump Trucks

● Plow Trucks

● Tow Trucks

● Passenger Vans

● Box Trucks

● Pickup Trucks

Can you fix and inspect my trailer?

We can’t say we fix any type of trailer but we fix most of them, including:

● Car dollies

● Boat trailers

● Landscape Trailers

● We also can handle trailer state inspection & repairs.

Finding a reliable source for trailer inspection can be difficult, but we make it easy at MOBILE AUTO TRUCK REPAIR LAS VEGAS. Our team has the knowledge and experience to ensure that your trailer is street safe and legal. You can trust us because we won’t try and sell you on unnecessary repairs.

How can I keep my truck from rusting and rotting?

You can’t stop corrosion. However, there are ways to drastically improve the life of your truck. Have your truck washed and waxed every month, and especially before a snow storm when there will be lots of salt on the roads. When our mechanics examine your truck they look for potential problems and can seal up areas with the early stages of rust. A little rust oleum on the undercarriage of your truck can add years to the life of the vehicle.

CALL FOR US:

● Commercial Truck Repair Near Las Vegas NV

● Commercial Truck Repair Cornwall

● Mobile Commercial Truck Repair

● Semi-Truck Repair Shops

● Mobile Truck Repair

● 24 Hour Truck Repair

● Commercial Truck Repair Kingston

● Truck Repair Shop Near Las Vegas NV

● How Much Does It Cost To Service A Semi Truck

● Cost Of Freight Truck

● Long Haul Truck Cost

● Cost Of Owning A Semi Truck

● Truck Cost Per Km

● Straight Truck Cost Per Mile

● Truck Delivery Cost

● Trucking Cost Per Mile Las Vegas NV

BEST COMMERCIAL TRUCK REPAIR SERVICE IN LAS VEGAS NV

MOBILE AUTO TRUCK REPAIR LAS VEGAS

REQUEST MORE INFORMATION. CONTACT US NOW!

Mobile Auto Truck Repair Las Vegas

Best Mobile Mechanic & Mobile Auto Truck Repair in Las Vegas Nevada!

CALL (702) 560-5357 MOBILE MECHANIC – 1, http://www.lvmobilemechanic.com/

CALL (702) 560-2682 MOBILE MECHANIC – 2, http://mobileautotruckrepairlasvegasnv.com/

CALL (702) 560-5869 TOWING & ROADSIDE ASSISTANCE

OPEN 7 days 24 Hours

SERVICE AREA: Las Vegas, Summerlin, Henderson, Green Valley Nevada 89108

WEB: www.mobilemechanicinlasvegas.com

EMAIL: [email protected]

http://mobileautotruckrepairlasvegasnv.com/

#mobilemechaniclasvegas

#mobileautorepairlasvegas

#mobiletruckrepairlasvegas

#onsiteautorepairlasvegas

#roadsideassistancelasvegas

#24hourautorepairlasvegas

#24hourtruckrepairlasvegas

CALL US FOR:

· Mobile Repair

· Mobile Mechanic for Cars

· Mobile Mechanic for Trucks

· Mobile Mechanic for RVs

· Flat Tire Repairs

· Jumpstarts

· Batteries

· Starters & Alternators

· Shocks & Struts

· Mobile Welding

· Radiators

· Mechanic

· Auto Repair Shop

· Car Repair and Maintenance

· Car Service

· Auto Repair Shops and Mechanics

· Car Repair

· Truck Repair

· On Site Brake Repair

· On Site Auto Repair

· Emergency Auto Services

· Your Mechanic

SERVICE AREA:

Cities: Henderson, Las Vegas NV 89109, North Las Vegas, Summerlin

Las Vegas neighborhoods: Aliante, Anthem/Anthem Country Club, Chinatown, Downtown Las Vegas, Green Valley, Lake Las Vegas, Las Vegas Country Club, MacDonald Highlands, Mountain's Edge, Paradise Palms, Queensridge& One Queensridge Place, Seven Hills, Southern Highlands, Summerlin, Summerlin South, The Lakes, The Ridges, West Las Vegas

Service Area Zip Codes: 88901, 88905, 89101, 89102, 89104, 89106, 89107, 89108, 89109, 89110, 89116, 89117, 89124, 89125, 89126, 89127, 89128, 89129, 89130, 89131, 89133, 89134, 89136, 89137, 89138, 89143, 89144, 89145, 89146, 89147, 89149, 89151, 89152, 89153, 89154, 89155, 89157, 89158, 89161, 89162, 89163, 89164, 89166, 89185.

0 notes

Text

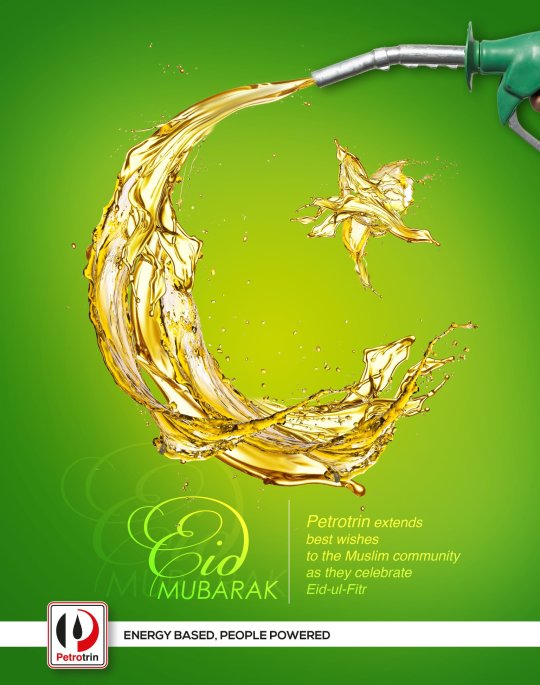

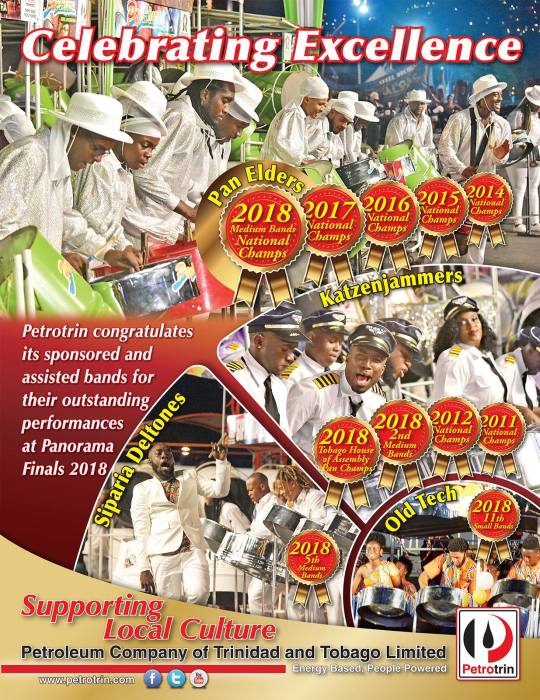

Petroleum Company of Trinidad and Tobago Limited (Petrotrin) was a state-owned oil company in Trinidad and Tobago. Its principal activities were the exploration, development and production of hydrocarbons in addition to the manufacturing and marketing of petroleum products.

As a State-enterprise, Petrotrin was under the direct control of the Minister of Finance acting as the Corporation Sole, and the Ministry of Energy as the line ministry that provides specialized technical analyses and statutory approvals for the company’s operations.

History

The company was established in 1993 by the merger of Trintopec and Trintoc, two state-owned oil companies. A third company, Trinmar Ltdwas merged into the company in 2000.[3] Trintoc was formed from the assets of Shell Trinidad Ltd in 1974 and Texaco in 1985. Trintopec was formed in 1985 when the government purchased the interests of Trinidad Tesoro, a joint venture between the government and Tesoro Oil Company, which was created to purchase the assets of British Petroleum (BP) in 1969. Trinmar was formed when the government purchased the offshore exploration assets of Trinidad Northern Areas Limited (TNA) which was formed by the then "Big Three"; British Petroleum, Texaco and Shell.

These companies were formed from a suite of earlier companies including Trinidad Oilfields Limited (TOL), United British Oilfields of Trinidad (UBOT), Trinidad Leaseholds Limited (TLL), Trinidad Petroleum Development Co (TPD), Apex Trinidad Oilfields (APEX/ATO) and Kern Trinidad Oilfields (KTO), which had themselves been formed to first able commercialize oil finds in Trinidad in the early twentieth century.[4]

Petrotrin operated in land and marine acreage across southern Trinidad. In some instances, the company has engaged in joint ventures, lease operator-ships, farm-outs and incremental production services contracts to support its exploration and production activities. In 2004, Petrotrin was granted an automatic stake in all exploration and production arrangements with foreign companies in Trinidad and Tobago.

In 2018, 90% of Petrotrin’s sales to the local market have been fuel – 46% is from gasoline, 37% from diesel, 11% from jet fuel and 5% from liquefied petroleum gas (LPG or cooking gas). Petrotrin exported to Caricom market with the main countries being Jamaica, Barbados and Guyana.[5]

Refining

Petrotrin operated Trinidad and Tobago's single petroleum refinery, located at Pointe-à-Pierre, just north of the city of San Fernando and is popularly known as the Pointe-a-Pierre Refinery. The refinery produced liquid petroleum gases, unleaded motor gasoline, avjet/kerosene, diesel/ heating oil, fuel oil and aviation gasoline among other products. It has driven the country's economy and placed the country in the hydrocarbon sector.

In 1913, former sugar estates in the area was purchased for plans to build a refinery[6] by Trinidad Leaseholds Ltd, a British subsidiary of Central Mining Company headquartered in the United Kingdom. In 1917, the refinery was built and began production at 75,000 barrels of oil per day (bpd). Its first upgrade occurred in 1928 with the construction of the No 3 and 4 Topping plants. During World War II the refinery was identified as an asset to be “protected at all cost” as a major supplier of aircraft fuel for the Allied forces.[7] By 1940, the refinery went through another expansion, a top secret project known as Project 1234 and by May 1942, the first Catalytic Cracking Unit came on stream[8] where refining capacity in Trinidad and Tobago was recorded at 28.5 million barrels per year. At the end of World War II, the refinery was recognized as the largest in the British empire.

In 1956, Trinidad Leaseholds Ltd was acquired by Texaco where by April 1960, the No 8 Topping Unit came on stream along with a lubricating oil plant, canning plant and a paraffins plant with production increasing to 360,000 barrels per day. Following the unrest of the 1970 Black Power Revolution, the refinery continued to be viable and by late 1984, Texaco assets including the refinery was acquired by the State and placed under the state company Trintoc which itself was merged to form Petrotrin in 1993. By 1997, upgrades were done moving production from 90,000 to 160,000 barrels per day. More upgrades were done on the plants as recent as 2011. By being the only refinery in operation in the Caribbean, Trinidad & Tobago became the supplier of refined petroleum products to the rest of the region.[9]

Petrotrin produced 48,047 barrels per day (7,638.9 m3/d) and had proven reserves totaling 439,585 million barrels (6.98884×1010 m3).

The refinery had a capacity of 190 thousand barrels per day (30,000 m3/d) and it was the only refinery in the world that operated alongside a wildlife park.[10]

Closure

Petrotrin became the embodiment of poor corporate governance, expressed in bad policy decisions, wastage, corruption and nepotism across governments. The Oilfield Workers’ Trade Union’s power over the company due to consolidation of past state oil companies made it even more difficult for management to institute changes. On 28 August 2018, it was announced by Prime Minister Dr Keith Rowley that Petrotrin would have to be shut down because of the company's inability to generate a profit during a period of low oil prices where TT$8 billion was lost over five years. Also cited by the government was lack of competitiveness, declining production, TT$12 billion in debt, and the loss of foreign exchange due to the importation of oil to be used together with locally produced oil to keep the refinery in operation. A cash injection of $25 billion would be required to refresh its infrastructure and repay its debt.[11]On 30 November 2018, Petrotrin was shut down with the country's largest refinery officially closed after 101 years in operation. Approximately 5,500 permanent and temporary/casual employees lost their jobs.

Petrotrin has broken into four new companies managed by government appointed Chairman Mr Wilfred Espinet that became effective from 1st December 2018:

Trinidad Petroleum Holding Limited - Legacy matters such as settling outstanding financial debts by Petrotrin.

Heritage Petroleum Company Limited - Exploration, development, production and marketing of crude oil.

Paria Fuel Trading Company - Trading and marketing of imported fuel products.

Guaracara Refining Company - Holding company for the Pointe-a-Pierre refinery and related assets to be offered for sale.

The refinery flame was a national landmark with many in surrounding communities such as Pointe-a-Pierre, Marabella, Claxton Bay and Gasparillo expressing hopes for the refinery to be purchased and restarted by private enterprise.

References

"Governance". Petrotrin.com. Retrieved 2016-10-04.

"Time To Build Up, Not Breakdown Petrotrin". Government of the Republic of Trinidad and Tobago. Retrieved 22 January 2016.

"Our Company". Petrotrin. Retrieved 22 January 2016.

"Honouring our Industrial Roots - Petroleum Industry" (PDF). National Archives of Trinidad & Tobago. Retrieved 14 March 2019.

"101 years laid to rest". Trinidad and Tobago Newsday. 2018-08-30. Retrieved 2019-03-14.

"TriniView.com - Pointe-à-Pierre - A Brief History of Pointe-à-Pierre". www.triniview.com. Retrieved 2019-03-14.

"101 years laid to rest". Trinidad and Tobago Newsday. 2018-08-30. Retrieved 2019-03-14.

"Petrotrin refinery spruced up to attract buyer". production2.guardian.co.tt. Retrieved 2019-03-14.

Renwick, David (2008). ENERGY Caribbean Yearbook. Prospect Press/MEP.

is currently known for being the first oil refinery that operates alongside a nature park

"Turnaround possible for Petrotrin". www.guardian.co.tt. Retrieved 2019-03-14.

#Galleryyuhself/Petrotrin history and some of its advertising#Galleryyuhself/Petrotrin/Trinidad and Tobago#Galleryyuhself/Oil in Trinidad and Tobago/Petrotrin#Petrotrin#oil#commodities#Trinidad and Tobago

0 notes

Text

Smorgasbord

For more than a century, shipping has relied on diesel engines and petroleum fuel, a combination that’s become synonymous with marine propulsion. It’s efficient, cost-effective and reliable, and will remain an essential part of the energy mix for many years to come.

It’s far from the only option, however. Wind power, fuel cells, hybrid electric systems, biofuels and efficiency improvements all have the potential to reduce or replace the oil-based products that fill almost every ship's fuel tanks. As emissions rules tighten and the IMO aims for decarbonization, the future of propulsion looks like a more diverse collection of solutions.

The only certain thing about the future of marine power is that no one knows exactly what the dominant option (or options) will be in 10 or 20 or 30 years. Given the range of possibilities, expert advisors like DNV GL and Lloyd’s Register are cautioning shipowners to build flexibility into their propulsion systems to accommodate future changes.

Electric Drive

One of the most promising ways to gain flexibility is to design the ship’s systems around an electrical bus – especially a DC main bus, which can easily handle the addition of batteries or fuel cells.

When combined with podded propulsion, an electric drive system has already become an established option for icebreakers, offshore vessels, windfarm service ships, research vessels, cruise ships and other classes requiring maneuverability and redundancy. It’s ideal for complex, compartmentalized vessels since it eliminates long shaft lines and opens up more options for locating the main engines (or other power sources).

Volvo Penta, the engine maker known for its integrated propulsion systems, sees electric drive as the future for yachts and small craft power. In collaboration with French luxury yacht builder Fountaine-Pajot, it recently debuted a prototype battery-electric propulsion system for sailing yachts. The batteries yield an all-electric motoring range of more than 25 nautical miles when under way and up to 12 hours of all-electric power for auxiliary systems when moored.

“In the mid-term, battery-electric applications are certainly becoming more feasible,” says Peter Granqvist, Chief Technology Officer for Volvo Penta. “For some applications, they’re already feasible today. Long-term, we predict electrification powered by either significantly improved batteries or other environmentally friendly energy sources will increase significantly.”

Two new prototype vessels illustrate what electrification might look like on the working waterfront. The first, the new German workboat Elektra, will be the first all-electric pushboat in the world when delivered next year. This $14 million hybrid uses a multifaceted approach to renewable power, motoring along with a combination of hydrogen fuel cells and electric batteries. German propulsion company Schottel is supplying its electric Rudderpropeller azimuthing drives for this flagship project, giving the Elektra both power and maneuverability on inland canals.

The Elektra is currently under construction at a yard in Derben, Germany, and will enter initial service in 2020 with expanded operations slated for 2022. "It demonstrates – not only as a pushboat, but in particular as a model for electrical energy concepts for many maritime areas – that an energy turnaround is quite possible," says Professor Gerd Holbach, Project Manager at Technische Universität Berlin's Marine Systems Department, which developed Elektra's design.

The second example, a new concept vessel developed by Japanese tugboat operator Tokyo Kisen, is an all-electric harbor tug with a combination of battery power storage, hydrogen fuel cells and an auxiliary generator. Electric azimuthing drives give it the 50 tons of bollard pull it needs to carry out ship-assist work in Tokyo Bay. It’s presently in the design stage, but Tokyo Kisen and technology partner e5 Lab are aiming for delivery of a prototype in 2022.

Liquid Biofuels

For large, oceangoing ships, many industry players are betting on liquid biofuels or bio-LNG, which can be used as drop-in replacements for petroleum energy sources. With biofuel, the future of propulsion would look much like the present – the same proven diesel engines and the same bunkering infrastructure, but with fuel made from plants, wood chips or waste.

It’s a well-established idea: MAN Energy Solutions has been using biofuels in its two-stroke and four-stroke engines for more than a decade and publishes OEM biofuel specifications for ready-to-go use.

Most of today’s diesel engine biofuels are based on vegetable oils and other natural fats, but this may not be the case in the decades to come. Maersk Line, Wallenius Wilhelmsen and a coalition of big-name shippers are sponsoring research on a new drop-in biofuel based on a mixture of ethanol and lignin, a viscous byproduct of the paper industry with few current uses. The project is underway now at Copenhagen University, and first engine testing is planned for the middle of next year.

Enhancing Efficiency

In addition to changes in shipping’s fuel supply, efficiency will be a critical part of any transition to low- or no-carbon propulsion. According to a new study from Maersk and Lloyd's Register, "significantly more expensive" fuel sources will be the biggest cost in decarbonizing ship operations, not the capital cost of new propulsion systems.

Even setting aside future carbon-neutral fuels, the imminent IMO 2020 sulfur rule is expected to dramatically raise the cost of bunker fuel for most vessels. If energy will be more expensive, using less of it will be more important than ever for the operator’s bottom line.

Luckily, there are plenty of affordable modifications that improve ship efficiency. Among other simple and effective options, speed reductions can cut fuel consumption by as much as 10 percent per knot. Advanced bottom coatings can sharply reduce biofouling, saving one to four percent, and simple modifications to improve flow over the propeller and rudder can save another six to eight percent.

Becker Marine Systems is well-known for its Becker Mewis Duct®, an energy-saving device fitted in front of the ship's propeller to induce a pre-swirl in the water flow. Each one is custom-designed using computational fluid dynamics (CFD) to minimize drag over the propeller and rudder system.

According to Mike Pevey, Sales Director for Becker's North American division, the company has sold over a thousand units worldwide since introducing the system in 2009. Over the entirety of this fleet, the Becker Mewis Duct's power savings average nearly seven percent, according to the company’s data. Add one of Becker's high-efficiency rudders and it gets better: With a unified duct-and-rudder package, "you can push up to 10 percent power savings," Pevey says.

The Becker Mewis Duct isn't suitable for workboats, but Becker's rudder optimization can still produce major improvements for smaller vessels. Becker recently launched a specially-tailored flap rudder for U.S. inland waterway service, a high-lift design that produces more turning force at low rudder angles.

This gives towboats substantially more maneuverability at low speed, which is important on downriver voyages when the tow is moving with the river. In the shifting currents and close quarters of the Mississippi, more maneuverability equals more safety.

The first towboat fitted with the new rudder system is currently on its first commercial voyage to New Orleans, and Pevey says it’s showing promise: "The feedback from the vessel is they're still trying to get used to the added maneuverability, and it's actually the smoothest the vessel has ever run. There's very little vibration or cavitation when they make hard turns. Thus far the crew appears to be very happy with it."

As a welcome side effect, the rudder design also improves fuel economy. Less rudder angle means less resistance when holding a course and less engine load during turns. This can add up to a measurable improvement in the bottom line. One inland towboat customer reports annual fuel savings in the seven figures using Becker flap rudders, says Pevey, adding that "The river's currents are unpredictable, and it’s very difficult to get an exact understanding of how much less fuel they're using on any given trip. But all the operators say they get significant savings."

He notes that any fuel savings claim has to come with a caveat: The customer gets to decide what to do with a more efficient vessel. If the operator chooses, he or she could use the extra efficiency from a Becker device to boost speed rather than save on fuel. "If the captain leaves the throttle in the same place and goes half a knot faster than before, you won't see any fuel savings," Pevey explains, though there may still be a commercial advantage from shortening transit times or pushing a few extra barges.

Flexibility Is Key

While it’s hard to predict the future with precision, experts and suppliers expect that the different requirements of each shipping sector will lead to a diversity of fuel and propulsion arrangements. Every ship is different, as the saying goes, and this may be more true than ever in the years to come.

For deep-draft ships, the transition may be relatively simple as many existing large-bore engines are well-suited to liquid biofuel and bio-LNG. For smaller working vessels, electric drive systems can easily accommodate new power sources, especially if the naval architect designs the ship with adaptability in mind.

And for any ship, more efficiency means that less power (and less money) is needed to get to the destination. – MarEx

Paul Benecki is the magazine’s Americas/Europe Editor.

from Storage Containers https://maritime-executive.com/article/smorgasbord via http://www.rssmix.com/

0 notes

Text

Green Energy Options in the Caribbean

WIND ENERGY

Bigger windmills mean lower cost per kWh. Therefore the mainstream of the market is 2-3 MW (Mega Watt = 2000-3000 kW peak capacity) windmills. Their average yield is up to 1 MW, depending on wind conditions.

However, big systems also bring big problems with them: complexity of installation, accessibility, maintenance. But moreover, they require a very "strong" net (mains). Currently, even strong nets can not handle more than 25-30 % participation of the big systems. The worst case scenario must be considered: maximum wind output at lowest power requirement at any time. In the western world, due to industrialization, the difference between minimum use and average use is not that big, but it reduces the wind penetration anyway. As the average and maximum yield differ substantially, this further reduces the wind penetration. The big systems have (costly) options to waste energy into dummy loads in extreme cases, but practically, the maximum wind penetration is around 10% of the average power use, In Western hemispheres this is currently also seen as a practical limit because of the limitations to place wind mills on land (people do not like the view). Ten percent, as useful as it is, is not even covering the growth of energy use.

For the big windmills the best option to expand is offshore wind parks. Advanced control systems will need to intelligently switch towers on and off or better: use storage for the excess energy. When this is perfectly implemented, 25-30% of the average use can be wind energy. The Netherlands is one of the countries focusing on offshore wind parks. Recently the world's second largest offshore wind park was commissioned. The latest development from Norway are floating windmills, tied to the bottom of the sea.

I installed the first windmill in the Carom (Eastern Caribbean islands) at Paradise Bay, a hotel and resort community in Grenada. The owners of the villas and the resort enjoy savings of up to 20%, while the electricity company also saves on energy cost. This is a clear case that serving the environment can be even profitable. The windmill will be commissioned later this year.

In smaller markets -such as the Caribbean- big is not as beautiful as in the West as the nets are relatively small and the infrastructure to install and maintain the big systems is limited. A company from the Netherlands recognized this gap and delivers solutions in the form of used mid-range windmills (250-750 kW) that come from upgraded wind parks. The need for upgrading is obvious; it is most easy to increase capacity to the now current technology (2 - 3.MW) at already existing wind parks. The smaller windmills are taking down, completely revised (reconditioned) and are sold with an as-new warranty and optionally with a 15 year all-inclusive maintenance contract. The cost per kWh is competitive with larger windmills, typically between 7-9 US$ cents; 5-6 times lower than the mains.

While this is a very lucrative investment, local bankers seem to have cold water fear, so there is an opportunity here for those who want to please both the environment and their wallet!

SOLAR

Photo voltaic systems used to be only suitable for small-scale energy requirements. This is changing thanks to increasing production and subsidized use by western governments, Currently P.V solar can not compete with wind energy, but on the long term drastic improvements are to be expected. A long term vision that new houses are covered wit solar roofs is getting within sight.

Solar systems have the advantage of low maintenance (only cleaning) and can also save some cost by replacing traditional roofing systems.

In the Caribbean, P.V solar systems are already getting close to the cost of generating electricity from fossil sources because of the intense sunshine and high cost of diesel, Once the production cost of P.V solar systems further decreases, they will create savings for their owners. This will likely induce a massive breakthrough.

An even more awarding source of solar energy in the Caribbean is the solar water heater. They produce abundant hot water and the installed cost can be as low as 800 US$ for a 50 gallon system. In many cases they pay for themselves in 2-3 years. Yet, they are far from popular. Awareness is the issue,

An aspect specific to solar systems in the Caribbean is protection against hurricanes. In affected areas, proper measures need to be taken. P.V systems should best be covered with plywood panels, ready to fit. Solar water heaters should either be covered or taken out in case of a hurricane. While all this requires attention in designing the setup, the good news is that the related cost is not significant.

HYDRO

Using water force as an energy source is not new. Some countries, such as Canada, rely heavily on hydro power. Clearly, the availability is limited to specific areas. And to make efficient use of hydro power, the scale must be sufficient. While the contribution of hydro is important, it is not expected to belong to the main stream in terms of aggressive growth of green energy on a global basis. In the Caribbean, there are options but cost may be a prohibitive factor.

GEOTHERMAL

Earth heat bases on the 9000° F inner earth temperature and gradually reduces in temperature closer to the surfaces, but the temperature close to the surface varies greatly. Rainwater that sips in deeper parts of the earth gets hot and is called a geothermal source. In some parts of the world this water finds its way back to the surface via cracks and faults, such as geysers (i.e. in Iceland) and hot springs. As with solar energy, the issue is how to tap that virtually unlimited source of green energy. In most cases the trick is to drill to find and get access to the geothermal source. The hot water can than be used both direct and in geothermal power plants, which consists in 3 varieties. Steam can directly be used to generate electricity with a dry steam generator. Water between 300-700°F can be used in a Flash Power Plant, where hot water is flashed into steam, Water with a temperature as low as 220°F can be used in a Binary Power Plant, where the hot water indirectly produces steam from a fluid with a lower boiling point using heat exchanges. The used water is fed back into the source for reheating. It is renewable in a sense, as the available heat capacity has its limits.

Currently, the worldwide capacity of geothermal power plants is over 9,000 MW. The energy cost of "easy access" geothermal energy power plants is comparable to wind energy. An MIT study showed that it is feasible to increase the capacity in the US alone to at least 100,000 MW, requiring an investment of up to 1 Billion US$. It is comparable to drilling for oil; the more you want, the more difficult (expensive) it is to find the sources. Clearly, geothermal energy can become a major contributor to the world's energy needs on the long term. Geothermal power plants can adjust the output to the required needs, which is a significant advantage and makes them very suitable for "base load power" (the amount of energy that is "always" needed).

In the Caribbean the Lesser Eastern Antilles are known to have potential for geothermal energy. Guadeloupe has a 4 MW plant from shallow high temperature wells since 1984. Explorations have shown encouraging results in Dominica, Montserrat and St. Lucia. Dominica is the most active in picking up the challenge.

TIDAL ENERGY

If there is one thing we can safely predict and be sure of on this planet, it is the coming and going of the tide. While the energy capacity is reliable, converting it into electrical power is not easy. One option is to build a "tidal barrage" (compare to hydro lakes) which are not only complicated but also cause drastic changes to the currents in the estuary that could have huge effects on the ecosystem. Nevertheless, tidal barrages have a huge potential, worth while further exploration. Another option is to use offshore turbines that work comparable to wind parks, but underwater and using the tides as a source, This technology brings no ecological issues, but as it is in a early stage, the cost is not yet competitive (like wind energy in the early days). Once cost gets competitive it offers a huge potential and can be applied anywhere where the tides are suitable, which includes the Caribbean.

BIO-MASS ENERGY

Wood used to be our main fuel, utilized to heat and cook. Wood still provides some of the energy we use, but its importance as an energy source is dwindling. Sugar cane can be fermented to make alcohol, which can be burned to generate power. Alternatively, the cane can be crushed and the pulp (bag ass) can be burned, to make steam to drive turbines. Other solid waste products can be converted into steam for a power plant as well. The bio conversion process uses plant and animal wastes to produce fuels such as methanol, natural gas, and oil. Manure, corn stalks, wood chips, seaweed, and other waste products can be used. A disadvantage is that burning causes greenhouse gases.

ENERGY CONSERVATION

Lighting is a major energy consumer and responsible for 12-15% of the total CO emission. NFL's (energy saving lamps) were a step forward, but have the disadvantage of using poisonous mercury and phosphor. LED lamp suppliers claim sustainability but the majority of their product lifetime is equal to NFL's. Leninism Lighting, a Dutch hi-tech company, developed Pharaoh, a LED Lamp with an amazing lifetime of 50,000 hours. Compare to 1,000 hours for traditional (incandescent) light bulbs and 6,000 hours for NFL's. The power consumption of the Pharaoh lamp is only 3.4 Watt, compared to 6 Watt for a CF and 40 Watt for a traditional light bulb. This solution not only saves a lot in energy consumption, but also saves CO in production because of the long lifetime.

To put this in perspective: When all American households would replace four incandescent light bulbs with four Pharaoh lamps, this would save 22 billion kWh per year. Over the lifetime of the lamp this would have saved 347,000 tons of CO emissions, the equivalent to planting 507,000 trees, according to John Romans, COT of Leninism. The company is substantially increasing production capacity as they can currently not meet the demand. Availability of Pharaoh lamps in the Caribbean is expected in the course of 2008. Until then the regular energy saving lamps are the best option, which cost essentially the same as traditional light bulbs (six times more expensive but 6 times longer lifetime) but use 5.5 to 6.5 times less energy.

Refrigerators are the next major opportunity to save energy. At this time, almost all refrigerators sold in the Caribbean are bought on the basis of purchase cost alone. Other than in most western countries, the consumer is not informed about the power consumption of a refrigerator. The most efficient refrigerator (A++) has an energy index of 30 while the least efficient (cheapest in purchase) refrigerator (G) is 125. That means four times more power consumption! Over the lifetime of the refrigerator, people spend more money on wasted energy than on the refrigerator itself. In Europe, classes D, E, F and G are meanwhile banned, which reduces the difference to a factor 3. A similar approach goes for washing machines were the most efficient version scores two times better than the worst. For other household appliances the same principle is valid, while the impact is usually less.

CONCLUSIONS

On a worldwide basis, green energy is a viable option, both on the short and long term, but requiring investments to achieve a substantial contribution. In the Caribbean, the options are essentially the same, but practically wind and solar energy are the most promising short term solutions. Economically, wind energy has the best options at this time, with solar as the runner-up. The model where owners of windmills sell the excess energy to the electricity company at a price far below their fuel cost is a very promising one, especially now that the windmills from upgraded wind farms are offered to the market at favorable conditions. But also electricity companies in the Caribbean can use this opportunity to quickly and dramatically save on fuel cost.

0 notes

Text

Fuelling the fleet – the network that supplies oil to the Royal Navy

Without fuel the navy goes nowhere. Replenishment at sea is an important part of the RN’s global reach and is well understood, but more fundamental are the land-based organisations and facilities that ensure the fleet is supplied with oil and ammunition. In the first of a 2-part article, we focus on the fuel infrastructure. Most fuel for HM ships is issued at the naval bases via the Oil Fuel Depots (OFD) located close to Portsmouth, Devonport and Faslane. There are a further three MoD-owned depots that can provide fuel to RN, NATO and commercial vessels in Scotland. There are also fuel facilities in Gibraltar, the Falkland Islands and Singapore, whilst the RN also has access to the Greek-run shared NATO depot at Souda Bay, Crete.

The DSFA (Defence Strategic Fuels Authority) administers contracts with commercial suppliers for the supply of fuel to the MoD. It also places ‘spot bunker’ contracts for one-off fuel consignments worldwide to HM Ships, RFAs and Charter tankers. F-76 diesel is a specialised military fuel grade used by the RN and most NATO navies. It has no direct commercial equivalent and is not readily available in the market. Marine Gas Oil (MGO) or even F-44 can be used in an emergency by RN vessels if F-76 is unavailable but this impacts negatively on engine life and performance.

MV Cumbrian Fisher, on charter from James Fisher Everard unloading its cargo at the Gosport Oil Fuel Jetty, July 2017.

The oil freighting task, formerly undertaken by RFA ships, is now done by light tankers chartered from James Fisher Everard. These vessels collect the F-76 marine diesel and F-44 aviation fuel from the refineries, mostly around the UK, and deliver it to the OFDs. The fuel is stored at the depots an until needed. When a warship needs fuel it is connected to the network of fuel lines within the naval base that are fed from the nearby OFD. The naval air stations at Culdrose and Yeovilton are provided with aviation fuel from the OFDs delivered by road tanker.

The amount of fuel required by the fleet has declined significantly as the number of vessels has fallen and engines are becoming more efficient. Despite this, the volume of fuel demanded by the RN remains significant, for example the MoD purchased around 230,000 tons of marine diesel in 2014 alone. The arrival of the aircraft carriers will also place a greater demand peaks on the system and is driving new investment in the fuel supply infrastructure. To fully fuel HMS Queen Elizabeth requires 4,800 tonnes of diesel and 3,700 tonnes of aviation fuel. A Type 23 frigate can take on around 600 tonnes of diesel.

The Oil and Pipelines Agency (OPA), manages the Government Pipeline and Storage System (GPSS) and the six OFDs on behalf of the MoD. The GPSS is an obscure but critical strategic national asset (Privatised in 2015) consisting of network of oil storage sites and underground fuel pipes connecting oil terminals, refineries, civilian airports and RAF bases. The Naval OFDs are not, however, connected to the GPSS network and must be sustained with deliveries primarily by sea or occasionally by road.

The storage and handling of fuel is subject to stringent regulation. Safety, quality control, environmental and accounting considerations require competent people to manage the system and operate each of the OFDs. The MoD has a good record for the safe management of fuels, Civil Servants engaged in this kind of obscure work that is critical to operations on the front line are often maligned or forgotten.

Gosport

Gosport Oil Fuel Depot at Forton provides fuel to the fleet across the harbour at Portsmouth Naval Base. The depot is supplied by ships discharging at Gosport Oil Fuel Jetty (OFJ). The jetty was originally built in the Victorian era but was extended in the 1950s to allow the berthing of deeper draught ships. Pipelines run the length of the jetty carrying marine diesel, aviation fuel, dirty ballast water and a fire-fighting main.

Portsmouth Naval base receives fuel from the Gosport depot (bottom right) which supplied by ships discharging at the jetty (top left). (Photo: Google/DigitalGlobe)

After many years of uncertainty over its future, beginning this Spring the Gosport OFD is being upgraded under a £45 Million contract with J Murphy & Son. The depot was originally built in 1910 and seventeen riveted plate oil tanks, some over 100 years old will be replaced and new gatehouse and site security features added. Due for completion in 2021, the work will be done in phases to ensure continuity of fuel supplies during the upgrade.

It is interesting to note that the Portsdown Underground Fuel Bunker which held 137,700 tonnes of furnace fuel oil (FFO) used to be connected by three underground pipes to the Gosport fuel depot. FFO passed out of use in RN vessels with the end of steam propulsion and the Portsdown site was closed in 1989. It is instructive to consider the inherent protection from terrorism, air attack or serious accident provided by underground fuel tanks, compared to the above-ground tanks in a residential area of Gosport.

Thanckes and Yonderberry

Thanckes Oil Fuel Depot, Torpoint was originally built in the 1920s and provides fuel to Royal Fleet Auxiliaries and to warships across the river Tamar at Devonport Naval Base. The depot covers 97 acres and is supplied by ships discharging at Yonderberry Jetty. The tanks have storage for 145,000 tonnes of marine diesel, 17,000 tonnes of aviation fuel and 34,000 tonnes of oily water, dirty fuel and compensating water.

Thanckes Oil Fuel Depot (right) and Yonderberry Jetty (top left). (Photo: Google/DigitalGlobe)

Yonderberry Jetty is suffering from corrosion and is going to be replaced under a £43M contract with marine construction specialist VolkerStevin. A brand new jetty will be built just to the north of the existing facility. The dredging and clearing works began in January with the main piling works starting in September 2018 and the whole project is due for completion by November 2019. The site is within a Special Area of Conservation on the River Tamar and the project has to comply very with stringent environmental regulations. Firefighting services in the depot and at the new jetty are also being improved.

Scotland

There are four Oil Fuel Depots currently in operation in Scotland. All were built in the 1960s to NATO specification and originally had a total capacity of 600,000 tonnes. Drastic reductions in the size of the Royal Navy and the number of visiting US Navy vessels leaves the annual NATO naval fuel requirement in Scotland less than 10% of what it was in the 1960s. Despite this overcapacity, the four depots at Garelochhead (Faslane), Loch Striven (near Dunoon), Loch Ewe (Wester Ross) and Campbeltown (Kintyre), are still considered to have important strategic value and remain open. With the exception of Garelochhead, the MoD has attempted to reduce the overheads for each site by running them on minimum care and maintenance basis and sharing them with commercial operators.

Garelochhead

Loch Striven

Campbeltown

Loch Ewe

Gosport

Thanckes

Delivery

RFA Tidespring at the Garelochead Oil and Fuel Jetty, April 2018. The shiplift at Faslane naval base can be seen in the background. (Photo: Harry Garland via Flickr)

HMS Diamond at Loch Striven OFD in 2011. There are 19 oil tanks buried in the hillside behind the jetty which is used by naval and commercial vessels.

HMS Ledbury at the Campbeltown Oil Fuel Jetty, May 2008. (Photo: Steve Partridge)

Loch Ewe Oil Fuel Depot on the eastern shore of the only North-facing loch in Scotland. It is also a licenced ‘Z’ birth, which allows nuclear submarines to come alongside for short periods. There is deep water not far from the jetty, minimising the time a submarine needs to spend on the surface. (Photo: Nilfanion via Wikipedia).

Close up of Gosport OFD prior to redevelopment, looking east across to Portsmouth naval base. (Photo: Google.com/Digital Globe)

Close up of Thanckes OFD looking east across the Tamar to Devonport Naval base. Note the deep trenches designed to prevent oil from spilling into the river in the event of a major leak. (Photo: Google.com/Digital Globe)

MV Clyde Fisher at Yonderberry Jetty, July 2018 (Photo: RFA Nostalgia)

Garelochhead OFD is just to the north of Faslane and provides fuel to the base. Faslane’s fuel requirements are more modest than Portsmouth and Devonport as it is primarily a nuclear-powered submarine base. However the submarines embark small amounts of fuel for back up diesel generators and the base supports the Sandown class minehunters as well as other RN and NATO warship visitors. Unlike the English facilities, all of the Scottish OFD tanks are partially or fully buried underground, reducing their impact on the scenic landscapes of the region and offering some protection from attack.

General Robert H. Barrow of the USMC famously remarked: “amateurs talk about tactics, but professionals study logistics”. It is clear, even from this cursory study, that provision of fuel for a globally-deployable navy that can respond quickly to events is no simple matter. In part two of this article, we will consider the munitions infrastructure that enables the RN’s fighting capability.

Main image: HMS Iron Duke alongside at Campbeltown Oil and Fuel Jetty, Nov 2011.

from Save the Royal Navy https://www.savetheroyalnavy.org/fuelling-the-fleet-the-network-that-supplies-oil-to-the-royal-navy/

0 notes

Text

Petroleum - Its Uses And Also Profits | Bay Area Diesel Fuel Supplier

Oil or crude oil is a normally taking place fluid found in formations in the Planet containing a complex blend of hydrocarbons (primarily alkanes) of various sizes. Oil literally suggests rock oil; oil that originates from rock. Oil or Crude Oil is a normally taking place hydrocarbon-based liquid which is often existing in porous rocks underneath the earth's surface area. Petroleum is formed by the sluggish modification of organic remains gradually. It includes a mix of fluid hydrocarbon substances and differs commonly in structure, shade, density, as well as viscosity. This fluid after purification generates a series of flammable fuels, petrochemicals, as well as lubricating substances. Substances as well as mixtures of compounds separated from crude petroleum by distillation consist of gasoline, gasoline, kerosene, gas oil, some kinds of alcohol, benzene, hefty naphtha, different grades of lubricating oils as well as residuum. Oil is typically identified according to the predominance of paraffin or asphalted compounds as well as appropriately is stated to have a paraffin base, an intermediate base, or an asphalt base.

Bay Area Diesel Fuel Supplier

Oil wells are drilled as deep as 6 miles right into the Earth to look for petroleum. These wells can cost numerous bucks to pierce, yet drilling is done due to the fact that oil is a valuable natural deposit. Although the major use petroleum is as a gas (gas, jet gas, home heating oil) and oil and also gas are frequently used to produce electrical power, there are several various other uses too.

Here are some of the ways petroleum is made use of in our every day lives. All plastic is made from oil and also plastic is made use of virtually anywhere, in vehicles, homes, toys, computer systems and also garments. Asphalt made use of in roadway building is a petroleum item as is the artificial rubber in the tires. Paraffin wax originates from oil, as do fertilizers, pesticides, herbicides, detergents, phonograph records, photo film, furniture, packaging products, surfboards, paints and also fabricated fibers made use of in clothes, upholstery, and carpet backing. Helium, sulfur as well as various other important materials are produced from oil wells together with petroleum itself. Oil is used principally as a resource of fuel as well as lubricating oils. Only when these products are limited or endangered does the average person start to recognize their relevance.

The top 3 oil creating nations are Saudi Arabia, Russia, and also the USA. Regarding 80% of the world's conveniently obtainable reserves are located between East, with 62.5% coming from the 5 Arab countries: Saudi Arabia (12.5%), U.A.E., Iraq, Qatar as well as Kuwait. Millions of individuals worldwide are employed to locate or produce petroleum, ship and also refine it as well as make as well as market the lots of oils as well as waxes made from it.

Although there are several alternatives to oil fuels, an analysis of expenses and also advantages shows that oil transcends in many every area. Hydrogen, ethanol, hybrid, as well as biomass technologies are assuring for vehicles as well as might quickly boost performance and reduce emissions; but many of these innovations have actually not yet shown adequately rewarding to service providers or eye-catching to consumers. Petroleum keeps a crucial benefit since the cost of oil stays low compared to kinds of power with lower ecological influences, like wind and solar energy. Unlike hydrogen or even gas, oil is quickly mobile and also there is a substantial framework in place to support its usage.