#Automotive Piston Market

Explore tagged Tumblr posts

Text

The global automotive piston market is evolving rapidly, reaching a market size of US$ 4.3 Billion in 2023. With a projected growth to US$ 5.5 Billion by 2032, at a CAGR of 2.6%, this market is a key area of focus for the automotive industry. Learn more about the trends and factors driving this growth in IMARC Group’s latest report.

0 notes

Text

Automotive Piston Market is Driven by Strict Regulations to Decrease GHG Emissions

The automotive piston market was USD 4,199.2 million in 2023, and it will increase to USD 5,806.1 million, advancing at a 4.8% compound annual growth rate, by 2030.

The need for automotive pistons is rising because the middle-class population can now easily buy cars owing to its increasing disposable salary as well as urbanization in developing nations.

Moreover, governments across the globe have implemented strict rules to decrease greenhouse gas emissions, in reply to the rising environmental worries.

As a result, vehicle manufacturers are now utilizing cleaner as well as more fuel-effective engines to comply with these regulations. New piston materials and designs are necessary to attain these goals, as they can improve combustion effectiveness and decrease engine friction.

The aluminum category, based on material, is a significant contributor, because of the lightweight character of pistons produced from this material than those produced from steel and cast iron. This aids in engine weight reduction, which is key for improving performance as well as fuel economy.

The commercial vehicles category, based on vehicles, accounted for a significant share in 2023, of 65%, and it will further advance at approximately 4.5% CAGR, during this decade. The need for commercial vehicles has significantly expanded over the years because of the speedy trade globalization and rising e-commerce activities.

The thermal barrier category, based on coating, is leading the automotive piston market, as thermal barrier coating offers a solution for many issues associated with engine durability and performance.

The flat-top category, on the basis of shape, will advance rapidly in the coming years, primarily because of its tinnier surface area. This led to less carbon formation, which keeps the engine clean and avoids knocking. Moreover, their enhanced compression ratio and reduced combustion chamber volume enhance combustion productivity.

Furthermore, their enhanced thermal productivity results from less heat being wasted through the cylinder walls. In addition, flat-top pistons comprise thicker crowns, which improve the firmness in high-performance engines.

APAC was the largest contributor to the industry in 2023, with over 40% share, and it will further advance at approximately 5.5% compound annual growth rate, in the years to come. The regional industry is driven by the expansive automotive sector of China.

Furthermore, with their increasing vehicle sales and production, South Korea and India are also major contributors to the APAC industry. This is because such factors consistently boost the need for these automobiles’ components among aftermarket entities and OEMs.

It is because of the strict policies for reducing greenhouse gas emissions and the move towards direct-injection gasoline engines, the automotive piston industry will continuously progress in the coming years.

Source: P&S Intelligence

#Automotive Piston Market Share#Automotive Piston Market Size#Automotive Piston Market Growth#Automotive Piston Market Applications#Automotive Piston Market Trends

1 note

·

View note

Text

Automotive Engine Piston Market SWOT Analysis, Business Growth Opportunities by Top Companies and Key Players

Global Automotive Engine Piston Market research report published by Exactitude Constancy reveals the current outlook of the global and key regions from the following perspectives: Key players, countries, product types, and end industries. The report studies the top companies in the global market and divides the market into several parameters. This Automotive Engine Piston Market research report pinpoints the industry's competitive landscape to understand the international competition. This report study explains the expected growth of the global market for the upcoming years from 2024 to 2030. This research report is accumulated based on static and dynamic perspectives on business.

The global automotive engine piston market is expected to grow at a 4.0% CAGR from 2024 to 2030. It is expected to reach above USD 2.82 billion by 2030 from USD 1.98 billion in 2023.

Browse Complete Summary and Table of Content @

https://exactitudeconsultancy.com/ja/reports/4749/automotive-engine-piston-market/

#Automotive Engine Piston Industry#Automotive Engine Piston Market 2024#Automotive Engine Piston Market Analysis#Automotive Engine Piston Market Research Report#Automotive Engine Piston Market Demand#Automotive Engine Piston Market Growth#Automotive Engine Piston Market Insights#Automotive Engine Piston Market Revenue#Automotive Engine Piston Market Share#Automotive Engine Piston Market Size#Automotive Engine Piston Market Trends

0 notes

Text

Automotive Piston Market Will Reach USD 5,806.1 Million By 2030

The automotive piston market has garnered USD 4,199.2 million in revenue in 2023, and it is projected to rise at the rate of 4.8% from 2024 to 2030, to capture USD 5,806.1 million by 2030. The need for automotive pistons is growing because middle-class individuals can now buy cars due to their increasing per-capita income and urbanization in developing nations. The aluminum category grips a…

View On WordPress

#Automotive Aftermarket#Automotive Engineering#Automotive Industry#Automotive Piston#Engine Components#Engine Efficiency#Engine Innovation#Engine Power#High-Performance Engines#Lightweight Pistons#Market Players#market trends#Piston Design#Piston Manufacturing#Piston Materials#Piston Technology#Piston Types#Vehicle Performance

1 note

·

View note

Text

Launched a century ago, the Bugatti Type 35 didn’t just make a single impact—it revolutionized the racing world with its innovative design and engineering. The car became legendary not only for its initial capabilities when it debuted in 1924 but also for the continuous improvements Bugatti implemented throughout its production. Ettore Bugatti was one of the first automobile manufacturers to grasp the marketing potential of winning races on Europe’s renowned circuits and road tracks, which brought considerable publicity to his brand. Confident as he was in the capabilities of his new car, even Bugatti could not have predicted that the Type 35 would become the most successful race car in history, achieving 2,500 victories during its active racing career.

The first Type 35, released in 1924, was equipped with a 1,991cc eight-cylinder engine, delivering 90 PS in race trim. By early 1926, Bugatti had increased the engine size to 2,262cc for the Type 35T, named after the famous Targa Florio road race in Italy, which it won, with two smaller-engined Type 35s finishing close behind. Despite this success, Ettore Bugatti realized that to stay ahead of the competition, he needed more than just increased engine displacement. He knew that the future of performance lay in forced induction, even though he was initially not a fan of superchargers, which were seen as inefficient at the time.

“It’s no secret Ettore Bugatti preferred naturally aspirated engines and was not an early enthusiast of supercharging due to its perceived inefficiency,” says Luigi Galli, Specialist for Heritage and Certification at Bugatti. “However, what’s less well known is that Bugatti was forward-thinking about the potential of forced induction, experimenting with superchargers even before the Type 35 debuted at its first race in Lyon in August 1924. In fact, Bugatti applied for French patent number 576.182 on January 22, 1924, for a ‘Compresseur ou pompe à palettes,’ a rotary vane supercharger design that could provide extra power on demand by forcing pressurized air into the carburetor. If Bugatti was going to use a supercharger, he was determined to innovate in his own way.”

As a result, Ettore Bugatti, alongside the Italian engineer Edmond Moglia, developed a unique three-rotor Roots-type supercharger, differing from the common two-rotor designs of the time. This supercharger was strategically mounted on the engine’s offside, which allowed it to warm up more quickly and improve overall engine cooling—a principle that remains relevant in modern engine design. The Type 35TC, where “TC” stands for Targa Compressor, was introduced in late 1926. It evolved into the Type 35B in 1927, featuring a larger radiator and cowling, known as the ‘Miramas’ design, which enhanced cooling capabilities. This configuration enabled the Type 35B to produce up to 130 PS, achieving speeds over 205 km/h (150 mph).

By late 1930, further refinements led to what many consider the ultimate version of the Type 35B. This final iteration featured a twin-cam, two-valve-per-cylinder engine, a twin fuel filler cap, improved suspension, wheels, brakes, and tires, as well as a lower-mounted supercharger relief valve. Bugatti’s relentless pursuit of perfection extended to optimizing every element of the combustion system, from sculpted pistons and cylinder heads to the use of aviation-grade fuel, which boosted the output to 140 PS.

Today, at Bugatti’s atelier in Molsheim, each Bugatti model is hand-assembled with the same meticulous attention to detail that Ettore Bugatti applied to the Type 35. A century later, Bugatti’s engineers and designers continue to push the boundaries of automotive excellence, upholding a legacy of innovation and performance that began with the groundbreaking Type 35.

8 notes

·

View notes

Note

OMG I'm such a dumbass I knew you did one on the GR Yaris before too, and I love her ALSO, but I actually meant the GR Supra 😳🫣 (slip of the tongue)

Gotcha.

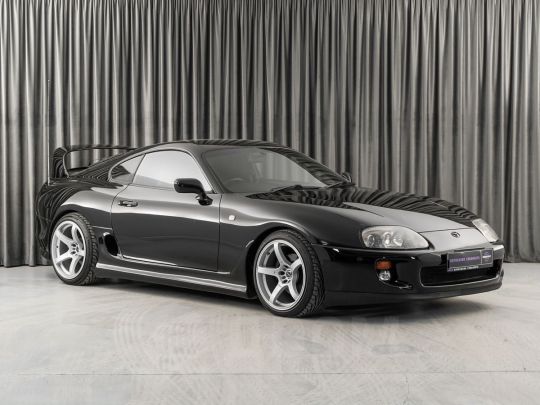

Since I managed to take some two weeks to answer this (got distracted both by real life obligations and other posts that were meant to be very quick to make. Meant to.) y'all may have forgotten, but our dear friend of the blog had asked for opinions on the GR Yaris, hinting to its controversial status. Turns out the GR Supra is what that request, and thus that hint, was actually about - so let's talk about the car and the controversy that engulfs it.

In 1993, Toyota launched the fourth generation of its rear wheel drive sportscar (well, arguably a bit of a Grand Tourer, i.e. something more oriented to cruising than a sportscar) the Supra - which was born a quarter century earlier as a more upmarket, six cylinder version of the Celica, graduating from Celica Supra to its own dignified name with the third generation I talked about that one time I forgot to check what blog I was reblogging with.

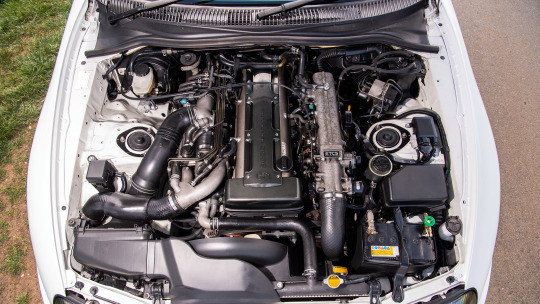

But this time, things would be different. Most notably because the inline six the Mk4 Supra came out with was an absolute MONSTER.

Remember how I talked about the GT-R's RB26 engine being one of the greatest, most coveted production engines to ever come out of Japan? Well, the 2JZ-GTE is the other.

It was larger at 3 liters, no less powerful, and to reduce turbocharger lag it used two of them sequentially: first air goes in the smaller, more responsive turbo, then gradually some of it gets sent to the bigger turbo to make it start spinning, then when it gets going the two are finally used in conjunction. (Imagine the big turbo as a hung husband that takes a while to get it up and the small turbo as an eager stepson ready to take over until the hung one can join in for a spitroast. Or something. I don't watch porn with real people, but from what I gather the plots seem to resemble how sequential turbos work.) It even at one point got Variable Valve Timing, i.e. the ability to vary the time in which the valves open depending on engine speed, which allows to optimize tuning for performance and efficiency! (Cool thing to go over in detail if y'all want me to.) And also, the kind of things that engine is able to take make me wish I hadn't used up my porn analogy quota.

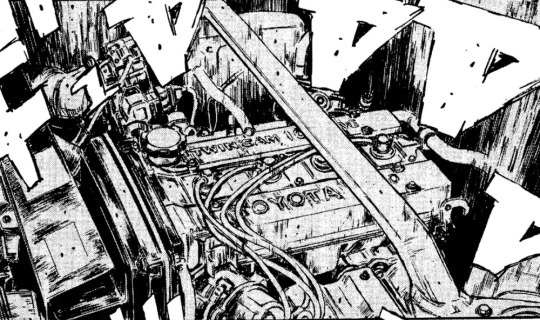

See, to chop off eons of nuance, an engine is just a big block of metal with a lot of bits attached, and the two main measures of an engine's potential are the slope of the line in the Bits Fiddled With / Power Output graph and how far up (It's up, right? The second axis you specify is the vertical one, right?) you can take it before the block becomes the weakest link - with another important point being when you need to start messing with internals, i.e. the components inside the engine, e.g. pistons (the things the boom pushes down), camshaft (the thing the pistons spin) and connecting rods (you can guess).

So for instance, just to make the point that an engine can be beloved without having much overall tuning potential, in one of Toyota's most beloved engines, the 4A-GE four cylinder illustrated above (yes, the one from that white and black car in all the eurobeat videos), some pin the block's limit as low as 250hp. The 2JZ, tho? It can take 800hp without even messing with the internals, and once you get your grubby hands on those you can keep pushing the line to some 2000hp. That is two Bugattis. That is 40 times my car. That is well above the power level where "tires that will at any point grip" and "tires that are in any way road legal" stop intersecting.

I am not in the slightest exaggerating when I say that this and the Skyline GT-R are widely regarded as the top of Japan's 20th century automotive production. The Messi & Ronaldo of the Japanese Domestic Market. It is absolutely no coincidence this was the hero car in The Fast And The Furious.

And then in 2002, as all things, its production ended, and given the abysmal sales and catastrophic recession, Toyota decided that would be that.

And then, years later, The Teasening began.

I want to stress, almost half of my conscious life (I choose to believe the stretch from birth to kindergarten is just run-up) the world was in some state of getting teased with talk of a new Supra. The trademark on the name was renewed in 2010. In 2014 they dropped the FT-1 concept, and of course that became speculation about what the production version would look like.

Because come the fuck on, it's not gonna look like that.

Or was it?

Only five entire years and much more teasing later would we officially get an answer, when after seventeen years, the Toyota GR Supra (and for those wondering what GR means, y'all should've clicked the Yaris link >:C) hit the streets.

You know what, good enough.

Good enough to earn itself a sea of words of praise, Jason Cammisa's "The most punch-above-its-weight sportscar ever made" just some among them.

It did have its share of problems at the start, like its power being 335hp and not 382, a lack of manual transmission, and the inability to spec it with a less powerful 4 cylinder engine - well, I don't know who considered that last one a problem, but Toyota's updates solved that one too.

The Supra has a much bigger problem than those though, one no little update can solve. That red car in the background.

See, the new Supra is actually a joint venture with BMW, who made a new model of its Z4 roadster out of the platform. And unlike with the other joint-venture sportscar Toyota sells, people are big mad about that. Why?

See, the interior is engulfed in BMW switchgear and the drivetrain is all BMW (the manual gearbox took until this year to come out because BMW did not have one for that engine so Toyota had to modify another BMW transmission to fit), giving people the impression that this was less of a joint venture and more of a BMW project that Toyota tacked its design on top of, which is a problem whether true or not.

See, a range-topping sportscar is supposed to represent what the brand is capable of - having it done by someone else (or so the criticism goes) is a bit like performing Hallelujah in playback.

Actually, a better musical analogy: You know "I'm back bitch" singles? When a humongous artist drops a new record with a humongous lead single about absolutely nothing but reaffirming they're the biggest fucking deal in the universe? Without Me, Bad, Gimme More, so on. Well, think of SexyBack - one of the most monumental phenomenons of its decade, most incontrovertibly proving Justin Timberlake sat atop the goddamn world. Now, imagine if, after all the years that went by between that record and the next, when he finally came out with Suit And Tie all the verses were Jay-Z. Going from a humongous statement about having the power to reach the top of the game and stay there to having to get absolutely carried by what in this logic is essentially a competitor. Basically, that's the critics' complaint: the supra went from 2JZ to too much Jay-Z.

And therein lies the other problem of the Supra: the Supra.

See, any time you evaluate something, you do so relative to its context - and when you give it a nameplate, you make that context include where else that nameplate has been. An undeserved name may not just be stupid, but even outright kill the car in some's eyes, see the case of the Dodge Dart, or get me to talk about the Ford Capri prototype recently spotted if you want to find out what I'm like when I lose my cool. (I'd liken this phenomenon to undeserved Grammies but I already used my music analogy quota too.) So the Toyota Supra does not just need to be good, it needs to deserve the name. And some argue it doesn't. But why? This thing is no less powerful, no slower, hell it's not even any bigger or heavier and we've gone over how rare that is these days! So is it the lack of backseats and a targa version? No, no one gives a crap about those. It's something deeper.

Sometimes, the problem with a revival is people base their expectation not on what the original was like in the context of its time but what it's like in the context of today (for example, I've heard people call the latest GT-R "too computerized, too assisted, far from the pure driving experience of its predecessors", when its predecessors had some of the most technologically advanced driving assists of their time and could only be called "pure" and "analog" by comparison with cars decades newer). But of course, that'll only be some people - so if what the original car looks like to modern eyes and what the original car represented at its time are two different enough concepts, any revival will receive some criticism for not being one of the two.

But for the Supra, this compounds with another problem: the original Supra (as in the previous generation, since no one gives a crap about the first three), to modern eyes, looks like a thousand-horsepower flame-spitting beast, because that's what all Supras have been turned into, and that's why you know of Supras in the first place (it sure isn't because people bought it!), and that, consciously or not, exacerbates the problem of misplaced expectations to a level akin to hearing an NBA player is about to have a brother and expecting the baby to be a 6'4" three-shooter.

But I wasn't asked about the controversies, I was asked about my take. And my take is: no realistic expectation of what a Supra would look like today was disappointed - at least not by where the car stands today. Well, unless the expectation involved backseats.

"But it was made by BMW" and so? This is a new Supra, and a good one - what does it matter how it got here? Especially when this is an upgrade over the Z4 in every way - looks way better, drives better, and now has a manual that the Z4 doesn't.

Okay, almost every way: the Supra's roof won't get out of the way. If only though, if only. Could you imagine a Toyota product that looks this good, sounds this good, goes this fast, and has a drop top? ...and maybe backseats?

Well, I can.

Yes, the badge and core concept may have some people consider it from midlife crisis mobile to old man's car. (though we know it's not a car bought by old men because if that was the case someone would be buying these). But just try to imagine sitting in this thing.

Take a couple of seconds to take in that picture and truly immerse yourself. You're in a Lexus LC500 Convertible, with a V8 at your right foot's command, its spectacular sound ready to battle the perfect sound system serenading you with your fanciest CD, because of course Lexuses still come with CD players.

Are you immersed? Okay: Someone just called your Lexus a midlife crisis car. See? You don't give a shit either, do ya.

Automatic only though. The pain. Oh, and it kind of costs as much as two Supras. But, you know, neither of those Supras will be convertibles!

Links in blue are posts of mine about the topic in question - if you liked this post, you might like those!

49 notes

·

View notes

Photo

Jaguar XKR “Badcat”

Launched in 1996 and always more of a grand tourer than an out-and-out sports car, the Jaguar XK8 shared its chassis with the Aston Martin DB7, making it the thinking man’s choice for anyone in the market for a powerful, rear-wheel-drive luxury sports car.

Whilst those figures might be impressive for the XKR; it wasn't quite enough for our petrolhead vendor Graham, who in 2007 embarked on a 13-year journey to improve and modify the once standard 1998 XKR into this stunning 632hp unique Jaguar, more commonly known as the ‘Badcat’

The Badcat started life as a 1998 Jaguar XKR, which Graham saw for sale in 2007 and having a soft spot for the X100, plus having been looking for a car for a while, this was snapped up straight away. Driving the car for a few weeks was enjoyable, but as with any petrolhead, it wasn’t long before Graham started looking into tuning options for the XKR.

This started with a smaller top pulley and larger bottom pulley fitted to the supercharger, and this was complemented with a Racing Green ECU piggy back upgrade to keep on top of the fueling due to the faster spinning supercharger. The result was 456hp, an impressive 64bhp gain from the standard bhp.

With the 4.0 litre pushed to its limits, Graham was on the lookout to further improve the performance of the XKR, and this was the start of taking the car to an entirely new level. Graham found a new Range Rover 4.4 litre V8 which became the next base for the project. The engine was rebuilt using stronger high spec’ bespoke forged pistons from German automotive parts manufacturer Capricorn, which kicked off the need to have parts purpose made rather than buying off the shelf items.

The upgrade to the 4.4 litre brought the power up to an impressive 480bhp; it was never quite enough, and the need for more power continued. This need was realised when in 2012 when Graham, assisted by Jaguar expert Tom Lenthall, found an uprated Eaton supercharger which was originally destined for an XKR GT3 racing car. This was fitted along with some other improvements to bring the XKR to 510hp.

In 2016 whilst on a track day at Goodwood, flying at over 140 mph, the 4.4 litre detonated, melting five out of the eight pistons. The cause was put down to poor fuel pick-up from the standard Jaguar tank, which would later be resolved with a bespoke designed, foam-filled ally fuel tank with swirlpot fabricated by CKL Racing, containing two Walbro 450 high-pressure fuel pumps. Only one of the pumps is needed and more than capable of providing enough fuel for spirited driving; the other pump was simply fitted as a backup. Luckily the cylinder block suffered only minor scoring and was sent off to be rebuilt at performance engine experts Classic and new forged pistons from JE in America. This gave Graham the opportunity to develop even more power, and with a freshly built engine, a new twin-screw supercharger, a Whipple W175AX, was sourced from the USA. Although being told it would not fit by the company director, Graham had other ideas. With some well calculated CAD drawing and CNC machining, the charger was made to fit, pushing the XKR to the enormous power it now produces.

79 notes

·

View notes

Photo

Auto Repair Shop

Disc Brake Types

There are many different types of disc brakes on the market. They include cable-operated mechanical and hydraulic disc brakes.

In hydraulically actuated brakes, the master cylinder forces a caliper to squeeze the brake pads against the disc or rotor to slow and stop the car. There are two common caliper designs: floating (single piston) and fixed.

Some rotors are made from two pieces: the braking surface and the carrier. This design allows them to expand more without warping, which increases their braking power.

The braking surface is also sometimes riveted to the carrier. This reduces friction between the rotor and the carrier, which improves fuel economy.

Many motorcycle and sports car discs have holes or slots cut through them for better heat dissipation, to aid in surface-water dispersal, to reduce noise, to reduce mass, or to promote cosmetics. However, this can damage the pad material over time and reduce their effectiveness at high temperatures.

2 notes

·

View notes

Photo

(via Global Automotive Alloys Market | Trends, Forecast 2024-2030)

The primary applications for Automotive Alloys include Engine Components, Exhaust Systems and Structural Components, among Other Components/Systems (including Brake Systems, Steering Mechanisms & Transmission Parts). Engine Components account for a considerable share of the global market for Automotive Alloys, since these are essential to maintain reliable vehicle performance and efficiency. Critical components, such as pistons, valves and crankshafts are fabricated using these high-performance alloys that offer superior strength and thermal resistance. Owing to these factors, the demand for Automotive Alloys in fabricating Engine Components would post the fastest growth. However, Structural Components corner the largest share of demand for of Automotive Alloys, since these primarily comprise chassis frames, body panels and suspension systems that form an integral part in maintaining a vehicle's safety and integrity.

0 notes

Text

Hydraulic Components Market Insights and Future Growth Forecast 2024 - 2032

The hydraulic components market is a vital segment of the broader hydraulic systems industry, underpinning various applications across manufacturing, construction, agriculture, and automotive sectors. With the increasing demand for efficient machinery and automation, the market for hydraulic components is experiencing significant growth. This article provides an in-depth analysis of the hydraulic components market, exploring key drivers, challenges, market segmentation, regional insights, and future trends.

Understanding Hydraulic Components

Hydraulic components are mechanical devices that utilize pressurized fluid to transmit power and perform work. These components are essential for the operation of hydraulic systems, which are widely used in various industries for tasks such as lifting, pushing, pulling, and powering machinery.

Key Types of Hydraulic Components

Hydraulic Pumps: Convert mechanical energy into hydraulic energy, generating fluid flow necessary for hydraulic systems.

Hydraulic Cylinders: Convert hydraulic energy back into mechanical energy, providing linear motion for various applications.

Hydraulic Valves: Control the flow and direction of hydraulic fluid, ensuring efficient system operation and safety.

Hydraulic Motors: Transform hydraulic energy into rotational motion, powering equipment and machinery.

Market Dynamics

Growth Drivers

Increasing Automation in Industries

The trend towards automation in manufacturing and construction is driving the demand for hydraulic components. Hydraulic systems provide the necessary force and precision required in automated machinery, making them essential for modern production processes.

Infrastructure Development

Global investments in infrastructure development are boosting the hydraulic components market. Projects involving roads, bridges, and public transportation systems require advanced hydraulic solutions to enhance efficiency and productivity.

Technological Advancements

Innovations in hydraulic technology, such as the development of smart hydraulic systems and improved materials, are enhancing the performance and reliability of hydraulic components. These advancements are attracting investment and fostering market growth.

Challenges

Environmental Regulations

Stricter environmental regulations aimed at reducing emissions and promoting sustainability are posing challenges for hydraulic component manufacturers. Compliance with these regulations may require significant investments in research and development.

Volatility in Raw Material Prices

The prices of key raw materials used in hydraulic component manufacturing, such as metals and polymers, can be volatile. Fluctuations in material costs can impact the overall pricing and profitability of hydraulic components.

Competition from Alternative Technologies

The hydraulic components market faces competition from alternative technologies such as electric and pneumatic systems. As industries seek more sustainable and efficient solutions, hydraulic components must demonstrate their value and efficiency to remain competitive.

Market Segmentation

By Component Type

Pumps: Hydraulic pumps are categorized into gear pumps, piston pumps, and vane pumps, each serving specific applications.

Cylinders: Hydraulic cylinders include single-acting and double-acting cylinders, used in various lifting and pushing applications.

Valves: Hydraulic valves are classified into directional control valves, pressure relief valves, and flow control valves.

Motors: Hydraulic motors are available in gear, piston, and vane designs, each suitable for different operational needs.

By Application

Construction: Hydraulic components are widely used in construction equipment, including excavators, bulldozers, and cranes.

Manufacturing: Hydraulic systems power machinery in manufacturing processes, enabling automation and precision.

Agriculture: Agricultural machinery, such as tractors and harvesters, increasingly relies on hydraulic components for efficient operation.

Automotive: The automotive industry utilizes hydraulic components in systems like brakes and steering, enhancing vehicle performance and safety.

By Region

North America: The North American hydraulic components market is driven by robust manufacturing and construction sectors.

Europe: Europe's focus on sustainability and technological advancements is fostering growth in the hydraulic components market.

Asia-Pacific: Rapid industrialization and urbanization in countries like China and India are propelling the demand for hydraulic components.

Latin America: The growth of construction and agricultural sectors in Latin America is expected to boost the hydraulic components market.

Middle East & Africa: Ongoing infrastructure projects and investments in various sectors are driving demand for hydraulic components in this region.

Regional Insights

North America

North America is a leading market for hydraulic components, primarily driven by its strong manufacturing and construction industries. The region is characterized by technological advancements and the presence of major players in the hydraulic sector.

Europe

Europe's hydraulic components market is influenced by stringent environmental regulations and a shift towards sustainable practices. Innovations in hydraulic technology are enhancing efficiency, making it a key region for growth.

Asia-Pacific

The Asia-Pacific region is witnessing rapid industrialization, resulting in increased demand for hydraulic components. Countries like China and India are investing heavily in infrastructure and manufacturing, driving market growth.

Latin America

Latin America is experiencing growth in construction and agriculture, creating opportunities for hydraulic component manufacturers. Investment in infrastructure projects is expected to boost demand in the region.

Middle East & Africa

The Middle East and Africa are focusing on infrastructure development and modernization, driving the demand for hydraulic components. Investments in various sectors are creating a favorable market environment.

Future Trends

Focus on Sustainability

As industries shift towards more sustainable practices, the hydraulic components market is expected to embrace eco-friendly technologies. Manufacturers will invest in developing biodegradable hydraulic fluids and energy-efficient systems.

Integration of IoT and Smart Technologies

The integration of Internet of Things (IoT) technologies in hydraulic systems will enhance real-time monitoring, predictive maintenance, and operational efficiency. Smart hydraulic systems will provide better data insights, driving improvements in performance.

Advances in Materials Science

Innovations in materials science will lead to the development of lighter, stronger, and more durable hydraulic components. This will enhance the efficiency and longevity of hydraulic systems across various applications.

Conclusion

The hydraulic components market is poised for significant growth, driven by increasing automation, infrastructure development, and technological advancements. While challenges such as environmental regulations and competition from alternative technologies exist, the opportunities for innovation and sustainability offer a promising future. As the market evolves, a focus on smart technologies and eco-friendly practices will shape the future of hydraulic components, reinforcing their essential role in various industries worldwide.

More Trending Reports

Genset Market Growth

Offshore Wind Market Growth

AC Drives Market Growth

Gas Insulated Substation Market Growth

0 notes

Link

0 notes

Text

https://www.verifiedmarketreports.com/product/automotive-piston-equipment-market/

0 notes

Text

Honda's Heritage: Engineering Excellence and Motorsport Success

Introduction - Overview of Honda's founding and early history - Key milestones in Honda's development - Importance of engineering excellence and motorsport in Honda's identity Section 1: Early History and Founding of Honda - Soichiro Honda and Takeo Fujisawa: The Visionaries - Founding of Honda Motor Co., Ltd. in 1948 - Early products: From bicycles to motorcycles Section 2: Engineering Excellence - Commitment to Innovation: Early breakthroughs and patents - Key technologies: VTEC, hybrid systems, and fuel efficiency - Notable models: Civic, Accord, and their engineering feats - Advancements in safety and sustainability Section 3: Honda in Motorsport - Entry into motorcycle racing: Dominance in MotoGP and other circuits - Transition to automobile racing: Formula 1 debut in the 1960s - Success in various motorsport disciplines: IndyCar, Touring Car, and more - Notable achievements and records Section 4: Iconic Models and Their Impact - The Honda Civic: Evolution and global influence - The Accord: Setting standards for family sedans - The NSX: Supercar performance with everyday usability - S2000, CRX, and other enthusiast favorites Section 5: Global Expansion and Market Influence - Honda's growth in North America, Europe, and Asia - Manufacturing plants and global workforce - Market strategies and consumer trust - Impact on global automotive industry Section 6: Honda's Commitment to Sustainability - Development of hybrid and electric vehicles - The Honda Clarity series and future plans - Green manufacturing practices and environmental initiatives Section 7: The Future of Honda - Upcoming technologies and models - Vision for the next decade - Maintaining heritage while innovating for the future Article Segment Early History and Founding of Honda The story of Honda begins with Soichiro Honda, a visionary engineer with a passion for machinery and innovation. Born in 1906 in Hamamatsu, Japan, Soichiro's fascination with mechanics started at an early age, helping in his father's bicycle repair shop. His entrepreneurial spirit led to the founding of Tokai Seiki, a company specializing in piston rings, which later evolved into Honda Motor Co., Ltd. in 1948. Alongside Soichiro was Takeo Fujisawa, a strategic partner who played a crucial role in shaping the business side of the company. Together, they forged a path that would lead Honda from manufacturing motorized bicycles to becoming the world’s largest motorcycle manufacturer by 1959. Engineering Excellence Honda's commitment to engineering excellence is evident in its continuous innovation and technological advancements. One of the cornerstones of Honda's engineering prowess is the Variable Valve Timing and Lift Electronic Control (VTEC) system, introduced in the late 1980s. This technology allowed Honda engines to offer both fuel efficiency and high performance, setting new standards in the automotive industry. Honda’s hybrid technology, showcased in models like the Insight and Accord Hybrid, exemplifies its dedication to sustainability without compromising performance. The development of the Integrated Motor Assist (IMA) system paved the way for more efficient hybrid powertrains, reinforcing Honda's reputation as a pioneer in green automotive technology. Honda in Motorsport Honda's venture into motorsport began with motorcycle racing in the 1950s. The company quickly established itself as a dominant force in the Grand Prix motorcycle racing circuit, winning numerous championships. This success laid the foundation for Honda’s entry into Formula 1 in 1964. Despite a challenging start, Honda secured its first F1 victory in 1965, marking the beginning of a storied career in automobile racing. Over the decades, Honda has amassed numerous accolades across various motorsport disciplines, including IndyCar, MotoGP, and Touring Car Championships. The company’s racing philosophy—using motorsport as a proving ground for new technologies—has resulted in innovations that trickle down to their consumer vehicles, enhancing performance and reliability. Iconic Models and Their Impact The Honda Civic, introduced in 1972, is perhaps the most iconic model in Honda’s lineup. Known for its reliability, fuel efficiency, and innovative design, the Civic has undergone numerous transformations, each generation setting new benchmarks in the compact car segment. Its global popularity has made it a cornerstone of Honda’s success. The Honda Accord, another stalwart of the brand, has been lauded for its blend of comfort, performance, and safety. Debuting in 1976, the Accord quickly became a favorite among families and automotive enthusiasts alike. Its influence is reflected in its numerous awards and its status as a top seller in multiple markets. The NSX, Honda’s answer to the supercar market, debuted in 1990. It combined exotic looks with everyday usability, thanks to advanced technologies like an all-aluminum body and mid-engine layout. The NSX redefined the supercar segment by proving that high performance and reliability could coexist. Global Expansion and Market Influence Honda’s strategic global expansion began in the 1960s with the establishment of subsidiaries in North America and Europe. Today, Honda operates in over 150 countries, with manufacturing plants across the globe. This widespread presence not only caters to regional markets but also enables Honda to adapt to local preferences and regulations, strengthening its global footprint. In the United States, the establishment of Honda of America Manufacturing in 1979 marked a significant milestone. It was the first Japanese automaker to build a manufacturing facility in the U.S., symbolizing Honda’s commitment to becoming a truly global company. This move has been instrumental in building consumer trust and solidifying Honda’s reputation for quality and reliability. Honda's Commitment to Sustainability In recent years, Honda has intensified its focus on sustainability, spearheading the development of hybrid and electric vehicles. The Honda Clarity series, which includes fuel cell, plug-in hybrid, and electric models, exemplifies the company’s dedication to alternative energy solutions. Honda’s environmental initiatives extend beyond vehicle emissions to include green manufacturing practices and efforts to reduce the overall environmental impact of its operations. The company’s goal of achieving carbon neutrality by 2050 highlights its proactive approach to sustainability. Through continuous innovation and a commitment to green technology, Honda aims to lead the automotive industry towards a more sustainable future. The Future of Honda As Honda looks to the future, the company is poised to continue its legacy of engineering excellence and motorsport success. Upcoming technologies, such as advanced electric powertrains, autonomous driving systems, and connected vehicle solutions, promise to keep Honda at the forefront of automotive innovation. Honda’s vision for the next decade includes expanding its lineup of electric vehicles, enhancing safety features, and further reducing its environmental footprint. By maintaining a balance between honoring its heritage and embracing future technologies, Honda is well-positioned to navigate the evolving automotive landscape. Conclusion Honda’s journey from a small workshop in Hamamatsu to a global automotive leader is a testament to its unwavering commitment to engineering excellence and motorsport success. The company’s innovative spirit, embodied by its iconic models and technological breakthroughs, continues to inspire and influence the automotive industry. As Honda moves forward, it remains dedicated to preserving its heritage while pioneering new frontiers in mobility, ensuring its legacy endures for generations to come. General Questions Q: When was Honda founded? A: Honda Motor Co., Ltd. was founded on September 24, 1948, by Soichiro Honda and Takeo Fujisawa in Hamamatsu, Japan. Q: What was Honda's first product? A: Honda's first product was a motorized bicycle called the "Honda Type A" using a surplus military generator engine. The first complete motorcycle made by Honda was the "Dream D-Type" in 1949. Q: What is Honda's philosophy? A: Honda's philosophy is centered around "The Power of Dreams," emphasizing innovation, engineering excellence, and a commitment to creating products that improve lives. Engineering Excellence Q: What is VTEC, and why is it significant? A: VTEC (Variable Valve Timing and Lift Electronic Control) is a system developed by Honda to optimize engine performance. It allows for variable valve timing, improving fuel efficiency at low RPMs and increasing power at high RPMs, making Honda engines both efficient and powerful. Q: What are some notable Honda models known for their engineering excellence? A: Notable models include the Honda Civic, Accord, NSX, S2000, and the Insight hybrid. These vehicles are celebrated for their reliability, innovation, and performance. Q: How has Honda contributed to hybrid technology? A: Honda introduced the Insight in 1999, which was the first hybrid vehicle available in North America. The development of the Integrated Motor Assist (IMA) system paved the way for Honda's continued advancements in hybrid technology. Motorsport Success Q: When did Honda first enter motorsport? A: Honda entered motorsport in the 1950s, starting with motorcycle racing. The company made its debut in Formula 1 in 1964. Q: What are some of Honda’s significant achievements in motorsport? A: Honda has achieved numerous victories in MotoGP, Formula 1, IndyCar, and Touring Car Championships. Notable successes include multiple Constructor's Championships in F1 and numerous wins in MotoGP. Q: Why is motorsport important to Honda? A: Motorsport serves as a testing ground for new technologies and innovations that often find their way into Honda's consumer vehicles. It also helps to enhance the brand's performance image and engineering credentials. Iconic Models Q: What makes the Honda Civic so popular? A: The Honda Civic is popular due to its reliability, fuel efficiency, and innovative design. It has been a top-seller worldwide and has evolved over multiple generations to meet changing consumer needs. Q: What is special about the Honda NSX? A: The Honda NSX, introduced in 1990, was a groundbreaking supercar that combined high performance with everyday usability. Its mid-engine layout, all-aluminum body, and advanced technologies set new standards in the supercar segment. Q: How has the Honda Accord influenced the market? A: The Honda Accord has set benchmarks in the family sedan market with its blend of comfort, performance, safety, and reliability. It has won numerous awards and remains a favorite among consumers globally. Sustainability Q: What steps is Honda taking towards sustainability? A: Honda is focusing on the development of hybrid and electric vehicles, such as the Clarity series, and implementing green manufacturing practices. The company aims to achieve carbon neutrality by 2050. Q: What is the Honda Clarity series? A: The Honda Clarity series includes vehicles powered by different alternative fuel technologies: Clarity Fuel Cell (hydrogen), Clarity Electric (battery-electric), and Clarity Plug-In Hybrid (combination of gasoline engine and electric motor). Q: How does Honda plan to achieve carbon neutrality by 2050? A: Honda plans to achieve carbon neutrality through advancements in electric and hybrid vehicle technology, increasing energy efficiency, utilizing renewable energy in manufacturing, and investing in sustainable practices across its operations. Future of Honda Q: What future technologies is Honda developing? A: Honda is working on advanced electric powertrains, autonomous driving systems, and connected vehicle technologies. The company is also exploring hydrogen fuel cell technology and other sustainable energy solutions. Q: How does Honda balance its heritage with innovation? A: Honda maintains its heritage by continuing to focus on engineering excellence and motorsport success while embracing new technologies and sustainability initiatives. This balance ensures the brand remains relevant and innovative. Q: What upcoming models can we expect from Honda? A: While specific future models may vary, Honda's upcoming lineup is expected to include new electric vehicles, updated hybrid models, and vehicles featuring advanced driver-assistance systems and connectivity features. Read the full article

0 notes

Text

0 notes

Text

The Future of Automotive Mechanical Oil Pumps: Innovations and Challenges

Market Overview

The automotive mechanical oil pump market will generate an estimated revenue of USD 18.2 billion in 2024, and it is expected to witness a CAGR of 2.3% during 2024–2030, to reach USD 20.9 billion by 2030. The growth is attributed to increasing demand of passenger and commercial vehicles in the global market under the stringent emission standards. Optimal performance and efficiency of the engine are crucial, and this is why mechanical oil pumps are important.

There is need to improve the fuel economy that at the same time will lower the running cost while at the same time extending the period between major engine overhauls hence lowering maintenance costs. Higher consumption of efficient cars, higher cost of fuel, and the increased standard of emissions are the recent trends that have shaped the global automotive industry.

As a result, many nations are donating the equipment for the installation of oil pumps that further contribute to the durability of the car. Used in every automotive engine, the automatic oil pump assists in starting and stopping the car, and in maintaining the oil pressure the pistons provide while it lubricates the various parts of the engine. They are both aimed at raising the fuel economy of the car in question.

The increase in the production of ICE and other hybrid electric vehicles is a major factor influencing the automotive mechanical oil pump market, as these are one of the several parts of the lubrication system. With the increasing consumption of automobiles, mechanical oil pumps are bought by the OEMs for fitment during automobile manufacturing.

Key Insights

Wet sump category holds a larger market share of 65% in 2024.

Commonly used in smaller engines with minimal lubrication needs and lower power consumption.

Preferred in most automotive engines due to simplicity, cost-effectiveness, low weight, and minimal maintenance.

Passenger vehicles category accounts for the largest share of 40% in 2024.

Higher production volume to meet increasing demand for personal mobility worldwide.

Gasoline category dominates the market in 2024 with around 50% share.

Requires less-frequent servicing compared to diesel engines and is cost-effective.

Depend heavily on mechanical oil pumps for lubrication and cooling.

Hybrid category is expected to be the faster-growing category with a CAGR of 3.7% during 2024–2030.

Growth driven by environmental concerns and regulations against pure-ICE vehicles.

EV sales are rising, but high costs and inadequate charging infrastructure push HEV/PHEV sales, offering benefits of both ICEs and BEVs.

Vane category is expected to witness the highest CAGR of 2.6% during 2024–2030.

Vane pumps, known as surface tension pumps, enhance fluid velocity and handle less-viscous fluids at high pressures better than gear pumps.

OEMs hold a larger share of 70% in 2024.

Growth driven by demand for mechanical oil pumps integrated into vehicles during manufacturing.

OEMs provide better parts compared to the aftermarket, ensuring efficient lubrication and reduced fuel consumption to meet emission regulations.

APAC holds the largest revenue share of 45% in 2024 and is expected to develop at the highest CAGR of 2.7% from 2024 to 2030.

Growth driven by the expanding automotive sector in regional developing countries.

Strict emission regulations in APAC improve air quality and resolve environmental issues.

Mechanical oil pumps help reduce friction, increase efficiency, and optimize engine lubrication.

In India, the automotive industry produced 25.93 million vehicles in FY2023.

Contributed 8% of the country’s exports and 7.1% of India’s GDP.

Includes three-wheelers, two-wheelers, passenger vehicles, commercial vehicles, and quadricycles.

Source: P&S Intelligence

#Automotive Mechanical Oil Pump Market Share#Automotive Mechanical Oil Pump Market Size#Automotive Mechanical Oil Pump Market Growth#Automotive Mechanical Oil Pump Market Applications#Automotive Mechanical Oil Pump Market Trends

1 note

·

View note