#Automotive Lubricants Industry Insight

Explore tagged Tumblr posts

Text

Increasing Automation and Demand for Eco-friendly Lubricants support the Industrial Lubricants Market Growth| MarketsandMarkets™

Industrial lubricants are special fluids used to reduce friction and wear between two surfaces in contact with each other, such as the mating moving parts of an engine or a machine. They help reduce energy losses, improve machine efficiency, and extend equipment life. Commonly used industrial lubricants include mineral oils and synthetic fluids, greases, and waxes. Industrial lubricants are…

View On WordPress

#automotive lubricants industry#automotive lubricants market#automotive motor oil market#biolubricants market#construction lubricants market#COVID-19 Impact on Industrial Lubricants Market#Global Industrial Lubricants Market#Industrial Lubricants#Industrial Lubricants business research report#Industrial Lubricants Industry Trends#Industrial Lubricants Market#Industrial Lubricants Market Analysis#Industrial Lubricants Market Overview#Industrial Lubricants Market Share#Industrial Lubricants research insights#Industrial Lubricants Research Report#lubricant additives industry#lubricants market size#marine lubricants market

0 notes

Text

Demystifying Gripping Pliers: Tips for Everyday and Professional Use

Gripping pliers are hand-operated tools that have solidified their status as a non-negotiable resource in various venues, from everyday household applications to professional undertakings. They have proven so versatile and reliable that you can't possibly do without them. Here, in this blog, we dive into the anatomy, the uses, tips on maintaining gripping pliers, and practical insights into maximising its utility.

Understanding the Anatomy: Key Features of Gripping Pliers

Gripping pliers are designed to be available in various shapes and sizes, depending on the intended task. The following are some key features to become familiar with: Jaws: Jaws are the parts that are used to hold, grip, or manipulate objects firmly. These are made in flat, serrated, or curved forms, depending on the type of pliers. Handles: Typically coated for comfort and grip, the handles allow for a firm grasp and control during operation. Pivot Point: This central axis enables the jaws to move smoothly when pressure is applied. Cutting Edge: Many gripping pliers come equipped with cutting edges to handle wires, nails, or small metal pins. Understanding these components helps in selecting the right gripping pliers for your specific needs.

Every Day Hacks: How to Use Gripping Pliers Around the House

Gripping pliers can be used as the best home tool. Here are a few ways to use them

effectively: To hold small screws, nails, or other materials, gripping pliers can be used. For twisting wires in electrical repair purposes, gripping pliers can twist and tighten very precisely. Opening Stubborn Lids: Struggling with jar lids? Gripping pliers can provide the extra leverage needed to loosen them. DIY Repairs: Whether fixing a bike chain or assembling furniture, gripping pliers offer firm control and reliability. Removing Nails: Their strong grip makes them ideal for pulling out nails and tacks from surfaces.

Professional Applications: Making the Most of Your Gripping Pliers

In professional settings, gripping pliers can be put to several uses. Here's how they come in handy: Clamp Materials: Pliers can clamp two pieces of metal together during welding or soldering tasks. Bend Metals and Wires: Round-nose gripping pliers are best for bending thin metals and making intricate designs in wirework. Cut Small Pins and Wires: Diagonal cutting pliers can reach tight spaces to cut wires or pins into desired length. Loosening Nuts and Bolts: They provide extra grip and leverage for the manipulation of nuts and bolts, even in difficult-to-reach places. Industrial Assembly: Automotive, construction, and more gripping pliers make the assembling of parts much easier and efficient.

Tips for Maintenance: How to Keep Your Pliers in Prime Condition

Correct care ensures your gripping pliers remain dependable for a long time. Follow these maintenance tips: Cleaning: Wipe your pliers after each use to remove dirt, grease, or debris. Lubrication: Periodically apply a light oil to the pivot point to ensure smooth movement. Storage: Store your pliers in a dry area to prevent rust or corrosion. Avoid Overuse: Use pliers within their intended capacity to avoid damaging the jaws or handles. Inspect for Damage: Always check for wear and tear before use to ensure safe operation.

Choosing the Right Gripping Pliers for Every Task

Selecting the right gripper depends on your specific needs. Here are some types to consider: Combination Pliers: Versatile and multipurpose, ideal for gripping, cutting, and bending. Needle-Nose Pliers: Perfect for reaching into tight spaces and handling small objects. Diagonal Cutting Pliers: Designed for precise cutting tasks. Locking Pliers: Provide a strong grip and can lock in place for hands-free operation. Slip-Joint Pliers: Adjustable jaws make them suitable for a range of gripping tasks. Assess the task and choose the best functionality pliers available.

Conclusion

Gripping pliers are essential tools for any individual that is to work on minor repairs around the house or professional projects. With the right maintenance, they prove to be a trusted assistant for many years. Through understanding the features, applications, and care of gripping pliers, you will be able to fully tap into their potential in your toolkit.

FAQs

Q1: What are gripping pliers used for?

A: Gripping pliers are used for holding, bending, cutting, and clamping various materials, making them suitable for the extent of house repair to an industrial level. Q2: How do I choose the right gripping pliers?

A: Consider the task - combination pliers for general use, needle-nose pliers for tight spaces, and locking pliers for extra grip. Q3: Can gripping pliers cut through thick wires?

A: These types of pliers can only cut thin wires. A wire cutter of heavy-duty types is needed if thicker wires need to be cut. Q4: How do I prevent my pliers from rusting?

A: I regularly clean the pliers and keep them in a dry place. Applying light oil may also prevent rust. Q5: Are grippliers good for working on delicate work?

A: Yes, some, such as needle-nose pliers, are for fine work and delicate things.

Author

Sonia is a passionate and experienced blogger with over five years of experience creating engaging, high-quality content. With more than 3,000 blogs in her portfolio, Sonia blends creativity and research to provide well-informed and interesting stories on different niches. Her concentration on topics which are relatable and have a personal touch to work makes her a voice which is trusted in the world of blogging. Sonia believes in doing her best; therefore, every piece that she writes is both informative and inspiring.

Gripping pliers https://krishanbrothers.com/gripping-pliers/

Comments

1 note

·

View note

Text

Rubber Process Oil Market Opportunity, Driving Factors And Highlights of The Market

The global rubber process oil market size was estimated at USD 2.19 billion in 2023 and is projected to grow at a CAGR of 4.3% in terms of revenue from 2024 to 2030. The global product demand is increasing due to its critical role in the manufacturing of various products, including tires, footwear, and industrial goods.

This surge is driven by the growing automotive industry, particularly in emerging markets, where vehicle production and ownership are rising rapidly. In addition, the expanding infrastructure and construction sectors are boosting the need for rubber-based materials. Furthermore, advancements in rubber processing technology and the shift towards environmentally friendly and sustainable products are propelling the demand for high-quality, non-toxic products. These oils enhance the performance, durability, and longevity of products, making them indispensable in both industrial and consumer applications.

Rubber process oils are essential additives used in the production of rubber compounds. These oils are derived from petroleum and are integrated into the manufacturing process to enhance the properties of the final product. They act as plasticizers, making the rubber softer and more pliable, which is crucial during the mixing and molding stages. Depending on their formulation, these products can be categorized into three main types: paraffinic, naphthenic, and aromatic, each offering distinct properties suited for different applications.

Gather more insights about the market drivers, restrains and growth of the Rubber Process Oil Market

Key Rubber Process Oil Company Insights

Some of the key players operating in the global rubber process oil market include Shell Plc, Chevron USA Inc., H&R GROUP, and Sunoco Lubricants, among others.

• Shell Plc, a global leader in energy and petrochemicals, has a robust portfolio of rubber process oils designed to meet the diverse needs of the end-use industry. Their product line includes high-quality paraffinic, naphthenic, and aromatic oils, known for their excellent solvency, stability, and performance characteristics. Shell's rubber process oils are engineered to enhance the processing efficiency, elasticity, and durability, making them suitable for a wide range of applications including tires, industrial goods, and consumer products. The company's commitment to sustainability and innovation drives the development of eco-friendly formulations that comply with stringent environmental regulations, ensuring that their products meet the evolving demands of the global market.

• Chevron is a prominent player in the global oil and gas industry, offering a comprehensive range of rubber process oils tailored for various manufacturing processes. Chevron's product portfolio includes premium paraffinic and naphthenic oils that are highly valued for their superior performance in enhancing flexibility, durability, and processing efficiency. These oils are widely used in the production of tires, footwear, and industrial products. Chevron's focus on research and development ensures that their products not only meet industry standards but also address the growing demand for environmentally friendly and sustainable solutions, reinforcing their position as a trusted supplier in the overall industry.

• H&R GROUP is a leading specialty chemical company with a strong presence in the rubber process oil market. The company offers a diverse range of high-quality aromatic, naphthenic, and paraffinic products designed to improve the performance, processability, and longevity of rubber products. H&R's oils are utilized in various applications including tire manufacturing, wire and cable coverings, and automotive components. The company's dedication to innovation and sustainability is reflected in its development of eco-friendly and low-aromatic content oils that meet global environmental standards. H&R GROUP's extensive expertise and commitment to quality make it a preferred supplier for manufacturers seeking reliable and efficient process oil solutions.

Recent Developments

• In February 2024, Nordmann announced expansion of its distribution agreement with Ergon International, the world’s largest manufacturer of naphthenic process and base oils.

• In January 2022, Safic-Alcan, a global speciality chemicals distributor, announced partnership agreement with Repsol. This agreement pertains to the Rubber industries in Belgium, Germany, Greece, Italy, Luxembourg, the Netherlands, Poland, Romania, Russia, South Africa, Sweden, Denmark, Norway, and Finland.

• In March 2019, Nynas AB introduced its newest biobased rubber process oil.

Global Rubber Process Oil Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global rubber process oil market report based on material product, application, and region.

Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Aromatic

• Paraffinic

• Naphthenic

• Other Products (If Any)

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Tyre

• Footwear

• Wire & Cable Covering

• Flooring Materials

• Paints & Coatings

• Adhesive & Sealants

• Other Applications (If Any)

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

• Asia Pacific

o China

o India

o Japan

o South Korea

o Malaysia

o Indonesia

o Vietnam

o Indonesia

o Thailand

• Central & South America

o Brazil

o Argentina

• Middle East and Africa

• Saudi Arabia

• South Africa

Order a free sample PDF of the Rubber Process Oil Market Intelligence Study, published by Grand View Research.

#Rubber Process Oil Market#Rubber Process Oil Market Size#Rubber Process Oil Market Share#Rubber Process Oil Market Analysis#Rubber Process Oil Market Growth

0 notes

Text

Automotive Bearing Market Insights: Revolutionizing Efficiency and Sustainability in Global Mobility Solutions

The automotive bearing market is a cornerstone of modern vehicle engineering, ensuring smooth operations and optimal functionality across diverse automobile components. Bearings play a crucial role in reducing friction, improving efficiency, and enhancing durability in cars, commercial vehicles, and specialty vehicles. With advancements in automotive technology, the demand for high-performance, lightweight, and energy-efficient bearings has surged. This blog delves into the key aspects of the automotive bearing market, including industry trends, growth drivers, challenges, and future opportunities.

Market Overview and Trends

The global automotive bearing market is experiencing significant growth, driven by rising vehicle production, technological innovations, and stringent fuel efficiency regulations. The introduction of electric and hybrid vehicles has further reshaped the industry, as these vehicles demand specialized bearings tailored for electric motors and regenerative braking systems. Key trends include the use of advanced materials such as ceramics and composites, integration of smart sensors into bearings, and a shift towards more eco-friendly lubricants.

Moreover, Industry 4.0 and IoT-enabled technologies have contributed to the rise of smart bearings. These advanced products offer real-time data on parameters like temperature, load, and lubrication, enhancing operational efficiency and predictive maintenance capabilities. Manufacturers are focusing on reducing the overall carbon footprint, which aligns with global sustainability objectives.

Key Growth Drivers

Increasing Vehicle Production: As global economies recover post-pandemic, the demand for personal and commercial vehicles is rising, fueling the need for automotive bearings.

Electrification of Vehicles: The transition to electric and hybrid vehicles requires innovative bearing designs to cater to unique operational demands.

Technological Innovations: Advancements in material science and manufacturing processes have resulted in lightweight, durable bearings with enhanced performance.

Stringent Emission Norms: Regulatory mandates worldwide have driven manufacturers to adopt energy-efficient components, boosting the adoption of advanced bearings.

Aftermarket Expansion: The growing vehicle fleet has accelerated demand in the aftermarket segment, further driving revenue growth.

Challenges and Constraints

While the market offers promising growth opportunities, certain challenges persist. Fluctuations in raw material prices can impact profitability, while complex supply chain dynamics post-pandemic pose additional concerns. Furthermore, the transition to electric vehicles requires a reorientation of traditional bearing design and manufacturing processes, demanding significant investment in research and development.

Regional Dynamics

Asia-Pacific: Dominates the automotive bearing market due to its large vehicle production capacity, especially in China, India, and Japan.

North America: Driven by high adoption rates of advanced technologies and robust electric vehicle markets.

Europe: Focused on sustainability and emission reduction, with key contributions from Germany and the Nordic countries.

Rest of the World: Emerging markets in South America and Africa are showing steady growth, driven by increasing automotive investments.

Future Opportunities

The automotive bearing market is set to benefit from collaborations and partnerships among OEMs, suppliers, and technology providers. The rise of autonomous vehicles and advanced driver assistance systems (ADAS) presents opportunities for innovative bearing solutions with high precision and reliability. Furthermore, investments in green technologies and renewable energy sources will continue to shape the future of the industry.

0 notes

Text

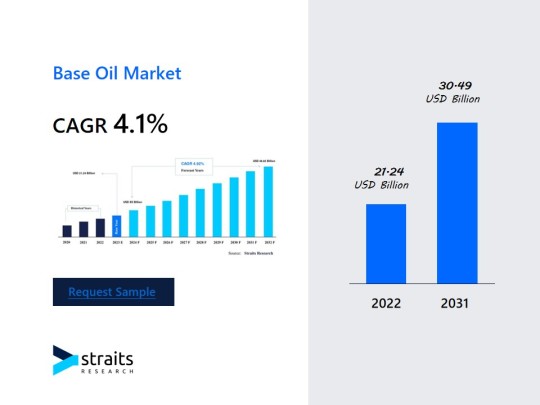

Base Oil Market Key Insights: Global Trends and Growth Forecasts by 2031

The global base oil market was valued at USD 21.24 billion in 2022. It is projected to grow from USD 22.76 billion in 2023 to USD 48.82 billion by 2031, registering a compound annual growth rate (CAGR) of 4.92% during the forecast period (2023–2031).

Overview of the Base Oil Market

The global base oil market is on a robust growth trajectory, driven by increasing demand for high-performance lubricants across various industries. Base oils, the primary ingredients in lubricants, play a crucial role in the formulation of oils used for automotive, industrial, and metalworking applications. As industrial activity ramps up worldwide and the automotive sector continues its evolution, base oils are expected to experience heightened demand in the coming years.

In 2022, the base oil market was valued at USD 21.24 billion and is forecasted to expand to USD 48.82 billion by 2031, growing at a CAGR of 4.92%. This growth is attributed to the increasing industrialization in emerging markets, rising demand for advanced lubricants, and a greater focus on energy-efficient solutions.

Market Definition

Base oils are refined from crude oil and used as the foundation for creating lubricants, oils, and other products, such as hydraulic fluids, metalworking fluids, and automotive oils. The classification of base oils is determined by their performance properties, with each type offering specific benefits based on application requirements. As key raw materials for a range of applications, base oils are essential to maintaining the smooth operation of machinery and vehicles.

Get a Full PDF Sample Copy of the Report @ https://straitsresearch.com/report/base-oil-market/request-sample

Market Dynamics: Key Trends, Drivers, and Opportunities

Key Trends:

Growing Adoption of Synthetic and High-Performance Oils: There is an increasing shift toward synthetic and high-performance base oils, particularly Group III and Group IV oils, which offer better oxidation stability, improved low-temperature performance, and longer-lasting protection for engines and industrial machinery. This trend is expected to accelerate as consumers and industries alike seek more efficient and durable oils.

Integration of Green and Sustainable Technologies: As environmental concerns continue to rise, there is a growing emphasis on the development of eco-friendly and sustainable base oils. The industry is witnessing innovations in bio-based oils and processes that use renewable feedstocks, reducing the overall carbon footprint of oil production and usage. This shift aligns with global sustainability goals and is likely to enhance market prospects.

Key Market Drivers:

Industrial Growth and Expansion in Emerging Markets: The expansion of industrial activities in emerging markets, particularly in Asia-Pacific, is one of the primary drivers for the base oil market. Rapid infrastructure development, increased manufacturing capacity, and growing demand for automotive lubricants are propelling the need for high-quality base oils. As industrial production ramps up, base oils will continue to be in high demand for applications ranging from hydraulic oils to industrial lubricants.

Technological Advancements in Lubricants and Oils: Advancements in lubricant technology, especially the demand for more energy-efficient and high-performance oils in automotive and industrial applications, are significantly driving the base oil market. Group II and Group III base oils, known for their superior properties, are gaining popularity due to their enhanced performance in high-temperature environments and longer service life.

Key Market Opportunities:

Expanding Automotive Sector and Electric Vehicle Production: As the automotive sector continues to grow, especially in emerging economies, the demand for lubricants is increasing. Additionally, the rise of electric vehicles (EVs) presents a unique opportunity for the base oil market. Even though electric vehicles require fewer oils and lubricants, the growing market for hybrid and electric vehicles will necessitate a shift toward specialized lubricants, creating new opportunities for base oil manufacturers.

Rising Demand for Metalworking Fluids and Hydraulic Oils: Base oils used in metalworking fluids, industrial oils, and hydraulic fluids represent a significant opportunity for market growth. As industries such as construction, mining, and manufacturing expand, the demand for high-performance industrial oils and lubricants is rising, offering strong growth prospects for the base oil market.

Market Segmentation

The base oil market is segmented based on type, application, and end-user industry. This segmentation helps understand the market's diverse needs and the opportunities available across various sectors.

By Type:

Group I

Group II

Group III

Group IV

Group V

By Application:

Hydraulic Oil

Automotive Fluid

Metalworking Fluids

Industrial Oil

Other

By End-User:

Industry

Construction

Automobile

Agriculture

Marine

Other

For more detailed segmentation and insights, visit: https://straitsresearch.com/report/base-oil-market/segmentation

Key Players in the Base Oil Market

The base oil market is highly competitive, with several global players leading the way in product innovation, capacity expansion, and market consolidation. The key players in the market include:

Royal Dutch Shell PLC

Exxon Mobil Corporation

H&R Ölwerke Schindler GmbH

Chevron Corporation

BP plc

Saudi Arabian Oil Co.

Petronas Pvt. Ltd.

Evonik Industries AG

Ergon Inc.

Nynas AB

Total S.A.

SK Lubricants Co. Ltd

S-Oil Corporation

Sinopec Group

Repsol S.A.

PetroChina Company Limited

Neste Oil

MOGoil GmbH

Lotos Oil SP. Z O.O.

GS Caltex Corporation

Calumet Specialty Products Partners Lp

Avista Oil AG

These companies are focusing on expanding their production capabilities, enhancing product quality, and exploring new geographic markets to tap into the growing demand for high-performance base oils.

Regional Analysis

Dominated Region: The Asia-Pacific region is the largest market for base oils, driven by the rapid industrialization in countries like China, India, and Japan. The region's booming automotive and manufacturing sectors, along with increasing infrastructure projects, are fueling the demand for base oils in various applications, such as automotive lubricants, industrial oils, and hydraulic fluids.

Fastest Growing Region: North America is expected to be the fastest-growing region for the base oil market. The U.S. and Canada are focusing on sustainable technologies and improving automotive and industrial production. Additionally, the rising demand for high-performance lubricants and oils is driving market growth in this region.

Conclusion

The base oil market is poised for significant growth, driven by industrial expansion, technological advancements, and the increasing need for high-performance lubricants. With a projected CAGR of 4.92%, the market is set to reach USD 48.82 billion by 2031. As demand grows across various industries, particularly in emerging markets, base oil manufacturers are well-positioned to capitalize on the opportunities in the automotive, industrial, and metalworking sectors.

For more information or to customize the report before purchasing, visit: https://straitsresearch.com/buy-now/base-oil-market

About Us:

StraitsResearch.com is a leading market research and market intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & market research reports.

Contact Us:

Email: [email protected] Tel: +1 646 905 0080 (U.S.), +44 203 695 0070 (U.K.) Website: https://straitsresearch.com/

0 notes

Text

Lubricant Additives Market Growth, Drivers, Trends & Forecast 2024-2031

The global lubricant additives market is poised for significant growth, driven by the rising demand for high-performance lubricants across automotive, industrial, and marine sectors. According to SkyQuest Technology, the market is projected to reach a valuation of USD 24.1 billion by 2031, expanding at a CAGR of 4.3% from 2024 to 2031. Lubricant additives play a crucial role in enhancing the performance, durability, and efficiency of lubricants, making them indispensable across multiple industries.

Market Drivers: What’s Fueling the Growth?

The demand for lubricant additives is primarily driven by several key factors:

Rising Automotive Production and Sales The expanding automotive industry, especially in emerging markets, is a major growth driver. Additives such as dispersants, detergents, and viscosity modifiers improve engine performance and fuel efficiency, meeting modern vehicle requirements.

Stringent Environmental Regulations Increasing government regulations aimed at reducing emissions and improving fuel economy are pushing manufacturers to develop eco-friendly additives. Low-sulfur and high-performance additives are gaining traction.

Growth in Industrial Machinery Rapid industrialization and the increasing adoption of advanced machinery across sectors like manufacturing, construction, and energy have elevated the demand for high-quality lubricants with specialized additives.

Advancements in Additive Technologies Continuous R&D efforts have led to the development of innovative additives that enhance lubricant properties, such as anti-wear, anti-corrosion, and oxidation stability.

Request a Sample Report - https://www.skyquestt.com/sample-request/lubricant-additives-market

Market Segmentation: Key Categories

The lubricant additives market is segmented based on type, application, and end-use:

By Type

Dispersants: Prevent sludge formation by keeping contaminants in suspension.

Viscosity Index Improvers: Enhance the lubricant's viscosity stability under varying temperatures.

Detergents: Eliminate deposits and maintain engine cleanliness.

Anti-Wear Agents: Protect surfaces from frictional damage.

Others: Including antioxidants, rust inhibitors, and friction modifiers.

By Application

Engine Oils: The largest segment, essential for vehicles and machinery.

Gear Oils: Used in transmission systems for smooth operation.

Hydraulic Fluids: Widely utilized in industrial and mobile equipment.

Metalworking Fluids: Growing demand from manufacturing industries.

By End-Use Industry

Automotive: Leading the market due to growing vehicle fleets.

Industrial: Driven by the need for efficient machinery lubrication.

Marine and Aviation: Growing focus on enhancing equipment longevity.

Speak to an Analyst - https://www.skyquestt.com/speak-with-analyst/lubricant-additives-market

Regional Insights: Market Trends Across the Globe

North America North America leads the market due to strong demand for advanced lubricants in automotive and industrial applications. The U.S., in particular, is witnessing robust growth due to its large industrial base and stringent environmental policies.

Europe Europe remains a significant market, driven by automotive innovations and regulatory pressure to reduce carbon emissions. Countries like Germany and the UK are key contributors.

Asia-Pacific The Asia-Pacific region is the fastest-growing market, fueled by rapid urbanization, industrialization, and a growing automotive industry in China, India, and Japan. The rising demand for fuel-efficient vehicles further accelerates growth.

Rest of the World The Middle East, Latin America, and Africa are witnessing steady growth due to increasing industrial activities and infrastructure development projects.

Key Players in the Lubricant Additives Market

The lubricant additives market is competitive, with leading companies focusing on innovation, strategic partnerships, and sustainability:

Chevron Oronite Company LLC

The Lubrizol Corporation

BASF SE

Afton Chemical Corporation

Infineum International Limited

Evonik Industries AG

Croda International PLC

Lanxess AG

Dorf Ketal Chemicals

Chevron Corporation

Wuxi South Petroleum Additives Co., Ltd.

These players are developing advanced additive solutions that comply with environmental regulations while enhancing the efficiency and performance of lubricants.

Make a Purchase Inquiry - https://www.skyquestt.com/buy-now/lubricant-additives-market

Key Trends Shaping the Lubricant Additives Market

Focus on Bio-Based Lubricants The shift toward bio-based lubricants and additives is gaining momentum as industries prioritize sustainability and lower environmental impact.

Rising Adoption of High-Performance Lubricants With modern engines operating under extreme conditions, there is increasing demand for additives that enhance thermal stability and wear protection.

Technological Advancements Innovations in additive formulations, such as nanotechnology-based lubricants, are enhancing efficiency and extending lubricant lifespans.

Growing Use of Additives in Electric Vehicles (EVs) The rise of electric vehicles has opened new opportunities for additives designed to optimize cooling, lubrication, and system efficiency.

The Road Ahead for Lubricant Additives

The global lubricant additives market is on a steady growth trajectory, driven by advancements in automotive technology, stringent environmental regulations, and the rise of industrial activities. As the demand for fuel-efficient and eco-friendly solutions grows, market players are focusing on developing innovative, high-performance additives to meet evolving industry requirements.

With Asia-Pacific emerging as a hotspot for growth and bio-based solutions becoming a focal point, the lubricant additives market is set for transformative changes in the years to come.

#Lubricant Additives Market#Lubricant Additives Market Size#Lubricant Additives Market Share#Lubricant Additives Market Trends#Lubricant Additives Market Growth#Lubricant Additives Market Outlook#Lubricant Additives Market Key Players#Lubricant Additives Market Overview#Lubricant Additives Market Competitor#Lubricant Additives Market Insights#Lubricant Additives Market Forecast#Lubricant Additives Market Analysis#Lubricant Additives Market Statistics#Lubricant Additives Market Data#Lubricant Additives Market PDF#Lubricant Additives Market Excel#Lubricant Additives Market Strategy#Lubricant Additives Market Innovations

0 notes

Text

Global Market Insights: Leading Silicone Emulsion Manufacturers and Key Players

The global silicone emulsion market is experiencing significant growth, driven by its wide-ranging applications across industries such as automotive, construction, personal care, textiles, and agriculture. Silicone emulsions are water-based dispersions of silicone oils, offering excellent thermal stability, lubrication, water repellency, and eco-friendliness. These characteristics have made silicone emulsions a preferred choice in many sectors. In this evolving market, silicone emulsion manufacturers play a crucial role in driving innovation and meeting global demand for high-performance and sustainable solutions.

Market Overview and Growth Drivers

The global silicone emulsion market is poised for steady growth due to several factors:

Industrial Expansion: Increasing demand for advanced materials in industries like construction, textiles, and automotive is fueling the growth of silicone emulsions.

Eco-Friendly Solutions: Water-based silicone emulsions are preferred over solvent-based alternatives due to their environmentally friendly nature, aligning with sustainability goals.

Versatility: Silicone emulsions are used in diverse applications, including release agents, coatings, lubricants, water repellents, and personal care products.

According to market studies, the global silicone emulsion market is expected to grow at a CAGR of 6-7% in the coming years. Emerging economies in Asia-Pacific, Latin America, and Africa are driving demand, while developed markets continue to invest in technological advancements.

Key Industries Driving Demand

Automotive

Silicone emulsions are widely used as lubricants, release agents, and polishes in the automotive industry. They help reduce friction, improve durability, and enhance the appearance of automotive components.

Construction

The construction industry leverages silicone emulsions for water-repellent coatings, anti-corrosion treatments, and mold-release agents. Their durability and ability to withstand extreme weather conditions make them invaluable for modern construction solutions.

Textiles and Leather

Silicone emulsions provide a soft finish, water repellency, and shine to fabrics and leather products. Manufacturers use them to enhance the quality and appearance of textiles.

Personal Care

Silicone emulsions are integral to personal care products such as hair conditioners, skin creams, and lotions. They offer excellent spreadability, non-greasy texture, and smooth application.

Agriculture

In agriculture, silicone emulsions act as surfactants and spreaders in pesticides and fertilizers, improving their efficiency and coverage on crops.

Leading Silicone Emulsion Manufacturers and Key Players

The competitive landscape of silicone emulsion manufacturers is characterized by innovation, research and development, and expanding production capacities. The following key players dominate the global market:

Global Chemical Giants

Leading chemical companies are at the forefront of silicone emulsion production. They invest heavily in R&D to introduce high-performance and eco-friendly silicone emulsions. These manufacturers cater to industries ranging from automotive to personal care, ensuring consistent quality and innovation.

Regional Manufacturers

In growing markets like Asia-Pacific, several regional players are gaining traction by offering cost-effective silicone emulsions tailored to local needs. Countries like India and China have emerged as hubs for silicone emulsion production, contributing significantly to the global supply.

Sustainability-Focused Companies

A growing number of silicone emulsion manufacturers are prioritizing sustainable solutions by developing water-based, solvent-free formulations. These eco-friendly products address environmental concerns and comply with strict regulations worldwide.

Specialized Suppliers

Some manufacturers focus on niche applications, such as high-performance silicone emulsions for medical devices, food-grade lubricants, or advanced coatings. Their specialized products cater to unique industrial demands.

Market Trends and Innovations

The silicone emulsion market is witnessing several trends that reflect the evolving needs of industries and consumers:

Sustainability and Green Chemistry: The shift toward eco-friendly, low-VOC silicone emulsions aligns with global sustainability initiatives. Manufacturers are investing in green technologies to reduce environmental impact.

Customization: Silicone emulsion manufacturers are developing tailored products to meet the specific performance requirements of various industries, enhancing customer satisfaction.

Technological Advancements: Innovations such as nano-structured silicone emulsions are revolutionizing performance, offering improved durability and functionality.

Regional Expansion: Key players are expanding their operations in emerging markets like India, China, and Brazil to capitalize on rising industrial demand.

Challenges for Manufacturers

While the silicone emulsion market holds significant potential, manufacturers face challenges such as:

Fluctuations in raw material prices.

Compliance with strict environmental regulations.

Competition from alternative materials.

Addressing these challenges requires constant innovation, cost optimization, and adherence to sustainability standards.

Conclusion

The global silicone emulsion market continues to grow, driven by diverse industrial applications and increasing demand for sustainable solutions. Silicone emulsion manufacturers play a pivotal role in this expansion, focusing on innovation, quality, and eco-friendliness to meet market needs. As industries adopt advanced materials to improve product performance and sustainability, silicone emulsions will remain essential in sectors ranging from automotive and construction to personal care and agriculture. With the right combination of research, technology, and regional outreach, leading manufacturers are poised to shape the future of this dynamic market.

0 notes

Text

Global Grease Market: Key Drivers, Size, and Share Forecast (2024-2032)

The global grease market size was valued at USD 6.36 billion in 2023. The market is projected to grow from USD 6.60 billion in 2024 to USD 9.49 billion by 2032 at a CAGR of 4.6% during the forecast period. Grease offers effective lubrication across an array of operating conditions such as heavy loads and high temperature. The rising product deployment across numerous industries, such as mining and construction, fuels industry growth.

Segmentation:

Mineral Oil Segment Registered Major Share Owing to Friction-Reducing Properties

Based on base oil, the market is segregated into synthetic oil, bio-based oil, and mineral oil. The mineral oil segment accounted for a prominent share of the global market in 2023. The oil assists in decreasing wear and friction between moving parts, which is one of the major attributes fueling segment growth.

Automotive Segment Led the Market Due to Benefit of Smooth Longevity of Auto Parts

By application, the market is categorized into mining, power generation, construction, food & beverage, agriculture, automotive, and others. The automotive segment bagged a dominating position of the global market in 2023. The use of grease provides smooth longevity of automotive parts and offers protection against corrosion, water, friction, and wear, driving segmental expansion.

On the basis of geography, the market has been analyzed across Europe, Latin America, North America, Asia Pacific, and the Middle East & Africa.

Report Coverage:

The report represents an account of the key trends in the market. It further gives an insight into the prominent factors anticipated to drive market expansion over the coming years. An analysis of the market based on various segments has also been provided in the report. The market has been analyzed based on base oil, application, and geography.

List of Key Players Mentioned in the Report:

Exxon Mobil Corporation (U.S.)

Total Energies (France)

Shell PLC (U.K.)

Chevron Corporation (U.S.)

P. PLC (U.K.)

FUCHS (Germany)

Sinopec (China)

PETRONAS (Malaysia)

CONDAT Group (France)

Klüber Lubrication (Germany)

Request For Sample Report: https://www.fortunebusinessinsights.com/enquiry/sample/grease-market-110042

Drivers and Restraints:

Market to Witness New Opportunities with Increasing Development of Eco-Friendly Products

The growing adoption of environment-friendly products and soaring environmental awareness are anticipated to boost grease market growth. The use of eco-friendly solutions provides cost savings in terms of cleanup and disposal. In addition, there has been an enforcement of strict environmental regulations in Europe, North America, and Asia Pacific, leading to the development of eco-friendly lubricating solutions.

Nevertheless, uncertainties associated with the cost of raw materials owing to geopolitical tensions and volatility of oil and gas prices may hinder industry growth.

Regional Insights:

Asia Pacific Accounted for Prominent Share Driven by Launch of High-Speed Rail Systems

Asia Pacific market size reached USD 2.81 billion in 2023. The regional grease market share stood at a major position in the global market owing to the launch of high-speed rail systems to improve transport infrastructure in the region.

North America is touted to expand owing to the increasing mining and construction sectors in the region.

Key Market Trends

Growing Demand for High-Performance Grease: The increasing need for equipment that operates under extreme conditions has driven the demand for synthetic and specialty greases. These products offer better performance in terms of temperature resistance, load-carrying capacity, and durability.

Shift Toward Eco-Friendly Grease: Environmental concerns and stringent regulations are driving the growth of bio-based greases, particularly in developed markets like Europe and North America. These greases reduce the environmental impact and provide sustainable solutions for various industries.

Technological Advancements: The development of new additives and thickeners that enhance grease performance is another key trend. Innovations in nano-lubricants and self-healing grease are expected to boost market growth over the forecast period.

Increasing Demand from Emerging Economies: Rapid industrialization and urbanization in countries like India, China, and Brazil are boosting the demand for grease in construction, automotive, and industrial sectors.

Focus on Maintenance Efficiency: As industries aim to reduce downtime and increase the lifespan of machinery, the use of high-quality lubricants like grease is becoming crucial. This trend is particularly strong in sectors like manufacturing, where equipment reliability is key to operational success.

Get More Information: https://www.fortunebusinessinsights.com/grease-market-110042

Competitive Landscape:

Leading Industry Players Strike Partnerships to Consolidate their Positions in the Market

Major market players are forging collaborations and undertaking capacity expansion initiatives to consolidate industry positions. These steps are also being deployed for gaining a competitive edge. B.P. PLC and Exxon Mobil Corporation are some of the leading companies in the market.

Key Industry Development:

February 2024 – Chevron announced the addition of Rykon to its product portfolio. The overbased calcium sulfonate complex grease has been launched for improving durability and enhancing uptime for next-gen equipment.

0 notes

Text

Global Industrial Degreaser Market Analysis 2024: Size Forecast and Growth Prospects

The industrial degreaser global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Industrial Degreaser Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The industrial degreaser market size has grown strongly in recent years. It will grow from $20.17 billion in 2023 to $21.43 billion in 2024 at a compound annual growth rate (CAGR) of 6.2%. The growth in the historic period can be attributed to industry-specific customization, market demand for water-based solutions, focus on regulatory compliance, bio-based and solvent-free solutions, environmental regulations.

The industrial degreaser market size is expected to see strong growth in the next few years. It will grow to $26.12 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to continued regulatory emphasis, growing sustainability awareness, enhanced packaging sustainability, market expansion of water-based solutions, increasing demand for customized solutions. Major trends in the forecast period include bio-based and solvent-free solutions, advanced technology integration, water-based degreasers, packaging innovations, technological advancements.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/industrial-degreaser-global-market-report

Scope Of Industrial Degreaser Market The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Industrial Degreaser Market Overview

Market Drivers - The rising automotive production is expected to propel the growth of the industrial degreaser market going forward. Automotive production refers to manufacturing motor vehicles, including passenger automobiles, light trucks, and commercial vehicles. This involves creating the vehicle's concept, design, and specifications, including its appearance, performance, and safety features. Industrial degreasers in the automotive industry facilitate the cleaning and maintenance of vehicle parts. The automotive sector widely adopts degreasers for cleaning and maintaining various components of vehicles. For instance, in May 2023, according to the European Automobile Manufacturers' Association (ACEA) a lobbying and standards group of the automobile industry, in 2022, 85.4 million motor vehicles were produced worldwide, an increase of 5.7% compared to 2021. Therefore, the rising automotive production is driving the growth of the industrial degreaser market.

Market Trends - Major companies operating in the industrial degreaser market are developing innovative products such as, high-purity hydrocarbons and alcohol degreasers to better serve customer needs. High-purity hydrocarbons and alcohol degreaser refers to using highly purified solvents for vital cleaning applications. These solvents are frequently used in degreasers to remove grease, lubricants, cutting fluids, corrosion inhibitors, and other pollutants commonly found in industrial applications. For instance, in July 2023, Molyslip, a UK-based manufacturer of specialist lubricants, launched SLIPCLEAN RD. This unique cleaner and degreaser is formulated to remove various industrial soils and impurities, including oil, grease, carbon deposits, inks, and semi-cured adhesives. SLIPCLEAN RD is created with high-quality hydrocarbons and alcohol to ensure maximum cleaning power while leaving no residue. The product's rapid evaporation rate ensures quick drying, resulting in immaculate surfaces.

The industrial degreaser market covered in this report is segmented –

1) By Type : Water-Based, Solvent BasedBy Grade 2) By Liquid-Based, Petroleum-Based, Bio-Based, Other Grades 3) By Application: Automative, Manufacturing, Pharmaceutical, Aviation, Other Applications

Get an inside scoop of the industrial degreaser market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=13680&type=smp

Regional Insights - North America was the largest region in the industrial degreaser market in 2023. The regions covered in the industrial degreaser market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the industrial degreaser market report are BASF SE, The Dow Chemical Company, 3M, Henkel AG & Co. KGaA, The Sherwin-Williams Company, Evonik Industries, Emerson Industrial Automation, Ecolab Inc., DuPont de Nemours, Inc., Akzo Nobel N.V., Eastman Chemical Company, Clariant AG, Diversey, Inc., Stepan Company, Quaker Chemical Corporation, Superior Industries Inc., Valvoline Inc., RUST-OLEUM, A.W. Chesterton Company, Castrol, Aervoe Industries, Inc., Sunburst Chemicals, Inc., NCH Corporation, QualiChem, Inc., PETROFER Chemie H. R. Fischer GmbH + Co. KG

Table of Contents 1. Executive Summary 2. Industrial Degreaser Market Report Structure 3. Industrial Degreaser Market Trends And Strategies 4. Industrial Degreaser Market – Macro Economic Scenario 5. Industrial Degreaser Market Size And Growth ….. 27. Industrial Degreaser Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Maximize Operational Uptime with Precision Machine Condition Monitoring

Machine Condition Monitoring Industry Overview

The global machine condition monitoring market size is expected to reach USD 5.46 billion by 2030, according to a new report by Grand View Research, Inc. The industry is anticipated to grow at a lucrative CAGR of 7.6% from 2025 to 2030. Exponential demand for monitoring services to avoid machinery failure will propel the penetration of condition-monitoring systems. End-users have exhibited an unprecedented demand for predictive maintenance tools to bolster asset life, minimize machine failure and reduce maintenance costs. Stakeholders envisage revenue-boosting potentials in maintaining machine health and reducing downtime with advanced software and tools. The emergence of the Industrial Internet of Things (IIoT) has propelled the measurements, such as pressure, vibration, and temperature.

Machine condition monitoring helps measure equipment, enhance production efficiency, and reduce unplanned downtime. Industrial IoT has provided promising growth potential following the growing footfall of smart sensors across North America, Europe, and the Asia Pacific. Leading companies are poised to prioritize vibration, torque, and temperature monitoring to foster monitoring processes. For instance, vibration diagnosis has gained ground to boost the detection of possible faults, mainly due to the adoption of IoT technology and advanced algorithms.

Gather more insights about the market drivers, restrains and growth of the Machine Condition Monitoring Market

Thermography techniques have gained ground for condition monitoring to highlight aspects of energy loss and minimize carbon emissions and operating costs. The technology has become sought-after to assess and identify thermal issues stemming from improper lubrication, worn or obsolete components, and misalignments. Lately, infrared thermography has garnered popularity in detecting thermal anomalies to provide thermal images of a machine component. Moreover, technology has gained ground in power transformers across industrial facilities, power plants, and substations.

Growth avenues could be pronounced in Asia as the automotive, oil & gas, power generation, and aerospace industries witness technological advancements and innovation. The need to optimize maintenance resources, prevent breakdowns and monitor power generation plants has augured growth for machine condition monitoring manufacturers and suppliers. Industry participants have expedited investments in temperature and vibration data and wireless communication. Besides, the need to prevent downtime and asset failures has furthered the demand for intelligent sensors and predictive maintenance across China, India, Japan, and Australia.

The competitive landscape emphasizes bullish growth strategies, including product offerings, technological advancements, mergers & acquisitions, collaboration, and geographical expansion. Forward-looking companies are poised to reinforce their strategic approaches to bolster predictive maintenance. For instance, in May 2021, Emerson announced the introduction of the PACEdge industrial edge platform to boost open connectivity and scalability. Besides, in June 2020, National Instruments announced the acquisition of OptimalPlus to strengthen enterprise software capabilities and offer business-critical insights. Industry players could expand their penetration in software and connectivity to foster productivity.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

The global rope access services market size was valued at USD 3.24 billion in 2024 and is projected to grow at a CAGR of 8.4% from 2025 to 2030.

The global virtual influencer market size was estimated at USD 6.06 billion in 2024 and is projected to grow at a CAGR of 40.8% from 2025 to 2030.

Machine Condition Monitoring Market Segmentation

Grand View Research has segmented the global machine condition monitoring market report based on monitoring technique, component, product type, application, architecture type, plant type, monitoring process, end use, and region:

Machine Condition Monitoring Technique Outlook (Revenue, USD Billion, 2017 - 2030)

Torque Monitoring

Vibration Monitoring

Oil Analysis

Thermography

Corrosion Monitoring

Others

Machine Condition Monitoring Component Outlook (Revenue, USD Billion, 2017 - 2030)

Hardware

Portable/Handheld Condition Monitoring Units

Software

Services

Machine Condition Monitoring Product Type Outlook (Revenue, USD Billion, 2017 - 2030)

Valves

Compressors

Turbines

Gearbox

Motors

Bearings

Couplings

Others

Machine Condition Monitoring Application Outlook (Revenue, USD Billion, 2017 - 2030)

HVAC Systems

Turbines & Generators

Material Handling

Conveyors

Pump Systems

Sprockets

Bushings & Hubs

Control Cabinet Monitoring

Paper Presses

Storage Rooms

Motor Control

Lubricant Level Monitoring on CNC Machines

Others

Machine Condition Monitoring Architecture Type Outlook (Revenue, USD Billion, 2017 - 2030)

Public Cloud

Edge Platform

Hybrid Cloud

On-premises

Machine Condition Monitoring Plant Type Outlook (Revenue, USD Billion, 2017 - 2030)

Greenfield Plant

Brownfield Plant

Machine Condition Monitoring Process Outlook (Revenue, USD Billion, 2017 - 2030)

Online Condition Monitoring

Portable Condition Monitoring

Machine Condition Monitoring End Use Outlook (Revenue, USD Billion, 2017 - 2030)

Mining

Primary Metals

Power Generation

Automotive

Oil & Gas

Aerospace

Food & Beverages

Chemicals

Marine

Pharmaceutical

Pulp & Paper

Others

Machine Condition Monitoring Regional Outlook (Revenue, USD Billion, 2017 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Asia Pacific

China

India

Japan

Australia

South Korea

Latin America

Brazil

MEA

UAE

South Africa

KSA

Key Companies profiled:

ALS

Emerson Electric Co.

General Electric

Honeywell International Inc.

Megget PLC

NATIONAL INSTRUMENTS CORP

Parker Hannifin

Rockwell Automation, Inc.

SKF

Schaeffler AG

Key Machine Condition Monitoring Company Insights

Some key players in the machine condition monitoring market, such as Emerson Electric Co., General Electric, Honeywell International Inc., and SKF, are actively working to expand their customer base and gain a competitive advantage. To achieve this, they are pursuing various strategic initiatives, including partnerships, mergers and acquisitions, collaborations, and the development of new products and technologies. This proactive approach allows them to enhance their market presence and innovate in response to evolving security needs.

Emerson Electric Co. is a global technology and engineering company specializing in automation solutions and industrial equipment. Within the machine condition monitoring sector, Emerson Electric Co. offers a comprehensive suite of products and services designed to optimize asset performance and enhance operational efficiency. Their monitoring solutions leverage advanced technologies, including IoT and AI, to provide real-time insights into equipment health, enabling predictive maintenance strategies. Emerson Electric Co 's portfolio includes wireless sensors, diagnostic tools, and software platforms that facilitate seamless data integration and analysis.

General Electric is known for its diverse portfolio across various sectors, including aviation, healthcare, and renewable energy. In the machine condition monitoring space, General Electric provides advanced solutions that leverage predictive analytics and IoT technology to enhance asset reliability and performance. Their digital offerings, such as the GE Digital Twin technology, enable real-time monitoring and analysis of equipment health, facilitating proactive maintenance strategies.

Recent Developments

In July 2024, I-care, a predictive maintenance and industrial performance solution, acquired assets and licenses of Germany-based Sensirion AG's predictive maintenance product line. This deal boosts I-care's presence in Germany and strengthens its global leadership in industrial predictive maintenance while ensuring continuity for Sensirion AG's former customers.

In June 2024, SPM Instrument AB., a Sweden-based company, acquired Status Pro Maschinenmesstechnik GmbH a Germany based, a condition monitoring expert. The acquisition will support SPM Instrument AB's innovation and growth in the sector, allowing the company to strengthen its presence in Germany and enhance customer service capabilities.

In March 2024, KCF Technologies launched Piezo Sensing as part of its SMARTsensing suite, enhancing machine health monitoring with high-resolution data and advanced fault detection. This technology enables early detection of issues, reducing downtime maintenance costs and improving operational efficiency and safety across various industrial applications.

Order a free sample PDF of the Machine Condition Monitoring Market Intelligence Study, published by Grand View Research.

0 notes

Text

Synthetic Lubricants Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

Synthetic Lubricants Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Synthetic Lubricants Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Synthetic Lubricants Market market size was valued at USD 17.2 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 22.9 Billion by 2031, growing at a CAGR of 3.28% during the forecast period (2023–2031).

Get Free Request Sample Report @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

TOP Key Industry Players of the Synthetic Lubricants Market

Royal Dutch Shell

ExxonMobil

Sasol

Valvoline

British Petroleum

Chevron

Morris Lubricants

Dow

Indian Oil

Petronas

Lukoil

Idemitsu Kosan

Fuchs

Total Energies

Sinopec

Global Synthetic Lubricants Market: Segmentation

As a result of the Synthetic Lubricants market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Applications

Engine Oil

Transmission Fluids and Hydraulic Fluids

Metalworking Fluids

Greases

Others

By End-User

Power Generation

Automotive and Transportation

Heavy Equipment

Food and Beverage

Others

By Type

Polyalphaolefin

Esters

Polyalkylene Glycol

Browse Full Report and TOC @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Synthetic Lubricants Market#Synthetic Lubricants Market Share#Synthetic Lubricants Market Size#Synthetic Lubricants Market Research#Synthetic Lubricants Industry#What is Synthetic Lubricants?

0 notes

Text

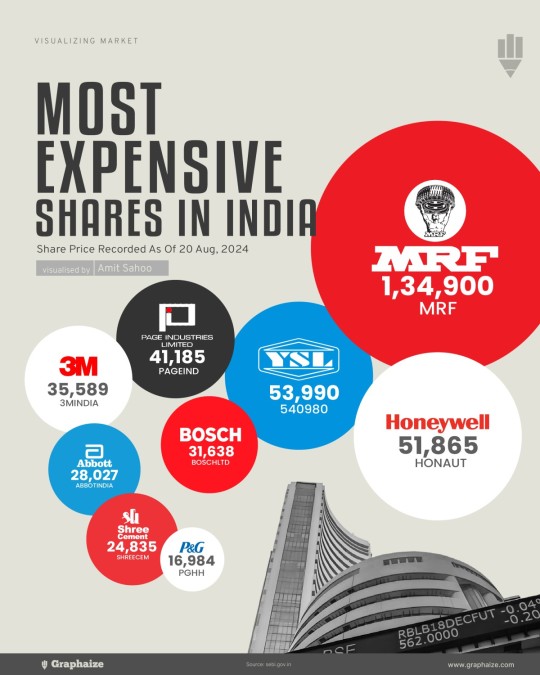

Most Expensive Shares in India 2024: Insights

Investing in high-value shares can be a profitable but often daunting venture, especially in a market like India, where stock prices can soar to unimaginable levels. If you’re curious about the most expensive shares in India for 2024, you’re in the right place! Let’s explore some of the priciest shares in India and understand what makes them so valuable.

When we talk about high-priced stocks, it’s not just about the number of shares you hold, but the quality and profitability of each one. Shares with high prices often reflect a company’s solid market position, strong brand reputation, and consistent performance. Although these shares can’t usually be purchased in bulk, their potential for profit often outweighs their hefty price tags.

For those looking to diversify their portfolio with quality over quantity, these expensive shares are worth a closer look. Let’s dive into the top high-value shares in India and what makes them stand out.

Top High-Value Shares in India for 2024

MRF Ltd (Madras Rubber Factory)

MRF Ltd, known as India’s largest tyre manufacturer, holds the title for the most expensive shares in India. With a stock price of Rs. 1,34,900, MRF dominates the market, thanks to its robust market share, brand reputation, and commitment to quality.

The company doesn’t just produce tyres; it also specializes in treads, tubes, and conveyor belts and has expanded into motorsports and rubber manufacturing. MRF’s high share price is driven by its leadership in the tyre industry, consistent financial performance, and a limited number of outstanding shares, which maintains high demand among investors.

Honeywell Automation India Ltd

Honeywell Automation India Ltd, a subsidiary of Honeywell International Inc., provides automation and control solutions across various sectors like industrial, building, and home automation. With a share price of Rs. 51,865, Honeywell Automation stands out for its advanced technological solutions and steady growth in the automation industry.

The company’s high market value is a result of its association with the globally recognized Honeywell brand and its consistent growth, which attracts both domestic and international investors.

Yamuna Syndicate Ltd

Engaged in commodities trading, Yamuna Syndicate Ltd deals in petroleum, lubricants, and industrial gases. The company also distributes automotive products, batteries, and other industrial commodities. With a share price of Rs. 53,990, Yamuna Syndicate Ltd enjoys high investor interest due to its strong performance in the commodities market and the scarcity of its shares.

The high demand and limited availability of Yamuna Syndicate shares contribute significantly to its soaring stock price, making it one of the most valuable investments in India’s market.

Page Industries Ltd

Page Industries Ltd, the exclusive licensee of Jockey and Speedo brands in India, manufactures, distributes, and markets innerwear, leisurewear, and sportswear under the Jockey label. Page Industries’ shares are priced at Rs. 41,185, supported by a loyal customer base, premium product offerings, and steady demand in the apparel sector.

Page Industries has created a niche in the Indian apparel market, making it one of the most expensive shares and a valuable asset for investors seeking steady returns from a reliable brand.

The most expensive shares in India represent some of the most successful and stable companies in the market today. From MRF’s tyre empire to Page Industries’ popular Jockey brand, these stocks reflect the best of India’s corporate sector. While their high prices may seem intimidating, their potential for steady returns makes them attractive to many investors.

0 notes

Text

Metalworking Fluids Market Dynamics, Growth Prospect and Consumption Analysis till 2030

The global metalworking fluids (MWFs) market, valued at USD 12.17 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth is expected to be fueled by rising demand for automotive and heavy industry machinery, as well as significant activity in sectors like machinery, metal fabrication, and transportation equipment. These industries are primary drivers of MWF demand, as they rely on these fluids for effective machining and metalworking processes. The production of MWFs involves crude oil as a fundamental raw material. Refined, processed, and blended from crude oil, the base oils in MWFs make up approximately 40% of the total cost of these fluids. Key products like neat cutting oils, soluble oils, and corrosion-preventive oils are developed from this crude oil refining and heating process, which is essential for producing motor oils, lubricants, and MWFs.

The MWF market benefits substantially from the growth of the automotive industry, where MWFs play a critical role in reducing friction between work pieces and tools, removing metal chips, ensuring high surface quality, and extending tool life. This ultimately increases the efficiency and productivity of machining processes, meeting high production demands. Consequently, the demand for MWFs is expected to remain steady as these industries expand.

In North America and Europe, manufacturing is a key sector, driving MWF demand due to advancements in manufacturing techniques for complex products and the high export rate of equipment for construction, power, agriculture, and automotive applications. The strong growth of end-use industries in Asia Pacific also contributes to MWF demand in North America and Europe, as more consumers in Asia Pacific increasingly opt for advanced machinery across sectors like automotive, agriculture, and construction.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

The global market is highly competitive, with the big international brands focusing on developing long-term relationships with end-users. With a rise in the manufacturing, automotive, and transportation sectors, the competition is also anticipated to increase in the coming years. Companies such as Houghton International Inc., BP plc, Exxon Mobil Corporation, and Total SA have a high degree of integration across the value chain as they are also engaged in producing various MWFs. These companies have established themselves as key manufacturers and focus on R&D for novel product uses.

The metalworking fluid market trend is being driven by increased demand for automotive and heavy industry, as well as the growing preference for lightweight components in high performance applications such as heavy machinery, transportation equipment, automotive and construction.

Product Segmentation Insights:

The mineral-based MWFs segment accounted for the largest market share in 2023, representing over 48.06% of total market revenue. Mineral oils are widely used due to their cost-effectiveness, making them popular among small- and medium-sized manufacturers who prioritize affordability. This trend is expected to support stable growth in mineral oil-based MWFs over the forecast period. Mineral oils find applications in various machining processes, including turning, grinding, broaching, drilling, and milling, due to their basic yet reliable performance characteristics.

On the other hand, synthetic MWFs are expected to experience the highest CAGR during the forecast period. These synthetic fluids offer several advantages, such as extending tool life, improving surface finishes, and minimizing friction, making them highly suitable for precision applications. Synthetic oils also provide benefits like reducing waste and extending sump life, which is critical in large-scale manufacturing. As a result, synthetic MWFs have seen a steady increase in adoption, particularly among large-scale manufacturers, and this growth is projected to continue as demand rises for higher-performance fluids.

In recent years, semi-synthetic MWFs have gained traction in many countries, contributing to the overall penetration of synthetic MWFs. Additionally, the growing concerns over environmental impacts associated with petroleum-based products have led to stringent environmental regulations and government initiatives promoting sustainable alternatives. Consequently, the production of bio-based MWFs has surged, offering a more environmentally friendly option that meets regulatory requirements and aligns with the industry's push toward sustainability.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

#Metalworking Fluids Market Share#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Industry

0 notes

Text

Machine Condition Monitoring Market 2030 Key Growth Drivers, Challenges & Leading Key Players Review

The global machine condition monitoring market was valued at approximately USD 3.49 billion in 2024 and is expected to experience steady growth with a compound annual growth rate (CAGR) of 7.6% from 2025 to 2030. The growth is largely driven by the rising need for advanced diagnostics to assess and monitor machine health, which helps to prevent failures and optimize equipment performance. Condition monitoring has become crucial for manufacturers aiming to improve operational efficiency, reduce unexpected downtime, and better manage spare parts and costs. The push towards lean manufacturing has further accelerated the adoption of these systems, enabling companies to streamline production and achieve greater cost predictability.

Gather more insights about the market drivers, restrains and growth of the Machine Condition Monitoring Market

Regional Insights:

North America Machine Condition Monitoring Market Trends

North America held the largest market share, accounting for over 36% of revenue in 2024. The region, particularly the U.S. and Canada, is experiencing increasing demand for machine condition monitoring solutions across industries such as power generation, aerospace, oil & gas, marine, and food & beverages. Vibration monitoring has become particularly important in the oil & gas sector, where it is used to analyze oil conditions in machinery lubricants on offshore platforms. With the rise in offshore oil exploration, companies in North America are well-positioned to strengthen their market presence by integrating advanced monitoring technologies. This trend indicates a growing emphasis on predictive maintenance and reliability to enhance operational efficiency and ensure safety.

U.S. In the United States, the machine condition monitoring market is expanding as manufacturers embrace Industry 4.0 practices to improve productivity. Industry 4.0 encourages the adoption of smart technologies and predictive maintenance to reduce equipment downtime and associated costs. As a result, predictive maintenance is being widely implemented across the U.S. manufacturing sector, allowing businesses to perform timely repairs, minimize unplanned shutdowns, and extend the lifespan of machinery, all of which are contributing to market growth.

Asia Pacific Machine Condition Monitoring Market Trends

Asia Pacific is expected to see the highest growth rate in the machine condition monitoring market. Within the region, China is the largest market, followed by India and Japan, driven by extensive manufacturing activities and governmental support for Industry 4.0 initiatives. As these countries continue to adopt smart manufacturing technologies, the demand for condition monitoring solutions is expected to grow. Furthermore, global leaders in condition monitoring technology, such as SKF, General Electric, and Honeywell International Inc., are actively investing in research and development in the region. These companies are also expanding their presence in Asia Pacific, which is further contributing to the market's strong growth trajectory.

Europe Machine Condition Monitoring Market Trends

Europe’s machine condition monitoring market is projected to grow significantly over the coming years. The increase is largely due to substantial investments in automation and digitalization across industries such as manufacturing, automotive, and energy. Additionally, strict regulations related to equipment safety and environmental impact are motivating companies to adopt condition monitoring technologies. By integrating these advanced monitoring solutions, European companies are able to meet regulatory standards, reduce operational risks, and achieve higher efficiency, which is helping to drive market expansion in the region.

Browse through Grand View Research's Category Next Generation Technologies Industry Research Reports.

The global postal automation system market size was estimated at USD 903.7 million in 2024 and is projected to grow at a CAGR of 7.0% from 2025 to 2030.

The global generative AI market size was valued at USD 16.87 billion in 2024 and is projected to grow at a CAGR of 37.6% from 2025 to 2030.

Key Companies & Market Share Insights: