#Automotive Fuel Tank Market Trends

Explore tagged Tumblr posts

Text

Automotive Fuel Tank Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Fuel Tank Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Fuel Tank Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Fuel Tank Market is experiencing robust growth driven by the expanding globally. The Automotive Fuel Tank Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Fuel Tank Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. The size of the automotive fuel tanks market was $16.64 billion in 2018 and is expected to reach $20.09 billion by 2026, with a CAGR of 2.38% during the forecast period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/102796

Key Strategies

Key strategies in the Automotive Fuel Tank Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Fuel Tank Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Fuel Tank Market.

Major Automotive Fuel Tank Market Manufacturers covered in the market report include:

Yachiyo Industry Co., Ltd.(Japan)

Continental AG(Germany)

Kautex Textron GmbH & Co. KG(Germany)

TI Automotive Inc. (U.K)

Magna International Inc.(Canada)

YAPP Automotive Parts Co. Ltd.(China)

SMA Serbatoi S.P.A. (Italy)

The Plastic Omnium Group (France)

Martinrea International Inc. (Canada)

Unipres Corporation (Japan)

The automotive industry is working towards developing lightweight vehicles to reduce fuel emission and enhance the performance of the vehicles. The automotive OEMs are spending a high percentage on research to innovate and develop lightweight materials for producing automotive components to decrease the weight of the vehicles. The automotive sector is shifting from the traditional metal tanks to plastic tanks since the recent past. Plastic tanks have become the preferred choice of automotive manufacturing companies owing to its various inherent advantages over metal fuel tanks and is gaining high popularity in the market. These tanks are produced using High-Density Polyethylene (HDPE). Owing to the flexible property of the plastic tanks, they can be customized according to the requirement of the OEMs.

Trends Analysis

The Automotive Fuel Tank Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Fuel Tank Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Fuel Tank Market Solutions.

Regions Included in this Automotive Fuel Tank Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Fuel Tank Market.

- Changing the Automotive Fuel Tank Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Fuel Tank Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Fuel Tank Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Fuel Tank Market?

► Who are the prominent players in the Global Automotive Fuel Tank Market?

► What is the consumer perspective in the Global Automotive Fuel Tank Market?

► What are the key demand-side and supply-side trends in the Global Automotive Fuel Tank Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Fuel Tank Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Fuel Tank Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive Fuel Tank Market#Automotive Fuel Tank Market Share#Automotive Fuel Tank Market Size#Automotive Fuel Tank Market Trends#Automotive Fuel Tank Market Growth#Automotive Fuel Tank Market Insights

0 notes

Text

Automotive Fuel Tank Market Analysis, Size, Share, Growth, Trends, and Forecast, 2024-2034

The Automotive Fuel Tank market report offered by Reports Intellect is meant to serve as a helpful means to evaluate the market together with an exhaustive scrutiny and crystal-clear statistics linked to this market. The report consists of the drivers and restraints of the Automotive Fuel Tank Market accompanied by their impact on the demand over the forecast period. Additionally, the report includes the study of prospects available in the market on a global level. With tables and figures helping evaluate the Global Automotive Fuel Tank market, this research offers key statistics on the state of the industry and is a beneficial source of guidance and direction for companies and entities interested in the market. This report comes along with an additional Excel data-sheet suite taking quantitative data from all numeric forecasts offered in the study.

Get Sample PDF Brochure @ https://www.reportsintellect.com/sample-request/2911192

Key players offered in the market: Inergy Kautex TI Automotive Yachiyo Hwashin Magna Steyr FTS Futaba SKH Metal Sakamoto Donghee Tokyo Radiator

Additionally, it takes account of the prominent players of the Automotive Fuel Tank market with insights including market share, product specifications, key strategies, contact details, and company profiles. Similarly, the report involves the market computed CAGR of the market created on previous records regarding the market and existing market trends accompanied by future developments. It also divulges the future impact of enforcing regulations and policies on the expansion of the Automotive Fuel Tank Market.

Scope and Segmentation of the Automotive Fuel Tank Market

The estimates for all segments including type and application/end-user have been provided on a regional basis for the forecast period from 2024 to 2034. We have applied a mix of bottom-up and top-down methods for market estimation, analyzing the crucial regional markets, dynamics, and trends for numerous applications. Moreover, the fastest & slowest growing market segments are pointed out in the study to give out significant insights into each core element of the market.

Automotive Fuel Tank Market Type Coverage: - Metal Fuel Tank Plastic Fuel Tank

Automotive Fuel Tank Market Application Coverage: - Commercial Vehicles Passenger Vehicles

Regional Analysis:

North America Country (United States, Canada) South America Asia Country (China, Japan, India, Korea) Europe Country (Germany, UK, France, Italy) Other Countries (Middle East, Africa, GCC)

Also, Get an updated forecast from 2024 to 2034.

Discount PDF Brochure @ https://www.reportsintellect.com/discount-request/2911192

The comprehensive report provides:

Reasons to Purchase Automotive Fuel Tank Market Research Report

Covid-19 Impact Analysis: Our research analysts are highly focused on the Automotive Fuel Tank Market covid-19 impact analysis. A whole chapter is dedicated to the covid-19 outbreak so that our clients get whole and sole details about the market ups & downs. With the help of our report the clients will get vast statistics as to when and where should they invest in the industry.

About Us: Reports Intellect is your one-stop solution for everything related to market research and market intelligence. We understand the importance of market intelligence and its need in today's competitive world.

Our professional team works hard to fetch the most authentic research reports backed with impeccable data figures which guarantee outstanding results every time for you.

Contact Us: [email protected] Phone No: + 1-706-996-2486 US Address: 225 Peachtree Street NE, Suite 400, Atlanta, GA 30303

#Automotive Fuel Tank Market#Automotive Fuel Tank Market trends#Automotive Fuel Tank Market future#Automotive Fuel Tank Market size#Automotive Fuel Tank Market growth#Automotive Fuel Tank Market forecast#Automotive Fuel Tank Market analysis

0 notes

Link

0 notes

Text

Global Hydrogen Valve Market Size, Share, Growth and Forecast 2032

Global Hydrogen Valve Market is projected to witness a CAGR of 7.38% during the forecast period 2025-2032, growing from USD 350.71 million in 2024 to USD 619.91 million in 2032. The market has experienced significant growth in recent years and is projected to witness prosperous growth owing to the expansion of hydrogen infrastructure, rapid investments in hydrogen fueling stations, and increasing focus on decarbonization. The global hydrogen valve market demand is projected to rise due to rising hydrogen requirements, government initiatives to boost hydrogen production and consumption, and increasing emphasis on clean fuels. The rising awareness concerning reducing carbon emissions drives the demand for hydrogen valves, as hydrogen proved to be a clean energy alternative. Emerging countries and companies are efficiently investing in hydrogen production, distribution, and efficient storage, and the requirement for efficient and reliable valves will rise. In addition, the governments of emerging countries are implementing policies and granting monetary and non-monetary incentives to encourage the usage of hydrogen technologies as part of their climate action plans. Not only this, but the government is also increasing the amount of investment in hydrogen infrastructure development, propelling the growing requirement for hydrogen-concerned equipment.

Hydrogen is widely used in industrial processes, including ammonia production, refining, and fuel cells. The advancement and expansion in these industries and the adoption of hydrogen technologies will propel the requirement for specialized valves to handle the hydrogen efficiently and safely. Moreover, companies in the market plan to introduce a new range of valves to meet all the required safety conformance for hydrogen infrastructure.

For instance, in December 2024, Christian Bürkert GmbH & Co. KG announced the launch of ultra-high-pressure valves for hydrogen applications that can control hydrogen up to 1,000 bars, suitable for grid infrastructure and vehicle fueling stations.

Ongoing Technological Advancements Drive the Hydrogen Valve Market Globally

Technological advancements include integrating high-performance materials and processes to confirm stable operations under different conditions, driving the global hydrogen valve market demand in the forecast period. Automation and artificial intelligence are reshaping the global hydrogen valve market by improving the effectiveness and reliability of production procedures. Artificial integration enables predictive maintenance, reduces maintenance costs and downtime, and allows manufacturers to anticipate equipment failures, driving the global market for hydrogen valves in the forecast period. In addition, hydrogen valves embrace digitization and the trend toward intelligence, accomplishing more flexible and efficient functions. The application of high-performance materials and manufacturing technologies enables hydrogen valves to function in a comprehensive range of temperatures and pressures. This advancement in hydrogen valve technology will propel market growth in the forecast period. Furthermore, companies in the market are introducing high-performance and advanced valves for automotive and other industries to expand their market presence and product portfolio.

For instance, in March 2024, Eaton Corporation plc introduced a next-generation fuel tank isolation valve for hybrid electric vehicles to address evaporative emissions that accumulate when the gas engine is not in operation. The new fuel tank isolation valve is easier to mount as these are 27% lighter, 39% smaller, and comprises 24% fewer components than its predecessor.

Rising Concern for Renewable Energy Surges Demand for Hydrogen Valve

The rising awareness concerning renewable energy is driving the global hydrogen valve market demand as hydrogen valves are important for the efficient operation of fuel cells and ensuring proper pressure and volume for high performance. Additionally, the demand for hydrogen valves is rising owing to its diverse range of applications in the energy sector, specifically in power plants and utility systems. These valves control the pressure and flow of hydrogen within the renewable energy system to ensure efficient usage and safe operation of hydrogen. They also allow for the storage of excess energy when they are used in hydrogen storage systems within the power plants during off-peak periods. The surging demand for hydrogen valves can also be attributed to the growing adoption of hydrogen-powered generators to offer backup or off-grid power in applications where renewable energy sources may be unavailable. Companies in the market are announced to expand the product line to satisfy the rising customer requirement for hydrogen valves with larger bore sizes.

For instance, in May 2024, Acme Cryogenics Inc., part of OPW and Dover Corporation, a clean energy solution company, announced that it had developed new 6” and 8” valves for its Model CV Valve product line to meet the evolving requirements of their customers.

Hydrogen Ball Valve Dominates the Global Hydrogen Valve Market Share

Hydrogen ball valve dominates the global market for hydrogen valves owing to technological advancements, rapid investment by the governments of emerging countries in hydrogen infrastructure, and the rising adoption of hydrogen as a clean energy source. Industries are shifting towards sustainable energy solutions, and hydrogen is emerging as a key player throughout this shift. The global hydrogen ball valve market demand is projected to rise due to its significance for controlling and managing hydrogen flow in different applications. The rising awareness concerning carbon emissions, stringent government rules and regulations, and increase in pollution drive the demand for hydrogen ball valves in the hydrogen valve market in the forecast period. In addition, the technological advancements in valve materials and designs have enhanced the performance and safety of hydrogen ball valves, coupled with making them suitable for corrosive environments and high pressure, propelling the global hydrogen valve market growth in the forecast period. Furthermore, companies in the market are placing huge volume orders of ball valves for a diverse range of applications including heat production and others.

For instance, in October 2024, RWE Gas Storage West placed an order for 1400 ball valves from Hartmann Valves GmbH for a new hydrogen storage facility in Lingen. The ball valves are proposed to allow the connection of the cavern in Gronau-Epe to the planned hydrogen network.

Asia-Pacific Registers the Largest Market Share in the Global Market

Asia-Pacific holds the largest market share in the global hydrogen valve market owing to rapid industrialization and the rising requirement for clean energy sources coupled with stringent and favorable government rules and regulations. The governments of emerging countries, including Japan, India, China, and others, are significantly promoting hydrogen production and infrastructure development through incentive and supportive policies. In addition, the government is increasing its investment in hydrogen infrastructure projects, including distribution networks, production facilities, and storage systems, driving the Asia Pacific hydrogen valve market growth. Moreover, the countries in the Asia Pacific are focusing on reducing greenhouse gas emissions and shifting towards sustainable energy solutions, further fostering the requirement for hydrogen valves. The Asia-Pacific market for hydrogen valves is projected to continue its dominance owing to continuous technological advancements, strategic collaborations, and the introduction of factories within the industry.

For instance, in September 2022, Crane Company announced the inauguration of its new engineered check valve factory in Satara, Maharashtra to support the demands of a wide range of industries within the chemical processing, petrochemical, and energy sectors, including renewable energy and other evolving markets, such as hydrogen production.

Download Free Sample Report

Future Market Scenario (2025 – 2032F)

The global shift towards renewable energy sources, including hydrogen, is driving the need for specialized valves to manage hydrogen flow safely and efficiently.

Governments worldwide are setting ambitious targets to reduce greenhouse gas emissions, leading to increased investments in hydrogen infrastructure and technologies.

Innovations in valve materials and designs enhance the performance and safety of hydrogen valves, making them more suitable for high-pressure and corrosive environments.

The expansion of hydrogen production facilities and storage systems requires reliable valves to control and regulate hydrogen flow, ensuring safe and efficient operations.

Report Scope

“Hydrogen Valve Market Assessment, Opportunities and Forecast, 2018-2032F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of the global hydrogen valve market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between 2025 and 2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business models, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/hydrogen-valve-market

Latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

Plastic Resin Market: Key Trends and Innovations Driving Industry Growth

The global plastic resin market size is expected to reach USD 1.07 trillion by 2030, according to a new report by Grand View Research, Inc. It is projected to expand at a 4.5% CAGR over the forecast period. The increasing consumption of plastic resins in construction, automotive, electrical, and electronics applications is boosting the market growth. Government intervention to reduce overall vehicle weight to improve fuel efficiency and reduce carbon emissions has prompted automakers to use resins to replace steel and aluminum in automotive components.

Favorable federal regulations on CO2 emissions set by agencies such as the National Highway Traffic Safety Administration and the Environmental Protection Agency (EPA), as well as EU initiatives to develop plastics applications for light-weight and fuel-efficient cars, are expected to fuel global growth and promote the market. However, the ongoing health crisis and the lockdown imposed by various governments to contain the spread of the coronavirus pandemic have led to a decline in the consumption of plastic resins. It is expected to further negatively impact the market growth in the years to come.

Strict restrictions governing the recyclability and deterioration of traditional building materials like metal and wood are likely to boost the demand for textiles in pipes, windows, cables, storage tanks, and other uses. Plastics are long-lasting and energy-efficient, as well as cost-effective and safe, which encourages their usage in construction. The global market is segmented into crystalline resin, non-crystalline resin, engineering plastics, and super engineering plastics by type. The crystalline resin was the largest segment, accounting for 61.9% of global sales in 2021. The crystalline resin segment mainly includes epoxy, polyethylene, and polypropylene resins.

Gather more insights about the market drivers, restrains and growth of the Plastic Resin Market

Plastic Resin Market Report Highlights

• Crystalline resins (epoxy, polyethylene, and propylene) segment accounted for a prominent share in the market by the end of 2023 and is further expected to witness maximum growth over the forecast period

• As of 2023, China accounted for the maximum revenue share in the market, with 40.24%. Rising consumer disposable income in the country and ascending demand for luxury cars are expected to have a positive impact on the automotive industry

• The advent of bio-based plastic resins has played a prominent role in food and beverage, and pharmaceutical applications. Polymers such as PET and PC are increasingly utilized in the beverages packaging and consumer goods sector

Plastic Resin Market Segmentation

Grand View Research has segmented the global plastic resin market report based on product, application, and region:

Plastic Resin Product Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

• Crystalline Resin

o Epoxy

o Polyethylene

o Polypropylene

• Non-crystalline Resin

o Polyvinyl Chloride (PVC)

o Polystyrene (PS)

o Acrylonitrile Butadiene Styrene (ABS)

o Polymethyl Methacrylate (PMMA)

��� Engineering Plastic

o Nylon

o Polybutylene Terephthalate (PBT)

o Polycarbonate (PC)

o Polyamide

• Super Engineering Plastic

o Polyphenylene Sulfide (PPS)

o Polyether Ether Ketone (PEEK)

o Liquid Crystal Polymer (LCP)

Plastic Resin Application Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

• Packaging

o Food

o Beverage

o Medical

o Retail

o Others

• Automotive

• Construction

• Electrical & Electronics

o OA Equipment & Home Appliances

o Electronic Materials

o Others

• Logistics

• Consumer Goods

• Textiles & Clothing

o Clothing

o Industrial use

o Others

• Furniture & Bedding

• Agriculture

• Medical Devices

• Others

Plastic Resin Regional Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

o Italy

o Poland

o Spain

• China

• Asia

o India

o Japan

o Thailand

o Malaysia

o Indonesia

o Vietnam

o Singapore

o Philippines

• Pacific

• Central & South America (MEA)

o Brazil

o Argentina

• Middle East and Africa (MEA)

o Saudi Arabia

o UAE

o Oman

Order a free sample PDF of the Plastic Resin Market Intelligence Study, published by Grand View Research.

#Plastic Resin Market#Plastic Resin Market Size#Plastic Resin Market Share#Plastic Resin Market Analysis#Plastic Resin Market Growth

0 notes

Text

Compressed Natural Gas (CNG) Market Growth Potential: Size, Share, and Industry Forecast to 2032

The global Compressed Natural Gas (CNG) Market is experiencing significant growth, driven by the increasing demand for cleaner transportation fuels and the transition toward sustainable energy solutions. Compressed natural gas, known for its lower carbon emissions and cost-effectiveness compared to traditional fossil fuels, is gaining popularity in the automotive and industrial sectors. This press release provides a detailed analysis of the market overview, emerging trends, drivers, restraints, segmentation, regional analysis, and future outlook.

Market Overview

The compressed natural gas market has grown steadily due to rising environmental concerns and the adoption of alternative fuels in transportation and industrial applications. The market is projected to achieve a compound annual growth rate (CAGR) of over 7% during the forecast period, supported by favorable government policies and technological advancements in CNG storage and distribution.

Free Sample: https://www.statsandresearch.com/request-sample/37626-covid-version-global-compressed-natural-gas-market

Emerging Trends

Adoption in Light and Heavy-Duty Vehicles: Increasing use of CNG in passenger cars, buses, and trucks is a key growth trend.

Infrastructure Expansion: Development of CNG refueling stations globally is enhancing accessibility and driving market growth.

Integration with Renewable Gas: CNG blended with biomethane or renewable natural gas (RNG) is gaining traction as a sustainable fuel option.

Advancements in Storage Technology: Innovations in lightweight and high-capacity CNG storage tanks are improving vehicle performance and adoption.

Market Drivers

Environmental Benefits: Lower greenhouse gas emissions compared to gasoline and diesel make CNG an attractive alternative fuel.

Cost Efficiency: CNG offers lower fuel costs per kilometer, appealing to both individual consumers and fleet operators.

Government Incentives: Subsidies, tax benefits, and favorable regulations encourage the adoption of CNG vehicles and infrastructure.

Energy Security: Domestic production of natural gas reduces dependence on imported fuels, enhancing energy security in many countries.

Market Restraints

Limited Refueling Infrastructure: Insufficient CNG stations in certain regions pose challenges to widespread adoption.

Initial Conversion Costs: High costs associated with converting traditional vehicles to CNG can deter potential users.

Range Limitations: CNG vehicles have a shorter range compared to diesel and gasoline vehicles, impacting long-haul applications.

Request Discount: https://www.statsandresearch.com/check-discount/37626-covid-version-global-compressed-natural-gas-market

Market Segmentation

The compressed natural gas market is segmented based on source, application, and vehicle type.

By Source:

Associated Gas

Non-Associated Gas

Unconventional Sources (Shale Gas, Coalbed Methane)

By Application:

Automotive

Industrial

Power Generation

By Vehicle Type:

Passenger Cars

Light Commercial Vehicles (LCVs)

Heavy Commercial Vehicles (HCVs)

Regional Analysis

North America: The United States leads the CNG market with growing adoption in public transportation and freight sectors.

Europe: Countries like Germany and Italy are at the forefront due to stringent emission regulations and incentives for CNG adoption.

Asia-Pacific: Rapid urbanization, growing transportation needs, and supportive government policies in countries like India and China drive market growth.

Latin America: Brazil and Argentina are prominent markets, supported by abundant natural gas reserves and favorable energy policies.

Middle East & Africa: Expanding natural gas infrastructure and government initiatives to reduce reliance on oil-based fuels contribute to market development in the region.

Future Outlook

The global compressed natural gas market is set to grow significantly, driven by increasing investments in CNG infrastructure, advancements in vehicle technology, and rising awareness about the environmental benefits of alternative fuels. Governments and private sectors are expected to collaborate on expanding refueling networks and promoting CNG as a sustainable energy solution.

As the world transitions toward a low-carbon economy, compressed natural gas is likely to play a pivotal role in reducing emissions and enhancing energy security. Industry stakeholders must focus on addressing infrastructure gaps, advancing storage technologies, and promoting public awareness to unlock the full potential of the CNG market.

Full Report: https://www.statsandresearch.com/report/37626-covid-version-global-compressed-natural-gas-market/

0 notes

Text

Global Heat Resistant Polymer Market: Growth Drivers and Competitive Landscape

The global heat resistant polymer market size was valued at USD 17.9 billion in 2023 and is anticipated to grow at a CAGR of 9.9% from 2024 to 2030. This growth is driven by the increasing demand from the electronics and electrical industries, where these polymers are essential for manufacturing components that can withstand high temperatures. The shift of the automotive sector towards lightweight and fuel-efficient vehicles has spurred the use of heat-resistant polymers in engine components and under-the-hood applications.

The aerospace industry relies heavily on these materials for their durability and performance in extreme conditions. The advancements in polymer technology and the rising trend of miniaturization in various sectors are propelling market growth. Regulations play a significant role in shaping the global heat resistant polymer market. Stringent environmental policies, such as the European Union’s REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, mandate using safer and more sustainable materials, driving the demand for eco-friendly heat resistant polymers.

In addition, fire safety standards, such as the U.S. UL 94 flammability rating, require materials to meet specific flame retardancy criteria, influencing the development and adoption of flame-retardant polymers. In the automotive sector, regulations to reduce vehicle emissions and improve fuel efficiency, such as the Corporate Average Fuel Economy (CAFE) standards in the U.S., encourage using lightweight, high-performance polymers. These regulatory frameworks ensure safety and environmental compliance and stimulate innovation and growth within the heat resistant polymer market.

Heat Resistant Polymer Market Report Highlights

The fluoropolymers segment accounted for 31.9% of the market revenue in 2023, attributed to their exceptional heat and chemical resistance. This makes them valuable in demanding industrial applications, especially in the automotive and aerospace sectors.

The automotive segment dominated the market in 2023. Heat resistant polymers are extensively used in various automotive applications, including under-the-hood components such as engine covers, air intake manifolds, and radiator end tanks.

The aerospace and defense segment is expected to grow at the fastest CAGR over the forecast period from 2024 to 2030 driven by the aerospace industry’s stringent requirements for materials that can perform reliably under extreme conditions, including high temperatures, pressure, and exposure to aggressive chemicals.

The UK heat resistant polymer market is experiencing steady growth, driven by the country’s focus on innovation and high-performance materials.

Global Heat Resistant Polymer Market Segmentation

This report forecasts revenue & volume growth of the Heat Resistant Polymer market and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global agrochemicals market report based on application, end use and region:

Product Outlook (Volume, Kilo Tons; Revenue, USD Million, 2018 - 2030)

Fluoropolymer

Polyphenylene Sulfide

Polyimides

Polybenzimidazole

Polyether Ether Ketone

Others

End Use Outlook (Volume, Kilo Tons; Revenue, USD Million, 2018 - 2030)

Transportation

Electronics & Electrical

Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Italy

Spain

Russia

Denmark

Sweden

Norway

Asia Pacific

Japan

China

India

Thailand

South Korea

Latin America

Brazil

Argentina

Middle East & Africa

South Africa

Saudi Arabia

UAE

Order a free sample PDF of the Heat Resistant Polymer Market Intelligence Study, published by Grand View Research.

0 notes

Text

Hydrogen Fueling Station Market: Growth, Trends and Opportunities Through 2024-2033

The Hydrogen Fueling Station Market is expanding as global efforts to reduce carbon emissions and transition to clean energy sources gain momentum. As a zero-emission fuel, Hydrogen offers a promising alternative for heavy transportation and industrial applications. With various regions actively investing in hydrogen infrastructure, the Hydrogen Fueling Station Market is witnessing significant growth.

According to BIS Research, the Hydrogen Fueling Station Market is projected to grow from $1,538.8 million in 2023 to $8,195.1 million by 2033, with a CAGR of 18.21%.

Market Growth and Trends

The market for hydrogen fuel stations is expected to grow as government incentives and corporate investments drive the development of hydrogen ecosystems. The deployment of hydrogen fuel cell vehicles (FCVs) in regions like Europe, Asia, and North America further accelerates market growth. As infrastructure expands, hydrogen is anticipated to play a key role in achieving global sustainability goals. Request a Free Sample Report on the Hydrogen Fuel Station Market

Key Technologies Shaping the Market

Several technologies are crucial to hydrogen fuel station development:

· Compressed Hydrogen Storage: This method stores hydrogen at high pressures (typically 350–700 bar) to maximize storage capacity within fueling stations, ensuring that sufficient hydrogen is available for vehicle refueling. Compressed storage is essential for the quick, efficient, and safe refueling of fuel cell vehicles, allowing drivers to refuel in a manner similar to conventional gas stations.

· Cryogenic Storage Solutions: Cryogenic storage involves cooling hydrogen to extremely low temperatures (below -253°C) to store it as a liquid, which occupies far less volume than gaseous hydrogen. This solution allows for stable, long-term storage, making it suitable for applications that require large hydrogen reserves. Cryogenic tanks maintain hydrogen at these low temperatures, reducing boil-off and enabling effective transportation and storage, especially for high-demand sites or remote locations.

· Hydrogen Production via Electrolysis: Electrolysis technology splits water into hydrogen and oxygen using electricity, and when powered by renewable energy sources, it enables green, on-site hydrogen generation. This method not only reduces reliance on external hydrogen supply chains but also supports a sustainable fuel cycle by minimizing transportation emissions.

Demand Drivers

Key factors driving demand in the Hydrogen Fuel Station Market include:

· Government Incentives for Clean Energy: Policies, subsidies, and tax breaks for hydrogen infrastructure make clean energy more accessible, encouraging investments and speeding up the development of hydrogen fueling stations.

· Growing Fuel Cell Vehicle (FCV) Adoption: The rise in FCVs, favored for their zero emissions and efficiency, is increasing the need for a widespread hydrogen fueling network to support expanding use across sectors like public transit and freight. Download Complete TOC of the Hydrogen Fuel Station Market Report

On-Field to Lead the Hydrogen Fuel Station Market

The on-field segment, especially within the automotive sector, is expected to dominate due to the rising adoption of FCVs. As more vehicles rely on hydrogen, accessible fueling stations are becoming essential for seamless operation, particularly for fleet and commercial vehicle applications.

Download the free sample page Click Here !

Key Players

· Air Liquide

· Nel ASA

· Linde plc

· Air Products and Chemicals, Inc.

· McPhy Energy S.A.

· Iwatani Corporation

· Ingersoll Rand

· Chart Industries

· H2 MOBILITY

· Sera GmbH

· Powertech Labs Inc.

· Galileo Technologies S.A.

· Nikola Corporation

· Atawey

Get More Market Insights on Advanced Materials Chemicals and Fuel

Conclusion

With a global shift toward clean energy, the Hydrogen Fuel Station Market is positioned for robust growth, driven by environmental goals and the transition away from fossil fuels. As governments and private sectors ramp up investments in hydrogen infrastructure, hydrogen fueling stations are becoming essential for supporting a sustainable energy ecosystem. These stations will not only cater to fuel cell vehicles but also serve broader applications, including industrial and residential power needs. Hydrogen’s versatility and ability to produce zero emissions make it a prime candidate for long-term energy solutions, positioning hydrogen fueling stations as a cornerstone in the evolving landscape of green transportation and energy innovation. BIS Research, recognized as a best market research company, provides premium market intelligence reports on deep technologies poised to cause significant market disruption in the coming years.

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, diagnostics, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data analysis, blockchain technology, 3D printing, advanced materials and chemicals, agriculture and FoodTech, mobility, robotics and UAVs, and aerospace and defense, among others

0 notes

Link

0 notes

Text

Unlocking Precision: The Growth of the Chemical Milling Market

The Chemical Milling Market has gained momentum in recent years due to its crucial role in industries such as aerospace, automotive, medical, electronics, and defense. This niche manufacturing process, which uses chemical solutions to etch precise patterns or remove layers from metal parts, allows for the creation of lightweight and complex components with unparalleled precision. This article delves into the market's current trends, key players, growth factors, and emerging innovations.

Introduction to Chemical Milling

Chemical milling, also known as chemical etching, is a subtractive manufacturing process used to produce intricate metal parts by dissolving specific portions of the metal with chemical solutions. Industries favor chemical milling for its precision, cost-efficiency, and ability to work with various metals, including aluminum, titanium, steel, and copper alloys.

The process finds widespread application in sectors demanding high accuracy, such as aerospace, where lightweight and durable components are crucial. Beyond aerospace, the process has gained traction in the electronics and medical industries, driven by advancements in technology and the growing demand for customized solutions.

Market Overview

The global chemical milling market was valued at approximately $X billion in 2023 and is projected to grow to $Y billion by 2030, registering a CAGR of Z% during the forecast period. This growth can be attributed to increasing demand for lightweight components, advancements in chemical etching technologies, and the rise of renewable energy applications requiring precise metal parts.

Key Industries Driving Demand

Aerospace & Defense Chemical milling is extensively used for creating structural components, fuel tanks, and turbine blades. With the expansion of commercial aviation and defense budgets, demand for chemically milled parts is surging.

Automotive In electric vehicles (EVs) and autonomous vehicles, chemical milling is used to manufacture lightweight components, improving energy efficiency and reducing emissions.

Electronics The rise of miniaturized devices and high-density interconnects (HDI) has fueled the need for precise chemical etching techniques in circuit boards and microelectronic components.

Medical Devices Chemical milling is critical for producing surgical instruments, implants, and other medical equipment with complex geometries and high precision.

Emerging Trends in the Chemical Milling Market

1. Eco-Friendly Etching Solutions

Regulatory pressure to reduce environmental impact has led to the development of eco-friendly chemical solutions. These innovations focus on reducing hazardous waste and energy consumption.

2. Integration with Automation

Automation is transforming chemical milling processes, ensuring greater accuracy and reducing lead times. Automated systems enable real-time monitoring, enhancing quality control and efficiency.

3. Advancements in Photochemical Machining

Photochemical machining, a subset of chemical milling, uses photoresist technology for precise patterning. This method is gaining popularity in electronics and micromechanical applications.

4. 3D Chemical Milling

While traditionally applied to flat surfaces, advancements now allow for 3D etching, enabling more complex part geometries.

5. Increased Use of Recyclable Materials

Manufacturers are shifting toward using recyclable and sustainable materials to align with global sustainability goals, reducing both costs and environmental impact.

Challenges in the Market

Despite its advantages, the chemical milling market faces challenges:

Regulatory Restrictions The use of hazardous chemicals in the etching process is subject to stringent environmental regulations, particularly in developed regions such as North America and Europe.

High Competition from Additive Manufacturing Additive manufacturing (3D printing) is rapidly advancing, offering an alternative for creating complex metal components. However, chemical milling maintains its edge in terms of precision and scalability.

Rising Raw Material Costs Fluctuating prices of metals such as titanium and aluminum can impact production costs, creating pricing pressure for manufacturers.

Regional Insights

North America

North America remains a dominant player in the chemical milling market due to its well-established aerospace and defense industries. The region also invests heavily in R&D, driving technological advancements in the field.

Europe

Europe's chemical milling market benefits from the automotive industry's focus on lightweight materials. Countries such as Germany and the UK are hubs for innovation in chemical etching solutions.

Asia-Pacific

Asia-Pacific is witnessing rapid growth, driven by the booming electronics industry in countries like China, South Korea, and Japan. The region's low production costs and expanding automotive sector contribute to market expansion.

Middle East & Africa

Though smaller in scale, the Middle East is emerging as a key market, with investments in aerospace and defense projects boosting demand for chemical milling.

Key Players in the Market

Several prominent companies are driving innovation and competition in the chemical milling market:

Orbel Corporation

Advanced Chemical Etching Ltd.

Tech-Etch, Inc.

United Western Enterprises, Inc.

VACCO Industries

Chemcut Corporation

Precision Micro Ltd.

Photofabrication Engineering, Inc.

UWE Bristol

Tecan Ltd.

These companies focus on developing advanced etching technologies, eco-friendly solutions, and automated processes to stay ahead in the competitive landscape.

Future Outlook

The chemical milling market is poised for significant growth as industries increasingly adopt lightweight and precise manufacturing solutions. Emerging applications in renewable energy and electric vehicles, coupled with advancements in automation and green chemistry, will further propel the market.

However, to maintain sustainability and competitiveness, companies must focus on overcoming challenges such as environmental concerns and competition from alternative technologies.

Conclusion

The chemical milling market stands at the intersection of precision engineering and technological innovation. With its versatility and efficiency, chemical milling continues to be a cornerstone of modern manufacturing, meeting the needs of various industries. As the market evolves, driven by technological advancements and sustainability goals, chemical milling will remain a critical process for producing high-quality metal components.

Browse More

Sodium Dichromate Market Overview

Microfiltration Membrane Market Analysis

Fluosilicic Acid Market Trends and Size

0 notes

Text

The Unstoppable Rise of Pressure Washers in a Cleaning-Obsessed World Pressure washers have become an indispensable tool in both residential and commercial settings, revolutionizing the way we approach cleaning tasks. These powerful machines harness the force of high-pressure water to blast away dirt, grime, and stubborn stains from a variety of surfaces. As the global market for pressure washers continues to expand, it's clear that these versatile devices are here to stay. The Evolution of Pressure Washing Technology The pressure washer industry has come a long way since its inception. What started as a simple concept has transformed into a sophisticated market filled with innovative products and cutting-edge technology. From Humble Beginnings to Modern Marvels The first pressure washers were rudimentary devices, often cobbled together from existing pump and engine components. These early models were primarily used in industrial settings, where their power could be harnessed for heavy-duty cleaning tasks. As the technology improved, manufacturers began to see the potential for smaller, more user-friendly units that could be marketed to homeowners and small businesses. Today's pressure washers are a far cry from their predecessors. Advanced materials and engineering have resulted in machines that are more powerful, efficient, and versatile than ever before. Modern pressure washers come equipped with features like adjustable nozzles, detergent injection systems, and even smart technology that allows for remote operation and monitoring. The Rise of Electric Pressure Washers While gas-powered pressure washers have long been the standard for heavy-duty applications, electric models have gained significant traction in recent years. These eco-friendly alternatives offer several advantages over their gas-powered counterparts, including lower noise levels, reduced maintenance requirements, and zero emissions. Electric pressure washers have become particularly popular among homeowners and light commercial users who appreciate their convenience and ease of use. As battery technology continues to improve, we're likely to see even more powerful and portable electric models hitting the market in the coming years. Innovative Features Driving Market Growth Manufacturers are constantly pushing the boundaries of what pressure washers can do. Some of the most exciting innovations in recent years include: Dual-fuel systems that allow users to switch between gas and electric power sources Smart pressure washers that can be controlled via smartphone apps Self-contained units with built-in water tanks for ultimate portability Eco-friendly models that use recycled water or incorporate water-saving technologies These advancements are not only making pressure washers more appealing to a wider range of consumers but are also opening up new applications and market segments for the industry. Market Dynamics and Growth Projections The pressure washer market is experiencing steady growth, driven by a combination of factors ranging from increased awareness of hygiene to technological advancements in the industry. Global Market Trends and Forecasts According to recent market research, the global pressure washer market is poised for significant expansion in the coming years. Valued at USD 2466.31 Million in 2023, the market is projected to reach USD 3452.8 Million by 2032, growing at a compound annual growth rate (CAGR) of 3.42% from 2024 to 2032. This growth is being fueled by several key factors, including: Increasing demand for efficient cleaning solutions in both residential and commercial sectors Growing awareness of the importance of maintaining clean and hygienic environments Technological advancements leading to more user-friendly and versatile pressure washer models Expansion of the construction and automotive industries, which are major end-users of pressure washing equipment As the market continues to expand, we're likely to see increased competition

among manufacturers, leading to further innovation and potentially more affordable options for consumers. Regional Market Analysis While the pressure washer market is growing globally, certain regions are experiencing more rapid expansion than others. North America and Europe currently dominate the market, thanks to high levels of disposable income and a strong culture of DIY home maintenance. However, the Asia-Pacific region is emerging as a key growth area for pressure washer manufacturers. Rapid urbanization, increasing industrialization, and rising standards of living in countries like China and India are driving demand for efficient cleaning solutions. As these markets mature, we can expect to see a shift in the global landscape of pressure washer production and consumption. Market Segmentation and Key Players The pressure washer market can be broadly segmented based on power source (electric, gas, and diesel), end-user (residential, commercial, and industrial), and application (vehicle cleaning, gardening, industrial cleaning, and others). Some of the leading players in the global pressure washer market include: Kärcher Nilfisk Briggs Stratton STIHL Generac AR North America Stanley Black Decker Deere Company Snow Joe These companies are constantly innovating and expanding their product lines to maintain their competitive edge in an increasingly crowded market. Applications and Use Cases Pressure washers have found their way into a wide range of industries and applications, showcasing their versatility and effectiveness in tackling diverse cleaning challenges. Residential Applications In the residential sector, pressure washers have become a staple tool for homeowners looking to maintain the appearance and value of their property. Some common residential applications include: Cleaning driveways, sidewalks, and patios Removing mold and mildew from exterior walls and fences Preparing surfaces for painting or staining Washing vehicles, boats, and recreational equipment The popularity of pressure washers among homeowners has led to the development of more compact and user-friendly models specifically designed for residential use. These units often come with a variety of attachments and accessories to tackle different cleaning tasks around the home. Commercial and Industrial Use Cases In the commercial and industrial sectors, pressure washers play a crucial role in maintaining cleanliness, safety, and operational efficiency. Some key applications in these areas include: Cleaning heavy machinery and equipment in manufacturing plants Maintaining fleet vehicles in transportation and logistics companies Removing graffiti and cleaning public spaces in urban areas Sanitizing food processing facilities and commercial kitchens Industrial-grade pressure washers are typically more powerful and durable than their residential counterparts, capable of handling heavy-duty cleaning tasks on a daily basis. Many commercial users opt for trailer-mounted or skid-mounted units that offer greater mobility and flexibility for large-scale cleaning operations. Specialized Applications Beyond general cleaning tasks, pressure washers have found their way into several specialized applications that leverage their unique capabilities: Hydro-demolition: Using ultra-high-pressure water jets to remove concrete and other materials in construction and renovation projects Marine cleaning: Removing barnacles and marine growth from boat hulls and docks Agriculture: Cleaning and sanitizing livestock facilities and equipment Firefighting: Using high-pressure water mist systems for fire suppression in certain scenarios As technology continues to advance, we're likely to see pressure washers adapted for even more specialized applications across various industries. Environmental Considerations and Sustainability As awareness of environmental issues grows, the pressure washer industry is increasingly focusing on sustainability and eco-friendly practices. Water Conservation Efforts

One of the primary concerns surrounding pressure washer use is water consumption. To address this issue, manufacturers are developing more efficient nozzle designs and pressure control systems that maximize cleaning power while minimizing water usage. Some innovative approaches to water conservation in pressure washing include: Recirculation systems that collect and reuse water during cleaning operations Smart pressure washers that adjust water flow based on the cleaning task at hand Integration of rainwater harvesting systems for use with pressure washers These efforts not only help conserve a precious resource but also make pressure washers more appealing to environmentally conscious consumers and businesses. Eco-Friendly Cleaning Solutions Another area of focus for the industry is the development of environmentally friendly cleaning solutions and detergents. Traditional cleaning agents often contain harsh chemicals that can be harmful to plants, animals, and waterways when they enter the environment through runoff. Many manufacturers now offer biodegradable and phosphate-free cleaning solutions specifically formulated for use with pressure washers. These eco-friendly alternatives are designed to be just as effective as their chemical-heavy counterparts while minimizing environmental impact. Energy Efficiency and Emissions Reduction For gas-powered pressure washers, reducing emissions and improving fuel efficiency are key priorities. Manufacturers are investing in cleaner-burning engines and exploring alternative fuel options like propane and biodiesel. Electric pressure washers, of course, produce zero emissions during operation. As the electrical grid becomes greener with the integration of renewable energy sources, the environmental footprint of electric pressure washers will continue to shrink. Some companies are also exploring hybrid power systems that combine the benefits of both gas and electric power sources, offering users greater flexibility and potentially reducing overall environmental impact. Conclusion The pressure washer market is poised for continued growth and innovation in the coming years. As these versatile machines become more powerful, efficient, and environmentally friendly, we can expect to see them play an increasingly important role in maintaining cleanliness and hygiene across a wide range of industries and applications. From homeowners looking to keep their properties in top condition to industrial users tackling the toughest cleaning challenges, pressure washers have proven themselves to be indispensable tools in our modern world. As technology continues to advance and environmental concerns shape product development, the future of pressure washing looks brighter – and cleaner – than ever before. https://gardenreview.us/the-unstoppable-rise-of-pressure-washers-in-a-cleaning-obsessed-world/?feed_id=202&_unique_id=672d96245b150 https://gardenreview.us/the-unstoppable-rise-of-pressure-washers-in-a-cleaning-obsessed-world/?feed_id=202&_unique_id=672d96245b150

0 notes

Text

Linear Low-Density Polyethylene Market Size, Share, Trends, Growth and Competitive Outlook

"Global Linear Low-Density Polyethylene Market – Industry Trends and Forecast to 2027

Global Linear Low-Density Polyethylene Market, By Process Type (Gas Phase, Slurry Loop, Solution Phase), Application (Films, Rotomolding, Injection Molding, Others), End-User Industry (Packaging, Building and Construction, Automotive, Electrical and Electronics, Agriculture, Household, Leisure, Sports), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2027

Access Full 350 Pages PDF Report @

**Segments**

- By Product Type: - Butene-LLDPE - Hexene-LLDPE - Octene-LLDPE

- By Application: - Films - Extrusion Coating - Injection Molding - Rotomolding - Others

- By End-Use Industry: - Packaging - Agriculture - Automotive - Construction - Others

Linear low-density polyethylene (LLDPE) market is segmented based on product type, application, and end-use industry. The product type segment includes butene-LLDPE, hexene-LLDPE, and octene-LLDPE. Butene-LLDPE is widely used due to its versatile properties and cost-effectiveness. Hexene-LLDPE offers improved toughness and puncture resistance, making it suitable for applications requiring durability. Octene-LLDPE provides excellent strength and sealability, making it ideal for high-performance packaging solutions.

When it comes to applications, LLDPE is utilized in various sectors such as films, extrusion coating, injection molding, and rotomolding. Films segment dominates the market owing to the extensive use of LLDPE in packaging films, agricultural films, and industrial films. Extrusion coating applications are growing due to the increasing demand for protective coatings in the food and beverage industry. Additionally, LLDPE's use in injection molding offers manufacturers the advantage of producing intricate shapes with high efficiency.

Moreover, the end-use industry segment of the LLDPE market includes packaging, agriculture, automotive, construction, and others. The packaging industry holds a significant share as LLDPE is a preferred choice for flexible packaging due to its moisture barrier properties. In the agriculture sector, LLDPE is extensively used in greenhouse films, mulching films, and silage wrap. The automotive industry utilizes LLDPE for various components such as fuel tanks, bumper fascia,The linear low-density polyethylene (LLDPE) market segmentation by product type, application, and end-use industry provides a comprehensive understanding of the diverse usage and demand patterns of this versatile polymer. The product type segment reveals the distinct properties and applications of butene-LLDPE, hexene-LLDPE, and octene-LLDPE. Butene-LLDPE stands out for its balanced properties and cost-effectiveness, making it a popular choice in various industries. Hexene-LLDPE offers enhanced toughness and puncture resistance, catering to applications where durability is paramount, such as in heavy-duty packaging. Octene-LLDPE, known for its superior strength and sealability, finds niche applications in high-performance packaging solutions requiring robust barrier properties.

Moving on to the application segment, LLDPE finds versatile use in films, extrusion coating, injection molding, rotomolding, and other diverse applications. Films, being the dominant application, witness a strong demand for LLDPE due to its flexibility, transparency, and moisture barrier properties. This segment encompasses packaging films for food and non-food items, agricultural films for crop protection and mulching, and industrial films for various industrial applications. The extrusion coating application is gaining traction, driven by the need for protective coatings in the food and beverage industry to ensure product safety and freshness. Meanwhile, injection molding applications capitalize on LLDPE’s moldability, enabling the production of intricate shapes with high efficiency, especially in the manufacture of automotive components, consumer goods, and medical devices.

In the end-use industry segment, the LLDPE market caters to packaging, agriculture, automotive, construction, and other sectors. The packaging industry emerges as a key consumer of LLDPE, leveraging its moisture barrier properties, flexibility, and cost-effectiveness for a wide range of packaging solutions. In agriculture, LLDPE plays a vital role in greenhouse films, mulching films, and silage wrap, offering protection and enhancing crop**Global Linear Low-Density Polyethylene Market**

- **Process Type** - Gas Phase - Slurry Loop - Solution Phase

- **Application** - Films - Rotomolding - Injection Molding - Others

- **End-User Industry** - Packaging - Building and Construction - Automotive - Electrical and Electronics - Agriculture - Household - Leisure - Sports

The global linear low-density polyethylene (LLDPE) market is witnessing significant growth, driven by the increasing demand for flexible and durable packaging solutions across various industries. The market segmentation based on process type, application, and end-user industry offers valuable insights into the consumption patterns and opportunities in the LLDPE market. Gas phase, slurry loop, and solution phase are the key process types in LLDPE production, each offering distinct advantages in terms of efficiency, cost-effectiveness, and product quality.

In terms of applications, LLDPE finds extensive usage in films, rotomolding, injection molding, and other specialized applications. Films remain a dominant application segment, with LLDPE being the preferred choice for packaging films due to its excellent moisture barrier properties and flexibility. The rotomolding segment is witnessing growth, driven by the demand for durable and lightweight products in industries such as automotive, agriculture, and leisure. Injection molding applications of LLDPE are gaining traction due to the polymer's versatility in producing

Key points covered in the report: -

The pivotal aspect considered in the global Linear Low-Density Polyethylene Market report consists of the major competitors functioning in the global market.

The report includes profiles of companies with prominent positions in the global market.

The sales, corporate strategies and technical capabilities of key manufacturers are also mentioned in the report.

The driving factors for the growth of the global Linear Low-Density Polyethylene Market are thoroughly explained along with in-depth descriptions of the industry end users.

The report also elucidates important application segments of the global market to readers/users.

This report performs a SWOT analysis of the market. In the final section, the report recalls the sentiments and perspectives of industry-prepared and trained experts.

The experts also evaluate the export/import policies that might propel the growth of the Global Linear Low-Density Polyethylene Market.

The Global Linear Low-Density Polyethylene Market report provides valuable information for policymakers, investors, stakeholders, service providers, producers, suppliers, and organizations operating in the industry and looking to purchase this research document.

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Linear Low-Density Polyethylene Market Landscape

Part 04: Global Linear Low-Density Polyethylene Market Sizing

Part 05: Global Linear Low-Density Polyethylene Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Reasons to Buy:

Review the scope of the Linear Low-Density Polyethylene Market with recent trends and SWOT analysis.

Outline of market dynamics coupled with market growth effects in coming years.

Linear Low-Density Polyethylene Market segmentation analysis includes qualitative and quantitative research, including the impact of economic and non-economic aspects.

Regional and country level analysis combining Linear Low-Density Polyethylene Market and supply forces that are affecting the growth of the market.

Market value data (millions of US dollars) and volume (millions of units) for each segment and sub-segment.

and strategies adopted by the players in the last five years.

Browse Trending Reports:

In Line Uv Vis Spectroscopy Market Collagen Casings Market Oilfield Scale Inhibitor Market Metal Based Catalysts Market Laundry Detergents Market Gaucher Disease Market Preventative Healthcare Technologies And Services Market 11d Printing Gases Market Airport Security Market Anxiety Disorder Market Laboratory Developed Tests Ldts Market Variable Rate Technology Market Military Drones Market Thawing Equipment Market Personal Care Contract Manufacturing Market Carbon Steel Market Drug Discovery Services Market Electric Bidet Seat Market Automotive Parts Packaging Market Sleep Tech Devices Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

The Evolution and Significance of Rotational Moulding: Insights from Inborn

In the world of manufacturing, rotational moulding stands out as a versatile and innovative technique for producing a wide range of plastic products. This process has gained immense popularity due to its ability to create complex shapes and durable items with exceptional quality. At the forefront of this industry is Inborn, a renowned rotational mold manufacturer dedicated to delivering top-notch rotational moulds and Rotational Molded product.

Understanding Rotational Moulding

Rotational moulding, also known as rotomoulding, is a process that involves heating plastic resin in a hollow mould. The mould is rotated along two axes, allowing the resin to coat the inner surfaces evenly. As the mould continues to rotate, the resin melts and fuses, ultimately solidifying into the desired shape. This method is particularly effective for creating large, hollow, and seamless products, making it ideal for various applications in industries such as automotive, marine, toys, and outdoor furniture.

Advantages of Rotational Moulding

One of the primary benefits of rotational moulding is its flexibility in design. Unlike other manufacturing processes, such as injection moulding, which may require significant investment in machinery and tooling, rotational moulding offers a more cost-effective solution for producing low to medium quantities of products. This makes it an excellent choice for startups and businesses looking to bring innovative designs to market without the burden of high initial costs.

Additionally, rotational moulding allows for the use of a wide range of materials, including polyethylene, polycarbonate, and nylon. This versatility enables manufacturers to create products that meet specific performance requirements, such as UV resistance, impact resistance, and chemical stability.

Inborn: Your Trusted Rotational Mold Manufacturer

As a leading rotational mold manufacturer, Inborn specializes in designing and producing high-quality rotational moulds that cater to diverse industries. With a commitment to excellence, Inborn utilizes advanced technology and skilled craftsmanship to ensure that every mould meets the highest standards of precision and durability. Their experienced team works closely with clients to understand their unique needs and provide customized solutions that enhance product performance.

Inborn's expertise extends beyond just manufacturing moulds; they also focus on creating innovative rotational molded products. Their extensive product range includes tanks, containers, automotive parts, and playground equipment, all of which are designed to provide superior strength and longevity. By investing in research and development, Inborn continuously improves its processes and products to keep pace with industry trends and customer demands.

Rotational Molded Products: Applications and Benefits

Rotational molded products have become integral to various sectors due to their numerous advantages. For instance, in the automotive industry, rotomoulded parts are used for fuel tanks, bumpers, and interior components, offering lightweight solutions that enhance vehicle efficiency. In the outdoor furniture market, rotational molded products resist harsh weather conditions and provide long-lasting durability.

Moreover, the seamless design of rotational molded products eliminates the risk of leaks and weak points, ensuring enhanced performance and reliability. This characteristic makes them particularly suitable for applications requiring containment, such as water tanks and chemical storage containers.

Conclusion

In conclusion, rotational moulding is a dynamic and efficient manufacturing process that continues to evolve and adapt to the changing needs of various industries. With Inborn as a trusted rotational mold manufacturer, businesses can access high-quality rotational moulds and innovative rotational molded products that meet their specific requirements. Whether you're looking to create a new product or enhance an existing one, Inborn's expertise and commitment to quality make them the ideal partner in your manufacturing journey. For more information on their offerings, visit Inborn today.

1 note

·

View note

Text

Breather Vent Market Size, Share, Analysis and Opportunities by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Breather Vent Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Breather Vent Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Breather Vent Market?

The breather vent market is expected to grow at a CAGR of 7.8% during the forecast period of 2024 to 2032.

What are Breather Vent?

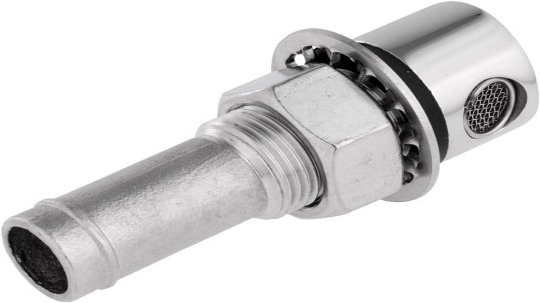

A breather vent is a specialized device designed to allow air to flow in and out of a sealed container or system, such as tanks, vessels, or pipelines, while keeping out contaminants, dust, and moisture. Its primary function is to equalize pressure changes that occur due to temperature variations, liquid transfers, or operational activities, thereby safeguarding the integrity of the container and its contents. Breather vents may include filters or check valves to enhance their effectiveness, ensuring that only clean air enters while allowing gases to escape safely. By maintaining proper pressure and preventing vacuum conditions, breather vents play a crucial role in the safe and efficient functioning of various industrial applications, including chemical storage, fuel tanks, and wastewater treatment systems.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1927

What are the growth prospects and trends in the Breather Vent industry?

The breather vent market growth is driven by various factors and trends. The breather vent market is witnessing consistent growth, propelled by the rising demand for effective pressure management solutions across various sectors, including oil and gas, chemical processing, and wastewater treatment. As regulations concerning safety and environmental protection tighten, companies are increasingly utilizing breather vents to maintain the integrity of their storage systems and prevent contamination. The market features a diverse range of products, including vents equipped with advanced functionalities such as filters, check valves, and automated monitoring systems that enhance both performance and reliability. Additionally, the growing emphasis on sustainable practices and the need for efficient resource management are contributing to market expansion. With ongoing technological innovations and heightened awareness of air quality and safety, the breather vent market is well-positioned for further growth, serving a variety of applications across multiple industries. Hence, all these factors contribute to breather vent market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Inline Breather Vent

Threaded Breather Vent

Bayonet Breather Vent

Customized Breather Vent

By Material:

Metal Breather Vent

Plastic Breather Vent

Composite Breather Vent

By End-Use Industry:

Automotive

Aerospace and Defense

Manufacturing

Oil and Gas

Chemicals and Pharmaceuticals

Electronics

Food and Beverage

Others

By Sales Channel:

Direct Sales

Distributor Sales

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Parker Hannifin Corporation

Donaldson Company, Inc.

MANN+HUMMEL GmbH

L. Gore & Associates, Inc.

Pall Corporation

Porvair Filtration Group

Eaton Corporation plc

SMC Corporation

Bosch Rexroth AG