#Automotive Rubber Tube Market Growth

Explore tagged Tumblr posts

Text

Automotive Rubber Tube Market Overview and Growth Opportunities Ahead 2024 - 2032

The automotive rubber tube market plays a crucial role in the automotive industry, providing essential components for a variety of vehicle systems. This article explores the market's current landscape, trends, applications, and future outlook.

Overview of Automotive Rubber Tubes

The automotive rubber tube market is a vital component of the automotive industry, supporting various systems that enhance vehicle performance and safety. Automotive rubber tubes are flexible, durable components made primarily from synthetic rubber. They are used in a variety of applications within vehicles, including fuel systems, cooling systems, and air conditioning systems. Their ability to withstand high temperatures, pressure, and chemical exposure makes them vital for ensuring vehicle performance and safety.

Key Types of Automotive Rubber Tubes

Fuel Tubes: Used to transport fuel from the tank to the engine, these tubes must resist high pressures and chemical degradation.

Cooling Hoses: Essential for the vehicle's cooling system, these tubes transport coolant and help maintain optimal engine temperatures.

Air Intake Hoses: These tubes connect the air filter to the engine, ensuring proper airflow and performance.

Market Dynamics

Drivers of Growth

Rising Automotive Production: The growth in global vehicle production is a significant driver for the automotive rubber tube market.

Technological Advancements: Innovations in rubber materials and manufacturing processes enhance the performance and lifespan of rubber tubes.

Stringent Emission Regulations: Increasing regulatory pressure for lower emissions is pushing manufacturers to adopt more efficient components, including rubber tubes.

Challenges Facing the Market

Raw Material Price Volatility: Fluctuations in the prices of rubber and other raw materials can impact production costs.

Competition from Alternatives: The emergence of alternative materials, such as plastic and metal, poses a challenge to the rubber tube market.

Environmental Concerns: Growing concerns about sustainability and the environmental impact of rubber production may affect market dynamics.

Applications of Automotive Rubber Tubes

Fuel Systems

Automotive rubber tubes are essential for fuel delivery in internal combustion engines. Their resistance to fuel-related chemicals ensures safe and efficient operation of the fuel system.

Cooling Systems

Rubber hoses in cooling systems are critical for regulating engine temperatures, preventing overheating, and ensuring optimal performance.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, rubber tubes facilitate the circulation of refrigerants, contributing to passenger comfort and vehicle climate control.

Market Trends

Shift Towards Electric Vehicles (EVs)

The rise of electric vehicles is reshaping the automotive landscape. While rubber tubes will continue to play a role, there is increasing demand for specialized components tailored to EV systems.

Focus on Lightweight Materials

There is a growing trend towards using lightweight materials in automotive manufacturing. Rubber tubes are being designed to be lighter while maintaining strength and durability, contributing to overall vehicle efficiency.

Integration of Smart Technologies

The incorporation of smart technologies in vehicles is influencing the design of rubber tubes. Future developments may include sensors integrated into rubber tubes for monitoring performance and health.

Future Outlook

Market Projections

The automotive rubber tube market is projected to grow steadily over the next several years, driven by increasing automotive production and the need for advanced components. Analysts predict a compound annual growth rate (CAGR) of approximately 5% during this period.

Innovations on the Horizon

Innovations in materials science, such as the development of eco-friendly rubber compounds and advanced manufacturing techniques, are expected to transform the automotive rubber tube market. Additionally, the growing emphasis on sustainability may lead to the introduction of recycled rubber products.

Conclusion

As the industry evolves, driven by technological advancements and changing consumer demands, the market for automotive rubber tubes is expected to grow and adapt. Companies looking to remain competitive should focus on innovation and sustainability to meet the needs of the modern automotive landscape.

#Automotive Rubber Tube Market Size#Automotive Rubber Tube Market Trend#Automotive Rubber Tube Market Growth

0 notes

Text

The Global Synthetic Rubber Market: Trends, Challenges, and Opportunities

Synthetic rubber, a critical material in industries ranging from automotive to healthcare, has been an integral part of modern manufacturing for decades. With advancements in technology and growing industrial demands, the global synthetic rubber market continues to evolve. However, this growth is accompanied by challenges and opportunities that shape its future trajectory. This article delves into the current trends, challenges, and opportunities within the global synthetic rubber market.

Current Trends in the Synthetic Rubber Market

1. Increasing Demand from the Automotive Sector

The automotive industry is one of the largest consumers of synthetic rubber, primarily for tire manufacturing. As the global demand for vehicles grows, particularly in emerging markets, the need for high-performance synthetic rubber continues to rise. Electric vehicles (EVs) have further boosted demand, requiring specialized rubber for lightweight, energy-efficient tires and components.

2. Advancements in Synthetic Rubber Technology

Innovations in synthetic rubber production have enhanced the material's performance and durability. For instance, the development of high-performance elastomers offers improved resistance to heat, chemicals, and wear, meeting the stringent requirements of industries like aerospace and oil exploration. Such advancements expand synthetic rubber's applicability across diverse sectors.

3. Focus on Sustainable Alternatives

Sustainability is a growing priority across industries, and synthetic rubber is no exception. Manufacturers are exploring bio-based raw materials to reduce dependence on petroleum. Efforts to produce eco-friendly synthetic rubber, such as bio-isoprene and bio-butadiene, are gaining traction as industries align with global environmental goals.

4. Growth in Healthcare Applications

Synthetic rubber's properties, such as flexibility, biocompatibility, and resistance to chemicals, make it essential in the healthcare sector. The demand for gloves, seals, and medical tubing has surged, particularly during and after the COVID-19 pandemic, highlighting synthetic rubber's importance in critical healthcare applications.

Challenges Facing the Synthetic Rubber Market

1. Volatility in Raw Material Prices

Synthetic rubber production relies heavily on petroleum-based raw materials, such as butadiene and styrene. Fluctuations in crude oil prices directly impact production costs, creating challenges for manufacturers to maintain profitability and price stability.

2. Environmental Concerns

The production and disposal of synthetic rubber pose environmental challenges. Non-biodegradable waste, energy-intensive manufacturing processes, and reliance on fossil fuels have drawn criticism. Stricter environmental regulations worldwide are pressuring manufacturers to adopt greener practices, which often require significant investment.

3. Competition from Natural Rubber

In some applications, natural rubber offers advantages such as better elasticity and lower costs. The competition between synthetic and natural rubber poses challenges, especially in markets where natural rubber is more readily available.

4. Global Supply Chain Disruptions

The synthetic rubber industry, like many others, has faced disruptions due to geopolitical tensions, trade restrictions, and the COVID-19 pandemic. These disruptions have impacted raw material availability and production schedules, leading to delays and increased costs.

Opportunities in the Synthetic Rubber Market

1. Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and Africa present significant growth opportunities. Rising industrialization, urbanization, and increasing vehicle ownership in these regions drive demand for synthetic rubber in automotive, construction, and consumer goods.

2. Sustainability and Circular Economy Initiatives

The push toward sustainable practices offers opportunities for innovation. Manufacturers investing in bio-based raw materials, recycling technologies, and energy-efficient production methods can align with consumer and regulatory demands, creating a competitive edge.

3. Diversification of Applications

While the automotive sector remains the largest consumer, other industries such as electronics, construction, and aerospace are increasingly incorporating synthetic rubber. Products like seals, gaskets, and vibration dampers demonstrate the material's versatility, opening new avenues for market expansion.

4. Digitalization and Smart Manufacturing

Adopting digital tools such as predictive analytics, IoT, and AI in manufacturing processes can optimize production, reduce waste, and enhance product quality. These advancements not only improve efficiency but also reduce the environmental footprint of synthetic rubber production.

Future Outlook

The global synthetic rubber market is poised for growth, driven by technological advancements and increasing demand across diverse industries. However, addressing challenges like environmental impact, raw material volatility, and supply chain disruptions will be crucial for sustained progress.

Manufacturers that prioritize sustainability, invest in innovation, and tap into emerging markets will be best positioned to capitalize on opportunities. As the industry evolves, synthetic rubber will continue to play a pivotal role in shaping modern manufacturing and meeting the demands of a rapidly changing global economy.

Synthetic rubber remains a cornerstone of industrial innovation, offering versatility, durability, and performance. By navigating challenges and embracing emerging opportunities, the industry can drive growth while contributing to a more sustainable future.

0 notes

Text

Caps & Closures Market: Technological Advancements in Flip-Top and Screw Closures

The Caps & Closures Market plays a crucial role in packaging solutions for multiple industries, including food, beverages, pharmaceuticals, and cosmetics. With the growing demand for sustainable and user-friendly packaging, this market is evolving rapidly with innovations in materials and designs.

Read Complete Report Details of Caps & Closures Market: https://www.snsinsider.com/reports/caps-and-closures-market-2831

Market Segmentation

By Raw Material

Plastic

Types: Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), Polyethylene Terephthalate (PET).

Growth Drivers: Lightweight, cost-effectiveness, and wide applicability.

Trends: Increasing adoption of recyclable and biodegradable plastics.

Metal

Types: Aluminum, Steel, Tin.

Growth Drivers: Demand for premium packaging in beverages and pharmaceuticals.

Trends: Development of rust-resistant and resealable metal caps.

Others

Description: Includes glass, rubber, and composite materials.

Growth Drivers: Niche applications in high-end cosmetic packaging.

Trends: Use of hybrid materials for functional and aesthetic appeal.

By Product Type

Roll-On Balls

Description: Used primarily in deodorants, roll-on perfumes, and medicinal applications.

Growth Drivers: Demand for precision and convenience in dispensing.

Trends: Customization and eco-friendly alternatives to plastic balls.

Plastic Caps

Description: Includes screw caps, flip tops, and snap closures.

Growth Drivers: High demand from the food & beverage industry for lightweight and resealable options.

Trends: Integration of tamper-evident and child-resistant features.

Closures

Description: Used to seal containers like bottles, jars, and tubes.

Growth Drivers: Growth in packaged consumer goods and beverages.

Trends: Development of resealable and spill-proof closures.

Other Caps

Description: Specialty caps such as dispensing caps, droppers, and threaded closures.

Growth Drivers: Rising demand from personal care and healthcare segments.

Trends: Use of smart caps with embedded sensors for product freshness monitoring.

By End Use

Food

Description: Caps and closures for jars, cans, and containers for sauces, spreads, and condiments.

Growth Drivers: Increasing consumption of ready-to-eat and packaged foods.

Trends: Use of vacuum-sealed caps for extended shelf life.

Pharmaceutical

Description: Closures for medicine bottles, syrups, and tablet containers.

Growth Drivers: Growing healthcare infrastructure and demand for secure packaging.

Trends: Adoption of tamper-evident and child-proof caps.

Cosmetics

Description: Caps for creams, lotions, and makeup products.

Growth Drivers: Rising demand for premium and personalized cosmetics packaging.

Trends: Use of aesthetically pleasing closures made from metal and glass.

Beverage

Description: Includes closures for bottled water, juices, and alcoholic beverages.

Growth Drivers: Growth in the consumption of beverages, especially functional drinks.

Trends: Lightweight and resealable caps for on-the-go convenience.

Automotive

Description: Used for containers of lubricants and automotive fluids.

Growth Drivers: Expansion in the automotive industry.

Trends: Development of leak-proof and durable caps.

Packaged Water Bottles

Description: Closures for PET bottles and reusable water containers.

Growth Drivers: Increasing demand for bottled water in urban areas.

Trends: Shift to biodegradable and recyclable cap materials.

Others

Description: Includes closures for industrial, chemical, and household products.

Trends: Use of multi-layered caps for improved sealing performance.

By Region

North America

Growth Drivers: High demand for convenience packaging and innovation in smart caps.

Trends: Focus on reducing plastic waste through recyclable materials.

Europe

Growth Drivers: Regulatory push for sustainable packaging and high adoption in beverages.

Trends: Use of bio-based materials in caps and closures.

Asia-Pacific

Growth Drivers: Rising consumption of packaged foods and beverages due to urbanization.

Trends: Increasing investment in manufacturing facilities for eco-friendly closures.

Latin America

Growth Drivers: Expansion in the food & beverage and personal care sectors.

Trends: Shift to lightweight caps for cost optimization.

Middle East & Africa

Growth Drivers: Growth in the pharmaceutical and bottled water industries.

Trends: Development of durable and tamper-proof closures for extreme conditions.

Market Trends and Opportunities

Sustainability: Rising demand for biodegradable and recyclable materials in caps and closures.

Customization: Increasing consumer preference for aesthetic and functional designs.

Smart Packaging: Growing adoption of caps with NFC or RFID technology for authentication and freshness tracking.

Innovation: Development of lightweight, resealable, and spill-proof designs.

Regulatory Compliance: Manufacturers focusing on food safety and tamper-proofing requirements.

Market Outlook

The Caps & Closures Market is poised for steady growth, driven by demand across diverse industries such as food, beverages, and pharmaceuticals. The transition towards sustainable and user-centric packaging solutions will define future trends, with Asia-Pacific expected to dominate in terms of production and consumption.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

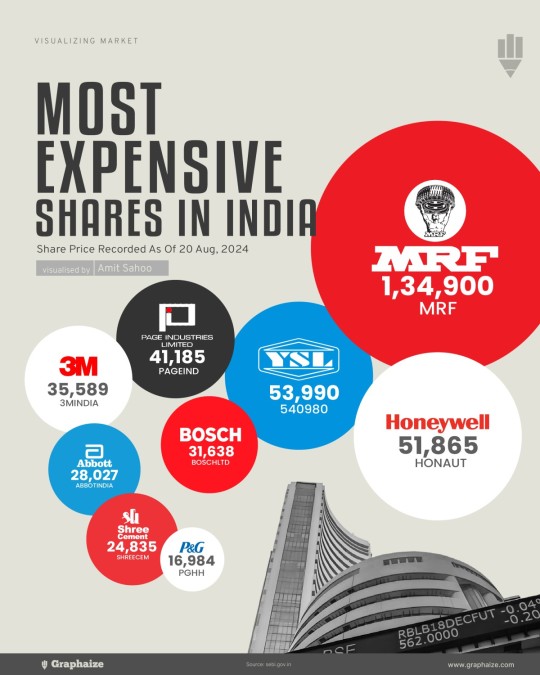

Most Expensive Shares in India 2024: Insights

Investing in high-value shares can be a profitable but often daunting venture, especially in a market like India, where stock prices can soar to unimaginable levels. If you’re curious about the most expensive shares in India for 2024, you’re in the right place! Let’s explore some of the priciest shares in India and understand what makes them so valuable.

When we talk about high-priced stocks, it’s not just about the number of shares you hold, but the quality and profitability of each one. Shares with high prices often reflect a company’s solid market position, strong brand reputation, and consistent performance. Although these shares can’t usually be purchased in bulk, their potential for profit often outweighs their hefty price tags.

For those looking to diversify their portfolio with quality over quantity, these expensive shares are worth a closer look. Let’s dive into the top high-value shares in India and what makes them stand out.

Top High-Value Shares in India for 2024

MRF Ltd (Madras Rubber Factory)

MRF Ltd, known as India’s largest tyre manufacturer, holds the title for the most expensive shares in India. With a stock price of Rs. 1,34,900, MRF dominates the market, thanks to its robust market share, brand reputation, and commitment to quality.

The company doesn’t just produce tyres; it also specializes in treads, tubes, and conveyor belts and has expanded into motorsports and rubber manufacturing. MRF’s high share price is driven by its leadership in the tyre industry, consistent financial performance, and a limited number of outstanding shares, which maintains high demand among investors.

Honeywell Automation India Ltd

Honeywell Automation India Ltd, a subsidiary of Honeywell International Inc., provides automation and control solutions across various sectors like industrial, building, and home automation. With a share price of Rs. 51,865, Honeywell Automation stands out for its advanced technological solutions and steady growth in the automation industry.

The company’s high market value is a result of its association with the globally recognized Honeywell brand and its consistent growth, which attracts both domestic and international investors.

Yamuna Syndicate Ltd

Engaged in commodities trading, Yamuna Syndicate Ltd deals in petroleum, lubricants, and industrial gases. The company also distributes automotive products, batteries, and other industrial commodities. With a share price of Rs. 53,990, Yamuna Syndicate Ltd enjoys high investor interest due to its strong performance in the commodities market and the scarcity of its shares.

The high demand and limited availability of Yamuna Syndicate shares contribute significantly to its soaring stock price, making it one of the most valuable investments in India’s market.

Page Industries Ltd

Page Industries Ltd, the exclusive licensee of Jockey and Speedo brands in India, manufactures, distributes, and markets innerwear, leisurewear, and sportswear under the Jockey label. Page Industries’ shares are priced at Rs. 41,185, supported by a loyal customer base, premium product offerings, and steady demand in the apparel sector.

Page Industries has created a niche in the Indian apparel market, making it one of the most expensive shares and a valuable asset for investors seeking steady returns from a reliable brand.

The most expensive shares in India represent some of the most successful and stable companies in the market today. From MRF’s tyre empire to Page Industries’ popular Jockey brand, these stocks reflect the best of India’s corporate sector. While their high prices may seem intimidating, their potential for steady returns makes them attractive to many investors.

0 notes

Text

Silicone Elastomers Market Future Trends to Look at | BIS Research

Silicone Elastomers are a class of synthetic polymers known for their exceptional flexibility, durability, and resistance to extreme temperatures and environmental conditions

The Silicone Elastomers market was valued at $19.18 billion in 2022, and it is expected to grow at a CAGR of 8.51% and reach $45.37 billion by 2032.

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data, blockchain technology, Silicone Elastomers Material , advanced materials and chemicals, agriculture and FoodTech, mobility, robotics, and aerospace and defense, among others.

Silicone Elastomers Overview

The silicone elastomers encompass synthetic rubber materials derived from silicone polymers. These elastomers, formulated with reactive linear molecules, cross-linking agents, and reinforcement materials, offer exceptional mechanical properties, including elasticity, tear strength, and resilience. Their high flexibility and ability to withstand mechanical stress without permanent deformation make them ideal for dynamic applications. Notably, silicone elastomers exhibit superior heat resistance, enduring temperatures from -50°C to over 200°C, making them suitable for extreme environments.

The silicone elastomers are defined by the versatile applications of synthetic rubber materials derived from silicone polymers. These elastomers are created by compounding reactive linear molecules with cross-linking agents and reinforcement materials, resulting in excellent mechanical properties such as elasticity, tear strength, and resilience. Known for their flexibility and ability to endure mechanical stress without permanent deformation, silicone elastomers are ideal for dynamic uses

Market Drivers

By Advancements in the Electronics and Electrical Sectors

Growing demand in Automotive Industry

Advancements in Medical Technology

Rising Electronics and Electrical Sector

Sustainability Trends

Growing Consumer Goods

Key Companies

Dow

Wacker Chemie AG

Momentive Performance Materials

Shin-Etsu Chemical Co., Ltd.

China National Bluestar (Group) Co., Ltd.

Rogers Corporation

Cabot Corporation

Reiss Manufacturing Inc.

MESGO S.p.A.

CHT Germany GmbH

Bellofram Elastomers

Grab a look at the report page click here !

Market Segmentation for Silicone Elastomers

By End User Industry

By Type

By Process

By Region

Recent Developments in the Global Silicone Elastomers Market

• In June 2024, Wacker Chemie AG announced the construction of a new production site in Karlovy Vary, Czech Republic, marking a significant step in enhancing its focus on silicone specialties in Europe. • In January 2024, SIGMA Engineering and Momentive Performance Materials announced a strategic partnership aimed at optimizing material data for silicone elastomers to enhance the reliability of process simulations using SIGMASOFT Virtual Molding. • In April 2022, Shin-Etsu Chemical Co., Ltd. announced the development of its new TC-BGI Series, a thermal interface silicone rubber sheet designed for high-voltage electric vehicle components. This series addresses the growing demand for electric cars, which require smaller, lighter components with high energy density.

Have a look at the free sample click here !

Applications of Silicone Elastomers Market

Automotive Industry: Seals, gaskets, and hoses.

Medical Devices: Implants, seals, and flexible tubing.

Electronics: Insulating components and encapsulation.

Consumer Goods: Kitchenware, seals, and flexible membranes.

Visit our Next Generation Fuel/ Energy Storage Solutions

Key Players

Dow

Henkel

Chase Corporation

H.B. Fuller

Electrolube

Conclusion

In conclusion, the Silicone Elastomers market serves as the backbone of global communication, addressing the need for rapid and reliable data transmission. The growth of this market is fueled by technological advancements, the expanding telecommunications landscape, emerging 6G sector and the ongoing digital transformation.

The increasing adoption of 5G networks, the rise of cloud computing, and the growth of data centers are key factors propelling the demand for both Silicone Elastomers s.

Silicone Elastomers are integral to the functioning of the digital economy, enabling seamless communication, connectivity, and data sharing across industries, homes, and businesses.

0 notes

Text

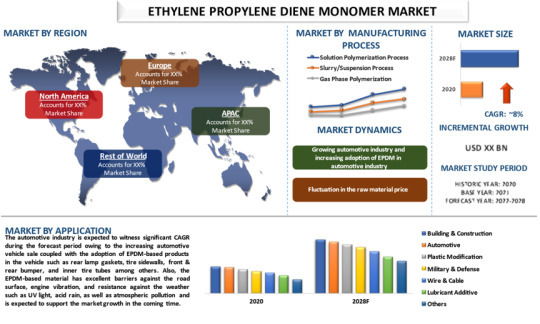

Ethylene Propylene Diene Monomer (EPDM) Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Ethylene Propylene Diene Monomer (EPDM) Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Manufacturing Process (Solution Polymerization Process, Slurry/Suspension Process, and Gas Phase Polymerization); Application (Building & Construction, Automotive, Plastic Modification, Military & Defense, Wire & Cable, Lubricant Additive, and Others); Region/Country.

The Ethylene Propylene Diene Monomer (EPDM) market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Ethylene Propylene Diene Monomer (EPDM) market. The Ethylene Propylene Diene Monomer (EPDM) market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Ethylene Propylene Diene Monomer (EPDM) market at the global and regional levels.

Market Overview

Ethylene Propylene Diene Monomer (EPDM) is a synthetic material obtained from natural gas and thermal cracking petroleum products such as naphtha. EPDM is widely used in low-slope buildings, automotive applications, and construction applications due to their longer durability and superior resistance to environmental factors such as UV, ozone, and other weather condition. In recent times, the EPDM witnessed significant demand due to its increasing demand from the automotive industry, manufacturing & construction industry attributed to its lower cost, higher moldability, and longer durability. Also, the EPDM could be used as an alternative to silicon rubber and could also be incorporated in the hose, O-ring, accumulator bladder, diaphragms, and connectors for wire & cables among many other applications on the account of their higher resistance towards tearing, abrasive, solvent, and temperature.

Factors such as technological advancement coupled with the growing number of industries and manufacturing units along with the new product launches in the market are some of the prominent factors that are positively influencing the market growth globally.

Some of the major players operating in the market include DowDuPont Inc., Exxon Mobil Corporation, Lion Elastomers, Johns Manville, SK Global Chemical Co. Ltd, Lanxess AG, Mitsui Chemical Inc., PetroChina Company Limited, Kumho Polychem, and Versalis S.p.A.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the manufacturing industry along with supply chain disruption, regulatory and policy changes, labor reliance, working capital management, and liquidity & solvency management. The Ethylene Propylene Diene Monomer (EPDM) market has been significantly affected during these times owing to the gap between supply and demand.

The global Ethylene Propylene Diene Monomer (EPDM) market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on application, the market is segmented into building & construction, automotive, plastic modification, military & defense, wire & cable, lubricant additive, and others. The automotive industry is expected to witness significant CAGR during the forecast period owing to the increasing automotive vehicle sale coupled with the adoption of EPDM-based products in the vehicle such as rear lamp gaskets, tire sidewalls, front & rear bumper, and inner tire tubes among others. Also, the EPDM-based material has excellent barriers against the road surface, engine vibration, and resistance against the weather such as UV light, acid rain, as well as atmospheric pollution and is expected to support the market growth in the coming time.

Based on the manufacturing process, the market is segmented into solution polymerization process, slurry/suspension process, and gas phase polymerization. The solution polymerization segment is expected to witness significant growth during the forecast period due to the higher concentration and lower required amount for the optimized performance. Additionally, solution polymerization is used to manufacture both crystalline and amorphous polymer grades and is expected to support market growth.

Ethylene Propylene Diene Monomer (EPDM) Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the rapid industrialization and growing automotive industries along with the electronic & electrical industry, consumer goods industry, and medical sector in the region. Also, the ongoing infrastructural projects and increasing disposable income of the individual are expected to support market growth in the coming time. Furthermore, EPDM has also been used as a substitute for thermoplastic olefins and thermoplastic vulcanizate in the manufacturing industry. Also, the lower cost of the raw material coupled with the lower cost of production associated with the lower labor cost propels the market for the EPDM. Moreover, the growing research & development activities, increasing investment, and technological investment are expected to derive the market in the coming time. For instance, in March 2022, Arlanxeo a Netherland-based firm announced to increase in its production capacity by 15% for its EPDM plant based in Changzhou, China.

The major players targeting the market include:

DowDuPont Inc.

Exxon Mobil Corporation

Lion Elastomers

Johns Manville

SK Global Chemical Co. Ltd

Lanxess AG

Mitsui Chemical Inc.

PetroChina Company Limited

Kumho Polychem

Versalis S.p.A.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Ethylene Propylene Diene Monomer (EPDM) market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are influencing the Ethylene Propylene Diene Monomer (EPDM) market over the forecast period?

• What are the global challenges, threats, and risks in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are propelling and restraining the Ethylene Propylene Diene Monomer (EPDM) market?

• What are the demanding global regions of the Ethylene Propylene Diene Monomer (EPDM) market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Titanium Dioxide Market - SWOT Analysis [2023-2028]

Recycled Carbon Fiber Market - SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Rubber Export from India: What You Need to Know

India is one of the largest producers of natural rubber in the world, and rubber export from India plays a significant role in the country's economy. India's rubber industry is well-established, with a long history of cultivation and processing. This article will explore the dynamics of rubber export from India, looking at the data, key products, challenges, and opportunities, all in a question-and-answer format.

What is the Importance of Rubber Export from India?

Rubber export from India is crucial for several reasons. First, it contributes significantly to the country's GDP and provides employment to millions of people, from farmers to factory workers. The export of rubber products from India also helps earn foreign exchange, which is vital for the country's economic stability. Additionally, India's rubber industry supports various sectors, including automotive, healthcare, and manufacturing, both domestically and internationally.

How Has the Rubber Export Data Evolved?

Examining rubber export data from India reveals a pattern of steady growth over the years. According to the Rubber Board of India, the country exported around 60,000 metric tons of natural rubber in the 2022-2023 fiscal year, an increase of about 15% compared to the previous year. This growth is driven by the rising demand for natural rubber in global markets, where it is used in everything from tires to medical supplies. The overall value of rubber exports from India is estimated to exceed USD 3 billion annually, highlighting its economic significance.

What Types of Rubber Products are Exported from India?

The export of rubber products from India is diverse and includes several key categories:

Natural Rubber: India is known for producing high-quality natural rubber, which is used extensively in the automotive and manufacturing sectors.

Rubber Sheets: These are used in various industrial applications, including flooring, gaskets, and seals.

Rubber Tubes and Hoses: Widely used in automotive, agricultural, and industrial machinery.

Rubber Gloves: A significant product for the healthcare industry, especially in recent years due to increased demand for personal protective equipment (PPE).

Rubber Belts: Used in machinery for manufacturing, mining, and agricultural purposes.

What are the Key Markets for Rubber Export from India?

India exports rubber and rubber products to a wide array of countries. Some of the primary markets include:

United States: One of the largest consumers of Indian rubber, particularly for automotive and industrial uses.

China: A major importer of natural rubber and related products for its vast manufacturing sector.

Germany and Other European Countries: Known for high demand in automotive and engineering industries.

Japan: A key player in the automotive industry, importing significant quantities of natural rubber from India.

Also Read: Unlocking Global Markets: How to Find International Buyers for Export

Why is Natural Rubber Export from India Significant?

Natural rubber export from India is significant because it meets the growing global demand for sustainable and environmentally friendly materials. Unlike synthetic rubber, natural rubber is biodegradable and has a lower carbon footprint, making it an attractive choice for companies looking to improve their sustainability credentials. Furthermore, natural rubber is prized for its superior elasticity, resilience, and durability, essential qualities for various industrial applications.

How Does India Ensure the Quality of Its Rubber Exports?

India maintains strict quality control measures to ensure that its rubber exports meet international standards. The Rubber Board of India plays a pivotal role in overseeing the quality and standards of natural rubber production. This includes testing for purity, strength, and elasticity, as well as ensuring that the rubber is free from contaminants. Indian exporters also adhere to international certifications, such as ISO and ASTM, to assure global buyers of the quality and reliability of Indian rubber products.

What are the Challenges Facing Rubber Export from India?

While the rubber export industry in India is thriving, it faces several challenges:

Price Volatility: Global rubber prices are subject to fluctuations due to factors like changes in supply and demand, geopolitical tensions, and economic downturns.

Competition: India faces stiff competition from other major rubber-producing countries, such as Thailand, Indonesia, and Malaysia.

Quality Consistency: Maintaining consistent quality across large volumes of rubber can be challenging, especially given the variations in production conditions across different regions.

Environmental Concerns: The industry must balance production needs with environmental sustainability, addressing issues such as deforestation and biodiversity loss.

How is the Indian Government Supporting the Rubber Export Industry?

The Indian government has implemented several measures to support the rubber export industry:

Incentives and Subsidies: Providing financial assistance and subsidies to rubber farmers and exporters to enhance productivity and competitiveness.

Infrastructure Development: Investing in infrastructure to improve logistics and reduce transportation costs, making Indian rubber products more competitive globally.

Research and Development: Funding R&D initiatives to improve rubber cultivation techniques, enhance quality, and develop new rubber products.

Trade Agreements: Negotiating trade agreements with major importing countries to facilitate easier market access and reduce tariffs.

What are the Opportunities for Growth in the Rubber Export Market?

Despite the challenges, there are significant opportunities for growth in the rubber export market:

Increasing Demand for Eco-Friendly Products: As global consumers and industries become more environmentally conscious, the demand for natural rubber, an eco-friendly alternative to synthetic rubber, is likely to rise.

Technological Advancements: Innovations in rubber processing and product development can open new markets and applications for Indian rubber.

Expansion into Emerging Markets: Exploring new markets in Africa and South America, where industrialization is increasing, could offer new opportunities for Indian rubber exporters.

How Does Rubber Export from India Impact Local Economies?

Rubber export from India has a profound impact on local economies, particularly in states like Kerala, Tamil Nadu, and Karnataka, where rubber plantations are concentrated. The industry provides employment to millions of people, from plantation workers to those involved in processing and logistics. Additionally, rubber cultivation supports rural development by enhancing infrastructure, healthcare, and education facilities in plantation areas.

What is the Future Outlook for Rubber Export from India?

The future outlook for rubber export from India is optimistic. The global demand for rubber is expected to grow, driven by increased industrialization, urbanization, and technological advancements. India's strategic initiatives to improve quality, enhance productivity, and expand market reach will likely strengthen its position as a leading rubber exporter. Moreover, the focus on sustainable practices will ensure long-term growth and competitiveness in the global market.

Conclusion: Why is Rubber Export from India a Key Economic Driver?

Rubber export from India is a key economic driver due to its contribution to the country's GDP, employment generation, and foreign exchange earnings. As the global market for rubber continues to expand, India is well-positioned to capitalize on this growth. By maintaining high quality standards, embracing sustainable practices, and exploring new markets, India can continue to be a major player in the international rubber trade.

Recent Blogs: The Rising Phenomenon of Cow Dung Export from India Understanding the Dynamics of Vegetable Export from India Cotton Export from India: A Detailed Guide

#rubber export from india#rubber export data#export of rubber products from India#natural rubber export from india#rubber export

0 notes

Text

Rubber Export from India: An All-Inclusive Guide

India, a land of diverse agricultural and industrial activities, has emerged as a significant player in the global rubber market. The country's rubber export sector has seen substantial growth over the years, driven by its rich natural resources and a well-established industrial base. In this article, we will explore the nuances of rubber export from India, delving into the statistics, major products, and key markets, while highlighting the pivotal role of natural rubber in this sector.

Introduction to Rubber Export from India

India's rubber industry is a vital component of its economy, contributing significantly to both employment and foreign exchange earnings. The tropical climate of the country, particularly in states like Kerala, Tamil Nadu, and Karnataka, provides an ideal environment for rubber cultivation, making India one of the leading producers and exporters of rubber in the world.

Overview of Rubber Export Data

The export data for rubber products from India showcases a promising trend. According to the Rubber Board of India, the country exported over 1.2 million tonnes of rubber and rubber products in the fiscal year 2022-2023. This included both natural rubber and various value-added products. The export of rubber products from India is not limited to raw rubber; it encompasses a wide range of goods, including tyres, tubes, footwear, industrial rubber goods, and latex products.

Major Rubber Products Exported from India

India's rubber export portfolio is diverse, reflecting the country's capacity to produce a wide array of rubber-based products. Some of the major products include:

Natural Rubber: India exports significant quantities of natural rubber, primarily in the form of RSS (Ribbed Smoked Sheets) and TSR (Technically Specified Rubber).

Tyres and Tubes: Indian tyre manufacturers are globally recognized, and tyres are one of the largest segments in the rubber export market.

Footwear: Rubber-based footwear, including sandals, shoes, and boots, is another major export item.

Industrial Rubber Goods: These include conveyor belts, hoses, and rubber sheets used in various industrial applications.

Latex Products: Gloves, balloons, and medical products made from latex also contribute to the export figures.

Key Markets for Indian Rubber Exports

India's rubber export data market is geographically diverse, with key destinations spread across various continents. The major markets include:

United States: The US is one of the largest importers of Indian rubber products, particularly tyres and industrial goods.

European Union: Countries like Germany, France, and Italy are significant importers of Indian rubber, especially footwear and latex products.

Asia-Pacific: China, Japan, and South Korea are prominent buyers of Indian natural rubber and rubber products.

Middle East and Africa: These regions also represent growing markets for Indian rubber exports.

Natural Rubber Export from India

Natural rubber plays a crucial role in India's rubber export scenario. The country produces high-quality natural rubber, which is in demand globally. The natural rubber export from India primarily includes RSS and TSR, which are used extensively in the automotive and industrial sectors. India’s ability to produce and export natural rubber of consistent quality has made it a preferred supplier for many countries.

Government Initiatives and Support

The Indian government, through the Rubber Board and other agencies, has implemented several initiatives to boost rubber export. These include:

Incentives and Subsidies: Financial incentives and subsidies are provided to rubber farmers and exporters to enhance production and export capabilities.

Research and Development: Investment in R&D to improve the quality of rubber and develop new rubber products.

Infrastructure Development: Enhancing infrastructure for storage, transportation, and processing of rubber to meet international standards.

Challenges Facing the Rubber Export Sector

Despite the positive trends, the rubber export sector in India faces several challenges:

Fluctuating Prices: Global rubber prices are volatile, affecting the profitability of exports.

Quality Standards: Meeting stringent international quality standards can be challenging for some exporters.

Environmental Concerns: Sustainable cultivation and processing practices need to be adopted to address environmental issues.

Future Prospects of Rubber Export from India

The future of rubber export from India looks promising, with increasing demand for rubber products globally. The country’s focus on improving quality, diversifying product ranges, and exploring new markets is likely to yield positive results. Additionally, advancements in technology and sustainable practices will play a crucial role in enhancing India's competitiveness in the global rubber market.

Conclusion

The rubber export sector in India is a vital part of the country's economy, providing significant employment opportunities and contributing to foreign exchange earnings. With its diverse product range and expansive global market reach, India is poised to strengthen its position as a leading exporter of rubber and rubber products. The concerted efforts of the government, coupled with the industry's commitment to quality and innovation, will ensure that India continues to play a crucial role in the global rubber industry.

#rubber export from India#rubber export data#export of rubber products from India#natural rubber export from India#rubber export

0 notes

Text

Isoprene Rubber Prices Trend | Pricing | Database | Index | News| Chart

Isoprene Rubber Prices a synthetic rubber known for its similar properties to natural rubber, has seen fluctuating prices influenced by various market dynamics. The pricing trends of isoprene rubber are closely linked to factors such as raw material costs, supply chain disruptions, demand fluctuations, and broader economic conditions. The production of isoprene rubber involves the polymerization of isoprene, a hydrocarbon derived from petroleum, making its price sensitive to changes in crude oil prices. When oil prices rise, the cost of producing isoprene rubber tends to increase, leading to higher prices for the end product. Conversely, a drop in oil prices can reduce production costs and consequently lower isoprene rubber prices.

Demand for isoprene rubber is another critical factor affecting its price. It is widely used in various industries, including automotive, manufacturing, medical devices, and consumer goods. The automotive industry, in particular, is a significant consumer of isoprene rubber, using it for tires, belts, hoses, and other components. An increase in automobile production or a surge in the replacement tire market can drive up demand, putting upward pressure on prices. Similarly, any slowdown in the automotive sector can lead to reduced demand and lower prices. The medical industry also relies on isoprene rubber for products like gloves and medical tubing, so shifts in healthcare demands can impact prices as well.

Get Real Time Prices of Isoprene Rubber: https://www.chemanalyst.com/Pricing-data/isoprene-rubber-1501

Supply chain stability plays a crucial role in the pricing of isoprene rubber. Disruptions caused by geopolitical tensions, natural disasters, or logistical challenges can restrict the supply of raw materials or finished products, leading to price volatility. For instance, if a major isoprene rubber manufacturing facility experiences a shutdown due to technical issues or natural calamities, the supply can be significantly affected, resulting in price spikes. Additionally, the global nature of the supply chain means that international trade policies and tariffs can influence prices. Trade restrictions or tariffs on raw materials like crude oil or isoprene monomer can increase production costs, thereby raising the price of isoprene rubber.

Technological advancements and innovation in production processes can also impact isoprene rubber prices. Improvements in manufacturing efficiency, alternative sourcing of raw materials, and advancements in synthetic rubber technology can lead to cost reductions, which may be passed on to consumers through lower prices. Conversely, investment in new technologies or compliance with stringent environmental regulations can increase production costs, leading to higher prices. The balance between technological progress and regulatory compliance is therefore a key factor in determining isoprene rubber pricing trends.

Global economic conditions significantly influence the pricing of isoprene rubber. During periods of economic growth, increased industrial activity and consumer spending typically boost demand for products that use isoprene rubber, leading to higher prices. In contrast, economic downturns can result in reduced industrial output and consumer spending, lowering demand and prices. Inflationary pressures, currency fluctuations, and changes in interest rates can also impact the cost structure of isoprene rubber production and pricing. For example, a weaker currency can make imports of raw materials more expensive, thereby increasing production costs and prices.

Environmental and sustainability considerations are becoming increasingly important in the rubber industry, including the production of isoprene rubber. There is growing pressure on manufacturers to adopt sustainable practices and reduce the environmental impact of their operations. This can include investing in renewable energy sources, improving waste management practices, and developing more environmentally friendly production processes. While these initiatives are crucial for long-term sustainability, they can also lead to higher production costs in the short term, potentially increasing the price of isoprene rubber.

Market competition also plays a significant role in determining isoprene rubber prices. The presence of multiple suppliers in the market can lead to competitive pricing strategies, benefiting consumers with lower prices. However, if the market is dominated by a few large players, they may have greater pricing power and can influence market prices to their advantage. Mergers and acquisitions in the industry can also impact competition and pricing dynamics. Increased consolidation can reduce competition and lead to higher prices, while the entry of new players can enhance competition and drive prices down.

In summary, isoprene rubber prices are influenced by a complex interplay of factors including raw material costs, demand from various industries, supply chain stability, technological advancements, global economic conditions, environmental considerations, and market competition. Understanding these factors is essential for stakeholders in the isoprene rubber market to navigate price fluctuations and make informed decisions. The future pricing trends of isoprene rubber will continue to be shaped by these multifaceted influences, making it a dynamic and challenging market to predict.

Get Real Time Prices of Isoprene Rubber: https://www.chemanalyst.com/Pricing-data/isoprene-rubber-1501

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Isoprene Rubber#Isoprene Rubber Price#Isoprene Rubber Prices#Isoprene Rubber Pricing#Isoprene Rubber News

0 notes

Text

Nitrile Butadiene Rubber Market Report: Trends, Analysis, and Projections

Nitrile Butadiene Rubber (NBR) is a synthetic rubber with excellent oil and chemical resistance, making it indispensable across various industries. This blog explores the dynamics of the global NBR market, analyzing key drivers, applications, emerging trends, and future growth prospects.

Understanding the NBR Market:

Nitrile Butadiene Rubber (NBR) Also known as Buna-N or Nitrile Rubber, is a versatile elastomer synthesized from butadiene and acrylonitrile monomers. Its unique properties such as oil resistance, heat resistance, and durability make it a preferred material in automotive, oil and gas, aerospace, healthcare, and industrial applications.

Market Dynamics:

Automotive Sector: NBR is extensively used in automotive applications such as seals, gaskets, hoses, O-rings, and fuel system components due to its resilience to oils, fuels, and harsh environments, contributing to vehicle performance and reliability.

Oil and Gas Industry: NBR seals, gaskets, and O-rings are vital in oil and gas equipment, pipelines, and offshore installations, providing sealing solutions that withstand hydrocarbons, chemicals, and extreme temperatures.

Medical and Healthcare: NBR's compatibility with a wide range of fluids and sterilization methods makes it ideal for medical gloves, seals in medical devices, tubing, and pharmaceutical packaging, ensuring safety, hygiene, and product integrity.

Industrial Applications: NBR finds applications in industrial machinery, pumps, hydraulic systems, conveyor belts, seals for industrial equipment, and vibration isolation mounts due to its resilience and mechanical properties.

Applications Across Industries:

Automotive: Seals, gaskets, hoses, O-rings.

Oil and Gas: Seals, gaskets, O-rings, hoses.

Medical: Gloves, seals, tubing, pharmaceutical packaging.

Industrial: Seals, conveyor belts, vibration mounts.

Market Trends:

High-Performance Grades: Increasing demand for high-performance NBR grades with enhanced oil resistance, heat resistance, low-temperature flexibility, and compatibility with various fluids, meeting stringent industry standards and performance requirements.

Bio-Based NBR: Growing interest in bio-based and sustainable rubber materials drives research and development efforts towards bio-based NBR formulations, aligning with environmental sustainability goals and reducing dependency on fossil fuels.

Advanced Manufacturing Processes: Innovations in NBR production processes, compounding techniques, and polymer additives improve material properties, processing efficiency, and cost-effectiveness, driving market competitiveness.

Future Prospects:

The global NBR market is poised for steady growth, driven by the expanding demand from key industries, technological advancements, and sustainability initiatives. Investments in research, product development, and market expansion strategies will shape the market's trajectory and unlock new opportunities for stakeholders.

Conclusion:

Nitrile Butadiene Rubber (NBR) continues to be a critical material in various industries due to its unique properties and versatile applications. Understanding market trends, technological innovations, and sustainability imperatives is essential for stakeholders in the NBR market to capitalize on growth opportunities and address evolving industry needs effectively. With a focus on performance, sustainability, and application diversification, the NBR market presents promising prospects for continued growth and innovation in the global rubber and elastomer industry landscape.

0 notes

Text

Isoprene Market by End-User | Recent Developments

The European Automobile Manufacturers’ Association noted that approximately 85.4 million motor vehicles were manufactured in 2022 globally. The growth in vehicle production has led to a surge in the adoption of isoprene in tire production. The International Rubber Group reported that global tire production reached around 16.87 million tons in 2021, a 9% increase from 2020. Additionally, isoprene’s resilience, tensile strength, and abrasion resistance have increased its adoption in the rubber and medical industry. As noted by Triton’s report, the global isoprene market will likely register revenue growth at a CAGR of 7.65% over the forecast years 2023-2030.

The demand for eco-friendly tires, synthetic rubber, and footwear has further elevated the deployment of polyisoprene, styrene-isoprene styrene, etc. These factors have also influenced several R&D for effective isoprene applications. For instance, in 2022, researchers at the Leibniz Institute of Plant Biochemistry and Martin Luther University Halle-Wittenberg developed the precise conditions for the enzymatic breakdown of synthetic polyisoprene rubber.

Tire, Adhesive, & Rubber: Expanding Scope of Isoprene Market

Fastest End-user: Tires expected to advance with 7.91% of CAGR during 2023-2030

Tires are essential for vehicles like trucks, tractors, buses, aircraft landing gear, forklifts, etc., as they offer traction and cushioning for wheels. In this regard, polyisoprene tires possess strength, wear resistance, and resilience. Estimates indicate polyisoprene to witness the fastest growth in terms of usability at a CAGR of 8.07% during 2023-2030. While polyisoprene is widely preferred, isobutylene-isoprene’s elastomeric properties are ideal for tire inner and high-pressure tubes. This has prompted various strategic initiatives, including halo butyl rubber manufacturing facilities by Sibur in India, with an annual production target of 60,000 metric tons.

Increased vehicle demand and auto sales benefits have soared the demand for isoprene for tire production globally, especially in the Asia-Pacific. As per estimates, China and Japan contribute around 70% of global tire manufacturing. Therefore, expanding automotive sector creates opportunities for the Asia-Pacific isoprene market.

Revenue Growth: Adhesives expected to register a CAGR of 7.30%

Isoprene adhesives, known for their flexibility, bridge gaps on surfaces in various industries, including aerospace, medical, and electrical. In the medical industry, adhesives find applications in catheters, tapes, etc. In this regard, polyisoprene finds application as a substitute for natural rubber. Isoprene demand in this sector is because it reduces Type I allergies while mitigating nitrosamine synthesis.

As a result, several players have made significant adhesive advancements, significantly boosting the studied market’s growth. For example, in 2020, Henkel inaugurated its largest adhesive production facility in India, supporting nearby regions like the Middle East. Similarly, Arkema established a sizable adhesive factory in Japan, catering to sectors such as hygiene, packaging, labeling, etc.

Due to its outstanding tack and high flexibility, styrene-isoprene styrene (SIS) is also employed to develop adhesives. Estimates suggest SIS is set to expand in volume as it is largely used as a hygiene adhesive in personal care items such as baby diapers, feminine hygiene products, etc. Due to the availability of thermoplastic elastomers in producing these products, the demand for styrene-isoprene styrene is anticipated to increase over the forecast years.

2023-2030: Industrial Rubber Witness Volume Growth at 4.62%

Industrial rubber finds application across diverse sectors such as construction, automotive, and manufacturing. Isoprene in industrial rubber has increased, particularly in construction. It is commonly employed in wall and floor coverings, mechanical rubber goods, geo-membranes, elevators, wiper blades, rubber hoses, etc. Isoprene rubber is well-suited for industrial purposes due to its suspension capacity, rubber reusability, and versatility. The category is projected to expand rapidly due to urbanization, increased disposable income, and population growth.

In addition to the volatile cost of natural rubber, technological advancements in isoprene rubber, including styrene isoprene styrene, polyisoprene, and butyl rubber, fuel the expansion of the isoprene market. For instance, Zeon Corp and Yokohama Rubber Co Ltd co-developed a new technology to produce isoprene from biomass for synthetic rubber production.

Bio-Based Isoprene: A Sustainable Opportunity

The surge in natural gas supply over recent years has shifted ethylene production away from naphtha to ethane cracking. This transition has significantly reduced isoprene production, leading to volatile polyisoprene market prices. Consequently, more sustainable routes for isoprene production involving bio-based products are being explored.

Biomass shows promise as a renewable feedstock for polyisoprene used in the rubber industry. Bio-based isoprene holds potential in various applications, including medical appliances, footwear, rubber tires, fragrances, and polymeric materials. For instance, in 2023, Ginkgo Bioworks collaborated with Visolis to decarbonize tire manufacturing while promoting bio-based isoprene use. Hence, the growing focus on eco-friendly approaches is expected to create affluent opportunities for the isoprene market.

FAQs:

Q1) What is the volume growth of the global isoprene market?

The global isoprene market is expected to witness volume growth at a CAGR of 5.15% during the forecast period 2023-2030.

Q2) Which grades of isoprene are employed across end-user industries?

Polymer and chemical are widely employed grades across end-user industries.

0 notes

Text

Fueling Industry: Insights into the Isobutene Market

Isobutene, also known as isobutylene, is a crucial building block in the petrochemical industry, with applications spanning from fuel additives and polymers to rubber and pharmaceuticals. As a key intermediate in the production of various chemicals and materials, the isobutene market plays a vital role in fueling industrial processes and driving innovation across multiple sectors. Understanding the dynamics, trends, and applications of isobutene provides valuable insights into the broader landscape of the petrochemical industry and its downstream markets.

At the heart of the isobutene market lies the versatility and importance of this hydrocarbon molecule as a feedstock for a wide range of chemical processes. Isobutene is primarily derived from petroleum refining and petrochemical production processes such as steam cracking and catalytic cracking. It serves as a precursor for the production of important chemicals such as methyl tert-butyl ether (MTBE), isooctane, butyl rubber, polyisobutene, and various alkylates. Additionally, isobutene is used in the production of antioxidants, lubricants, and pharmaceuticals, demonstrating its diverse range of applications across industries.

Moreover, the isobutene market is driven by growing demand from end-use industries such as automotive, construction, packaging, and healthcare. In the automotive sector, isobutene derivatives such as MTBE and isooctane are used as fuel additives to improve octane ratings, enhance combustion efficiency, and reduce emissions in gasoline blends. Additionally, isobutene-based elastomers such as butyl rubber are prized for their high resilience, impermeability, and resistance to heat, ozone, and chemicals, making them ideal for applications such as tire inner tubes, seals, and gaskets.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS10055

Furthermore, the isobutene market is influenced by technological advancements, regulatory policies, and market dynamics that shape supply and demand dynamics. Technological innovations in refining and petrochemical processes have led to improvements in isobutene production efficiency, yield, and purity, driving down production costs and expanding market opportunities. Additionally, regulatory policies aimed at reducing emissions, promoting energy efficiency, and transitioning to cleaner fuels are driving the adoption of isobutene-based additives and alternatives in gasoline and other fuels. Furthermore, market dynamics such as supply chain disruptions, geopolitical tensions, and shifting consumer preferences can impact isobutene prices, availability, and market dynamics.

Additionally, the isobutene market is characterized by a competitive landscape with multiple players operating across the value chain, from upstream production to downstream processing and distribution. Major petrochemical companies, refineries, and chemical manufacturers are key players in the isobutene market, leveraging their technological expertise, economies of scale, and global reach to capitalize on market opportunities. Additionally, smaller players such as specialty chemical companies and independent refiners play niche roles in the isobutene market, focusing on specific applications, derivatives, or regional markets.

Despite the opportunities for growth, the isobutene market also faces challenges, including price volatility, environmental concerns, and regulatory compliance. Fluctuations in crude oil prices, supply-demand imbalances, and market speculation can lead to volatility in isobutene prices, impacting profitability and investment decisions for industry stakeholders. Additionally, environmental concerns such as air pollution, greenhouse gas emissions, and water contamination associated with isobutene production and use pose challenges for regulatory compliance and public acceptance. Furthermore, regulatory frameworks governing the production, handling, and transportation of isobutene and its derivatives vary across regions, requiring industry players to navigate complex compliance requirements and risk management strategies.

In conclusion, the isobutene market is a critical component of the petrochemical industry, serving as a key building block for the production of various chemicals, materials, and fuels. With its diverse range of applications, technological advancements, and market dynamics, the isobutene market plays a pivotal role in fueling industrial processes and driving innovation across multiple sectors. By understanding the trends, drivers, and challenges of the isobutene market, industry stakeholders can identify opportunities for growth, differentiation, and sustainability in this dynamic and evolving sector.

0 notes

Text

Versatile Solutions: Saudi Arabia's Progression in Elastomer Market for 2023 and Beyond

Saudi Arabia's industrial landscape is witnessing dynamic transformations, with elastomers emerging as essential materials driving innovation and progress across various sectors. In 2023, the Elastomer market in Saudi Arabia stands as a fundamental component in the Kingdom's manufacturing and industrial development. This article aims to delve into the significance, potential trends, and implications of elastomers in Saudi Arabia's industrial ecosystem.

The Role of Elastomers in Industry: Elastomers, a class of polymers exhibiting rubber-like elasticity, resilience, and flexibility, serve as versatile materials used in a myriad of industrial applications. These materials offer unique properties, including durability, chemical resistance, and thermal stability, making them indispensable in sectors such as automotive, construction, healthcare, and more.

Key Factors Driving Saudi Arabia's Elastomer Market:

Automotive Industry Growth: The expansion of the automotive sector in Saudi Arabia drives the demand for elastomers in manufacturing various components, including tires, hoses, gaskets, seals, and automotive interiors, enhancing vehicle performance and safety.

Construction and Infrastructure Development: Elastomers play a crucial role in the construction industry, used in sealants, adhesives, roofing materials, and insulation, contributing to improved building durability, energy efficiency, and safety.

Healthcare and Medical Devices: The demand for elastomers in healthcare applications, including medical tubing, gloves, implants, and pharmaceutical packaging, continues to grow, driven by stringent quality and safety requirements.

Oil and Gas Sector: Elastomers find extensive use in the oil and gas industry for seals, gaskets, and O-rings, providing resistance to harsh environmental conditions and ensuring efficient operations in exploration and production.

Challenges and Opportunities: While the demand for elastomers remains robust, challenges such as price volatility of raw materials, fluctuating market dynamics, and technological advancements in alternative materials exist. However, these challenges also present opportunities for innovation, research in sustainable elastomers, and strategic collaborations across industries.

For More Info@ https://www.gmiresearch.com/report/saudi-arabia-elastomer-market-2019-2026/

Future Outlook and Conclusion: As Saudi Arabia progresses into 2023, the Elastomer market holds promise for growth and diversification. Collaborations between manufacturers, technological advancements in material sciences, and a focus on sustainable elastomers will drive market expansion. The Kingdom's commitment to industrial development and investments in various sectors bode well for the future of elastomers in Saudi Arabia.

In conclusion, while specific market projections for the Saudi Arabia Elastomer market in 2023 might not be readily available, the significance of these materials in enhancing industrial processes cannot be overlooked. With ongoing technological advancements and strategic initiatives, elastomers are poised to continue playing a pivotal role in supporting Saudi Arabia's industrial growth and innovation across diverse sectors.

0 notes

Text

Styrene Butadiene Styrene Rubber Market Size, Scope, Growth Opportunities, Trends by Manufacturers And Forecast to 2030

The global styrene butadiene styrene rubber market is valued at US$ 5.5 Million in 2023 and is projected to reach US$ 6.3 Million by 2030, growing at a CAGR of 4.90% from 2023 to 2030. SBS rubber is a synthetic rubber that is produced by the copolymerization of styrene and butadiene. It is a versatile material with a wide range of properties, including good abrasion resistance, low heat resistance, and good elasticity. SBS rubber is used in a variety of applications, including tires, footwear, adhesives, and sealants.

Styrene-butadiene-styrene is the name of a thermoplastic elastomer composed of butadiene and styrene. A different kind of block copolymer comprises a long chain of polystyrene and a middle chain of polybutadiene. Because styrene-butadiene-styrene possesses qualities of both rubber and polymers, its market demand is rising. Although polybutadiene offers flexibility, styrene-butadiene-styrene polystyrene offers excellent strength and durability. The diverse applications of styrene-butadiene-styrene in a range of industries, including electrical and electronic equipment, shoe soles, and many more, contribute to the rise in demand for this material on the global market.

Get your Sample Report with Latest Market Information! https://absolutemarketresearch.com/Global-Styrene-Butadiene-Styrene-Rubber-Market/1792/request-sample

Styrene butadiene styrene rubber (SBS) is a type of thermoplastic elastomer (TPE) that is made from the copolymerization of styrene and butadiene. The styrene units in SBS provide the material with its hardness and stiffness, while the butadiene units give it its elasticity and resilience. The ratio of styrene to butadiene in the polymer can be varied to control the properties of the material. For example, a higher styrene content will produce a harder, more rigid material, while a higher butadiene content will produce a softer, more elastic material.

SBS is typically synthesized by a free radical polymerization process in which styrene and butadiene monomers are heated in the presence of a free radical initiator. The initiator breaks down into free radicals, which then attack the monomers and initiate the polymerization reaction. The polymer chains grow by adding monomers to the ends of the chains. The ratio of styrene to butadiene in the polymer depends on the relative amounts of the monomers and the reaction conditions.

SBS is a block copolymer, which means that it is made up of alternating blocks of styrene and butadiene units. The styrene blocks are more rigid and glassy, while the butadiene blocks are more flexible and rubberier. The alternating arrangement of the blocks gives SBS its unique properties.

The growth of the market is driven by several factors, including:

Increased demand from the automotive industry: SBS rubber is used in a variety of automotive components, such as tires, seals, and hoses. As the automotive industry continues to grow, the demand for SBS rubber is expected to increase.

Growing demand from the adhesives and sealants industry: SBS rubber is used in a wide variety of adhesives and sealants, due to its good adhesion and elasticity. As the construction and packaging industries continue to grow, the demand for SBS rubber is expected to increase.

Rising demand from the medical device industry: SBS rubber is used in a variety of medical devices, such as catheters, tubing, and implants. As the medical device industry continues to grow, the demand for SBS rubber is expected to increase.

Key Takeaways:

The global styrene butadiene styrene rubber market is valued at US$ 5.5 Million in 2023 and is projected to reach US$ 6.3 Million by 2030, growing at a CAGR of 4.90% from 2023 to 2030.

The growth of the SBS rubber market is being driven by the increasing demand for thermoplastic elastomers (TPEs) in various industries, including automotive, construction, and consumer goods.

The automotive industry is the largest end-use sector for SBS rubber, accounting for over 40% of the global market in 2023.

The Asia Pacific region is the largest market for SBS rubber, accounting for over 50% of the global market in 2023.

Regional Outlook:

Asia Pacific is the largest market for SBS rubber, accounting for over 50% of the global market in 2023. The growth of the SBS rubber market in Asia Pacific is being driven by the rapid growth of the automotive and construction industries in the region.

Europe is the second largest market for SBS rubber, accounting for over 30% of the global market in 2023. The growth of the SBS rubber market in Europe is being driven by the increasing demand for TPEs in the automotive and construction industries.

North America is the third largest market for SBS rubber, accounting for over 15% of the global market in 2023. The growth of the SBS rubber market in North America is being driven by the increasing demand for TPEs in the automotive and construction industries.

Key Players:

Dow Chemical Company

Asahi Kasei Corporation

Kumho Petrochemical Co., Ltd.

LG Chem

Sinopec Styrene Butadiene Rubber Co., Ltd.

Segmentation:

By type, the market is segmented into:

Block styrene-butadiene-styrene (SBS)

Random styrene-butadiene-styrene (SBS)

Hydrogenated styrene-butadiene-styrene (HSBS)

By application, the market is segmented into:

Automotive

Construction

Consumer goods

Industrial goods

By region, the market is segmented into:

Asia Pacific

Europe

North America

South America

Middle East and Africa

0 notes

Text

Most Expensive Shares in India 2024: Insights

Investing in high-value shares can be a profitable but often daunting venture, especially in a market like India, where stock prices can soar to unimaginable levels. If you’re curious about the most expensive shares in India for 2024, you’re in the right place! Let’s explore some of the priciest shares in India and understand what makes them so valuable.

When we talk about high-priced stocks, it’s not just about the number of shares you hold, but the quality and profitability of each one. Shares with high prices often reflect a company’s solid market position, strong brand reputation, and consistent performance. Although these shares can’t usually be purchased in bulk, their potential for profit often outweighs their hefty price tags.

For those looking to diversify their portfolio with quality over quantity, these expensive shares are worth a closer look. Let’s dive into the top high-value shares in India and what makes them stand out.

Top High-Value Shares in India for 2024

MRF Ltd (Madras Rubber Factory)