#Asphalt Plant Functions

Explore tagged Tumblr posts

Text

Way an Asphalt Batch Plant Functions - Atlas Technologies

With the batch mix plants, the process of mixing begins when the aggregates are unloaded in the specific bins of its feeders. A conveyor moves the aggregates from the bins to a drying drum which is fitted with a set of internal flights designed to dry the contents efficiently.

#Asphalt Batch Plant Functions#Asphalt Plant Functions#Counter Flow Drum Plants Function#Parallel Flow Drum Plants Function

0 notes

Photo

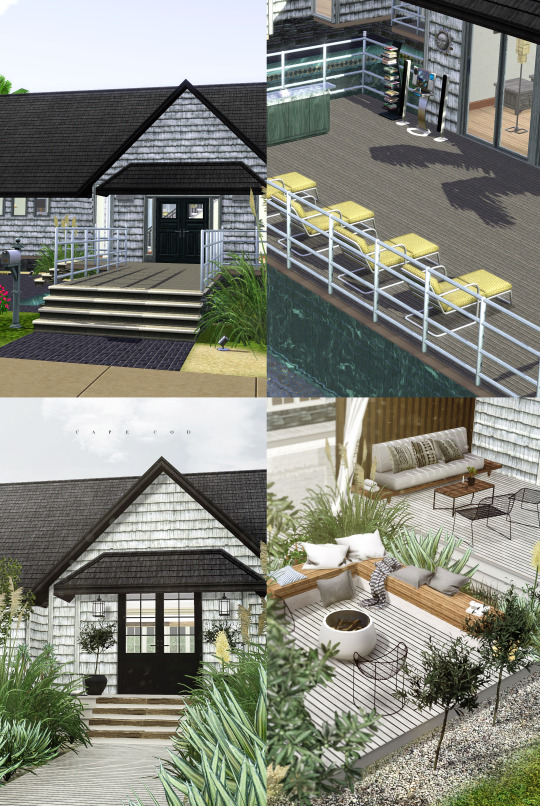

LET’S RENOVATE CHALLENGE: SUNSET VALLEY

My twist on the popular Sunset Valley remodels, in challenge form! I have always enjoyed the distinct architectural styles and thought behind the TS3 base game houses, but they definitely could be improved with a refresher for the modern times.

R U L E S

Pick a Sunset Valley house from this list. Renovate one interior or exterior space (or the entire house if you’re up for it!) sensitively with cc—while retaining as much as possible of the original charm, functional intentions, and architectural features. Post the before & afters, EA’s lot description, and your design notes! Tag some friends if you like ♡ Original post for reference.

C A P E / C O D

See the full reno: 1 / 2 / 3 / 4

I chose “Unabridged” to renovate, my favourite house in Sunset Valley (and Max’s house from Gen 2, for old legacy readers).

2br, 2ba / 455 Sunnyside Blvd. / 40x40 / A traditional cape style house is made modern by bridging a large custom pool. Easy living on this beach front property will make you feel like you are on vacation every day of the week.

My interpretation of the description (and floor plan) was a summer house meant for a young rich couple who love to entertain. I liked how the house was built like a classic grey-shingled Cape Cod cottage, but they did a pretty shit job at the “made modern” part, especially for the drab interior which had no relationship with the exterior. There was also a lot of wasted space due to the excessive wraparound pool and fenced decks. So, my main goals were to make the outdoor spaces practical for gatherings, align the interior with the Cape Cod style, and reconnect the home with the natural landscape.

C H A N G E / L O G

Extended foundations to match façade + straightened out kinky walls

Reconfigured layout to add laundry (replacing second bathroom)

Removed ugly metal railings and unfinished second “level”

Replaced steel windows with white casements

Redecorated with light neutral palette, natural timbers, accents of navy blue and brass (cape cod / mid-century farmhouse style)

Replaced front entrance bridge with landscaped timber boardwalk

Downsized asphalt carpark, changed to sand

Downsized pool, replaced with landscaping for privacy and garden space

Reshaped and layered decks to become proper garden living zones connected to the pool + beach, with timber decking, outdoor kitchen, al fresco dining, firepit, lawn, outdoor shower

Planted olive trees, almond trees, coastal grasses

T A G S

@lazysunjade / @amuhav / @keibea / @moonsonnet / @itssimplythesims / @enable--llamas / @catharsim / @plumbobem / @ariadnew / @obscurus-noctem / @descendantdragfi / @architectural-sims / @hypernov-a + everyone who would like to try this challenge, i tag you ❤

#let's just pretend this challenge hasn't been in my drafts for an entire year#you don't have to do the overly detailed change log haha#disclaimer: my after pics are edited vs the raw before pics#although i don't think any amount of editing can save ea's decorating tastes lmfao#sims 3#ts3#simblr

130 notes

·

View notes

Text

Mallek uses the equal sign as the word "is", a quirk which, when enacted upon the parallel lines in his name, begets the word Maizek. I'd previously thought this referred to magic, given the motif of disillusionment in the story, but now I suspect the point is "maize", as in corn. Couple points potentially to that effect:

One of the cereals in his apartment is FURY POPS (ty to @momestuck's old liveblog), a curious distortion of Corn Pops

Your hard landing on the asphalt in a Bad End is titled "Sweet Plant"

On the off chance that "Adalov" functioned as a distortion of "idol of", I ran a search for maize gods and found the paired (or else blurred) Aztec gods Centeotl and Chicomecoatl, whose names mean "dried maize on the cob" and "seven serpents", respectively. The latter maize god might explain Mallek's snake lusus.

More free associative: Native American connotations of the mohawk aside, Mallek's wisp of hair made me think of the silk atop ears of corn. So the matter of his ears being pierced, and his candy corn horns being pierced, gave me the sudden impression that Mallek's horns themselves were a piercing, looping through the ear of corn that is his head... the reading of horns as psychic antennae would color his interest in an underground space without a strong wireless signal, maybe

The "exploding buttery kernels" bit from Polypa's route also points towards to a weird cageyness around corn... as does the name "Konyyl", if we can read that as a distortion of kernel. Her last name Okimaw is also a Cree word for Chieftain, so the Native American connection to corn would persist... also weird how if you take her first name as Colonel it becomes two leadership titles in a row. Master Chief ass

14 notes

·

View notes

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum: Long service life Energy saving Low emission Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

Let's appreciate some cases of Xinyiguang's LED floor screen

Stay at home, go shopping, and walk on the road. Our common floor materials include carpet, wood plank, marble, cement road, asphalt and other types, but no matter how fancy, pattern, and color change, they all have a common feature-slightly "dull". Some people say that it is fun and convenient, just change it frequently. It sounds very embarrassing, you can change the carpet every day, but you can't pry the floor every day. Have you heard of Xinyiguang LED floor tile screen? Through the LED display, the visual interactive experience is immersive, giving people: the indoor floor tile screen with the experience of "sitting at home, the world is under the feet"; stepping and jumping, and the intelligent interaction of playing and dancing floor tile screen; waterproof and dustproof, super heavy outdoor floor tile screen. It can be tiled on the ground and displayed slowly, or it can be used to create a dreamy and flashing stair screen that climbs up the steps. Onlooker No. 1: It sounds amazing, do floor tile screens with so many functions really exist? Onlooker No. 2: Need to be powered on? Is it safe? Onlooker No. 3: Will it be crushed? Yes, yes, all of the above! Chinese people don’t lie to Chinese people. The editor of Digital Audio-Video Engineering Network couldn’t stand everyone’s urging, and decided to go to Xinyiguang with everyone to learn about it. It was an eye-opener. Experience the fun of "seeing is owning". 2022 CCTV Spring Festival Opera Gala-P2.976-300 square meters

Shenyang-TV Station-106.25 square meters

Yinchuan-Planning Pavilion-330 square meters

Xinjiang-Museum-P3.91-250 square meters

Zhejiang - Qiandao Lake Tourist Attraction - 240 square meters

Shanghai-Audi Flagship Store-P3.91

Russia - Stavropol - P2.976-288 square meters

Wuhan K11-P6.25 Indoor - 280 square meters

Q&A session

1. Is it safe? Quiet heat dissipation The power box of the LED intelligent interactive floor tile screen box adopts a die-cast aluminum box with good heat dissipation, and a special heat dissipation device is designed by a professional R&D team to achieve a better silent heat dissipation function. 2. Is it waterproof? The bottom case, mask, power cord and signal line of the waterproof and moisture-proof LED floor tile screen module are specially designed and equipped with waterproof and moisture-proof materials. They are made of raw materials with low moisture absorption coefficient. The front and back of the body can reach the waterproof level of IP45. 3. Is it reliable? The anti-slip and wear-resistant LED intelligent interactive floor tile screen mask is made of imported PC materials, which has high wear resistance and flexibility, and good high and low temperature resistance. And designed according to the principle of mechanics, Xinyiguang mask has good anti-slip and load-bearing functions. 4. Is it hard? Super load-bearing Each component of Yiguang LED intelligent interactive floor tile screen, according to different mechanical designs, has an ultimate load-bearing capacity of up to 3 tons per square meter. Onlookers 1, 2, and 3: Awesome! Is that brand okay? Editor: Founded in 2012, Xinyiguang is a professional supplier of global application products and solutions. Xinyiguang has a modern manufacturing plant of 8,000 square meters. The core R&D team has more than 20 years of experience in professional research and development. The company has obtained a number of valid patent certificates and a number of test reports to provide users with high-quality products and services. And in December 2021, it was awarded the "2021 Famous Brand of LED Floor Tile Screen" by Digital Audio Video Engineering Network. The trophy is still warming up, what do you think? Onlooker No. 1: Wow, it's so powerful, I will arrange a basketball court with LED floor tiles for the village immediately, the cubs in our village must not lose to the next village! Low-key arrangement... Onlooker No. 2: I heard it a long time ago! We have 4 in our village, 1 each in the east, west, north, and south. Onlooker No. 3: Tsk tsk tsk, you guys are so naive. I want to arrange a big floor tile screen for the entrance of my house, so that everyone will envy my house! The indoor LED floor tile screens, intelligent interactive floor tile screens, and outdoor LED floor tile screens developed and produced by Xinyiguang have various installation styles of floor tile screens and stair screens. The product cabinets are made of hard materials such as die-casting aluminum, aluminum plates, and iron. Increase the strength of the box, strong and wear-resistant. It's really good, the boss remembers to stock up for the New Year, because it will be a big hit in 2022! Read the full article

2 notes

·

View notes

Text

Flat Roofing Contractor Services

Are you in the market for a new roof or in need of repairs? Look no further than flat roofing contractor services! Flat roofs have become increasingly popular due to their modern, sleek design and practicality. Whether you are building a new commercial property or revamping your current residential space, our expert team can provide top-notch installation, maintenance and repair services to ensure that your roof is not only functional but also aesthetically pleasing. Keep reading to learn more about the benefits of flat roofing and how we can help bring your vision to life!

What is a flat roof?

A flat roof is a type of roofing system that has a generally level surface, instead of the traditional sloped surface found on most roofs. While there are a few different types of flat roofs, the most common type is a membrane roof. Membrane roofs are made from layers of waterproof material that are fastened together and then sealed with tar or another type of adhesive.

Different types of flat roofs

There are four main types of flat roofs: built-up roofs, single-ply membranes, spray foam roofs, and vegetative roofs. Built-up roofing is one of the most common types of flat roofing. It consists of multiple layers of asphalt or tar paper that are bonded together with adhesive or hot mopping. This type of roofing is very durable and can last up to 20 years with proper maintenance. Single-ply membrane roofs are made from a single layer of synthetic material, such as PVC or TPO. These roofs are very popular because they are easy to install and repair. They are also resistant to UV rays, making them a good choice for areas that receive a lot of sunlight. However, they can be susceptible to damage from high winds and hail. Spray foam roofs are made from polyurethane foam that is sprayed onto the roof surface. This type of roofing provides excellent insulation and can help reduce energy costs. However, it is important to ensure that the foam is applied correctly in order to avoid leaks. Vegetative roofs are also known as green roofs or living roofs. They consist of a layer of vegetation that is planted over the top of the roof membrane. Vegetative roofs provide excellent insulation and can help improve air quality in urban areas.

Advantages and disadvantages of a flat roof

Flat roofs are a type of roofing system that is commonly used in commercial and industrial buildings. They are also becoming increasingly popular in residential applications. Flat roofs have many advantages, including their low cost, durability, and easy maintenance. However, there are also some disadvantages to consider before choosing a flat roof for your home or business. Advantages: 1. Low cost: Flat roofs are typically much cheaper to install than pitched roofs. This is because they require less materials and labor to construct. 2. Durability: Flat roofs are very durable and can last for decades with proper care and maintenance. 3. Easy maintenance: Flat roofs are easy to inspect and repair, thanks to their accessible nature. Inspections can be performed from the ground level without the need for special equipment or training. Disadvantages: 1. Limited drainage: Flat roofs can sometimes suffer from poor drainage due to their lack of slope. This can lead to pooled water on the surface of the roof, which can damage the roofing materials over time. 2. Heat retention: Flat roofs tend to retain heat more than pitched roofs, which can make them less energy-efficient in warm climates. 3. Snow accumulation: In areas with heavy snowfall, flat roofs can sometimes suffer from accumulation due to their lack of slope. This can put extra strain on the roofing materials and lead to premature wear or even collapse if not properly managed

How to find a reputable flat roofing contractor

The best way to find a reputable flat roofing contractor is to ask around for recommendations. Talk to friends, family, and neighbors who have had flat roofs installed or repaired recently, and see if they had a good experience with their contractor. Once you have a few names, research each one online to see what others are saying about them. Look for reviews on independent sites like Google and Yelp, and check the contractor’s website and social media accounts for customer testimonials. When you’ve narrowed down your choices, contact each contractor to get a quote for your project. Be sure to ask about their experience with flat roofs, what type of materials they use, and whether they offer any warranties or guarantees. Get at least three quotes so you can compare prices and services before making your final decision.

Flat roofing contractor services

A good flat roofing contractor will provide a wide range of services to their clients. These services can include anything from repair and maintenance, to new construction. Here are just a few of the things that you should expect from your contractor: -Inspection and Assessment: A good contractor will always start with a thorough inspection of your roof. They will look for any signs of damage or wear and tear. Once they have assessed the condition of your roof, they will be able to give you a realistic estimate of the costs for repairs or replacement. -Repair and Maintenance: If your roof is in need of repairs, a good contractor will be able to fix it quickly and efficiently. They will also be able to provide you with regular maintenance services, such as cleaning and checking for leaks, to keep your roof in top condition. -New Construction: If you are looking to have a new roof installed, a good contractor will be able to handle the entire process for you. They will work with you to choose the right materials and design for your needs, and then they will handle all of the installation work.

Conclusion

Flat roofing can provide a durable and cost-effective solution for any construction project. With the help of a professional flat roofing contractor, you can make sure that your new roof will be installed in an efficient and timely manner. Make sure to research different contractors in order to find one with the experience and expertise needed to get the job done right. With their help, you’ll have peace of mind knowing that your flat roof is built and maintained properly for years to come.

2 notes

·

View notes

Text

Husband Roofing & Contracting

In the heart of Long Beach, Mississippi, Husband Roofing & Contracting stands as a distinguished figure in the community for Roof Repair Long Beach, MS. With our roots deeply planted in the local landscape, we offer comprehensive roofing solutions that cater to both residential and commercial clients. Our suite of services includes meticulous Residential Roofing and steadfast Commercial Roofing, ensuring every structure under the sun-bleached skies of Long Beach is well covered.

Understanding the ever-changing temperament of coastal weather, we are equipped to handle Storm Damage Repair with precision. The impact of such events on your property is swiftly managed by our team to restore the security and comfort of your premises promptly. For those looking to elevate their home's durability while maintaining its visual appeal, our Asphalt Shingle Roofing and modern Metal Roofing options provide a harmonious balance between resilience and style.

We go beyond just roofing at Husband Roofing & Contracting; our expertise extends to water management systems including robust Gutters and sleek Seamless Gutters, designed to seamlessly blend with your exteriors. Moreover, we install dependable K-Style Gutters that not only function optimally but also add an aesthetic touch. To keep maintenance at bay, consider our effective Gutter Guard solutions that will ensure leaves and debris don't disturb the flow.

Aiming for a complete facade makeover? Our siding services are comprehensive: from classic Vinyl Siding to sophisticated Composite Siding, right through to traditional stucco finishes that imbue elegance into any home or business establishment.

No matter your need, be it a simple roof fix or a holistic upgrade with Roof Replacement or Flat Roofing, Husband Roofing & Contracting remains dedicated to delivering quality service in Long Beach, MS. Contact us today; let us envelop your abode in protection and poise.

Address: Hayes Rd, Long Beach, MS, 39560 Website

Phone: (228) 687-7663 Company Email: [email protected] Company hours: Mon - Fri: 08:00 - 17:00

Pinterest

Coub

Buzzfeed

Academia.edu

Penzu

1 note

·

View note

Text

Understanding the Heat Transfer Fluids Market: Trends and Growth Drivers

The global heat transfer fluids market was valued at USD 11.06 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2024 to 2030. One of the primary drivers of this market growth is the rapid global adoption of concentrated solar power (CSP), which significantly boosts the demand for heat transfer fluids (HTFs). These fluids are essential industrial products derived primarily from petroleum sources, and they play a key role in preventing overheating and storing thermal energy. The primary raw materials used in the production of HTFs include crude oil, silica, and base oils.

The core attributes of heat transfer fluids include low viscosity, a non-corrosive nature, high thermal conductivity and diffusivity, and the ability to operate under extreme phase transition temperatures. These characteristics make HTFs invaluable in a wide range of industrial applications. They are crucial in ensuring the efficient transfer of heat in various processes, particularly in energy generation and thermal storage systems.

The United States is a key player in the global CSP market, contributing significantly to the installed capacity for concentrated solar power. The U.S. strategically utilizes its CSP plants to deliver power outputs during periods of exceptionally high demand, making the role of heat transfer fluids even more critical. These fluids are integral to improving the efficiency of CSP plants by aiding in the collection of energy from the solar field and transporting it to energy storage systems. The stored thermal energy can be used to generate electricity even after sunset or during cloudy weather conditions, providing a significant advantage over other renewable energy sources, such as photovoltaic (PV) systems.

Gather more insights about the market drivers, restrains and growth of the Heat Transfer Fluids Market

Product Insights

The glycol-based heat transfer fluids segment is expected to be the fastest-growing product category, with a projected revenue CAGR of 4.1% over the forecast period. Glycol-based fluids are favored for their excellent antifreeze properties, which make them suitable for a wide range of applications. This segment is also seeing an increasing shift towards bio-based glycols, which are becoming an important component in HTF formulations due to their environmental benefits. Bio-based glycols are particularly attractive because they can be used in both high and low-temperature applications, offering versatility across a variety of industrial sectors.

Mineral oils, another common type of heat transfer fluid, are widely used in radiator heaters, which are essential in both commercial and residential applications. These oils are preferred for their high resistance to chemical oxidation and thermal cracking, making them durable under various operational conditions. They are also non-toxic and non-corrosive, which enhances their safety and usability. Furthermore, mineral oils provide high thermal conductivity and specific heat, allowing for efficient heat transfer. However, one limitation of mineral oils is their high degradation rate when exposed to extreme temperatures over long periods.

Another important class of HTFs is alkylated aromatic compounds, which are typically formulated for use in closed-loop heating systems based on the Rankine cycle. These HTFs are particularly suitable for high-temperature applications in industries such as asphalt production, gas processing, tank cleaning, and plastic manufacturing. Alkylated aromatic compounds are versatile, functioning efficiently in both the vapor phase and liquid phase. They are known for their excellent fluid and heat transfer properties, which make them ideal for processes involving relatively low temperatures while still maintaining stability and performance under challenging conditions.

Heat transfer fluids market is experiencing steady growth driven by the expanding use of concentrated solar power (CSP), increasing demand for energy storage solutions, and advancements in heat transfer fluid formulations. Glycol-based HTFs are emerging as the fastest-growing segment, while mineral oils and alkylated aromatic compounds continue to dominate key industrial sectors. As technologies evolve and the demand for renewable energy and efficient thermal management increases, the heat transfer fluids market is poised for continued expansion and innovation.

Order a free sample PDF of the Heat Transfer Fluids Market Intelligence Study, published by Grand View Research.

#Heat Transfer Fluids Market#Heat Transfer Fluids Market Analysis#Heat Transfer Fluids Market Report#Heat Transfer Fluids Industry

0 notes

Text

15 Most Underrated Skills That'll Make You A Rockstar In The Roofing Contractors Wilmington Nc Industry

Roofing design Trends in Wilmington NC and Eastern North Carolina - Coastal Influences on Roofing Materials -In Wilmington, NC, and the broader Eastern North Carolina area, coastal weather patterns significantly influence roofing design trends. Durability is a major concern for both homeowners and contractors in the region due to its vulnerability to hurricanes and intense thunderstorms. Roofing materials like heavy-duty architectural tiles, metal roofing systems and impact-resistant options have become more popular. These materials not only withstand high winds but also offer longer lifespans compared to traditional asphalt shingles. Reflective or 'cool roof' options are also being used to combat heat absorption, which is common in coastal homes.

When Professionals Run Into Problems With Wilmington Roofing Company, This Is What They Do

Aesthetic Appeal Meets Functionality

Roofing designs in this locale are not solely about practicality; aesthetic appeal plays a crucial role as well. Many homeowners choose styles that complement traditional Southern architecture, while still incorporating contemporary elements. To harmonize with the surrounding landscape, color palettes tend to be natural shades of grays and browns. To this end, dimensional shingles that mimic the look of wood shakes or slate tiles without compromising on resistance to weather conditions are often selected for their visual appeal and structural integrity.

Don't Make This Silly Mistake With Your Roof Repair Wilmington Nc

Sustainable Roofing Solutions

With an increasing awareness of environmental concerns, sustainable roofing solutions have risen in popularity across Wilmington and Eastern North Carolina. Green roofs with plant life can reduce the urban heat island effect and provide additional insulation. Rainwater harvesting systems can be installed during roof construction to help manage stormwater runoff, and provide an alternate water source for landscaping. Furthermore, solar-ready roofs are designed to facilitate the later installation of photovoltaic products like solar panels or integrated solar tiles.

15 Hilarious Videos About Metal Roof Installers Near Me

Embracing Technology Advancements

Technology advancements have revolutionized how roofers approach installations and repairs in Wilmington NC and its environs. Drone technology now assists in conducting thorough roof inspections safely and efficiently--particularly valuable after extreme weather events when rapid assessments are necessary for insurance claims or urgent repairs. Moreover, advanced software tools aid contractors in designing more effective roofing systems tailored to individual buildings' specifications while ensuring compliance with OSHA requirements for safety protocols.

Customization Options Are Many

Today's consumer demand leans towards customization--a trend reflected in local roofing projects as well. Homeowners are looking for unique color and material combinations that will make their home stand out, while still maintaining a cohesive aesthetic within the neighborhood. Custom-crafted metal work detailing like cupolas, eave brackets, or ridge crestings gives homes a distinctive character while preserving functional benefits like added ventilation or enhanced architectural lines.

The Pros And Cons Of Metal Roofing Companies Near Me

In effect this means...

For those considering a new roof or maintenance on an existing one in Wilmington NC or Eastern North Carolina at large it's essential to be informed about current trends influencing both material choices and design aesthetics--as well as how these trends marry with today's technological innovations which aim at making roofing more durable safer environmentally friendly all without sacrificing style By staying abreast with these developments homeowners can ensure they make choices that will protect enhance add value their property years come

Historical facts about roofer

Roofers are professionals who specialize in the construction and maintenance of roofs. Roofers have played a vital metal roofing companies near me role in protecting buildings from the weather elements such as rain, snow, sun, and wind. Based on the text, here are some historical facts regarding roofers:

Roofers must have knowledge and skills to work with a variety of roofing materials, including shingles, single-ply membranes like EPDM rubber or PVC or TPO membranes. They may also need to be familiar with bitumen, metal tiles or sheets, or even innovative technologies such as solar shingles.

Roofing is an ancient trade that evolved with the development of different types of living structures. Roofers have used local materials throughout history - from clay tiles and stones slabs to straw and wood.

In medieval Europe for example, thatchers would use bundles of reed or straw to create watertight roofs with steep slopes; this method remains part of traditional craftsmanship in some regions today.

As industrialization progressed in the 19th century so did roofing techniques which saw advancements like the mass production of clay tiles and metal roofing components.

Roofers are often physically demanding because they have to perform heavy lifting, climbing, bending and kneeling in all kinds of weather conditions.

Safety is a major concern in the construction industry, given its inherent dangers. Falls from heights are one of the leading causes of injuries among roofers and other construction workers.

Various protective measures have been implemented over time through legislation such as United States' OSHA standards which mandate specific fall protection systems for workers operating at certain heights.

The trade's equipment has evolved from simple ladders ropes hammers nails into more advanced tools such pneumatic nail guns mechanical hoists energy-efficient products facilitate installation remove old materials while improving overall efficiency safety on job sites.

Modern training programs apprenticeship opportunities now exist prepare individuals entering into this profession providing them necessary competencies safely effectively perform their duties as professional roofers.

The adoption of green technologies such as vegetative roofs, rainwater harvesting systems and photovoltaic panel represents a significant shift in building practices towards sustainable ones. This highlights the role that innovation plays in adapting to environmental challenges faced by society today.

Despite technological advances, the fundamental roles and responsibilities of a roofer are largely unchanged. These include assessing the proper system, repairing it when necessary, fitting different types of material to ensure imperviousness in various weather conditions.

12 Global trends show there's steady demand for skilled roofers though job growth is projected be modest due factors such aging workforce advances technology chances

youtube

0 notes

Text

Journal 6- Field Trip 4

Waste to Energy Facility

My experience at the Lee County Waste to Energy Facility was unique. I learned the importance of prioritizing throwing away trash/waste to where it belongs. The important reason is because if we do. It protects our Earth, environment, ecosystem, etc. That keeps our Earth as healthy as possible and prioritizing that is crucial because we are the only planet with living organisms.

To begin with, there is a statistic that per person, one ton of trash is generated per year. That is an average of 4.4 pounds per day. The importance of four-to-five R's is important, which is to reduce, reuse, recycle, and recover/rethink. Reducing requires making smarter choices about what we consume and ways we try to sustain it as long as we can. To reuse, we repair, share, sell, barter, and buy second-hand. There are many ways we can do this, and for example, we can donate clothing, supplies, and other things that we don't use. Instead of throwing it in the trash, we reuse and pass it along, which helps our ecosystem. Recycling is important by making sure we recycle the appropriate items in the recycling bin/trash. The reason this is important is because throwing away things that aren't recyclable in the trash affects the recyclable items, so throwing trash into the trash is important. To recover is to recognize your waste for the resource that it is and dispose of it properly. With that being said, we must throw the trash where it belongs instead of littering and throwing it away where it doesn't belong. To rethink, everyone has to reconsider their decisions to reuse, reduce, recycle, recover, and make sure we all make the right decision within those circumstances.

At the facility, I learned about the recycling plant and its importance. The recycling plant is a mechanical, electronic & manual separation of materials to sell to manufacturers. All residential recycling goes to the Material Recovery Facility. The importance of this is that when we recycle, those items can be reused to make things we need. Recycling helps save trees and other important environmental things that don't have to be taken down to recreate our daily supply. With the recycling plant, it is important we throw away bags in the trash and not recycle them because those bags can affect the recycling plant. system.

The construction & demolition facility (C&D) is an important system that's in the Lee County Waste & Energy facility. The C & D facility represents 1/3 of all waste generated, such as landfill, drywall, dock pilings, PVC, asphalt shingles recovered, clean wood, metal, concrete, RSM, rigid plastic, cardboard, etc. The importance of this system is, in a way, how the Lee County facility generates its money because it sells things items that are recycled to businesses. The system helps with the facility in a way that this facility helps maintain our Earth. The yard waste has over 122,000 tons of processed; this waste can be reused, so if anyone is interested, there is a facility that provides this for free in the Lee County Area. We learned the importance of tires back in the day. Tire changes require new ones every 10k miles; nowadays, tires can last up to 50k miles before new ones, which helps preserve tire waste and the effect it has on the Lee County Waste Facility and the Earth as a whole. The facility functions with water and power, so this helps save that.

The consequences for littering and placing trash in areas that it doesn't belong are severe and is something not many people know. It depends on how much is littered it can be as bad as a 3rd degree felony and the dumping costs everyone money. Sustainability in Lee County is the leader in all North America because that county prioritizes it higher than everyone else. We as a world need to reach that level and that is something that is controllable by us humans. The sustainability this does helps future generations for however long the world exists. This helps meet our own needs without compromising the ability of future generations to meet their needs which helps save our planet.

0 notes

Text

KNOW YOUR ASPHALT DRUM MIX PLANT: ESSENTIAL COMPONENTS and OPERATIONAL INSIGHTS

Gajjar Equipments Private Limited is a manufacturer, supplier, and exporter of Asphalt Mixing Plant, Asphalt Batch Mix Plants, Asphalt Drum Mix Plants, Counterflow Asphalt Drum Mix Plants, Mobile Drum Mix Plants, and more. We are based in Ahmedabad, Gujarat, India. In road construction and infrastructure development, asphalt drum mix plants are crucial machinery for producing hot mix asphalt (HMA). This article delves into the key components and working principles of these plants, providing a clear understanding of their importance and how they function in the construction industry. INTRODUCTION TO ASPHALT DRUM MIX PLANTS Asphalt drum mix plants are essential for road construction, facilitating the efficient production of hot mix asphalt. This crucial material is used in building and maintaining roads, highways, and other transportation infrastructures. These plants are versatile, accommodating projects of various sizes—from compact, portable units to large, high-capacity stationary installations. KEY COMPONENTS OF ASPHALT DRUM MIX PLANTS EXPLAINED Cold Feed Bins: These initial storage units hold aggregates like gravel, sand, and stone in separate compartments sorted by size. Their role is to ensure precise blending of these materials before they enter the drying drum. Features include multiple compartments, adjustable gates for regulating aggregate flow, and vibrating motors to maintain a steady feed rate. Conveyor System: This system moves aggregates from the cold feed bins to the drying drum. It comprises a robust belt conveyor built to handle heavy loads, with variable speed controls to adjust the conveyor speed based on production needs. Additionally, it includes a dust suppression system to minimize dust emissions during transfer. Drying Drum: This component is where aggregates are heated and dried before being mixed with bitumen. The drum features internal flights to lift and shower the aggregates, ensuring uniform heating. It’s insulated for energy efficiency and continuously rotates to achieve even drying and heating. Mixing Drum: Here, the heated aggregates and bitumen are thoroughly mixed to create hot mix asphalt. The drum’s continuous rotation ensures uniform mixing, with precision weighing systems maintaining the correct proportions of aggregates and bitumen. Mixing paddles further enhance the homogeneity of the asphalt mix. Burner: The burner generates the necessary heat for drying aggregates in the drying drum. It is flexible in its fuel options, accommodating diesel, fuel oil, or natural gas, and it includes automatic ignition and temperature control for efficient and controlled heating. Bitumen Tanks: These tanks store asphalt cement (bitumen) at controlled temperatures until it is mixed with the aggregates. They come equipped with heating coils to maintain the viscosity of the bitumen, agitators to prevent settling, and a pumping system for accurate transfer to the mixing drum. Baghouse Filter: This filter is crucial for environmental compliance, capturing dust and particulate matter produced during asphalt production. It features high-efficiency filtration, automatic cleaning systems to extend filter life, and mechanisms for proper dust collection and disposal or reuse. Control Panel: The control panel is the brain of the asphalt drum mix plant, enabling operators to monitor and manage various parameters like temperature, moisture content, and production rates. It boasts user-friendly interfaces, real-time monitoring, and automated controls for precise and efficient plant operations. HOW ASPHALT DRUM MIX PLANTS WORK The operation of an asphalt drum mix plant follows a series of steps to maintain the continuous production of high-quality hot mix asphalt: 1. Weighing Virgin Aggregates: The virgin aggregates (such as sand, gravel, and crushed stone) are individually weighed from the cold feed bins using a variable, continuous, and automatic belt speed. The proportions are determined by the control systems. Once weighed, the aggregates are transferred to the dryer via a charging conveyor. 2. Drying and Heating: The aggregates enter the primary zone of the drum mix plant, where heat from the burner dries and heats them. Next, the aggregates move to the secondary zone, where asphalt is added. Here, the aggregates and asphalt are thoroughly blended. Continued drying also occurs in the secondary zone. 3. Aggregate Flow and Mixing: Drum mixers are equipped with flights (internal paddles) that direct the aggregate flow and spread the aggregates across the cross-section of the drum. The aggregates must not only rotate with the revolving motion of the drum but also spread out sufficiently. This ensures quick and efficient heating and drying of all particles. 4. Continuous Asphalt Production: The drum mix plant produces the asphalt concrete mix continuously. To manage this continuous flow, a temporary holding bin or surge silo is used. Various conveying devices can transport the asphalt concrete from the discharge end of the drum mixer to the holding bin or surge silo. Common means of transport include bucket elevators, drag slat conveyors, and belt conveyors. Whether you're undertaking a small-scale project or a major development, asphalt drum mix plants are essential. They drive the progress and upkeep of road networks globally. With their unmatched efficiency in producing high-quality asphalt, these plants are pivotal in shaping the future of transportation infrastructure. Trust Gajjar Equipments Pvt. Ltd. for your road construction needs, and elevate your projects with our state-of-the-art solutions. Contact us today for inquiries or to place an order! View Product: Click Here Read the full article

0 notes

Text

Benefits of Choosing Desert Gold Stabilized DG for Landscaping

Materials for landscaping projects, whether residential or commercial, frequently need to strike a balance between practicality and beauty. Composed granite (DG) has steadily gained popularity among these materials for its versatility, cost-effectiveness, and environmental benefits.

Within the spectrum of DG options, Desert Gold Stabilized DG stands out as a premier choice, particularly for those looking to add a touch of warmth and elegance to their outdoor spaces.

What is Desert Gold Stabilized DG?

Desert Gold Stabilized DG is decomposed granite treated with a stabilizing agent. This agent binds the particles together, creating a firm yet absorbent surface ideal for landscaping applications.

The "Desert Gold" variant refers to the distinct warm, golden hue that adds a sunlit charm to any landscape.

How Desert Gold Stabilized DG is Produced

Desert Gold Stabilized DG is produced by collecting naturally weathered granite. This granite is then crushed granite into fine particles. The stabilizing agent, often a natural or organic compound, is mixed in to provide cohesion.

This mixture helps the material maintain its structure and longevity, making it resistant to erosion and displacement.

The Unique Appeal of Desert Gold

The appeal of Desert Gold Stabilized DG lies in its warm, earthy tones that evoke the natural beauty of desert landscapes.

This color complements various plantings and hardscaping elements, from succulents and cacti to modern metal and wood features.

Its rich golden shade can transform pathways, patios, and garden beds into inviting, cohesive outdoor environments.

Environmental Benefits of Desert Gold Stabilized DG

In today's environmentally conscious world, sustainable landscaping materials are more important than ever. Desert Gold Stabilized DG offers several environmental advantages, making it eco-friendly for landscaping projects.

Permeability and Water Conservation

One of Desert Gold's Stabilized DG's key environmental benefits is its permeability. Unlike impervious surfaces like concrete or asphalt, stabilized DG allows water to penetrate through, reducing runoff and promoting groundwater recharge.

This property makes it an excellent choice for xeriscaping or areas prone to drought, as it supports water conservation efforts.

Erosion Control and Soil Stabilization

When used on slopes or in areas susceptible to erosion, Desert Gold Stabilized DG can help stabilize the soil. The stabilizing agent ensures the material remains in place even during heavy rains, minimizing soil displacement and erosion.

This makes it a practical choice for pathways, driveways, and garden beds where maintaining soil integrity is crucial, particularly when incorporating white sand landscaping.

Natural and Non-Toxic

Desert Gold Stabilized DG comprises natural granite and organic stabilizers, making it a non-toxic and safe option for residential and commercial landscapes.

It does not release harmful chemicals into the environment, ensuring that your outdoor space remains healthy for plants, pets, and humans.

Practical Benefits of Desert Gold Stabilized DG in Landscaping

Beyond its environmental perks, Desert Gold Stabilized DG provides a number of useful advantages that improve the functioning and aesthetics of any landscape.

Durability and Longevity

Desert Gold Stabilized DG is far more durable than unstabilized DG thanks to the stabilizing agent.

Initially, it can withstand foot traffic, weather fluctuations, and even light vehicular use without deteriorating quickly.

This durability makes it ideal for high-traffic areas like pathways, driveways, and patios.

Low Maintenance Requirements

One of Desert Gold Stabilized DG's standout features is its low-maintenance nature. Once installed, it requires minimal upkeep compared to other landscaping materials.

Regular maintenance typically involves occasional sweeping to remove debris and periodic recompacting to maintain a smooth surface.

Cost-Effectiveness

Desert Gold Stabilized DG offers excellent value when considering the cost of crushed granite landscaping materials. Its relatively low cost per square foot, durability, and It's an affordable alternative because it requires little upkeep for small and large projects.

Moreover, its installation is straightforward and does not require specialized labor, reducing costs.

Versatility in Application

Desert Gold Stabilized DG is incredibly versatile and suitable for various landscaping applications. It can be used for:

Pathways: Creates stable, attractive walkways that blend seamlessly with natural surroundings.

Patios: Provides a firm yet comfortable surface for outdoor seating and dining areas.

Garden Beds: Offers a natural, weed-resistant covering for garden beds and plantings.

Driveways: Withstands light vehicular traffic, making it a practical choice for residential driveways.

Aesthetic Enhancement

Stabilized decomposed granite's warm, golden hue adds an elegant and natural look to any landscape. It complements various architectural styles, from modern to rustic, and works well with traditional and drought-tolerant plantings.

The color also reflects sunlight, brightening outdoor spaces and creating a welcoming atmosphere.

Installation Tips for Desert Gold Stabilized DG

Moreover, proper installation is critical to maximizing the benefits of Desert Gold Stabilized DG. Here are some tips to ensure a successful project.

Site Preparation

Before installing charcoal landscaping rock, the site should be adequately prepared. This involves removing any existing vegetation, debris, and topsoil.

The area should then be graded to ensure proper drainage. A compacted crushed granite gravel base is recommended to provide a stable foundation.

Layering and Compaction

Desert Gold Stabilized DG should be spread in layers, typically 2-3 inches thick. Each layer should be compacted using a roller or plate compactor to achieve a firm, stable surface. This process should be repeated until the desired thickness is achieved.

Edge Restraints

Edge restraints should be installed to prevent the DG from spreading or shifting over time. These can be made from various materials, including metal, wood, or stone, and should be firmly anchored into the ground.

Watering and Final Compaction

After the final layer is spread and compacted, the surface should be lightly watered to activate the stabilizer. Once the water has been absorbed, a final compaction should be performed to lock the material in place.

Comparing Desert Gold Stabilized DG to Other Landscaping Materials

However, when planning a landscaping project, it's essential to compare different materials to ensure you're making the best choice for your needs. Here's how Desert Gold Stabilized DG stacks up against other popular options.

Desert Gold Stabilized DG vs. Concrete

Due to its durability, concrete is a common choice for pathways, patios, and driveways. However, it lacks the permeability of Desert Gold Stabilized DG, leading to water runoff and potential drainage issues.

Additionally, concrete can crack over time, especially in areas with freeze-thaw cycles, whereas stabilized decomposed granite is more flexible and resistant to such damage.

Desert Gold Stabilized DG vs. Gravel

Gravel is another popular landscaping material, particularly for driveways and garden paths. While cost-effective and easy to install, it tends to shift and scatter over time, requiring frequent maintenance.

Desert Gold Stabilized DG, on the other hand, remains in place due to its stabilizing agent, reducing the need for ongoing upkeep.

Desert Gold Stabilized DG vs. Mulch

Mulch is often used in garden beds to retain moisture and suppress weeds. However, it can decompose over time, requiring regular replenishment.

Desert Gold Stabilized DG and crown granite provide similar benefits without frequent replacement, making them more long-lasting.

Design Ideas Using Desert Gold Stabilized DG

Incorporating Desert Gold Stabilized DG may improve the visual attractiveness of your outside space when included into your landscaping design. However, here are some creative ideas to inspire your next project.

Desert-Inspired Pathways

Create winding pathways through your garden or yard using Desert Gold Stabilized DG. The warm tones of the DG will evoke a desert-like feel, particularly when paired with drought-tolerant plants like agave, yucca, and cactus. Add boulders and stone accents to enhance the natural look.

Elegant Patio Spaces

Using Desert Gold Stabilized DG as the base material, transform your patio into an inviting outdoor living area.

Pair it with comfortable seating, potted plants, and a fire pit to make a comfortable meeting area.

The DG's natural color will complement various furniture styles and outdoor décor.

Low-Maintenance Garden Beds

Use Desert Gold Stabilized DG as a ground cover around plants and shrubs for a low-maintenance yet visually appealing garden.

Its warm color highlights the greenery, and its weed-resistant properties will keep your garden neat with minimal effort.

Rustic Driveways

Enhance your home's curb appeal with a rustic driveway made from stabilized decomposed granite.

Its natural appearance will blend seamlessly with the surrounding landscape, creating a cohesive look.

Plus, its robustness ensures that it will withstand the wear and tear of daily use.

Maintenance Tips for Desert Gold Stabilized DG Landscapes

Although Desert Gold Stabilized DG is low-maintenance, there are a few best practices to keep your landscape looking its best.

Regular Sweeping

Regularly sweep your Desert Gold Stabilized DG surfaces to prevent debris from accumulating. This will help maintain the material's appearance and prevent the growth of weeds or moss.

Recompacting

Over time, the DG may become slightly loose or uneven, particularly in high-traffic areas. Recompacting these areas will restore the material's firmness and evenness, ensuring a smooth and stable surface.

Weed Control

While Desert Gold Stabilized DG is naturally weed-resistant, some weeds may still manage to penetrate. Hand-pulling or spot-treating with an organic herbicide can help manage this issue without harming the surrounding environment.

Reapplication of Stabilizer

The stabilizing agent may wear down over time in areas with heavy use. Reapplying the stabilizer as needed will help maintain the material's cohesive properties and extend its lifespan.

The Value of Desert Gold Stabilized DG in Landscaping

Choosing the suitable materials for your landscaping project can make all the difference in functionality and beauty. Desert Gold Stabilized DG offers a unique combination of durability, environmental benefits, and visual appeal, making it an exceptional choice for various applications. Its warm, golden hue can enhance any outdoor space, while its low-maintenance and eco-friendly properties ensure that it remains a practical and sustainable option for years to come.

Conclusion

Regarding landscaping, Desert Gold Stabilized DG offers a blend of practicality, environmental benefits, and aesthetic appeal that few other materials can match.

Whether you're designing a new garden path, creating an elegant patio space, or seeking a durable, low-maintenance ground cover, Desert Gold Stabilized DG is a choice that combines beauty with functionality.

By investing in this versatile material, you'll enjoy a landscape that's not only visually stunning but also sustainable and easy to maintain.

0 notes

Text

Why Should We Choose Mobile Drum Mix Asphalt Plant ?

One Trailer Mounted Mobile Drum Mix Asphalt Plant Realizes the High Integration of Asphalt Plant.

One transport trailer can realize all the functional requirements of the asphalt mixing station (filling, drying, mixing, storage of finished products, operation), which meets the user's requirements for fast installation, fast transition, and rapid production.

Mobile Asphalt Plant is asphalt mix manufacturing equipment in the form of one or some mobile modules mounted on chassis, so it features fast relocation and rapid reassembly, and pre-production preparation time can be saved greatly.

#asphalt mixing plant#asphalt plant#mobile drum plant#asphalt drum mix plant#mobile asphalt drum mix plant#mobile asphalt plant#drum mix plant#asphaltplant#heavy equipment#concrete#road construction#bitumen#construction#mobile hot mix plant

2 notes

·

View notes

Text

Unit 5 Blog #1

For this open-ended prompt, I wanted to discuss the concept and importance of integrating nature and greenspaces into urban environments and how various people and locations have been working on this. Growing up in a rural area I would always be caught off guard by the lack of greenery when visiting big cities like Toronto. Living in Guelph currently is a good middle ground, as there are still abundant greenspaces here, but bigger cities tend to have sad-looking individual trees in dirt plots barely big enough for them, and I have always found this unfortunate. Luckily, as time has passed and the importance of greenspaces for both the environment and the mental and physical health of humans, integrating these spaces into cities has become more common.

Corrigan (2023) defines green infrastructure as “urban infrastructure of natural or semi-natural systems strategically designed and implemented to manage water, air quality, biodiversity, and other environmental issues in cities and urban environments”. He notes that there are four key components to green infrastructure, consisting of natural vegetation, water management systems, urban design, and ecosystem services (Corrigan, 2023). In order, these categories include factors such as parks, forests, and green roofs; rain gardens, permeable pavements, and bioswales; mixed-use spaces, walkable areas, and connections between greenspaces; and a range of beneficial services, such as improved air and water quality, biodiversity support, etc. (Corrigan, 2023).

After reading this list, there were a couple terms I wanted to know more about, as I was unfamiliar with “bioswales” and “permeable pavement”.

According to the City of Calgary (2016), bioswales are stormwater management practices that can reduce runoff and provide storage for excess water in ways that mimic the landscape’s own water cycle practices. A functional bioswale will consist of a growing media layer, a filter layer, rock reservoir, underdrain pipe leading to the storm sewer system, an emergency overland escape route, and vegetation on the surface to protect and rejuvenate the growing media (City of Calgary, 2016). In addition to providing an important mechanism for stormwater management, bioswales provide habitat for increased biodiversity, carbon sequestering, and an appealing visual (City of Calgary, 2016).

Permeable/porous pavement is, as one would assume, a replacement for standard asphalt or concrete that will allow rainfall to pass through (Capital Regional District). This can take the form of individual paving blocks or cobblestones; plastic or other grid systems filled with sand, gravel, or living plants; or mixed concrete and asphalt that create a permeable surface (Capital Regional District). There is significant variation within these forms that can be chosen based on purpose, aesthetic, or material availability (Capital Regional District). Some notable advantages of this pavement are reduction of runoff volume, pollutant removal, groundwater recharge, heat management, and even greater longevity than many commonly used asphalt surfaces (Capital Regional District).

I would be curious to hear from others about what interesting green infrastructure you know of being planned or implemented!

References

City of Calgary. (2016). Low Impact Development Guidelines. https://www.calgary.ca/content/dam/www/uep/water/documents/water-documents/development-approvals-documents/2019/module-two-bioretention-bioswales.pdf

Corrigan, S. (2023). How to build resilient cities with green infrastructure. Citygreen: Urban Landscape Solutions. https://citygreen.com/green-infrastructure-in-urban-planning/

Permeable Paving. Capital Regional District. (n.d.). https://www.crd.bc.ca/education/stormwater-wastewater-septic/green-stormwater-infrastructure/permeable-paving

1 note

·

View note

Text

Pressure Washing Chemicals for Roof Cleaning: Safe and Effective Solutions

Maintaining a clean roof is essential not only for aesthetic reasons but also for the longevity of the structure. Over time, roofs can accumulate dirt, mold, algae, and other debris that can weaken the roof’s materials and reduce their effectiveness. Pressure washing has emerged as one of the most efficient methods to keep roofs clean. However, without the right pressure washing chemicals, the process might not deliver the desired results, and it could even harm the roof.

This article explores safe and effective solutions when using pressure washing chemicals for roof cleaning and offers tips to use pressure washing chemicals properly for optimal results.

The Importance of Choosing the Right Chemicals

Before diving into the pressure washing process, it's crucial to choose the right chemicals to ensure safe and effective cleaning. Roofs are made from different materials, including asphalt shingles, metal, tile, or wood, each requiring specific care. Using harsh chemicals or the wrong type of cleaner can damage these materials, leading to costly repairs or even roof replacement. On the other hand, selecting the right pressure washing chemicals will not only clean but also protect your roof, extending its lifespan.

Common Types of Roof Cleaning Chemicals

When it comes to pressure washing roofs, several types of chemicals are commonly used, each with specific functions:

Sodium Hypochlorite (Bleach-based cleaners): Sodium hypochlorite is a powerful chemical often found in roof cleaning solutions. It effectively kills algae, mold, and mildew while lifting dirt from the roof surface. However, it must be used with caution, as high concentrations can be harmful to vegetation and may discolor certain types of roofs.

Sodium Hydroxide (Lye): This is a heavy-duty cleaning agent, ideal for removing grease, oil, and organic stains. It's highly effective but requires careful handling due to its corrosive nature. It is typically diluted in pressure washing solutions to minimize the risk of damage to roof surfaces and surrounding areas.

Trisodium Phosphate (TSP): TSP is commonly used in roof cleaning products as a degreaser and detergent. It works well on tough stains and is generally considered safe for roofs. However, it may need to be combined with other chemicals for more stubborn organic growths like moss or lichen.

Ammonium Compounds (Quats): Quaternary ammonium compounds are non-corrosive chemicals that are effective in killing moss, algae, and fungi. These are gentler than bleach-based cleaners and are often used for roofs with delicate surfaces such as tile or slate.

Eco-friendly Cleaners: Many homeowners prefer eco-friendly pressure washing chemicals that are biodegradable and non-toxic. These solutions are typically less aggressive but can still offer effective cleaning, especially when combined with high-pressure water.

Safe and Effective Tips to Use Pressure Washing Chemicals

To ensure the safety and effectiveness of your roof cleaning, here are some key tips to use pressure washing chemicals:

Choose the Right Chemical for Your Roof Material: Each roof material reacts differently to chemicals. For example, sodium hypochlorite works well for asphalt shingles but might not be suitable for metal or wood roofs. Research your roof type and use only compatible cleaning agents.

Dilute Chemicals Properly: Concentrated chemicals can cause damage not only to the roof but also to plants, gutters, and nearby structures. Always follow the manufacturer’s instructions on dilution ratios. This ensures that the chemical is effective without being overly harsh.

Pre-wet the Roof and Surrounding Areas: Before applying any chemical, pre-wet the roof and the plants around your house. Wetting the surface helps reduce the absorption of chemicals into the roof material, minimizing the risk of damage. Pre-wetting plants and shrubs protects them from potential chemical runoff.

Apply with Low Pressure: Even though pressure washing involves using high-pressure water, roofs are delicate surfaces. When applying chemicals, use low pressure to avoid damaging shingles or tiles. Once the chemical has been applied, allow it to sit for 10-20 minutes to loosen the dirt and kill the algae or moss before rinsing with higher pressure.

Rinse Thoroughly: After the cleaning solution has done its job, ensure that you rinse the roof thoroughly with clean water. Any residual chemicals left on the surface can weaken roofing materials over time. Pay particular attention to any chemical runoff, ensuring that it doesn’t pool around plants or drainage areas.

Perform Regular Maintenance: While a deep clean using pressure washing chemicals may only be necessary once every few years, regular maintenance is key. Use gentler cleaners and low-pressure washes every 6-12 months to prevent significant buildup of debris, mold, or algae.

Eco-friendly and Safety Considerations

Whenever using pressure washing chemicals, consider both environmental impact and safety. Avoid letting chemical runoff enter storm drains, rivers, or lakes, as many of these cleaning agents can be toxic to aquatic life. You can also opt for biodegradable cleaners that are less harmful to the environment while still being effective against stains and organic growth on your roof.

Additionally, always use personal protective equipment (PPE) when handling chemicals. Gloves, eye protection, and non-slip shoes are essential to avoid accidents. If you’re unsure about using chemicals safely, hiring a professional pressure washing service is a safer alternative.

Conclusion

Pressure washing your roof can be a highly effective way to maintain its cleanliness and prolong its lifespan, but only if the right chemicals are used properly. By following the appropriate safety measures and tips to use pressure washing chemicals, you can achieve a clean roof without compromising its integrity or harming the environment.

With the right solutions and techniques, your roof can remain in top condition for years, protecting your home and enhancing curb appeal.

0 notes

Text

Batch Mix or Drum Mix Plant? A Comparison for Your Project

When choosing the right asphalt plant for your construction project, understanding the differences between drum mix and batch mix plants is crucial. Each type of plant has its unique features, benefits, and limitations that can significantly impact your project’s efficiency, cost, and quality. In this blog, we’ll dive into the details of each plant type, compare them, and offer tips to help you make an informed decision.

Asphalt Mixing Plants

Asphalt mixing plants are essential in road construction, providing the asphalt needed for paving. There are two primary types of asphalt mixing plants: drum mix plants and batch mix plants. Each has its own operational mechanisms and use cases.

Asphalt Drum Mix Plant

How It Operates

An asphalt drum mix plant continuously produces asphalt by combining aggregates, bitumen, and additives in a drum. The materials are fed into the drum where they are heated and mixed in a continuous flow process. The mixture is then discharged from the drum and can be used immediately.

Key Components

Drum Mixer: The core component where mixing takes place.

Cold Aggregate Feeder: Feeds aggregates into the drum.

Burner: Heats the aggregates and bitumen.

Control Panel: Manages the operation and quality control.

Bitumen Tank: Stores and supplies bitumen to the mixer.

Advantages

Continuous Production: Allows for constant operation and high output.

Lower Operating Costs: Less fuel and labor compared to batch plants.

Simple Design: Easier to operate and maintain.

Disadvantages

Lower Quality Control: Less precise control over mix quality compared to batch plants.

Limited Flexibility: Harder to adjust mix designs and proportions.

Higher Emissions: Can have a greater environmental impact due to continuous operation.

Ideal Use Cases

Large-Scale Projects: Suitable for projects requiring high production volumes.

Road Paving: Efficient for continuous paving jobs where consistent quality is less critical.

Asphalt Batch Mix Plant

Description and Functionality

An asphalt batch mix plant produces asphalt in batches rather than continuously. The plant mixes a predetermined quantity of aggregates and bitumen at a time, allowing for precise control over the mix.

How It Operates

The batch mix process involves heating and mixing aggregates and bitumen in discrete batches. The process ensures that each batch meets specific quality standards before being discharged for use.

Key Components

Batcher: Measures and batches the aggregates.

Drying Drum: Heats the aggregates before mixing.

Mixing Tower: Combines aggregates with bitumen in a controlled environment.

Control System: Provides precise control over mix formulations and quality.

Cold Aggregate Feeder: Delivers aggregates to the drying drum.

Advantages

Superior Quality Control: Provides more precise and consistent mix quality.

Flexibility: Easier to adjust mix designs and proportions for different projects.

Lower Emissions: Typically more environmentally friendly due to batch processing.

Disadvantages

Higher Initial Cost: More expensive to purchase and set up.

More Complex Operation: Requires more skilled labor and maintenance.

Lower Production Capacity: Generally produces less asphalt compared to drum mix plants.

Ideal Use Cases

High-Quality Pavements: Best for projects requiring stringent quality control and varied mix designs.

Smaller to Medium Projects: Suitable for projects where flexibility and mix quality are critical.

Comparative Analysis

Production Efficiency

Drum Mix Plants: Higher production efficiency due to continuous operation.

Batch Mix Plants: Lower production efficiency as it operates in batches but provides higher quality control.

Mix Quality

Drum Mix Plants: May have more variability in mix quality.

Batch Mix Plants: Offers superior control and consistency in mix quality.

Environmental Impact

Drum Mix Plants: Potentially higher emissions due to continuous operation.

Batch Mix Plants: Generally lower emissions and better adherence to environmental regulations.

Cost Considerations

Drum Mix Plants: Lower operational costs and initial investment but less flexibility.

Batch Mix Plants: Higher initial costs but can result in cost savings through improved quality and reduced waste.

Flexibility and Adaptability

Drum Mix Plants: Less flexible in terms of mix design changes.

Batch Mix Plants: More adaptable to different mix designs and requirements.

Factors to Consider When Choosing a Plant

Project Size and Scope

Consider the scale of your project. Larger projects with high asphalt demand may benefit from the continuous production of drum mix plants, while smaller or quality-focused projects may be better suited to batch mix plants.

Budget Constraints

Assess your budget for both initial investment and ongoing operational costs. Drum mix plants generally have lower initial costs, whereas batch mix plants, though more expensive upfront, can offer long-term savings through quality control.

Environmental Regulations

Ensure that the plant you choose complies with local environmental regulations. Batch mix plants often have an edge in meeting stringent environmental standards.

Quality Requirements

Evaluate the quality standards required for your project. If high-quality, consistent asphalt is critical, a batch mix plant may be the better choice.

Consult a Leading Construction Equipment Manufacturer Today!

Choosing the right asphalt plant can significantly impact the success of your project. For personalized advice and to explore the best options for your needs, consult with a leading construction equipment manufacturer. They can provide valuable insights and recommendations tailored to your specific project requirements.

For more information, read our detailed comparison and make an informed decision that ensures the best outcomes for your asphalt mixing needs.

Visit at: Batch Mix or Drum Mix Plant? A Comparison for Your Project

0 notes