#Aluminum Extrusion Electrical Panel

Explore tagged Tumblr posts

Text

#Aluminum Extrusion Electrical Panel#Aluminium Profiles For power Distribution#Aluminium Extrusion Profiles for Solar Panels#Aluminium Profile For Solar Panel#aluminium window profile manufacturers in india#aluminium window profile manufacturers

0 notes

Text

Alpha 1 (1979) by "Bill". "Alpha 1 (pictured here in front of my parents' garage) was built around 1979, and was primarily a "show" robot. He never had any real "brains" (unless you count the mass of pink-spraypainted styrofoam peanuts in the dome), but was remote-controlled by a set of switches at the end of a 20 foot cable. He stood over 6 feet tall, and was entirely exo-skeletal, with no internal supports. He was built almost entirely of sheet aluminum, with a plywood base. He was powered by two "gel-cell" marine batteries stacked vertically in his lower torso, which could be disconnected at the "waist" for transport. Two heavy-duty motorized wheels provided movement. From the control panel, the operator could run either wheel forward or backward, steering like a tank. He could also raise and lower both arms, open and close the hands, and extend and retract the two power car antennas on the sides of the head. Lights on the "face" came from car dashboard indicators and turn signals, and were flashed and sequenced by some simple electronics. The arms were operated by electric car-window motors and gear-boxes, and the hands were made from bicycle brake calipers and steel extrusions actuated by 12volt "linear actuators", and were capable of crushing pop cans flat (steel, back then - not aluminum!) and cracking nuts. Alpha could also grab a rope or chain suspended from the ceiling and actually lift himself off the ground with one hand. Not bad, considering he weighed in at over 150 lbs! He once made a trip to a demo at the 1987 Nebraska State Fair, riding "standing up" in the passenger's seat of my tiny Fiat X1/9. With the car's removable top off, "Alphie's" head stuck up over 4 feet above the windshield. I seat-belted him in, turned on his lights, and enjoyed the dropping jaws of other motorists. I think we nearly caused some accidents that day…" – My Home Robot Projects, by Bill.

16 notes

·

View notes

Text

Choosing the Right Aluminum Supplier for Strength and Versatility

Aluminum is one of the most widely used materials in construction, manufacturing, and various industries due to its lightweight, corrosion resistance, and durability. A reliable aluminum supplier ensures access to premium-quality aluminum products for applications ranging from architectural structures to industrial machinery and household items. Selecting the right supplier can make a significant difference in the quality, efficiency, and cost-effectiveness of your projects.

Why Choose a Trusted Aluminum Supplier?

High-Quality Materials – Reputable suppliers provide aluminum with superior strength, corrosion resistance, and finish quality.

Variety of Products – From sheets and coils to extrusions and bars, a good supplier offers a wide range of aluminum products.

Customization Options – Many suppliers provide customized aluminum solutions, including cutting, bending, and anodizing.

Competitive Pricing – A trusted supplier ensures fair pricing without compromising on quality.

Reliable Delivery & Stock Availability – Ensuring timely supply of materials is crucial for industrial and construction projects.

Sustainability & Recycling – Many suppliers focus on eco-friendly aluminum production and recycling processes.

Types of Aluminum Products Offered by Suppliers

Aluminum Sheets & Plates: Used in construction, automotive, and aerospace applications.

Aluminum Extrusions: Custom profiles for doors, windows, frames, and industrial uses.

Aluminum Coils & Foils: Commonly used in packaging, electronics, and roofing.

Aluminum Tubes & Pipes: Ideal for transportation, HVAC systems, and structural applications.

Anodized & Coated Aluminum: Provides enhanced durability and aesthetic appeal.

Industries That Rely on Aluminum Suppliers

Construction & Architecture: Used in facades, doors, windows, and structural components.

Aerospace & Automotive: Lightweight and strong material for aircraft, vehicles, and transportation.

Manufacturing & Industrial Applications: Components for machinery, equipment, and consumer goods.

Electronics & Electrical Industry: Used in heat sinks, casings, and wiring applications.

Renewable Energy: Aluminum is widely used in solar panels and wind turbines.

How to Choose the Best Aluminum Supplier?

Reputation & Experience: Check reviews, industry presence, and track record.

Material Quality & Certification: Ensure the supplier meets industry standards and provides certified aluminum.

Customization & Processing Capabilities: Look for suppliers offering cutting, bending, and coating services.

Delivery & Logistics Support: A supplier with efficient distribution ensures on-time deliveries.

Sustainability Practices: Eco-conscious suppliers contribute to reducing environmental impact.

Conclusion

Choosing the right aluminum supplier is essential for ensuring high-quality, durable, and cost-effective aluminum products for your projects. Whether you need aluminum for construction, manufacturing, or specialized applications, partnering with a trusted supplier guarantees superior performance and long-term value. Invest in quality aluminum today and enhance the efficiency and reliability of your operations.

0 notes

Text

Aluminum Extrusion Market Report: Opportunities and Challenges (2023-2032)

The Aluminum Extrusion Market is projected to grow from USD 81,423.94 million in 2023 to an estimated USD 162,766.83 million by 2032, with a compound annual growth rate (CAGR) of 8.00% from 2024 to 2032.

The Aluminum Extrusion Market is witnessing significant growth due to its increasing applications across various industries such as construction, automotive, aerospace, and electronics. Aluminum extrusion involves shaping aluminum alloy into desired profiles using a hydraulic press, offering benefits like lightweight, corrosion resistance, and high strength-to-weight ratio. The construction industry remains the largest end-user, driven by the demand for energy-efficient and sustainable building materials. Additionally, the automotive sector is increasingly adopting aluminum extrusions to enhance vehicle performance and fuel efficiency. Key market players, including Norsk Hydro ASA, Arconic Inc., and Constellium N.V., are focusing on innovation and expanding their production capabilities to meet the growing demand. The Asia-Pacific region dominates the market, with China being the largest producer and consumer of aluminum extrusions, followed by North America and Europe. Technological advancements, along with the rising emphasis on recycling and eco-friendly manufacturing processes, are expected to further propel market growth.

The Aluminum Extrusion Market is influenced by various dynamic factors that drive its growth and shape its future. Understanding these dynamics is crucial for stakeholders to navigate the market effectively. Key market dynamics include:

Drivers:

Growing Demand in Construction: The construction industry is a major driver of the aluminum extrusion market. The need for lightweight, durable, and energy-efficient materials in building and infrastructure projects is fueling the demand for aluminum extrusions. Aluminum's ability to be easily shaped and its strength-to-weight ratio make it ideal for windows, doors, curtain walls, and structural components.

Automotive Industry Adoption: The automotive industry is increasingly adopting aluminum extrusions to reduce vehicle weight and enhance fuel efficiency. The shift towards electric vehicles (EVs) further boosts this demand, as lightweight materials are essential for improving battery life and performance. Aluminum extrusions are used in various automotive parts, including chassis, frames, and body panels.

Technological Advancements: Innovations in extrusion technology, such as advanced die design and automation, are enhancing the efficiency and quality of aluminum extrusion processes. These advancements enable the production of complex and precise profiles, meeting the specific needs of various industries.

Sustainability and Recycling: Aluminum is highly recyclable, and the emphasis on sustainability is driving the adoption of recycled aluminum in extrusion processes. The ability to recycle aluminum without losing its properties makes it an attractive material for environmentally conscious manufacturers and consumers.

Restraints:

Volatility in Raw Material Prices: Fluctuations in the prices of raw materials, particularly aluminum ingots, can impact the profitability of aluminum extrusion manufacturers. Price volatility is influenced by factors such as changes in supply and demand, geopolitical issues, and trade policies.

High Initial Costs: The setup and operational costs associated with aluminum extrusion facilities can be high. Investments in advanced machinery, dies, and skilled labor are substantial, which can be a barrier for new entrants and small-scale manufacturers.

Competition from Alternative Materials: While aluminum offers many advantages, it faces competition from other materials such as steel, composites, and plastics. These materials may be preferred in certain applications due to their specific properties or lower costs.

Opportunities:

Expansion in Emerging Markets: Emerging economies, particularly in Asia-Pacific and Latin America, present significant growth opportunities for the aluminum extrusion market. Rapid urbanization, industrialization, and infrastructure development in these regions drive the demand for aluminum extrusions.

Development of New Applications: Continuous research and development efforts are leading to the discovery of new applications for aluminum extrusions. Innovations in product design and material science are expanding the use of aluminum extrusions in industries such as aerospace, electronics, and renewable energy.

Integration with Advanced Manufacturing Techniques: The integration of aluminum extrusion with advanced manufacturing techniques such as 3D printing and additive manufacturing offers new possibilities for creating complex and customized profiles. This integration enhances the versatility and application range of aluminum extrusions.

Challenges:

Environmental Regulations: Compliance with stringent environmental regulations related to emissions and waste management can pose challenges for aluminum extrusion manufacturers. Adapting production processes to meet these regulations requires significant investment and continuous monitoring.

Skilled Labor Shortage: The aluminum extrusion industry requires skilled labor for the design, operation, and maintenance of extrusion machinery. A shortage of skilled workers can impact production efficiency and quality, posing a challenge for manufacturers.

Key players

Arconic Corp.

Bahrain Aluminum Extrusion Company

Constellium N.V.

Gulf Extrusions Co. LLC

Hindalco Industries Ltd.

Kaiser Aluminum

Norsk Hydro ASA

QALEX

More About Report- https://www.credenceresearch.com/report/aluminum-extrusion-market

The Aluminum Extrusion Market is evolving rapidly, driven by advancements in technology, shifting consumer preferences, and increasing demand across various industries. Key trends shaping the market include:

1. Lightweighting in Automotive and Aerospace Industries:

Automotive: The push for fuel efficiency and reduced emissions is driving the use of aluminum extrusions in vehicle manufacturing. Aluminum is increasingly used for body frames, engine components, and chassis, contributing to lighter vehicles and improved performance. The rise of electric vehicles (EVs) further accelerates this trend, as lighter materials enhance battery efficiency and range.

Aerospace: Similarly, the aerospace industry is adopting aluminum extrusions to reduce aircraft weight, thereby improving fuel efficiency and payload capacity. The demand for high-strength, lightweight materials is driving innovation in extrusion technologies for aerospace applications.

2. Sustainability and Recycling:

The aluminum extrusion market is benefiting from the growing emphasis on sustainability and the circular economy. Aluminum is highly recyclable, and using recycled aluminum reduces energy consumption and environmental impact. Companies are investing in technologies and processes that enhance recycling efficiency and promote the use of recycled materials in extrusion products.

3. Advancements in Extrusion Technology:

Technological advancements in extrusion processes are enabling the production of complex and precise profiles. Innovations such as multi-hole dies, improved cooling systems, and automation are enhancing productivity and product quality. These advancements allow for greater design flexibility and the ability to meet specific application requirements in various industries.

4. Expansion in Emerging Markets:

Emerging economies, particularly in Asia-Pacific and Latin America, are witnessing rapid industrialization and urbanization, driving the demand for aluminum extrusions. Infrastructure development, construction projects, and the growth of manufacturing sectors in countries like China, India, and Brazil are creating significant market opportunities. Increased foreign investments and government initiatives to boost infrastructure further support this trend.

5. Growth in the Construction Sector:

The construction industry remains a major consumer of aluminum extrusions. The demand for energy-efficient and sustainable building materials is driving the use of aluminum in windows, doors, curtain walls, and structural components. Aluminum's durability, corrosion resistance, and aesthetic appeal make it an ideal choice for modern construction projects. The trend towards green buildings and sustainable architecture is further boosting the adoption of aluminum extrusions.

6. Customization and Tailored Solutions:

There is a growing demand for customized aluminum extrusion solutions that meet specific design and performance criteria. Manufacturers are offering tailored extrusions to cater to unique requirements in industries such as electronics, medical devices, and consumer goods. The ability to provide bespoke solutions enhances customer satisfaction and opens new market opportunities.

7. Integration with Advanced Manufacturing Techniques:

The integration of aluminum extrusion with advanced manufacturing techniques such as additive manufacturing (3D printing) is creating new possibilities for complex and intricate designs. This integration allows for the production of components with enhanced functionality and reduced material wastage. It also facilitates rapid prototyping and small-batch production, meeting the needs of innovative and specialized applications.

8. Digitalization and Industry 4.0:

The adoption of digital technologies and Industry 4.0 principles is transforming the aluminum extrusion industry. Smart manufacturing, IoT-enabled equipment, and data analytics are improving process control, efficiency, and product quality. Digitalization enables real-time monitoring, predictive maintenance, and optimization of extrusion operations, enhancing overall productivity and competitiveness.

Segments

Based on Product

Shapes

Rods and Bars

Pipes and Tubes

Based on Application

Building & Construction

Automotive & Transportation

Consumer Goods

Electrical & Energy

Other Applications

Browse the full report – https://www.credenceresearch.com/report/aluminum-extrusion-market

Browse Our Blog: https://www.linkedin.com/pulse/aluminum-extrusion-market-analysis-bm14f

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Automotive Aluminum Market Trends: Driving Industry Innovation

The automotive aluminum market comprises aluminum and aluminum alloy sheets, extrusions and castings that are used in various automotive components and parts due to their light weight and corrosion resistance properties. Aluminum helps reduce vehicle weight and improve fuel efficiency. It is used in engine components, wheels, structural parts and body panels of automobiles.

The Global Automotive Aluminum Market is estimated to be valued at US$ 58.33 Billion in 2024 and is expected to exhibit a CAGR of 12% over the forecast period from 2024 to 2031. Key players operating in the automotive aluminum market are Alcoa Inc., Arconic Inc., UACJ Corporation, CHALCO, AMG Advanced Metallurgical Group, Norsk Hydro ASA, Constellium N.V., Novelis Inc., and Rio Tinto Group. Second paragraph is talking about the growing demand in market and third paragraph is talking about global expansion of market. Key players related content comprises key players related content. Key players operating in the automotive aluminum market are Alcoa Inc., Arconic Inc., UACJ Corporation, CHALCO, AMG Advanced Metallurgical Group, Norsk Hydro ASA, Constellium N.V., Novelis Inc., and Rio Tinto Group. The increasing production of electric vehicles worldwide is fueling the demand for lightweight automotive aluminum. Aluminum helps electric vehicles achieve longer driving ranges by enhancing efficiency. Apart from increasing electric vehicle adoption, stringent fuel efficiency and emission norms are also driving the need for lightweight materials in conventional gasoline vehicles. This is positively impacting the adoption of automotive aluminum across different vehicle segments. Furthermore, aluminum use allows automakers to meet Corporate Average Fuel Economy (CAFE) standards mandated in the USA and Canada as well as emission regulations worldwide. Geographically, the Asia Pacific region dominates the global automotive aluminum market and the trend is expected to continue during the forecast period. This is attributed to presence of emerging economies like China and India where electric vehicle sales are surging exponentially along with quick growth of the automotive industry. Various automakers are setting up aluminum production facilities or partnering with aluminum producers in the region to ensure adequate metal supply and cost competitiveness. Market key trends:

One of the key trends gaining momentum in the global automotive aluminum market is the rising preference for aluminum-intensive vehicle architecture using principles of modular construction. This allows flexible combination of different body variants on the same platform with aluminum. Using aluminum extrusions and castings enables modular vehicle design and assembly. This helps automakers offer diversified model options to customers while reducing development costs through commonalization.

Porter’s Analysis Threat of new entrants: New automotive aluminum companies find it difficult to enter the market due to high initial investments and established brand loyalty of customers towards existing big players. Bargaining power of buyers: Buyers have moderate bargaining power due to availability of close substitute materials like steel and presence of many established aluminum suppliers. Bargaining power of suppliers: A few large companies dominate the global aluminum supply chain, giving them significant influence on prices of aluminum needed by automotive industry. Threat of new substitutes: Aluminum faces competition from substitute materials like plastics, magnesium and carbon fiber, but it is irreplaceable for its light weight and corrosion resistance properties in automotive applications. Competitive rivalry: Intense competition exists among key players to improve production capacities and offer innovative aluminum solutions. Geographical Regions North America dominates the global automotive aluminum market in terms of value due to large automotive production and presence of key market players in the US and Canada. Asia Pacific is projected to be the fastest growing regional market between 2024-2031 encouraged by increasing vehicle manufacturing and use of aluminum body panels in China and India to reduce vehicle weight for improving fuel efficiency.

0 notes

Text

Aluminium Sheet Dealers In Chennai

Aluminium Sheets or Plates, Grade and Specifications

Aluminum sheet or aluminum plate is the result of the basic process of raw aluminum being pressed and rolled into a sheet under high pressure. It is commonly used as kitchen utensils and packaging in the food industry. Aluminum panels are also commonly used for automotive bodies and frames. This metal sheet is also commonly used in the building and construction industry for items such as partitions, drains, etc.

Aluminumor aluminium is also a very popular metal used as sheet metal due to its flexibility, wide-ranging options, cost effectiveness, and other properties. The four most common aluminium grades available as sheet metal include -

1100-H14

3003-H14

5052-H32

6061-T6

Tempered & Grade Aluminium

Grade 6082 is the most common commercial aluminum profile and sheet, while T6 is the most common tempered grade.

Grade 6063 is a medium-strength alloy, it is the most common aluminum for extrusion.

When it comes to commercial aluminum profiles, T6 is the most popular tempered aluminum available.

If you need high quality aluminium sheets, you should contact aluminium sheet dealers in Chennai.Aluminium metal and its alloys are widely used in aircraft manufacturing, building materials, durable consumer goods (refrigerators, ACs, cooking utensils), electrical conductors, chemical equipment, etc. substances and food.

Specifications Aluminum alloy sheet

Width----------------------------------------600-1300mm

Thickness------------------------------------0.8-3.0mm

Alloy------------------------------------------1050, 1060, 1100, 3003, 8011

Temper---------------------------------------H12, H14, H16, H18, H22, H24, H26

Why Metal & Alloy Industries

Metal &Alloy Industries is one of the best aluminium sheet dealers in Chennai providing a qualityrange of aluminium sheets or plates of different specifications. Our expertise lies in providing quality aluminum sheets made of quality raw materials.

They are known for their durability, corrosion resistance, rugged construction, and load-carrying properties. Its range is sourced from trusted and certified sources who design these panels and panels according to industry standards and regulations.The company specializes in providing customers with a wide range of Aluminum Sheets in various shapes such as hexagonal, wire, rectangular, flange, valve, coupling, nipple, block, and angle.

0 notes

Text

Exploring the Versatility and Applications of Section Aluminium

Section aluminium, also known as aluminum extrusions, is a fascinating and versatile material that has revolutionized various industries due to its unique properties and wide range of applications. This article delves into the world of section aluminium, shedding light on its composition, manufacturing process, and the diverse fields it impacts. From construction and transportation to consumer electronics and renewable energy, section aluminium's adaptability has made it an indispensable resource in modern engineering.

The Anatomy of Section Aluminium:

Section aluminium is a type of aluminium that is transformed into specific shapes through the extrusion process. It begins as raw aluminium billets, which are heated and then pushed through a die to create the desired cross-sectional profile. The resulting sections can have intricate designs, and their dimensions can range from simple rods and bars to complex geometries. This process allows for precise customization and adaptability, making section aluminium suitable for a wide range of applications.

Manufacturing Process and Sustainability:

The extrusion process used to create section aluminium offers several advantages in terms of sustainability. The energy required for extrusion is relatively low compared to other manufacturing methods, and the process generates minimal waste. Additionally, aluminium is highly recyclable, allowing section aluminium to contribute to circular economy practices. Manufacturers often use recycled aluminium to produce section aluminium, further reducing its environmental impact.

Applications Across Industries:

Section aluminium's versatility is reflected in its extensive applications across various industries:

a. Construction: Section aluminium plays a crucial role in modern construction, offering lightweight, durable, and corrosion-resistant solutions for structural components, curtain walls, windows, and doors.

b. Transportation: The automotive and aerospace industries utilize section aluminium for its weight-saving properties, contributing to fuel efficiency and improved performance.

c. Consumer Electronics: Section aluminium is used in the manufacturing of electronics casings, heat sinks, and frames due to its thermal conductivity and electrical properties.

d. Renewable Energy: Solar panel frames, wind turbine components, and other renewable energy systems benefit from section aluminium's strength and resistance to harsh environmental conditions.

e. Furniture and Design: The design and furniture sectors leverage section aluminium's malleability to create modern, aesthetically pleasing pieces that are both functional and stylish.

Innovations and Future Prospects:

Ongoing research and technological advancements continue to enhance the properties of section aluminium. New alloy compositions and surface treatments are being developed to improve strength, corrosion resistance, and overall performance. As industries push the boundaries of what is possible, section aluminium is expected to remain at the forefront of innovative engineering solutions.

Section aluminium, with its remarkable versatility, sustainable manufacturing process, and wide-ranging applications, has become a staple material in various industries. Its ability to adapt to diverse requirements while maintaining structural integrity and aesthetic appeal makes it an indispensable asset for modern engineering and design.

0 notes

Text

Aluminium Formwork System Technology

Shashikant Zarekar - Brand Manager

The important element of having a successful structural construction is to have the right formwork system. That is, to have formwork system which has high trust and safety factor and is manufactured as per up-to-date technology available in the market. Alu-Form technology is used to produce high quality durable and affordable buildings. This technology incorporates electrical fittings, plumbing with greater efficiency as a part of overall building plan. Hence, you should look for below characteristics to choose correct Formwork System for your project:

Trustful, Secure, Efficient, and Cutting-Edge technology.

A good formwork is made up of high-strength aluminium extrusion which weighs very less compared to steel formwork. This technology helps to achieve more superior concrete finishing and quicker completion of project construction.

Advantages of Aluminium Formwork System Technology

Below are the key benefits:

1. Improvement in Quality: The Aluminum Formwork technology results in good concrete finishing which does not require plastering and eliminates grinding task due to joints created by panels. 2. Ecofriendly: The best advantage of Aluform Technology is the repetition. The Aluminum panels can be recycled event after 250 repetitions compared to max repetition of 50 in Steel Formwork and about 5-10 repetition in Conventional Formwork. This ability to recycle results in less harm to the environment. 3. Reduction in Cost: As this technology requires assembly period of 6-10 days cycle, a Reduction in the construction period will directly result in reduction of cost of the construction. 4. Safety: The method of formwork system allows large working area for jobsite workers (with fewer props) and increase in their efficiency. 5. Design and Jobsite Planning: The Aluminum Formwork is a “modular” formwork; i.e. there is no constraint on any architectural or structural design.

To know more about us follow the link given below:

0 notes

Text

File Under Wierd Stuff I have heard.

I have seen and heard a lot of stuff. Some were impressive others not so much. I just found a rare bird for sale on Quebec.

This is from the CAM online listing.

This is a Bertagni BES D120 dipole speaker array. BES stands for Bertagni Electro Acoustic Systems. The ad claims US made which may be true. I recall a connection to Argentina. A friend even bought a pair of D60s which is basically 1/2 of this thing. And yes I heard them. Once in a store and later at my friend's place.

These are interesting as the speaker is a metal frame that holds conventional voice coils forming magnet motors. The voice coil is attached to the back of a foam slab. The foam slab is the speaker. There is some funky shaping and contouring of the foam. I recall Yamaha tried something similar.

There is a woofer part a mid-range part and a tweeter. The Tweeter is a piezo-electric disk the others are conventional motors. There is another slab on the back normally so it is basically a damped dipole. The surface area is BIG so it actually ties to the air pretty well.

Here is the back side removed from a picture I pulled off the interweb. The thing in the middle of each panel is the woofer motor.

The concept is clever. It is a different solution to the speaker cone problem or the planar diaphragm problem or something like that.

My recollection is very faded. My reference at the time was double Advents so the room impression at the dealer was positive. My friend bought some, had them for a few weeks ,then sold them. It was mostly the small room being the problem I think. They never sounded right. The Frame was aluminum extrusion so it could be improved with more mass and probably damping of the frame somehow. However it sounds stock it would benefit from tweaking.

They look cool and sound comes out. It is not a bad concept really. And if rare is a turn on yup it is rare.

I think everything has been tried at one time or another.

2 notes

·

View notes

Text

Aluminium Extrusion Profiles

Discover top-quality aluminium extrusion profiles at DHAATU FABEX, your trusted source for durable and innovative aluminum solutions. We offer a wide range of profiles tailored for various applications, including architectural, industrial, and custom designs. Our products are engineered with precision to deliver strength, lightweight performance, and long-lasting durability. For More Details Visit Us.

#Aluminium Extrusion Profiles#Automotive Aluminium#Aluminum Extrusion Electrical Panel#aluminium construction profiles#aluminium ips tube manufacturer

0 notes

Text

Advantages of Making UV DTF Stickers

When people's understanding of transparent materials still stays in glass products, acrylic is gradually replacing glass through its performance advantages. How excellent is this kind of material with transparent texture, gorgeous colors, patterns, and shapes? We will introduce it from the following aspects.

What is acrylic

Acrylic is commonly known as specially treated plexiglass, a chemical name polymethylmethacrylate. Its transparency and light transmittance are like glass. It is an important thermoplastic. The research and development of acrylic have a history of 100 years. The polymerizability of acrylic acid was discovered in 1872; The polymerizability of methacrylic acid was known in 1880; In 1901, after the research on the synthesis method of propylene propionate was completed, it was mostly used in industry, such as aircraft windshields, tank field mirrors, etc. Until 1948, the birth of the world's first acrylic bathtub marked a new milestone in the application of acrylic in the design industry.

Manufacturing technology of acrylic

sheet

The molding process of acrylic sheets is divided into casting, injection molding, extrusion, thermal molding, etc.

Casting molding is mainly used for the molding of plates and bars. The formed acrylic products need to be processed before they can be used. The cast acrylic plate has strong rigidity and strength, and also has strong flexibility in color and texture.

Characteristics of acrylic

Light density, acrylic is a very light material, and the density is only 1.17 ~ 1.20g/cm ³, It is about half of the ordinary glass and 43% of metallic aluminum.

High light transmittance and the light transmittance of the pure acrylic transparent plates are more than 90%. Similarly, with 6mm as the reference, compared with glass, the light transmittance of ordinary glass is generally 82-83%, and that of 6mm ultra-white glass is 90% - 92%.

The impact resistance is strong, 16 times that of ordinary glass, and there is almost no risk of fracture.

Acrylic has excellent electrical insulation, which should be found in many electronic products, such as some very small component insulators used in tablet computers, mobile phones, computers, stereos, televisions, and other products.

It is not afraid of moisture, water, mold, and bacteria. Acrylic is very waterproof and moisture-proof. It can be used to make fish tanks and bathtubs. It can also be used to make endless swimming pools and aquariums.

Acrylic has strong plasticity and can be processed into the desired shape at will. Acrylic materials are lighter than ordinary glass materials, and the cutting and processing technology is not complex, so acrylic products can basically meet the customized needs of all walks of life.

The difference between acrylic and PVC. Acrylic and PVC are two completely different materials. PVC board is a board with a honeycomb mesh structure made of PVC as raw material. It is a kind of vacuum plastic film, which is used for the surface packaging of all kinds of panels, so it is also called decorative film and adhesive film and is used in building materials, packaging, medicine, and many other industries.

UV DTF stickers

&

Acrylic

sheets

UV DTF stickers have appeared in the industry a few years ago, but the public does not know much about this emerging product, and the name can not directly express what it is. With the development of technology and more people participating in the industry, an intuitive name has been made for UV transfer stickers, that is, crystal labels, named for their crystal clear appearance.

The acrylic background wall made with UV DTF stickers is not only beautiful but also very durable. UV DTF stickers have high fastness and are waterproof and moisture-proof. They are an excellent choice for making acrylic background walls.

1 note

·

View note

Text

FSW Products

Cheeven is committed to the development, application and promotion of FSW friction stir welding technology. Pro in friction stir welding, Cheeven has rich experience in R & D and production of FSW products, especially in the design and manufacturing of battery tray, electric cabinets, motor products and aluminium alloy water cooling parts of new energy vehicles. After production FSW welding, the company will conduct professional ultrasonic nondestructive testing and provide FSW products testing reports.

As one of the leading friction stir welding companies, Cheeven has independently developed additive friction stir welding technology with upper and lower double heads and intelligent visual friction stir welding technology, which is at the leading level in the same industry.

TYPES OF FRICTION STIR WELDING PRODUCTS

Battery Tray

Battery tray, suitable for new energy vehicles, aluminum alloy materials, integral casting or aluminum profile welding, heat dissipation profiles, customized according to the picture.

Water Cooling Plate

New energy vehicle battery water cooling and heat dissipation, aluminum with strong thermal conductivity, fast water cooling and heat dissipation, aluminum alloy material, not easy to corrode, customized on demand.

Battery Cold Plate

Aluminum alloy, stainless steel and other materials, suitable for new energy vehicles, semiconductors, medical equipment, aerospace, with a variety of processing technologies, support for drawing customization.

Photovoltaic Cooling Panel

Aluminum alloy material water cooling, cold aluminum plate, water cooling plate, trial photovoltaic system industry, heat dissipation profile, friction stir welding process.

Medical Equipment Water Cooling Plate

High quality, aluminum alloy, water cooling radiator, medical equipment water cooling plate, heat dissipation profile, medical equipment, for medical equipment.

Copper Water Cooling Plate

Cold copper plate, suitable for medical equipment, semiconductor industry, excellent thermal conductivity, heat dissipation material.

Semiconductor Cooling Plate

Semiconductor water-cooling plate, suitable for semiconductor equipment, the main material is aluminum alloy, stainless steel, used in new energy vehicles, semiconductors, medical equipment, aerospace, various machining technologies

Water-cooled Motor Housing

Cheeven is pro in producing cooling/cold channel, water colored aluminum motor housing, aluminum alloy motor housing, main processes include aluminum extrusion, friction stir welding water channel, suitable for new energy vehicles, heat dissipation profiles.

Water Cooling Controller

Aluminum vehicle control unit shell, electric vehicle main drive controller, main processes include die casting, friction stir welding water channel, heat dissipation profiles, customized drawings, electric control box shell.

Aluminum Alloy Wheel Welding

Automobile friction stir welding FSW aluminum rim, automobile wheel hub with good noise function, the main materials are aluminum alloy, stainless steel, suitable for automobile field.

Products

FSW Products

Battery Tray

Water Cooling Plate

Battery Cold Plate

Photovoltaic Cooling Panel

Medical Equipment Water Cooling Plate

Copper Water Cooling Plate

Semiconductor Cooling Plate

Water-cooled Motor Housing

Water Cooling Controller

Aluminum Alloy Wheel Welding

Carbon Nanotubes Products

Electric Heating Radiator

Die Casting Products

New Metal Alloy

Friction Stir Welding Process

Friction Stir Welding ProcessFriction Stir Welding ProcessVIDEO

FRICTION STIR WELDING PROCESS

The working process of FSW friction stir welding can be summarized as follow.

1. First both the work plates are clamped together same as in the butt joint. Both plate's weldable surfaces are in contact with one another.

2. Now a rotating tool pin is inserted into workpieces at the interface surfaces until the tool shoulder touched the workpiece. This will deform the material plastically due to heating by friction force. This is a state of the joining process in which, inter-molecular diffusion will deform the material plastically due to heating by friction force.

3. Now the rotating tool is moving forward along the joint line. This will form a joint behind the tool.

4. The tool continuously moves unlit the whole weld is formed. After the joining process, the tool is separated from the workpiece. The hole created by the tool pin remains in the welding plates.

Its work can be clearly understood by the following video.

1 note

·

View note

Link

0 notes

Photo

Used Electrical Panels from a dismantled power plant. Estimated to be 250-300 tons. EU origin. To be delivered on CFR basis. End Buyers or Traders who understand this notion are welcome to connect. WhatsApp: +971 561-456-354 Visit: https://waterlink-corp.com #waterlinkcorp Profile #Extrusion #Radiators #AluminumRadiators #HighPurityAluminum #Tense #Nonferrous #UBC #Scrap #Scrapmetal #Aluminum #Recycling #Metalscrap #TaintTabor #Extrusion #Foil #lme (at Sharjah, Dubai UAE) https://www.instagram.com/p/Cdt1cgEj4Nk/?igshid=NGJjMDIxMWI=

#waterlinkcorp#extrusion#radiators#aluminumradiators#highpurityaluminum#tense#nonferrous#ubc#scrap#scrapmetal#aluminum#recycling#metalscrap#tainttabor#foil#lme

0 notes

Photo

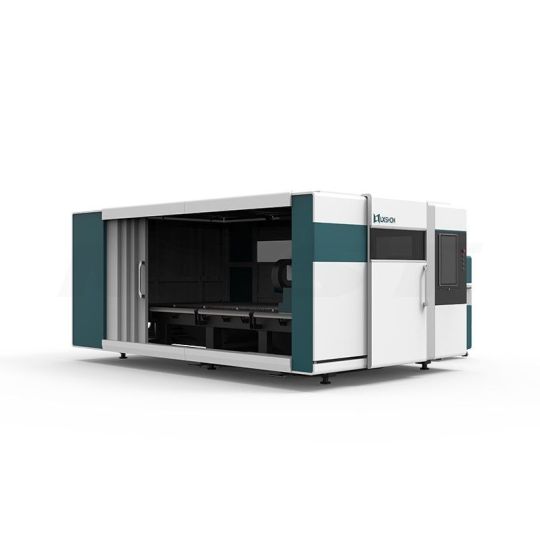

LX3015C-0 China cnc best metal plate enclosed fiber laser cutting sheet machine stainless steel carbon steel iron aluminum price

Stainless Steel Laser Cutter Description

LXSHOW LASER LX3015C-O is a product specially designed for sheet metal laser cutting machine. It has stronger cutting ability and higher cutting precision. Do you want to know more about it? The product details page below can help you.

Safety and Environment Protection

With a fully enclosed design;

The observation window adopts an European CE Standard laser protective glass;

The smoke produced by cutting can be filtrated inside, it's non-polluting and environmentally friendly;

Monitoring system

Real-time observe the machine running through the panel

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Transmission And Precision

LXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

Intelligent Autofocus

The high efficiency cooling:

Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.

Chase the light aperture:

Through the pore diameter of 35 mm, effectively reduce the stray light interference, ensuring cutting quality and service life.

Automatic focus:

Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.

High speed cutting:

25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.

Independent Control Cabinet

Dust-proof

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

Automatic Thermostat

The control cabinet is equipped with air conditioner for automatic constant temperature.This can prevent excessive temperature damage to components in summer.

0 notes

Text

Is Aluminum Extrusion Profile Good For Solar Panels?

The solar panel is a device that absorbs sunlight and converts it into electricity. Solar panels are used to power things, such as lights, water pumps for wells, and battery chargers for automobiles and cell phones. Solar panels are used in combination with batteries to power remote places that are not connected to the power grid.

In the solar panel industry, aluminum alloy is an important material. In recent years, as the world gradually realized the importance of solar energy and the development of the solar industry, with the improvement of people’s understanding of solar energy, more people are willing to install solar cells on their own home.

However, a problem that is often encountered by consumers is that the price of solar panels is very high. In order to reduce costs, aluminum alloy is a material that can be used to produce solar panels structure such as aluminum extrusion profile, block, c section etc.

Aluminum is a light, strong, and heat-resistant metallic chemical element. It is a common component of most alloys. As an alloying element, it can be used to improve the properties of other metals. It is mainly used in the manufacturing of framing structure and construction components in solar industries.

The aluminum profile is a type of extrusion material. The aluminum profile is an extrusion or a continuous sheet of aluminum that is cut into specific lengths to meet a design specification and is then formed into a desired profile.

As the leading aluminum extrusion profile manufacturer, we are committed to supplying high quality aluminum extrusion profile. We strive to provide our customers with the best extrusion profile used for solar panel mounting structure at the best price. Our aluminum extrusion profiles are designed, manufactured, and exported from our state-of-the-art production lines in India.

0 notes