#Aluminum Composite Panels

Explore tagged Tumblr posts

Text

Aluminum Composite Panels "Majestic Mountains & Mosques

Take your designs to the next level with personalized aluminum composite sheets. We'll print them on a 3mm thick panel that will stay put come sunshine or rain. They come in seven sizes, so you can choose the one that fits your needs. All sheets come with pre-mounted hanging hardware for easy installation.

.: Material: 3mm thick aluminum composite panel .: Seven sizes to choose from .: Suitable for indoor and outdoor use .: Pre-mounted hanging hardware .: Matte finish .: Horizontal and vertical options available

YOU can Gat it from here

#Aluminum Composite Panels#digital art#art#Islamic Garden Design#Garden Wall Cladding#Modern Islamic Architecture#Mosque Garden Decor#Islamic Landscape Panels#Composite Wall Art#Aluminum Panels for Gardens

0 notes

Text

Mountain aluminum composite panels

Bring the serene beauty of a quiet dawn over majestic mountains into your space with these durable aluminum composite panels. Perfect for both indoor and outdoor use, these waterproof and scratch-resistant panels feature vibrant colors and a matte finish. Ideal for nature lovers and outdoor enthusiasts, these panels make a stunning addition to any home or office decor. Perfect for celebrating nature, Earth Day, or simply adding a touch of tranquility to your space.

Product features - Durable 3mm aluminum composite material - Waterproof, UV-resistant, and scratch-resistant - Ready to hang with pre-mounted hardware - Vibrant colors with crisp printing - Suitable for indoor and outdoor use

Care instructions - Clean with water or mild soap, and a soft cloth.

You can from get it now here

1 note

·

View note

Text

Aluminum composite panels (ACM) are a type of composite material made from two thin sheets of aluminum bonded to a polyethylene core. They are lightweight, durable, and easy to maintain. ACM panels are often used in exterior applications, such as cladding, roofing, and signage. Here are some of the benefits of using ACM panels: Lightweight. ACM panels are lightweight, which makes them easy to install and maintain. Durable. ACM panels are durable and can withstand the elements. Easy to maintain. ACM panels are easy to maintain and do not require regular cleaning or painting. Versatile. ACM panels can be used in a variety of applications, including cladding, roofing, signage, and insulation. Cost-effective. ACM panels are a cost-effective option for a variety of applications. If you are looking for a material for an exterior application, ACM panels are a good option. They are lightweight, durable, easy to maintain, and versatile.

Please call or fill out our online form to request an estimate or ask general questions about our services. We are excited to serve you!

(718) 517-9178

https://www.skywindowsnj.com/

#aluminumcompositepanels#acppanels#compositepanels#aluminiumcompositepanels#exteriorpanels#cladding#roofing#signage#insulation#cost-effective#lightweight#contractor#brooklyn windows#window installation nyc#design#nyc windows#Aluminum composite panels

0 notes

Text

Aluminum Composite Panels | ACM Panels Toronto

CLL Metal provides high-quality aluminum composite panels (ACM) for commercial & residential projects. Choose from a variety of finishes and contact us in Toronto & GTA! https://cllmetal.com/services/aluminum-composite-panels-acm/

0 notes

Text

ACP Sheets Manufacturer - E3 ACP

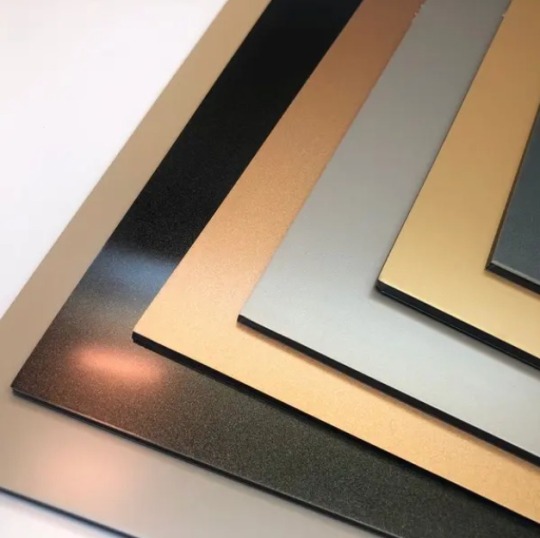

E3 ACP is the first company to establish an ACP sheet manufacturer Plant in South India. Aluminium Composite Panels are versatile and characterful available in a wide range of colors and finishes offered by E3.

These include wooden, stone, sparkle, gloss, pebbles, and more. It is possible to bend, fold, and turn this material into shapes that are impossible with any other material. As E3 ACP is never complacent about quality, ACP sheets are developed after extensive quality-testing.

ACP Panels with impeccable finishing gives a state-of-the-art appearance to any structure available in density of 2 mm up to 6 mm maximum. They're notably designed in metal based, featherlight installation, simple to install, flexible designs,eco-friendly, rainfall resistance, termite proof , and UV resistant.

1 note

·

View note

Text

aluminum panle

#This aluminum composite panel features a stunning image of clouds at sunset#adding a serene and calming vibe to any space. Perfect for nature lovers and those seeking a peaceful atmosphere in their home or office. I#or for those who love sunsets and dreamy landscapes.#https://printify.com/app/product-details/67675a584304398efb0dec93?fromProductsPage=3

2 notes

·

View notes

Text

Which ACP Sheet Is Suitable for Commercial Building Elevation?

Aluminum Composite Panels (ACP) have become a popular choice for commercial building elevations due to their aesthetic appeal, durability, and ease of maintenance. ACP sheets consist of two aluminum sheets with a non-aluminum core, offering strength, flexibility, and resistance to weather elements.

When choosing an ACP sheet for commercial building elevations, several factors such as aesthetic requirements, durability, and environmental conditions need to be considered. Let’s explore the types of ACP sheets best suited for commercial buildings.

1. Fire-Resistant ACP Sheets

In commercial buildings, safety is a primary concern. Fire-resistant ACP sheets are specifically designed with fire-retardant cores that comply with international fire safety standards. These sheets reduce the spread of fire, providing additional safety and peace of mind for building occupants.

Fire-rated ACP sheets are essential for high-rise buildings, hotels, hospitals, and public offices. When selecting ACP for your building's elevation, ensure that it has the proper fire rating as per local building codes and regulations.

2. High-Density ACP Sheets for Durability

Commercial buildings often face harsh environmental conditions, from pollution to extreme weather. High-density ACP sheets are designed to withstand these conditions, offering enhanced durability and resistance to wear and tear. These sheets are ideal for buildings in areas prone to high winds, heavy rains, or extreme heat.

Their robust composition ensures long-term performance without fading, warping, or denting. High-density ACP sheets maintain their aesthetic appeal for years, even in tough environments, making them a great choice for office complexes, retail outlets, and hotels.

3. UV-Resistant ACP Sheets

UV radiation can cause fading, discoloration, and degradation of building facades. To combat this, UV-resistant ACP sheets are engineered with a special coating that prevents the panels from losing their color and gloss over time.

These sheets are especially beneficial for buildings located in sunny regions or areas with high UV exposure. By choosing UV-resistant ACP sheets, building owners can ensure that their commercial building's elevation remains vibrant and visually appealing, reducing maintenance costs related to fading and discoloration.

4. Customizable ACP Sheets for Unique Designs

For commercial buildings aiming for a unique, modern, or brand-specific design, customizable ACP sheets are the best choice. These sheets can be produced in a variety of colors, textures, and finishes, including matte, gloss, and metallic options. Customizable ACPs allow architects to create distinctive facades that align with the building's purpose and brand identity.

Whether you’re designing a corporate office, restaurant, or retail space, the ability to personalize the ACP sheets ensures that your building stands out and makes a lasting impression.

Conclusion

Choosing the right ACP sheet for commercial building elevation is crucial for both the building's appearance and longevity. Fire-resistant, high-density, UV-resistant, customizable, and eco-friendly ACP sheets each offer distinct advantages that make them ideal for different commercial applications. Consider the specific needs of your building, including safety, aesthetics, environmental conditions, and sustainability goals, to select the most suitable ACP sheet for your commercial building's elevation.

1 note

·

View note

Text

CladCore - Your go-to for Aluminum Composite Panel installation in Metro Manila. Visit us at cladcorealuminumcompositepanel.com.

1 note

·

View note

Text

Geartech Aluminum Composite Panel Production Line

Geartech Aluminum Composite Panel Production Line The aluminum composite panel production line plays a crucial role in the manufacturing of durable and aesthetically appealing building materials. These panels are widely used in exterior and interior facades, signage, and cladding due to their combination of lightweight properties, strength, and ease of maintenance. To achieve these benefits, the production process must be carried out with precision and attention to detail.

0 notes

Text

The canopy made of aluminum composite panels is light, noise-proof, and easy to shape. Kanopi yang terbuat dari panel komposit aluminium ringan, kedap kebisingan, dan mudah dibentuk. المظلة المصنوعة من ألواح الألومنيوم المركبة خفيفة الوزن، ومقاومة للضوضاء، وسهلة التشكيل.

0 notes

Text

Aluminum Composite Panels Market Industry Size Forecast

0 notes

Text

#Aluminum Composite Panels Market Market#Aluminum Composite Panels Market Market Share#Aluminum Composite Panels Market Market Size#Aluminum Composite Panels Market Market Research#Aluminum Composite Panels Market Industry#What is Aluminum Composite Panels Market?

0 notes

Text

youtube

Goodsense will be at the 136th Canton Fair showcasing our latest innovations in #AluminumCompositePanel and #AcrylicMirror! We’ll at #CantonFair from Oct. 15-27, 2024. See you at our booth!

Phase 1 Date: Oct.15th-19th, 2024 Booth No.: 11.1 G01-02 F47-48 Add.: No. 382, Yuejiang Zhong Road, Guangzhou 510335, China

Phase 2 Date: Oct. 23rd-27th, 2024 Booth No.: 12.2 D37-41 E07-09 Add.: No. 382, Yuejiang Zhong Road, Guangzhou 510335, China

See you at our booth!

1 note

·

View note

Text

ACP Sheet Manufacturing Company in India - Best Suppliers & Dealers

Looking for reliable ACP sheet manufacturers in India? Our company specializes in producing top-grade aluminum composite panels. Contact us for more information.

Visit us:- https://e3groupindia.com/

#ACP Sheet Manufacturer in India#Aluminum Composite Panel#ACP Sheet Suppliers#ACP Sheet Dealers#ACP Sheet Manufacturing Company#Top-grade ACP Sheets#Exterior Cladding Solutions#Interior Design Materials#Construction Materials#Building Materials

0 notes

Text

aluminum panle

#An aluminum composite panel feathePyramids#perfect for adding an exotic and ancient atmosphere to any indoor or outdoor space. This panel is ideal for those who appreciate Egyptian c#making it a great addition to home decor during Egyptian or historical-themed celebrations.#https://printify.com/app/product-details/676750f352818688bc00fce2?fromProductsPage=3

0 notes