#Aircraft Cleaning Chemicals Market

Explore tagged Tumblr posts

Text

The global economy experienced heavy headwinds throughout 2019-2021, as some countries witnessed subdued growth, while others grappled with economic slowdowns. The COVID-19 pandemic has levied undue pressure across industries globally and caused a major economic crisis in the US, India, Italy, the UK, Germany, India, Japan, South Korea, the UK, and many others.

0 notes

Text

Global Aircraft Cleaning Chemical Market

Market Growth and Projections

Current Valuation: The market was valued at approximately USD 2,321 million in 2023.

Projected Growth: It is expected to reach around USD 3,378.7 million by 2030, expanding at a compound annual growth rate (CAGR) of over 5.5% during the forecast period. GlobeNewswire

Key Drivers

Increasing Air Travel: The rise in global air passenger traffic necessitates regular and efficient cleaning of aircraft to ensure passenger safety and satisfaction.

Stringent Regulatory Standards: Governments worldwide are implementing stricter regulations on aircraft cleanliness to ensure the safety and health of passengers and crew, driving the demand for compliant cleaning chemicals.

Environmental Concerns: There is a growing shift towards eco-friendly and biodegradable cleaning solutions, with manufacturers developing products that are effective yet environmentally sustainable.

Emerging Trends

Bio-based Cleaning Solutions: The industry is witnessing a move towards bio-organic aircraft cleaners, driven by environmental concerns and regulatory pressures.

Technological Advancements: Innovations in cleaning agents, including the development of more effective and cost-efficient products, are making aircraft cleaning chemicals more attractive to airlines and other users.

For More : https://tinyurl.com/4jmzv5ry

Regional Insights

North America: Currently holds the largest market share, attributed to the presence of leading airline operators and maintenance service providers, along with stringent regulatory norms.

Asia-Pacific: Anticipated to witness the highest growth rate, driven by the rapid expansion of the aviation industry and increasing air passenger traffic in countries like China and India.

Challenges

Raw Material Availability: Challenges related to the availability of essential raw materials pose a restraint on market expansion.

Environmental Impact: Improper usage of cleaning chemicals may cause damage to aircraft parts, and environmental changes may affect chemical properties, posing challenges for consistent product performance.

0 notes

Text

Petroleum Products

Understanding Petroleum Products: Key Insights and Industry Regulations

Petroleum products play an essential role in our daily lives, fueling industries, transportation, and various other sectors. From crude oil to refined petroleum products, the industry offers a wide range of goods that are integral to the global economy. This article explores various aspects of petroleum products, including their uses, classifications, regulations, and major suppliers like Zarko Petroleum Products, YVB Petroleum Products, and Yellowhead Petroleum Products.

What Are Petroleum Products?

Petroleum products are derived from the processing of crude oil through refining processes such as fractional distillation. These products include fuels like gasoline, diesel, kerosene, and jet fuel, as well as lubricants, waxes, and asphalt. These products are categorized based on their chemical properties and their use in industries such as transportation, energy, manufacturing, and even in consumer goods.

Types of Petroleum Products

Some of the most common petroleum products include:

Gasoline: Used primarily as a fuel for vehicles.

Diesel: Powers trucks, trains, and some types of machinery.

Jet Fuel: Essential for aviation.

Kerosene: Used for heating and cooking in some regions.

Lubricants: Keep engines running smoothly by reducing friction.

Asphalt: Used in road construction and roofing materials.

Refined petroleum products undergo additional processing, making them safer and more efficient for commercial and residential use.

What Is the Biggest Limitation in the Production of Petroleum Products?

The production of petroleum products faces several challenges, with one of the biggest limitations being the environmental impact of fossil fuel extraction and processing. Additionally, the refining process requires significant energy, leading to concerns about sustainability and carbon emissions. Innovations in clean petroleum products and the development of renewable energy solutions are necessary to address these challenges.

Petroleum Products Regulations and Acts

Regulations govern the production, distribution, and sale of petroleum products to ensure safety, quality, and environmental compliance. In some countries, these regulations are encapsulated in acts like the Petroleum Products Act 120 of 1977 and Petroleum Products Amendment Bill. These legal frameworks aim to control aspects such as the storage, transportation, and taxation of petroleum products.

In 2024, the Petroleum Products Bill 2024 and amendments to the existing regulations are expected to reshape the industry, addressing concerns about the environmental impact and encouraging more sustainable practices in the production and distribution of petroleum products.

Suppliers of Petroleum Products

Companies like Zarko Petroleum Products, YVB Petroleum Products, Yellowhead Petroleum Products Ltd, Muambongue Petroleum and Yau Fat Hong Petroleum Products are leading suppliers of petroleum products in their respective regions. These companies are involved in the marketing of petroleum products, ensuring that consumers and industries have access to a reliable supply of fuels, lubricants, and other essential goods.

Uses of Petroleum Products

The uses of petroleum products are vast and varied, from everyday transportation to powering machinery in the industrial sector. Some common uses include:

Fueling vehicles: Gasoline and diesel are the primary fuels for cars, trucks, and buses.

Energy production: Many power plants rely on petroleum products like fuel oil to generate electricity.

Manufacturing: Petroleum products are used in the production of plastics, fertilizers, and chemicals.

Aviation: Jet fuel is necessary for aircraft operations, making it a crucial component of the global transportation network.

Harmful Effects of Petroleum Products

Despite their widespread use, petroleum products have several harmful effects. They contribute to air pollution, global warming, and soil contamination when spilled. Many petroleum products are toxic, and improper handling can lead to adverse health effects. This is why regulations such as the Petroleum Products Amendment Act are essential in managing the environmental and health risks associated with these products.

Petroleum Products Exports

Countries like India are major exporters of petroleum products, supplying markets across the globe. India exports products like diesel, jet fuel, and liquefied petroleum gas (LPG) to various countries. The tax collection on petroleum products and the associated excise duties on petroleum products play a significant role in the country’s economy.

The Role of Petroleum Products in Global Trade

The transportation of petroleum products is a key aspect of the global supply chain. Companies involved in the export of petroleum products from regions like the Middle East, the United States, and Southeast Asia facilitate the global distribution of these products. The specifications and quality control of petroleum products are vital in ensuring that they meet international standards for safety and efficiency.

Innovations in Petroleum Products: From Refining to Sustainability

With the growing focus on sustainability, the industry is exploring cleaner alternatives and innovations in refining processes. The rise of biofuels, solar energy, and electric vehicles represents a shift away from traditional petroleum products, pushing the sector towards more sustainable energy solutions. The petroleum products amendment bill is expected to further support these developments by incorporating green initiatives into the legislative framework.

Conclusion

Petroleum products are integral to modern society, driving industries, transportation, and energy production. However, as the world faces environmental challenges, the future of petroleum products lies in balancing their essential use with the need for sustainability. Companies like Zarko Petroleum Products, YVB Petroleum Products, Muambongue Petroleum and Yellowhead Petroleum Products Ltd are at the forefront of this change, working within the constraints of petroleum products regulations to provide high-quality, reliable products while addressing environmental concerns.

The ongoing development of the Petroleum Products Amendment Bill and the push toward cleaner energy will ultimately shape the future of the industry, making it possible to enjoy the benefits of petroleum products while minimizing their harmful effects.

1 note

·

View note

Text

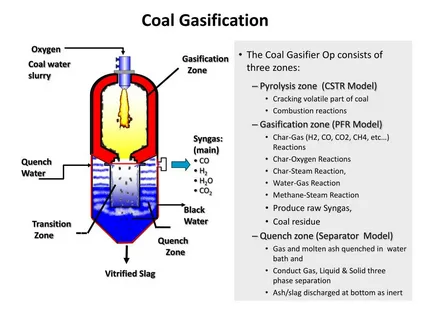

Global Coal Gasification Market 2024-2034: Technology, Feedstock & Growth

The Coal Gasification market report is predicted to develop at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2034, when global Coal Gasification market forecast size is projected to reach USD 38.63 Billion in 2034, based on an average growth pattern. The global Coal Gasification market revenue is estimated to reach a value of USD 23.36 Billion in 2024

𝐂𝐥𝐚𝐢𝐦 𝐲𝐨𝐮𝐫 𝐬𝐚𝐦𝐩𝐥𝐞 𝐜𝐨𝐩𝐲 𝐨𝐟 𝐭𝐡𝐢𝐬 𝐫𝐞𝐩𝐨𝐫𝐭 𝐢𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲:

https://wemarketresearch.com/reports/request-free-sample-pdf/coal-gasification-market/1624

Globally, and particularly in Asia Pacific, the coal gasification industry is producing excellent quantities of chemicals, fertilizers, and hydrogen. Future market expansion is also anticipated to be accelerated by the increasing number of methanol-infused fuels utilized in hybrid cars and aircraft. Traditional coal-fired power plants burn the majority of coal, but it can also be transformed into other energy products like gas, electricity, and hydrogen.

Market Drivers for Coal Gasification

Rising Energy Demand: As the global population grows and industrial activities expand, the demand for energy continues to increase. While renewable energy sources like wind and solar are gaining traction, they cannot yet meet the global energy demand on their own. Coal gasification offers a way to utilize the world’s vast coal reserves more efficiently and with lower emissions compared to traditional coal combustion.

Environmental Concerns: With increasing pressure to reduce greenhouse gas emissions and combat climate change, coal gasification presents a promising solution. By capturing carbon emissions and enabling the production of cleaner fuels, coal gasification can help achieve environmental goals while still utilizing existing coal resources. Governments and corporations are also investing in technologies like carbon capture and storage (CCS) to make coal gasification even more environmentally friendly.

Coal Gasification Market Growth Factors

The increase of coal reserves in developing nations encourages the market to expand throughout the ensuing years.

Growing emphasis on clean and efficient energy sources and decreasing dependency on natural gas and fossil fuels are the main factors propelling the coal gasification market's growth throughout the forecast period.

The demand for coal gasification is expected to increase during the forecast period due to the rising urbanization and industrialization.

Underground coal gasification (UCG), which turns coal into valuable gases without the need for mining, is being adopted quickly, which is expected to drive market growth.

Opportunity: Supportive government investment and initiatives

The market for coal gasification is expected to rise throughout the forecast period thanks to increased government initiatives and investment. The government is aggressively working to develop sustainable and environmentally friendly methods of producing electricity.

Coal Gasification Market Segmentation

By Technology

Fixed-Bed Gasifiers

Moving Bed

Dry Ash

Fluidized-Bed Gasifiers

Bubbling Fluidized Bed

Circulating Fluidized Bed

Entrained-Flow Gasifiers

Single-Stage

Multi-Stage

Plasma Gasification

High-Temperature Gasification

Plasma Arc Technology

Integrated Gasification Combined Cycle (IGCC)

By Feedstock

Sub-Bituminous Coal

Bituminous Coal

Anthracite

Petroleum Coke

Biomass/Coal Blends

Municipal Solid Waste (MSW)

Others

By Gas Output

Synthetic Gas (Syngas)

Methane-Rich Gas

Hydrogen-Rich Gas

By End-use Industry

Energy and Utilities

Chemicals and Petrochemicals

Oil and Gas

Metals and Mining

Transportation

Others

Key Market Players

General Electric (GE)

Royal Dutch Shell

Siemens Energy

ThyssenKrupp AG

Air Products and Chemicals, Inc.

KBR Inc.

Mitsubishi Heavy Industries

Synthesis Energy Systems

Huaneng Clean Energy Research Institute

China Coal Energy Group

Sasol Limited

Air Liquide

BHEL (Bharat Heavy Electricals Limited)

Key Benefits For Stakeholders

The report provides exclusive and comprehensive analysis of the global coal gasification market scope, trends along with the coal gasification market forecast.

The report elucidates the coal gasification market trends along with key drivers, and restraints of the market. It is a compilation of detailed information, inputs from industry participants and industry experts across the value chain, and quantitative and qualitative assessment by industry analysts.

Porter’s five forces analysis helps analyze the potential of the buyers & suppliers and the competitive scenario of the market for strategy building.

The report entailing the coal gasification market analysis maps the qualitative sway of various industry factors on market segments as well as geographies.

The data in this report aims on market dynamics, trends, and developments affecting the coal gasification market demand.

Conclusion

The coal gasification market is poised for growth as it offers a potential solution to the global energy crisis while addressing environmental concerns. With its ability to produce cleaner energy and enable carbon capture, this Technology Presents a way to utilize the world’s vast coal reserves in a more sustainable manner. While challenges remain, ongoing technological advancements and investments in research and development are likely to drive the evolution of coal gasification, making it a key player in the energy landscape for years to come.

0 notes

Text

Top 15 Market Players in Global Aviation Maintenance Chemicals Market

Top 15 Market Players in Global Aviation Maintenance Chemicals Market

The aviation maintenance chemicals market has experienced significant growth, driven by the expanding aviation industry and the increasing demand for aircraft maintenance and servicing. Below are some of the top companies shaping the global aviation maintenance chemicals market:

BASF SE A leading chemical manufacturer, BASF SE provides advanced solutions for cleaning, corrosion inhibition, and surface treatment in aviation.

3M Company Known for its innovative chemical solutions, 3M offers a wide range of aircraft maintenance products such as adhesives, sealants, and surface protectants.

ExxonMobil Corporation ExxonMobil specializes in aviation lubricants, hydraulic fluids, and other essential chemicals for aircraft maintenance.

Arrow Solutions Focused on aviation-specific products, Arrow Solutions is a trusted supplier of cleaning agents, degreasers, and corrosion inhibitors.

The Dow Chemical Company Dow offers a variety of high-performance chemicals tailored for cleaning, de-icing, and surface coating applications in the aviation sector.

Henkel AG & Co. KGaA Henkel's product portfolio includes advanced adhesives, sealants, and coatings specifically designed for aviation maintenance.

Eastman Chemical Company Eastman is a key player in the production of aviation hydraulic fluids, engine oils, and cleaning chemicals.

PPG Industries, Inc. PPG specializes in coatings, sealants, and other maintenance products for both commercial and military aircraft.

Shell Aviation A global leader in aviation fuels and lubricants, Shell also offers a range of aircraft maintenance chemicals.

Callington Haven This company provides innovative solutions for aircraft cleaning, disinfection, and corrosion control.

Chemetall GmbH (A BASF Company) Chemetall delivers cutting-edge technologies for surface treatment and cleaning in the aviation sector.

Klüber Lubrication Klüber focuses on aviation-specific lubricants and specialty chemicals for enhanced performance and safety.

Rochester Midland Corporation Known for its environmentally friendly products, Rochester Midland supplies cleaning agents and maintenance chemicals for aviation.

Celeste Industries Corporation Celeste offers customized solutions for aircraft cleaning and cabin hygiene.

Zep Aviation Products Zep specializes in cleaning and maintenance chemicals that cater to various aircraft surfaces and components.

Request report sample at https://datavagyanik.com/reports/global-aviation-maintenance-chemicals-market-size-production-sales-average-product-price-market-share-import-vs-export-united-states-europe-apac-latin-america-middle-east-afri/

Top Winning Strategies in Aviation Maintenance Chemicals Market

The competitive landscape of the aviation maintenance chemicals market is shaped by several winning strategies adopted by leading players. Here are the key approaches driving success in this industry:

Product Innovation Continuous R&D efforts to develop eco-friendly and high-performance chemicals have become a priority for market leaders.

Strategic Partnerships Collaborations with airlines, MRO (maintenance, repair, and overhaul) companies, and OEMs (original equipment manufacturers) help expand market reach.

Regional Expansion Companies are focusing on expanding their operations in emerging markets such as Asia-Pacific and the Middle East to tap into growing aviation demand.

Sustainability Initiatives The adoption of green chemistry and sustainable manufacturing practices is gaining momentum, driven by regulatory pressures and customer preferences.

Custom Solutions Offering tailor-made products for specific maintenance needs helps companies differentiate themselves in the market.

Technological Advancements Integration of technologies like predictive analytics and IoT-enabled maintenance solutions enhances the effectiveness of chemical applications.

Mergers and Acquisitions Strategic acquisitions allow companies to strengthen their product portfolios and expand their market presence.

Request a free sample copy at https://datavagyanik.com/reports/global-aviation-maintenance-chemicals-market-size-production-sales-average-product-price-market-share-import-vs-export-united-states-europe-apac-latin-america-middle-east-afri/

#Aviation Maintenance Chemicals Market#Aviation Maintenance Chemicals Production#average price#revenue#top trends#market players

0 notes

Text

Shipbuilding Market Trends: Anticipated Growth to USD 197.94 Billion by 2030

Shipbuilding Market Overview

shipbuilding market is poised for significant growth over the next decade, driven by advancements in technology, increasing maritime trade, and rising demand for military and commercial vessels. Shipbuilding plays a critical role in supporting the global economy, connecting continents through trade and ensuring naval dominance for defence operations. This report explores key segments of the shipbuilding market, including ship type, production processes, end-user applications, and regional insights, along with a comprehensive forecast till 2030.

The shipbuilding industry encompasses the design, construction, and outfitting of various types of vessels. It is influenced by growing international trade, the need for sustainable shipping solutions, and strategic military initiatives. Technological advancements such as automation, digital twins, and modular construction techniques are revolutionizing the industry, making shipbuilding more efficient and sustainable.

According to the latest findings, the global shipbuilding market is expected to grow steadily, supported by increasing demand for cargo ships, passenger vessels, and advanced military ships. Regions such as Asia-Pacific are emerging as prominent hubs for shipbuilding due to their robust infrastructure, technological expertise, and favourable government initiatives.

Browse Report – Explore the report’s contents, sections, and key insights by browsing through its detailed information.

Key Market Segmentation

1. Ship Type

The market can be segmented based on the type of ships built, including:

Cargo Ships: These vessels dominate the market, catering to the rise in global trade and logistics.

Container Ships: High demand for containerized goods drives the need for modern, fuel-efficient container vessels.

Tankers: Growing demand for oil, chemicals, and LNG transport fuels the construction of specialized tankers.

Multi-Purpose Ships: Increasing versatility in logistics boosts the market for adaptable, multi-purpose vessels.

Car and Passenger Ferries: Rising maritime tourism and coastal transportation contribute to the demand for passenger ferries.

Others: Including naval ships, offshore vessels, and fishing boats that serve specific industries.

The cargo ship segment currently holds the largest market share, but passenger ferries and tankers are anticipated to witness strong growth due to increasing demand for clean fuel transport and tourism-driven investments.

2. Process

The shipbuilding process is segmented into several phases:

Designing: Modern designs integrate environmental standards, fuel efficiency, and automation technologies.

Production Planning: Digital tools enable streamlined production schedules and resource optimization.

Cutting and Processing: Advanced machinery ensures precision in cutting metal components for vessel construction.

Assembling and Launching: Shipyards employ modular techniques for faster, efficient vessel assembly and launch.

Outfitting: Integration of systems, electronics, and interior components brings the vessel to completion.

Technological innovations such as robotics, computer-aided design (CAD), and 3D printing are driving efficiency across all stages, reducing delivery times and production costs.

3. End User

The market is primarily divided into two major end users:

Commercial: This includes cargo ships, container vessels, oil tankers, and passenger ships. Increasing trade volumes and the expansion of maritime tourism are propelling this segment.

Military: Defense agencies globally are investing heavily in modern naval fleets, including submarines, destroyers, and aircraft carriers to enhance maritime security.

The commercial segment dominates the shipbuilding market, accounting for a larger share due to the growing demand for cargo transportation and sustainable shipping solutions. However, the military segment is also gaining momentum as nations focus on enhancing their naval capabilities.

Regional Analysis

1. Asia-Pacific

Asia-Pacific leads the global shipbuilding market, with countries like China, South Korea, and Japan at the forefront. The region’s strong infrastructure, skilled workforce, and government incentives have cemented its dominance. South Korea specializes in LNG carriers and advanced vessels, while China focuses on bulk carriers and container ships.

2. Europe

Europe’s shipbuilding industry is driven by a focus on sustainability and innovation. European shipyards are renowned for building high-end cruise ships, offshore vessels, and defense ships. The region’s commitment to green technologies is fostering the development of eco-friendly vessels.

3. North America

In North America, the United States plays a key role, primarily in military shipbuilding. Rising investments in naval modernization and defense contracts are supporting market growth. Additionally, offshore oil and gas exploration boosts the demand for specialized vessels.

4. Rest of the World

Regions such as the Middle East, Africa, and Latin America are emerging players, focusing on building infrastructure for offshore oil exploration, fisheries, and maritime tourism.

Market Drivers and Opportunities

Several factors are propelling the growth of the shipbuilding market:

Growth in International Trade: The rise in global trade and e-commerce drives the demand for cargo and container ships.

Naval Modernization: Governments are investing in advanced naval fleets to bolster national security.

Technological Advancements: Adoption of smart technologies like AI, automation, and 3D printing is transforming shipbuilding processes.

Focus on Sustainability: The industry is shifting toward eco-friendly fuels such as LNG and hydrogen-powered vessels.

Opportunities lie in developing smart ships, expanding offshore exploration, and catering to the increasing demand for maritime tourism.

Challenges

Despite its growth prospects, the market faces certain challenges:

High Production Costs: Advanced technologies and raw material costs remain barriers for small shipbuilders.

Environmental Regulations: Strict emission standards require significant investments in green technologies.

Supply Chain Disruptions: Global disruptions impact the availability of components and skilled labor.

Conclusion

The shipbuilding market is poised for robust growth, driven by technological advancements, rising maritime trade, and the need for modern, fuel-efficient ships. Asia-Pacific will remain the epicenter of global shipbuilding, while Europe and North America focus on sustainability and naval modernization. Opportunities for innovation and sustainability will shape the future of the industry, making it a vital sector for the global economy.

Request Free Sample Report - Receive a free sample report to preview the valuable insights and data we offer.

About US

Market Research Future (MRFR) is a global market research company that takes pride in its services, offering a complete and accurate analysis about diverse markets and consumers worldwide. Market Research Future has the distinguished objective of providing the optimal quality research and granular research to clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help answer your most important questions.

Contact US

Market Research Future (part of Wants tats Research and Media Private Limited),

99 Hudson Street,5Th Floor New York 10013, United States of America

Sales: +1 628 258 0071 (US) +44 2035 002 764 (UK)

Email: [email protected]

#Shipbuilding Market Share#Shipbuilding Market Trends#Shipbuilding Market Analysis#Shipbuilding Market Demand#Shipbuilding Market Uses

0 notes

Text

0 notes

Text

Ceramic Matrix Composites Market Business Growth, Opportunities and Forecast, 2030

The global ceramic matrix composites market size was estimated at USD 3.40 billion in 2022 and is expected to grow at a compounded annual growth rate (CAGR) of 12.8% from 2023 to 2030.

High-temperature stability in addition to reduced weight and high strength is expected to propel the growth. The chemical industry had an unanticipated turning point in the first half of 2020. These businesses, which were already coping with complicated long-term patterns, saw the combined consequences of the COVID-19-related economic crisis and the oil price crash. The global pandemic has significantly influenced the market.

Additionally, the high cost of ceramic fibers has greatly influenced market growth. Unlike carbon fiber, which is used in most metal and polymer composites and, thus, is produced in bulk, other ceramic fibers are produced in small quantities which refrains them from the cost benefits of mass production.

Gather more insights about the market drivers, restrains and growth of the Ceramic Matrix Composites Market

Detailed Segmentation:

Product Insights

The oxides segment led the market and accounted for more than 30.14% share of the global revenue in 2022. Improved properties of oxide composites such as no oxidation and high fracturing toughness in addition to the less expensive production process are expected to trigger its demand for aerospace, defense, and energy & power applications.

The sic segment is projected to register a CAGR of 12.8% in terms of value over the forecast period. The higher initial cost of SiC ceramic matrix composites is the most prominent growth barrier for the segment. Other costs indulged during usage and transportation, such as cleaning costs and repositioning costs also restrain the growth.

Carbon products held a significant revenue share in 2022 due to the large-scale production of carbon fibers to fulfill the increased demand for CF and CFRP products globally, the costs of carbon/carbon ceramic matrix composites are significantly cheaper than silicon carbide/silicon carbide and oxide/oxide ceramic matrix composites.

Application Insights

The aerospace segment led the market and accounted for more than 41.95% of the global revenue share in 2022.Factors such as the rising preference of consumers for manufacturing noses, rudders, fins, leading edges, body flaps, hot structures, tiles, and panels for aircraft are anticipated to drive the demand in the aerospace segment during the forecast period.

Their excellent impact strength coupled with high hardness makes these composites suitable for manufacturing bullet-proof armor and insulation in small arms weapons platforms. A majority of ceramic materials are transparent to certain types of energy, light, etc. and, as a result of this, they are widely used for infrared domes, sensor protection, and multi-spectral windows.

Regional Insights

North America dominated the market and accounted for over 46.4% of the revenue share in 2022. The presence of major aviation industries, their investment in developing ceramic matrix components for manufacturing aviation components, and collaborations with government agencies for upgrading defense equipment are some of the essential factors anticipated to propel the CMC demand in North America.

Over-consumption of oil in Asia Pacific has stimulated the need for energy security with a focus on deriving energy from alternate sources which include natural gas. Ceramic matrix composites are thus likely to play a major role in this segment. In addition, the growing need for fuel-efficient aircraft engines is also going to boost the market to reduce operational costs.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global indium market size was valued at USD 1.03 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030.

• The global inorganic scintillators market size was valued at USD 512.9 million in 2023 and is anticipated to grow at a CAGR of 7.4% from 2024 to 2030.

Key Companies & Market Share Insights

The market is characterized by the presence of various small- and large-scale players, resulting in a moderate level of concentration in the market. To serve a larger customer base, they are also trying to expand their product portfolio by focusing on developing cost-effective composites with enhanced properties.

A large number of manufacturers are focused on backward integration to keep product quality under control. The industry participants emphasize on expanding their product portfolio by developing innovative solutions and cheaper products with superior properties to cater to the increasing consumer demand.

Some prominent players in the global ceramic matrix composites market include:

• 3M Company

• COI Ceramics, Inc.

• Coorstek, Inc.

• General Electric Company

• Kyocera Corporation

• Lancer Systems LP

• SGL Carbon Company

• Ultramet, Inc.

• Ube Industries, Ltd.

Ceramic Matrix Composites Market Segmentation

Grand View Research has segmented the global ceramic matrix composites market report based on product, application, and region:

• Product Outlook (Volume, Tons, Revenue, USD Million, 2018 - 2030)

• Oxides

• Silicon Carbide

• Carbon

• Others

• Application Outlook (Volume, Tons, Revenue, USD Million, 2018 - 2030)

• Aerospace

• Defense

• Energy & Power

• Electrical & Electronics

• Others

• Regional Outlook (Volume, Tons, Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

o Spain

o Italy

• Asia Pacific

o China

o India

o Japan

o South Korea

• Middle East & Africa

• Central & South America

o Brazil.

Order a free sample PDF of the Ceramic Matrix Composites Market Intelligence Study, published by Grand View Research.

#Ceramic Matrix Composites Market#Ceramic Matrix Composites Market size#Ceramic Matrix Composites Market share#Ceramic Matrix Composites Market analysis#Ceramic Matrix Composites Industry

0 notes

Text

Hydrophobic Technologies: A Shield Against Water Damage

The global hydrophobic coatings market is on a steady growth path, driven by the increasing demand for advanced coating technologies across various industries. According to the report, the market is projected to grow at a compound annual growth rate (CAGR) of over 4% during the forecast period of 2022-2028. In 2022, the market was valued at over USD 2.1 billion and is expected to exceed USD 2.7 billion by 2028.

What Are Hydrophobic Coatings?

Hydrophobic coatings are specialized surface treatments that repel water and reduce the surface's affinity to moisture. These coatings are often used to prevent corrosion, reduce contamination, and enhance product durability. Hydrophobic coatings are widely used across industries like automotive, aerospace, electronics, and construction for their water-repellent properties.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/1505

Market Dynamics and Growth Drivers

Several factors are driving the expansion of the global hydrophobic coatings market:

Increased Demand in Automotive and Aerospace Sectors: Hydrophobic coatings are used to enhance the durability and performance of vehicles and aircraft. These coatings reduce water retention and protect surfaces from environmental factors such as rain, snow, and ice, which can cause damage or corrosion.

Growth in the Electronics Industry: The electronics industry is increasingly adopting hydrophobic coatings to protect devices from water damage. These coatings are essential in consumer electronics such as smartphones and tablets, where water resistance is a critical feature.

Rising Applications in Construction: In the construction industry, hydrophobic coatings are applied to materials such as concrete and glass to improve water resistance, prevent mold growth, and enhance the longevity of building materials. The expansion of construction activities globally is contributing to market growth.

Advancements in Nanotechnology: The development of nanotechnology has led to innovations in hydrophobic coatings, offering enhanced properties such as self-cleaning and anti-fouling. These advancements are expanding the applications of hydrophobic coatings in various sectors.

Regional Analysis

North America: The North American hydrophobic coatings market is growing steadily, driven by strong demand in industries such as automotive, aerospace, and electronics. The U.S. is a key market in the region, with significant investments in research and development of advanced coatings technologies.

Europe: Europe holds a prominent share of the hydrophobic coatings market, supported by the presence of well-established automotive and aerospace industries. Countries such as Germany, the U.K., and France are leading the adoption of hydrophobic coatings in these sectors.

Asia-Pacific: The Asia-Pacific region is expected to witness rapid growth in the hydrophobic coatings market due to rising industrialization, increased automotive production, and expanding electronics manufacturing. China, Japan, and South Korea are major contributors to the market's growth in this region.

Latin America and Middle East & Africa: These regions are experiencing gradual growth in the hydrophobic coatings market, driven by the expansion of infrastructure development and increasing industrial activities.

Competitive Landscape

The global hydrophobic coatings market is competitive, with several major players and emerging companies offering innovative solutions. Key players in the market include:

BASF SE: A leading global chemical company providing a wide range of coatings solutions, including hydrophobic coatings for various industries.

PPG Industries, Inc.: A major player in the coatings industry, offering advanced hydrophobic coatings for automotive, aerospace, and industrial applications.

3M Company: Known for its innovative coating solutions, 3M provides hydrophobic coatings for electronics, automotive, and other sectors.

Akzo Nobel N.V.: A global leader in specialty chemicals, Akzo Nobel offers hydrophobic coatings with applications in construction, automotive, and marine industries.

The Sherwin-Williams Company: Provides a range of industrial coatings, including hydrophobic coatings for enhancing product durability and performance.

Report Overview : https://www.infiniumglobalresearch.com/reports/global-hydrophobic-coatings-market

Challenges and Opportunities

The hydrophobic coatings market faces challenges such as high costs of advanced coating materials and fluctuating raw material prices. Additionally, regulatory restrictions on certain chemical components may impact market dynamics.

However, there are significant opportunities for growth, particularly with the increasing focus on sustainable and eco-friendly coatings. Innovations in nanotechnology and the development of coatings with enhanced functionalities such as self-cleaning and anti-corrosion properties present avenues for market expansion. Companies investing in research and development to improve coating performance and reduce costs are likely to benefit from the growing demand.

Conclusion

The global hydrophobic coatings market is poised for steady growth, driven by increasing applications in automotive, aerospace, electronics, and construction industries. With revenue expected to surpass USD 2.7 billion by 2028, the market presents substantial opportunities for innovation and investment. As technological advancements and sustainability concerns continue to shape the industry, hydrophobic coatings will play a critical role in enhancing the durability and performance of products across various sectors.

0 notes

Text

Heat Pump 2024 Industry Outlook, Research, Trends and Forecast to 2030

Heat Pump Market Size & Trends

The global heat pump market size was estimated at USD 88.7 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 9.4% from 2024 to 2030. Favorable government policies for energy-efficient solutions and lowering carbon footprint are anticipated to boost market growth over the forecast period. Many governments are providing subsidies or incentives and tax credits & rebates for the installation of heat pumps are expected to further fuel the demand for energy-efficient heat pumps, thereby, benefitting the growth of heat pump industry.

According to the U.S. Department of Energy, a 30% tax credit can be claimed for buying a property in the U.S. that has qualified heat pumps installed in connection with an existing or new dwelling unit. Italy's Conto Termico incentive scheme provides grants that cover 30-35% of costs of installing renewable heating systems in buildings. Australia also provides national grants to municipals for heat pump installation. Moreover, heat pump industry is significantly affected by the availability of raw materials, such as metals like iron & steel, adhesives, rubber, chemicals, and plastics. Thus, fluctuations in raw material prices have a direct impact on manufacturing costs, which can limit market growth to some extent.

Gather more insights about the market drivers, restrains and growth of the Heat Pump Market

The temperature of soil in most areas of the U.S. is warmer than air during winters and cooler in summers. Ground source heat pumps use the ground's constant temperature to cool and heat buildings. According to the Environmental Protection Agency (EPA), GHPs are the most cost-effective, environmentally clean, and energy-efficient systems for cooling and heating buildings, including homes, offices, schools, and hospitals, owing to which demand for heat pumps is expected to increase in the U.S. over the forecast period.

The U.S. government has provided personal tax credits and direct incentives on product installation, which encourage the installation of heat pumps. Improving energy efficiency across various industries is one of the major objectives of governments across the world. The rising need for renewable energy sources, along with extensive government support in the form of subsidies, incentives, and other monetary benefits, is projected to fuel market growth over the forecast period. Air Source technology is expected to dominate the market in the U.S. over the forecast period due to rising awareness about adverse effects of greenhouse gas emissions. Furthermore, increasing population along with increasing need for eco-friendly air conditioning in housing sector is expected to drive demand for air-source technology in the U.S.

Fast-paced industrialization along with growing population has resulted in massive energy consumption across the world. According to EIA’s U.S. residential energy consumption survey, heating, cooling, & ventilation accounted for half of total home energy consumption. In 2021, based on total fuel consumption, natural gas accounted for 44%, and fuel oil & propane accounted for a 9.0% share. Furthermore, electricity was the most consumed energy source across the U.S. with households accounting for 47%. Thus, increasing demand for energy-efficient solutions and growing carbon footprints across the globe are expected to drive the market’s growth over the forecast period.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The global aerostructure materials market size was estimated at USD 82.63 billion in 2023 and is projected to grow at a CAGR of 7.2% from 2024 to 2030. This growth is attributed to the increasing preference for sustainable and efficient aerostructure to decrease the overall weight of an aircraft and reduce fuel consumption. Additionally, the growing number of regulations and standards to reduce carbon emissions is further increasing aircraft manufacturers' inclination toward eco-friendly aerostructure materials, thereby, fueling the market growth.

The global CNC router machine market size was estimated at USD 691.0 million in 2023 and is projected to grow at a CAGR of 3.5% from 2024 to 2030. The increasing need for automation and precision in manufacturing processes across various industries primarily drives the rising demand for CNC router machines. CNC routers have become essential tools as companies strive to enhance efficiency, reduce human errors, and maintain consistent product quality. For example, the automotive industry utilizes CNC routers for precise component manufacturing, aligning with the trend toward electric vehicles and advanced manufacturing techniques.

Heat Pump Market Segmentation

Grand View Research has segmented the global heat pump market based on technology, capacity, operation type, application, and region:

Heat Pump Technology Outlook (Revenue, USD Billion, 2018 - 2030)

Air Source

Air to Air

Air to Water

Water Source

Geothermal

Heat Pump Capacity Outlook (Revenue, USD Billion, 2018 - 2030)

Up to 10 kW

10-20 kW

20-50 kW

50-100 kW

100-200 kW

Above 200 kW

Heat Pump Operation Type Outlook (Revenue, USD Billion, 2018 - 2030)

Electric

Hybrid

Heat Pump Application Outlook (Revenue, USD Billion, 2018 - 2030)

Residential

Industrial

Commercial

Heat Pump Region Outlook (Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

Sweden

Norway

Spain

Finland

Asia Pacific

China

Japan

Australia

India

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

UAE

Saudi Arabia

Order a free sample PDF of the Heat Pump Market Intelligence Study, published by Grand View Research.

Key Companies profiled:

Carrier

Daikin Industries, Ltd

Robert Bosch GmbH

Lennox International

Johnson Controls, Inc.

Midea Group

Hitachi, Ltd.

Ingersoll Rand Plc.

Rheem Manufacturing Company

HAIER(GENERAL ELECTRIC)

Panasonic Holdings Corporation

Danfoss

Fujitsu

LG Electronics, Inc.

Samsung

Recent Developments

In January 2023, Johnson Controls acquired Hybrid Energy AS. Hybrid Energy's innovative technology will provide customers with fresh, cost-effective solutions while tackling decarbonization and sustainability efforts in Europe and beyond.

0 notes

Text

The Ultimate Guide to Water Repellent Coatings by ADT Industries

In today’s world, where durability and longevity of materials are paramount, water repellent coatings have become indispensable across various industries. ADT Industries, a leader in innovative coating solutions, brings you the ultimate guide to understanding and utilizing water repellent coatings.

What are Water Repellent Coatings?

Water repellent coatings are specialized treatments applied to surfaces to make them resistant to water penetration. These coatings work by creating a hydrophobic layer, which causes water to bead up and roll off rather than being absorbed. This technology is essential for protecting materials from water damage, increasing their lifespan, and maintaining their appearance.

Applications of Water Repellent Coatings

1. Construction Industry:

*Protects buildings and structures from water infiltration and damage.

*Enhances the durability of concrete, bricks, and stones.

2. Textile Industry:

*Used on fabrics to make them water-resistant.

*Ideal for outdoor clothing, tents, and awnings.

3. Automotive Industry:

*Applied to car exteriors to prevent water spots and corrosion.

*Used on windshields for better visibility during rain.

4. Electronics:

*Protects electronic components from moisture, ensuring longevity and reliability.

5. Aerospace:

*Critical for protecting aircraft from moisture-related damage and corrosion.

Benefits of ADT Industries’ Water Repellent Coatings

1. Enhanced Durability:

*Our coatings significantly extend the life of materials by preventing water-related degradation.

2. Cost-Effective:

o By reducing the need for frequent repairs and replacements, our coatings offer excellent value for money.

3. Aesthetic Preservation:

*Keeps surfaces looking new by preventing water stains and mold growth.

4. Environmental Protection:

*Our coatings are designed to be environmentally friendly, reducing the need for harsh cleaning chemicals.

Why Choose ADT Industries?

1. Innovative Solutions:

*ADT Industries leads the market with cutting-edge technology and innovative solutions tailored to meet diverse industry needs.

2. Quality Assurance:

*We are committed to delivering the highest quality products, ensuring reliable and consistent performance.

3. Customer Support:

*Our team of experts is dedicated to providing exceptional customer service and support, helping you choose the right coating for your needs.

4. Sustainable Practices:

*We prioritize sustainability in our manufacturing processes, contributing to a greener planet.

How to Apply Water Repellent Coatings

Applying water repellent coatings can vary depending on the surface and type of coating used. Here are general steps for application:

1. Surface Preparation:

*Clean the surface thoroughly to remove any dirt, grease, or previous coatings.

2. Application:

*Apply the coating evenly using a brush, roller, or spray, following the manufacturer’s instructions.

3. Drying:

*Allow the coating to dry completely. This can take anywhere from a few hours to a day, depending on the product and environmental conditions.

4. Maintenance:

*Periodically inspect the coated surface and reapply the coating as needed to maintain its effectiveness.

Conclusion

Water repellent coatings by ADT Industries offer unparalleled protection and value across a wide range of applications. Whether you are looking to protect your home, vehicle, textiles, or electronics, our high-quality coatings provide the durability and performance you need. Trust ADT Industries for innovative, reliable, and environmentally friendly coating solutions.

For more information or to explore our range of products, visit our website or contact our expert team today www.adtchemical.com /+91 9619304200 Protect your investments with the best — choose ADT Industries.

1 note

·

View note

Text

Applications of Hastelloy in Different Industries

Hastelloy, a family of nickel-based alloys, is renowned for its exceptional resistance to corrosion, making it a material of choice across various industries. Its unique properties enable it to perform effectively in environments that would be detrimental to other materials, thus driving its widespread application.

About SMM Industries

SMM Industries has been at the forefront of the specialty alloys market for over a decade. Our dedication to excellence and customer-centric approach has made us a preferred choice for businesses seeking high-performance Hastelloy Products Supplier and Manufacturer. We pride ourselves on our state-of-the-art manufacturing facilities, stringent quality control processes, and a team of experts who are passionate about delivering the best solutions to our clients.

In the chemical processing industry, Hastelloy plays a crucial role due to its ability to withstand highly corrosive environments. It is commonly used in reactors, heat exchangers, and pipes where it encounters a wide range of harsh chemicals and temperatures. The alloy’s resistance to pitting and stress-corrosion cracking ensures long-term durability and safety, which are paramount in the processing of aggressive chemicals such as hydrochloric acid, sulfuric acid, and chlorine.

The aerospace industry also benefits significantly from Hastelloy’s properties. Aircraft and spacecraft components must endure extreme conditions, including high temperatures and corrosive environments. Hastelloy’s high-temperature strength and oxidation resistance make it ideal for use in jet engines, exhaust systems, and other critical components that operate under severe thermal and mechanical stress. Its reliability in such demanding applications helps ensure the safety and performance of aerospace machinery.

In the oil and gas industry, the challenges of deep-sea drilling and extraction operations require materials that can resist the corrosive effects of seawater and harsh chemicals. Hastelloy Products Supplier and Manufacturer is extensively used in downhole tubing, wellheads, and other subsea equipment. Its exceptional corrosion resistance to hydrogen sulfide and chlorides, commonly found in these environments, helps prevent equipment failure and extends service life, reducing maintenance costs and downtime.

The pharmaceutical industry, where purity and contamination control are vital, also leverages Hastelloy's properties. Equipment such as reactors, mixers, and storage vessels must resist corrosion to avoid contamination of the pharmaceutical products. Hastelloy Products Supplier and Manufacturer non-reactivity and ease of cleaning make it an ideal material for maintaining the high standards of cleanliness required in pharmaceutical manufacturing processes.

Additionally, Hastelloy Products Supplier and Manufacturer is employed in the power generation industry, particularly in nuclear power plants. The alloy’s ability to withstand high temperatures and radiation makes it suitable for use in reactor cores, heat exchangers, and containment vessels. Its durability under extreme conditions helps ensure the safe and efficient operation of nuclear power facilities.

Conclusion

Choosing the right Hastelloy Products Supplier and Manufacturer is crucial for the success of your projects. SMM Industries is committed to providing top-quality Hastelloy solutions that meet the demanding requirements of various industries. With our focus on quality, technical expertise, and customer satisfaction, we are your trusted partner for all your Hastelloy needs.

Contact us today to learn more about our products and how we can assist you in achieving your project goals.

To know more: https://www.smmindustriesllp.com/hastelloy-products/

0 notes

Text

Ethylene-tetrafluoro-ethylene (ETFE) Market Report: Trends, Analysis, and Projections

Ethylene-tetrafluoro-ethylene (ETFE) is a high-performance fluoropolymer known for its exceptional properties, making it a preferred choice in various industries. This blog explores the dynamics of the global ETFE market, analyzing key drivers, applications across sectors, emerging trends, and future growth prospects.

Understanding the ETFE Market:

Ethylene-tetrafluoro-ethylene (ETFE) Is a fluoropolymer with a unique combination of properties including high transparency, excellent chemical resistance, thermal stability, and mechanical strength. These attributes make ETFE suitable for diverse applications in construction, aerospace, automotive, renewable energy, and more.

Market Dynamics:

Architectural Applications: ETFE is used in architectural membranes for roofs, facades, and canopies due to its lightweight nature, UV resistance, durability, and ability to create innovative, transparent structures in modern building designs.

Automotive and Aerospace: In automotive and aerospace industries, ETFE films find applications in wire insulation, tubing, fuel lines, and aircraft interiors due to their chemical inertness, low flammability, and electrical properties.

Renewable Energy: ETFE is used in photovoltaic (PV) modules as a transparent and durable encapsulation material, enhancing solar panel efficiency and longevity in harsh environmental conditions.

Industrial Applications: ETFE coatings and linings provide corrosion resistance and chemical inertness in industrial equipment such as tanks, pipes, valves, and chemical processing components.

Applications Across Industries:

Construction: Architectural membranes, roofing, facades.

Automotive and Aerospace: Wire insulation, tubing, interiors.

Renewable Energy: PV module encapsulation.

Industrial: Coatings, linings for corrosion resistance.

Market Trends:

Focus on Sustainable Construction: Growing demand for sustainable and energy-efficient buildings drives the use of ETFE in architectural applications, as it allows natural light penetration while reducing energy consumption for lighting.

Innovations in ETFE Films: Advances in ETFE film technology, including self-cleaning properties, anti-fog coatings, and improved UV stability, cater to specific industry needs and enhance product performance.

Emerging Applications: Increased adoption of ETFE in emerging sectors such as medical devices, aerospace composites, and electrical insulation systems due to its versatility, reliability, and material properties.

Future Prospects:

The global ETFE market is poised for significant growth, fueled by increased infrastructure development, sustainability initiatives, technological advancements, and expanding application areas. Investments in research, manufacturing capabilities, and market partnerships will shape the market's evolution and unlock new growth opportunities.

Conclusion:

Ethylene-tetrafluoro-ethylene (ETFE) stands out as a versatile fluoropolymer with wide-ranging applications across industries, from construction and automotive to renewable energy and beyond. Understanding market dynamics, technological innovations, and sustainability imperatives is crucial for stakeholders in the ETFE market to leverage growth opportunities effectively. With a focus on innovation, sustainability, and diverse application development, the ETFE market presents promising prospects for continued growth and leadership in the global polymer industry landscape.

0 notes

Text

Breathing Easy: Insights into the Commercial Aircraft Oxygen System Market

Safety is paramount in aviation, and one crucial aspect of ensuring passenger safety aboard commercial aircraft is the provision of reliable oxygen systems. Commercial aircraft oxygen systems play a vital role in providing breathable air to passengers and crew in the event of an emergency, such as cabin depressurization or smoke in the cabin. As aviation technology evolves and safety regulations become increasingly stringent, the commercial aircraft oxygen system market continues to evolve to meet the demands of the industry.

One of the primary drivers behind the commercial aircraft oxygen system market's growth is the aviation industry's relentless focus on safety and risk mitigation. Regulatory authorities, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), mandate stringent requirements for commercial aircraft oxygen systems to ensure they meet the highest safety standards. This includes regulations governing oxygen storage, distribution, and delivery systems, as well as requirements for oxygen masks and emergency oxygen supply durations.

Moreover, advancements in aircraft design and technology have led to improvements in commercial aircraft oxygen systems, making them more efficient, reliable, and user-friendly. Modern aircraft are equipped with sophisticated oxygen generation systems (OGS) that produce oxygen onboard using chemical reactions or electrolysis, eliminating the need for bulky and heavy oxygen cylinders. These OGS systems provide a continuous supply of oxygen to the cabin, ensuring passengers and crew have access to breathable air at all times, even during extended flights.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS25946/?utm_source=Govind-Article

Additionally, the increasing demand for air travel, particularly in emerging markets, is driving the growth of the commercial aircraft oxygen system market. As air traffic continues to grow, airlines are expanding their fleets and investing in new aircraft equipped with state-of-the-art oxygen systems. Retrofitting existing aircraft with upgraded oxygen systems is also becoming increasingly common as airlines strive to enhance passenger comfort and safety and comply with evolving regulatory requirements.

Furthermore, the COVID-19 pandemic has highlighted the importance of cabin air quality and passenger health and safety, leading to renewed focus on commercial aircraft oxygen systems. While cabin depressurization events are rare, ensuring passengers have access to clean and breathable air is essential for their well-being and peace of mind. Airlines and aircraft manufacturers are exploring new technologies and innovations to enhance cabin air filtration and ventilation systems, further bolstering the importance of oxygen systems in commercial aircraft.

Despite the opportunities for growth, the commercial aircraft oxygen system market also faces challenges, including cost constraints, regulatory compliance, and technological complexity. Developing and certifying oxygen systems for commercial aircraft is a highly regulated and time-consuming process, requiring extensive testing and validation to ensure compliance with safety standards and regulations. Additionally, the COVID-19 pandemic has disrupted global supply chains and manufacturing operations, leading to delays and shortages of critical components for oxygen systems.

In conclusion, the commercial aircraft oxygen system market plays a critical role in ensuring passenger safety and comfort aboard commercial aircraft. As the aviation industry continues to evolve and adapt to changing passenger needs and regulatory requirements, the demand for advanced and reliable oxygen systems will remain strong. By investing in innovation, safety, and regulatory compliance, manufacturers and suppliers of commercial aircraft oxygen systems can capitalize on opportunities for growth and contribute to safer and more comfortable air travel experiences for passengers around the world.

0 notes

Text

The Aircraft Fuel Cell Market size is projected to grow from USD 1.6 Billion in 2023 to USD 5.7 Billion by 2035, at a CAGR of 10.8% from 2023 to 2035. Aircraft fuel cells serve a vital function in the aviation industry by providing efficient and clean power generation for various applications. Fuel cells convert the chemical energy of fuels, like hydrogen or hydrocarbon, into electricity through an electrochemical process. In Aircraft Fuel Cell Industry, these are utilized for propulsion systems, enabling more efficient and environmentally friendly aircraft engines. They also find application as auxiliary power units (APUs), supplying electricity for aircraft systems during ground operations and reducing reliance on traditional engine-based power generation. Additionally, fuel cells are used as backup power sources in emergency situations, ensuring uninterrupted operation of critical systems. By powering essential equipment and systems, such as communication, navigation, and safety devices, fuel cells enhance aircraft safety and reliability.

#Aircraft Fuel Cells#Aircraft Fuel Cells Market#Aircraft Fuel Cells Industry#Global Aircraft Fuel Cells Market#Aircraft Fuel Cells Market Companies#Aircraft Fuel Cells Market Size#Aircraft Fuel Cells Market Share#Aircraft Fuel Cells Market Growth#Aircraft Fuel Cells Market Statistics

0 notes

Text

Aircraft Recycling Market Soars to New Heights, Valued at $11.28 Billion in 2030

Aircraft recycling is a systematic process encompassing the dismantling, salvaging, and responsible disposal of aircraft that have reached the conclusion of their operational life, spanning commercial airliners, cargo planes, military aircraft, and various other types. The primary objective of aircraft recycling is to maximize the recovery of valuable materials, components, and parts from retired aircraft while minimizing environmental impact. The multi-stage aircraft recycling process begins with the removal of the aircraft from active service and its transportation to a specialized recycling facility. Trained professionals then assess the aircraft's condition, creating a comprehensive inventory of its components. Subsequently, the dismantling phase involves the careful removal of materials like aluminum, titanium, steel, and composites, followed by sorting, cleaning, and preparation for recycling or resale.

To Know More Request Sample of this Report@ https://www.infiniumglobalresearch.com/market-reports/sample-request/402

Aircraft recycling not only focuses on material recovery but also involves the retrieval of valuable aircraft parts. These components can undergo refurbishment and find a second life in the aftermarket, providing cost-effective alternatives for aircraft operators and maintenance providers. The process also addresses the safe disposal of hazardous materials in compliance with environmental regulations, including chemicals, fuels, and other potentially harmful substances. Aligned with sustainability and environmental responsibility principles, aircraft recycling significantly contributes to reducing the carbon footprint of the aviation industry. By diverting aircraft from landfills and promoting material reuse, the industry actively supports the concept of the circular economy, fostering a more eco-friendly and resource-efficient aviation sector.

The growth of the aircraft recycling market is propelled by the increasing number of retired airplanes. As more aircraft reach the end of their operational lives, the demand for recycling services experiences a corresponding surge, driving the expansion of the aircraft recycling industry. The economic benefits of recovering valuable materials and aircraft parts further contribute to the market's growth. Recoverable metals such as aluminum, titanium, steel, and composite materials are recyclable, and airlines worldwide are increasingly adopting recovered aircraft parts. While the establishment of recycling facilities and the acquisition of necessary equipment involve substantial upfront costs, potentially hindering market growth, the rapidly growing aftermarket for aircraft parts presents lucrative opportunities for the aircraft recycling market.

Enquire Here Get Customization & Check Discount for Report @ https://www.infiniumglobalresearch.com/market-reports/customization/402

The aircraft recycling market is segmented into North America, Europe, Asia Pacific, and the rest of the world. North America is expected to hold a maximum share of the aircraft recycling market during the projected period. North America has one of the world’s largest and most established aviation industries. This region is home to numerous major airlines, aircraft manufacturers, and Maintenance, Repair, and Overhaul (MRO) facilities. Thus, the retirement and decommissioning of aircraft occur frequently, providing a consistent source for aircraft recycling companies. The sheer volume of retired aircraft in North America ensures a steady demand for recycling services. Moreover, the Europe region is anticipated to grab a significant share of the aircraft recycling market due to strict environmental regulations. The continent has been at the forefront of implementing strict environmental regulations and promoting sustainable aviation practices. As a result, aircraft operators and airlines in Europe are compelled to adopt eco-friendly recycling methods, to align with these stringent environmental standards.

Key Market Players:

Aircraft End-of-Life Solutions (AELS)

TARMAC AEROSAVE

ecube,inc

AIR SALVAGE INTERNATIONAL LTD

Aviation International Recycling

Vallair

VIRTUSTRADE RECYCLING AIRPLANES

ComAv - Commercial Aviation Services

VAS Aero Services, LLC

CAVU Aerospace Inc.

More Insights on this report, Speak to Our Analyst @ https://www.infiniumglobalresearch.com/market-reports/enquiry/402

About Us:

Infinium Global Research LLP is started with a single motto of being business partner of first choice. We at Infinium work on the strengths of our clients to ensure we help them consolidate their market position. We firmly believe in the fact that ‘if you are able to develop newer opportunities then you find there is no dearth of opportunities for you. With our strategic research approaches and deep dive in the market segments, we try to find out new opportunities that our clients can encash with their existing resources. Our experts with over 100 years of cumulative experience in research offer the best in the industry services to our clients to ensure that they achieve their business goals.

Contact us:

Infinium Global Research LLP 2nd Floor, Ganadish Empire

Rahatani Chowk, Pimple Saudagar

Pimpri-Chinchwad, Maharashtra 411027

Call us: +91 99239 50043

#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes