#Air dryer for air compressor Manufacturers

Explore tagged Tumblr posts

Text

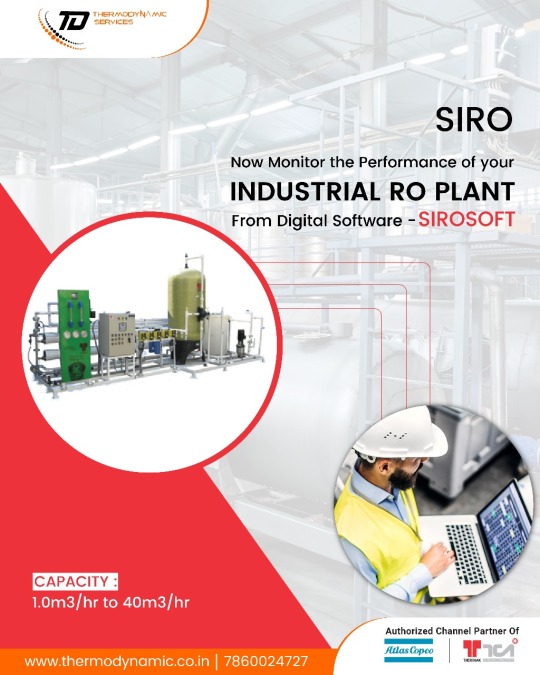

Atlas Copco Air Compressor Dealer in Uttar Pradesh - Thermodynamic Services

Welcome to Thermodynamic Services, your trusted partner for top-notch industrial air compressors and compressed air solutions in Uttar Pradesh. As the premier Atlas Copco dealer in the region, we take pride in delivering cutting-edge technology and reliable products to meet your diverse compressed air needs.

Atlas Copco Air Compressors in Uttar Pradesh:

At Thermodynamic Services, we specialize in offering a comprehensive range of Atlas Copco air compressors in Uttar Pradesh. Our commitment to quality and efficiency ensures that your industrial operations run smoothly with the most advanced and reliable compressed air solutions.

Atlas Copco Dealer in Kanpur:

If you are based in Kanpur and searching for a reliable Atlas Copco dealer, look no further than Thermodynamic Services. We bring you the latest models of Atlas Copco air compressors, combining innovation and durability to enhance your industrial processes.

Industrial Air Compressor Manufacturer & Supplier in Kanpur:

As a leading industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services provides customized solutions tailored to meet the unique requirements of your business. Our state-of-the-art compressors are designed to optimize energy efficiency and minimize downtime.

Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:

Thermodynamic Services is your go-to Atlas Copco compressed air dryer dealer in Uttar Pradesh. Our range of air dryers ensures that your compressed air is free from moisture, contaminants, and impurities, guaranteeing the longevity and efficiency of your equipment.

Unmatched Quality and Reliability:

When you choose Thermodynamic Services, you invest in unparalleled quality and reliability. Our partnership with Atlas Copco, a global leader in compressed air technology, ensures that you receive products that adhere to the highest industry standards.

Customer-Centric Approach:

At Thermodynamic Services, customer satisfaction is our priority. Our team of experienced professionals is dedicated to understanding your specific needs and providing tailored solutions. We believe in building lasting relationships with our clients through exceptional service and support.

Conclusion:

For all your industrial air compressor needs in Uttar Pradesh, Thermodynamic Services stands as the preferred choice. As the foremost Atlas Copco dealer in the region, we guarantee top-quality products, unmatched reliability, and a customer-centric approach. Elevate your industrial processes with Thermodynamic Services – your trusted partner for compressed air solutions.

conatct us on 91 78600 24711

#industrial air compressor dealer in uttar pradesh#Atlas Copco Air Compressor#Atlas Copco Air Compressors in Uttar Pradesh:#Atlas Copco Dealer in Kanpur#Industrial Air Compressor Manufacturer & Supplier in Kanpur:#Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:#industrial air compressor needs in Uttar Pradesh

5 notes

·

View notes

Text

Super Fast Technology: Top Chiller & Air Dryer Manufacturer

Super Fast Technology: Leading the Way as the Best Chiller Plant Manufacturer in India and Delhi

When it comes to industrial cooling solutions, Super Fast Technology stands out as a market leader. With a rich legacy of innovation and quality-driven manufacturing, the company has firmly positioned itself as the best chiller plant manufacturer in India and the best chiller plant manufacturer in Delhi. Whether you're looking for precision-engineered chiller systems, air dryers, or compressor tanks, Super Fast Technology offers a wide array of efficient, high-performance products tailored to diverse industry needs.

Pioneers in Chiller Manufacturing Across India and Delhi

Super Fast Technology is trusted by clients across various sectors—from pharmaceuticals and beverages to chemical processing and manufacturing. The company’s extensive range of chillers includes:

1. Screw Chillers

Known for their efficiency and reliability, Super Fast Technology is recognized among the top screw chiller manufacturers in India and screw chiller manufacturers in Delhi. These chillers are ideal for large-scale industrial cooling and HVAC applications.

2. Scroll Chillers

Compact yet powerful, scroll chillers are gaining popularity for medium-scale operations. As leading scroll chiller manufacturers in India and scroll chiller manufacturers in Delhi, Super Fast Technology provides durable and energy-efficient models to meet specific industrial requirements.

3. Oil Chillers

Specialized for applications that require maintaining low oil temperatures, the company is also known as one of the best oil chiller manufacturers in India and oil chiller manufacturers in Delhi. These chillers are commonly used in hydraulic systems and machine tools.

4. Glycol Chillers

Used extensively in food, beverage, and pharmaceutical industries, Super Fast Technology has earned a reputation as reliable glycol chiller manufacturers in India and glycol chiller manufacturers in Delhi. These chillers are designed for low-temperature applications and glycol-based cooling processes.

5. Beverage Chillers

Beverage companies trust Super Fast Technology for consistent cooling performance. As trusted beverage chiller manufacturers in India and beverage chiller manufacturers in Delhi, the company ensures hygienic and temperature-controlled processing environments.

6. Air Cooled Chillers

Cost-effective and energy-saving, Super Fast Technology is a prominent name among air cooled chiller manufacturers in India and air cooled chiller manufacturers in Delhi. These chillers are best suited for regions with limited water resources.

Air Dryer Systems: Reliable and Efficient

Alongside its diverse range of chillers, Super Fast Technology also excels in air drying solutions.

1. Refrigerated Air Dryers

Designed to remove moisture from compressed air systems, Super Fast Technology is a well-established refrigerated air dryer supplier in Delhi and refrigerated air dryer manufacturer in Delhi. These dryers play a vital role in protecting machinery and maintaining system efficiency.

2. High-Pressure Air Dryers

For industries requiring ultra-dry air at high pressures, the company ranks high among high pressure air dryer manufacturers in India and high pressure air dryer manufacturers in Delhi.

3. General Air Dryers

As a top air dryer manufacturer in Delhi, Super Fast Technology offers a comprehensive range of air dryers that are tailored to meet various moisture-removal needs across sectors.

Air Compressor Dryer Systems and Tanks

A crucial part of many manufacturing and industrial setups is the air compressor dryer system. Super Fast Technology provides end-to-end solutions as a leading supplier of:

Air Compressor Dryer System in Delhi

Air Compressor Dryer System in India

These systems are designed for seamless integration and superior air quality.

The company also manufactures reliable compressor storage tanks and provides competitive pricing for:

Air Compressor Tank Price in India

Air Compressor Tank Price in Delhi

Water Cooling and Condenser Solutions

1. Water Chillers

As one of the top water chiller manufacturers in Delhi and water chiller suppliers in Delhi, Super Fast Technology ensures consistent and high-efficiency cooling for numerous industrial applications.

2. Water-Cooled Condensers

The company is also a trusted water cooled condenser manufacturer in Delhi, offering durable systems built to withstand harsh environments and ensure long operational life.

Heat Exchanger Manufacturing

Heat exchangers are integral to efficient thermal transfer. As a reputed heat exchanger manufacturer in Delhi, Super Fast Technology delivers solutions that support energy conservation and optimized system performance.

Why Choose Super Fast Technology?

Custom Solutions: Each system is tailored to client requirements for optimum performance.

Energy Efficiency: Products are designed for lower power consumption and minimal environmental impact.

After-Sales Support: Unmatched customer service with quick maintenance and troubleshooting support.

Experience and Expertise: With years of industry experience, Super Fast Technology offers high-tech, scalable solutions.

Conclusion

If you're seeking robust and reliable industrial cooling and compressed air solutions, Super Fast Technology is your ideal partner. Recognized as the best chiller plant manufacturer in India and Delhi, their products are a benchmark in quality and innovation. From air dryers to scroll chillers, from compressor tanks to heat exchangers, the brand continues to serve as a one-stop destination for excellence in engineering.

For more information, product demos, or pricing details, get in touch with Super Fast Technology today.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers in india#Screw chiller manufacturers in delhi#Oil chiller manufacturers in India#Oil chiller manufacturers delhi#Glycol chiller manufacturers India#Glycol chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturers in Delhi#Water Chiller Supplier in Delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Beverage chiller manufacturers in india#Beverage chiller manufacturers in delhi#High pressure air dryer manufacturers in india#High pressure air dryer manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#heat exchanger manufacturer in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi

0 notes

Text

Airomach Engineers: Leading Chiller & Air Dryer Solutions

Airomach Engineers: Leading the Future of Industrial Cooling and Compressed Air Solutions in India

In the realm of industrial cooling and air management systems, Airomach Engineers has firmly established itself as a pioneer. With a strong foundation in innovation, quality manufacturing, and tailored engineering solutions, the company is widely recognized as the Best chiller plant manufacturer in India and Best chiller plant manufacturer in Delhi.

Serving diverse industries such as food processing, pharmaceuticals, beverages, plastics, and heavy engineering, Airomach Engineers offers an extensive range of high-performance equipment — from water chillers and screw chillers to refrigerated air dryers and air compressor systems.

Chiller Systems Tailored for Performance

Screw Chillers: Power Meets Precision

Airomach Engineers stands tall among Screw chiller manufacturers in India and Screw chiller manufacturers in Delhi, offering robust screw chiller systems designed for high capacity and continuous operation. These chillers are ideal for large-scale industrial applications that demand energy-efficient cooling with minimal maintenance.

Scroll Chillers: Compact, Efficient & Reliable

When it comes to small to mid-scale cooling applications, Airomach is one of the top Scroll chiller manufacturers in India and Scroll chiller manufacturers in Delhi. Their scroll chillers are known for their quiet operation, compact design, and high efficiency — making them ideal for commercial buildings, laboratories, and more.

Oil Chillers: Specialized Cooling for Machines

Industrial equipment such as CNC machines and hydraulic presses require precise oil temperature control. As trusted Oil chiller manufacturers in India and Oil chiller manufacturers in Delhi, Airomach delivers oil chillers engineered for accuracy, durability, and performance in demanding environments.

Glycol Chillers: Consistent Cooling for Sensitive Applications

Whether it's food-grade applications or chemical industries, Airomach is a trusted name among Glycol chiller manufacturers in India and Glycol chiller manufacturers in Delhi. Their glycol chillers offer consistent cooling, corrosion resistance, and temperature control down to sub-zero levels.

Beverage Chillers: Designed for Purity and Efficiency

Airomach has carved a niche among Beverage chiller manufacturers in India and Beverage chiller manufacturers in Delhi with chillers specifically designed to maintain product quality and safety. Their beverage chillers are hygienically built, energy-efficient, and compliant with industry standards.

Air Cooled and Water Cooled Chillers

As a comprehensive Air cooled chiller manufacturer in India and Air cooled chiller manufacturer in Delhi, Airomach delivers units with advanced compressor technologies and low noise levels. Additionally, their Water cooled condenser manufacturers in Delhi category offers water-efficient systems ideal for environments with limited air flow.

Refrigerated Air Dryers & Air Compressor Systems

Refrigerated Air Dryers

Moisture in compressed air can cause significant equipment damage and product contamination. Airomach is a preferred Refrigerated Air Dryer Supplier in Delhi and Refrigerated Air Dryer Manufacturer in Delhi, providing dryers that ensure dry, clean, and reliable air for industrial use.

High Pressure Air Dryers

For applications requiring ultra-dry and high-pressure air, Airomach leads as High pressure air dryer manufacturers in India and High pressure air dryer manufacturers in Delhi, with systems engineered for safety, efficiency, and long-term reliability.

Air Compressor Dryer Systems

Airomach Engineers also ranks high in delivering complete Air Compressor Dryer System in Delhi and Air Compressor dryer system in India packages. These integrated systems help industries maintain superior air quality, reduce maintenance costs, and increase productivity.

Air Compressor Tanks and Heat Exchangers

Airomach provides durable and cost-effective compressed air storage solutions, making them a go-to source for Air Compressor Tank Price in India and Air Compressor Tank Price in Delhi. Whether for large or small-scale setups, their air receiver tanks are certified, tested, and built to last.

The company also excels as a Heat exchanger manufacturer in Delhi, delivering shell and tube, plate, and customized heat exchangers suitable for diverse thermal transfer applications.

Why Choose Airomach Engineers?

Unmatched Expertise: With years of experience in manufacturing and engineering, Airomach offers highly customized solutions tailored to specific industrial needs.

Pan-India Presence: Trusted across the country, Airomach is a recognized name for chillers and air dryers — from Delhi to the remotest corners of India.

Quality Assurance: All products go through rigorous testing and comply with international manufacturing standards.

Competitive Pricing: From Air Compressor Tank Price in Delhi to chillers and air dryers, Airomach ensures the best value for money.

Customer Support: With round-the-clock support and service centers across the country, Airomach delivers reliability beyond just products.

Final Thoughts

If you're looking for premium industrial cooling systems and air management solutions, Airomach Engineers is your trusted partner. With a reputation as the Best chiller plant manufacturer in India and a proven track record in Delhi and beyond, Airomach continues to push boundaries in engineering excellence.

Whether you need a Scroll chiller, Oil chiller, Refrigerated air dryer, or an Air compressor system, Airomach offers world-class solutions with unmatched reliability and performance.

For more details, contact Airomach Engineers today and get a custom solution tailored to your industrial needs.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers in india#Screw chiller manufacturers in delhi#Oil chiller manufacturers in India#Oil chiller manufacturers delhi#Glycol chiller manufacturers India#Glycol chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturers in Delhi#Water Chiller Supplier in Delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Beverage chiller manufacturers in india#Beverage chiller manufacturers in delhi#High pressure air dryer manufacturers in india#High pressure air dryer manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#heat exchanger manufacturer in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi

0 notes

Text

PRECO is a leading Manufacturer Supplier of Air Compressors, Air Dryers, and Chillers in India, offering high quality, energy efficient solutions for industrial applications to boost performance and reliability.

Founded in 1993 in Mumbai, Pioneer Refrigeration Engineering Co. is a Leading Manufacturers, Supplier, Distributor & Service Provider Specializing in Air Compressors, Air Dryers, Chillers, and All Types of Industrial Refrigeration Equipment with Repair & Services. With over three decades of experience, we deliver cutting-edge solutions for compressed air treatment and industrial cooling, helping businesses optimize their processes and improve air quality.

0 notes

Text

Choosing the right air dryer for your industry involves careful consideration of your specific needs, the type of dryer, energy efficiency, and budget. By evaluating these factors, you can select a dryer that not only meets your compressed air quality requirements but also provides long-term savings and reliability. Whether your industry demands ultra-dry air or you need a cost-effective solution, there is an air dryer out there that’s perfect for your application.

0 notes

Text

youtube

We recently supplied a 40 CFM air dryer to Flexible Steel Lacing Co Pvt Ltd at their Chennai, Tiruvallur plant, complete with a pre-air filter, carbon air filter, and necessary connection accessories. This air dryer system is designed to remove moisture and contaminants from compressed air, ensuring optimal equipment performance and longevity. By delivering clean, dry air, it reduces maintenance costs, prevents corrosion, and enhances overall operational efficiency. Our comprehensive compressed air solutions are tailored to meet the unique needs of industrial applications, ensuring reliability and efficiency.

#dryer#air dryer#air compressor#compressor service#dryer sales#dryer filter#pre filter#carbon filter#pneumatic systems#pneumatic compressor service#compressor sales#pneumatic blowers#chennai#manufacture#sales & service#www.svblowers.in#Youtube

1 note

·

View note

Text

Questions to Ask Reciprocating Compressor Manufacturers in Delhi Before Purchase

When searching for Reciprocating Compressor Manufacturers in Delhi, Like G.S Machinery it is crucial to ask the right questions to ensure you make an informed decision. These compressors are significant investments, and understanding your specific requirements is the first step. Assess your needs regarding capacity, pressure, and application to have a clear conversation with the manufacturers. This approach ensures you find a compressor that perfectly matches your operational demands.

Experience and Expertise

A critical question to ask is about the manufacturer’s experience and expertise. How long have they been in the industry, and what kind of projects have they handled? Manufacturers with extensive experience typically have a better understanding of different industry requirements and can offer valuable insights. Their expertise can help you navigate the complexities of choosing the right reciprocating compressor, ensuring you get a reliable and efficient product.

Quality Standards and Certifications

Quality is paramount when investing in a reciprocating compressor. Inquire about the quality standards and certifications that the manufacturer adheres to. Do they comply with national and international standards? Certifications such as ISO can be indicative of their commitment to quality. Understanding their quality control processes can give you confidence in the durability and performance of the compressor you are purchasing.

Customization Options

Every industry has unique needs, and sometimes, off-the-shelf solutions may not be ideal. Ask the manufacturers about their customization options. Can they tailor the reciprocating compressor to suit your specific requirements? Customization can include modifications in design, capacity, and additional features that enhance the compressor's functionality for your particular application. This flexibility can be crucial in ensuring optimal performance and efficiency.

Comparing Alternatives

While focusing on reciprocating compressors, it is also beneficial to consider other types of compressors, such as those offered by Screw Compressor Manufacturers in Delhi, like G.S Machinery. Understanding the differences and advantages of various compressor types can help you make a well-rounded decision. Screw compressors, for example, might be more suitable for certain applications due to their continuous operation and lower maintenance requirements.

Maintenance and Support Services

Maintenance is an integral part of owning a reciprocating compressor. Inquire about the maintenance services provided by the manufacturer. Do they offer regular maintenance and after-sales support? Knowing the extent of support available can save you time and money in the long run. A manufacturer that provides comprehensive maintenance and support services ensures that your compressor remains in peak condition, minimizing downtime and maximizing productivity.

Energy Efficiency

Energy efficiency is a key consideration in today’s environmentally conscious world. Ask the manufacturer about the energy efficiency of their compressors. How do they ensure that their products consume less energy while delivering optimal performance? Energy-efficient compressors not only reduce operational costs but also contribute to sustainability efforts. Manufacturers committed to energy efficiency are likely to incorporate advanced technologies and innovations in their products.

Warranty and Guarantee

Another important aspect to discuss is the warranty and guarantee offered by the manufacturer. What kind of warranty do they provide for their reciprocating compressors? A robust warranty policy is a sign of confidence in their product's quality and reliability. Understanding the terms and conditions of the warranty can help you make a more informed decision and provide peace of mind knowing that the manufacturer stands behind their product.

Additional Offerings

Manufacturers often provide a range of products beyond reciprocating compressors. It’s worth asking about other related products they offer, such as those from Chiller And Air Dryer Manufacturers in Delhi, like G.S Machinery. Integrating compatible systems from the same manufacturer can streamline your operations and ensure better overall efficiency. Knowing all the options available can help you build a more cohesive and efficient setup.

Customer Reviews and Testimonials

Lastly, don’t forget to ask for customer reviews and testimonials. What do other customers have to say about their products and services? Reviews can provide valuable insights into the manufacturer’s reliability, product quality, and customer service. Positive testimonials can reinforce your confidence in choosing the right manufacturer, while negative reviews can help you identify potential red flags.

#Reciprocating Compressor Manufacturers in Delhi#Screw Compressor Manufacturers in Delhi#Chiller And Air Dryer Manufacturers in Delhi

0 notes

Text

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

#Air dryer compressor#Compressed Air Piping#Pressure Vessels#Pressure Vessel Manufacturers#Plate type heat exchangers

0 notes

Text

Super Fast Technology is a manufacturer of compressed air and cooling system since 2013. An ISO 9001:2015 certified company, we specialise in design, engineering and fabrication of compressed air dryers, filters, air coolers and receivers.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers in india#Screw chiller manufacturers in delhi#Oil chiller manufacturers in India#Oil chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Water Chiller Supplier in Delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi

0 notes

Text

In need of a genuine air compressor for your industry? PRECO is one of the leading high-performance reciprocating air compressor suppliers in Mumbai, Maharashtra, and it is assured of performance and durability for all your needs. Air compressors are the very basic components of several industries, and they offer power to several applications. In particular, reciprocating compressors are commendable in their vast efficiencies and long life expectancy and produce high-pressure air. Because these compressors utilize a piston-driven scheme to compress air, they are particularly appropriate for use in manufacturing, automotive, construction, and other applications. When looking for a reliable manufacturer of reciprocating air compressors, you may safely rely upon PRECO. Founded in Mumbai, Maharashtra, PRECO is situated in Mumbai, Maharashtra, India. is a leading reciprocating air compressor manufacturer of high-quality compressors engineered from the design stage to suit the specified requirements of the industrial end-user.

#Reciprocating Air Compressor Supplier in India#Reciprocating Air Compressor Manufacturer#air dryer supplier#air compressor manufacturer#air compressor supplier#air compressor

0 notes

Text

The Importance of Air Dryer Compressors: A Comprehensive Guide

Air dryer compressors are vital in a wide range of industrial and commercial applications, delivering dry, clean, and efficient compressed air for optimal performance. By removing moisture and subtle impurities from the air, they help create a healthier and safer work environment. In humid conditions, compressed air dryers play an essential role in maintaining uninterrupted operations and preventing costly downtime. In this article, we will explore the importance of air dryer compressors, and their various types, highlight their applications, and offer practical tips for selecting the ideal system to meet specific needs.

What is an air dryer compressor?

An air dryer supplier is a specialised device or system designed to remove moisture from the air, ensuring the efficient process of compressed air systems. These systems are essential for facilities utilising compressed air, as compression significantly increases the relative humidity in a given space, potentially leading to operational challenges. Air dryer compressors serve using various methods, depending on the type of system in place. Regardless of the mechanism, their primary goal is to extract moisture from the air to prevent vapor condensation, allowing the system to work at peak efficiency. Common techniques employed by compressed air dryer manufacturers include adsorption, filtration, absorption, refrigeration, and diffusion, all of which work to eliminate excess moisture and maintain optimal performance.

Why is an air dryer supplier important?

Air dryer supplier is essential for well-functioning air compressor systems. Moisture is unavoidable with air compression — it’s a natural byproduct of the system, and without removal, your facility will soon have a moisture problem. Here are some of the advantages you can expect when you add air dryer compressors to the compression system:

Prevents freezing: If vapor condenses into water, the water can freeze in the face of low temperatures. Freezing can lead to jams in moving parts. It can also stash on process lines and interfere with process or product fluid movement.

Removes contamination: Contamination is a danger for industries using high-purity compressed air. Places like plasma generation, food and pharmaceutical products manufacturing, laser cutting and welding, painting, coating, and shot blasting all require pure compressed air to work. If water builds up, efficiency decreases, productivity slows or products get damaged.

Halts water buildup: Water will build up in small pockets within downstream equipment without moisture removal. Too much buildup can cause sensitive equipment to perform inaccurately, harming production quality and output.

Reduces microbial growth: The pharmaceutical and food and beverage industries use compressed air to mix and convey products. Water is prone to bacteria growth, and any water in the condensed air system can quickly lead to food and beverage spoilage or contamination. Additionally, small amounts of microbes in pharmaceutical plant products can result in entire batches being thrown out to avoid health risks.

Improves efficiency: If your facility uses air-powered equipment and tools powered by energy from compressed air systems, water will reduce its efficiency. It can damage internal parts and reduce the power delivered, impacting production.

Inhibits corrosion: Water is excellent at corroding steel. Components like pipes, drums, vessels, and tanks are commonly made from steel and will begin to break down when moisture buildup turns to water and corrosion. When corrosion conditions, process, and product streams can quickly become contaminated.

How does the air dryer supplier work?

At the most basic level, air dryer compressors separate moisture from industrial process air. Moisture is inherent to compressed air, so the air dryer must take that air and remove the excess moisture from it. This is done through diffusion, absorption, filtration, or refrigeration. Each method sends compressed air through the system, drawing out the water so that the system can work efficiently and without damage.

The action of an air dryer supplier and the way it protects compressed air from excess moisture will vary depending on the type of air dryer supplier used. The standard types of air dryer compressors include:

Refrigerated dryers: The most common type of air dryer compressors will see in an industrial compressed air system is the refrigerated dryers. These work by a simple mechanism of using one or more heat exchangers to cool down the hot compressed air, condense out the bulk of the water, and remove the water through a separator equipped with an automatic drain. If you are looking for a reasonably-priced dryer and do not need unusually high drying capabilities, these are often the best and most economical choices.

Desiccant dryers: If you are in a harsh situation where air is subject to very low temperatures or your products or environment cannot handle any moisture at all, a desiccant dryer may better serve you. These dryers use a material such as activated alumina to absorb water from the compressed air.

Specialty gas and liquid dryers: Water is not the only moisture-related contaminant that could impact on a facility. Many industries work with gases or liquids that might interfere with production. If your company works with exotic or dangerous gases or liquids that need drying, such as benzene, butane, hydrogen, or landfill gas, there are specialty dryers designed to safely remove moisture from these products. They work similarly to air dryers but focus on their specific gas or liquid removal instead of just water.

Membrane dryers: Membrane dryers are very efficient dryers that dehumidify and depress the dew point as the air comes into the system. These dryers have an absorbent membrane that allows water vapor to pass through. The membrane catches the water vapor, lowering the dew point temperature so condensation cannot occur. They are becoming increasingly popular as they require no electricity, have a low installation cost, are easy to maintain, and perform quietly.

Deliquescent dryers: Deliquescent dryers are another brand of electricity-free, economical air dryer compressors. They work using a pressure vessel containing dissolving salt tablets that absorb water vapor. Compressed air runs through the dryer, and the salt pulls all the water out. The salt dissolves with the water, turning into a brine that collects in a special tank. Meanwhile, the air passes out through the system moisture-free.

How to choose the right air dryer compressor

Understand your requirements

Evaluate the desired dew point for your application.

Identify the airflow rate (CFM) needed for your operations.

Consider the environment

Evaluate the ambient temperature and humidity levels of your workspace.

Choose an air dryer supplier that can handle these conditions effectively.

Energy efficiency

Opt for energy-efficient models to save operational costs.

Look for features like automatic drain valves to reduce wastage.

Space constraints

Consider the size of the equipment, especially for smaller facilities.

Compact options like membrane air dryers may be ideal.

Budget and maintenance

Balance initial costs with long-term savings from reduced maintenance and energy consumption.

Check for easy access to replacement parts and reliable service support.

Maintenance tips for air dryers recommended by compressed air dryer manufacturers

Regular filter replacement: Prevent clogging by replacing air filters frequently.

Monitor dew point: Ensure the system is delivering the required air quality.

Inspect drains: Keep drain valves clean and operational to avoid water build-up.

Scheduled servicing: Conduct routine maintenance checks to identify and address potential issues.

Wrapping up:

Air dryer compressors are vital in ensuring the efficiency, reliability, and longevity of industrial processes. Investing in the right type and maintaining it properly, can protect the equipment, improve product quality, and achieve cost savings. Whether you’re in manufacturing, healthcare, or construction, choosing the right air dryer supplier tailored to your needs is key to optimizing your operations. By partnering with reliable compressed air dryer manufacturers, can ensure that your systems remain efficient and the operations run smoothly.

0 notes

Text

Best Pulverizer Machine Manufacturer in Ahmedabad

A pulverizer machine is a high-speed, mechanical device designed to crush and grind various materials into fine powder or granules. These machines play a crucial role across industries like food processing, pharmaceuticals, chemicals, agriculture, and construction. Pulverizers are used to break down raw materials such as spices, grains, plastics, coal, and minerals to ensure easy handling, efficient mixing, or improved chemical reaction. The design and capacity of pulverizers may vary depending on the specific application, from small-scale laboratory models to large industrial setups. With rising demand for finely ground output in food safety and chemical precision, the need for advanced pulverizing machines is growing rapidly. Modern pulverizer machines are equipped with robust construction and features such as adjustable grinding fineness, dust control systems, and energy-efficient motors. Types of pulverizers include impact pulverizers, hammer mills, and micro pulverizers—each offering unique benefits based on the application. For instance, impact pulverizers are ideal for medium-hard materials, while micro pulverizers are used for ultra-fine grinding. These machines are typically built from stainless steel or heavy-duty mild steel to ensure long-term durability and corrosion resistance. With compact designs and minimal maintenance needs, many pulverizer machines are also suitable for continuous and batch processing operations. Air compressor accessories and parts are essential components that enhance the performance, durability, and functionality of air compressors across industrial, commercial, and domestic applications. These accessories include air filters, regulators, lubricators, pressure gauges, hoses, quick-connect couplers, dryers, and condensate drains, each contributing to the efficient and safe operation of the air compression system. Choosing the right parts ensures optimal air quality, minimizes pressure loss, and reduces wear and tear on the compressor unit.

For More Details Click Here: https://www.indiantradebird.com/product/pulverizer-machine

0 notes

Text

Desiccant Air Dryers Market set to hit $1454.4 million by 2035

Industry revenue for Desiccant Air Dryers is estimated to rise to $1454.4 million by 2035 from $670.0 million of 2024. The revenue growth of market players is expected to average at 7.3% annually for the period 2024 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/desiccant-air-dryers-market-research-report

Desiccant Air Dryers is critical across several key applications including oil and gas industry, food processing industries, pharmaceutical manufacturing and electronics manufacturing. The report unwinds growth & revenue expansion opportunities at Desiccant Air Dryers’s Technology Type, Industry Application, Product Capacity, Product Design and Functionality including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Desiccant Air Dryers market is characterized by intense competition, with a number of leading players such as Atlas Copco, Ingersoll Rand, SPX Flow, Gardner Denver, Kaeser Compressors, Quincy Compressor, ANEST IWATA Corporation, MATSUI, Beko Technologies, SMC Corporation, Parker Hannifin Corp and Van Air Systems..

The Desiccant Air Dryers market is projected to expand substantially, driven by growing pharmaceutical and food processing industries and advancements in desiccant air dryer technology. This growth is expected to be further supported by Micro industry trends.

Moreover, the key opportunities, such as expanding opportunities in renewable energy sector, climbing demand in food & beverage industry and technological progress and innovation, are anticipated to create revenue pockets in major demand hubs including U.S., Germany, China, Japan and India.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two most active and leading regions in the market. With challenges like high initial investment and technological complexity, Desiccant Air Dryers market’s supply chain from material suppliers / component manufacturers / assembly & production to end-user is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including Vietnam, South Africa and Brazil for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

#DesiccantAirDryers#CompressedAirTreatment#AirDryerTechnology#IndustrialDryingSolutions#PharmaManufacturing#FoodProcessingEquipment#ElectronicsManufacturing#IngersollRand#AtlasCopco#IndustrialAirDryers#DryingTechnology#IndustrialMachineryMarket#SMCCorporation#ParkerHannifin#SPXFlow#B2BMarketResearch#DataStringConsulting#EmergingMarkets2025#RenewableEnergyGrowth#GlobalIndustrialTrends

0 notes

Text

Understanding Key Components of Industrial Air Systems

Industrial air systems play a vital role in a wide range of industries. Whether in manufacturing, pharmaceuticals, food processing, or another field, these systems provide the necessary air supply for various processes while maintaining efficiency and safety. If you're someone who works with or manages industrial operations, understanding the key components of air systems is necessary to ensure optimal performance and reduce downtime within your facility. So, in this article, let's take a closer look at all the fundamental components of industrial air systems.

Air Compressors

Air compressors are the heart of the industrial air systems. They convert mechanical energy into compressed air, which is then used to power tools, machines, and other equipment. There are a variety of air compressors, such as rotary screws, centrifugal compressors, reciprocating, etc—all with their own benefits and applications. Air compressors also differ in size, so choose according to the air system's needs. An extensive system may require a vast compressor, while smaller systems may operate efficiently with compact or portable units designed for lower air demand.

Compressed Air Filters

A compressed air filter plays a crucial role in ensuring the air is clean for industrial processes. Impurities like dust, oil, water, and other particles reside in compressed air and affect equipment performance. A compressed air filter removes those impurities by using a combination of different mechanisms. These filters come in different types, including absorber, coalescing, and absorber filters. Particulate filters trap solid particles, while coalescing removes water and oil from the air. On the other hand, absorber filters remove traces of oil vapour and other contaminants affecting air quality.

Sterile Air Filters

If you're aware of the food processing, pharmaceuticals, and healthcare industries, you know just how critical air quality is. In these sectors, even small contaminants in compressed air can have serious implications, from affecting products to compromising patients' safety. Therefore, to ensure that the air is free of these contaminants, sterile filters are used to remove particles and harmful microorganisms, leaving clean and safe air. Now, let's understand how these filters serve different roles in different industries.

In food processing, sterile air filters are used to maintain the safety and hygiene of food products. The filters prevent airborne contaminants from entering processing and packaging areas.

In the pharmaceutical industry, contaminants can affect the production of medications, violating stringent regCompressed Air Filters, Sterile Air Filters, Nitrogen Gas Generatorulatory standards. Thus, sterile filters are used to maintain the quality and purity of all the medicines being manufactured.

In laboratories and medical facilities, sterile filters ensure that the air used in sensitive environments is free from harmful contaminants and microorganisms.

Air Dryers

Compressed air can be cleaned using filters, but what about its moisture? You may not know, but excessive moisture in compressed air can cause rust, corrosion, and contamination of machinery and products. This can also impact the quality of the air system, leading to increased energy consumption and increased energy failures. That's where air dryers offer a game-changing solution. These dryers are used to remove moisture from compressed air. Air dryers come in various types, such as refrigerated, membrane, and desiccant. Refrigerated dryers cool the air and cause the moisture to condense and separate from the air, while desiccant dryers absorb moisture using materials. On the other hand, membrane dryers use a semi-permeable membrane to allow water vapour to pass through, effectively removing moisture from the air.

When choosing the right air dryer, you need to consider the required level of dryness and your application needs.

Nitrogen Gas Generators

Some industrial applications require nitrogen gas for processes like packaging, metal fabrication, and chemical production. As nitrogen gas is inert, it does not react with other substances, making it ideal for preventing contamination or oxidation. A nitrogen gas generator is one of the key components of an air system that produces nitrogen on-site. These systems separate nitrogen from the air using either a membrane or PSA (Pressure Swing Adsorption) technology. The system filters out oxygen and other gases and provides a reliable source of nitrogen. Additionally, it eliminates the need for expensive bottled nitrogen.

In food processing industries, nitrogen is commonly used to displace oxygen in packaging materials. This helps preserve the freshness and shelf life of the food product. In electronics manufacturing industries, nitrogen gas generators are used to maintain a controlled nitrogen environment for sensitive processes.

Pressure Regulators

After compressing, filtering, and drying the air, it is delivered to the various parts of the system at the correct pressure. Pressure regulators maintain the desired pressure levels within the air system to prevent over-pressurization, which could damage equipment or cause safety issues.

Wrapping Up

I hope you're now familiar with the above key components of the air system. Each component–from air compressors to filters, dryers, and pressure regulators- is vital in delivering clean, dry, and safe air for industrial processes. By understanding these key components and their unique functions, industries can optimize their operations, reduce energy consumption, and maintain high levels of product safety and quality Compressed Air Filters

1 note

·

View note

Text

Benefits Of Water Cooled Compressor and Evaporative Condensers

Both technologies have their distinct benefits and serve crucial purposes in specific contexts. In this article, we discuss the benefits of Water Cooled Compressors and Evaporative Condensers.

#Pressure Vessel Manufacturers#Air Dryer Manufacturers In India#Oil Free Reciprocating Compressor#Pressure Vessels#Compressed Air Piping

0 notes