#Air Operated Pump manufacturers

Explore tagged Tumblr posts

Text

AODD Pump: The Reliable Choice for Industrial Fluid Transfer

AODD Pumps are the reliable choice for industrial fluid transfer, offering unmatched durability and efficiency. We specialize in high-quality AODD Pump designed for tough industrial applications. Our pumps are built to resist corrosion, ensuring long-lasting performance in various environments. Whether you're handling chemicals, slurries, or abrasive liquids, Nirmala Pumps provides solutions that guarantee smooth and efficient fluid transfer.

#diaphragm pump#aodd pump#nirmalapumps#air operated pump#suppliers#manufacturers#ahmedabad#industry#gujarat

0 notes

Text

Understanding the Mechanics of AODD Pumps

Air-Operated Double-Diaphragm (AODD) pumps are used to displace fluids by using compressed air. These pumps move fluids of various viscosities, even those with suspended solids. Not just that, AODD pumps can also handle corrosive and aggressive fluids with ease. These pumps are used for applications in a range of industries, including chemical processing, wastewater management, mining, construction, cleaning supplies and pharmaceuticals. Visit: https://www.idexindia.in/understanding-the-mechanics-of-aodd-pumps/

#aodd pump manufacturers#aodd pump supplier#Diaphragm Pump#Pneumatic Air Pump#air operated double diaphragm pump#IDEX_India

0 notes

Text

Reliable Performance, Trusted Results: The Benefits of a 35L Air Operated Grease Pump

A 35L air-operated grease pump offers several advantages that make it a powerful and reliable tool for a variety of applications. These advantages include:

High pumping capacity: A 35L air-operated grease pump has a large capacity, allowing for the efficient transfer and distribution of a significant amount of grease. This high pumping capacity reduces downtime and increases productivity, as more grease can be applied in a shorter amount of time.

Easy operation: 35L air operated grease pumps are designed for easy operation. They typically feature a simple and user-friendly design, allowing operators to quickly and easily load grease into the pump and connect it to the desired application. This ease of operation minimizes the time and effort required to use the pump, making it an efficient and convenient tool.

Air-powered reliability: 35L air operated grease pumps are known for their reliability and consistent performance. They use compressed air to power the pump, eliminating the need for electricity or manual operation. This air-powered operation ensures that the pump is always ready for use and can deliver a consistent flow of grease without any interruptions.

Versatility: A 35L air-operated grease pump is versatile and can be used for a wide range of applications. It can handle various grease viscosities and is suitable for use in industrial settings, automotive workshops, construction sites, and other environments where lubrication is required. Its versatility makes it a valuable tool for different industries and applications.

Durability: 35L air operated grease pumps are built to withstand challenging working conditions. They are typically constructed from robust materials such as stainless steel or heavy-duty cast iron, ensuring long-lasting durability. This durability allows the pump to withstand tough working environments, including exposure to chemicals, dirt, and high-pressure applications, without experiencing significant wear or damage.

Cost-effective: Investing in a 35L air-operated grease pump can be cost-effective in the long run. These pumps are designed to minimize waste by efficiently delivering the desired amount of grease to the application. This reduces the need for excessive grease usage and helps to extend the lifespan of lubrication components. Additionally, the reliability and durability of 35L air operated grease pumps reduce the need for frequent repairs or replacements, resulting in cost savings over time.

In summary, a 35L air-operated grease pump manufacturers offers several advantages, including high pumping capacity, easy operation, air-powered reliability, versatility, durability, and cost-effectiveness. These qualities make it a powerful and reliable tool for efficiently applying grease in various industrial and automotive settings, ensuring smooth and reliable operation of machinery and equipment.

0 notes

Text

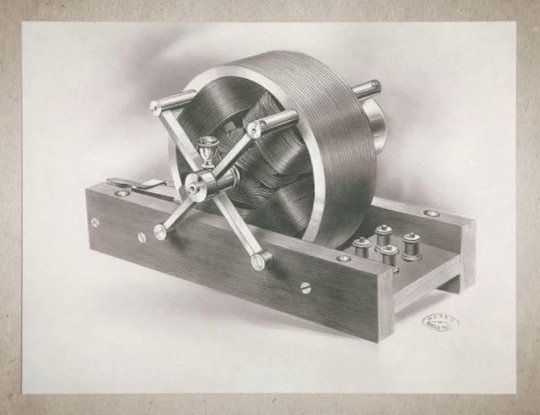

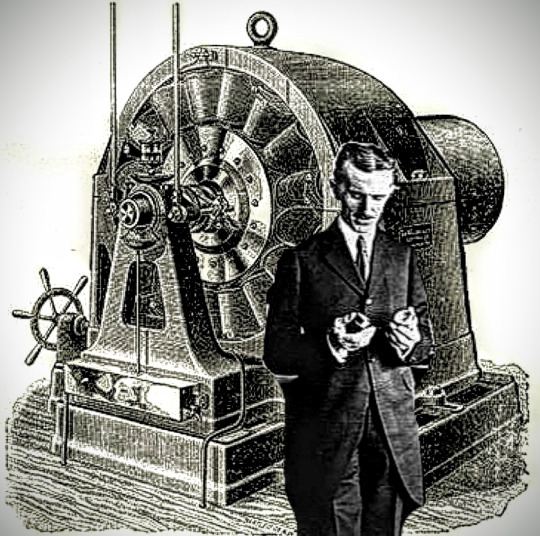

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Note

Would you be willing to share your sources relating to the submarine/submersible technology? I believe you, but I’d love to a. read more on the subject and b. Share something that isn’t a tumblr post with a family member

i linked wikipedia articles in my reblog which, themselves, have sources in their references, but i'm not sure what specifically you're asking for a source on.

i presume you're asking why i asserted a sphere is safer than a cylinder which is more or less just physics and not strictly related to subs. a cylinder has more surface area than a sphere of the same diameter therefore it has more surface for pressure to act on. moreover the nature of material manufacture means that a cylinder has more seams (2) than a sphere (1).

spherical pressure hulls are usually made of two halves of forged titanium or steel then fused together along one seam. the titan was two halves of a titanium sphere attached to the ends of a carbon-fiber tube. where the tube was joined to the spheres it made two seams. this is really oversimplifying it but the point is to highlight that seams can provide a point of failure because they're not part of the same continuous material. the more seams the more potential points of failure

if you're asking about the DSVs themselves, when it comes to functional deep-sea capable vessels i guess it's important to point out the difference between a "submarine" (the long tube shape you see used in the military) and a deep-sea vessel like a bathysphere (which is not a submarine because of its lack of mobility).

submarines, especially modern ones, can handle some pretty impressive depths but they don't go anywhere near as deep as vessels designed to travel to the deep sea. military sub max operational depths are probably classified but their reported depths are in the hundreds of meters

modern dsv's dive past ten thousand meters. which is way, way more pressure.

so to understand modern DSVs, here's the description of the batysphere concept and some of the original designs, which which were the first deep-sea capable vessels just much more primitive. they were lowered on cables and didn't travel on their own power. so they weren't really vehicles

here's the next logical step, the bathyscaphe, which allowed it to move up and down under its own power, however the crew cabin is still a sphere. you can see them protruding from the bottom of the vessel in some photos

"deep-submergence vehicles" (which i linked in that reblog) are a bit more closer to submarines in terms of design and mobility, but their crew cabin designs are still spherical, with few exceptions. the deepest-traveling ones are spherical

crew cabins are pressure vessels. meaning they're built to withstand the force of the pressure of the water outside the vehicle. DSV's may have multiple components in compartments that don't look spherical at all from the outside but it makes sense when you realize some of these compartments aren't pressure vessels. some are solid foam. some even flood with sea water by design

take a look at this diagram of the Alvin with crew inside:

the largest pressure vessel is the crew cabin. there's a few other smaller pressure vessels to provide variable ballast (flooded with sea water or pumped with air) and some mercury vessels to provide leveling trims (to tell which way is up)

the rest of the vehicle is either pressure-resistant foam or empty space in which water can get in because the components inside are small enough and engineered to withstand the pressure. remember, because water pressure acts in all directions, the less surface area you have, the less pressure you need to worry about to maintain whatever function you need to perform. since the crew compartment is so big and so important, it's the thickest titanium and probably engineered to more exacting safety standards than some of the other parts

a couple people have already commented more on what i posted with good insight into things i can't explain as well. here's someone going into detail about the sphere vs cylinder issue:

and here someone linked a very informative youtube about the manufacture of the DSV Limiting Factor including footage of the crew compartment being forged from titanium

99 notes

·

View notes

Text

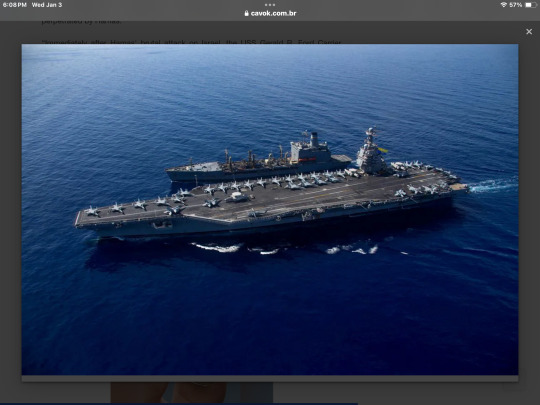

Aircraft carrier USS Gerald Ford will return from mission in defense of Israel

The largest aircraft carrier in the United States returns from the Mediterranean Sea, where it has been parked for almost three months.

Fernando Valduga By Fernando Valduga 03/01/2024 - 08:27in Military, War Zones

The U.S. Navy has determined that its largest aircraft carrier, the USS Gerald R. Ford (CVN-78), will return home after a nearly three-month mission to defend Israel in the Middle East.

The USS Gerald Ford has been stationed at a close distance of Israel's attack in the Mediterranean Sea since October, in an effort to prevent the country's war against Hamas from turning into a regional conflict. However, the U.S. Navy states that the ship will begin its journey back home "in the next few days" and will be replaced by the USS Bataan - an amphibious assault ship named after a battle fought in the Philippines during World War II.

The USS Gerald R. Ford is one of the largest aircraft carriers in the world and the latest and most advanced aircraft carrier in the United States. He was already in the Mediterranean - involved in naval exercises with Italy - before receiving orders to provide support to Israel's Defense Forces after the October 7 terrorist attacks perpetrated by Hamas.

“Immediately after Hamas' brutal attack on Israel, the USS Gerald R. Ford Carrier Strike Group was ordered to go to the eastern Mediterranean to contribute to our regional deterrence and defense posture,” the U.S. Navy said in a statement.

U.S. Defense Secretary Lloyd Austin extended Ford's detachment three times in the hope that his presence would dissuade Iran and groups aligned with Iran, especially Hezbollah from Lebanon, from attacking Israel.

The ship, which carried about 5,000 sailors and more than 100 warplanes in eight squadrons, is now returning to its naval base in Virginia. However, the USS Dwight D. Eisenhower will remain in the Red Sea to face the recent attacks on commercial ships perpetrated by Yemen's Houthi rebels.

“The DoD (Department of Defense) will continue to leverage its posture of collective force in the region to dissuade any state or non-state actor from escalating this crisis beyond Gaza,” the Navy said.

At the end of October, a U.S. Navy warship located in the northern Red Sea shot down three cruise missiles along with a batch of drones that were launched from Yemen and appeared to target Israel, the Pentagon said.

Tags: Military Aviationaircraft carrierUSN - United States Navy/U.S. NavyWar Zones - Middle East

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

BRAZILIAN AIR FORCE

FAB signs contract for logistical support of Armed Forces H225M aircraft

03/01/2024 - 08:07

B-2 over-volut at Rose Bowl 2024 in Pasadena, California. (Photo: Mark Holtzman / West Coast Aerial)

MILITARY

VIDEOS: How was the overfly of the B-2 bomber at the Rose Bowl on the first day of 2024

02/01/2024 - 20:01

MILITARY

South Korea selects ELTA Systems radar solutions for its new early warning aircraft

02/01/2024 - 16:00

MILITARY

Aero Vodochody will modernize the L-39ZA Albatros from Bulgaria

02/01/2024 - 14:00

ARMAMENTS

Raytheon guarantees $340 million contract to manufacture more StormBreaker pumps

02/01/2024 - 11:00

MILITARY

From 2024, Russian Aerospace Forces will receive Su-57 fighters with new AL-51F1 engines

02/01/2024 - 09:13

17 notes

·

View notes

Text

Increase your manufacturing productivity with Modular Venturi Vacuum Pump! This powerful vacuum offers up to 28" Hg, can be easily installed due to its robust construction. The vacuum is responsive and consumes minimal air, making it an energy efficient option. Make use of a dependable and adequate vacuum system to enhance your operations!

👇 Contact Us for More Details👇 📧 [email protected] 📞 +91 9787878732 🌐 https://www.nayagi.in/iminorgren

#ModularVenturiVacuumPump#VenturiVacuumPump#VacuumPump#Vaccon#Vacuum#Iminorgren#imi#Automation#VacuumTechnology#Productivity#engineering#Innovation#Efficiency#HighPerformancePump#industrialproducts#supplier#IndustrialSuppliesDealers#NayagiIndustrialTechnologies

2 notes

·

View notes

Text

Mechanical Engineering Basics: A Beginner's Guide

Welcome to the world of mechanical engineering—a field that drives innovation, shapes our daily lives, and fuels industries from aerospace to automotive. Whether you're contemplating a career in mechanical engineering or just curious about what it entails, this guide will walk you through the essentials. We'll break down what mechanical engineering is, its key areas, essential skills, educational pathways, and much more. By the end of this post, you’ll have a solid understanding of what it means to be a mechanical engineer and how you can embark on this exciting career.

Mechanical engineering is everywhere—from the cars we drive to the smartphones we use. It’s a diverse field that combines principles of physics, mathematics, and material science to design and build machines and systems. But what exactly does a mechanical engineer do? And why should you consider a career in mechanical engineering?

In this guide, I’ll help you unravel the mysteries of mechanical engineering. Whether you’re thinking about pursuing a degree in this field or just want to understand it better, we’ll cover all the basics you need to know.

1. What is Mechanical Engineering?

Definition

Mechanical engineering is a branch of engineering that focuses on the design, analysis, and manufacturing of mechanical systems. It involves applying principles of physics and materials science to solve engineering problems and create new technologies. Essentially, it’s about making things work efficiently and effectively.

Historical Background

Mechanical engineering has a rich history that dates back to ancient civilizations. From the early water wheels and windmills to the revolutionary steam engines of the Industrial Revolution, mechanical engineering has been instrumental in technological advancements. Understanding its history gives us insight into how far the field has come and its impact on modern technology.

Core Principles

At the heart of mechanical engineering are three core principles:

Forces and Motion: Understanding how forces interact with objects and how they move is fundamental. This includes studying concepts like torque, momentum, and kinematics.

Energy: Mechanical engineers work with various forms of energy, including thermal, mechanical, and potential energy, to design efficient systems and processes.

Materials: The properties of materials—such as strength, elasticity, and thermal conductivity—are crucial in selecting the right materials for different applications.

2. Key Areas of Mechanical Engineering

Thermodynamics

Thermodynamics deals with the principles of heat and energy transfer. It’s essential for designing systems like engines, refrigerators, and air conditioners. Understanding concepts like the laws of thermodynamics, heat cycles, and entropy helps engineers optimize energy use and improve system efficiency.

Fluid Mechanics

Fluid mechanics involves the study of fluids (liquids and gases) and their behavior under various conditions. It’s crucial for applications such as designing pumps, aircraft, and hydraulic systems. Engineers use fluid mechanics to analyze and predict how fluids will interact with surfaces and move through systems.

Mechanics of Materials

This area focuses on how materials deform and fail under different types of stress. Mechanics of materials is important for designing structures and components that can withstand forces without breaking. Engineers study stress, strain, and material properties to ensure reliability and safety in their designs.

Dynamics and Control

Dynamics deals with the motion of objects and forces acting on them. Control systems involve regulating and managing the behavior of dynamic systems. Together, they help engineers design systems that can move and operate smoothly, like robotics or automated manufacturing systems.

Manufacturing Processes

Manufacturing processes cover the techniques used to produce parts and products. This includes methods like casting, machining, welding, and additive manufacturing (3D printing). Understanding these processes helps engineers select the best methods for producing high-quality, cost-effective components.

Mechanical Design

Mechanical design involves creating and developing mechanical systems and components. It requires a combination of creativity and technical knowledge to develop designs that meet specific requirements and constraints. Engineers use design principles, CAD software, and prototyping to bring their ideas to life.

3. Essential Skills for Mechanical Engineers

Mathematical Proficiency

Mechanical engineering relies heavily on mathematics, including calculus, algebra, and differential equations. These mathematical tools are used to model physical systems, analyze forces, and solve complex problems. A strong grasp of math is essential for success in this field.

Problem-Solving Skills

Engineers are often faced with complex problems that require innovative solutions. Strong analytical and critical thinking skills help engineers identify issues, evaluate options, and implement effective solutions. Being a creative problem solver is a key trait of successful mechanical engineers.

Technical Knowledge

Mechanical engineers need a solid understanding of engineering principles, materials science, and mechanics. This technical knowledge allows them to design, analyze, and optimize mechanical systems effectively. Staying current with technological advancements is also important.

Software Skills

In today’s digital world, proficiency with engineering software is crucial. CAD (Computer-Aided Design) software, simulation tools, and other engineering applications help engineers create designs, test simulations, and visualize their projects. Familiarity with these tools enhances productivity and accuracy.

Communication Skills

Effective communication is essential for collaborating with team members, presenting ideas, and documenting work. Mechanical engineers often work in teams and must be able to explain complex concepts clearly and concisely. Strong communication skills help ensure that projects run smoothly and meet objectives.

4. Educational Pathways

Degrees and Certifications

To become a mechanical engineer, you typically need a bachelor’s degree in mechanical engineering or a related field. Advanced degrees, such as a master’s or Ph.D., can open up additional opportunities for specialization and research. Certifications, such as Professional Engineer (PE) licensure, may also be required for certain positions.

Accreditation

When choosing an educational program, it’s important to select a school that is accredited by a recognized body. Accreditation ensures that the program meets industry standards and provides a quality education. Look for programs accredited by organizations like the Accreditation Board for Engineering and Technology (ABET).

Continuing Education

Mechanical engineering is a constantly evolving field. To stay competitive and up-to-date, engineers often engage in continuing education and professional development. This can include attending workshops, earning certifications, or participating in industry conferences.

5. Tools and Technologies

Engineering Software

Modern mechanical engineers rely on various software tools to assist with design, analysis, and simulation. CAD software helps create detailed 2D and 3D models of components and systems. Simulation tools allow engineers to test and validate their designs under different conditions. Mastery of these tools is essential for modern engineering practice.

Lab Equipment

Mechanical engineering labs are equipped with a range of instruments and machinery used for testing and experimentation. Common lab equipment includes tensile testers, flow meters, and thermal chambers. Hands-on experience with these tools is crucial for understanding how theoretical concepts apply in practice.

Emerging Technologies

The field of mechanical engineering is rapidly advancing with new technologies. Innovations such as robotics, 3D printing, and artificial intelligence are transforming the way engineers design and manufacture products. Staying informed about these trends can open up exciting opportunities and keep your skills relevant.

6. Career Opportunities

Industry Sectors

Mechanical engineers work in a variety of sectors, including automotive, aerospace, energy, and manufacturing. Each sector offers unique challenges and opportunities. Whether you’re interested in designing vehicles, developing renewable energy solutions, or working on cutting-edge technologies, there’s likely a niche for you.

Job Roles

Mechanical engineers can pursue various roles, including design engineer, manufacturing engineer, project manager, and research scientist. Each role involves different responsibilities and requires a unique set of skills. Exploring different job roles can help you find a career path that aligns with your interests and goals.

Career Growth

Mechanical engineering offers numerous opportunities for career growth. With experience, you can move into higher-level positions, such as senior engineer or engineering manager. Specializing in a particular area or pursuing advanced degrees can also enhance your career prospects.

7. Real-World Applications

Case Studies

Mechanical engineering projects can range from developing new medical devices to designing efficient energy systems. For example, engineers working on medical devices might design prosthetic limbs that enhance patients' mobility, while those in energy might work on optimizing wind turbines for better performance.

Problem-Solving Examples

Mechanical engineers tackle a wide range of problems, from improving the fuel efficiency of cars to designing safer buildings. By applying engineering principles and creative solutions, they address real-world challenges and contribute to technological advancements.

8. Challenges and Future Trends

Current Challenges

Mechanical engineers face several challenges, including sustainability, resource management, and integrating new technologies. Addressing these challenges requires innovative thinking and a commitment to finding solutions that balance performance with environmental and economic considerations.

Future Trends

The future of mechanical engineering is bright and full of potential. Emerging trends such as smart materials, advanced robotics, and sustainable manufacturing are shaping the industry. Engineers who stay abreast of these trends will be well-positioned to lead and innovate in the coming years.

Mechanical engineering is a dynamic and rewarding field that plays a crucial role in shaping the world around us. By understanding its core principles, key areas, and career opportunities, you can gain a clearer picture of what it means to be a mechanical engineer. If you’re considering a career in mechanical engineering, it’s an exciting field with endless possibilities and opportunities for growth.

FAQs

What is mechanical engineering? Mechanical engineering is a branch of engineering that involves designing, analyzing, and manufacturing mechanical systems. It combines principles of physics, mathematics, and materials science to create and improve technologies.

What are the core principles of mechanical engineering? The core principles include forces and motion, energy, and materials. These principles help engineers understand how to design and build efficient mechanical systems.

What skills are important for a mechanical engineer? Important skills include mathematical proficiency, problem-solving abilities, technical knowledge, software skills, and strong communication skills.

What degree do I need to become a mechanical engineer? Typically, you need a bachelor’s degree in mechanical engineering or a related field. Advanced degrees and certifications can enhance career opportunities.

What types of industries employ mechanical engineers? Mechanical engineers work in various industries, including automotive, aerospace, energy, manufacturing, and robotics.

What are some common tools used in mechanical engineering? Common tools include CAD software for design, simulation tools for testing, and various lab equipment for experimentation.

What is thermodynamics, and why is it important? Thermodynamics is the study of heat and energy transfer. It’s crucial for designing systems like engines and refrigerators to ensure they operate efficiently.

How can I stay updated with advancements in mechanical engineering? Staying updated involves continuing education, attending industry conferences, and following emerging technologies and trends.

What career opportunities are available for mechanical engineers? Career opportunities include roles such as design engineer, manufacturing engineer, project manager, and research scientist.

What are the future trends in mechanical engineering? Future trends include advancements in robotics, smart materials, and sustainable manufacturing practices.

I hope this guide has provided you with a comprehensive understanding of mechanical engineering. If you're considering a career in this field, it offers exciting opportunities and challenges that can make a significant impact on the world. Feel free to dive deeper into each topic and explore how you can contribute to the future of engineering.

3 notes

·

View notes

Text

The Essential Guide to Wastewater Treatment Plants: Turning Waste into Resource

Wastewater treatment plants (WWTPs) are the unsung heroes of urban infrastructure. As they work tirelessly behind the scenes, they transform contaminated water into a clean resource that can be safely returned to the environment or even reused. In this article, we’ll explore the critical role of wastewater treatment plants, their processes, and the benefits they bring to our communities and ecosystems.

Understanding Wastewater: What Is It?

Before delving into the intricacies of treatment plants, it’s vital to understand what wastewater is. Wastewater is any water that has been adversely affected by human activity. This can include:

Domestic Wastewater: From sinks, toilets, and showers in households.

Industrial Wastewater: Generated from manufacturing processes and commercial activities.

Stormwater: Rainwater that collects pollutants as it flows over surfaces.

Proper management of these types of wastewater is crucial for public health and environmental protection.

The Importance of Wastewater Treatment Plants

Wastewater treatment plants are essential for several reasons:

Public Health: Proper treatment of wastewater prevents the spread of waterborne diseases.

Environmental Protection: Treated water reduces pollution in rivers, lakes, and oceans, preserving aquatic ecosystems.

Resource Recovery: Many plants can recover valuable resources, such as nutrients and energy, from wastewater.

Sustainable Practices: Modern WWTPs incorporate technologies that promote sustainability, reducing their carbon footprint.

The Process of Wastewater Treatment

The treatment of wastewater is a complex process that typically involves several stages. Let’s break down these stages:

1. Preliminary Treatment

In this initial stage, large debris such as sticks, leaves, and plastic are removed from the wastewater. This is usually done through screening and grit removal processes.

2. Primary Treatment

After preliminary treatment, wastewater moves to primary treatment, where solids settle to the bottom, forming sludge. This process removes about 50-70% of suspended solids and approximately 30% of biological oxygen demand (BOD).

3. Secondary Treatment

Secondary treatment is crucial for further reducing organic matter. This stage usually involves biological processes, where microorganisms break down organic pollutants. There are various methods used in secondary treatment, including:

Activated Sludge Process: In this method, air is pumped into the wastewater, allowing microorganisms to feed on the organic material.

Trickling Filters: Wastewater is distributed over media, allowing microorganisms to grow and treat the water as it trickles through.

4. Tertiary Treatment

Tertiary treatment is an advanced stage that further polishes the water. This can involve filtration, nutrient removal, and disinfection processes like chlorination or ultraviolet (UV) light treatment. The goal is to ensure that the water is safe for discharge or reuse.

5. Sludge Management

Throughout the treatment process, sludge is generated. This sludge must be treated separately to reduce its volume and make it safer. Common methods include anaerobic digestion, which produces biogas, and composting, which can create a valuable soil amendment.

Innovations in Wastewater Treatment

The landscape of wastewater treatment is evolving, thanks to technological advancements. Here are some innovations transforming the industry:

1. Membrane Bioreactors (MBRs)

MBRs combine biological treatment with membrane filtration, allowing for higher quality effluent and smaller footprint operations. This technology is ideal for areas with limited space.

2. Constructed Wetlands

These engineered ecosystems mimic natural wetlands to treat wastewater. They are cost-effective and environmentally friendly, providing additional habitats for wildlife.

3. Resource Recovery Facilities

Modern WWTPs are increasingly focusing on recovering valuable resources from wastewater. This includes extracting nutrients like nitrogen and phosphorus, which can be used as fertilizers, and capturing biogas for energy production.

The Benefits of Wastewater Treatment Plants

Investing in wastewater treatment has far-reaching benefits:

1. Economic Advantages

Efficient wastewater treatment supports local economies by ensuring clean water for industries and agriculture. It also creates jobs in engineering, operations, and maintenance.

2. Environmental Sustainability

By reducing pollution and conserving water resources, wastewater treatment plants contribute to a healthier planet. They play a critical role in combating climate change by mitigating greenhouse gas emissions from untreated wastewater.

3. Improved Public Health

Access to treated wastewater prevents health risks associated with untreated sewage. This is especially crucial in developing regions where sanitation infrastructure may be lacking.

Challenges Facing Wastewater Treatment Plants

Despite their importance, wastewater treatment plants face several challenges:

1. Aging Infrastructure

Many WWTPs are outdated and require significant investment to upgrade. Aging systems may lead to inefficiencies and increased pollution.

2. Climate Change Impacts

Extreme weather events and rising sea levels can impact the operation of wastewater treatment facilities. Adapting to these changes is crucial for future resilience.

3. Public Awareness and Engagement

Many communities are unaware of the vital role that WWTPs play. Increasing public engagement can foster support for necessary investments and improvements.

Conclusion: The Future of Wastewater Treatment

Wastewater treatment plants are more than just facilities for cleaning water; they are essential components of sustainable urban development. As technology continues to evolve, these plants will become even more efficient and capable of recovering resources, ultimately contributing to a circular economy.

By recognizing the importance of wastewater treatment and supporting innovations in the field, we can ensure that our communities remain healthy and our environment is preserved for future generations. Investing in wastewater treatment Plant is not just about managing waste; it’s about embracing a sustainable future.

2 notes

·

View notes

Text

Defoamers in Wastewater Treatment - Mitigating Foam and Improving Processes

In the realm of wastewater treatment, foam can be a persistent nuisance, hindering efficiency and complicating operations. From excessive foaming in aeration tanks to foam buildup in clarifiers and digesters, foam-related issues can lead to process disruptions, increased maintenance costs, and compromised treatment performance. Fortunately, defoamers offer a practical solution for mitigating foam and improving processes in wastewater treatment plants. In this comprehensive guide, we explore the role of defoamers in wastewater treatment, their benefits, and the different types available from leading manufacturers in India.

Understanding Foam Formation in Wastewater Treatment

Foam formation in wastewater treatment processes can occur due to various factors, including:

Organic Matter: The presence of organic compounds in wastewater, such as proteins, fats, and surfactants, can contribute to foam formation by stabilizing air bubbles and increasing surface tension.

Microbial Activity: Microorganisms present in wastewater can produce extracellular polymeric substances (EPS) that promote foam stability and persistence.

Mechanical Agitation: Agitation caused by aeration, mixing, or pumping can introduce air into the wastewater, leading to foam formation.

Chemical Reactions: Certain chemical reactions, such as the release of gases during anaerobic digestion, can result in foam generation.

The Role of Defoamers in Wastewater Treatment

Defoamers, also known as antifoaming agents, are chemical additives designed to disrupt foam formation and promote foam collapse in wastewater treatment processes. By reducing surface tension and destabilizing foam bubbles, defoamers help prevent foam buildup and facilitate the smooth operation of treatment units. Some common applications of defoamers in wastewater treatment include:

Aeration tanks

Clarifiers and thickeners

Digesters

Filtration systems

Sludge dewatering processes

Types of Defoamers

Defoamers used in wastewater treatment are available in various formulations, each suited to specific applications and operating conditions. Some of the most common types of defoamers manufactured in India include:

Silicone-Based Defoamers:

Silicone-based defoamers are widely used in wastewater treatment due to their excellent foam-suppressing properties and chemical stability. These defoamers are effective across a wide pH range and can withstand high temperatures, making them suitable for diverse wastewater treatment applications.

Alcohol-Based Defoamers:

Alcohol-based defoamers contain alcohol compounds that disrupt foam formation and promote bubble coalescence. These defoamers are often used in wastewater treatment processes where silicone-based formulations may not be suitable due to compatibility issues with certain chemicals or materials.

Glycol-Based Defoamers:

Glycol-based defoamers utilize glycol compounds to combat foam formation in wastewater treatment. These defoamers are known for their fast-acting properties and low toxicity, making them suitable for use in environmentally sensitive applications.

Benefits of Using Defoamers in Wastewater Treatment

Improved Process Efficiency: By reducing foam buildup and preventing process disruptions, defoamers help wastewater treatment plants maintain optimal process efficiency and throughput.

Cost Savings: Defoamers help minimize downtime, reduce maintenance requirements, and enhance the performance of treatment equipment, resulting in cost savings for wastewater treatment plants.

Enhanced Treatment Performance: By mitigating foam-related issues, defoamers enable wastewater treatment plants to achieve better treatment outcomes, including improved effluent quality and compliance with regulatory standards.

Versatility: Defoamers are available in various formulations to suit different wastewater treatment applications, ensuring versatility and adaptability to specific process requirements.

Choosing the Right Defoamer Manufacturer in India

When selecting a defoamer manufacturer in India, it's essential to consider factors such as product quality, technical support, and reliability. Look for a manufacturer with a proven track record of supplying high-quality defoamers for wastewater treatment applications. Additionally, ensure that the manufacturer offers comprehensive technical support and assistance to help you select the right defoamer for your specific needs.

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) – Your Trusted Defoamer Manufacturer in India

As a leading manufacturer of specialty chemicals in India, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) offers a wide range of defoamers specifically designed for wastewater treatment applications. Our silicone-based, alcohol-based, and glycol-based defoamers are formulated to deliver exceptional performance, reliability, and cost-effectiveness.

With decades of experience in the chemical industry and a commitment to innovation and quality, ICPL is your trusted partner for all your defoamer needs. Whether you're operating a municipal wastewater treatment plant, an industrial wastewater facility, or a specialized treatment unit, we have the expertise and resources to provide customized defoamer solutions tailored to your requirements.

Conclusion

In conclusion, defoamers play a crucial role in mitigating foam and improving processes in wastewater treatment plants. Whether it's silicone-based, alcohol-based, or glycol-based formulations, defoamers offer effective solutions for combating foam-related issues and enhancing the efficiency and performance of treatment operations. By choosing the right defoamer manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL), wastewater treatment plants can benefit from high-quality defoamers and comprehensive technical support to meet their foam control needs effectively.

#Glycol Based Defoamer Manufacturer in India#Alcohol Based Defoamer Manufacturer in India#Defoamer Manufacturer in India#Silicone Based Defoamer Manufacturer in India

4 notes

·

View notes

Text

Air Operated Diaphragm Pumps for Corrosive Fluids

Air Operated Double Diaphragm Pump uses two diaphragms to move liquids in and out, powered by compressed air. It’s great for handling thick, abrasive, or corrosive fluids. For more details visit our website.

0 notes

Text

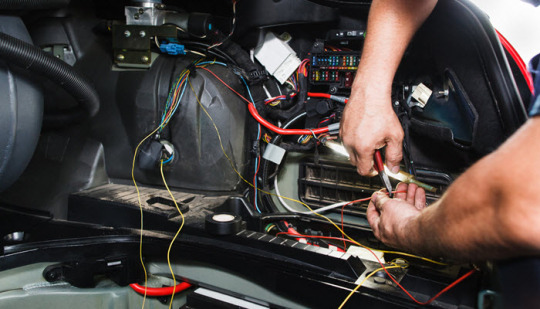

Navigating the World of BMW Car Electrical Services for Reliability and Innovation

In the ever-evolving landscape of automotive technology, luxury car manufacturers like BMW continue to push the boundaries, integrating sophisticated electrical systems to enhance driving experiences. As demand grows for newer models equipped with advanced features, the reliance on electricity becomes more pronounced, powering a plethora of components that contribute to performance, safety, and convenience.

The Role of Electrical Systems in Modern Cars:

The heart of the technological revolution in automobiles lies in the intricate electrical systems that power various special features. These systems draw their energy from sources like batteries and alternators, allowing innovative components to function seamlessly. Over time, automobile engineers have introduced cutting-edge systems, powered by electricity, to provide essential features that contribute to the overall performance of the vehicle.

Components Powered by Electrical Systems:

Luxury cars, particularly those from brands like BMW, boast an array of advanced systems that rely on electrical power. From air conditioning and stereo systems to windshield wipers and exterior lights, the electrical system plays a pivotal role in enabling these features. Additionally, smart functionalities such as ABS, vehicle stability control, cruise control, and anti-theft systems are made possible by the robust electrical infrastructure within the vehicle.

Primary Functions Powered by Electricity:

Beyond the convenience features, the electrical system in modern cars also powers essential components responsible for the vehicle's primary functions. The starter motor, spark plugs, fuel pump, and oxygen sensors are crucial elements that ensure the car starts smoothly, runs efficiently, and adheres to emission standards. The intricate network of circuits facilitates the flow of current, making these components integral to the overall performance of the vehicle.

Electric and Hybrid Cars: Meeting Environmental Demands:

With an increasing emphasis on reducing emissions and diminishing reliance on fossil fuels, electric and hybrid cars have gained popularity. Electric cars operate solely on battery power, producing zero emissions, while hybrid cars can seamlessly switch between petrol and electricity. These environmentally friendly vehicles underscore the importance of electrical systems, making their regular maintenance and service a top priority.

The Need for Electrical Services:

As cars become more complex with advanced electrical systems, the demand for electrical services has risen. Electrical issues in a vehicle can manifest in various ways, from difficulty starting the car to malfunctions in accessories. When faced with electrical faults, it becomes imperative to inspect critical components such as the battery, alternator, wiring, starter, spark plugs, fuses, relays, and various sensors. Regular inspection and maintenance ensure optimal performance and prevent potential issues that could compromise safety.

Electrical Repairs: Addressing Common Issues:

When a car exhibits electrical problems, several components may require inspection and, if necessary, repairs. Common issues include battery problems, faulty connections, issues with switches, relays, fuses, wires, or the output devices themselves. Signs of electrical faults may include difficulty starting the car, prolonged start times, stalling, and malfunctioning accessories. In-depth examination of critical components, such as the ignition system, lighting system, and various sensors, is crucial for identifying and rectifying issues promptly.

Conclusion:

In conclusion, the evolution of electrical systems in BMW cars reflects the dynamic nature of automotive technology. From powering luxurious amenities to supporting the essential functions of the vehicle, the electrical system is a cornerstone of modern automobiles. As the automotive industry continues to innovate, with a growing emphasis on environmental sustainability, the role of electrical systems becomes even more critical. Regular electrical services and repairs, conducted by qualified professionals at BMW service centers, are essential to ensure the longevity, safety, and optimal performance of these advanced vehicles. Embracing the advancements in electrical systems not only enhances the driving experience but also contributes to a greener and more sustainable future for the automotive industry.

1 note

·

View note

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

Wait! These Are Heat Pump Fake News?!

Fake News 1: Heat pumps don't work in cold climates.

Truth 1: The most heat pumps can be found in the coldest climates. More than half of all households in Norway have one. For example, the min ambient working temp. in heating mode of Harnitek 6KW air source heat pump YHPK-06V1TBA is around -25°C.

Fake News 2: Heat pumps won't keep you warm.

Truth 2: Households who installed a heat pump report that they are as comfortable or more comfortable than before the installation in survey. 81% have seen the level of comfort improve.

Fake News 3: A heat pump needs to stay on all the time.

Truth 3: You never switch the heat pump off manually but this does not mean the heat pump is operating all the time. The system automatically adjusts to outside and indoor temperatures and ramps down when it is warmer.

Fake News 4: Heat pumps don't work in existing buildings.

Truth 4: From long-standing research:" The research results clearly show that heat pumps as heating sources function reliably also in existing buildings. As a rule, the units worked flawlessly."

Fake News 5: Heat pumps don’t work in old buildings.

Truth 5: Recent results from the UK indicate that there is no significant variation in performance based on house age. Houses do not have to be extensively renovated in order to allow for the installation of a heat pump. For example, we harnitek's heat pump also works well in a 1950s house. Below is a pic from our user ins: @ultra_bungle.

Fake News 6: Heat pumps are unaffordable.

Truth 6: Many countries offer subsidies for heat pumps & with running costs included heat pumps can offer lifetime savings over fossil fuel systems. For example, the UK is providing £100 million in support for businesses and consumers to bring more heat pump manufacturing to the UK. That's why Harnitek passed MCS certification in 2021, now once users buy Hannitek's air source heat pumps, they will receive government subsidies. And we are working on more certifications in different countries, to help users get more affordable heat pumps.

Fake News 7: Heat pumps cost more to run & increase heating bills.

Truth 7: The main energy of the heating water of the air source heat pump system is the air from the surroundings. It only needs to use 1/4 or 1/5 of the electric energy that is equivalent to the electric water heater to get enough hot water. This makes its heating bills obviously lower than the electric water heater or electric boiler.

1 note

·

View note

Text

Finland acquires JDAM and SDB I weapon systems for its F-35 fighters

Fernando Valduga By Fernando Valduga 03/01/2024 - 13:00 in Military

The Patria and the Finnish Defense Forces signed a service agreement to develop the capabilities of Finland's F-35 program, specifically purchases of JDAM and SDB I ammunition.

Major General Jari Mikkonen, Head of the Logistics Command of the Finnish Defense Forces (FDFLOGCOM) signed the contract for the acquisition of JDAM and SDB I ammunition for the F-35 multifunctional fighters on February 29, 2024. The Finnish Minister of Defense authorized the Logistics of the Defence Forces Command to conduct the acquisition.

The object of the acquisition is the JDAM and SDB I systems with related equipment and services in the years 2024–2030. The acquisition is referred to as the Total Package Approach (TPA), which means that, in addition to the JDAM and SDB I pumps, the acquisition includes transport sets of BRU-61 ammunition, training material, manuals, spare parts, accessories, transport services and manufacturer instructions, as well as training services and supplier support. Contains spare parts and support services for manufacturers and suppliers by 2030.

The acquisition contract is in dollars and its indexed maximum price is US$ 96.1 million. Purchase payments will take place during the years 2024-2030.

The acquisition will be carried out in accordance with the Foreign Military Sales (FMS) procedure between the authorities of the USA and Finland, in which the Defense Forces Logistics Command will conclude the acquisition contract with the United States administration.

The JDAM (Joint Direct Attack Munition) is a modular guidance kit for 500, 1,000 or 2,000 pound bombs of the Mark 80 series. In addition to a guidance kit, a fuse or sensor is installed in the pump, depending on the intended use. A bomb equipped with JDAM can perform precision attacks on fixed or mobile targets at short range.

The SDB I (Small Diameter Bomb I) is a glider pump capable of accurately hitting medium-range targets. Thanks to the relatively small size of the pump, a fighter is able to carry a larger number of SDB I bombs at a time.

Guided bombs and glider bombs are part of the weapons acquisition package that allows the Finnish Air Force to have the ability to support other Forces in combat activities. The weapons of the F-35 fighters from Finland will be acquired in stages until the year 2035. The phased implementation of the acquisition of weapons will make it possible to optimize the composition of weapons as the Finnish F-35 program progresses.

"Some of the types of weapons to be purchased can also be used with our current fleet of F/A-18 Hornet. Therefore, when we make the transition to the F-35, we will be able to profit from the skills and experience in systems acquired so far," said the Director of the F-35 Program, Colonel (retired), Henrik Elo.

Tags: Military AviationF-35 Lightning IIIlmavoimat/Finnland Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

The U.S. Navy award includes 14 new P-8s for Canada, three for Germany.

MILITARY

Boeing receives contract for 17 P-8A Poseidon aircraft, for Canada and Germany

01/03/2024 - 11:00

MILITARY

Czech Republic will modernize its JAS39 Gripen fighters

01/03/2024 - 09:00

INCIDENTS

German frigate fires missiles by mistake at USAF's Reaper drone in the Red Sea

01/03/2024 - 08:00

MILITARY

Ukraine shoots down 13 military jets in 11 days, bringing the Russian Air Force closer to the deadly organizational spiral

01/03/2024 - 00:39

MILITARY

Russia intends to restore the production of A-50 AWACS aircraft

29/02/2024 - 21:22

A U.S. Marine Corps XQ-58A Valkyrie, a highly autonomous and low-cost tactical unmanned aerial vehicle, conducts its second test flight with two U.S. Air Force F-35A Lightning II aircraft designated for the 33ª Fighter Wing, 96ª Test Wing at Eglin Air Base, Florida, on February 23, 2023. (Photo: U.S. Air Force / Master Sgt. John McRell)

MILITARY

USMC Valkyrie completes second test flight

29/02/2024 - 19:28

O

12 notes

·

View notes

Text

🔷️ #CentrifugalPump Installation and Commissioning Guide

The process of installing and commissioning a centrifugal pump is crucial to ensuring optimal performance and longevity. Here’s a structured approach to make sure your pump operates efficiently and reliably:

1. Pre-Installation Inspection:

1️⃣Inspect the pump and all related components for any potential damage that may have occurred during transit.

2️⃣Ensure that all required parts and accessories for installation are present.

2. Location Selection:

Choose a suitable installation location for the pump considering easy access, proper ventilation, and proximity to the fluid source.

3. Foundation Preparation:

Prepare a strong and level foundation that can support the pump and motor assembly’s weight, ensuring proper alignment with the connected piping system.

4. Piping Installation:

1️⃣Install the suction and discharge pipes with proper sizing, support, and alignment.

2️⃣Use appropriate fittings and seals to avoid any potential leaks.

5. Electrical Connection:

Connect the motor to the power source as per the manufacturer’s instructions, ensuring correct grounding and overload protection.

6. Alignment:

1️⃣Align the pump and motor shafts accurately using precision tools to minimize vibration and wear.

2️⃣Follow the manufacturer’s alignment guidelines to achieve proper fit.

7. Coupling Installation:

1️⃣Install the coupling between the pump and motor shafts, ensuring it fits properly and is aligned.

2️⃣Tighten coupling bolts to the recommended torque values.

8. Priming the Pump:

Fill the pump casing and suction piping with the pumping fluid, ensuring any trapped air is vented to prevent cavitation and ensure proper priming.

9. Startup:

1️⃣Gradually start the motor and monitor for any unusual vibrations or noises.

2️⃣Verify that the pump is operating within its designated performance parameters (flow rate, pressure, etc.).

10. Performance Testing:

1️⃣Conduct performance tests to verify the pump’s flow and head meet the specifications.

2️⃣Compare power consumption with the manufacturer’s data to ensure efficiency.

11. Safety Checks:

1️⃣Ensure all safety covers and guards are securely in place.

2️⃣Verify the functionality of safety devices such as pressure relief valves and temperature sensors.

12. Documentation:

Maintain detailed records of the installation, including alignment measurements, test results, and any adjustments made.

13. Training:

Provide operators with training on proper operation, maintenance, and troubleshooting procedures for the centrifugal pump.

14. Maintenance Schedule:

Establish a regular maintenance schedule that includes tasks such as lubrication, alignment checks, and vibration analysis to ensure long-term reliability.

✅This approach not only guarantees that the centrifugal pump performs optimally but also aligns with our commitment to providing sustainable and reliable water solutions.

#PumpInstallation #CentrifugalPumps

#WaterSolutions

#PumpMaintenance

#Efficiency

0 notes