#Agricultural automation

Explore tagged Tumblr posts

Text

Smart Farms-Background,Principles,Advantages,Disadvantages,Applications,Outlook

Background Smart farms are an innovative agricultural system that integrates information and communication technology with agriculture, aiming to enhance efficiency and productivity compared to traditional farming methods. The need to introduce new technologies and methods in agriculture has become increasingly urgent due to climate change and population growth, necessitating an increase in food production and improved efficiency in crop production.

Principles

Sensors and IoT Technology:

Smart farms utilize various sensors and IoT (Internet of Things) technology to monitor crop growth conditions, soil status, and weather information in real-time. This allows farmers to assess the health of their crops and take necessary actions.

Automation and Robotics:

Smart farms employ automation and robotics to automate farming tasks. Robots perform tasks such as planting, maintenance, and harvesting, while automated systems reduce labor demands and enhance productivity.

Big Data and Artificial Intelligence:

Smart farms use big data and artificial intelligence to predict crop yields and provide optimal growing conditions. This enables farmers to develop efficient production plans and improve crop quality.

Advantages

Increased Productivity:

Smart farms significantly boost productivity through automated and optimized cultivation management. Efficient farming systems reduce work time and increase crop yields.

Resource Conservation:

Smart farms efficiently manage resources such as water, fertilizer, and energy, minimizing waste. Through sensors and data analysis, farmers can predict the exact needs of crops and use resources efficiently.

Improved Quality:

Smart farms enhance crop quality through precise cultivation management and monitoring. By identifying the optimal harvest time and conditions, high-quality agricultural products can be produced.

Disadvantages

High Cost:

Establishing a smart farm requires expensive sensors, robots, and other equipment, leading to high initial investment costs. Maintenance and upgrade costs also need to be considered.

Dependence on Technology:

Smart farms rely heavily on the latest technology, necessitating the ability to adapt to technological changes. Rapid advancements in technology may render implemented systems obsolete quickly.

Applications

Precision Agriculture:

Smart farms offer optimal growing conditions by precisely monitoring crop growth, soil conditions, and weather. This enables farmers to observe crop growth in real-time and take necessary actions.

Automated Agriculture:

Smart farms automate farming tasks using robots and automated equipment. Robots perform tasks such as planting, maintenance, and harvesting, reducing labor demands and enhancing productivity.

Data-Driven Decision Making:

Smart farms use sensor data and big data analysis to predict crop yields and establish optimal production plans. This enables efficient production management for farmers.

Resource Management:

Smart farms efficiently manage resources such as water, fertilizer, and energy, minimizing waste. Through sensors and data analysis, farmers can predict resource usage accurately and allocate resources efficiently.

Outlook Smart farms are bringing about innovative changes in the agricultural sector, contributing to increased efficiency in crop production and minimizing environmental impact. With the further development of sensor technology, big data analysis, and artificial intelligence, smart farms are expected to play a crucial role in leading the future of agriculture.

#poster#smart#smart farms#farms#automatics#Vertical farming#Precision agriculture#Hydroponics#Aquaponics#IoT in agriculture#Agricultural automation#Crop monitoring systems#Smart greenhouse

1 note

·

View note

Text

NEC X invests in AgTech startup VERDI, integrates AI-powered platform with NEC’S CropScope smart farming initiative

View On WordPress

#Agricultural Automation#Agricultural Innovation#Agricultural Tech - Farming Tech#Agriculture#AgTech Startup#Artificial Intelligence in Agriculture#Farm Machinery#Food and Agribusiness#Innovation in Food and Agribusiness

0 notes

Text

Ready to farm like never before? Dive into the world of Smart Farming. Discover the secrets to farming smarter and shaping a greener tomorrow! https://www.smartmia.in/

0 notes

Text

Automation and Robotics Revolutionizing Harvesting in Agriculture

In modern agriculture, the integration of automation and robotics is transforming how crops are harvested. The utilization of cutting-edge technology, such as automated machinery and robotics, is enhancing efficiency, precision, and sustainability in harvesting operations. This article delves into the significant impact of automation and robotics on agricultural harvesting practices, highlighting its benefits, challenges, and the future outlook.

0 notes

Text

AI is changing the game in #logistics and #agriculture, but we need to be mindful of the ethical side of things.

At Pranathi Software Services, we’re here to help you navigate these challenges with AI that’s ethical, responsible, and sustainable. Ready to make smarter, more impactful AI choices? Let’s talk: https://www.pranathiss.com 👉📧 [email protected] 👉📲 +1 732 333 3037

#Algorithm#Logistics#EthicalAI#Sustainability#Innovation#agriculture#automation#AIproducts#AIservices

6 notes

·

View notes

Text

Meticulous Research® forecasts the irrigation automation market to be worth $12.7 billion by 2032, growing at a 16.6% CAGR from 2025 to 2032.

#Irrigation Automation Market#Irrigation Automation#Automatic Irrigation#Automatic Watering System#Automatic Irrigation System#Auto Irrigation System#Agricultural Irrigation Automation#Plant Irrigation System#Automation in Drip Irrigation#Sprinkler Automation#Automated Irrigation System

1 note

·

View note

Text

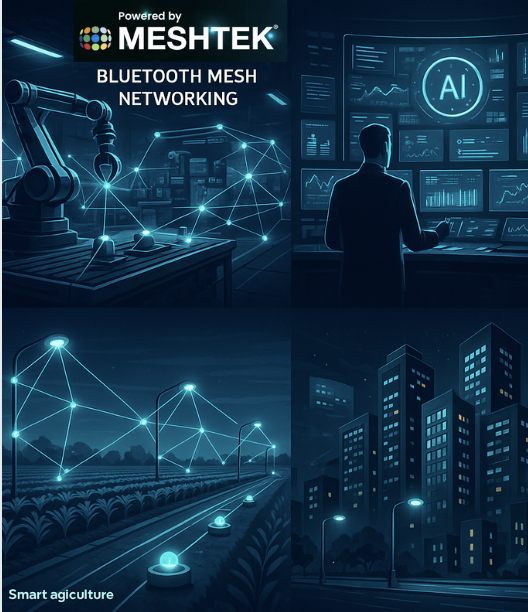

Connected Intelligence: Powering Tomorrow with Bluetooth Mesh

MeshTek’s advanced Bluetooth Mesh Networking seamlessly integrates across diverse sectors — from industrial automation and AI-driven operations to smart agriculture and urban lighting. Real-time data flow, secure communication, and synchronized control across a decentralized, energy-efficient IoT network. Designed for scalability and precision, MeshTek’s platform enables smarter environments through robust, low-latency connectivity.

#Bluetooth Mesh Networking#Smart Lighting#Industrial Automation#AI Connectivity#Smart Agriculture#MeshTek IoT#Edge Devices#Real-Time IoT Control#Scalable Mesh Network#IoT Infrastructure

1 note

·

View note

Text

There’s an ecological/economic theory called Metabolic Rift that I think is relevant to your observations here. It’s not one-to-one but I think there’s a real link, and it also connects what you’re describing into a broader picture of capitalism and imperialist agendas.

Quick excerpt from the Wikipedia page that made me make the connection.

“Up until the 16th or 17th century, cities' metabolic dependency upon surrounding countryside (for resources, etc.), coupled with the technological limitations to production and extraction, prevented extensive urbanization. Early urban centers were bioregionally defined, and had relatively light "footprints," recycling city nightsoils back into the surrounding areas.

However, with the rise of capitalism, cities expanded in size and population. Large-scale industry required factories, raw material, workers, and large amounts of food. As urban economic security was dependent upon its metabolic support system, cities now looked further afield for their resource and waste flows. As spatial barriers were broken down, capitalist society "violated" what were previously "nature-imposed conditions of sustainability."

With trade and expansion, food and fiber were shipped longer distances. The nutrients of the soil were sent to cities in the form of agricultural produce, but these same nutrients, in the form of human and animal waste, were not returned to the land. Thus there was a one-way movement, a "robbing of the soil" in order to maintain the socio-economic reproduction of society.

Marx thus linked the crisis of pollution in cities with the crisis of soil depletion.”

It's been years since I started seeing nutrient flows constantly in my daily life, and the more I study agriculture, the more I see them.

See, every time you harvest something, you take the nutrients in that item away from the soil, and they go somewhere else. When I put a banana peel in my compost bin, I think (a little gleefully) about how I've just added an exotic, different profile of nutrients to my own property--but I also think about that distant banana plantation that lost tons of nutrients per year to US grocery stores, and I wonder what they replaced those nutrients with.

The farmer across my field grows corn, which gets harvested for feed. Corn is a nitrogen-hungry crop. Every year, that corn sucks up nutrients, which get harvested and shipped away. The farmer, being a conventional farmer, mostly replaces those with a conventional fertilizer. Nitrogen is often applied to fields in the form of ammonia fertilizer, which is made via a process that binds nitrogen in the air with hydrogen from natural gas. This feels like a vast resource, but of course we know it's not inexhaustible and not without cost.

Ideally, said farmer does soil tests and applies a carefully considered amount of ammonia. It is taken up by the growing plants and relatively little is lost. Possibly (often), though, some of the ammonia is leached out via rain and ends up in waterways, where it causes plant overgrowth and algal blooms, which harm the waterways in several ways, and turn those nutrients from a resource into a contaminant.

Meanwhile, the corn is also uptaking a variety of other nutrients from the soil which the commercial fertilizer is NOT replacing. Year by year, those nutrients get shipped off to distant feedlots and depleted in the soil. Eventually, those nutrients are gone from my neighbor's field and, quite possibly, languishing in a manure lagoon somewhere in, say, Indiana, where one can only hope it's properly treated and made into compost. But, you know. Not necessarily.

When I buy compost at the store, it's usually based in either cow manure or "forest products". Hopefully, depending on brand, those forest products MIGHT be collected municipal yard waste. Which is pretty good. Those suburbanites don't want their leaves, I do, win/win.

Except that because those suburbanites raked their yard waste, they now need at some point to fertilize their trees, shrubs, and turf grass. Meanwhile, they've eliminated habitat for the many insects that use leaf litter to either overwinter or reproduce. They may not be counting the costs, but the costs don't stop existing.

The ebb and flow of nutrients is something that, in the current system, goes utterly unregarded by most of the people taking part in the process. Even gardeners bring nutrients onto their soils mostly without thinking about the places those nutrients came from. I think in a sustainable world, that needs to change.

Also probably we need to do a hell of a lot more cover-cropping.

#environmental science#ecology#global climate change#agriculture#leftism#Marxism#colonialism#fully automated luxury gay space communism

6K notes

·

View notes

Text

How Philomena Mbura Is Inspiring Africa’s Next Generation of AI Innovators via Zindi

Philomena Mbura Before sunrise in Nairobi, while most of the city was still asleep, a young Philomena Mbura would already be awake, her mind alive with questions. In a world where girls were often nudged toward safe, traditional careers, Philomena’s relentless curiosity set her on a path few dared to imagine. Her childhood mornings were marked by the hum of city life, the rattle of early buses,…

#Agriculture#AI#AI Automation#AI Ecosystem#AI Healthcare#Artificial Intelligence#Data Science#Data Scientists#GenAI#Generative AI#Healthcare#Innovation#Machine Learning#Software Development#Technology

0 notes

Text

The AI Revolution: 10 Industries Being Transformed by AI

The relentless march of technology often brings about profound shifts, but few have been as sweeping and impactful as the current Artificial Intelligence (AI) revolution. Once confined to the realms of science fiction, AI has now permeated nearly every facet of our daily lives, quietly reshaping industries, redefining possibilities, and fundamentally altering how businesses operate. This isn’t…

#agricultural AI#agriculture AI tools#AI adoption#AI applications#AI benefits#AI challenges#AI evolution#AI for growth#AI impact on business#AI in agriculture#AI in banking operations#AI in cybersecurity#AI in education#AI in finance#AI in healthcare#AI in industries#AI in manufacturing#AI in media#AI in retail#AI in transportation#AI innovation#AI opportunities#AI revolution#AI solutions#AI strategy#AI-driven cyber defense#AI-driven insights#artificial intelligence transformation#automation#autonomous systems

0 notes

Text

Boosting Agricultural Efficiency with Smart Water Pump Controllers in Coimbatore

In moment’s presto- evolving agricultural sector, farmers are decreasingly espousing Agriculture Automation in Coimbatore to enhance productivity and save water. One of the most poignant results is the use of Automatic Water Pump Controllers in Coimbatore and Wireless Automatic Pump Control Systems. These systems are revolutionizing water management in farming, icing precise irrigation and optimal water usage.

The Need for Automation in Agriculture

Water scarcity and rising energy costs are two major challenges for farmers in Tamil Nadu and across India. Manual pump operation frequently leads to water wastage and inconsistent irrigation schedules. This is where Agricultural Automation System Manufacturers in Coimbatore, like Nile Controllers, come into the picture.

Benefits of Automatic Water Pump Controllers

Effective Water Usage An Automatic Water Pump Controller in Coimbatore helps cover and control pump operations based on real- time water situations, soil moisture, and time schedules. This ensures that crops admit the right amount of water at the right time

Why Choose Wireless Automatic Pump Control Systems?

Traditional wired systems have limitations in large spreads. With the advancement of IoT and wireless technology, Wireless Automatic Pump Control Systems offer remote monitoring and control through smartphones or web platforms. Nile Controllers provides slice- edge wireless results that allow farmers to operate pumps from anywhere, reducing the need for physical presence on- point.

Automatic Water Level Controllers A Must- Have for Farmers

Water storage tanks and borewells frequently face issues like overflow and dry handling. A dependable Automatic Water Level Controller in Coimbatore prevents these problems by regulating pump operation based on tank and sump water situations. This prevents motor damage and avoids water destruction.

Why Nile Controllers?

As one of the leading Agricultural Automation System Manufacturers in Coimbatore, Nile Controllers offers a complete range of pump control results acclimatized for agricultural requirements. From single- phase and three- phase pump controllers to GSM and wireless pump control systems, our products are trusted by hundreds of farmers across the region.

Key Features of Nile Controllers' Systems

Real- time monitoring

Auto start/ stop function

Load and dry run protection

Mobile app compatibility

Suitable for all types of pumps( submersible, open well, borewell)

Conclusion

Adopting smart irrigation results like Automatic Water Pump Controllers, Wireless Pump Control Systems, and Automatic Water Level Controllers in Coimbatore is no longer a luxury but a necessity for modern farming. Nile Controllers is committed to supporting farmers with affordable and dependable Agriculture Automation in Coimbatore.

Invest moment in agricultural automation and experience increased crop yield, reduced costs, and effective water management!

0 notes

Text

Revolutionizing Agriculture: The Rise of Robots and Mechatronics

In recent years, the agricultural industry has witnessed a significant transformation, with the introduction of advanced technologies such as robots and mechatronics. These innovations are reshaping the way farmers cultivate crops, manage livestock, and optimize their operations. As the world population continues to grow and the demand for food increases, the adoption of agricultural robots and mechatronics has become crucial in ensuring sustainable and efficient food production. Precision agriculture is a farming management approach that utilizes technology to optimize crop yields and minimize resource consumption. Agricultural Robots And Mechatronics play a vital role in this process by enabling farmers to collect precise data about their crops and perform tasks with unparalleled accuracy. These robots are equipped with sensors, cameras, and GPS systems that allow them to navigate fields autonomously, gather information about soil conditions, and monitor crop health. Get more insights on, Agricultural Robots and Mechatronics

0 notes

Text

Variable Frequency Drives for Agriculture and Industrial Pumping

In applications like agricultural irrigation, farm pumps, lake circulation, and river-fed infrastructure, variable frequency drives provide unmatched control, efficiency, and protection. VFDs precisely regulate motor speed to match real-time flow demand, maximizing energy savings while ensuring smooth system operation. Features such as blockage detection, dry run protection, pump stir cycle, and motor preheat function significantly reduce downtime, extend equipment life, and improve system reliability.

Quiet motor operation, advanced harmonic suppression, and optimized power factor design contribute to reduced operating costs and environmental impact. Whether operating a single high-power irrigation pump or managing a multi-pump station, variable frequency drives provide the intelligent control required to support advanced, water-driven infrastructure.

#variablefrequencydrive#acdrives#irrigation#pumps#pumpcontrol#vfds#agtech#infrastructure#efficiency#flowrate#motorcontrols#vfd#agriculture#automation#farming#speed#torque#voltage#current#phase#drives

0 notes

Text

Agriculture Automation and Control Systems Market: A Comprehensive Analysis

The agriculture automation and control systems market Analysis is undergoing rapid transformation as the industry increasingly adopts cutting-edge technologies to boost productivity and meet the demands of a growing global population. This blog offers a detailed analysis of the market, covering its current status, forecast, trends, segmentation, regional performance, key players, and future outlook.

Market Overview and Estimation

As of 2022, the global agriculture automation and control systems market was valued at USD 4.3 billion. It is expected to reach USD 6.69 billion by 2031, growing at a CAGR of 5.71% over the forecast period (2024–2031). This growth trajectory is primarily attributed to the rising need for efficiency in farming, labor shortages, and increasing awareness about sustainable agricultural practices. Technologies such as IoT (Internet of Things), artificial intelligence, and robotics are being increasingly integrated into agricultural operations to streamline processes, optimize input use, and enhance crop yields.

Latest News and out look

Recent developments in the market reflect the industry's move toward complete digitization and automation:

Internet of Things (IoT): Farmers are adopting IoT-enabled sensors and monitoring systems to track real-time data on soil moisture, nutrient levels, and climate conditions. This not only improves decision-making but also significantly reduces waste.

Autonomous Farm Equipment: Companies are designing unmanned aerial vehicles (UAVs), self-driving tractors, and robotic harvesters to automate labor-intensive processes like planting, spraying, and harvesting.

Artificial Intelligence (AI): AI algorithms are now being used to predict pest infestations, monitor crop health, and manage irrigation, enabling precision agriculture at scale.

Smart Greenhouses and Vertical Farming: With urbanization on the rise, smart greenhouses and controlled environment agriculture are gaining traction, especially in countries facing arable land scarcity.

Startups and Collaborations: Startups focusing on agritech are receiving significant investments. Established companies are collaborating with technology firms to develop innovative, scalable solutions for commercial agriculture.

Sample Link

Market Segmentation

The agriculture automation and control systems market is segmented by type and application.

By Type, the market encompasses several core technologies:

Yield Monitoring: Utilized primarily for mapping field variability and optimizing crop yields, yield monitoring systems are a critical component of precision farming. These systems help farmers collect and analyze crop data in real-time.

Irrigation Management: Automated irrigation systems manage water usage based on weather forecasts and soil moisture levels. This minimizes water waste and boosts crop health.

Field Mapping: Through GPS and sensor-based technologies, field mapping solutions provide detailed data on field conditions, soil types, and nutrient availability.

Weather Tracking and Forecasting: These systems gather meteorological data to help farmers plan their field activities, such as planting and harvesting.

Crop Scouting and Health Monitoring: UAVs and remote sensors help in monitoring plant health and detecting diseases or pests early, allowing for timely interventions.

Farm Labor and Inventory Management: Automation reduces dependence on manual labor, improves scheduling, and streamlines the supply chain from seed to market.

By Application, the market is divided into:

Commercial Farming: This segment dominates the market, accounting for over 70% of the global share. Large-scale operations adopt comprehensive automation systems for end-to-end efficiency.

Personal or Small-Scale Farming: While adoption is slower, small farms are increasingly integrating affordable, scalable solutions like mobile-based farm management apps and low-cost sensors.

Regional Analysis

United States: The U.S. leads in both adoption and innovation of agricultural automation systems. The market is bolstered by strong infrastructure, investment in agritech R&D, and favorable government initiatives such as subsidies for precision farming tools. U.S. farms widely use GPS-guided tractors, smart irrigation systems, and AI-driven crop monitoring. The country accounts for a significant share of the global market and continues to see steady growth supported by technological integration and sustainability goals.

Japan: Japan is emerging as a technological leader in smart farming, especially due to its aging farmer population and limited agricultural labor. The Japanese smart agriculture market is forecast to grow from 15.87 billion JPY in 2019 to 44.28 billion JPY by 2025, reflecting a robust CAGR of 11.8%. Government support, such as equipment subsidies and regulatory frameworks encouraging innovation, is instrumental in driving this growth. Japan is also seeing the adoption of automated tractors, drone-based monitoring systems, and AI for crop management in both open-field and indoor farming systems.

Key Highlights from the Market

AI and Data Analytics are becoming central to automated farming, enabling predictive maintenance of equipment, yield forecasting, and risk mitigation.

Hydroponics and Controlled Environment Agriculture are gaining popularity, especially in urban areas and countries facing land scarcity.

Collaborations and Technological Integration between agricultural equipment manufacturers and tech firms are creating more integrated, user-friendly systems.

Sustainability Initiatives are encouraging the use of automation to reduce water usage, greenhouse gas emissions, and chemical inputs.

Key Players and Competitive Landscape

Several companies are dominating the agriculture automation space with extensive product portfolios and strategic investments. The five major players with the largest market share include:

John Deere – A pioneer in autonomous tractors and precision agriculture solutions. Their focus on smart machinery places them at the top of the market.

AGCO Corporation – Known for brands like Fendt and Massey Ferguson, AGCO is aggressively expanding its automation capabilities through acquisitions and innovations.

Emerson Electric Co. – Offers a range of automation and control solutions tailored for agricultural use, contributing to more efficient farm operations.

Schneider Electric – Focuses on energy-efficient automation and digital transformation, helping farms optimize resource use.

Bonsai Robotics – A rapidly emerging player developing robotic solutions for harvesting and field operations, addressing labor shortages in agriculture.

These players continue to invest in R&D, expand their global footprint, and form strategic alliances to maintain competitive advantage.

Conclusion

The agriculture automation and control systems market is on an upward trajectory, fueled by a combination of necessity and innovation. As challenges like climate change, food security, and labor shortages intensify, the role of automation in agriculture becomes increasingly vital. Countries like the U.S. and Japan are setting benchmarks through their adoption of smart technologies and supportive policies. With robust growth forecasts and active participation from both tech giants and startups, the future of farming is undeniably digital. Embracing automation not only ensures sustainable food production but also opens new avenues for economic and environmental progress in agriculture.

0 notes

Text

Smart Agriculture Solution Drivers: Key Innovations Fueling the Future of Sustainable Farming

The smart agriculture solution market is experiencing remarkable growth due to the increasing integration of technology in farming practices. As global demand for food rises alongside environmental concerns and labor shortages, agriculture is undergoing a technological revolution. The driving forces behind this shift are diverse, ranging from advanced data analytics to sustainable farming initiatives.

1. IoT and Sensor Technology

One of the most significant drivers of smart agriculture is the use of Internet of Things (IoT) devices and sensors. These tools collect real-time data on soil moisture, weather conditions, crop health, and pest activity. This information allows farmers to make precise, data-driven decisions that improve productivity and reduce resource waste.

For example, moisture sensors can signal when a field needs watering, reducing water usage and promoting sustainability. This precision farming approach results in better crop yields and cost savings.

2. Artificial Intelligence and Machine Learning

AI and machine learning are transforming raw agricultural data into actionable insights. These technologies analyze complex datasets to predict crop performance, identify diseases early, and recommend the best times for planting and harvesting. AI-driven solutions are increasingly used for image recognition in drones, identifying pests and diseases quickly and accurately.

AI also plays a vital role in autonomous machinery, enabling tractors, harvesters, and drones to operate with minimal human intervention.

3. Climate Change and Sustainability Concerns

Climate change is a major challenge for global agriculture. Rising temperatures, erratic rainfall, and extreme weather events threaten food production. As a result, sustainable and climate-resilient solutions are becoming essential.

Smart agriculture solutions help mitigate these impacts by offering tools for climate-smart farming. Farmers can use predictive models to anticipate droughts, floods, or frost, and adapt their planting strategies accordingly. Sustainability is also promoted through reduced chemical usage and better resource management.

4. Labor Shortages and Automation

Many countries are facing a decline in agricultural labor, prompting the need for automated solutions. Smart machinery like autonomous tractors and robotic harvesters address labor gaps while improving efficiency and precision.

Automation also reduces the risk of human error and allows farmers to manage larger areas with fewer workers. This is especially beneficial in developed nations with aging farming populations.

5. Government Initiatives and Policies

Governments worldwide are recognizing the importance of digital agriculture and are supporting it through subsidies, policies, and research funding. For instance, the EU’s Common Agricultural Policy and India’s Digital Agriculture Mission are actively promoting smart technologies in farming.

These programs drive adoption by making technologies more accessible and affordable for small and medium-scale farmers, who might otherwise struggle to invest in such solutions.

6. Data Analytics and Farm Management Platforms

Data is at the heart of smart farming. Farm management systems allow farmers to centralize and analyze data from multiple sources—weather forecasts, satellite imagery, sensor readings, and machinery performance. With cloud-based platforms, farmers can plan irrigation, fertilization, and harvesting schedules with improved precision.

Such platforms also help in compliance with food safety standards and traceability, which are becoming increasingly important in the global supply chain.

7. Increased Global Food Demand

With the world population expected to reach nearly 10 billion by 2050, food production must increase significantly. Traditional farming methods alone cannot meet this demand without further straining the environment.

Smart agriculture solutions offer a way to grow more with less—maximizing land use, improving yields, and reducing input costs. This makes them critical tools in achieving global food security.

Future Outlook

The future of the smart agriculture solution market looks promising. With continuous innovation, costs are gradually decreasing, making technologies more accessible to farmers worldwide. As 5G connectivity expands, real-time data processing and remote farm management will become even more efficient.

In the coming years, we can expect smart agriculture to be central to addressing major agricultural challenges—from feeding a growing population to adapting to climate change. The convergence of technology and farming is no longer a luxury but a necessity for sustainable and productive agriculture worldwide.

#Smart Agriculture#Precision Farming#Agricultural Technology#IoT in Agriculture#AI in Farming#Sustainable Agriculture#Smart Farming Solutions#Farm Automation#Climate-Smart Agriculture#Agricultural Innovation

0 notes

Text

Smart Irrigation: The Future of Sustainable Farming

Smart Watering Revolution: How Automated Irrigation is Transforming Agriculture Forever

The sun beats down mercilessly on a vast cornfield in Kansas, but the farmer isn't worried about his crops. Miles away, sipping coffee in his kitchen, he watches his smartphone display real-time soil moisture levels, weather predictions, and irrigation schedules. With a tap, his automated system springs into action, delivering precisely the right amount of water exactly where it's needed. This isn't futuristic farming—it's happening right now, and it's revolutionizing agriculture worldwide.

Welcome to the irrigation automation revolution, a technological transformation that's reshaping how we grow food and manage water resources. According to recent research from Meticulous Research®, the global irrigation automation market is poised for explosive growth, projected to reach $12.7 billion by 2032 with an impressive 16.6% compound annual growth rate.

The Perfect Storm Driving Growth

Several powerful forces are converging to fuel this remarkable expansion. Climate change is making weather patterns increasingly unpredictable, while global population growth demands more food production from less available land. Traditional irrigation methods, with their notorious inefficiency and water waste, simply can't meet these challenges.

Enter smart irrigation systems—technological marvels that use sensors, timers, and sophisticated algorithms to deliver water with surgical precision. These systems monitor soil moisture, weather conditions, and plant needs in real-time, ensuring crops receive exactly what they need, when they need it. The result? Dramatically reduced water waste, improved crop yields, and significant cost savings for farmers.

Government support is accelerating adoption across the globe. From subsidies for smart farming equipment to water conservation mandates, policymakers are recognizing that automated irrigation isn't just an agricultural upgrade—it's an environmental necessity. Large-scale farming operations are leading the charge, but smaller farms are increasingly joining the movement as costs decrease and benefits become undeniable.

The Technology Behind the Magic

The irrigation automation market encompasses two main approaches: fully automatic systems that operate independently, and semi-automatic systems that require some human intervention. Automatic systems currently dominate the market, and for good reason. These sophisticated setups can adjust watering schedules based on weather forecasts, soil conditions, and plant growth stages—all without human input.

The variety of irrigation methods being automated is impressive. Sprinkler systems lead the market due to their versatility and relatively affordable installation costs. These systems can cover large areas efficiently while maintaining precise control over water distribution. However, drip irrigation is experiencing the fastest growth, and it's easy to see why. By delivering water directly to plant roots, drip systems achieve unparalleled efficiency, making them perfect for water-scarce regions and high-value crops.

The hardware driving these systems includes an array of sensors that would make a tech enthusiast jealous. Soil moisture sensors track underground conditions, weather-based sensors predict upcoming conditions, and flow sensors monitor water usage in real-time. Smart controllers process this data and make split-second decisions about when, where, and how much to water.

Beyond the Farm: Expanding Applications

While agriculture represents the largest market segment, irrigation automation is spreading far beyond traditional farming. Residential homeowners are embracing smart sprinkler systems that keep lawns green while slashing water bills. Golf courses are using precision irrigation to maintain pristine playing conditions while meeting strict water usage regulations. Even urban landscapes and public spaces are benefiting from these technologies.

Greenhouse operations are particularly enthusiastic adopters, where controlled environments allow automated systems to achieve near-perfect growing conditions. These enclosed spaces showcase the technology's potential, with some operations reporting 40-50% reductions in water usage alongside improved crop quality and yields.

Global Adoption Patterns

Asia-Pacific currently leads the global market, driven by massive agricultural sectors in China and India, where water scarcity issues make efficiency paramount. The region's rapid technological adoption and strong government support for agricultural modernization create ideal conditions for irrigation automation growth.

However, North America is experiencing the fastest growth rate, fueled by technological innovation and the presence of industry leaders like The Toro Company, Rain Bird Corporation, and Valmont Industries. These companies are pushing the boundaries of what's possible, developing increasingly sophisticated systems that integrate artificial intelligence, machine learning, and IoT connectivity.

Challenges and Opportunities

Despite the promising outlook, obstacles remain. High initial installation costs can deter smaller operations, while fragmented land ownership in some regions makes large-scale implementation challenging. Technical complexity can intimidate farmers accustomed to traditional methods, and in some areas, reliable internet connectivity required for smart systems remains elusive.

Yet these challenges are creating opportunities for innovation. Companies are developing more affordable, user-friendly systems while expanding support services. Mobile apps are making sophisticated irrigation management accessible to farmers regardless of their technical expertise.

The Future of Farming

As we look toward 2032, irrigation automation represents more than just technological advancement—it's a fundamental shift toward sustainable agriculture. In a world where every drop of water matters and food security hangs in the balance, these smart systems offer hope for feeding a growing population while preserving our planet's precious resources.

The smart watering revolution is just beginning, and its impact will be felt far beyond the farm gate.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5578

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Irrigation Automation Market#Irrigation Automation#Automatic Irrigation#Automatic Watering System#Automatic Irrigation System#Auto Irrigation System#Agricultural Irrigation Automation#Plant Irrigation System#Automation in Drip Irrigation#Sprinkler Automation#Automated Irrigation System

1 note

·

View note