#Advanced Corrugated Box Machinery

Explore tagged Tumblr posts

Text

Boost Your Production with Advanced Corrugated Box Machinery

In the dynamic world of packaging, having the right equipment is crucial for efficiency and quality. At boxmaker.tech, we offer a range of state-of-the-art corrugated box making machines designed to meet your production needs. Our machines are engineered for precision, speed, and reliability, ensuring your business stays ahead of the competition.

Corrugated Box Machinery Price: Affordable Excellence

Our corrugated box machinery is priced competitively to help you cut costs and increase profits. Despite the affordability, these machines do not compromise on quality or performance. The advanced features integrated into our equipment provide the highest efficiency and versatility in the market.

Innovative Box Making Machine for Short-Run and Serial Production

Our flagship box making machine, the BM2508-Plus, and the HMG200, are renowned for their simple yet robust designs. They are specialized for low to medium volume heavy-duty box production, handling everything from E flute to AAA flute with ease. With the ability to process sheets with thickness ranging from 2mm to 10mm, these machines cater to a wide array of packaging requirements.

Precision and Quality in Every Cut

Equipped with four cutting knives rotated by servo motors, our corrugated box machines ensure beautiful and flat sides on every box. The integrated slotting knife and creasing beam design enhance the precision of slotting and creasing, making your boxes not only functional but also aesthetically pleasing. The slotting width ranges from 7mm to 16mm, delivering excellent cutting performance without any burrs. Check corrugated box machine features.

Advanced Features for Optimal Performance

Our machines come with a continuous cardboard feeding system powered by a vacuum pump, ensuring accurate and consistent feeding. Additionally, the inline cold gluing auto application feature eliminates the need for an extra gluing machine, streamlining your production process.

Versatile and Efficient Box Maker Machine

The box maker machines at boxmaker.tech are compact yet powerful, integrating horizontal slotting and scoring, vertical slitting and creasing, and horizontal cutting all in one unit. They can produce specialized features such as hand holes, vent holes, and special-shaped rounded corners, catering to diverse packaging needs.

Reliable and Efficient Production

With two 500mm symmetrical slotting knives and four scoring/creasing wheels, our machines deliver the highest efficiency and versatility in box making. The cheap module and easy replacement features ensure minimal downtime and maximum productivity.

Comprehensive Support and Fast Shipping

At boxmaker.tech, we handle all details of your order, providing fast shipping to ensure timely delivery. Our excellent R&D team allows you to market test your business ideas before making final decisions, helping you monitor and control your risks effectively.

Conclusion

Choosing the right corrugated box manufacturing machine can significantly impact your production efficiency and profitability. At boxmaker.tech, we offer top-of-the-line corrugated box making machines at competitive prices, equipped with advanced features to meet all your packaging needs. Explore our range today and take your production to the next level.

For more information visit website - Boxmaker.tech

Contact us to know corrugated box machinery price

Downlaod products catalogue here Advanced Corrugated Box Machinery

1 note

·

View note

Text

Leading Packaging Box Manufacturers in India: Affordable and High-Quality Packaging Box Available | Shri Sai Printers

In today's competitive marketplace, effective packaging plays a crucial role in ensuring product safety and enhancing brand visibility. For businesses looking for reliable solutions, partnering with leading Packaging Box Manufacturers in India is essential. Among these manufacturers, Shri Sai Printers stands out for its commitment to delivering affordable, high-quality packaging solutions that cater to various industries.

Why Choose Shri Sai Printers?

Shri Sai Printers has established itself as a prominent name in the packaging industry, offering an extensive range of packaging boxes designed to meet diverse needs. Whether you're in the food, cosmetics, electronics, or retail sector, Shri Sai Printers provides tailor-made solutions that enhance the protection and presentation of your products. The company’s focus on quality, affordability, and customer satisfaction has earned it a loyal client base across India.

Diverse Product Range

Shri Sai Printers specializes in producing a wide variety of packaging boxes, including:

Corrugated Boxes: Ideal for shipping and storage, these boxes provide excellent protection against damage and are customizable in size and strength.

Printed Boxes: Enhance your brand visibility with high-quality printed packaging. Shri Sai Printers offers vibrant colors and various printing techniques to make your packaging stand out on the shelves.

Eco-Friendly Packaging: With the increasing demand for sustainable packaging solutions, Shri Sai Printers offers biodegradable and recyclable packaging options, helping businesses align with environmental goals.

Custom Packaging: Understanding that every business has unique requirements, Shri Sai Printers provides customized solutions that cater to specific product dimensions and branding needs.

Quality Assurance

Quality is paramount in the packaging industry, and Shri Sai Printers ensures that all products adhere to stringent quality control measures. The company uses advanced machinery and skilled professionals to produce durable packaging solutions that can withstand the rigors of transport and storage. Their commitment to quality has made them a preferred choice among Packaging Box Suppliers in India.

Competitive Pricing

Affordability is another key factor that sets Shri Sai Printers apart. The company believes that high-quality packaging should be accessible to businesses of all sizes. By optimizing production processes and sourcing materials efficiently, they offer competitive pricing without compromising on quality. This commitment to affordability makes them an ideal partner for startups and established businesses alike.

Customer-Centric Approach

Shri Sai Printers prioritizes customer satisfaction and aims to build long-term relationships with its clients. The team is dedicated to understanding client needs and providing timely solutions, ensuring that businesses receive their packaging on schedule. Their responsive customer service and willingness to accommodate specific requests make them a trusted name in the industry.

Conclusion

For businesses seeking high-quality and affordable packaging solutions, Shri Sai Printers is among the leading Packaging Box Manufacturers in Delhi. With a diverse product range, a strong focus on quality, and a commitment to customer satisfaction, they provide everything you need to ensure your products are well-protected and beautifully presented.

Choosing the right packaging is crucial for your brand’s success, and Shri Sai Printers stands ready to support you in achieving your packaging goals. Explore their offerings today and elevate your brand with their premium packaging solutions!

If you have a query, please contact us

Name: — Shyam Gupta

Email: — [email protected]

Phone: — +91 9899350149

Follow Our Social Media Pages

Facebook: — https://www.facebook.com/ShriSaiPrinter/

Twitter: — https://twitter.com/ShriSaiPrinters

#Packaging Box Manufacturers in India#Packaging Box Manufacturers in Delhi#Packaging Box Suppliers in India#Packaging Box Suppliers in Delhi#Packaging Box Wholesaler in India#Packaging Box Wholesaler in Delhi#Packaging Box Company in India#Packaging Box Company in Delhi#Packaging Box Manufacturers Company in India#Packaging Box Suppliers Company in India#Packaging Box Wholesaler Company in India#Packaging Box Manufacturers Company in Delhi#Packaging Box Suppliers Company in Delhi

0 notes

Text

Role and Importance of Cartoning Machines in Modern Packaging

In today's fast-paced industrial landscape, efficiency and automation are paramount, especially in the packaging sector. Among the various types of packaging machinery, cartoning machine stands out as a crucial component in the packaging line. This article delves into the significance, types, and advancements in cartoning machines, highlighting their role in optimizing production processes across various industries.

What is a Cartoning Machine?

A cartoning machine is an automated device designed to form, fill, and seal cartons or boxes, which are typically made of paperboard or corrugated fiberboard. These machines are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods, where products need to be packaged efficiently and securely for retail or distribution.

Types of Cartoning Machines

Cartoning machines come in various types, each tailored to specific packaging needs:

Horizontal Cartoning Machines:

These machines handle products that are inserted horizontally into the carton. They are ideal for packaging items like bottles, tubes, sachets, or any product that can be laid flat.

Horizontal cartoning machines are often used in the food industry for products like cereal boxes, frozen foods, and confectionery.

Vertical Cartoning Machines:

In this type, products are inserted vertically into the carton. They are typically used for packaging products like jars, cans, or any item that requires vertical stacking.

Vertical cartoning machines are prevalent in the pharmaceutical industry, where they are used to package bottles of medicine, vials, or small cartons of tablets.

Wrap-Around Cartoning Machines:

These machines wrap the carton around the product rather than inserting the product into a pre-formed carton. This method provides a snug fit, reducing the need for additional packing material.

Wrap-around cartoning is common in industries where product integrity during transit is a priority, such as in the beverage industry.

Sleeve Cartoning Machines:

Sleeve cartoning machines place a sleeve around the product, leaving the ends open. This type is often used for multi-pack items like canned beverages or boxes of toothpaste.

They are popular in the food and beverage industry for their ability to create attractive, easy-to-handle multipacks.

Key Features and Benefits of Cartoning Machines

Automation: One of the primary advantages of cartoning machines is their ability to automate the packaging process. This not only speeds up production but also reduces the need for manual labor, thereby lowering operational costs.

Consistency and Precision: Cartoning machines are designed to maintain high levels of consistency and precision, ensuring that each carton is filled, sealed, and labeled correctly. This reduces the risk of packaging errors, which can lead to product damage or recalls.

Versatility: Modern cartoning machines are highly versatile and can handle a wide range of product sizes and shapes. This flexibility is crucial for industries that produce a variety of products or frequently change packaging designs.

Compact Design: Many cartoning machines are designed to occupy minimal floor space, making them suitable for factories with limited space. Despite their compact size, these machines often come equipped with advanced features like touch-screen controls, automated size adjustments, and integrated quality control systems.

Sustainability: As sustainability becomes a focal point in manufacturing, many packaging robots are designed to minimize waste. They optimize material usage and are compatible with eco-friendly packaging materials, helping companies reduce their environmental footprint.

Advancements in Cartoning Technology

The evolution of cartoning machines has been marked by significant technological advancements aimed at enhancing efficiency and adaptability:

Robotics and AI Integration: The integration of robotics and artificial intelligence (AI) has revolutionized cartoning machines. These technologies enable machines to adapt to various packaging needs dynamically, improving speed and accuracy. AI-driven systems can also predict maintenance needs, reducing downtime.

Smart Packaging: Modern cartoning machines are increasingly equipped with smart packaging features, such as QR codes and RFID tags, that enhance product traceability and consumer engagement. These features are particularly valuable in industries like pharmaceuticals, where tracking and authenticity are critical.

High-Speed Operation: The demand for higher production rates has led to the development of high-speed cartoning machines capable of processing hundreds of cartons per minute. These machines are essential for large-scale manufacturing operations, where efficiency is key to meeting market demand.

Customization and Modularity: Today's cartoning machines offer a high degree of customization, allowing manufacturers to tailor the machines to their specific needs. Modularity in design enables companies to add or remove features as required, ensuring that the machine evolves with their production demands.

Conclusion

Cartoning machines play a pivotal role in the modern packaging industry, offering a blend of automation, precision, and versatility that is essential for efficient production. As technology continues to advance, these machines are becoming smarter, faster, and more adaptable, meeting the ever-changing needs of industries worldwide. For businesses looking to optimize their packaging processes, investing in a state-of-the-art cartoning machine is a step towards achieving greater efficiency, consistency, and sustainability in their operations.

0 notes

Text

Safeguarding Products, Simplifying Logistics: The Role of Industrial Packaging

In the intricate web of global commerce, the significance of industrial packaging cannot be overstated. As businesses navigate the complex landscape of production, distribution, and consumption, industrial packaging emerges as a critical component, playing a dual role in safeguarding products and simplifying logistics. This article sheds light on the pivotal role of industrial packaging in the modern commercial ecosystem, exploring its multifaceted impact and evolving trends.

The Backbone of Modern Commerce

Industrial packaging, often referred to as secondary or transit packaging, encompasses a broad spectrum of materials and containers designed to protect, store, and transport goods across varying distances and conditions. Unlike consumer-oriented packaging, industrial packaging is optimized for efficiency, durability, and safety during transit and storage, catering to the unique requirements of bulk shipments, heavy machinery, and large-scale goods.

Ensuring Product Integrity

At its core, the primary function of industrial packaging is to safeguard the integrity of products throughout the supply chain. Whether it involves shielding delicate electronic components from environmental hazards or securing massive machinery parts against physical damage, the role of industrial packaging in preserving the quality and functionality of goods cannot be overstated. This protection extends to safeguarding products from moisture, temperature variations, mechanical stress, and other potential risks that could compromise their condition.

Streamlining Logistics Operations

In addition to product protection, industrial packaging plays a vital role in simplifying logistics operations. The efficiency and reliability of packaging materials directly impact the speed, cost, and safety of transportation and storage. Well-designed industrial packaging solutions optimize space utilization, facilitate seamless handling, and minimize the risk of damage during loading, unloading, and warehousing. In doing so, they contribute to smoother logistics processes, reduced turnaround times, and enhanced overall supply chain performance.

Tailored Solutions for Varied Needs

The modern industrial packaging landscape is characterized by a diverse array of materials, designs, and customization options tailored to meet the unique demands of different industries and products. From robust corrugated boxes and wooden crates to specialized cushioning materials and protective coatings, packaging solutions are engineered to address specific challenges and ensure optimal protection for a wide spectrum of goods, ranging from automotive parts and industrial machinery to pharmaceuticals and consumer electronics.

Sustainable Packaging Imperative

Amidst the fundamental role played by industrial packaging, the imperative of sustainability has increasingly taken center stage. As environmental awareness and regulations drive a paradigm shift towards eco-friendly practices, industrial packaging is undergoing a transformation where recyclability, reusability, and material efficiency are becoming paramount considerations. Businesses are embracing sustainable materials and design strategies to minimize waste, reduce carbon footprint, and align with the growing ethos of corporate social responsibility.

Future Trajectories and Innovations

Looking ahead, the trajectory of industrial packaging is poised for continued evolution, propelled by technological advancements and shifting market dynamics. Concepts such as smart packaging, incorporating elements like RFID tracking and IoT sensors, are paving the way for enhanced visibility and control throughout the supply chain. Furthermore, advancements in bio-based materials, biodegradable polymers, and circular packaging models are expected to reshape the landscape, offering sustainable alternatives without compromising performance.

In the intricate dance of global commerce, industrial packaging stands as an unsung hero, quietly ensuring the safe passage of goods and the efficiency of logistics operations. From protecting delicate components to facilitating the movement of heavy industrial machinery, industrial packaging plays a multifaceted role in shaping the modern commerce landscape. As sustainability takes center stage, the future of industrial packaging promises to blend innovation with environmental stewardship, fostering a seamless and responsible approach to safeguarding products and simplifying logistics in the years to come.

0 notes

Text

Cardboard Box Making Machine BM2508

Discover Innovative Packaging Solutions with QINGDAO ANYBOX

At QINGDAO ANYBOX, we are dedicated to revolutionizing the packaging industry with our cutting-edge corrugated box-making solutions. With a strong focus on innovation and quality, we have developed a series of advanced cardboard box making machines, each protected by our own patents. Our commitment to excellence ensures that every step of the process, from research and development to production, sales, and after-sales service, is meticulously controlled and executed.

Pioneering Packaging Technology

Our state-of-the-art cardboard box machines are a testament to our dedication to innovation. We continually invest in research and development to bring the latest advancements to our customers, ensuring that our machines not only meet but exceed industry standards. By holding patents on our technologies, we guarantee that our solutions are both unique and highly effective, providing our customers with a competitive edge.

Comprehensive Control and Quality Assurance

At QINGDAO ANYBOX, we take pride in managing every aspect of our operations. Our integrated approach allows us to maintain strict quality control throughout the entire production process. From the initial concept to the final product, our team of experts ensures that each machine is crafted with precision and care. This comprehensive control not only enhances the quality of our products but also enables us to offer unparalleled reliability and consistency.

Tailored Solutions for Every Need

We understand that our customers have diverse packaging requirements, and we are committed to providing solutions that cater to their unique needs. Whether you need small quantity box orders quickly or have specific design requirements, QINGDAO ANYBOX has you covered. Our flexible production capabilities allow us to produce boxes of any size, ensuring that you receive the perfect packaging solution for your products.

Fast and Efficient Service

Time is of the essence in the packaging industry, and we strive to provide our customers with fast and efficient service. Our streamlined processes and advanced machinery enable us to deliver small quantity orders promptly without compromising on quality. This ensures that your products are always packaged and ready for market in a timely manner.

Customized Solutions for Special Requirements

At QINGDAO ANYBOX, we believe that every customer is unique, and so are their packaging needs. Our team of experienced designers and engineers work closely with you to develop customized solutions that meet your specific requirements. Whether it's a unique box design, specialized materials, or particular functionality, we are committed to creating the most suitable packaging solution for your business.

Unmatched Customer Support

Our commitment to customer satisfaction extends beyond the sale of our machines. We offer comprehensive after-sales service to ensure that our customers receive the support they need to maximize the value of their investment. From installation and training to maintenance and troubleshooting, our dedicated team is always ready to assist you.

Conclusion

QINGDAO ANYBOX is your trusted partner for innovative and reliable corrugated box-making solutions. With our patented technologies, comprehensive quality control, and commitment to customer satisfaction, we are dedicated to helping you achieve your packaging goals. Whether you need fast, small quantity orders or customized solutions for special requirements, QINGDAO ANYBOX has the expertise and capabilities to deliver. Experience the difference with QINGDAO ANYBOX and elevate your packaging to new heights.

0 notes

Text

Choosing the Right Collation Shrink Film for Your Packaging Needs

In the fast-paced world of food and beverage packaging, efficiency and product safety are paramount. Enter collation shrink films—a game-changing solution that can transform your packaging process. If you're a food packaging professional, beverage industry expert, or sustainability enthusiast, this guide is for you. We'll explore the benefits, applications, and selection criteria for collation shrink films to help you make informed decisions for your packaging needs.

What Are Collation Shrink Films?

Collation shrink films are specialized plastic films designed to bundle products together securely. They are commonly used in various industries, including food and beverage, pharmaceuticals, and retail. These films are applied using heat, causing them to shrink tightly around the products, creating a secure and stable package ready for transportation and storage.

Benefits of Using Collation Shrink Films

Collation shrink films offer several notable benefits:

Protection: They safeguard individual items from shifting, damage, and tampering during transit.

Visibility: Transparent films allow consumers to see the product, enhancing its appeal.

Branding: Customizable printing options enable companies to boost brand visibility.

Efficiency: Streamlined packaging processes save time and reduce labor costs.

Cost-Effectiveness: They are a more economical alternative to traditional corrugated boxes.

By understanding these benefits, you can appreciate why collation shrink films are an essential tool in modern packaging.

The Manufacturing Process of Collation Shrink Films

At Tilak Polypack, we take pride in our meticulous manufacturing process, ensuring our collation shrink films meet the highest standards of quality and performance.

Material Selection

We start by selecting premium-grade materials specifically designed for collation shrink applications. These materials provide the perfect balance of strength, flexibility, and shrink characteristics.

Film Extrusion

Using advanced extrusion machinery, we process these materials to create films with precise dimensions. This step ensures optimal shrinkage properties and consistent performance across all batches.

Printing and Customization

Customization is key to branding. We offer a range of printing options, allowing businesses to add logos, product information, and other branding elements to their shrink films. This customization not only enhances product presentation but also serves as a marketing tool.

With these steps, we ensure that our collation shrink films meet the diverse needs of our clients, offering both functionality and aesthetic appeal.

Choosing the Right Collation Shrink Film

Selecting the right collation shrink film involves several considerations. Here are some key factors to keep in mind:

Product Type and Size

Different products require different types of shrink films. Consider the dimensions and weight of the items you need to bundle. Heavier items may require thicker films for added strength, while lighter items can use thinner films.

Environmental Conditions

Think about the conditions under which your packages will be stored and transported. Films designed to withstand varying temperatures, humidity levels, and exposure to sunlight will ensure the integrity of your packages.

Branding Needs

If branding is important, opt for films that can be easily printed on. This allows you to add logos, product details, and other branding elements that can attract consumers and boost brand recognition.

By taking these factors into account, you can choose a collation shrink film that meets your specific packaging requirements.

Applications of Collation Shrink Films

Collation shrink films are incredibly versatile and find applications in various industries. Here are some of the most common uses:

Food and Beverage Industry

In the food and beverage sector, collation shrink films are used to bundle products like cans, bottles, and jars. This not only makes transportation easier but also enhances product presentation on store shelves.

Pharmaceutical Industry

Pharmaceutical companies use collation shrink films to package medicines and medical supplies. The secure bundling ensures that the products remain intact and uncontaminated during transit.

Retail Industry

Retailers use these films to bundle products like toys, electronics, and home goods. The transparency of the film allows customers to see the product clearly, making it more appealing.

These applications demonstrate the versatility and effectiveness of collation shrink films across different sectors.

Advantages Over Traditional Packaging

Collation shrink films offer several advantages over traditional packaging methods, such as corrugated boxes:

Cost-Effectiveness

Shrink films are generally more affordable than corrugated boxes. This cost savings can be significant, especially for businesses that handle large volumes of products.

Environmental Impact

Shrink films have a lower carbon footprint compared to corrugated boxes. They use less material and generate less waste, making them a more sustainable packaging option.

Enhanced Protection

The tight fit of shrink films provides better protection against moisture, dust, and tampering. This is particularly important for products that are sensitive to environmental conditions.

By opting for collation shrink films, businesses can achieve cost savings, reduce their environmental impact, and ensure better protection for their products.

Customizing Your Collation Shrink Films

One of the standout features of collation shrink films is their customizability. Here’s how you can tailor them to meet your specific needs:

Printed Designs

Custom printing allows you to add logos, product information, and other branding elements. This can make your packages more attractive and informative.

Color Options

While transparent films are common, you can also choose colored films to match your brand’s aesthetic. Colors can make your products stand out and create a cohesive brand image.

Thickness and Width

Depending on your requirements, you can select films of varying thickness and width. Heavier products may need thicker films, while lighter items can do with thinner ones.

Customizing your collation shrink films ensures that they meet your specific needs while also enhancing your brand’s visibility.

1 note

·

View note

Text

Paper Packaging Market Exploration: Unlocking Potential of Biodegradable Materials

Paper Packaging: Ensuring Safety and Sustainability

History and Evolution of wrapping paper

Paper has been used for packaging purposes for centuries. Packaging made from paperboard, or cardboard, first emerged in the 19th century as industrialization increased demand for transportation of goods. Corrugated cardboard was invented in the 1870s and helped spur the growth of wrapping paper. Early paperboard boxes were flat and had to be assembled, but automated machinery soon allowed for the mass production of pre-folded boxes ready for use. Throughout the 20th century, advancements in materials, printing technology, and production processes made wrapping paper more affordable and accessible around the world. Today, wrapping paper is ubiquitous and comes in many forms including corrugated boxes, cartons, bags, and wraps.

Ensuring Product Protection and Safety

A key function of any packaging is to protect the product inside from damage. Wrapping paper fulfills this crucial role through several methods. Corrugated cardboard in particular provides cushioning and structure to prevent crushing during transportation and storage. The compressible interior flutes of corrugated cardboard absorb and disperse impact forces. Multiple plies of the material add extra strength without much additional weight. Specialty papers can also be wax or polyethylene coated to increase water resistance for certain products. Some types of paper even form a partially airtight or water-tight seal when glued or taped together. This protects contents from external elements that could potentially compromise quality or safety. Overall, wrapping pape ris well-suited to safely contain, carry, and transport a wide range of goods.

Ensuring a circular future

Arguably the most pressing sustainability challenge globally is transitioning to a circular economy model that eliminates waste. As a naturally renewable resource, Paper Packaging lends itself well to circularity through composting or recycling at end of use. However, realizing its full circular potential depends on effective collection and processing infrastructure. On the collection side, curbside programs need high participation rates to recover enough paper for recycling. Industrial and commercial sectors also require convenient recycling solutions. Meanwhile, recycling mills must employ the latest sorting and cleansing technologies to handle mixed materials streams and produce high quality recycled fibers. Government policies that incentivize use of recycled content can also boost demand. With collective action, the paper cycle of harvest, production, use, and reclamation could operate as an almost entirely closed loop. This would reinforce wrapping paper standing as one of the most environmentally friendly options and support a circular, waste-free future.

0 notes

Text

Cost-Effective Strategies for Ordering Custom Boxes in Bulk

Ordering custom boxes in bulk can be a strategic move for businesses looking to reduce packaging costs while ensuring they have enough supply to meet demand. However, achieving cost efficiency requires careful planning and smart decision-making. This article explores various cost-effective strategies for ordering custom boxes in bulk, helping businesses maximize their investment and maintain high-quality packaging.

Understanding Your Packaging Needs

Before placing a bulk order for custom boxes, it’s crucial to have a clear understanding of your packaging requirements. Consider the following factors:

Product Dimensions: Accurately measure the dimensions of your products to determine the appropriate size of the boxes.

Material Requirements: Identify the type of material needed based on product fragility, weight, and environmental considerations.

Design Specifications: Decide on the design elements such as logos, colors, and additional features like handles or windows.

Quantity: Estimate the number of boxes you’ll need over a specific period, considering both current and future demand.

By having a comprehensive understanding of your needs, you can avoid overordering or underordering, which can both lead to unnecessary costs.

Choosing the Right Manufacturer

Selecting the right manufacturer is crucial for cost-effective bulk ordering. Here are some tips to help you choose wisely:

Compare Quotes: Request quotes from multiple manufacturers. Compare their pricing, but also consider the quality of materials, production capabilities, and delivery timelines.

Check Reviews and References: Look for reviews and ask for references from other businesses that have used the manufacturer’s services. This can provide insights into their reliability and quality.

Assess Capabilities: Ensure the manufacturer has the capability to handle large orders without compromising on quality. This includes checking their machinery, workforce, and quality control processes.

Negotiating Better Rates

When ordering custom boxes in bulk, don’t hesitate to negotiate with manufacturers. Here are some strategies for securing better rates:

Volume Discounts: Most manufacturers offer discounts for large orders. The larger the order, the lower the cost per unit. Negotiate for the best possible volume discount.

Long-Term Contracts: If you anticipate needing custom boxes regularly, consider signing a long-term contract with the manufacturer. This can lock in lower rates and provide price stability.

Bundling Services: Some manufacturers offer additional services like design, printing, and shipping. Bundling these services can sometimes result in a lower overall cost.

Optimizing Box Design

The design of your custom boxes can significantly impact costs. Here are some design optimization strategies:

Standard Sizes: Custom sizes can be more expensive. Whenever possible, use standard box sizes that are readily available and cheaper to produce.

Material Efficiency: Choose materials that offer the best balance between cost and durability. For instance, using thinner corrugated cardboard for lightweight items can reduce costs without compromising protection.

Minimalist Design: A minimalist design can reduce printing costs. Simple, clean designs that use fewer colors and less ink can be more cost-effective while still looking professional.

Streamlining the Ordering Process

Efficient ordering processes can lead to cost savings. Consider the following tips:

Forecast Demand Accurately: Use sales data and market analysis to forecast demand accurately. This can help you order the right quantity, avoiding excess inventory and storage costs.

Order in Advance: Plan your orders well in advance to avoid rush fees and take advantage of early order discounts.

Batch Orders: Instead of placing multiple small orders, batch your orders to meet the minimum order quantity for bulk discounts.

Reducing Shipping Costs

Shipping can be a significant expense when ordering custom boxes in bulk. Here are some ways to reduce shipping costs:

Choose Local Manufacturers: Working with local manufacturers can reduce shipping distances and costs.

Optimize Box Size: Ensure that the boxes are not too large for the products. Oversized boxes can increase shipping costs due to dimensional weight pricing.

Consolidate Shipments: Whenever possible, consolidate shipments to minimize the number of deliveries and reduce shipping fees.

Leveraging Technology

Technology can play a crucial role in making bulk ordering more cost-effective. Here are some ways to leverage technology:

Automated Inventory Management: Use inventory management software to track stock levels, forecast demand, and automate reordering processes.

Online Ordering Platforms: Utilize online platforms that connect you with multiple manufacturers. These platforms often provide competitive pricing and facilitate easy comparison.

Design Software: Use design software to create your box designs. This can save on design fees and ensure you have complete control over the design process.

Exploring Alternative Materials

Traditional materials like corrugated cardboard are popular, but exploring alternative materials can sometimes yield cost savings. Consider the following options:

Recycled Materials: Boxes made from recycled materials can be cheaper and more environmentally friendly.

Biodegradable Plastics: For certain products, biodegradable plastics might offer a cost-effective and sustainable packaging solution.

Innovative Materials: Keep an eye on new materials entering the market. Innovations in packaging materials can offer cost savings and improved performance.

Partnering with Suppliers

Building strong relationships with your suppliers can lead to cost benefits. Here’s how to develop beneficial partnerships:

Open Communication: Maintain open lines of communication with your suppliers. Discuss your needs and expectations clearly to avoid misunderstandings and delays.

Regular Reviews: Regularly review supplier performance and discuss any issues. This proactive approach can lead to continuous improvement and cost savings.

Collaborative Planning: Work with your suppliers to plan for future needs. Collaborative planning can help both parties manage production schedules more efficiently, reducing costs.

Evaluating Total Cost of Ownership

When assessing the cost-effectiveness of your custom box orders, consider the total cost of ownership (TCO) rather than just the upfront price. TCO includes:

Initial Purchase Price: The cost per unit for the custom boxes.

Shipping and Handling: All costs associated with shipping the boxes to your location.

Storage Costs: The expense of storing bulk orders if you do not have adequate space.

Quality Control: Any costs related to ensuring the boxes meet quality standards, including potential wastage from defective boxes.

Operational Efficiency: The impact of packaging on your operational efficiency, such as ease of assembly and packing speed.

Monitoring Market Trends

Stay informed about market trends and changes in the packaging industry. Being aware of fluctuations in material costs, new packaging technologies, and emerging best practices can help you make informed decisions and potentially capitalize on cost-saving opportunities.

Conclusion

Ordering custom boxes in bulk presents numerous opportunities for cost savings and operational efficiency. By understanding your packaging needs, choosing the right manufacturer, negotiating better rates, optimizing box design, streamlining the ordering process, reducing shipping costs, leveraging technology, exploring alternative materials, partnering with suppliers, evaluating the total cost of ownership, and monitoring market trends, businesses can achieve significant cost efficiencies while maintaining high-quality packaging.

These strategies not only help in reducing costs but also contribute to creating a sustainable, efficient, and effective packaging solution that can enhance brand image and customer satisfaction. By adopting a holistic approach to bulk ordering, businesses can ensure they are well-equipped to meet market demands and remain competitive in their respective industries.

1 note

·

View note

Text

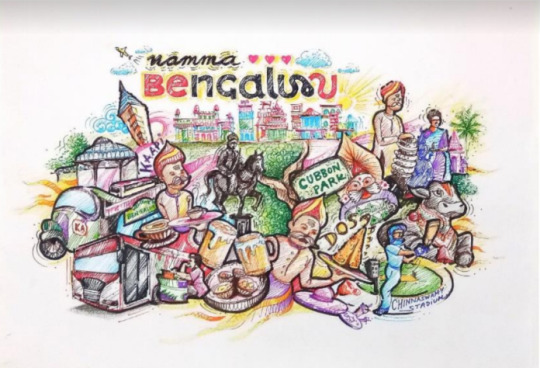

Bengaluru to host the premiere edition of Bharat Print Expo!

The Total Print and Package Converting exhibition will be held from 24-26 April 2025 at Bangalore International Exhibition Centre, Bengaluru.

"This is not just another printing exhibition," declares Anil Arora, President of ReEnvision Events Private Limited. "India is poised to become the world's third-largest economy within the next five years, and we acknowledge that specific sectors as well as regions of the country have played a crucial role in driving this growth. It is essential that we feature them prominently on our event calendar."

Bharat Print Expo is inspired by the county’s adoption of new Print and Converting technologies, coupled with the surge in e-commerce, evolving lifestyles, urbanization, and heightened awareness about personal health, that has significantly fuelled the expansion of the Print and Packaging sectors. Bengaluru is a city that mirrors its diversity, combining a rich cultural tapestry with advanced technologies. According to the Bengaluru Innovation Report, among the 780 major cities globally, 17 of the 20 fastest growing cities will be in India. Among them, Bengaluru is projected to have the world's fastest GDP growth at 8.5%, maintaining this pace until 2035. The vibrant city will hold the first edition of Bharat Print Expo, driving participation from all across the country along with a global brand presence. The venue selection was made based on a survey conducted among the exhibitors of our current show.

Exhibitor Profile

Bharat Print Expo 2025 will delve into the growing demand and prospects within South India and its surrounding areas. Exhibitors hailing from various parts of the nation will showcase cutting-edge products and solutions spanning the print and related industries, including- Printing Equipment: Offset/ Screen/ Digital/ Flexo/ Gravure; Prepress Equipment; Post-press & Packaging Converting Equipment; Label Converting & Printing Press; Paper Converting Machines; Adhesives & Consumables; Binding & Lamination; Paper, Films, Foils; Ink & Chemicals; Dies, Cutters, Rollers; Corrugated Box Making Machinery; Carton Folding Equipment; Testing Equipment, Inspection Systems & Accessories; Textile Printing Machines; 3D Printers; Wide Format Signage Printers; Plant Automation; Infrastructure, Trade Associations & Financial Organisations and Services & Software.

Visitor Profile

The exhibition will attract visitors from the entire Southern region, with extensive promotional activities planned to reach a wide audience. Targeted visitors from all over Bharat and Sri Lanka will also attend the Show. The profile will broadly include: Commercial Printers, Package Printers & Label Printers; Brand Owners & Print Buyers; Package Converters & Corrugated Box Manufacturers; Textile Printers & Professionals; Signage & Graphic Arts Specialists; Retailers, Manufacturers & Industry Suppliers; Packaging Professionals, Design Houses, Art Directors & Consultants; Trade publications, Advertising, Marketing, Media & PR Agencies; Government Bodies and Trade Associations.

Venue

The Bangalore International Exhibition Centre (BIEC) enhances its 77,000 square meters of covered space with aesthetically and functionally designed exhibition halls, along with vast open areas ideal for showcasing large and heavy machinery. The venue is conveniently linked via the Green Metro Line and is just a 45-minute drive from the airport and a 30-minute drive from the city centre.

Organizer

ReEnvision carries forward the legacy of its group companies that have launched or co-organized India’s most successful events in the printing and packaging sector including India Label Show, Pack Plus and PAMEX. ReEnvision Events Private Limited is a sister organization of Print-Packaging.com Private Limited.

"We are preparing to open bookings for the Show and anticipate a tremendous response from the industry,” concludes Anil Arora.

0 notes

Text

Top Benefits of Investing in a Corrugated Box Making Machine for Packaging Solutions

In today’s fast-paced business environment, efficiency and cost-effectiveness are paramount for companies in the packaging industry. A Corrugated Box Making Machine is a game-changer that offers unparalleled benefits, streamlining operations and enhancing productivity. Whether you run a small packaging unit or a large-scale manufacturing facility, investing in a Corrugated Box Maker Machine is a strategic move that can drive growth and profitability.

Here are the top benefits of incorporating a corrugated box making machine into your production process:

1. Enhanced Production Efficiency

Manual production of corrugated boxes can be time-consuming and labor-intensive. A Corrugated Box Machine automates the process, significantly increasing the speed of production. These machines can produce a large volume of boxes in a fraction of the time it takes to do so manually, ensuring that your business meets tight deadlines and large orders without compromising quality.

2. Superior Quality and Consistency

One of the standout advantages of using a Corrugated Box Maker Machine is the consistent quality it delivers. Manual processes often result in variations that can affect the strength and durability of the boxes. With a machine, you can maintain uniformity in box dimensions, structure, and durability, which is crucial for branding and customer satisfaction.

3. Cost Savings in the Long Run

While the initial corrugated box machinery price might seem like a significant investment, the long-term savings outweigh the upfront costs. Automating the box-making process reduces labor costs and material wastage, leading to a more efficient use of resources. Additionally, the ability to produce custom-sized boxes in-house can eliminate the need for outsourcing, further reducing expenses.

4. Customization Flexibility

Modern Corrugated Box Machines come equipped with advanced features that allow businesses to produce customized boxes tailored to specific client requirements. From different sizes and designs to personalized branding, these machines offer flexibility that can help businesses cater to niche markets and expand their customer base.

5. Reduced Material Wastage

Material wastage is a common concern in packaging production. A Corrugated Box Making Machine is designed to optimize material usage by precisely cutting and shaping corrugated sheets. This not only minimizes waste but also contributes to a more sustainable production process, which is increasingly important in today’s eco-conscious market.

6. Scalability for Growing Businesses

As your business grows, so does the demand for efficient production processes. A Corrugated Box Maker Machine can easily scale to meet increased production needs. With features like automated adjustments and high-speed operation, these machines ensure your business can handle growth seamlessly without the need for significant additional investments.

7. Improved Profit Margins

By reducing production costs, minimizing errors, and increasing efficiency, businesses can enjoy higher profit margins. Furthermore, the ability to meet larger orders and provide customized solutions gives companies a competitive edge, driving more sales and repeat business.

8. Competitive Advantage in the Market

Investing in the latest Corrugated Box Machine technology demonstrates a commitment to quality and innovation. It helps businesses stay ahead of the competition by delivering superior products and meeting client demands faster.

Conclusion

A Corrugated Box Making Machine is more than just a piece of equipment; it is a valuable asset that can revolutionize your packaging operations. With benefits ranging from cost savings and efficiency to enhanced product quality, the investment is worth every penny. Although the corrugated box machinery price may vary based on features and specifications, the long-term advantages far outweigh the cost.

For businesses looking to thrive in the competitive packaging industry, now is the perfect time to explore the wide range of Corrugated Box Machines available and take the first step toward operational excellence.

0 notes

Text

Mono Carton Box Manufacturer in Delhi

In the bustling metropolis of Delhi, amidst the vibrant tapestry of industries, stands a beacon of excellence in packaging solutions – the Mono Carton Box Manufacturer. Specializing in the production of cardboard boxes, this establishment epitomizes quality, reliability, packing shop and innovation. From custom boxes corrugated boxes to small cardboard boxes, their repertoire packaging material online caters to diverse needs across various sectors. Let us delve deeper into the realm of cardboard box manufacturing, exploring the intricacies of the process, the versatility of the products, and the significance of choosing the right packaging partner.

Understanding Cardboard Boxes

Cardboard boxes, often synonymous with packaging, are integral to modern-day logistics and storage solutions. They come in packing boxes various forms, each tailored to specific requirements. Corrugated boxes, characterized by their strength and durability, find extensive usage in shipping and transportation. Meanwhile, small cardboard boxes serve niche packing material online markets, offering compact and efficient packaging solutions. At the heart of this diverse array packing shop lies the expertise of manufacturers who adeptly transform raw materials into functional and aesthetic packaging solutions.

The Art of Cardboard Box Manufacturing

The process of cardboard box manufacturing is a symphony of precision and innovation. It begins with the selection of raw materials, primarily paperboard or corrugated fiberboard, sourced from sustainable forests. These packaging supply store materials undergo a series of treatments, including cutting, printing, creasing, and folding, orchestrated by state-of-the-art machinery. The result is a seamless integration of form and function, culminating in the creation of sturdy and visually appealing cardboard boxes.

Mono carton box: Redefining Packaging Standards

At the forefront of cardboard box manufacturing in Delhi stands the Mono Carton Box Manufacturer, renowned for its custom boxes packaging material online commitment to excellence. Mono carton box, characterized by their single-layered structure, packing boxes offer a lightweight yet robust packaging solution. With a keen focus on sustainability, these boxes are crafted using eco-friendly materials, ensuring minimal environmental impact. From product protection to brand promotion, mono carton box serve as versatile canvases, accommodating diverse packaging needs with ease.

The Role of Innovation in Packaging Solutions

In an era marked by rapid technological packing shop advancements, innovation serves as the cornerstone of progress in cardboard box manufacturing. From advanced printing techniques to customizable designs, custom boxes manufacturers packaging supply store continually push the boundaries of creativity and functionality. Moreover, the packing boxes integration packaging material online of smart packaging technologies, such as RFID tags and QR codes, enhances traceability and security, further augmenting the value proposition of cardboard boxes.

Choosing the Right Packaging Partner

Amidst the myriad options available in the market, selecting the right packaging partner is paramount for businesses packing shop seeking optimal solutions. Factors such as reliability, quality, and responsiveness play pivotal roles in this decision-making process. The Mono Carton Box Manufacturer in Delhi emerges as a trusted ally, offering comprehensive packaging solutions tailored to individual requirements. With a legacy of excellence spanning decades, they epitomize reliability and innovation in cardboard box manufacturing.

Conclusion:

In the dynamic landscape of packaging solutions, cardboard boxes reign supreme as indispensable assets to businesses worldwide. From corrugated boxes to small cardboard boxes, each variant serves a unique purpose, contributing packing material online packaging supply store to the seamless flow of goods and commodities. At the helm of packing boxes this industry stands the Mono Carton Box Manufacturer in Delhi, a beacon of innovation and reliability. Through their commitment to excellence, they continue to redefine packaging material online packaging standards, ensuring the safe and efficient transportation of goods across diverse sectors. As businesses navigate the complexities of modern-day logistics, the significance of choosing the right packaging partner cannot be overstated. In the Mono Carton Box Manufacturer, they find not just a supplier, but a strategic ally dedicated to their success.

0 notes

Text

From Concept to Delivery: Exploring the Supply Chain Strategies of Packaging Suppliers in Dubai

In the bustling landscape of Dubai's business environment, packaging suppliers play a pivotal role in ensuring products reach consumers efficiently and securely. Understanding the supply chain strategies employed by these suppliers is crucial for businesses aiming for seamless operations and customer satisfaction.

Efficient Sourcing Practices

Packaging suppliers in Dubai meticulously strategize their sourcing practices to ensure the availability of high-quality materials while maintaining cost-effectiveness. By leveraging their extensive networks and partnerships, these suppliers procure materials from reputable sources worldwide. Whether it's corrugated boxes, plastic containers, or specialized packaging, these suppliers prioritize sourcing materials that meet both functional and aesthetic requirements. From eco-friendly options to premium packaging solutions, Dubai's packaging suppliers offer a diverse range of materials to cater to various industries and client preferences.

Streamlined Production Processes

Once materials are sourced, packaging suppliers in Dubai employ streamlined production processes to transform raw materials into finished products. State-of-the-art manufacturing facilities equipped with advanced machinery and technology enable efficient production while adhering to stringent quality standards. From design conceptualization to prototype development, these suppliers collaborate closely with clients to ensure the final product aligns with their specifications. Moreover, flexibility and agility are integral aspects of Dubai's packaging companies, allowing them to accommodate varying production volumes and timelines to meet client demands effectively.

Optimized Logistics and Distribution

After the packaging is manufactured, efficient logistics and distribution channels ensure timely delivery to clients across Dubai and beyond. Packaging suppliers, including paper suppliers in Dubai, leverage sophisticated logistics solutions to manage inventory, optimize transportation routes, and minimize lead times. Whether it's local delivery within Dubai's bustling metropolitan areas or international shipping to global markets, these suppliers prioritize reliability and punctuality. Additionally, leveraging technology such as real-time tracking systems enhances transparency and allows clients to monitor the progress of their shipments seamlessly.

Conclusion:

In conclusion, exploring the supply chain strategies of packaging suppliers in Dubai unveils a well-coordinated ecosystem aimed at delivering quality products from concept to delivery. Efficient sourcing practices, streamlined production processes, and optimized logistics and distribution channels characterize the operations of these suppliers, ensuring seamless transactions and customer satisfaction. For businesses seeking reliable packaging solutions in Dubai, partnering with reputable companies such as Ace Paper guarantees access to premium materials and exceptional services tailored to their specific needs.

As one of the leading packaging suppliers in Dubai, Ace Paper stands out for its commitment to excellence and customer satisfaction. With a diverse range of packaging solutions and unparalleled expertise, Ace Paper caters to businesses across various industries, delivering innovative and sustainable packaging solutions tailored to their unique requirements. Contact Ace Paper today to elevate your packaging needs and experience unparalleled quality and reliability.

0 notes

Text

Exploring Emerging Materials: Industrial Packaging Market Dynamics

Industrial Packaging: Enabling Efficient Transportation and Storage of Manufactured Goods Importance of Effective Packaging for Manufactured Products Industrial packaging plays a vital role in effectively protecting manufactured goods from damage during transportation and storage. The packaging is designed to prevent breakage and ensure products reach customers inmint condition. Whether it's heavy machinery or fragile electronics, appropriate packaging is essential to minimize losses from product damage. Manufacturers rely on high-quality, robust packaging solutions to ship products safely and maximize revenue. Design and Material Selection based on Product Attributes The type of packaging used depends on the nature and specifications of the product. Factors like product weight, fragility, intended transport mode etc. are considered to design packaging suitable for the goods. Lightweight products may use corrugated boxes or paper wraps while heavy equipment requires wooden crates or customized load bearers. Materials used can range from cardboard, wood, plastics to composites depending on required strength, cost and sustainability objectives. Functional designs enable efficient handling, stacking and unitization for transport. Quality Assurance through Testing and Certification Rigorous testing simulating real-world distribution environments help ensure industrial packaging solutions meet international quality and durability standards. Certification helps manufacturing facilities and logistics companies certify that the packaging conforms to industrial and safety regulations. Packaging is subjected to vibration, compression, temperature and humidity cycling tests to confirm its ability to protect contents under typical shipping conditions by road, sea or air. This quality validation provides assurance of intact deliveries. Sustainable Practices for Environmental Stewardship With growing emphasis on sustainability, industry is focusing on reuse, recycling and reduced environmental impact of packaging materials. Use of recycled content and recyclable/biodegradable materials features prominently in packaging designs. Standardization encourages efficient utilization of transport and storage space. Collaborative efforts between manufacturers, suppliers and logistics firms encourage responsible packaging practices meeting global commitments. Harmonizing performance needs with eco-friendly attributes will factor strongly in the evolution of industrial packaging. Digital Transformation Enhances Supply Chain Visibility Adoption of Industry 4.0 technologies is driving digitization across supply chain networks. Intelligent packaging solutions are enhancing visibility and optimization. Technologies like RFID tags, sensors and IoT enable real-time tracking of shipment conditions and location updates. Analytics helps identify inefficiencies, improve route planning and reduce transit time. Integrating packaging data with digital supply chain twin simulations helps achieve continuous performance enhancement matching demand profile changes. The digital transformation will make industrial packaging an increasingly connected and intelligent asset. In conclusion, well-engineered industrial packaging plays a pivotal role in commercial success through reliable transportation and storage of manufactured goods. Continual innovation integrating material advancements, digital technologies and sustainability will future-proof the sector's contributions to seamless supply chain operations.

0 notes

Text

Diving into Industrial Applications: Varied Types of Corrugated Boxes

India has a dynamic industrial landscape. Here efficiency and reliability are crucial, and corrugated packaging solutions emerge as a powerful solution for businesses across diverse sectors. Offering a perfect blend of strength, versatility, and cost-effectiveness, corrugated packaging boxes play a critical role in safeguarding products, optimizing shipping, and enhancing brand image.

Choosing the right box for your specific needs can significantly impact your success, and this article delves into the exciting world of corrugated boxes in Pune.

Understanding the Spectrum of Corrugated Box Types:

Corrugated boxes come in a vast array of configurations, each designed to address specific requirements:

Shipper boxes: Crafted from corrugated paperboard, consisting of different plies of liner boards and fluted papers, sandwiched together to make 3, 5, or 7-ply boxes or master cartons.

Multicolour Printed Primary Cartons: Mono/Duplex carton boxes, sometimes referred to as folding cartons, are made of a single layer of cardboard and provide lightweight moisture and dust protection.

E-Flute Corrugated Boxes: E-flute cartons are made of fine flutes and are usually made of three layers of corrugated board and are die-cut and adaptable to a range of sizes, styles, and forms. They offer superior resistance to crushing and good compression strength.

Heavy Duty Packaging: Incorporated with double-wall or triple-wall boards and manufactured from high-grade kraft paper, these boxes enhance overall strength and durability. They provide additional structural reinforcement with edge corners for added stability or palletized box options for convenient and safe material handling.

Corrugated Partitions, Fitments & Inserts: Industries across the board are utilizing versatile corrugated grid partitions (dividers, fitments, inserts). They create compartments, cushion items, prevent shifting, and fill empty spaces – streamlining packing, protecting products, and delivering smiles.

Corrugated Packaging for Different Industries:

Now, let’s explore how various industries in Pune leverage these versatile corrugated packaging solutions:

Automobile & Auto Components: The practicality, durability and protective features that corrugated boxed offer allow automobile and automotive component manufacturers the freedom to optimise logistics. RWPL’s corrugated fitments are designed to cushion items during transport, eliminating the chance of damage or breakage of products.

Pharmaceuticals & Healthcare : Double and triple wall boxes ensure safe and secure transportation of sensitive medication and medical equipment. RWPL’s expertise lies in utilizing specialized coatings to maintain temperature control, adhering to stringent industry regulations, and ensuring the integrity of your pharmaceutical products.

Food & Beverage: Corrugated boxes with food-grade liners are essential for protecting and preserving food items. RWPL’s food packaging solutions comply with stringent food safety standards and can incorporate ventilation features for optimal freshness and spoilage prevention, safeguarding your food and beverage products throughout the supply chain.

Manufacturing: Sturdy corrugated boxes with stacking strength are vital for storing and transporting industrial parts and machinery. RWPL’s custom design capabilities optimize space utilization and protect fragile components, ensuring efficient and safe transportation within the manufacturing sector.

Electronics: Double and triple wall boxes with anti-static properties are crucial for protecting delicate electronic components from damage during transit. RWPL leverages advanced printing technology to create visually appealing and brand-strengthening box designs for electronics, enhancing brand image and customer experience for your Pune electronics business.

E-commerce: Single and double wall boxes are popular for their lightweight and cost-effective nature. RWPL, a leading Corrugated Boxes Manufacturer, caters to this demand by offering a wide range of standard and custom ecommerce boxes, including die-cut boxes for easy assembly and printed boxes for brand recognition, propelling your online business to new heights.

RWPL: Trusted Corrugated Packaging Solutions in Pune

Radhesham Wellpack, a leading Corrugated Boxes Manufacturer in Pune, has established a reputation for excellence. Here’s why they should be your trusted partner:

With 49+ years of experience, RWPL offers tailored corrugated box solutions for diverse industries. From standard selections to custom designs, they prioritize sustainable materials and utilize advanced printing for brand-strengthening boxes. Their efficient production ensures timely deliveries and cost-effective solutions, while their dedicated team provides comprehensive support for your packaging journey. Choose RWPL for your corrugated box needs and experience their commitment to excellence.

Conclusion:

Corrugated boxes, with their strength, affordability, and contribution to a more sustainable packaging industry, offer a practical and versatile solution for businesses of all sizes. They are a valuable asset for product protection, efficient shipping, and even innovative marketing strategies. As a leading Corrugated Boxes Manufacturer in Pune, RWPL is committed to providing businesses with high-quality, customized packaging solutions that meet their specific needs while contributing to a more sustainable future.

Faq's:

1. What Are Corrugated Boxes?

Corrugated boxes are made from layers of fluted paperboard (corrugated medium) sandwiched between two flat sheets of linerboard. The fluted layer creates a wave-like structure, providing strength and cushioning while remaining lightweight.

2. What Types of Industries Commonly Use Corrugated Boxes?

Corrugated boxes are incredibly versatile and used across diverse industries, including:

Automotive & Auto Components

Pharmaceuticals, Food & Beverage

Electronics, Manufacturing, Retail

Warehousing & Logistics

Furniture Industry

Fruits & Vegetables

E-commerce

3. Are corrugated boxes suitable for bulk packaging and storage in industries?

Absolutely! Double and triple wall boxes are ideal for bulk packaging and storage of heavier items. Custom-designed boxes can optimize space utilization and protect fragile components within the box.

4. Who is the best manufacturer of corrugated boxes in Pune?

Radhesham Wellpack is a leading Corrugated Boxes Manufacturer in Pune known for its:

Extensive experience catering to diverse industries

Wide range of standard and custom box options

Commitment to high-quality materials and sustainability

Advanced printing technology for brand-strengthening designs

Efficient production and timely deliveries

Reliable customer service and support

0 notes

Text

Presto Stantest eyes growing market for testing equipment

Presto Stantest exhibited its latest range of packaging testing equipment at the IntraPac show in Greater Noida. The products included testers for bursting strength, ECT/RCT, box compression, tearing, and peel strength for corrugated box manufacturing.

Based in Faridabad in Delhi-NCR, Presto Stantest manufactures testing equipment for paper, PET and preform, plastics and polymers, color grading, environmental friendliness, and packaging material. The pandemic has accelerated the need for testing methods for advanced packaging in a bid to address the changing consumer demands.

According to Vidur Malhotra, technical product specialist at Presto Stantest, IntraPac was an important show for the company. “Though it was held for the first time, we received a good footfall and inquiries. It is noteworthy how IPAMA gathered so many packaging companies under one roof in such a short time. Many of the companies who already use our equipment visited the show and so it was a good opportunity to connect.”

For Presto, the adoption of Industry 4.0 has begun, where everything needs to be connected. “At Presto, we are focusing on IoT (internet of things), upgrading all our machinery to touch screens. With digital advancements, our interface software and its integration suite are now more user-friendly. The testing process and results can now be viewed conveniently on laptops and smartphones,” Malhotra says.

India is increasingly showing its presence in the international markets and in line with this trend, 70% of Presto's production is exported. “Safety, especially in the European markets, is among the most important aspects. For any packaging to be safe, its quality is the most significant aspect. That is the space where we can see tremendous growth in the next five years.”

0 notes

Text

Biotechpackages Leads the Way in Printing Solutions

In the dynamic landscape of packaging printing, where innovation and precision are paramount, Biotechpackages emerges as a pioneering force, setting new standards in the industry. With a steadfast commitment to excellence and a focus on meeting the evolving needs of clients, Biotechpackages has become synonymous with quality, reliability, and innovation in printing Pakistan sector.

Introduction to Biotechpackages

Established with a vision to redefine packaging printing, Biotechpackages has consistently pushed the boundaries of conventional printing practices through cutting-edge technology, streamlined processes, and a talented team of professionals. Our journey towards excellence began with a clear objective – to provide comprehensive printing solutions that exceed expectations, drive brand success, and foster long-term partnerships with our clients.

The Art and Science of Packaging Printing

At the heart of Biotechpackages' success lies a fusion of artistry and technology. We understand that packaging is not just about wrapping a product; it's a powerful medium to communicate brand identity, convey information, and captivate consumers. With state-of-the-art printing machinery, advanced techniques, and a meticulous attention to detail, we transform concepts into captivating visual experiences.

Innovative Printing Solutions

Biotechpackages takes pride in its ability to offer a diverse range of printing solutions tailored to meet the unique requirements of each client. Whether it's flexible packaging, labels, corrugated boxes, or promotional materials, we leverage our expertise to deliver exceptional results. Our portfolio encompasses a wide array of printing techniques, including offset printing, flexography, digital printing, and more, ensuring versatility and adaptability across various projects.

Sustainable Printing Practices

As stewards of the environment, Biotechpackages is committed to integrating sustainability into every aspect of our operations. We embrace eco-friendly materials, employ energy-efficient practices, and implement waste reduction strategies to minimize our carbon footprint. By prioritizing sustainability, we not only contribute to environmental conservation but also empower our clients to align their brands with responsible practices.

The Biotechpackages Advantage

What sets Biotechpackages apart is not just our cutting-edge technology or extensive capabilities but our unwavering dedication to customer satisfaction. We approach every project with a collaborative mindset, working closely with clients to understand their vision, overcome challenges, and deliver results that surpass expectations. Our commitment to excellence is reflected in every aspect of our work – from the initial concept development to the final product delivery.

Driving Innovation in Pakistan's Printing Industry

As a leader in Pakistan's printing industry, Biotechpackages is at the forefront of innovation, constantly exploring new technologies and methodologies to enhance our capabilities. We invest in research and development to stay ahead of emerging trends, seize new opportunities, and continuously elevate the standards of excellence. Our relentless pursuit of innovation fuels our passion for excellence and drives us to achieve new milestones.

Empowering Brands for Success

At Biotechpackages, we understand that packaging plays a crucial role in shaping consumer perceptions and driving purchasing decisions. That's why we go above and beyond to ensure that every piece of packaging we produce not only meets the highest standards of quality but also effectively communicates the essence of the brand. By empowering brands with compelling packaging solutions, we help them stand out in a competitive market landscape and forge meaningful connections with consumers.

Collaborative Partnerships

Our success is built on the foundation of strong, collaborative partnerships with our clients. We believe in fostering open communication, transparency, and trust, ensuring that every project is executed seamlessly from inception to completion. Our dedicated team of professionals works tirelessly to understand the unique needs and objectives of each client, offering personalized solutions that drive tangible results and fuel long-term success.

Looking Towards the Future

As we look towards the future, Biotechpackages remains steadfast in its commitment to innovation, sustainability, and customer satisfaction. We will continue to push the boundaries of packaging printing, embrace emerging technologies, and adapt to the evolving needs of the market. With a relentless focus on quality and excellence, we are confident that Biotechpackages will continue to lead the way in Pakistan's printing industry, setting new benchmarks and inspiring others to follow suit.

Conclusion

In the realm of packaging printing, Biotechpackages stands as a beacon of excellence, driving innovation, sustainability, and customer satisfaction. With a rich legacy of craftsmanship, technological prowess, and a steadfast commitment to quality, we are poised to shape the future of Pakistan's printing industry and empower brands for success. Join us on this journey towards excellence, as we continue to redefine the art and science of packaging printing, one masterpiece at a time.

#Printing Pakistan#Printing Press#Packaging Printing#Packaging Companies#Packaging Company in Pakistan#Printing Company in Lahore

0 notes