#ALUMINUM SUPPLIERS

Explore tagged Tumblr posts

Text

0 notes

Text

China aluminum sheet suppliers and steel materials manufacturing supplier

#aluminum plate#aluminum sheet#aluminum foil#aluminum factory in china#china aluminum plate supplier#flat aluminum bus bar supplier#aluminum suppliers#aluminum plate supplier

0 notes

Text

Uncovering the Staggering Impact of Life Without Aluminum

Aluminum is everywhere. We use it to build homes and skyscrapers, to make cars and airplanes, and to package and preserve food. But what would life without aluminum be like? A world without this essential metal would be a drastically different place. Its staggering impact on our everyday lives would be hard to fathom. From the technology we use to the food we eat, aluminum is an integral part of our lives. Without it, we would be unable to lead the lifestyles we enjoy today. To truly understand the significance of aluminum, it’s essential to take a closer look at what life would be like without it.

What is aluminum, and why is it important?

Aluminum is a lightweight metal found in abundance on the Earth’s surface. It’s silvery-gray in colour and has many unique properties that make it incredibly useful in various applications. Its low density and high strength make it an ideal material for construction projects. Its ability to conduct electricity and heat makes it helpful in manufacturing electronics. Its corrosion resistance and non-magnetic properties make it useful in various other applications.

Aluminum is also a very abundant metal. It makes up 8% of the Earth’s crust and is the third most abundant element in the world. It’s also relatively easy to extract from its ore, making it a cheap and plentiful resource. All these factors combine to make aluminum an essential part of our lives.

How aluminum affects our everyday lives

Aluminum is used in countless ways in our everyday lives. From the cars we drive to the buildings we live and work in, aluminum plays an integral role in the infrastructure of our world. It’s also used to package and preserve food, create electronics, and manufacture countless other products. Without aluminum, many of the daily products would be unavailable or too expensive to be practical.

But aluminum doesn’t just affect the products we use. It also affects the way we live. Aluminum's lightweight, strong, and durable properties make it ideal for transportation applications. It’s used to make cars, airplanes, and ships, allowing us to travel quickly from one place to another. It’s also used to make bicycles and other vehicles, allowing us to explore our world more sustainably.

Aluminum’s impact on transportation

Aluminum plays an important role in the transportation industry. It’s used to make cars, airplanes, and ships, allowing us to explore our world easily. Without aluminum, these vehicles would be much more cumbersome, limiting our ability to travel.

Aluminum is also used to make bicycles, scooters, and other forms of personal transportation. This makes it easier for people to get around in an environmentally friendly way. Aluminum is also used to construct public transportation, such as subways and buses, which helps reduce traffic congestion and improve air quality.

Aluminum’s impact on construction

Aluminum is an essential material in the construction industry. Its lightweight and strong properties make it an ideal material for building homes, offices, and other structures. It’s also corrosion-resistant, making it an ideal material for long-lasting structures. Aluminum is also used in the construction of bridges, allowing us to traverse large bodies of water with ease.

Aluminum is also used in the construction of high-rise buildings. Its lightweight properties make it perfect for tall, multi-story buildings. Without aluminum, we would be unable to build the skyscrapers that dominate our cities today.

Aluminum’s impact on food packaging and preservation

Aluminum is also used in the food industry. It’s used to package and preserve food, allowing it to last longer and stay fresh. Aluminum foil is used to wrap and store food, preventing it from spoiling. Aluminum cans are used for packaging drinks, which helps preserve their flavour. Aluminum is also used to make cooking utensils, such as pots and pans, which makes cooking more accessible and more efficient.

Without aluminum, food would spoil quickly and be much more expensive. This would make it challenging to feed large populations and could lead to widespread hunger and malnutrition.

Aluminum’s impact on technology

Aluminum is also used in the technology industry. It’s used to make computers, smartphones, and other electronic devices. It’s also used to make wiring, which is essential for powering these devices. Aluminum is also used to manufacture solar panels, which are increasingly used to generate clean energy.

Without aluminum, many of the gadgets and devices we use daily would be unavailable. This would drastically change how we live and work, as many of our most important tasks are now done using technology.

Aluminum’s impact on the environment

Aluminum is also an important part of the environment. Its low density and corrosion resistance make it an ideal material for recycling. Aluminum can be recycled indefinitely; when it is recycled, it retains most of its original properties. This makes it a perfect material for use in a variety of applications.

Recycling aluminum also helps reduce the energy needed to produce new aluminum. This helps reduce the emissions associated with aluminum production, which helps reduce the impact of climate change.

Alternatives to aluminum

While aluminum is an essential material, some alternatives can be used in some applications. Steel and other metals can be used in place of aluminum in some applications. Composite materials, such as plastic and fibreglass, can also be used in some applications. These materials may not be as strong or light as aluminum, but they can still be used in some applications.

Conclusion

Aluminum is an essential material in our everyday lives. From the cars we drive to the technology we use, aluminum is an integral part of our world. With it, many of the products and services we rely on would be more affordable to be practical. Its impact on our everyday lives is staggering, and it’s important to recognize the importance of this essential metal.

Who are we

We are driven by the opportunities that Aluminum provides for creativity. We make it easy for customers in Canada and the USA to obtain the supplies they need for their creative projects. With us as your resource, you can explore endless options for inspiration!

Make sure to take full advantage of this one-stop opportunity to purchase the best Aluminum Coil, anodized aluminum sheets, and various coloured aluminum wire & foil. Plus, we provide immediate delivery - no waiting is necessary. Contact us at toll-free 866–860–0652 or visit our website for more information about our products or services. Now is the time to get the highest quality materials available right now!

0 notes

Text

PU Leather Makeup Case With Trolley | MSACase

Looking for a stylish and functional way to store and carry your makeup? Look no further than the MSACase PU Leather Makeup Case with Trolley! This professional-grade case is made from high-quality PU leather for a luxurious look and feel.

It features a spacious interior with compartments and organizers to neatly store your makeup, while the built-in trolley allows for easy mobility. We're the leading aluminum makeup trolley case supplier in China.

#Leather Makeup Case#PU Leather Makeup Case#aluminum makeup trolley case#aluminum makeup trolley case supplier#aluminum makeup trolley case wholesaler

2 notes

·

View notes

Text

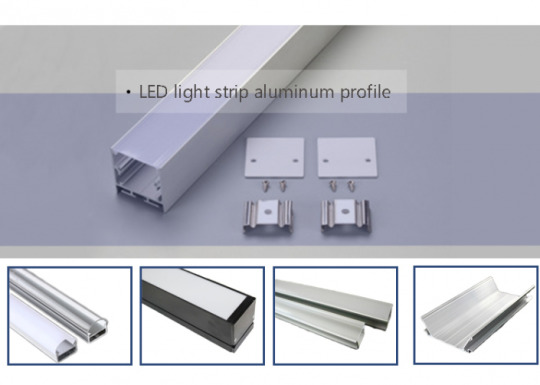

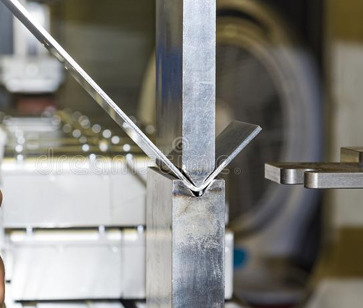

Exploring the Aluminum Profile Processing Intricacies

Aluminum profile is unique among components used in modern production because of their versatility and necessary nature. Applications for these extruded forms may be found in a wide range of sectors, including consumer products, electronics, automotive, and construction. A thorough grasp of material qualities, technical innovation, and precise engineering are all required in the exciting process of creating aluminum profiles.

Aluminum Profiles Significance

Because of their many benefits, aluminum profiles are the material of choice for a wide range of applications:

Lightweight

Power and Sturdiness

The corrosion free

Flexibility

The Procedure for Processing Aluminum Profiles

Design and Development of Die: Engineers develop the ideal profile form and proportions during the process's first design step. A unique die, or mold, is made after the design is complete in order to extrude the metal into the required shape.

Heating the billet: To prepare it for extrusion, aluminum billets, which are usually formed from primary or recycled aluminum, are heated to a particular temperature. In order to guarantee consistency and malleability, this preheating phase is critical.

Extrusion: Using mechanical or hydraulic pressure, the heated aluminum billet is pushed through a specifically made die. The metal takes on the shape of the profile as it goes through the die and emerges as a continuous length of extruded aluminum.

Quenching and Cooling: To maintain its shape and characteristics, the extruded aluminum profile is quickly cooled with either water or air. In order to achieve the appropriate mechanical characteristics and avoid distortion, this quenching procedure is essential.

Cutting and Finishing: Using precision saws or shears, the extruded aluminum profile is trimmed to the necessary lengths once it has cooled. The profile may also be modified by using additional machining techniques like punching, drilling, or milling to add holes or features. Lastly, surface treatments like powder coating or anodizing can be used to improve corrosion resistance and appearance.

Quality Control: Strict quality control procedures are followed during the whole Aluminum profile Process to guarantee that the final aluminum profiles have the required mechanical qualities, surface polish, and tolerances. To find any flaws or irregularities, this may entail visual inspections, mechanical testing, and dimensional inspections.

#Aluminum profile#Aluminum profile China#Aluminum profile Process#Aluminum profile Company#Aluminum profile Company China#Aluminum profile Manufacturer#Aluminum profile supplier

2 notes

·

View notes

Text

Explore TAG Hardware's Sidelite Rails, essential for office and storefront applications, providing secure fixation for fixed glass panels. Shop our range featuring a variety of U Channel series, including aluminum options, designed for optimal performance in glass installations. Visit: https://taghardware.ca/categories/storefronts-entrances/u-channels/sidelite-rails.html #SideliteRails #UChannels #TAGHardware

#Sidelite rails#Channel Mounting System#U Channel Series#Mechanical Channels#u channel aluminum#U channels#Aluminum U Channels#U Channels for Glass#U-Channels for Shower#1/4" Aluminum U Channel#U-CHANNEL FOR 12 MM GLASS Suppliers In Canada#Construction and Renovation Enthusiasts#Homeowners#Business Owners#Contractors#Interior Designers#Architects#Home DIY#DIY

1 note

·

View note

Text

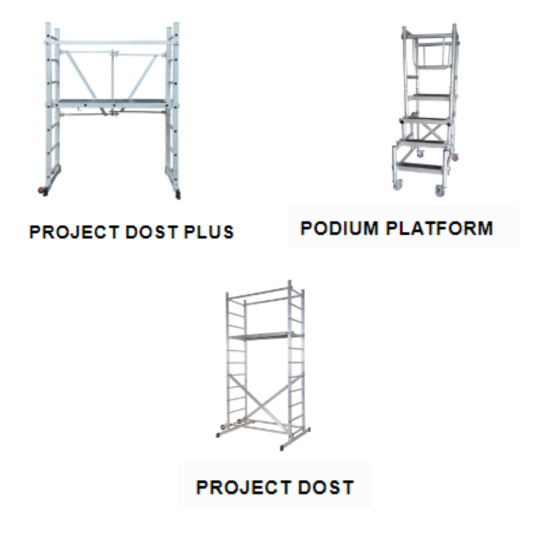

#Aluminum Scaffolding#Aluminum Scaffold Towers#Aluminum Scaffolding System#Aluminum Scaffolding Rental#Buy Aluminum Scaffold#Aluminum Scaffolding for Sale#Aluminum Scaffolding Suppliers#Aluminum Scaffold Platforms#Aluminum Scaffolding Rental Services#Aluminum Scaffolding Manufacturers#Lightweight Aluminum Scaffolding

2 notes

·

View notes

Text

Why Aircraft Aluminum Sheets Are Essential for Modern Aviation

The aviation industry has come a long way since the early days of wooden frames and fabric coverings. Today, modern aircraft rely heavily on advanced materials to ensure safety, efficiency, and performance. Among these materials, aircraft aluminum sheets stand out as a cornerstone of aerospace engineering. But what makes aluminum the preferred choice for aviation? Let’s explore the key benefits, including its exceptional strength-to-weight ratio and corrosion resistance.

The Strength-to-Weight Advantage

One of the most significant reasons aluminum sheets dominate the aviation industry is their unparalleled strength-to-weight ratio. Aircraft need to be both strong enough to withstand extreme conditions and lightweight to achieve optimal fuel efficiency.

Lightweight aluminum sheets for aviation are strong enough to endure high stress without adding unnecessary weight to the structure.

By reducing the overall weight of an aircraft, aluminum helps lower fuel consumption, which is crucial for both economic and environmental reasons.

This balance of strength and lightness has made aerospace-grade aluminum sheets a go-to material for fuselages, wings, and other structural components.

Corrosion Resistance for Longevity

Aircraft operate in diverse environments, from humid tropical regions to freezing altitudes. Corrosion is a constant threat, but corrosion-resistant aluminum for aircraft offers a reliable solution.

Aluminum forms a natural oxide layer that protects it from environmental damage, significantly extending its lifespan.

This corrosion resistance reduces maintenance costs and ensures the structural integrity of the aircraft over time.

In addition to its durability, the corrosion-resistant properties of aluminum make it ideal for external panels and parts exposed to harsh weather conditions.

Additional Benefits of Aircraft Aluminum Sheets

Malleability: Aluminum can be easily shaped and formed, making it suitable for complex aircraft designs.

Cost-Effectiveness: Compared to other aerospace materials like titanium, aluminum is more affordable, making it accessible for various applications.

Sustainability: Aluminum is recyclable, aligning with the aviation industry's growing focus on sustainability.

FAQs About Aircraft Aluminum Sheets

Q: What grades of aluminum are commonly used in aircraft construction? A: Common grades include 2024, 6061, and 7075, each offering unique properties suitable for different components.

Q: How does aluminum compare to other aerospace materials? A: While materials like titanium are stronger, aluminum offers a better balance of strength, weight, and cost for most applications.

Q: Can aluminum sheets be customized for specific aircraft designs? A: Yes, aerospace-grade aluminum sheets can be cut, shaped, and treated to meet the precise needs of any aviation project.

Call to Action

At Accromet, we specialize in providing high-quality aircraft aluminum sheets tailored to the needs of modern aviation. Whether you’re designing a commercial airplane or working on aerospace innovations, our lightweight aluminum sheets for aviation are the perfect solution.

Contact us today to learn more about our product range and discover how we can support your next project. Partner with Accromet for durable, reliable, and efficient aerospace-grade aluminum sheets!

#Lightweight aluminum sheet for aviation#Corrosion-resistant aluminum for aircraft#High-strength aluminum sheet for aerospace#Aircraft aluminum sheet suppliers

0 notes

Text

🔹 Premium Zinc Aluminium Steel Tanks in Dubai, UAE & Saudi Arabia 💧

Looking for high-quality zinc aluminium steel tanks in Dubai? 🌍 Prefab Tanks Dubai offers durable and corrosion-resistant zinc aluminium steel tanks in UAE, designed for water storage solutions in residential, commercial, and industrial applications. Our zincalume steel water tanks provide long-lasting protection against harsh environmental conditions, ensuring efficient water containment.

🌐 Visit Now: Zinc Aluminium Steel Tanks in Dubai-UAE

✅ Why Choose Our Zinc Aluminium Steel Tanks?

🔹 Highly Durable & Corrosion-Resistant – Our zincalume-coated water tanks in Saudi Arabia offer superior strength and longevity. 🔹 Versatile Applications – Perfect for water treatment tanks, steel bolted water tanks, and epoxy-coated water tanks.

🔹 Customizable Storage Solutions – Available in various sizes to meet commercial, industrial, and municipal water storage needs. 🔹 Trusted Quality – We are leading zinc-aluminum steel tank suppliers in Saudi Arabia, delivering premium water storage tanks worldwide.

🚀 Applications of Zinc Aluminium Steel Tanks

✔️ Zinc aluminium steel tanks in Dubai-UAE for large-scale industrial water storage 🏗️ ✔️ Zincalume steel water tanks in Saudi Arabia for municipal and agricultural applications 🚜 ✔️ Galvanized steel water tanks for reliable effluent & wastewater storage 💦 ✔️ Zinc aluminium water storage solutions in UAE for residential and commercial projects 🏠 ✔️ Zincalume steel water containment tanks for safe & hygienic water storage 🌿

At Prefab Tanks Dubai, we specialize in premium zinc aluminium steel tanks for water storage in Saudi Arabia, offering advanced water containment solutions that ensure safety, durability, and efficiency. Our steel bolted water tanks and epoxy-coated water tanks are engineered to meet international standards.

📞 Get in touch today for the best zinc aluminium steel tanks in Dubai, UAE, and Saudi Arabia! 🚀

🔗 Explore More

#WaterStorageSolutions #ZincAluminiumTanks #PrefabTanksDubai #SteelBoltedTanks #EpoxyCoatedTanks #GalvanizedSteelTanks #ZincalumeWaterTanks #IndustrialWaterStorage #WaterStorageSaudiArabia ��

#Zinc aluminium steel tanks in Dubai#Zinc aluminium steel tanks#Zinc aluminium steel tanks in UAE#Zinc aluminium steel tanks in Dubai-UAE#Prefabtanks in Dubai#Zincalume steel water tanks#Water Treatment Tanks#Steel Bolted Water Tanks#Epoxy Coated Water Tanks#Galvanized Steel Water Tanks#Zincalume steel water tanks in Saudi Arabia#Zincalume steel water tanks in Dubai#Zincalume steel tanks in Saudi Arabia#Zincalume steel water containment tanks#Zincalume-coated water tanks in Saudi Arabia#Zinc-aluminum steel tank suppliers Saudi Arabia#Zinc aluminium water storage solutions in UAE#Zinc aluminium steel tanks for water storage in Saudi Arabia

0 notes

Text

At our company, we offer ongoing procurement of aluminum scrap in various forms to meet diverse industry needs. Our product range includes high-quality aluminum wheel scrap, 6063 extrusion scrap, UBC (Used Beverage Cans) scrap, and aluminum radiator scrap, among others.

0 notes

Text

The Role of Aluminum Casting Suppliers in Aerospace and Automotive Industries

Aluminum casting plays a vital role in the manufacturing of components for the aerospace and automotive industries. Its lightweight, durable, and versatile properties make aluminum the material of choice for critical applications. High-performance parts are made possible by the expertise of aluminum casting suppliers. These suppliers ensure precision, quality, and innovation throughout the process.

This blog explores the significance of aluminum casting suppliers in the aerospace and automotive sectors. It details how these suppliers contribute to efficiency, safety, and technological advancement.

Why Aluminum is the Material of Choice

Aluminum’s popularity in the aerospace and automotive industries stems from its exceptional properties:

Lightweight: Aluminum significantly reduces the weight of vehicles and aircraft. It improves fuel efficiency and performance.

High Strength-to-Weight Ratio: Despite being lightweight, aluminum offers remarkable strength. Also, this makes it suitable for structural and load-bearing components.

Corrosion Resistance: Its natural resistance to rust and corrosion enhances durability, even in harsh environments.

Thermal and Electrical Conductivity: Aluminum is highly conductive. Therefore, this makes it ideal for heat management in engines and electrical systems.

Recyclability: Aluminum’s recyclability aligns with sustainability goals, an increasingly important factor in modern manufacturing.

The Role of Aluminum Casting Suppliers

Aluminum casting suppliers are more than just manufacturers. They are strategic partners in the development of advanced components for aerospace and automotive applications. Their role involves several critical functions:

1. Delivering High-Quality Components

Suppliers use advanced casting methods. These methods include die casting, sand casting, and investment casting. They produce parts with exceptional precision and durability. They ensure the components meet strict industry standards, such as those set by ISO or AS9100 for aerospace manufacturing.

2. Innovating with Advanced Technology

Modern aluminum casting suppliers use cutting-edge technologies. These technologies include 3D modeling, CNC machining, and computer-aided design (CAD). These tools enable the production of lightweight, high-performance parts. These parts meet the unique demands of both industries.

3. Customization and Flexibility

Every aerospace and automotive project comes with its own set of challenges. Suppliers provide customized solutions. They tailor components to specific requirements, whether it's an engine block for a high-performance car or a structural component for an aircraft.

4. Enhancing Efficiency

Suppliers help manufacturers reduce costs and streamline operations. They do this by optimizing production processes and material usage. Their expertise in mold design, tooling, and alloy selection minimizes waste and maximizes output.

5. Supporting Sustainability Goals

Suppliers play a key role in promoting environmental responsibility. Many incorporate recycled aluminum into their processes. They also adopt energy-efficient manufacturing techniques to help industries reduce their carbon footprint.

Applications in the Aerospace Industry

The aerospace industry requires materials that can withstand extreme conditions. These materials must also maintain lightweight properties. Aluminum casting suppliers meet these demands by producing components like:

Aircraft Fittings: Lightweight fittings that reduce overall aircraft weight without compromising safety.

Engine Components: Heat-resistant parts capable of enduring high temperatures in jet engines.

Structural Components: Durable yet lightweight castings used in fuselages and wings.

Precision-engineered aluminum parts help aerospace manufacturers achieve better fuel efficiency. They also help reduce emissions and enhance performance.

Applications in the Automotive Industry

The automotive sector relies on aluminum casting for lightweight vehicles. These vehicles meet stringent fuel efficiency and emission standards. Key applications include:

Engine Blocks and Cylinder Heads: High-strength components that improve engine efficiency while reducing weight.

Transmission Housings: Durable yet lightweight housings that enhance vehicle performance.

Chassis Components: Strong, corrosion-resistant parts used in suspension systems and other structural areas.

By partnering with reliable aluminum casting suppliers, automakers can produce vehicles that are safer, more efficient, and environmentally friendly.

Benefits of Partnering with a Reliable Aluminum Casting Supplier

Choosing the right aluminum casting supplier can make all the difference in achieving manufacturing excellence. Here’s why:

Consistent Quality Reliable suppliers prioritize quality control at every stage, from material sourcing to final inspection. It ensures every part meets the required specifications.

Timely Delivery With streamlined production processes and efficient logistics, top suppliers deliver components on time. Also, it supports seamless manufacturing schedules.

Cost-Effectiveness Suppliers with advanced technology and efficient operations offer competitive pricing without compromising quality.

Collaborative Approach Trusted suppliers offer expert advice on design, material selection, and production techniques. They work closely with clients to optimize results.

Final Thoughts

Aluminum casting suppliers are crucial partners for the aerospace and automotive industries. They drive innovation and excellence in manufacturing. They deliver lightweight, durable, and high-performance components. These components enable industries to meet their goals of efficiency, safety, and sustainability.

Whether it’s producing an intricate jet engine part or a high-performance car chassis, the role of an aluminum casting supplier is central to the success of modern engineering. With their expertise and commitment to quality, these suppliers continue to shape the future of aerospace and automotive technology.

0 notes

Photo

Aluminium | Aluminium Suppliers | Aluminium Products

Looking For dealing Company Aluminium products ? Visit Biggest b2b portal yellowpages.ae and find the details top aluminium suppliers.

VISIT HERE :- https://www.yellowpages.ae/subcategory/aluminium/aluminium-&-aluminium-products/5ec8c55cebee8a7379accc3f

0 notes

Text

Which aluminum briefcase features matter most?

Select excellent aluminum standards, ideally airplane level, guaranteeing lightweight compactness and vigorous assurance for your possessions. The case should endure the afflictions of everyday use and travel without imprinting or twisting.

Security Features

Search for briefcases with dependable locking systems, for example, blend locks or double essential locks, to defend delicate records and significant things. Supported pivots and corners of the aluminum briefcase add protection from altering and unapproved access.

Inside Organization

A well-designed interior with cushioned compartments, dividers, and pockets upgrades association and shields contents from scratches and harm. Consider customizable lashes or froth supplements to safely oblige different things.

Convenience and Comfort

Ergonomic handles, cushioned shoulder lashes, and smooth-moving wheels work with happy conveyance choices, particularly during broadened drives or travel. Lightweight plans limit strain while amplifying comfort.

Proficient Aesthetics

Pick a smooth design that mirrors your style and supplements your expert picture. Moderate feel with clean lines and a matte completion radiate incredible skill while keeping an immortal allure.

#aluminum briefcase features#aluminum briefcase#aluminum briefcase supplier#aluminum briefcase manufacturer#aluminum briefcase wholesaler#msacase aluminum briefcase

2 notes

·

View notes

Text

A Deep Dive into Die Casting Varieties, Benefits and Applications

Using high pressure, molten metal is injected into a cavity that has been pre-designed in a die casting process. The mold, often referred to as a die, is normally constructed of hardened steel and is divided into two halves: the fixed cover die and the moveable ejector die. To give the finished product the correct shape, the dies are carefully machined.

Die Casting Varieties Die casting may be divided into two main categories: hot chamber casting and cold chamber casting. In hot chamber die casting, a pool of molten metal, often zinc, is submerged underneath the injection mechanism. Although it might not be appropriate for metals with greater melting points, this technique works best for those with low melting points. On the other hand, cold chamber die casting includes ladling molten metal into a different chamber from which it is injected into the die. Higher melting point metals, including copper and aluminum, can be cast using die casting services.

Benefits Die casting is favored by many industries because of its many benefits, including:

The high degree of precision and minute details

Excellent aesthetic appeal and surface quality

Considering the high production rates and low cost, it is suitable for large-scale manufacturing.

The capacity to create intricate designs with thin walls and delicate features

Many different metals and alloys can be cast.

Due to the process's accuracy, little post-processing is needed.

Applications Die casting has a variety of uses in the automotive, aerospace, electronics, and consumer products sectors, among others. It is employed to make parts for appliances, electrical enclosures, engine blocks, transmission housings, and more. Die casting's adaptability enables producers to successfully satisfy the demands of numerous industries.

Conclusion Die casting has established itself as a crucial industrial process that combines accuracy, effectiveness, and adaptability. Die casting continues to make a significant contribution to the manufacturing of a wide variety of goods across several sectors because of its capacity to produce complicated metal components with extreme precision and surface polish. We may anticipate more improvements to die-casting techniques by die casting manufacturers as technology develops, which will eventually produce even more extraordinary outcomes and novel uses.

More details: cneasteel.com/blog

#Die Casting Process#Die Casting Services#Aluminum Die Casting#Die Casting manufacturer#Die Casting supplier#Die Casting China

2 notes

·

View notes

Text

#T-SLOT ALUMINIUM PROFILES AND ACCESSORIES MANUFACTURER IN INDIA#Welcome to Aluminium Profiles#a leading source for top-tier T-slot Aluminium profiles and accessories in India. Our commitment to excellence is reflected in our extensiv#KEY FEATURES:#Anodized Aluminium extrusion profiles with a thickness of 10 to 12 microns for superior quality.#Standard sizes include 2020#2040#3030#3060#4040#4080#4590#6060#8080#and 9090.#Special profiles like half-round corner aluminium profiles 3030R#4040R#and 4545R are also available.#Custom profiles can be requested#although they may require additional delivery time.#DISCOUNT SALES ON T-SLOT ALUMINUM EXTRUSION PROFILES:#Take advantage of our ongoing discount sales on all T-slot Aluminum extrusion profiles. As a trusted manufacturer#exporter#wholesaler#supplier#dealer#and distributor since 2014#we serve customers all over India#catering to diverse project requirements.

0 notes

Text

Accromet’s Aluminum Sheets: Lightweight Strength for Your Aircraft Projects

Introduction

When it comes to the aviation industry, the choice of materials plays a crucial role in the safety, durability, and performance of aircraft. Accromet’s aluminum sheets offer the perfect balance of strength, lightness, and versatility, making them ideal for aircraft projects. Whether you're building a new aircraft or performing repairs, Accromet’s high-quality, aircraft-grade aluminum sheets are a trusted solution for aerospace manufacturers and aviation professionals.

Why Choose Accromet’s Aluminum Sheets for Your Aircraft Projects?

Accromet’s aluminum sheets for aviation are designed to meet the stringent requirements of the aerospace industry. These sheets are manufactured to ensure lightweight yet high-strength properties, which are essential for the performance of modern aircraft. Here’s why our products stand out:

Lightweight: Our lightweight aluminum sheets for airplanes help in reducing the overall weight of the aircraft, enhancing fuel efficiency and performance.

High Strength: High-strength aluminum sheets for aircraft ensure durability and safety under extreme conditions, without compromising on weight.

Versatility: Available in multiple grades, sizes, and finishes, our aluminum sheets are perfect for a wide range of aerospace applications, including fuselages, wings, and interior components.

Compliance with Industry Standards: As trusted aerospace aluminum suppliers, we ensure that our products meet or exceed the quality standards required by aviation authorities, including FAA certification.

Key Benefits of Accromet’s Aircraft-Grade Aluminum Sheets

Superior Durability: Our aircraft-grade aluminum sheets are designed for superior resistance to corrosion, fatigue, and wear and tear. This makes them a perfect material for long-lasting aircraft parts that can withstand the demanding conditions of air travel.

Customization Options: Accromet offers a wide selection of aluminum sheets for aviation projects, allowing you to choose the perfect dimensions and thicknesses for your specific application.

Cost-Effective: While offering premium quality, Accromet’s products are competitively priced, making them an excellent choice for manufacturers looking to balance cost with performance.

Frequently Asked Questions (FAQs)

What are the advantages of using airplane aluminum sheets? Airplane aluminum sheets are known for their lightweight nature, which reduces fuel consumption, and their high strength, which ensures durability and safety. This combination of properties makes them an ideal material for aerospace applications.

What makes Accromet’s aluminum sheets different from other suppliers? Accromet stands out because we provide aircraft-grade aluminum sheets that meet the strictest industry standards. Our sheets are versatile, customizable, and available in multiple grades, ensuring that your project gets the exact material needed.

Are Accromet’s aluminum sheets FAA-approved? Yes, as leading aerospace aluminum suppliers, we ensure that our products comply with all relevant industry certifications, including FAA requirements for aviation-grade materials.

What thicknesses are available for aluminum sheets for aircraft? Accromet offers a variety of thicknesses for high-strength aluminum sheets for aircraft, ranging from thinner sheets for lightweight components to thicker sheets for structural parts.

Applications of Accromet’s Aluminum Sheets in Aviation

Accromet’s aircraft-grade aluminum sheets are used in various parts of an aircraft, including:

Fuselages

Wing structures

Aircraft skins

Aircraft flooring

Engine components

And more

Whether for building new aircraft or performing critical repairs, our lightweight aluminum sheets for airplanes are designed to handle the demanding requirements of the aviation industry.

Call to Action (CTA)

Ready to enhance your aircraft project with the strength and durability of Accromet’s aluminum sheets for aviation? Contact us today to discuss your requirements and get a quote for the perfect aircraft-grade aluminum sheets tailored to your needs. Let Accromet be your trusted partner in creating aircraft that soar to new heights!

Conclusion

When it comes to choosing materials for aircraft, you need reliable, high-quality options that guarantee safety and efficiency. Accromet’s airplane aluminum sheets provide the perfect solution for your aviation projects. With our high-strength aluminum sheets for aircraft, you’re assured of performance, durability, and cost-effectiveness. Reach out to Accromet and see how we can support your aerospace needs.

#Airplane aluminum sheets#Aircraft-grade aluminum sheets#Aluminum sheets for aviation#Aerospace aluminum suppliers

0 notes