#ADVANCEDMATERIALS

Text

Introducing the 2040 Futuristic Racing Suit: crafted from advanced, breathable, superhydrophobic, and highly elastic fabric. This suit seamlessly integrates a cooling system with thin, discreet tubes stitched along anatomical lines, ensuring maximum performance and comfort. Designed for complete freedom of movement and extreme elasticity, it embodies the perfect blend of cutting-edge technology and natural, ergonomic design. #FuturisticFashion #RacingSuit #TechWear #2040Innovation #AdvancedMaterials #GradoZero #PGZ #PGrado Zero

2 notes

·

View notes

Text

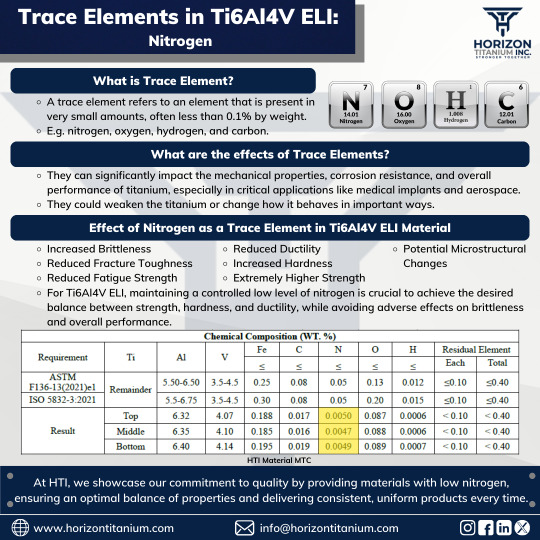

Trace Elements in Ti6Al4V ELI: The Impact of Nitrogen

When it comes to titanium alloys like Ti6Al4V ELI, trace elements such as nitrogen can have a significant impact on the material's mechanical properties. In this post, we dive deep into how trace amounts of nitrogen affect brittleness, fracture toughness, and strength.

Why does this matter?

1. Nitrogen can make your titanium alloy stronger, but there’s a balance! Too much can make it brittle. Too little, and you might lose strength. The key is finding that perfect balance.

2. In medical-grade titanium like Ti6Al4V ELI, precision is everything, and keeping nitrogen levels controlled ensures your material performs under the most demanding conditions.

Did you know? If the nitrogen content is low but your material still boasts high strength, you’re working with premium titanium! This means the strength is purely from the titanium and not from unwanted nitride phases like titanium nitride, which could weaken the material's long-term performance.

At HTI, we deliver consistent quality, ensuring that the material you get is optimized for strength, ductility, and durability—making it perfect for critical applications like medical implants.

For more technical insights, check out the composition chart in the post!

Let’s talk titanium! Have questions about material quality or trace elements? Drop a comment or reach out at [email protected]

#KnowYourTitanium#Titanium#Ti6Al4VELI#MaterialScience#TraceElements#NitrogenImpact#ChemicalComposition#MedicalGradeTitanium#Metallurgy#EngineeringExcellence#AdvancedMaterials#QualityControl#TitaniumStrength#TitaniumAlloys#PrecisionEngineering#HorizonTitanium#StrongerTogether

0 notes

Text

Thermal Spray Coating Equipment and Services Market: A Comprehensive Outlook for North America

The Thermal Spray Coating Equipment and Services Market is experiencing significant growth, particularly in North America, driven by a surge in demand across various industries. The rising need for enhanced durability, wear resistance, and corrosion protection in automotive, aerospace, and oil & gas sectors has fueled the adoption of thermal spray technologies. This market presents immense opportunities, backed by advancements in coating techniques, material innovations, and increasing investments in industrial infrastructure.

Overview of the Thermal Spray Coating Market

Thermal spray coatings involve the application of materials, such as metals, ceramics, or polymers, onto a surface using heat and pressure to create a protective layer. This technology is widely used to improve the performance and longevity of components exposed to harsh environments, extreme temperatures, or mechanical stress. Industries such as aerospace, automotive, power generation, healthcare, and oil & gas have embraced thermal spray coatings due to their ability to reduce maintenance costs, enhance operational efficiency, and improve the lifespan of machinery.

The North American market for thermal spray coating equipment and services is poised for growth, with significant demand for both advanced coatings and the equipment used to apply them.

Market Trends Shaping the Industry

Several key trends are shaping the North American thermal spray coating market:

1. Increasing Demand from the Aerospace Sector

The aerospace industry is one of the major drivers of the thermal spray coating market in North America. As aircraft manufacturers and MRO (maintenance, repair, and overhaul) providers seek to improve the efficiency and durability of critical components, the use of thermal spray coatings for turbine blades, landing gear, and engine components has become increasingly important. Thermal spray coatings enhance the corrosion resistance and thermal stability of parts exposed to extreme conditions, thereby improving performance and reducing maintenance downtime.

2. Rising Popularity of Eco-friendly Coatings

With growing concerns over environmental regulations and sustainability, there is an increasing demand for eco-friendly thermal spray coatings. Technologies such as High-Velocity Oxy-Fuel (HVOF) and cold spray techniques are gaining traction due to their ability to produce coatings with minimal environmental impact. These methods use less harmful materials and generate fewer emissions, aligning with the industry's push towards greener solutions.

3. Automotive Industry’s Shift Towards Lightweight Materials

The automotive industry is undergoing a transformation with the growing trend toward lightweight materials to improve fuel efficiency. Thermal spray coatings are applied to critical automotive parts such as engine components, transmission systems, and braking systems to reduce wear and tear, ensuring longer life and better performance. The shift towards electric vehicles (EVs) is also opening up new opportunities for thermal spray coatings, particularly in battery manufacturing and EV powertrain components.

4. Technological Advancements in Equipment

The development of advanced thermal spray equipment, including robotic systems and automated processes, is another factor driving market growth. These technologies improve the precision and efficiency of coating applications, enabling manufacturers to meet higher standards of performance and quality. Innovations in coating materials, such as nanostructured coatings and multi-functional coatings, are further enhancing the capabilities of thermal spray processes.

Market Analysis and Forecast

The North American thermal spray coating equipment and services market is projected to grow steadily, with analysts predicting 17.8 Billion at aCAGR of over 4.1 % from 2024 to 2030. This growth is primarily driven by the increasing need for protective coatings in key industries, technological advancements, and the expansion of industrial manufacturing facilities across the region.

United States: The U.S. accounts for the largest share of the North American market due to its strong presence in aerospace, automotive, and energy sectors. The country’s robust industrial base and the increasing focus on innovation have fueled the demand for high-performance coatings.

Canada: In Canada, the oil & gas industry is a major driver of thermal spray coatings, particularly for the protection of pipelines and equipment used in harsh environments. The Canadian market is also expected to benefit from increasing investments in infrastructure development.

Mexico: Mexico's growing automotive and aerospace manufacturing sectors are contributing to the region's overall market expansion. The country is becoming an attractive destination for thermal spray coating services, supported by its competitive manufacturing landscape.

Expert Insights and Market Share

Industry experts highlight the growing significance of thermal spray coatings in the context of sustainability and cost-efficiency. By reducing the need for frequent repairs and replacements, thermal spray coatings offer long-term savings for manufacturers, contributing to their widespread adoption.

Market Players: Key players in the North American thermal spray coating equipment and services market include Praxair Surface Technologies, Oerlikon Metco, and Bodycote. These companies are focusing on expanding their product portfolios and enhancing service capabilities to meet the increasing demand from various industries.

Market Share: The aerospace sector holds the largest share of the thermal spray coating market, followed by automotive and power generation. However, the oil & gas industry is expected to witness significant growth, particularly in the U.S. and Canada, driven by the need for enhanced corrosion protection.

Challenges and Opportunities

Despite the promising outlook, the thermal spray coating market faces challenges such as the high cost of equipment and the complexity of certain coating processes. However, advancements in automation and robotics are expected to reduce costs and improve accessibility for small and medium-sized enterprises.

The growing emphasis on R&D investments is also creating opportunities for the development of innovative coatings and equipment, further driving market growth. In addition, the trend toward digitization in manufacturing is expected to improve process control and quality assurance, contributing to the continued evolution of the thermal spray coating industry.

Download PDF Brochure :

A Promising Future for North America

The Thermal Spray Coating Equipment and Services Market in North America is set for sustained growth over the coming years, driven by increasing demand from key industries and advancements in coating technologies. With a focus on sustainability, innovation, and performance, thermal spray coatings are becoming a vital part of modern manufacturing, offering protection and enhancing the durability of components across multiple sectors.

As the market continues to evolve, companies that invest in advanced equipment, eco-friendly solutions, and customized services will be well-positioned to capitalize on the growing demand for thermal spray coatings in North America.

#ThermalSprayCoatings#IndustrialCoatings#AerospaceTechnology#AdvancedMaterials#SurfaceProtection#CoatingInnovation#NorthAmericaMarket

1 note

·

View note

Text

#OpticalSensors#Photonics#SensorTechnology#Optoelectronics#SmartSensors#AdvancedMaterials#SustainableMaterials

0 notes

Text

youtube

More Details: Title: International Research Awards on High Energy Physics and Computational Science by ScienceFather.

Website: physics.sciencefather.com

Visit Our Award Nomination : https://hep-conferences.sciencefather.com/award.../...

Contact us : [email protected]

Get Connected Here: ==================

Facebook : https://www.facebook.com/profile.php?id=100089114473152

Instagram : https://www.instagram.com/victoriaanisa1/

Twitter : https://twitter.com/Psciencefather

Pinterest : https://in.pinterest.com/victoriaanisa1/

Blog : https://physicscience23.blogspot.com/

tumblr : https://www.tumblr.com/blog/high-energy-physics

#BariumResearch#ScientificBreakthroughs#PIXE#EXAFS#EnvironmentalScience#AdvancedMaterials#ScienceExplained#ScienceFather#scifax#ScienceDad#proffessor#students#ResearchScholar#awardwinner#scientist#PhD#acedemic#Youtube

0 notes

Text

#Radome#InjectionMolding#Aerospace#DefenseTech#Telecommunications#AdvancedMaterials#AutomotiveIndustry#SatelliteCommunications#AviationTech#GlobalMarket#EngineeringInnovation#CompositeMaterials#Manufacturing#TechnologyTrends#MarketResearch

0 notes

Photo

The architectural landscape is increasingly challenged by the need to balance aesthetic innovation with functionality in a rapidly changing urban environment. Traditional building forms, often rigid and static, struggle to keep pace with the evolving demands of modern life, where fluidity and adaptability are essential. The challenge lies in creating structures that are not only visually striking but also resilient to environmental stresses and capable of enhancing human interaction within cities. A potential solution emerges through advanced materials and AI-enhanced design processes, which allow architects to transcend conventional limitations. The building illustrated here exemplifies this shift with its fluid, organic curves and dynamic form. By leveraging these innovative tools, designers can create structures that adapt to their surroundings, harmonizing with natural elements and urban demands. This approach redefines what is possible in architecture, moving beyond static forms to embrace designs that are as flexible and responsive as the environments they inhabit. Looking forward, designers and developers are encouraged to explore the potential of these new materials and technologies. The aspiration is to create urban spaces that are functional, emotionally resonant, and reflective of the dynamic nature of contemporary life. As we look to the future, architecture should aim to foster environments that are adaptive, interactive, and deeply integrated with the evolving cultural and technological landscape, offering spaces where human experience is elevated through design.

#architecture#futuristicdesign#urbaninnovation#fluidarchitecture#advancedmaterials#designfuture#modernarchitecture#urbanplanning#sustainablearchitecture#innovativebuildings#urbanlandscape#smartcities#materialscience#architecturaldesign#futuristicmovements#futurism#newarchitects#ianfulgar#fluidity

0 notes

Text

Cross Linking Agents Market projected to reach $13.6 billion by 2028

The report "Cross Linking Agents Market by Chemistry (Amino, Amine, Amide, Aziridine, Isocyanate, Carbodiimide), Application (Decorative, Industrial (Transportation Coatings, Industrial, Protective Coatings, Marine Coatings), & Region - Global Forecast to 2028", is projected to reach USD 13.6 billion by 2028, at a CAGR of 6.5% from USD 9.9 billion in 2023.

The Cross Linking Agent market is mainly driven by the factors including the demand for high-performance materials, increasing applications across industries, emphasis on sustainability, and advancements in technology and research.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=266941939

“Amine chemistry segment is projected to grow at third fastest CAGR, in terms of value, during the forecast period.”

Amines offer excellent cross-linking capabilities and compatibility with a wide range of polymers, making them ideal for various applications. Their strong bonding properties and ability to improve mechanical and thermal properties of materials drive their demand. Additionally, the rising focus on sustainability and the development of eco-friendly formulations using amines as cross-linking agents further contributes to the growth of this segment in the market.

“Industrial application segment is expected to lead the Cross Linking Agent market during the forecast period, in terms of value.”

The growth of the Industrial application segment in the cross-linking agents market is attributed to several key factors. Industries such as automotive, construction, electronics, and packaging demand cross-linked materials to enhance product performance and durability. Cross-linking agents provide improved mechanical properties, resistance to chemicals and weathering, and increased lifespan of industrial products. Stringent regulations and standards regarding product quality and reliability in industrial applications further drive the demand for cross-linking agents. Additionally, the growing focus on sustainable and eco-friendly solutions in the industrial sector fuels the adoption of cross-linking agents that offer reduced environmental impact. These factors collectively contribute to the rapid growth of the Industrial application segment in the cross-linking agents market.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=266941939

“Asia Pacific is expected to be the fastest growing market for Cross Linking Agents during the forecast period, in terms of value.”

The region's robust industrial and manufacturing sectors, particularly in countries like China, India, and Japan, drive the demand for cross-linking agents across various industries such as automotive, construction, electronics, and packaging. Moreover, rapid urbanization, infrastructure development, and increasing disposable incomes in the region contribute to the rising demand for high-performance materials that utilize cross-linking agents. Additionally, favorable government initiatives, investments in research and development, and a shift towards eco-friendly and sustainable solutions further stimulate the market's growth in the Asia Pacific region, solidifying its position as the largest and fastest-growing market for cross-linking agents.

New product launches, acquisitions, investments, and expansions are the major growth strategies adopted by the key players in the market. The key global players in the Cross Linking Agents market include BASF SE (Germany), Covestro AG (Germany), Allnex Group (Germany), Evonik Industries (Germany), Hunstman Corporation (US), Aditya Birla Corporation (India), Wanhua Chemicals Group Co. Ltd (China), The Dow Chemical Company (US), DSM Coatings Resins (China), and Ineos (UK).

#CrossLinkingAgents#ChemicalIndustry#PolymerScience#MaterialScience#IndustrialChemicals#AdhesiveTechnology#CoatingIndustry#Manufacturing#MarketTrends#InnovativeMaterials#ChemicalEngineering#ResinTechnology#AdvancedMaterials#ChemicalMarket#PolymerChemistry

0 notes

Text

In this video, we dive deep into the future of the Advanced Wind Turbine Blade Materials Market, exploring its growth trajectory from 2023 to 2034. Valued at US$ 5.0 billion in 2023, this dynamic industry is set to expand at a CAGR of 6.3% over the next decade, reaching an impressive US$ 9.8 billion by 2034.

0 notes

Text

What are the latest trends and innovations in the manufacturing industry?

The manufacturing industry is experiencing several trends and innovations that are transforming operations and improving efficiency. Here are some of the latest trends:

1.Industry 4.0: The creation of smart factories through the integration of cutting-edge technologies like big data analytics, artificial intelligence (AI), and the Internet of Things (IoT). Predictive maintenance, real-time monitoring, and more productive manufacturing procedures are made possible by these technologies.

2. Automation and Robotics: These technologies are being used more often in manufacturing to increase productivity, lower labor costs, and improve precision. Because of their capacity to securely assist human workers, collaborative robots, or cobots, are likewise becoming more and more popular.

3. Additive Manufacturing (3D Printing): 3D printing is becoming more and more popular for producing complicated parts, bespoke products, and quick prototypes. With this technique, production may be done on demand and waste can be decreased.

4. Digital Twins: Virtual representations of real assets or processes made possible by the application of digital twin technology. This makes it possible to simulate, analyze, and optimize manufacturing processes in a virtual setting prior to deployment.

5. Smart Supply Chains: Implementation of AI and blockchain to enhance transparency, traceability, and efficiency in supply chains. Smart supply chains enable better inventory management and demand forecasting.

6. Sustainability: A greater emphasis on energy-efficient procedures, eco-friendly material selection, waste minimization programs, and other sustainable manufacturing techniques. Reuse and recycling are encouraged through the integration of circular economy ideas.

7. Advanced Materials: The creation of novel materials with improved characteristics, such as alloys with high strengths, lightweight composites, and materials with intelligence that adapts to changes in the environment.

8. Augmented Reality (AR) and Virtual Reality (VR): Utilization of AR and VR for training, maintenance, and design processes. Workers can enjoy immersive experiences thanks to these technologies, which also aid in envisioning intricate industrial scenarios.

9. Cybersecurity: There is a growing focus on defending data and manufacturing systems against online attacks. The increasing digitization of production makes network and data security against hackers essential.

10. Predictive Analytics: Use of predictive analytics to forecast equipment failures, optimize production schedules, and improve overall operational efficiency. Minimizing downtime and making well-informed decisions are facilitated by data-driven insights.

These trends and innovations are shaping the future of manufacturing, driving efficiency, reducing costs, and improving product quality.

#Industry4.0#IoT#ArtificialIntelligence#3DPrinting#AdditiveManufacturing#Automation#Robotics#GreenManufacturing#SmartFactories#DigitalTwins#AdvancedMaterials#Blockchain

0 notes

Text

0 notes

Text

Elevate Your Projects with Peek Material

Are you ready to take your engineering projects to the next level? Discover the extraordinary capabilities of Peek (Polyether Ether Ketone) material. Experience the difference in quality and performance that only Peek Material can provide.

Visit Website - https://petronthermoplast.com/materials/peek-materials/?utm_source=Raveena_SEO&utm_medium=Raveena_Organic

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#Engineering#Innovation#PeekMaterial#AdvancedMaterials#Aerospace#Automotive#MedicalDevices#Electronics#IndustrialMachinery

0 notes

Text

#SuperEngineeringPlastics#HighPerformancePlastics#AdvancedMaterials#SustainablePlastics#EVMaterials#LightweightMaterials#RecyclablePlastics

0 notes