#6sigma

Explore tagged Tumblr posts

Text

we've got no future and we've got no past

#zero escape#virtue's last reward#vlr spoilers#akane kurashiki#sigma klim#sigmakane#618#6sigma#vlr#my art#yeah i should start actually posting all of this to Tumblr#fighting hard in the sigmakane mines on twitter btw if you want to see me go insane glittergoatss thats right two s-es#they make me insane

90 notes

·

View notes

Text

By Fandom:

The Royal Trio

・watching all the stars burn out (rated T-M, 85k words, series, 8-chapter longfic + 3 oneshots, finished)

A series exploring a scenario where the Royal Trio are romantically involved in the Third Semester, with Sumire and Akira finding about Goro's fate on January 26th, as well as the aftermath of the game's events.

・Please Hold My Hand (It’s For Practical Reasons, I Swear) (rated T, 6k words, oneshot)

A stray suggestion to get dinner in a fancy place leads to Sumire discovering a classy, but pricey restaurant in Ginza. Thankfully, they are running a couples discount — all they need is to just hold hands at the entrance. That shouldn’t be too bad, right?

・The One Mystery He'll Never Solve (rated T, 3.8k words, oneshot)

Goro has a terrible day at work, and Sumire and Akira take it upon themselves to comfort him.

・The Adventures of an Improbable Ghost (rated T, 10k words, oneshot)

A string of weird occurrences, a superstitious girlfriend, the absence of his voice-of-reason boyfriend, and a biased Tarot reader lead Akira to making a singular conclusion — he must be haunted. With a deadline set by a message from an unknown number, the Phantom Thieves now have to prepare for another heist. Or, rather, an ambush. On a ghost.

・Stone Thrown From a Glass House (rated T, 9.5k words, oneshot, also featuring RyuKitaAnn and MakoHaru)

Love is in the air, that much is clear. But when the Phantom Thieves discuss what's going on between Akira, Akechi, and Sumire, they quickly discover they are in a disagreement on who deserves to be together the most.

The argument splits them into three teams and sends them on a journey where some of them learn much more about themselves than they ever could have guessed, and are forced to confront the feelings they were completely oblivious to.

・Your Worst Sin (rated G, 3.4k words, oneshot)

Akira figures out the truth about Goro’s condition in January and approaches Maruki for a deal that can satisfy all sides.

・Hanamuke (rated G, 2.4k words, oneshot)

Exchanging flowers helps Akechi, Akira and Sumire express their thoughts in a more tangible way, including the things that are too often left unsaid.

・Team S: Suspicion [A Dead End] (rated M, archive warning for major character death, 6k words, oneshot)

A fusion between Zero Escape: Zero Time Dilemma and Persona 5.

Locked in a Pantry after Akira's sudden disappearance during the death game, Akechi and Sumire have to solve a puzzle to find a way out, and discover the truth behind what happened.

・Out of the Box (rated T, 5.6k words, oneshot)

With two weeks left before his birthday, Akira decides now is the time to find out what gift Akechi and Sumire have prepared for him. Sneaking out at night and breaking and entering may be involved.

・Something Comforting (rated T, 6k words, oneshot)

When Sumire and Goro visit Akira’s hometown, they face two major problems:

1) An almost complete ban on all public displays of affection

2) A boyfriend who is much worse for wear than he is willing to admit.

But it’s only a matter of finding the right solutions.

・The Bedlam (rated T, 4.6k words, oneshot)

After lengthy preparations and discussions, Sumire and Akechi reach the penultimate step in securing the gift for Akira's birthday - picking out a new bed. Between Sumire's insecurities, Akira's preferences being a mystery and the desire to get a one of a kind present, they may end up with more than they bargained for.

Shuake

・Promise of Destruction (fem-shuake, rated T, 2.8k words, oneshot)

Akeshu in the setting of Nier: Automata as A2B.

Suffering critical damage to the vital system chip, a runaway Justice-type android Akechi faces the prospect of a quick and painful death. But then, an android from the organisation meant to hunt her down presents her with a way out.

All it will cost her is to answer a single question.

Gen

・approach of the horizon (rated T, 700 words, oneshot)

Being a leader means planning, adapting, accounting for any projected losses. Being a leader means knowing that never walking out of the interrogation room is a possible outcome, one of the many, but not less probable simply because no one wants to think about it actually happening. He doesn't want to either. But he can't stop.

・Who do you want to be when you grow up?(background shukita, 1.4k words, oneshot)

On a whim, Ryuji asks Ren about his plans for the future. When Ren replies that he is stuck choosing between two possible career paths, the Phantom Thieves decide to hold a vote.

Akishinjimitsu

・Time Capsule (rated T, 6.5 k words, oneshot, akishinjimitsu)

Shinjiro, Akihiko and Mitsuru get together for a game of “Never Have I Ever” (and promptly discover the perils of playing with someone who knows you all too well).

Rookanis (F/M - all are set in the same continuity)

・Lucanis's Logbook, 6 (rated T, 3.3k words, oneshot)

Lucanis’s journal kept throughout the time between Rook’s disappearance at Tearstone Island and the day she’s rescued from the Fade.

・Today a Whisper, One Day a Scream (rated M, 1.8k words, oneshot)

Lucanis and Rook have a late-night discussion about her Calling.

・At the End of Her World (rated M, 11.3k words, oneshot)

After almost a decade of a tumultuous relationship, Rook and Lucanis made the choice to cut ties for good. Yet when Rook's time comes, Lucanis visits the Weisshaupt fortress to make good on a contract taken ten years ago — to see Rook through the end of her Calling.

・where the heart is (rated M, 2.9k words, oneshot)

When her ex-Antivan Crow, now-Grey Warden mentor brings Ghilasara Thorne outside the fortress on one early morning, she presents a revelation that will allow only one of them to leave alive.

SilverV (F/M)

・Extra Steps (rated E, 2.3k words, oneshot)

After some thinking, V comes up with a loophole that can let her and Johnny feel closer.

・Phantom Pains (rated T, 2.8k words, oneshot)

Johnny's thoughts after Temperance ending mixed in with flashbacks from the events of the game. A small retrospective on the formative moments of Johnny & V's (very weird) relationship.

・Hey Johnny, (rated G, 500 words, oneshot)

V writes a letter for Johnny to read in case of her passing.

6Sigma

・a lonely place (rated M, 5k words, oneshot)

In the years between the Decision Game and the AB game, Akane makes Sigma an offer to enter a relationship.

#flowers writes#flowers.txt#persona 5#royal trio#shuakesumi#persona 3#akishinjimitsu#dragon age#rookanis#cyberpunk 2077#silverv#zero escape#6sigma

4 notes

·

View notes

Text

Round 1, Matchup 7

Nangong Xu | Xu Shuanglin x Luo Fenghua is not pictured as I cannot find a picture of both characters.

#2ha#the husky and his white cat shizun#erha#leo fenghua#xu shuanglin#nangong xu#nangong xu x luo fenghua#xu shuanglin x luo fenghua#zero escape#ze#akane kurashiki#sigma klim#sigmakane#6sigma#vlr#virtue's last reward#zero escape vlr#virtues last reward#round 1

3 notes

·

View notes

Text

youtube

Was ist Six Sigma?🚀

In diesem Video zeigen wir Ihnen, was Six Sigma genau ist und wie es Unternehmen dabei hilft, Abläufe zu verbessern und Fehler zu verringern. Sie erfahren außerdem, wie der DMAIC-Zyklus funktioniert, welche Schritte dabei wichtig sind und welche Vorteile Six Sigma bietet. Perfekt für alle, die einen einfachen und schnellen Einstieg in das Thema suchen!

🎓 Dieses Video stammt aus unserem kostenlosen E-Learning Kurs „Was ist Six Sigma“. Schauen Sie hier direkt vorbei für weitere Informationen: https://www.vorest-ag.com/Six-Sigma/E-Learning/six-sigma-online-kurs-kostenlos

#SixSigma#Prozessoptimierung#DMAIC#Fehlerreduktion#VorestAG#Effizienzsteigerung#Qualitätsmanagement#6sigma#Six SigmaMethoden#SixSigmaDMAIC#Youtube

0 notes

Text

(999/vlr spoilers implied below)

normally im not really that into ships w junpei that arent junepei or at the very least c-team oriented - nothing wrong with 'em, they just don't really appeal most of the time. but i just had a thought about a semi-au aoipei thing where they get together in the apocalypse but in a way where its like. them using each other to cope with akane's loss.

its like a mirror of 6sigma except for someone that one of them thinks is dead and the other knows is alive but has utterly abandoned him. can anyone fucking hear me

#this similar concept but with snakepei & mourning over akane/aoi respectively is also appealing#but the irony of junpei making out with his elementary school crush's brother is also. funny to me. so here we are#junpei.txt#i feel like i had this idea years ago and its only resurfacing now but ill take what i can get

13 notes

·

View notes

Text

oh goodness. The one self-proclaimed 6sigma black belt I've met had the most frustrating understanding of statistics I've seen. Thought 30 samples was the minimum for any kind of significance, wouldn't hear about anything with fewer and wouldn't want to sample 30. When I told him I'd used a specific test for significance on nonconforming parts he was confused by the idea that I had calculated the result by calculating the means and standard deviations and kept asking me for a screenshot of the software. Brought in the most wildly nonconforming parts. And I will not get over my disbelief when I raised that a bunch of supplier data were clearly fabricated (wow you got the same variation in dimension on two completely different dimensions, in the same order for all 90 measurements on each part, and you did this one EIGHT DIFFERENT DIMENSIONS???) and couldn't get him to believe it until I presented it in front of a dozen other engineers whose jaws dropped at the audacity

i think about him often. every time I measure a part, probably, or think about statistics. someday I will let go of all this but it hasn't happened yet

#not to mention the other guy. who. claimed a hole was out of spec because IT WAS HOTTER IN INDIA WHEN THEY PUNCHED THE HOLE#Thermal expansion!! cte!!! never mind that it works the opposite direction and also ALL THE OTHER CORRECTLY SIZED HOLES WERE MADE IN INDIA#WHERE THE PART WAS MADE ALL AT ONCE#AND YOU DON'T GET A 0.1 MM DIFFERENCE ON A 6 MM HOLE WITH 10 CELSIUS CHANGE#my salute to the both of them for the amount I learned from both of them about what shit it was even possible to try to pull

120K notes

·

View notes

Text

Innovative Strategies for Advanced Problem Solving

Unlock the potential of cutting-edge techniques with "Innovative Strategies for Advanced Problem Solving. This guide equips individuals and teams with practical tools to tackle complex challenges efficiently. By blending creativity with proven methods, these strategies inspire confident decision-making and streamlined solutions, embodying the spirit of innovation and performance excellence that drives success.

0 notes

Text

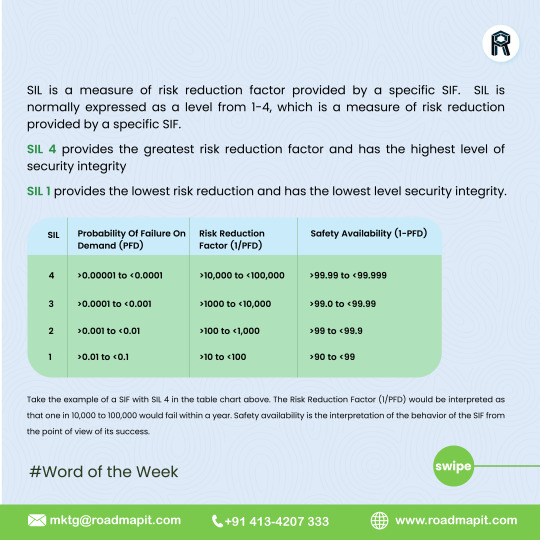

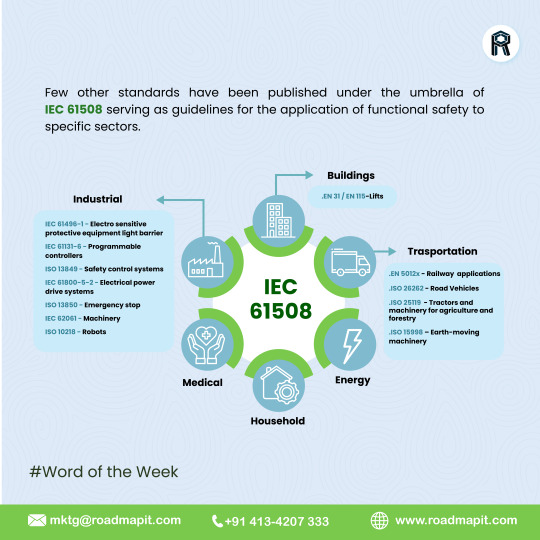

Design 4 6sigma

The main objective of DFSS is to design things right the first time with minimized defects or variations. It is a proactive approach to design with quantifiable data and proven design tools that can improve your chances of success.

#ProcessImprovement#SixSigmaDMADV#lean#LeanSixSigma#DMAIC#DMADV#Innovation#masterblackbelt #erp

#dfss#DesignForSixSigma#QualityExcellence#QualityManagement#CustomerSatisfaction#sixsigma#erpsoftware#wordoftheweek#erpsoftwareinchennai#erpsoftwareinbangalore#roadmapitsolutions#dairyindustry

0 notes

Text

Take Control of Quality and Results through Lean Six Sigma Training

While working on important projects and processes, it is crucial to eliminate any non-value-added elements and activities. With 6Sigma Consulting’s Lean Six Sigma Black Belt training, you will learn how to identify these elements and demonstrate team leadership in implementing the DMAIC model following Six Sigma principles. This comprehensive program equips you with the necessary skills to achieve improvement objectives for your organisation, resulting in increased financial profitability and customer satisfaction. Plus, upon completion, you will receive a globally recognised certificate with lifetime validity that can boost your job prospects and salary potential. Visit us at https://www.6sigmaconsulting.com.au/lean-six-sigma-black-belt-training/ and make the first step towards paving your way towards success!

0 notes

Video

dlf techpark sector 143 noida by 6sigma Realty Via Flickr: spaceonrentinnoida.in/dlf-techpark-noida-sector-143a/ DLF Techpark Noida Sector 143A offers premium office space on rent call 6sigma Realty at 9899920199/49 for best deal

0 notes

Link

0 notes

Text

the awful feeling of watching yourself become obsessed with a rarepair in a small fandom

#zero escape#zero escape spoilers#virtue's last reward#sigma klim#akane kurashiki#sigmakane#6sigma#my art#man#MANNN#im a sucker for kind of toxic detached but codependent interim lovers okay#obviously sigma and akane are in love with diana and junpei respectively#but the fact is they can't have them. not in this life#not when there's so much work to do#and after 45 years of collaboration on this massive project together i mean there's gotta be some complicated web of feelings#they're kind of using each other yeah#and im sure part of sigma hates akane for essentially ruining his life and forcing him into solitude with the weight of 6 billion lives#but also she's the only person who visits him#and she's the only person who can relate to that burden#SIGH#guess ill have to make the content myself

65 notes

·

View notes

Text

a lonely place

Getting my SIgma/Akane brainworms out into the world!

Rating: M

Word count: 5k

Tags: Post-Zero Escape: Zero Time Dilemma, Pre-Zero Escape: Virtue's Last Reward, set after the VLR ending of ZTD in the times before the AB game, Complicated Relationships, Angst, Implied/References Sex, Getting together, Kinda?

Summary:

“I was thinking we should enter a relationship.” Akane stands in front of his desk in a not-at-all suggestive manner. Her voice lacks any sultriness, tone better fitting a scientific proposition than the intention his brain fortuitously jumped to; he surmises he must have misunderstood. “We already have a relationship,” Sigma responds. “As colleagues. What else do you want?” “Oh.” She tilts her head. “Apologies if I was unclear. I meant a physical relationship.”

In the years between the Decision Game and the AB game, Akane makes Sigma an offer.

#zero escape#sigmakane#6Sigma#618#if you like them please come talk to me I really need that#they are so neat#not in the “I want them to be happy” kind of way#I want them to experience the special brand of misery induced by their unique circumstances#they are soooooooooooooooooooooooo#akane kurashiki#sigma klim

4 notes

·

View notes

Text

Why would someone practice Lean Thinking and not Six Sigma?

Lean Thinking and Six Sigma are both approaches to process improvement, but they have different focuses and goals. Lean Thinking, also known as Lean Management, is a method of improving efficiency and reducing waste in a process or organization by identifying and eliminating non-value-adding activities. It emphasizes the continuous flow of work, reducing inventory, and empowering employees to identify and solve problems. On the other hand, Six Sigma is a data-driven approach to process improvement that focuses on reducing defects and variability in a process. It emphasizes the use of statistical tools and techniques to identify and eliminate the root causes of problems.

It’s also possible that some companies may adopt both methodologies, as they can complement each other. Lean thinking can help identify areas for improvement, while Six Sigma can provide the tools and techniques for implementing and measuring those improvements. Another key difference between Lean thinking and Six Sigma is their scope. Lean thinking is typically applied to entire value streams or processes, while Six Sigma is applied to specific, individual processes within a value stream. This means that Lean Thinking is more focused on understanding the big picture and how different processes interact, while Six Sigma is more focused on understanding and improving specific processes in detail.

Lean thinking also tends to be more focused on the customer and their needs, while Six Sigma is more focused on the internal processes of an organization. This means that lean thinking is more likely to lead to changes that directly improve the customer experience, while Six Sigma is more likely to lead to changes that improve efficiency or reduce defects.

Another difference is the culture and mindset, Lean Thinking is more focused on continuous improvement and empowering employees, while Six Sigma is more focused on following a defined methodology and achieving specific goals. Six Sigma tends to be more hierarchical in nature, with a strong emphasis on training and certifying individuals at different levels. Lean thinking, on the other hand, is more focused on creating a culture of continuous improvement, with all employees being encouraged to identify and solve problems.

In summary, Lean Thinking and Six Sigma are both valuable approaches to process improvement, but they have different focuses, goals, and scopes. Depending on the specific needs and goals of an organization, one approach may be more appropriate than the other. Some companies may also adopt both methodologies and combine the strength of both to achieve better results.

#six sigma#six sigma certification cost#six sigma course#business#sigma rule#popular#six sigma certification#corporate#certification#6sigma#startup#founder

3 notes

·

View notes

Photo

「 tu fui, ego eris. 」 「 what you are, i was. what i am, you will be. 」

#zero escape#akane kurashiki#sigma klim#virtue's last reward#vlr#june#sigma#6sigma#sigmakane#vlr spoilers#tempo's art

1K notes

·

View notes

Photo

On this world Environment Day, Let's take a commitment together that as just a life on this planet We must conserve and take care of our only planet, and gift this in a best way to our future generation. World Environment Day is the most renowned day for environmental action. Since 1974, it has been celebrated every year on 5 June. www.USQC.us or contact : [email protected] #usqc #safety #quality #maritime #petroleum #oilandgas #courses #certification #HACCP #6sigma #sixsigma #followforfollowback #follow #follow4like #iso #iso26000 #transition #iso14001 #iso50001 #ascaccredited #americanquality #gmp #worldenvironmentday #oneplanet #onlyoneearth #Environment #sustainability #sustainable #environmentalresponsibility #socialresponsibility (at New Jersey) https://www.instagram.com/p/CebaQpZuNGY/?igshid=NGJjMDIxMWI=

#usqc#safety#quality#maritime#petroleum#oilandgas#courses#certification#haccp#6sigma#sixsigma#followforfollowback#follow#follow4like#iso#iso26000#transition#iso14001#iso50001#ascaccredited#americanquality#gmp#worldenvironmentday#oneplanet#onlyoneearth#environment#sustainability#sustainable#environmentalresponsibility#socialresponsibility

5 notes

·

View notes