#4 Axis Direct Drive Rotary Table

Explore tagged Tumblr posts

Text

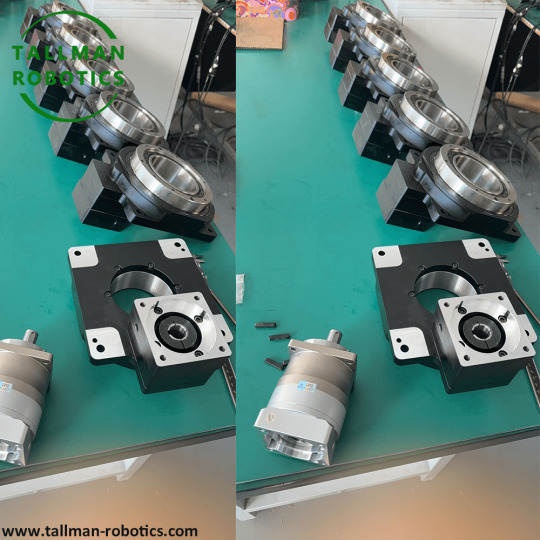

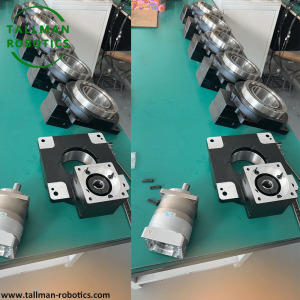

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes

Text

UCAM: Leading Precision Engineering and Innovative Rotary Solutions

UCAM is a pioneering manufacturer of 4th and 5th Axis CNC Rotary Tables in India and has been at the forefront of precision engineering since its inception in 1986. With over three decades of expertise, our state-of-the-art manufacturing facility is equipped with the latest technology and advanced machinery, enabling us to produce CNC Rotary Tables with unparalleled precision and durability. Known for customizing rotary solutions to meet specific needs, we serve various sectors, including Agriculture, Automobile, and Medical, both domestically and internationally.

In addition to CNC Rotary Tables, UCAM encompasses other specialized verticals. Nimble Machines, for example, focuses on high-precision Gear Hobbing Machines, with the VAJRA and TARANG Series representing the latest advancements in this area. Similarly, Nimble Electric provides an array of high-precision Torque Motors and Direct Drives, highlighted by the ORION series. These complementary products reflect UCAM’s commitment to meeting diverse industry requirements with precision and adaptability.

UCAM to Showcase Its Wide Range of Rotary Tables at IMTEX 2025

At IMTEX 2025, to be held in Bangalore from January 23-29, 2025, UCAM will exhibit an extensive range of technologies designed to promote productive and sustainable manufacturing practices. Our 4th and 5th-axis Rotary Tables are known for delivering high levels of precision and repeatability. In particular, our latest URQ-200HS Rotary Table offers enhanced speed and clamping torque, making it ideal for high-demand applications requiring both efficiency and precision.

UCAM’s Premier Product Lineup at IMTEX Exhibition:

URQ-200HS 4-Axis Rotary Table:

This model is a versatile, high-speed machining solution catering to a variety of production needs. With its modular structure and compact design, the URQ-200HS is ideal for space-constrained environments. It features straightforward maintenance, including easy backlash adjustments that ensure maximum repeatability. Especially well-suited for drill tap centers that require high-speed indexing, this series is a valuable asset for achieving increased productivity and accuracy in precision machining.

Our range of rotary tables addresses the needs of multiple industries. At IMTEX 2025, we will spotlight solutions specifically for the Machine Tool, Automotive, Defense, and General Engineering sectors.

Rotary Production System – URPQ 200:

Engineered for precision and versatility, this 4th-axis solution boosts machining productivity by accommodating multiple workpieces with similar operations. It guarantees high accuracy and repeatability, featuring a robust support system, a faceplate tailstock, and a modular fixture plate for enhanced stability and flexibility. An optional drop-in rotary union is available to facilitate greater clamping power for components. Its highly rigid base plate maintains alignment, making it particularly suitable for mass production scenarios demanding top-tier accuracy.

Rotary Tilting Table – Q Series:

The Q Series embodies engineering excellence with a robust, rigid design tailored for complex machining tasks. Users have the option of pneumatic or hydraulic clamping, and the tables come in both short and large swing variants to accommodate different workpiece sizes. Maintenance is user-friendly, with adjustments made easy for consistent repeatability. The Q Series Tilting Tables, including the USSR-200q and ULSR-200q models, integrate seamlessly with existing 3-axis setups to enable full 5-axis movement, supporting complex machining requirements.

Committed to innovation and customer satisfaction, UCAM will showcase its state-of-the-art solutions, reinforcing our position as a leader in the precision engineering field. We look forward to demonstrating how our products can enhance productivity and precision in manufacturing.

UCAM Pvt Ltd

www.ucamind.com

0 notes

Text

What’s The Difference Between A 5 Axis CNC Router Wood And a 3-Axis CNC Machine?

Five axis CNC routers are extremely unique in the woodworking industry, partly because it takes a skilled programmer and a skilled operator to properly marry the design with the desired outcome.

📷

Features of 5 axis cnc router:

5 to 1 Shimpo planetary Gear boxes on the X & Y Axes, helical rack and pinion design enhances accuracy and rigidity

FEA-engineered, heavy, wall, all-steel bridge, vertical columns, and table support base

Smart design allows for easy and unrestricted access to all sides of the machine

Standard 8-position, dynamic automatic rotary tool changer

Fanuc Oi-MF industrial control with Fanuc 1,500-watt servo package

12″, 24″ and 36″ of gantry clearance options available

What Is The Main Benefit Of A 5 Axis CNC Router?

• More axes mean more capacities. 5 Axis allows cutting on any of the five sides of an object based on one setup. Therefore, 5 axis cnc routers have the most possibilities than the 3 axis and 4 axis cnc routers. (For example, 5-axis can perfectly machining cavity models, which is impossible for the other two.)

• Besides this, you will also get business benefits like faster machining, better accuracy, better finish, etc.

Product Parameter

Description

Parameters

Stroke

1720*3040*750mm

System

Syntec control System

Countertop

Aluminum profile countertop

Rail

Taiwan HINWIN

Spindle

14KW SCM five-axis spindle + swing head

Tool magazine

8 disc change tools

Drive motor

Yaskawa, Japan

Inverter

Delta

Reducer

SHIMPO reducer

What’s the difference between a 5-axis and a 3-axis CNC machine?

In a 3 axis CNC machine, the three axes are the X-axis, the Y-axis, and the Z-axis. The X-axis moves left to right, the Y-axis moves from front to back, and the Z-axis moves up and down. A3 axis CNC machine can work on each axis at the same time.

A 3-axis CNC machine is able to simultaneously move across three different axes to cut a material into the desired shape. A 5-axis CNC machine instead allows the cutting tool to rotate in a multi-dimensional fashion in five directions at the same time, which:

Provides the ability to manufacture complex projects with precision

Reduces the need for tool changes

Increases speed and replicability

Lowers costs with automatisation and efficiency

With two 5-axis CNC machines and our highly skilled operators, we offer consistent and top-quality CNC wood cutting services to meet the specific needs of our customers, many of whom come to us with highly complex and bespoke projects.

0 notes

Text

Robotic Process Automation for Smartphone Manufacturing Market: Increasing Demand for Efficient Management Practices Report Till 2023

Industry Insight

While 2020 is being an extremely eventful year for robotic process automation for Smartphone manufacturing due to COVID-19 breakthrough, the global robotic process automation for Smartphone manufacturing market 2020 is showing some positive instincts, when studied by Market Research Future. As per COVID-19 impact analysis, the market has the potential to show immense growth, which is recorded at a rate of ~30.5% and is capable of reaching a valuation of USD 3992.6 million by 2023. The growth period has been estimated from the years 2018 to 2023. The earlier valuation accumulated by the market in 2017 was USD 807.9 million.

Top Driving Factors

The unforeseen challenges that occurred by the ongoing COVID-19 have influenced effectively to exhibit the long term growth projections on robotic automation Smartphone manufacturing market size. Thus, the study has identified a better growth perspective of the market with the help of some of the impacting factors prevailing is thus working in the factor to mark its future growth at a better pace.

The varying consumer interest has built a high need for deployment of technically advanced automation processes in the manufacturing and production process of the industry. A flexible production system with a high-end IT-enabled process offers a fast and safe production process, which is an efficient, flexible, reliable, and cost-effective solution. These factors have been necessarily considered as influential and responsible for the growth of the market.

Get Free Sample Report @ https://www.marketresearchfuture.com/sample_request/5219

In fact, economic pressure has also affected the performance and growth of an industry, which is also one of the factors behind utilizing the automation process in Samsung manufacturing. The significant advantage of automation over conventional manufacturing processes include upgrading in quality and robustness of a process or product, high throughput or productivity, and reduction of direct human labor cost and expenses. This is yet another primary reason for the high growth of the robotic automation Smartphone manufacturing market.

On the contrary, the factor of the scarcity of investment by small & medium size industry and less accessibility of trained professional in developing economies is showing signs of market growth been hindered to some extent in the forecast period.

Regional Framework

The study takes a closer look at critical regional dynamics and the trends that will create lucrative avenues in emerging regional markets for digital process automation. The geographical overview of the global robotic automation Smartphone manufacturing market has been conducted in four major regions, including North America, Asia Pacific, Europe, and the rest of the world.

Owing to the mounting development in the IT industry, North America is likely to lead the robotic process automation for the Smartphone manufacturing market in the forecast period. North America is one of the leading regions across the world in terms of market share. The market for robotic process automation for Smartphone manufacturing in this region has a huge demand owing to high growth in the IT industry and mounting adoption of smartphones by consumers.

Asia-Pacific has also successfully taken second place in the Smartphone manufacturing market in robotic process automation as it is expected to expand at a faster pace during the forecast era. It was owing to the enormous demand for robotic process automation for the manufacturing of Smartphones, the robotic process automation for the Smartphone industry is experiencing high growth. Asia Pacific is likely to observe the highest CAGR in the coming years owing to escalating demand for Smartphones, soaring demand for outsourcing services, and leading markets such as South Korea, China, and Japan.

The robotic process automation for the Smartphone manufacturing market in the European region is likely to witness rapid growth in the forthcoming period.

Segmentation of Market: Robotic Automation Smartphone Manufacturing

The global robotic automation Smartphone manufacturing market has further been segmented along the following lines:

In terms of the robot type segment, the market has included Cartesian, SCARA, 6-axis robot, articulated, redundant, delta, dual-arm, and parallel. Among these, the 6-axis robot segment contributed as the largest market share in 2017, with a market value of USD 168.7 million, and now it might register the highest CAGR during the forecast period. Also, SCARA is the best suited for high-speed assembly, knitting, packaging, and other material handling applications.

In terms of component segment, the market has included Motor, generators, motor controls, automation equipment, and power transmission equipment

In terms of organization segment, the market has included Small & medium enterprises and large enterprises.

Top Market Players

The foremost market players effective in the global market are identified Seiko Epson Corporation, ABB Ltd, KUKA Robotics, Yaskawa Electric Corporation, Nice Ltd, Denso Wave Inc., Fanuc Corporation, Pegasystems Inc., Nachi Robotic System Inc., and Redwood Software.

Table of Content:

3 Market Dynamics

3.1 Market Growth Factors

3.2 Market Drivers

3.2.1 High Focus Of Industry On Achieving Energy Efficiency In Manufacturing Process

3.2.2 Growing Deployment Of IoT In Industrial Process

3.2.3 Growing Smartphone Integration Platform

3.3 Market Restraints

3.3.1 Scarcity Of Investment By Small & Medium Size Industry Is Affecting The Market Growth

3.3.2 Less Availability Of Trained Professional In Developing Economies For Implementing And Processing Automation System

4 Executive Summary

5 Market Factor Analysis

5.1 Porter’s Five Forces Analysis

5.2 Supply Chain Analysis

5.2.1 Robotic Process Automation Architecture

6 RPA For Smartphone Manufacturers Market

6.1 Introduction

6.2 Market Statistics

6.2.1 By Robot Type

6.2.1.1 Cartesian

6.2.1.2 SCARA

6.2.1.3 Articulated

6.2.1.4 Delta

6.2.1.5 6-Axis Robots

6.2.1.6 Redundant

6.2.1.7 Dual-Arm

6.2.1.8 Parallel

6.2.1.9 Others

6.2.2 By Component

6.2.2.1 Motors

6.2.2.1.1 Fractional AC Motors

6.2.2.1.2 Fractional DC Motors

6.2.2.1.2.1 Fractional Brushed DC Motors

6.2.2.1.2.2 Fractional Brushless DC Motors

6.2.2.1.3 Integral Motors

6.2.2.1.3.1 Integral AC Motors (LV)

6.2.2.1.3.2 Integral DC Motors (LV)

6.2.2.1.4 Medium Voltage Motors

6.2.2.1.5 Servo Motors

6.2.2.1.6 Stepper DC Motors

6.2.2.2 Generators

6.2.2.2.1 Low Power Generators

6.2.2.2.2 Medium Power Generators

6.2.2.2.3 High Power Generators

6.2.2.3 Motor Controls

6.2.2.3.1 AC Drives

6.2.2.3.2 DC Drives

6.2.2.3.2.1 Brushed DC Drives

6.2.2.3.2.2 Brushless DC Drives

6.2.2.3.2.3 Stepper DC Drives

6.2.2.3.3 Medium Voltage Drives

6.2.2.3.4 Servo Drives

6.2.2.3.5 Soft Starters & MCCs

6.2.2.4 Automation Equipment

6.2.2.4.1 Discrete Controllers & Visualization

6.2.2.4.1.1 Computer Numerical Controllers

6.2.2.4.1.2 Embedded Computer Boards, Modules And Systems

6.2.2.4.1.3 Networking Infrastructure Devices

6.2.2.4.1.4 I/O Modules

6.2.2.4.1.5 Others

6.2.2.4.2 Process Control

6.2.2.4.2.1 Distributed Controller

6.2.2.4.2.2 Process & Temperature Controllers

6.2.2.4.2.3 Process Instrumentation Devices

6.2.2.4.2.4 Others

6.2.2.4.3 Switchgear

6.2.2.4.3.1 MCB & RCDs

6.2.2.4.3.2 Electro-Mechanical & Solid-State Relays

6.2.2.4.3.3 Electronic Control Relays

6.2.2.4.3.4 Others

6.2.2.5 Power Transmission Equipment

6.2.2.5.1 Rotary Products

6.2.2.5.1.1 Backlash Rated Geared Product

6.2.2.5.2 Gearboxes

6.2.2.5.2.1 Geared Motors

6.2.2.5.3 Linear Products

6.2.2.5.3.1 Actuator Rod Less

6.2.2.5.3.2 Actuator Rod Style

6.2.2.5.3.3 Hydraulic Actuators

6.2.2.5.3.4 Others

6.2.3 By Organization Size

6.2.3.1 Small & Medium Enterprises

6.2.3.2 Large Enterprises

6.2.4 By Region

6.2.4.1 North America

6.2.4.1.1 US

6.2.4.1.2 Canada

6.2.4.1.3 Mexico

6.2.4.2 Europe

6.2.4.2.1 Germany

6.2.4.2.2 UK

6.2.4.2.3 France

6.2.4.2.4 Rest Of Europe

6.2.4.3 Asia-Pacific

6.2.4.3.1 China

6.2.4.3.2 Japan

6.2.4.3.3 India

6.2.4.3.4 South Korea

6.2.4.3.5 Taiwan

6.2.4.3.6 Rest Of Asia-Pacific

6.2.4.4 Rest Of The World

6.2.4.4.1 Latin America

6.2.4.4.2 Middle East & Africa

Get Complete Report @ https://www.marketresearchfuture.com/reports/robotic-process-automation-for-smartphone-manufacturing-market-5219

About Us

Market Research Future (MRFR) is an esteemed company with a reputation of serving clients across domains of information technology (IT), healthcare, and chemicals. Our analysts undertake painstaking primary and secondary research to provide a seamless report with a 360 degree perspective. Data is compared against reputed organizations, trustworthy databases, and international surveys for producing impeccable reports backed with graphical and statistical information.

We at MRFR provide syndicated and customized reports to clients as per their liking. Our consulting services are aimed at eliminating business risks and driving the bottomline margins of our clients. The hands-on experience of analysts and capability of performing astute research through interviews, surveys, and polls are a statement of our prowess. We constantly monitor the market for any fluctuations and update our reports on a regular basis.

Media Contact:

Market Research Future

Office No. 528, Amanora Chambers

Magarpatta Road, Hadapsar,

Pune - 411028

Maharashtra, India

+1 646 845 9312

Email: [email protected]

0 notes

Text

Internet Of Things Applications in Rotary Table

The Internet of Things, or IoT, refers to the billions of physical devices around the world that are now connected to the internet, collecting and sharing data. A light bulb that can be switched on using a smartphone app is an IoT device or as serious as a self driving car, or as complicated as a jet engine that’s now filled with thousands of sensors collecting and transmitting data back to make sure it is operating efficiently. At an even bigger scale, smart cities projects are filling entire regions with sensors to help us understand and control the environment. IOT adds a level of digital intelligence to devices that would be otherwise dumb, enabling them to communicate real-time data without a human being involved, effectively merging the digital and physical worlds.

The term “Internet of Things” was coined by entrepreneur Kevin Ashton, one of the founders of the Auto-ID Centre at MIT. Since 2012, major changes in sensors have led to rapid maturing in the Internet of Things market – fuelling digital transformation for many businesses.

The Industrial Internet of Things (IIoT) or the fourth industrial revolution or Industry 4.0 is all names given to the use of IoT technology in a business setting. The concept is the same as for the consumer IoT; to use a combination of sensors, wireless networks, big data and analytics to measure and optimise industrial processes.

Stage IoT architecture which are:

STAGE 1: Sensors and actuators: sensors collect data from an environment/Machine and turn it into usable data.

STAGE 2: Internet gateways and Data Acquisition Systems: Data acquisition systems (DAS) are responsible for aggregating and converting the data. It connects to the sensor networks, aggregates the output, and converts the analog data to digital data.

STAGE 3: Edge IT Data Processing: enhanced analytics and pre-processing is performed, Edge IT systems also use machine learning CNC Rotary Table and visualization technologies, it generates useful results and only pass those to the next stage.

STAGE 4: Data centre and cloud: all the data that needs more in-depth analysis without requiring immediate feedback goes to cloud-based data centres. These data centres are capable of analyzing, handling, and storing huge amounts of data.

We at UCAM make Rotary Table smart and IOT enabled. IOT will help avoiding unplanned downtime — using analytics to predict equipment failure ahead of time to schedule orderly maintenance procedures otherwise known as Predictive Maintenance can help mitigate the damaging economics of unplanned downtime.

Monitor UCAM Product health live by monitoring different parameters like over pressure limit/under pressure limit, oil level status, critical temperature data, humidity data, Clamp/unclamp feedback. Analyzing the parameter will contribute in improvement of Product Performance.

UCAM is India’s largest manufacturer of 5th Axis Rotary Table, Rotary Production System, Multi spindle Manual Chucks, Direct Drive Rotary Tables, CNC Rotary Tables For Machine Builders, Torque Motor Rotary Table, Large Size Rotary Tables which are used for enhancing the productivity of VMC’s. Nimble Machines – A division of UCAM designs and manufactures high speed high precision CNC Gear Hobbing Machines. Nimble Electric – a division of UCAM designs and manufactures Torque motors.

0 notes

Text

Exploring the Benefits and Features of UCAM’s CNC Rotary Tables

Rotary tables have become indispensable tools in modern manufacturing, allowing for multi-axis machining that improves versatility, efficiency, and precision. UCAM, a leader in CNC rotary tables, offers products that stand out for their exceptional features and benefits. But what makes UCAM’s rotary tables so beneficial, and how do they set themselves apart in the market?

1. Precision and Accuracy

At the core of UCAM’s rotary tables is their focus on precision and accuracy. The ability to rotate a workpiece to exact angles ensures intricate parts are machined with minimal error, a critical need in industries where even slight deviations can impact functionality, such as medical devices and aerospace components. UCAM’s rotary tables are designed with high-precision gear systems that operate with minimal backlash, helping manufacturers achieve extremely tight tolerances. This makes them an ideal solution for applications that demand high accuracy and consistency.

2. Enhanced Productivity

One of the biggest advantages of rotary tables is their ability to combine multiple machining operations in one setup. This eliminates the need for repositioning and re-clamping the workpiece, significantly reducing cycle times and improving overall productivity. With UCAM’s rotary tables, manufacturers can complete complex parts more quickly and efficiently, improving throughput while maintaining high standards of quality.

3. Multi-Axis Machining Capabilities

UCAM’s rotary tables are engineered to provide 4-axis or 5-axis machining, unlocking a world of possibilities for manufacturers. From multi-sided machining to angled drilling and contouring, UCAM’s rotary tables bring an extra dimension of flexibility to machining processes, making it possible to produce complex geometries with ease.

4. Durability and Longevity

Manufacturers look for equipment that offers reliability and longevity, and UCAM’s rotary tables excel in both these areas. Built with high-strength materials, these rotary tables are designed to withstand heavy loads and rigorous machining environments. Their rugged construction ensures that they can operate continuously, offering long-term performance with minimal downtime.

Key Features of UCAM’s CNC Rotary Tables

UCAM’s rotary tables are known not just for their benefits but also for unique features that optimize performance and ease of use.

1. High-Quality Servo Motors

UCAM’s rotary tables are equipped with servo motors that provide precise control over rotational movements. These motors allow for quick, accurate positioning of the workpiece, making it easier to perform intricate machining operations. The servo-driven technology ensures that the rotary table operates smoothly, reducing the chances of errors or delays in production.

2. Zero Backlash Technology

One of the standout features of UCAM’s rotary tables is their zero backlash technology, particularly in their direct drive models. By eliminating backlash, these rotary tables offer smoother transitions between positions, improving the overall quality of the machined parts. This feature is particularly important for industries that require fine finishes and high-tolerance parts, such as medical devices and aerospace components manufacturing.

3. Compact and Space-Saving Design

UCAM’s rotary tables are designed with space efficiency in mind. Their compact design allows them to be integrated into CNC machining centers without taking up excessive space. Despite their smaller footprint, these rotary tables are capable of handling heavy loads and delivering high-precision results. This allows them to be used in various industries, ranging from small workshops to large-scale manufacturing operations. The space-saving design of UCAM’s rotary tables does not compromise on performance, offering a balance of compactness and power.

4. Ease of Integration

UCAM’s rotary tables come equipped with advanced control systems that easily integrate with CNC machines. These control systems allow for programmable automated indexing, making it possible to set up complex machining operations without the need for manual intervention. This improves both efficiency and accuracy.

Practical Applications of UCAM Rotary Tables

UCAM’s rotary tables are widely used in various industries where precision, flexibility, and efficiency are critical:

Aerospace: In the aerospace industry, UCAM’s rotary tables are used to machine complex components such as turbine blades, which require high precision and tight tolerances are essential.

Automotive: UCAM’s rotary tables facilitate the multi-axis machining of components like gears, camshafts, and engine parts, enhancing accuracy and reducing production times.

Medical Devices: Medical device manufacturing, which demands extreme precision, benefits significantly from the zero backlash technology in UCAM’s rotary tables, ensuring intricate geometries meet the highest standards.

Tool and Die Manufacturing: UCAM’s Rotary tables simplify the process of machining molds and dies, reducing setup times and improving part accuracy.

UCAM Rotary Tables—Your Path to Precision and Efficiency

UCAM’s rotary tables are more than just precision positioning devices—they are transformative solutions that empower manufacturers to unlock the full potential of multi-axis machining. With features like hydraulic clamping, servo motors, and zero backlash technology, these rotary tables offer enhanced productivity, flexibility, and accuracy across a wide range of industries.

By investing in UCAM’s rotary tables, businesses can not only improve their machining processes but also stay competitive in a market where precision and efficiency are key.

0 notes

Photo

Direct Drive 5 Axis

DD直驅5軸轉台

#Direct Drive 5 Axis#5 axis#5 axis direct drive rotary table#5 axis machining#cnc 5 axis#4 axis machining#cnc 4 axis#4 Axis Direct Drive Rotary Table#Solpower Taiwan#solpower motor#Solpower Spindle#Solpower Precision#Solpower Direct Drive#Solpower 5 Axis#Solpower 4 axis

1 note

·

View note

Photo

5 Axis Direct Drive Rotary Table By Solpower Motor

#Solpower#Solpower Taiwan#Solpower Motor#4 axis#4 Axis Direct Drive Rotary Table#cnc 4 axis#5 axis#5 axis machining#5 axis cnc#5 axis milling#5 Axis Direct Drive Rotary Table#4 axis cnc#Direct Drive Rotary Table#4th axis direct drive rotary table#5th axis direct drive rotary table#Sam Lee#motorized spindle#built in spindle#electric spindle#High Speed Spindle#milling spindle#Servo Motor#Linear Motor#Asynchronous Servo Motor#Synchronous Servo Motor#Spindle Motor#Belt Drive Spindle#Direct Drive Spindle#Direct Drive Motor

1 note

·

View note

Video

youtube

DD Rotary Table - Bearing System #SolpowerTaiwan

#Solpower#Solpower Taiwan#Solpower Motor#Direct Drive Rotary Table#5 Axis Direct Drive Rotary Table#4 Axis Direct Drive Rotary Table#4 Axis Machining#5 Axis Machining#CNC Machine Center#5 Axis Machine Center#4 Axis Machine Center#High Speed Direct Drive Rotary Table#Manufacturer#Exporter#Seller#UL Certified#iso 9001:2015#iatf 16949#made in house#Taiwan#Made In Taiwan

0 notes

Video

youtube

Solpower's Manufacturing Capabilities

ISO9001:2015 Certification, IATF 16949: 2016 Certification, and UL Certified

2 Factories, 3600 Square Meters, 26 Years Of Experience

4 Assembly Lines, Coordinate Measuring Machine (CMM)

Department Grinding Department .....

#Solpower#Solpower Motor#Solpower Taiwan#Direct Drive Rotary Table#4 Axis Direct Drive Rotary Table#5 Axis Direct Drive Rotary Table#Motorized Spindle#Belt Drive Spindle#Direct Drive Spindle#Servo Motor#Induction Motor#Linear Motor#Direct Drive Stator And Rotor#Stator and Rotor#Built In Spindle#Electric Spindle#eSpindle#CNC Spindle#Solpower Spindle#Asynchronous Motor#Synchronous Motor#Direct Drive Motor#The One Stop CNC Shop#CNC Machine Center#Manufacturer#Seller#Exporter

0 notes

Video

youtube

The What, Why and How of Direct Drive Rotary Tables #SolpowerTaiwan

#Direct Drive Rotary Table#5 axis direct drive rotary table#4 axis direct drive rotary table#5 axis#4 axis#4 axis machining#5 axis machining#cnc machine#ultra precision cnc parts#5 axis machine center#4 axis machine center parts#solpower#solpower taiwan#solpower motor#5 axis rotary table#4 axis rotary table#high speed rotary table#Direct Drive High Speed Rotary Table#CNC MACHINE CENTER#Mannufacturer#Supplier

0 notes

Photo

4 Axis Direct Drive Rotary Table

#4 axis#4 Axis Direct Drive#4 Axis Direct Drive Rotary Table#Solpower#Solpower Taiwan#Solpower Motor#Direct Drive Rotary Table#4 Axis Machining#CNC Machine Center#4 Axis Machine Center#Direct Drive Rotary Table Manufacturer#4 Axis Manufacturer#High Speed Rotary Table#Ultra Precision Machinining#Solpower 4 Axis#4 axis for milling

0 notes

Photo

4 axis direct drive rotary table

#4 axis#4 axis direct drive rotary table#4 axis rotary table#cnc 4 axis#4 axis machine center#solpower#solpower taiwan#solpower motor#the one stop cnc shop#Taiwan#milling machine#machine tooling

0 notes

Photo

4 Th Axis Direct Drive Rotary Table #Solpower

#Solpower#Solpower Taiwan#Solpower Motor#4 Axis#4 Axis Rotary Table#4 Axis Direct Drive Rotary Table#Direct Drive Rotary Table#4 Axis Machining#CNC Machine Center#High Speed 4 Axis#CNC 4 Axis#The One Stop CNC Shop#Manufacturer#Supplier#OEM#ODM#Taiwan#Made In Taiwan

0 notes

Photo

4 Axis Direct Drive Rotary Table 四軸分度盤

#Solpower#Solpower Taiwan#Solpower Motor#4 Axis#cnc 4 axis#4 Axis Rotary Table#4 Axis Direct Drive Rotary Table#Direct Drive Rotary Table#4 Axis Machining#4 axis machine center#4 Axis Machine#CNC Machine Center#Precision 4 Axis#High Speed Rotary Table#Solpower Machine Electronic Corp.#Made In Taiwan#manufacturer#suppliers#OEM#ODM#BRANDING#Taiwan

0 notes

Photo

4 Axis Direct Drive Rotary Table

#Solpower#Solpower Taiwan#Solpower Motor#4 Axis#4 axis machine center#Direct Drive Rotary Table#4 Axis Direct Drive Rotary Table#cnc 4 axis#4 Axis Rotary Table#cnc machine center

0 notes