#3D printing and environment

Explore tagged Tumblr posts

Text

Sustainable Materials and 3D Printing Industry: A Look at ESG Innovation

Sustainability priorities of environmental stewardship, workers’ safety, human rights and sound governance have become pronounced in the 3D printing industry. Additive manufacturing (AM) technology and solutions are well-placed to influence global issues and foster improvements through innovations, training, education and carbon footprint reduction. 3D printing, post-COVID-19, has become a game-changer as companies seek to assess the untapped potential of additive manufacturing. Prominently, 3D printing has amassed huge popularity among manufacturers, engineers and designers to keep up with the need for responsible energy consumption. Moreover, recycling, reducing, repurposing, reusing and repairing have ushered innovation in the global landscape. Companies are expected to exhibit product improvements and complement transparency, fairness, regulated, ethical and compliant operations.

3D printed parts and products have become palpable in end-products, including athletic shoes and printed cars. Stakeholders are exhibiting traction for additive manufacturing programs and embracing the responsibility to enhance lives and protect the environment. Exponential growth in digitization and a paradigm shift witnessed in the energy transition towards renewables have redefined the 3D printing landscape. Additive manufacturing could be instrumental in aerospace, manufacturing, automotive and healthcare sectors to reduce lead time, and material cost, leverage on-site production and underpin growth with sustainability targets. Amidst surging pressure to address supply chain issues and keep up with energy efficiency needs, industry players could explore opportunities in 3D printing.

Key Companies in this theme

• Stratasys, Ltd

• Materialise

• EnvisionTec Inc

• 3D Systems Inc

• GE Additive

• Autodesk Inc

• Canon Inc.

Discover more regarding the practices and strategies being implemented by industry participants from the 3D Printing Industry ESG Thematic Report, 2023, published by Astra ESG Solutions

Environmental Perspective

A notable shift towards AM technologies could lead to less energy consumption, reduced waste, optimized and enhanced supply chains and more recycling. In July 2021, eight companies joined the bandwagon to be part of the Additive Manufacturer Green Trade Association (AMGTA) to educate and promote the green upsides of 3D printing. Similarly, in May 2022, the global trade organization announced that 20 member companies received the 2022 Sustainability Awards. AM technologies are expected to boost environmentally friendly methods of manufacturing, mainly attributed to the innate ability to manufacture closer to the point of need, minimize material consumption and redesign parts to reduce energy consumption and weight.

Pioneering products, services and state-of-the-art technologies are unlocking opportunities and measuring sustainability metrics in line with ESG goals. The trend has become prevalent and prompted stakeholders to inject funds into sustainability portfolios. In December 2020, 3D Systems announced the rollout of its ESG initiative, bolstering its commitment to leveraging AM solutions for a host of applications. Companies are poised to advocate for sustainable technologies that will help minimize carbon emissions and eradicate waste. Notably, AM uses merely the material required to produce the final part, thereby playing an invaluable role in bolstering sustainability.

Social Perspective

3D printing has come on the horizon as a vital cog in fostering employees’ health and safety and social programs, including entrepreneurship and STEAM education. In April 2022, it was reported that Stratasys offered access to dozens of 3D printers and funded the FIRST Robotics Competition for high school students. The company also introduced the “learning by making” program with Jerusalem Municipality, spanning across state-religious, independent-religious, state-secular and Arab schools. Additionally, the company was reported to be resilient amidst havoc wracked by the COVID-19 pandemic. Stratasys inferred in its 2020-2021 ESG and Sustainability Report that it reduced the work to 80% capacity till the end of 2020. It helped them do away with the pandemic-induced layoffs. The company offered mental health seminars on depression, social connections and loneliness. Besides, it organized an in-person summer camp in 2021 to provide fun and relief to the teams and their families.

Stakeholders have furthered their focus on diversity to add value for shareholders, employees and customers. In doing so, embracing diverse teams could propel an inclusive culture and complement employees’ unique identities, experiences and backgrounds. For instance, in 2021, GE updated a few voluntary self-identification categories and selections pertaining to sexual orientation and gender identity (based on employee feedback). The company asserted in its 2021 Diversity Annual Report that around 3.7% of its U.S. employees identified themselves as having a disability, while over 10% of the U.S. employees are military veterans. Amidst call for equal pay for all, GE is gearing to attain 100% pay equity in each of its businesses.

Is your business one of participants of the Global 3D Printing Industry? Contact us for focused consultation around ESG Investing, and help you build sustainable business practices.

Governance Perspective

Stakeholders demand greater traceability and transparency as companies seek to build trust with customers, communities, investors and other parties. Corporate governance has come to the fore as an invaluable pillar to running a business sustainably. Additive manufacturing companies are expected to devote attention to corporate governance policies, and guidelines and invest in data-driven products and solutions. Leading players are emphasizing independent leadership for a robust compliance and internal controls with applicable laws, policies and regulations. Notably, Autodesk infers in its 2022 Impact Report that 90% of its Board of Directors are independent, while 50% are women.

Stakeholders are counting on AI and ML to streamline the business. Forward-looking companies anticipate additive manufacturing to foster logistics systems and bolster resilience through the incorporation of environmental and social aspects. Leading players are likely to prioritize sustainability reporting frameworks to further organizations’ governance disclosure. In essence, GE offers disclosure as per SASB standards and provides climate-related disclosures in line with the TCFD framework. For instance, the organization has been disclosing how it assesses, identifies and manages climate-related risks. Meanwhile, Eaton has set an audacious target (2030 Sustainability Target) of over 50% enhancements in safety metrics, disclose U.S. minority and global gender pay equity assurance results, and ensure no human rights violation from major suppliers. It has also set report priority issues in line with TCFD and SASB requirements. The company asserted that around 65% of its net sales stemmed from sustainable solutions in 2021.

As 3D printing brings a seismic shift in the global landscape, stakeholders are gearing to augment their leadership position in ESG. In doing so, prominent manufacturers and suppliers are poised to inject funds into organic and inorganic growth strategies. To illustrate, in November 2022, Stratasys announced the pouring of USD 10 million in Axial3D, wherein both companies will render a joint offering to provide the accessibility of patient-specific 3D printing solutions for medical device manufacturers and hospitals. Prevailing trends indicate the global 3D printing market size could register an impressive CAGR of 20.8% from 2022 through 2030. Industry dynamics suggest sustainability priorities will witness an upward growth trajectory with a focus on, including but not limited to, people-first strategies, innovation, climate actions and transparency.

About Astra – ESG Solutions By Grand View Research

Astra is the Environmental, Social, and Governance (ESG) arm of Grand View Research Inc. – a global market research publishing & management consulting firm.

Astra offers comprehensive ESG thematic assessment & scores across diverse impact & socially responsible investment topics, including both public and private companies along with intuitive dashboards. Our ESG solutions are powered by robust fundamental & alternative information. Astra specializes in consulting services that equip corporates and the investment community with the in-depth ESG research and actionable insight they need to support their bottom lines and their values. We have supported our clients across diverse ESG consulting projects & advisory services, including climate strategies & assessment, ESG benchmarking, stakeholder engagement programs, active ownership, developing ESG investment strategies, ESG data services, build corporate sustainability reports. Astra team includes a pool of industry experts and ESG enthusiasts who possess extensive end-end ESG research and consulting experience at a global level.

For more ESG Thematic reports, please visit Astra ESG Solutions, powered by Grand View Research

#3D Printing Industry ESG#3D Printing Industry#3D Printing Market#ESG and 3D Printing Industry#3d printing esg#3D printing and environment

0 notes

Text

Researchers at the University of California San Diego have developed a new type of material that could offer a sustainable and eco-friendly solution to clean pollutants from water. Dubbed an "engineered living material," it is a 3D-printed structure made of a seaweed-based polymer combined with bacteria that have been genetically engineered to produce an enzyme that transforms various organic pollutants into benign molecules. The bacteria were also engineered to self-destruct in the presence of a molecule called theophylline, which is often found in tea and chocolate. This offers a way to eliminate them after they have done their job. The researchers describe the new decontaminating material in a paper published in Nature Communications.

Continue Reading.

129 notes

·

View notes

Text

A research team led by engineers at the University of Virginia School of Engineering and Applied Science is the first to explore how an emerging plant-based material, cellulose nanofibrils, could amplify the benefits of 3D-printed concrete technology. "The improvements we saw on both printability and mechanical measures suggest that incorporating cellulose nanofibrils in commercial printable materials could lead to more resilient and eco-friendly construction practices sooner rather than later," said Osman E. Ozbulut, a professor in the Department of Civil and Environmental Engineering. His team's findings will be published in the September 2024 issue of Cement and Concrete Composites.

Read more.

#Materials Science#Science#3D printing#Concrete#Environment#Cellulose#Biomaterials#University of Virginia

8 notes

·

View notes

Text

#good news#science#environmentalism#nature#environment#disaster prevention#disaster preparedness#earthquake#3d printing#arcitecture#guatamala

36 notes

·

View notes

Text

"In the far western desert of Texas, a striking 3D-printed hotel with Swedish style will take shape over the coming years to present both the beauty and savings of 3D printing to the country and the world.

The architecture is handled by Swedish design architect Bjarke Ingels, while the printers will be supplied by Austin-based 3D printing company ICON, that [has] really taken the technology to the next level with 3D-printed batteries and whole neighborhoods besides.

The two are teaming up to transform the El Cosmico hotel/campground in Marfa, Texas, into a 62-acre remote hotel with an infinity pool, art exhibition hall, outdoor bathhouse, and outdoor kitchen, all designed as an homage to both the desert surroundings and the cosmic show on display in the night sky above.

The local West Texas earth is being added to the 3D printing cement mixture to ensure the luxury cabins blend in with their surroundings.

“The promise of 3D printing is that the printer doesn’t care how complex the design is, if it uses organic curvature, dome-like shapes, or hyperbolic paraboloids,” Ingels, an early investor in Icon and a frequent design collaborator on its 3D-printed projects, told AD.

“All it cares about is how long it takes to print and how much material [it is] going to deploy, so you can make a square box or a beautiful domed house at the same cost.”

That cost can be around 30% less than traditional methods, as well as 350% stronger depending on the size and scope of the project.

The hotel rooms will all feature skylights to allow unobstructed viewing of the night sky, and expansive views of the Davis Mountains. Just next door is Big Bend National Park, one of the largest in the Lower 48, and a paradise of desert exploration.

El Cosmico “2.0.” is predicted to begin construction in 2024."

-via Good News Network, 3/27/23

#3d printing#architecture#sustainable architecture#green architecture#solarpunk#environment#cement#construction#big bend national park#texas#united states#sweden#hotel#glamping#good news#hope

37 notes

·

View notes

Text

Started 3D printing recently and The Next Layer is prominent on Youtube

Apparently there's some controversy around this dude as someone who just cashes into Youtube trends or something but one video I saw had this guy who was like "this company (LDO) heard that I had to evacuate Israel because of the war and they were kind enough to send me this portable 3D printer" and he had the Israeli flag up in the background

So they're Zionists and steer clear of them

#i get that they and their family left because of fear of conflict but supporting and condoning this is madness#they're so quick to leave when israel barely gets attacked in civilian environments they are cowards and delusional#they really think everyone will do to them what they do to others. delusional psychopaths#palestine#israel#genocide#zionism#youtube#3d printing#the next layer

4 notes

·

View notes

Text

A More Realistic Artificial Skin May Lead to Medical Advances - Technology Org

New Post has been published on https://thedigitalinsider.com/a-more-realistic-artificial-skin-may-lead-to-medical-advances-technology-org/

A More Realistic Artificial Skin May Lead to Medical Advances - Technology Org

A new bioengineered skin model could improve testing of skincare products and lead to better ways to heal damaged skin.

Paul Dalton and Ievgenii Liashenko in the lab. Image credit: University of Oregon

University of Oregon researchers have teamed up with scientists with the French personal care company L’Oréal to develop a multilayered artificial skin that more accurately mimics real human skin, and can be grown in just 18 days. The advance relies on a novel 3D printing technique invented by Paul Dalton, an associate professor in the Phil and Penny Knight Campus for Accelerating Scientific Impact at the UO.

The research was published in the journal Advanced Functional Materials.

“This is the first known case of replicating quality skin tissue at full thickness, using different kinds of cells separated by a membrane,” said Ievgenii Liashenko, a research engineer in Dalton’s lab.

Creating an artificial skin isn’t as simple as growing cells in a petri dish. Real skin has multiple layers, with different kinds of cells that perform distinct functions. And in the body, cells are supported by an external network of proteins and other molecules. Called the extracellular matrix, this system helps cells stay in position and communicate with their neighbors, which is key to keeping all systems working properly.

To replicate this complex environment, the researchers designed a two-layered artificial skin, with the layers separated by a membrane.

A 3D printer making the extremely fine strands used to create a new generation of artificial skin. Image credit: University of Oregon

Researchers from Dalton’s lab and L’Oréal co-developed plastic scaffolds that mimic the extracellular matrix via a network of finely structured 3D printed threads. Then, L’Oréal researchers grew cultured cells in those scaffolds to create the artificial skin, with different cell types growing in each layer. The membrane prevents the cells in the different layers from mixing as they develop.

“Other attempts don’t have the same layering—it actually looks like real skin,” said Dalton, who is the Bradshaw and Holzapfel Research Professor in Transformational Science and Mathematics.

The underlying scaffolds resemble a mesh material made of many spaghetti-like threads, each much thinner than a human hair. To make the porous scaffold, members of Dalton’s team used a 3D printing technique they’ve developed called melt electrowriting. In that technique, an electric field pulls the molten printing plastic from a nozzle into a thin thread, enabling very precise control over the printing.

Some 3D printing techniques can create very fine details, but only small objects, Dalton said.

Other techniques allow easy fabrication of larger pieces, but at the expense of resolution. Melt electrowriting bridges that gap, allowing engineers to create relatively large objects with fine details.

The new skin model can be grown in just 18 days, the researchers found, rather than the 21 to 35 days it took to create previous scaffold-based artificial skin models. That makes it more viable to use in commercial lab testing.

The final product. Image credit: University of Oregon

L’Oréal is currently using the artificial skin to test cosmetics and skin care products. Going forward, both Dalton’s team and L’Oréal researchers plan to explore the many other potential uses for the underlying scaffolding in skin tissue engineering.

Other potential skin-related applications include healing diabetic foot ulcers and creating skin grafts for burn patients. Beyond skin, the scaffolds developed by Dalton’s team could support myriad biomedical applications, such as artificial blood vessels and structures to help regrow damaged nerves.

“While we’ve made this big advance with the skin, the design of the scaffold is crucial and could be applied more broadly,” Dalton said. “There are so many diseases and injuries in the world that aren’t being solved, so having an extra tool to try to tackle these is really valuable.”

The materials used in the scaffold are already FDA– approved for use inside the human body, making the path to real-world application smoother.

The fabrication facilities at the Knight Campus make it possible for Dalton’s team to scale up production of the materials, Dalton said. “This is the part of the Knight Campus projecting its expertise beyond UO to influence state-of-the-art research fields globally.”

Source: University of Oregon

You can offer your link to a page which is relevant to the topic of this post.

#3d#3D printing#applications#Art#artificial#artificial skin#blood#blood vessels#cell#cell types#Cells#Chemistry & materials science news#Design#details#Diseases#easy#electric field#Engineer#engineering#engineers#Environment#Fabrication#Facilities#FDA#Featured technology news#Full#gap#healing#human#Ideas

3 notes

·

View notes

Text

Forget...forget everything okay. Forget fandoms for a moment. Forget cosplay. Forget art. Forget education. Forget having a job and an income. Forget having friends. Forget having family. Forget significant others. Forget pets. Forget trauma. Forget positive things. Forget self care. Forget whatever it is you're doing right this moment.

I have had a brilliant idea.

I need. A 3d printed theme based doll house for my action figures. And I'm not talking the little scene setups people use to take pictures.

I'm talking to scale. 3d printed. Republic cruiser, that is like a doll house. And has furniture and shit. That's big enough to place my action figures in.

That is all. Continue with your life.

#star wars#clone troopers#star wars the clone wars#commander cody#obi wan kenobi#commander wolffe#delta squad#black series#black series action figures#tcw#3d printing#forget everything else#nothing else is as important as having a dollhouse for these guys#but a dollhouse of their environments#let me arrange furniture and action figures in a dollhouse just for them#i want it

17 notes

·

View notes

Photo

Link About It: This Week’s Picks Controlling lightning with lasers, transforming dumps into parks, mapping subterranean passageways and more The First 3D-Printed Two-Story Home in the US New York design firm Hannah, Germany-based company Peri 3D Construction, and Texas engineering and construction firm Cive have partnered to create the first 3D-printed two-story home in the US—currently being built in Houston. The 4,000-square-foot, three-bedroom property will serve as a case study on … https://coolhunting.com/uncategorized/link-about-it-this-weeks-picks-464/

#Link About It#Uncategorized#3D Printed Houses#3D Printing#Ace Hotels#Apparel#Archaeology#Architecture#Chemicals#China#Climate#Climate Change#Climate Crisis#Clothing#Conservation#Environment#Health#History#Hotels#Houses#Lasers#Lightning#LinkAboutIt#Nature#Parks#Photography#Preservation#Public Spaces#Science#Single-Use Plastic

1 note

·

View note

Text

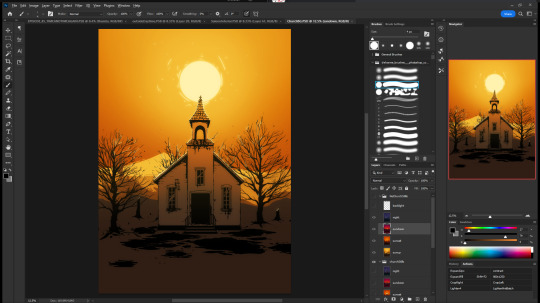

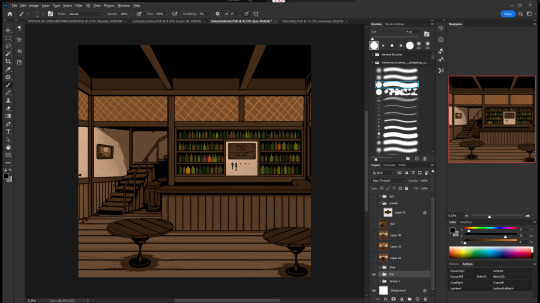

How I save time on backgrounds as a full-time webcomic artist

Hi! I make webcomics for a living, and I have to be able to draw a panel extremely fast to keep up with my deadlines. I draw about 50 panels a week, which gives me about 45 minutes per panel if I want any semblance of a healthy work-life balance.

Most webtoon artists save time on backgrounds by using 3d models, which works for them and is great! but personally I hate working in 3d... I went to school for it for a year and hated it so much I completely changed career paths and vowed never to do it again! So, this is how I save time without using any 3d, for those of you out there who don't like it either!

This tactic has also saved me money (3d models are expensive) and it has helped me converting my comic from scroll format into page format for print, because I have much more art to work with than what's actually in the panels. (I'll touch on this later)

So, first, I make my backgrounds huge. my default starting size is 10,000 x 10,000 pixels. My panels are 2,500 pixels wide, so my backgrounds are 4x that, minimum. Because of this, I make them less detailed than I could or that you might expect so it doesn't look weird against my character art when I shrink portions of it down.

I personally find it much easier to add in detail than to make "removing" details look natural at smaller sizes, but you might have different preferences than I do.

I also make sure to keep all of my elements on separate layers so that I can easily remove or replace them, I can move them to simulate different camera angles more easily, and it's simple to adjust the lighting to imply different times of day.

Then I can go ahead and copy/paste them into my episodes. I move the background around until it feels like it's properly fitting how I want.

Once I've done that in every panel, I'll go back through the episode and clean up anything that looks weird, and add in solid blacks (for my art style) Here's a quick before and after of what that looks like!

This makes 90% of my backgrounds take me just a few hours. This is my tactic when I'm working in an environment that an entire scene, or multiple scenes, will take place.

But many panels will inevitably have a location that's used exactly once, and it would waste time and effort to draw a massive background for those. So in 10% of cases, I just draw the single panel background in the episode. I save all of these, just in case I can re-use it later (this happens more often with outdoor locations, but I save them all nonetheless!)

I generally have to draw about 2 big backgrounds per episode, and 3-5 single-panel backgrounds per episode! At the beginning of an arc/book the number is higher, but as the series is continuing and I'm building up an asset library of indoor and outdoor elements to re-use for the book, the number generally goes down and I save more time.

My series involves time travel and mysteries, so there's a lot of new locations in it and we're constantly moving around. If I were working on a series that was more consistent in this aspect, this process would save me even more time!

Like I said earlier, this also saves me a lot of pain and gives me a lot more options as I'm converting from scroll format to print format!

panels that look like this in scroll format...

can look like this in print!

because I drew the background like this, so I didn't need to go through the additional effort to add in the extra detail to expand it outwards at all.

Anyways, I hope this helps someone! As always if it doesn't help, just go ahead and disregard. This is what I do and what works for me, and I feel like I only ever see time-saving tips for comics that involve 3d models and workflows, which don't work for me at all! I know there's more people like me out there, so this is for you!

Enjoy!

Also obligatory "my webcomic" if you want to see this in action or check it out!

#webcomic tips#webcomic making#comic tips#comic tutorial#art tutorial#art tips#time and time again#my ocs#digital art#ttawebcomic#hmmmm....#longpost#yeah it's a long post#I'll claim this one#lots of images#I hope this helps#I'm always worried when I make some kind of guide or tutorial people are gonna get mad at me lmao#I'm not saying 3d models are bad to use!!!#I just dont like them!#my brain doesnt work like that and it feels SO so so so tedious to me#TO ME PERSONALLY!!!#plenty of people see 3d models as a total lifesaver#and that's perfectly fine!#but yeah I don't see tutorials about saving time in comics that like... dont... mention 3d models...#like what about me and the other extremely particular girlies who hate 3d#anyways#yeah#just hoping this helps#nothing against 3d at all#I mean. ok personally yes against it cause it sucks for me to use

1K notes

·

View notes

Text

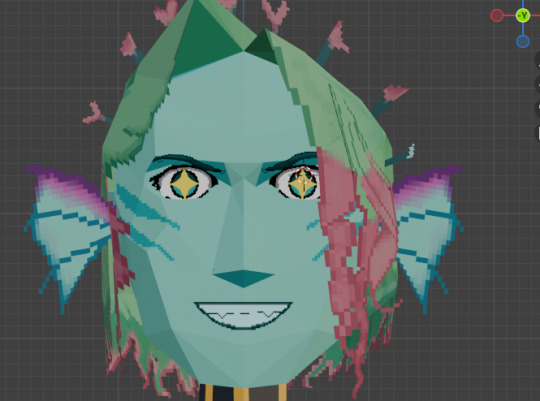

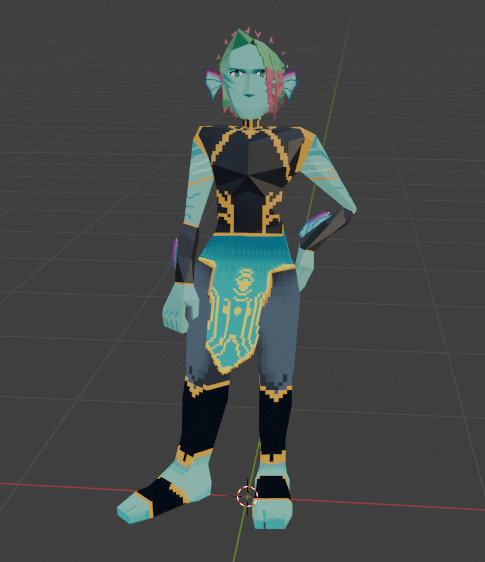

3D Gillion WIP

RAAGGHHH I have been in blender hell for like 3 weeks and I have nearly finished this low poly model of Gillion!!! Features a responsive 2d facial animation rig :3 I just have some bones to finish adding drivers to (and a sword and environment to model and texture) and then he is ready to animate!!! (nerd shit rant under cut)

I have been having a lot of fun learning blender!! in comparison to my first model in March of this year I think I have certainly come a long way!

Bonus: I am finally starting to understand the evil spaghetti

Here is the nodes for the 2d facial animation rig in all their glory! it's a whole process but a lot of fun I was using principled BSDF for shading up until the point of actually making the face rig which... does not work if you add a bunch of colour mix nodes so I had to switch to diffuse BSDF. If you're interested in learning how to make a rig this is the tutorial I followed it only covers the eyes but you can just copy the steps for making the eyes and use it to make additional bones for the mouth & eyebrows, adding them through colour mix nodes with alpha channels set to your textures like in my image!

I have also been using the pribambase plugin & aseprite to create my textures which I highly recommend! asesprite honestly is such a wonderful and intuitive program I had never made pixel art before starting this project and I know I certainly could be doing better (I am fully aware the model has mixels but I honestly don't hate the look personally which I know isn't the common take but whatever) but for my first time doing pixel art I'd say it's not too bad! Pribambase is a bit of a pain to set up now since the original creator has discontinued it and is no longer supporting it but it is still possible to find and use I am happy to teach anyone who would like to know!

Once the model is done I will be releasing my blender files & texture files as free to use for anyone who wants to animate with it or just play around & deconstruct! (with the exception of my animations) I am only learning myself so idk how useful they'll be but I would not have been able to make this model if it wasn't for kind modellers online who have released their files to deconstruct and learn from.

I have many plans for future blender projects all currently jrwi related (the brainrot is intense rn) & I am very excited to keep learning as I go! I currently have plans to make low-poly models of all the riptide pirates, the pd & the godslayers with animations in mind :p and I really wanna try some 3d sculpting (and maybe 3d printing) which I have wiwi in mind for... if any of these ideas get finished I will also release those models for free :)

156 notes

·

View notes

Text

Faeriekit's big fat library post: what is a public library for?

Things almost any public library will do:

Let you borrow books. (Specialty libraries and archives may not permit you to borrow delicate materials. You may be able to look at them nevertheless, but you dont know until you ask.)

Allow you to put items on hold! (Want us to pull a book or hold it for you? We'll set it aside under your name as soon as it's available!)

Allow you to join in for programming (may be as simple as kids storytimes, or as complicated as academic lectures. It's usually cooking classes and knitting sessions though when the budget gets short. We love outside presenters though, especially locals.)

Inter-library loans (don't have a rare book? We'll try to get it from another library!)

Things your library will PROBABLY let you do:

Let you borrow other forms of physical media, such as DVDs, Video Games, audiobooks, CDs, etc. (This may cost you extra depending on library policy.)

Let you borrow magazines! (It's not like you're paying for a subscription, unless you're me and you like mail. Let us get them for you.)

Print/fax/scan (depends on the tech available in your library; for instance, it costs your library money to maintain a fax-specific phone line, so they may not do fax. Again, price may vary.)

Access online databases! (Ah, Ebsco. We meet again.) (But sometimes there's some cool stuff. Genealogy databases, kids' encyclopedias, all kinds of cool stuff)

Borrow ebooks and eaudiobooks! And maybe even emagazines! (Despite what people say, Libby is NOT the only service that allows your library to share ebooks with your device. There's like five I can think of off the top of my head, and your library has to pay to play. Ask which service your library offers directly so you can get the good stuff)

Put up/look at flyers. (Good for sharing public information! I just used one of our advertised services to apply for low income housing. Love library wages...woo...)

Let you volunteer! Need something to add to your resume? Need wo build up some real world work skills in a low pressure environment?Spend some time with us!

Let you use public computers! Check your email or watch yt vids or apply for jobs. Up to you.

Play with board games or puzzles as long as you're there. They may even have a swap for people to trade!

Things your library MAY have to offer you:

Makerspace (cool tech that lives at the library you can use/pay to use, such as tools, 3d printers, etc.)

Borrowing cooler tech to take home (WiFi hotspots, single-use tablets, and other cool tech)

English courses! Learn with peers!

Borrowing actual tools! (I had one library card that let me borrow hiking stuff like tents and navigational tools and sewing machines and other cool stuff and they will not renew my card because policy changed and no I'm not crying—)

Museum passes (hey! Sometimes you can get into a museum for free or for cheap!)

Book requests (hey. If you tell the library to buy a book, we may just straight up buy it! Why not? It's a guaranteed circ!)

Social worker/social work help (depends on if your library can cut a deal with an organization that has social workers)

Paperwork help for seniors (I don't know how this works because our town handles this one.)

Notary public services! (This one's just straight up like. My boss.)

Tutoring services! (We have kid volunteers AND a paid online service subscription to a tutoring site. Not bad.)

Certain streaming options! (Movies and television right as your fingertips! Or. Well. You know.)

Home delivery for housebound folks! (This one again depends on staffing, resources, money, etc etc.)

Book purchase! (No, really. Sometimes there's old books for sale, or donor books for sale, to help keep libraries running.)

And, of course, sometimes your local librarians are geniuses and come up with things I haven't even thought of. The moral of the story is, libraries do a lot of things, but the majority of them, as you can probably tell, depend on size, budget, physical resources, and local support. If you are interested in any of these services, please reach out to your local library; even if they don't offer these services specifically, making your interest known tells the library what sort of things people are looking for in the community, and may even affect financial decisions down the road. The thing I would like to emphasize the most, however, is that you are likely already paying for these services in the form of tax dollars; if you do not physically go and find out what services you are entitled to, you will never be able to take advantage of them.

Call your local library today to find out the specifics!

137 notes

·

View notes

Photo

Researchers 3D print degradable polymers using salt

Dr. Emily Pentzer, associate professor in the Department of Materials Science and Engineering and the Department of Chemistry at Texas A&M University, is making 3D-printed polymers more environmentally friendly through a process that allows the polymers to naturally degrade over time. Pentzer's research is a collaborative effort that includes researchers from the Texas A&M College of Engineering, the Texas A&M Engineering Experiment Station, the Texas A&M Department of Chemistry and the University of Kashmir.

The research was published in the journal Angewandte Chemie.

"Our goal was to create sustainable degradable polymeric structures," Pentzer said. "We did this by leveraging the microstructures afforded by chemistry in conjunction with the macrostructures afforded by 3D printing."

Most commercial synthetic polymers consist of large molecules that do not break apart under normal conditions. When left in the environment, manufactured items such as Styrofoam cups or plastic containers break down into small pieces that are unseen by the naked eye, but the long polymer molecules remain present forever.

Read more.

24 notes

·

View notes

Text

#good news#nature#animals#environmentalism#science#climate change#conservation#environment#animal conservation#3d printing#extinction prevention

2 notes

·

View notes

Text

"An upcoming community center in Tanzania will be defined by its cutting-edge 3D-printed design. However, rather than being built from layered concrete as you'd usually expect with 3D-printed projects, its walls will be created using locally sourced soil.

The community center is being headed by Hassell, in collaboration with Australian-based charity foundation One Heart, for the Hope Village in Tanzania. It forms part of a wider plan to provide housing, a school, childcare and skills training to vulnerable young girls in Kibaha, eastern Tanzania.

"The Hope Village community hall design seeks to create a beautiful, functional, safe and uplifting environment that provides both hope and education for vulnerable girls," says Mark Loughnan, Principal and Head of Design at Hassell. "The hall is a welcoming space that creates an innovative central activity hub that also connects with its surrounding environment. The design and building process for the hall aims to engage the community and provide ongoing opportunities for local participation and education throughout construction."

Structurally, the community center is quite complex. Its walls (which are not load-bearing) will be built using soil sourced within 25 km (15.5 miles) of the site and a WASP 3D printer. WASP has been researching this stuff for years now and a previous project used a mixture of mud, straw, rice husk and lime. A similar process will be happening here, with a clay based earthen mixture being extruded out of a nozzle in layers to build up the walls. A representative at Hassell told us that the walls will also be reinforced with a thin wire mesh between layers.

Inside, the design brief calls for a large, open floorplan that suits the local climate, with a limited number of columns to ensure its flexibility. To achieve this, Hassell has conceived a central steel beam that serves as the structural spine of the hall. This will support a roof made from locally sourced timber sections. The roof will feature cladding made of readily available corrugated metal sheet panels, helping to keep costs down.

The project also involves the Institute for Advanced Architecture of Catalonia, IAAC, and ClarkeHopkinsClarke. We've no word yet on when it's expected to be completed, though prototype walls have already been produced.

Pictured: A prototype of the community center's 3D printed walls has already been created.

-via NewAtlas, August 13, 2024

#architecture#sustainable architecture#tanzania#africa#3d printing#sustainability#ecofriendly#good news#hope

222 notes

·

View notes

Text

even if i have to pay for it, i want to feel less lonely. it's not bad for me to want that, right?

i've heard a few wishes and requests for some kind of collected and/or even buyable version. thank you for your support and encouragement! i really appreciate it...!

i have to say though, my comic is sort of fundamentally not designed for other environments (including print) and is also strictly non-commercial

but i can uhh. give you pdfs so you can load them into a 3d book previewer and Pretend with me...... HRHJBDFDG

205 notes

·

View notes