#3D Printing Automation - 3D Printing Technology

Explore tagged Tumblr posts

Text

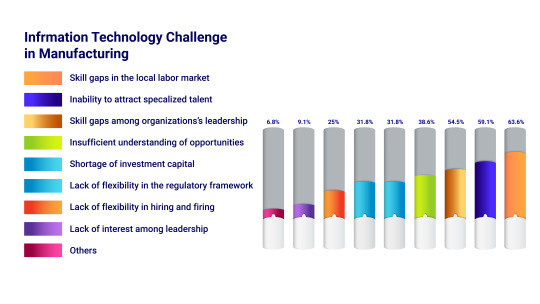

Efficient IT Implementation: 6 Steps for Manufacturing Companies to Succeed

The manufacturing industry has seen a significant transformation in recent years due to the introduction of various Information Technology (IT) innovations. These innovations have revolutionized manufacturing, making it more efficient, accurate, and profitable. In addition, IT solutions have enabled manufacturing companies to automate processes, analyze data, and optimize resources.

Information Technologies Role in Manufacturing

The manufacturing business has now reached a critical juncture because of the importance and significance of information technology (IT). For manufacturers to flourish in the market, they must compete internationally. As a result, the manufacturing sector is quickly changing for the betterment of the business, its workers, and its stockholders.

Digital technologies are altering every step of the value chain as they relate to the function of IT in the industrial industry. While developing new business models, this value chain combines product design, supply chain management, manufacturing, and customer experience. This blog will discuss how IT innovations are transforming the manufacturing industry.

Lets explore efficient IT implementation: 6 steps for manufacturing companies to succeed.

Automation (Robotics)

One of the most significant IT innovations in the manufacturing industry is automation, which involves using robots to carry out tasks previously done by humans. With automation, manufacturing businesses can produce products at a faster rate and with greater precision. It also eliminates the possibility of human error, thus improving the quality of the products.

The use of automation in the manufacturing sector has many advantages, including the following:

Automation helps companies reduce the time spent on manufacturing processes.

Companies can use capital and human resources by allocating workers involved in more important tasks.

Automation also improves the accuracy and quality of manufacturing engineering.

Automation helps do complex tasks and saves more expensive labor costs.

Automation helps manufacturers reach new heights of precision, safety, and productivity.

Automation also creates more jobs in the manufacturing sector.

Industrial Internet of Things (IIoT) or Smart Manufacturing

The Industrial Internet of Things (IIoT) is another IT innovation transforming the manufacturing industry. IIoT involves using sensors, devices, and software to monitor and control manufacturing processes. It enables manufacturers to collect data from their equipment and machines, allowing them to analyze and optimize their operations.

Smart manufacturing, a subset of IIoT, refers to integrating digital technologies into the manufacturing process. With smart manufacturing, manufacturers can connect all the elements of their manufacturing process, including people, machines, and materials, which can improve efficiency and reduce downtime.

The idea of "smart manufacturing" aids the manufacturing sector in several ways, including:

increasing output and reducing manufacturing costs.

communicating mechanically via the Internet.

identifying better opportunities for automated processes.

improving the workflow in the manufacturing plant.

monitoring the production process.

optimizing the entire manufacturing process.

working together to reduce errors.

3D printing (Additive Manufacturing)

Although it is still in its infancy, 3D printing has begun transforming manufacturing. Manufacturers, inventors, entrepreneurs, and small businesses can all benefit from 3D printing. It enables firms to create and produce high-quality goods more quickly. Also, it allows worldwide competition for entrepreneurs, small businesses, and inventors.

Advanced computer technology is used in additive manufacturing, also known as 3D printing, which favors digital designs for solid items. Todays manufacturers use technology to:

create prototypes.

produce parts in small numbers.

curtail time-to-market.

eliminate waste.

decrease production costs.

Additive manufacturing is excellent for higher-volume production because it reduces costs.

Predictive Analysis

Predictive analysis involves using data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes based on historical data.

Manufacturers can make goods to optimize profits by using predictive analytics to:

establish and prepare solutions for the manufacturing sector.

prevent prospective problems from occurring.

limit the harm as soon as possible if they do arise.

produce products to maximize profits.

Contemporary manufacturing operations and processes are evolving quickly due to a sharp rise in cloud storage capacities. As a result, extensive data analysis is used in predictive analytics to predict future consumer behavior and product demand trends.

Artificial Intelligence (AI)

Artificial Intelligence (AI) involves using algorithms and machine learning to analyze data and make decisions. In the manufacturing industry, AI is being used to improve the efficiency of the production process by optimizing the use of resources and reducing waste.

Predictive maintenance involves using AI algorithms to analyze data from machines and equipment to predict when care is needed. This helps to prevent downtime and reduces maintenance costs.

Automating processes and enabling machines are two benefits of algorithms AI to make complex decisions about

custom product configurations

Predictive/adaptive equipment maintenance

quality control (finding flaws)

Algorithms aid in data perception, pattern recognition, and experience-based learning in machines. For example, algorithms can recognize demand patterns for items across time, geographic markets, and socioeconomic segments when considering the supply chain.

On the other hand, sensors can monitor performance and operating conditions for preventive maintenance. Moreover, sensors can foresee failures and malfunctions so manufacturers can take preventative measures.

Blockchain Technology

Blockchain is a distributed ledger technology that allows for secure and transparent transactions. In the manufacturing industry, blockchain is used for supply chain management. With blockchain, manufacturers can track the movement of goods and materials through the supply chain, ensuring they are authentic and meet regulatory requirements.

By recording every step of a products journey, blockchain technology can help manufacturers to:

build more creative supply chains.

provide real-time visibility.

exact audit trails in the supply chain.

guard operations from fraud, theft, and cyberattacks.

take calculated business risks.

improve the loT by relieving IT of unnecessary technical complexity.

Cloud-based solutions are also becoming increasingly popular in the manufacturing industry. By using cloud-based solutions, manufacturers can access their data and applications from anywhere, allowing greater flexibility and mobility. This also allows for greater collaboration between teams and departments, improving communication and faster decision-making.

According to a report by MarketsandMarkets, the smart manufacturing market by enabling technologies for digital twins is expected to grow at a CAGR of 68.9% from 2022 to 2027, reaching USD 43.6 billion by 2027. Digital twins are being increasingly used to connect information about a physical product and its behavior in the real world with a 3D digital representation of that product.

Conclusion

The manufacturing industry has undergone a significant transformation in recent years due to the introduction of various IT innovations. Integrating IT into the manufacturing industry has significantly improved efficiency, quality, and profitability. Additionally, the use of IT in manufacturing has allowed for greater customization of products and the ability to produce smaller quantities without sacrificing efficiency. As we move forward, manufacturers must continue to embrace new IT innovations to remain competitive and drive growth in the industry.

Contact us now to get incredible manufacturing solutions.

#technology#information technology#automation#robotics#iiot#3d printing#artificial intelligence#blockchain

0 notes

Text

In today’s fast-paced world of logistics innovation and evolution have become the driving forces behind success. As we step into 2024, the logistics sector will undergo extensive disruptions, fueled by game-changing innovations that promise to revolutionize supply chain management as we know it.

At iFour, we take immense pride in our expertise in the logistics industry, and we are excited to share with you the trends that are currently transforming this dynamic sector in Australia. As a leading custom Logistics software development company, we understand the unique challenges and opportunities facing businesses in the Australian market.

Here are the key trends that are reshaping the logistics landscape and how our solutions can help your company stay ahead of the curve.

#Supply Chain Technology#E-commerce Logistics#Automation and Robotics#Blockchain in Logistics#Sustainable and Green Logistics#Last-Mile Delivery Solutions#Data Analytics and Predictive Insights#3D Printing in Logistics#IoT (Internet of Things) in Supply Chain#Artificial Intelligence in Transportation#On-Demand and Sharing Economy Logistics#Digital Twins in Warehousing#Autonomous Vehicles and Drones#Climate Change and Resilience Planning#Cross-Border Trade and Customs#Cybersecurity in Supply Chain#Inventory Management Strategies#Reverse Logistics and Returns#Multi-Modal Transportation#software outsourcing#software development company#.net development

0 notes

Text

Hobby Ideas 🎨💻🎵🧁🪴

💰 Hobbies to Make Money:

Freelance Writing

Photography

Graphic Design

Web Development

Online Selling (e.g., Etsy, Amazon, eBay, Shopify)

Blogging

Stock Trading

Real Estate Investing

Affiliate Marketing

Freelance Consulting

💪 Fitness Hobbies:

Running

Yoga

Weightlifting

Cycling

Swimming

Martial Arts

CrossFit

Hiking

Rock Climbing

Dance (e.g., Zumba, Hip-hop)

☀️ Outdoor Hobbies:

Camping

Fishing

Birdwatching

Gardening

Geocaching

Kayaking

Mountain Biking

Backpacking

Stargazing

Horseback Riding

💻 Technology Hobbies:

Programming

Robotics

3D Printing

Virtual Reality (VR) Gaming

Home Automation

Drone Flying

Cybersecurity

App Development

Electronics DIY

PC Building

🎵 Music Hobbies:

Playing an Instrument (e.g., Guitar, Piano)

Singing

DJing

Music Production

Songwriting

Music Recording

Karaoke

Music Theory

Joining a Band or Choir

Vinyl Collecting

📚 Brainy Hobbies:

Chess

Sudoku

Crossword Puzzles

Board Games

Reading

Learning a New Language

Brain Teasers

Logic Puzzles

Math and Mathematical Puzzles

Astronomy

✨ Other Hobbies:

Cooking and Baking

Painting and Drawing

Pottery and Ceramics

Woodworking

Knitting or Crocheting

DIY Home Improvement

Model Building (e.g., model trains, airplanes)

Collecting (e.g., stamps, coins, vintage items)

Volunteer Work

Meditation and Mindfulness

#hobbies#creative#creative inspiration#inspiration#creativity#creating#learning#skills#life skills#advice#life advice

741 notes

·

View notes

Text

AGARTHA Aİ - DEVASA+ (4)

In an era where technology and creativity intertwine, AI design is revolutionizing the way we conceptualize and create across various industries. From the runway to retail, 3D fashion design is pushing boundaries, enabling designers to craft intricate garments with unparalleled precision. Likewise, 3D product design is transforming everything from gadgets to furniture, allowing for rapid prototyping and innovation. As we explore these exciting advancements, platforms like Agartha.ai are leading the charge in harnessing artificial intelligence to streamline the design process and inspire new ideas.

AI design

Artificial intelligence (AI) has revolutionized numerous industries, and the realm of design is no exception. By leveraging the power of machine learning and advanced algorithms, AI is transforming the way designers create, innovate, and deliver their products. AI-driven tools enable designers to harness vast amounts of data, allowing for more informed decision-making and streamlined workflows.

In the context of graphic design, AI can assist artists in generating ideas, creating unique visuals, and even automating repetitive tasks. For instance, programs powered by AI design can analyze trends and consumer preferences, producing designs that resonate with target audiences more effectively than traditional methods. This shift not only enhances creativity but also enables designers to focus on strategic thinking and ideation.

Moreover, AI is facilitating personalized design experiences. With the help of algorithms that analyze user behavior, products can be tailored to meet the specific needs and tastes of individuals. This level of customization fosters deeper connections between brands and consumers, ultimately driving customer satisfaction and loyalty in an increasingly competitive market.

3D fashion design

In recent years, 3D fashion design has revolutionized the way we create and visualize clothing. Using advanced software and tools, designers can create lifelike virtual garments that allow for innovative experimentation without the need for physical fabric. This trend has not only streamlined the design process but has also significantly reduced waste in the fashion industry.

Moreover, 3D fashion design enables designers to showcase their creations in a more interactive manner. By utilizing 3D modeling and rendering technologies, designers can present their collections in virtual environments, making it easier for clients and consumers to appreciate the nuances of each piece. This immersive experience also helps in gathering valuable feedback before producing the final product.

Furthermore, the integration of 3D fashion design with augmented reality (AR) and virtual reality (VR) technologies is bringing a fresh perspective to the industry. Consumers can virtually try on clothes from the comfort of their homes, thereby enhancing the shopping experience. As this field continues to evolve, it promises to bridge the gap between creativity and technology, paving the way for a sustainable and forward-thinking fashion future.

3D product design

3D product design has revolutionized the way we conceptualize and create products. With advanced software tools and technologies, designers can now create highly detailed and realistic prototypes that are not only visually appealing but also functional. This process allows for a quicker iteration of ideas, enabling designers to experiment with various styles and functionalities before arriving at the final design.

One of the significant advantages of 3D product design is the ability to visualize products in a virtual environment. Designers can see how their creations would look in real life, which is essential for understanding aesthetics and usability. Additionally, this technology enables manufacturers to identify potential issues in the design phase, reducing costs associated with prototype development and rework.

Moreover, the rise of 3D printing has further enhanced the significance of 3D product design. Designers can swiftly turn their digital models into tangible products, allowing for rapid prototyping and small-batch manufacturing. This agility not only speeds up the time-to-market for new products but also paves the way for more innovative designs that were previously impossible to execute.

Agartha.ai

Agartha.ai is a revolutionary platform that merges artificial intelligence with innovative design, creating a new avenue for designers and creators alike. With the rapid advancements in technology, Agartha.ai leverages AI to streamline various design processes, enabling users to produce unique and captivating designs with ease.

The platform provides tools that empower both emerging and established designers to explore the possibilities of AI design. By utilizing intelligent algorithms, Agartha.ai can assist in generating design options, ensuring that creativity is not hindered but enhanced. This results in a more efficient workflow and allows designers to focus on the conceptual aspects of their projects.

One of the standout features of Agartha.ai is its ability to adapt to different design disciplines, such as 3D fashion design and 3D product design. By supporting a broad spectrum of design fields, it positions itself as a versatile tool that meets the evolving needs of today's creative professionals. Whether it's crafting intricate fashion pieces or developing innovative product designs, Agartha.ai is at the forefront of the design revolution.

329 notes

·

View notes

Text

Laser-based processes for metals are considered to be particularly versatile in industry. Lasers can be used, for example, to precision-weld components together or produce more complex parts using 3D printing -- quickly, precisely and automatically. This is why laser processes are used in numerous sectors, such as the automotive and aviation industries, where maximum precision is required, or in medical technology, for example for the production of customized titanium implants. However, despite their efficiency, laser processes are technically challenging. The complex interactions between the laser and the material make the process sensitive to the smallest of deviations -- whether in the material properties or in the settings of the laser parameters. Even minor fluctuations can lead to errors in production.

Read more.

#Materials Science#Science#Lasers#Materials processing#Metals#3D printing#Additive manufacturing#Powder bed fusion

3 notes

·

View notes

Text

Austin’s 3D printed neighborhood could signal a shift in homebuilding (video)

- By Nuadox Crew -

On the outskirts of Austin, Texas, a groundbreaking housing development is taking shape—literally—layer by layer. The project, a collaboration between homebuilding giant Lennar and construction tech firm Icon, marks the largest community of 3D printed homes in the world.

youtube

Video: "Inside The World’s Largest 3D Printed Neighborhood" by CNBC, YouTube.

With 100 houses built over two years, the initiative serves as a pilot for faster, more cost-effective construction methods.

The development comes at a critical time for the U.S. housing market, which faces a shortage of approximately four million homes. Rising labor costs and soaring material prices have made homeownership increasingly out of reach for many Americans. Against this backdrop, 3D printing is being tested as a viable way to increase supply and stabilize costs.

For Holly, one of the community’s first residents, the benefits are already evident. She and her family were drawn to the home’s sleek design and promise of energy efficiency. A year later, she reports consistently low electric bills—just $26 in January—and appreciates the home’s resistance to wind, fire, and mold. At just under $400,000, the price point is competitive with larger, traditionally built homes in the area.

At the heart of the construction process is Icon’s robotic technology, which can produce a house in roughly two weeks. The system relies on digital blueprints uploaded to a proprietary platform called Build OS, which automates structural reinforcement, wiring, and plumbing. With only three workers needed to operate the machinery, the process is a significant step toward labor reduction—a key factor in scaling affordable housing.

The project encountered early setbacks. Initial builds took longer and cost more than expected. But through trial and error, the team refined their methods—adjusting wall thickness and adopting more open floor plans to streamline production.

Lennar and Icon are already preparing their next phase: a new community featuring twice as many homes, lower price points, and enhanced 3D printing capabilities that could eventually fabricate complete building envelopes, including roofs and foundations. The technology also holds promise for disaster-prone regions, where fire-resistant materials and durable design could be life-saving.

Although 3D printed homes have yet to match the profitability of conventional construction, the partnership signals a broader transformation in an industry long resistant to change. If successful, this model could pave the way for more sustainable, resilient, and accessible housing across the country.

Header image credit: Icon

Related Content

What is Energy House 2.0?

Other Recent News

Ultra-thin wearable haptics: A flexible patch brings tactile sensations to virtual experiences.

Innovative sponge-like device harvests moisture directly from the air.

2 notes

·

View notes

Text

3D Printing: Africa's Solution to its Housing Crisis?

Is it the future of design in Africa?

3D Printing Concrete Structures in Angola

I recently came across an article on Arch Daily about the nation of Angola using 3D Printing Technology to address its housing shortage.

Like most other African nations the population boom happening across the continent, combined with the rapid urbanisation of previously rural population, a large demand has been placed on services to meet the needs of the ever expanding occupants.

One of those demands being housing. The culture of Africa is shifting, in a not so distant past, housing needs were met simply by building a hut in a rural community and most often by were built by the owner of the home. Fast forward to today where there are things now like zoning laws, building codes, health and safety regulations and by-laws that must be upheld by registered and qualified architects, engineers and other specialised building service providers, not to mention the evolving styles and need to meet contemporary design standards as well as the considerations for sustainability and environmental considerations and conservation efforts.

No longer is Africa like the past where basic housing needs were met through cultural designs that often fell into a community. In fact, Africa is growing even further away from its roots of cultural communities and adopting more individualistic mindset shifts which coincides with the growing urbanisation of the African social landscape.

There is no doubt that with the rise of technology that there is a shift being made to things becoming more automated in turn making 3D printing the future of where the construction industry is heading, with recent showcases from BIG and other large architectural practices envisioning the future of architectural design through 3D printing structures for space colonies on the moon and mars.

Design and the construction industry is changing, but is Africa set to keep up with this rapid pace at which the world is shifting? 3D printing still considerably in its early stages can hardly be considered to replace the labour force just yet, but the strides that have been made in the field have a considerable impact in the shift of contemporary design thinking.

The Angolan government has made a very progressive step in taking this bold approach in using this innovative method to meet the housing shortage needs of its nation. But would this significantly make a dent in the speed at which the houses are built? And if other nations were to follow suit there are a myriad of challenges that would need to firstly be overcome in order to effectively adopt this technology and incorporate it as a viable construction method to facilitate rapid construction for projects, those being

Lack of Consistent Power Supply

Skilled Labour in designing, operating, and maintaining the 3D printing equipment

Corruption and lack of accountability in meeting project deadlines and misuse of project funds, as well as nepotism within the Government.

The loss of cultural and individual identity of nations as designs and architecture become more homogeneous, using modular design to easily replicate and mass produce homes

Long-term environmental and sustainability impacts of these types of housing projects and their ultimate carbon footprint and lifecycle, as well as the impact on the circular economy

All in all, Africa has a long way to go before adopting 3D printing technology as its main mode of constructing housing and other projects, but these conversations can begin to take place among leaders and policy makers to ensure that African nations are keeping up to pace with the rising urbanisation and the growing advancements in the technological sphere of the construction industry.

youtube

youtube

youtube

#architecture#design#african#creativity#3d printing#african architecture#urban planning#urban landscape#cityscape#africa#3D Print#Youtube

2 notes

·

View notes

Text

3D Printing: Saving weight and space at launch

Additive manufacturing, also known as 3D printing, is regularly used on the ground to quickly produce a variety of devices. Adapting this process for space could let crew members create tools and parts for maintenance and repair of equipment on the spot, rather than trying to bring along every item that might be needed.

The ability to manufacture things in space is especially important in planning for missions to the moon and Mars because additional supplies cannot quickly be sent from Earth and cargo capacity is limited.

Research on the International Space Station is helping to develop the capability to address multiple needs using 3D printing.

Metal 3D Printer, a current investigation from ESA (European Space Agency), tests 3D printing of small metal parts in microgravity. Results could improve understanding of the function, performance, and operations of 3D printing in space with metal, as well as the quality, strength, and characteristics of printed parts. This work also could benefit applications on Earth that use metal, such as the automotive, aeronautical, and maritime industries.

3D Printing in Zero-G sent the first 3D printer, developed by NASA's Marshall Space Flight Center and Redwire (formerly Made in Space), to the space station in 2014. The printer used a process that feeds a continuous thread of plastic through a heated extruder and onto a tray layer by layer to create an object. The investigation produced more than a dozen parts, including a ratchet wrench, showing that researchers could send a design from the ground to the system on the station more than 200 miles above.

Comparing the parts made in space with those made on the ground showed that microgravity had no significant effect on the process.

Redwire then developed the Additive Manufacturing Facility (AMF), sent to the station in 2015. Researchers evaluated its mechanical performance and found improvements in tension strength and flexibility compared to the earlier demonstration, helping to further the technology for this type of manufacturing on Earth and in space.

In 2015 and 2016, Portable On Board 3D Printer tested an automated printer developed by the Italian Space Agency to produce plastic objects in space. The investigation provided insight into how the material behaves in microgravity, which could support development of European additive manufacturing technology for use in space.

Printing with other materials

Another approach is recycling plastic—for example, turning a used 3D-printed wrench into a spoon and creating items from the plastic bags and packing foam needed to send supplies to space. This technology could help reduce the amount of raw material at launch and cut down on the volume of waste that must be disposed of on long journeys.

The Refabricator, a machine created by Tethers Unlimited Inc, tested this approach and successfully manufactured its first object. Some issues occurred in the bonding process, likely caused by microgravity, but assessment of the material could help determine whether there are limits to how many times plastic can be re-used. Ultimately, researchers plan to create a database of parts that can be manufactured using the space station's capabilities.

Redwire Regolith Print (RRP) tested another kind of feedstock for 3D manufacturing in orbit, a simulated version of regolith, the dust present on the surface of the moon and other planetary bodies. Results could lead to development of technology for using regolith to construct habitats and other structures rather than bringing raw materials from Earth.

The space station also has hosted studies of a form of 3D printing called biological printing or bioprinting. This process uses living cells, proteins, and nutrients as raw materials to potentially produce human tissues for treating injury and disease, which could benefit future crews and patients on Earth.

Other manufacturing techniques tested on the orbiting lab include producing optical fibers and growing crystals for synthesizing pharmaceuticals and fabricating semiconductors.

TOP IMAGE: The first metal part 3D printed in space. Credit: ESA

CENTRE IMAGE: NASA Astronaut Butch Wilmore holds a ratchet wrench created with the 3D Printing in Zero-G printer. Credit: NASA

LOWER IMAGE: The Redwire Regolith Print facility before launch to the space station. Credit: Redwire Space

3 notes

·

View notes

Link

4 Min Read 3D Printing: Saving Weight and Space at Launch The first metal part 3D printed in space. Credits: ESA Science in Space March 2025 Additive manufacturing, also known as 3D printing, is regularly used on the ground to quickly produce a variety of devices. Adapting this process for space could let crew members create tools and parts for maintenance and repair of equipment on the spot, rather than trying to bring along every item that might be needed. The ability to manufacture things in space is especially important in planning for missions to the Moon and Mars because additional supplies cannot quickly be sent from Earth and cargo capacity is limited. Research on the International Space Station is helping to develop the capability to address multiple needs using 3D printing. NASA astronaut Jeanette Epps configures the Metal 3D Printer to produce experimental samples from stainless steel.NASA Metal 3D Printer, a current investigation from ESA (European Space Agency), tests 3D printing of small metal parts in microgravity. Results could improve understanding of the function, performance, and operations of 3D printing in space with metal, as well as the quality, strength, and characteristics of printed parts. This work also could benefit applications on Earth that use metal, such as the automotive, aeronautical, and maritime industries. Printing with plastic NASA Astronaut Butch Wilmore holds a ratchet wrench created with the 3D Printing in Zero-G printer.NASA 3D Printing in Zero-G sent the first 3D printer, developed by NASA’s Marshall Space Flight Center and Redwire (formerly Made in Space), to the space station in 2014. The printer used a process that feeds a continuous thread of plastic through a heated extruder and onto a tray layer by layer to create an object. The investigation produced more than a dozen parts, including a ratchet wrench, showing that researchers could send a design from the ground to the system on the station more than 200 miles above. Comparing the parts made in space with those made on the ground showed that microgravity had no significant effect on the process. Redwire then developed the Additive Manufacturing Facility (AMF), sent to the station in 2015. Researchers evaluated its mechanical performance and found improvements in tension strength and flexibility compared to the earlier demonstration, helping to further the technology for this type of manufacturing on Earth and in space. In 2015 and 2016, Portable On Board 3D Printer tested an automated printer developed by the Italian Space Agency to produce plastic objects in space. The investigation provided insight into how the material behaves in microgravity, which could support development of European additive manufacturing technology for use in space. Printing with other materials NASA astronaut Anne McClain installs the Refabricator in Feb. 2019.NASA Another approach is recycling plastic – for example, turning a used 3D-printed wrench into a spoon and creating items from the plastic bags and packing foam needed to send supplies to space. This technology could help reduce the amount of raw material at launch and cut down on the volume of waste that must be disposed of on long journeys. The Refabricator, a machine created by Tethers Unlimited Inc, tested this approach and successfully manufactured its first object. Some issues occurred in the bonding process, likely caused by microgravity, but assessment of the material could help determine whether there are limits to how many times plastic can be re-used. Ultimately, researchers plan to create a database of parts that can be manufactured using the space station’s capabilities. The Redwire Regolith Print facility before launch to the space station.Redwire Space Redwire Regolith Print (RRP) tested another kind of feedstock for 3D manufacturing in orbit, a simulated version of regolith, the dust present on the surface of the Moon and other planetary bodies. Results could lead to development of technology for using regolith to construct habitats and other structures rather than bringing raw materials from Earth. The space station also has hosted studies of a form of 3D printing called biological printing or bioprinting. This process uses living cells, proteins, and nutrients as raw materials to potentially produce human tissues for treating injury and disease, which could benefit future crews and patients on Earth. Other manufacturing techniques tested on the orbiting lab include producing optical fibers and growing crystals for synthesizing pharmaceuticals and fabricating semiconductors.

2 notes

·

View notes

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

2 notes

·

View notes

Text

How-To IT

Topic: Core areas of IT

1. Hardware

• Computers (Desktops, Laptops, Workstations)

• Servers and Data Centers

• Networking Devices (Routers, Switches, Modems)

• Storage Devices (HDDs, SSDs, NAS)

• Peripheral Devices (Printers, Scanners, Monitors)

2. Software

• Operating Systems (Windows, Linux, macOS)

• Application Software (Office Suites, ERP, CRM)

• Development Software (IDEs, Code Libraries, APIs)

• Middleware (Integration Tools)

• Security Software (Antivirus, Firewalls, SIEM)

3. Networking and Telecommunications

• LAN/WAN Infrastructure

• Wireless Networking (Wi-Fi, 5G)

• VPNs (Virtual Private Networks)

• Communication Systems (VoIP, Email Servers)

• Internet Services

4. Data Management

• Databases (SQL, NoSQL)

• Data Warehousing

• Big Data Technologies (Hadoop, Spark)

• Backup and Recovery Systems

• Data Integration Tools

5. Cybersecurity

• Network Security

• Endpoint Protection

• Identity and Access Management (IAM)

• Threat Detection and Incident Response

• Encryption and Data Privacy

6. Software Development

• Front-End Development (UI/UX Design)

• Back-End Development

• DevOps and CI/CD Pipelines

• Mobile App Development

• Cloud-Native Development

7. Cloud Computing

• Infrastructure as a Service (IaaS)

• Platform as a Service (PaaS)

• Software as a Service (SaaS)

• Serverless Computing

• Cloud Storage and Management

8. IT Support and Services

• Help Desk Support

• IT Service Management (ITSM)

• System Administration

• Hardware and Software Troubleshooting

• End-User Training

9. Artificial Intelligence and Machine Learning

• AI Algorithms and Frameworks

• Natural Language Processing (NLP)

• Computer Vision

• Robotics

• Predictive Analytics

10. Business Intelligence and Analytics

• Reporting Tools (Tableau, Power BI)

• Data Visualization

• Business Analytics Platforms

• Predictive Modeling

11. Internet of Things (IoT)

• IoT Devices and Sensors

• IoT Platforms

• Edge Computing

• Smart Systems (Homes, Cities, Vehicles)

12. Enterprise Systems

• Enterprise Resource Planning (ERP)

• Customer Relationship Management (CRM)

• Human Resource Management Systems (HRMS)

• Supply Chain Management Systems

13. IT Governance and Compliance

• ITIL (Information Technology Infrastructure Library)

• COBIT (Control Objectives for Information Technologies)

• ISO/IEC Standards

• Regulatory Compliance (GDPR, HIPAA, SOX)

14. Emerging Technologies

• Blockchain

• Quantum Computing

• Augmented Reality (AR) and Virtual Reality (VR)

• 3D Printing

• Digital Twins

15. IT Project Management

• Agile, Scrum, and Kanban

• Waterfall Methodology

• Resource Allocation

• Risk Management

16. IT Infrastructure

• Data Centers

• Virtualization (VMware, Hyper-V)

• Disaster Recovery Planning

• Load Balancing

17. IT Education and Certifications

• Vendor Certifications (Microsoft, Cisco, AWS)

• Training and Development Programs

• Online Learning Platforms

18. IT Operations and Monitoring

• Performance Monitoring (APM, Network Monitoring)

• IT Asset Management

• Event and Incident Management

19. Software Testing

• Manual Testing: Human testers evaluate software by executing test cases without using automation tools.

• Automated Testing: Use of testing tools (e.g., Selenium, JUnit) to run automated scripts and check software behavior.

• Functional Testing: Validating that the software performs its intended functions.

• Non-Functional Testing: Assessing non-functional aspects such as performance, usability, and security.

• Unit Testing: Testing individual components or units of code for correctness.

• Integration Testing: Ensuring that different modules or systems work together as expected.

• System Testing: Verifying the complete software system’s behavior against requirements.

• Acceptance Testing: Conducting tests to confirm that the software meets business requirements (including UAT - User Acceptance Testing).

• Regression Testing: Ensuring that new changes or features do not negatively affect existing functionalities.

• Performance Testing: Testing software performance under various conditions (load, stress, scalability).

• Security Testing: Identifying vulnerabilities and assessing the software’s ability to protect data.

• Compatibility Testing: Ensuring the software works on different operating systems, browsers, or devices.

• Continuous Testing: Integrating testing into the development lifecycle to provide quick feedback and minimize bugs.

• Test Automation Frameworks: Tools and structures used to automate testing processes (e.g., TestNG, Appium).

19. VoIP (Voice over IP)

VoIP Protocols & Standards

• SIP (Session Initiation Protocol)

• H.323

• RTP (Real-Time Transport Protocol)

• MGCP (Media Gateway Control Protocol)

VoIP Hardware

• IP Phones (Desk Phones, Mobile Clients)

• VoIP Gateways

• Analog Telephone Adapters (ATAs)

• VoIP Servers

• Network Switches/ Routers for VoIP

VoIP Software

• Softphones (e.g., Zoiper, X-Lite)

• PBX (Private Branch Exchange) Systems

• VoIP Management Software

• Call Center Solutions (e.g., Asterisk, 3CX)

VoIP Network Infrastructure

• Quality of Service (QoS) Configuration

• VPNs (Virtual Private Networks) for VoIP

• VoIP Traffic Shaping & Bandwidth Management

• Firewall and Security Configurations for VoIP

• Network Monitoring & Optimization Tools

VoIP Security

• Encryption (SRTP, TLS)

• Authentication and Authorization

• Firewall & Intrusion Detection Systems

• VoIP Fraud DetectionVoIP Providers

• Hosted VoIP Services (e.g., RingCentral, Vonage)

• SIP Trunking Providers

• PBX Hosting & Managed Services

VoIP Quality and Testing

• Call Quality Monitoring

• Latency, Jitter, and Packet Loss Testing

• VoIP Performance Metrics and Reporting Tools

• User Acceptance Testing (UAT) for VoIP Systems

Integration with Other Systems

• CRM Integration (e.g., Salesforce with VoIP)

• Unified Communications (UC) Solutions

• Contact Center Integration

• Email, Chat, and Video Communication Integration

2 notes

·

View notes

Text

Vehicle Design and Manufacturing Processes

Introduction: Vehicle design and manufacturing processes have evolved dramatically over the years. From manual assembly lines to high-tech automation, the automotive industry has witnessed numerous advancements that enhance vehicle performance, safety, and sustainability. This blog explores the latest trends in vehicle design and the manufacturing processes that are transforming the industry.

Design Considerations: Designing a vehicle is a complex and multi-disciplinary process that involves engineering, aerodynamics, ergonomics, safety, and aesthetics. Engineers must consider factors like fuel efficiency, performance, and environmental impact, all while ensuring the vehicle’s safety for occupants and pedestrians.

For example, modern car designs prioritize aerodynamics to reduce fuel consumption, with sleek shapes and specialized components that minimize air resistance. Additionally, the safety of the vehicle is ensured by incorporating advanced safety systems, such as collision avoidance technologies, airbags, and crumple zones.

Manufacturing Technologies: The rise of automation has revolutionized vehicle manufacturing. Robotic arms, AI, and 3D printing are now integral to automotive production. Robotics allows for faster and more precise assembly, while AI systems help in predicting maintenance needs and optimizing production schedules.

One significant advancement is the use of 3D printing for creating prototype parts and even some vehicle components. This technology enables manufacturers to design and produce intricate parts with reduced material waste and lower costs. Additionally, automation has sped up assembly lines, allowing for mass production while maintaining consistent quality.

Sustainability: As the world becomes more eco-conscious, the automotive industry has shifted toward more sustainable practices. Electric vehicles (EVs) are at the forefront of this revolution, offering a cleaner alternative to traditional gasoline-powered cars. In addition to EVs, car manufacturers are adopting environmentally friendly materials, such as recycled plastics and plant-based composites, to reduce the carbon footprint of their vehicles.

Furthermore, energy-efficient manufacturing practices, such as using renewable energy to power factories and reducing waste, are helping the industry move toward a more sustainable future.

Future Trends: The future of vehicle design and manufacturing is exciting. One of the biggest trends is the development of autonomous vehicles, which use sensors, AI, and machine learning to navigate roads without human intervention. These vehicles promise to increase safety, reduce traffic, and improve transportation efficiency.

Modular vehicle design is also gaining traction. This approach allows manufacturers to produce customizable vehicles with interchangeable components, which can be tailored to meet different customer needs.

Conclusion: The automotive industry is undergoing a revolution, driven by innovative design principles and advanced manufacturing technologies. As sustainability becomes increasingly important and new technologies such as autonomous driving and electric vehicles take center stage, the future of vehicle design looks promising. By continuing to prioritize safety, efficiency, and environmental responsibility, the industry will continue to transform how we think about transportation.

For comprehensive information and resources on engineering topics, please visit the Engineer's Heaven website.

2 notes

·

View notes

Text

Additive Manufacturing Market Size, Anticipating Growth Prospects from 2034

The world additive manufacturing market stands at US$ 26.79 billion in 2024 according to a fresh study released by Fact.MR, a market research and competitive intelligence firm. Global sales of additive manufacturing solutions are anticipated to grow ahead at 21.6% CAGR during 2024-2034.

More companies these days are likely to sustainable production practices because of their positive impacts on the environment. Compared to conventional production, additive manufacturing offers a number of environmental benefits. Energy and waste reduction are two significant benefits of additive manufacturing technologies over conventional production processes. Additive manufacturing eliminates the use of extra materials required for production with greater efficiency.

3D printing is chosen as the most advanced and latest manufacturing method. This technology is gaining popularity and capable of replacing conventional manufacturing methods in a number of end-use sectors. Medical, electronics, aerospace, defense, and other sectors are willing to embrace these additive manufacturing methods. Advances in electronics manufacturing are expected to result in more automation, and, in turn, additive manufacturing technologies.

Get Free Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9254

Key Takeaway from Market Study

The international additive manufacturing industry is valued at US$ 26.79 billion in the year 2024.

Global additive manufacturing technologies demand is to value at US$ 189.34 billion as of the year 2034.

The market is estimated to grow with a productive CAGR of 21.6% during 2024 to 2034.

North America will dominate with a share of 29.1% in the world's additive manufacturing industry as of the year 2034.

China's demand for additive manufacturing technologies is expected to grow at 22.4% CAGR between 2024 and 2034.

Canada's market is expected to be US$ 9.26 billion by the end of 2034.

The medical sector is expected to have 22.1% of the total market revenue worldwide by 2034.

"Growing usage of additive manufacturing methods across various industries, such as aerospace and defense, to create intricate parts and light-weight components is anticipated to be one of the major growth drivers," provides a Fact.MR analyst.

��Browse Full Report: https://www.factmr.com/report/additive-manufacturing-market

Key Market Players

Renishaw Plc.,

Wipro Limited,

Materialise,

ANSYS, Inc.,

Evonik,

Siemens Industry Software Inc.,

Stratasys Ltd.,

General Electric,

Xerox Corporation,

AMFG,

Mazak Corporation,

American Additive Manufacturing LLC,

Optomec are leading additive manufacturing solution providers.

Growing Adoption of Additive Manufacturing in Automotive Sector

Demand for additive manufacturing solutions in the automotive industry is forecasted to grow at 23% CAGR and reach a market value of US$ 27.64 billion by the end of 2034. Increased adoption of additive manufacturing methods is responsible for the simplification of the supply chain, speeding up prototyping, making customization easier, and allowing the manufacture of lightweight parts.

More Valuable Insights on Offer

Fact.MR, in its new offering, presents an unbiased analysis of the additive manufacturing market, presenting historical demand data for 2018 to 2023 and forecast statistics for 2024 to 2034.

The study divulges essential insights into the market based on product type (hardware, material, software), technology (power bed fusion, direct energy deposition, material jetting, material extrusion, photopolymerization), and application (medical, automotive, aerospace & defense, consumer electronics, architecture, industrial equipment, education & research institutions), across six major regions of the world (North America, Europe, East Asia, Latin America, South Asia & Oceania, and MEA).

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

How Will Interior Design Evolve in the Future?

Interior design is a dynamic field that continually adapts to new trends, technologies, and cultural shifts. As we look ahead, the future of interior design promises to be even more innovative and responsive to the needs of a changing world. In this article, we'll explore the trends and technologies that are set to shape the interiors of tomorrow.

1. Embracing Sustainable Design

One of the most significant shifts in interior design is the growing emphasis on sustainability. As concerns about climate change and resource depletion intensify, designers are prioritizing eco-friendly materials and practices.

Eco-Friendly Materials: The future will see a rise in the use of sustainable materials like reclaimed wood, bamboo, and recycled metals. These materials not only reduce environmental impact but also add a unique aesthetic to spaces.

Energy Efficiency: Future interiors will incorporate energy-efficient lighting, smart thermostats, and solar panels. Homes and offices will be designed to minimize energy consumption and reduce carbon footprints.

2. Smart Homes and Integrated Technology

Smart home technology is revolutionizing how we interact with our living spaces. The future will see even more integration of smart devices, creating homes that are not only more convenient but also more efficient.

Voice-Controlled Systems: Imagine controlling your entire home with just your voice. From adjusting lighting to setting the thermostat, voice-controlled systems will make daily tasks effortless.

Automated Solutions: Future homes will feature advanced automation systems that can learn and adapt to your routines. This includes everything from automated blinds that adjust based on sunlight to refrigerators that order groceries when supplies run low.

3. Personalization and Customization

As technology advances, so does our ability to personalize our living spaces. The future of interior design will see a shift towards highly customized environments that reflect individual tastes and lifestyles.

3D Printing: 3D printing technology will allow for the creation of bespoke furniture and decor items. This means that you can have unique, one-of-a-kind pieces that perfectly fit your space and style.

Modular Furniture: Future homes will increasingly feature modular furniture that can be easily reconfigured to suit different needs and occasions. This flexibility will be especially valuable in smaller living spaces.

4. Biophilic Design

Biophilic design, which seeks to connect occupants more closely to nature, will become a central theme in future interiors. This approach not only enhances aesthetic appeal but also promotes well-being.

Natural Elements: Expect to see more use of natural materials like stone, wood, and plants. Large windows and indoor gardens will bring the outdoors inside, creating a calming and rejuvenating atmosphere.

Health Benefits: Biophilic design has been shown to reduce stress, improve mood, and boost productivity. Future interiors will leverage these benefits to create healthier living and working environments.

5. Flexible and Multi-Functional Spaces

As urbanization continues and living spaces become more compact, the need for flexible and multi-functional interiors will grow. Future designs will focus on maximizing the utility of every square foot.

Convertible Furniture: Furniture that can serve multiple purposes will be key. Think of sofas that convert into beds, desks that transform into dining tables, and walls that can be moved to create different room configurations.

Adaptable Layouts: Future homes will feature layouts that can be easily adapted to different activities. This could include movable walls or partitions that allow for seamless transitions between work, leisure, and living spaces.

6. Wellness-Centric Design

The future of interior design will place a greater emphasis on wellness. As people become more health-conscious, interiors will be designed to support physical and mental well-being.

Ergonomic Furniture: Expect to see more furniture designed with ergonomics in mind, promoting better posture and reducing strain.

Air and Water Quality: Future homes will incorporate advanced filtration systems to ensure clean air and water, contributing to overall health.

7. Minimalism with a Twist

While minimalism will continue to be a popular trend, future interior design will infuse it with more personality and warmth.

Warm Minimalism: This approach combines the clean lines and simplicity of minimalism with cozy textures and inviting colors. The result is a space that feels both serene and welcoming.

Functional Minimalism: Future minimalism will focus on functionality, ensuring that every piece of furniture and decor serves a purpose. This creates uncluttered spaces that are easy to maintain and live in.

8. Tech-Infused Spaces

As technology continues to advance, it will become even more seamlessly integrated into our living spaces.

Augmented Reality (AR): AR will allow homeowners to visualize changes to their interiors before making them. This could include trying out new paint colors, furniture arrangements, or decor items virtually.

Smart Kitchens: The kitchens of the future will be equipped with smart appliances that can help with meal planning, grocery shopping, and even cooking. This will make it easier to maintain a healthy diet and save time.

9. Cultural and Global Influences

Globalization and cultural exchange will continue to influence interior design, bringing diverse styles and ideas into homes around the world.

Ethnic Decor: Expect to see more incorporation of decor items from different cultures, adding richness and diversity to interiors.

Global Design Trends: Designers will draw inspiration from around the world, blending traditional and contemporary elements to create unique and eclectic spaces.

10. Focus on Longevity and Timelessness

In contrast to the fast fashion trend in clothing, future interior design will emphasize longevity and timelessness.

Quality Over Quantity: There will be a shift towards investing in high-quality, durable furniture and decor that can withstand the test of time.

Timeless Aesthetics: Interiors will favor classic designs and neutral color palettes that won't go out of style, ensuring that spaces remain elegant and relevant for years to come.

Conclusion

The future of interior design is exciting and full of possibilities. From sustainability and smart technology to personalization and wellness, the trends and innovations on the horizon promise to transform how we live and interact with our spaces. As we move forward, the key will be to embrace these changes while creating environments that are not only beautiful but also functional, healthy, and reflective of our personal values and lifestyles. The interiors of the future will be more than just spaces to live in—they will be spaces that enhance our lives in meaningful ways.

4 notes

·

View notes

Text

Food Processing Revolution: Innovations Shaping the Industry

In the dynamic domain of food processing, innovation serves as the fundamental basis for advancement. The food processing business has seen a significant evolution over time, mostly influenced by technological improvements, shifting customer preferences, and an increasing recognition of the importance of sustainability and health. The revolution in question has had a profound impact on the methods employed in the production, packaging, and consumption of food. Make Vadodara the hub of your efficient food processing. Explore solutions for improved productivity, quality, and compliance at Modern Food Products - ranked among the top companies in the Food processing industry in Vadodara!

This blog post aims to explore the noteworthy advancements that are now affecting the food processing industry and their impact on its overall trajectory.

· Automation and Robotics:

In the dynamic domain of food processing, innovation serves as the fundamental basis for advancement. The food processing business has seen a significant evolution over time, mostly influenced by technological improvements, shifting customer preferences, and an increasing recognition of the importance of sustainability and health. The revolution in question has had a profound impact on the methods employed in the production, packaging, and consumption of food. This blog post aims to explore the noteworthy advancements that are now affecting the food processing industry and their impact on its overall trajectory.

· Internet of Things (IoT) and Data Analytics:

The incorporation of Internet of Things (IoT) technology in the food processing industry enables the continuous monitoring of production lines in real time, hence facilitating the achievement of optimal performance and the reduction of wastage. Internet of Things (IoT) devices have the capability to gather significant data, which can be subjected to analysis in order to enhance process optimisation, forecast maintenance requirements, and enhance overall quality control. The utilisation of data analytics offers significant insights into customer behaviour, hence empowering enterprises to customise their products in accordance with specific tastes.

· 3D Printing in Food Manufacturing:

The utilisation of 3D printing technology in the realm of food manufacturing has garnered significant attention due to its ability to provide novel and tailored solutions for the creation of complicated and personalised food designs. The utilisation of 3D printing technology has the capacity to significantly transform our understanding and production of food, encompassing the creation of distinctive shapes and textures, as well as the printing of customised nutritional profiles. This technological advancement presents promising prospects for fostering culinary innovation and addressing specific nutritional needs.

· Food Preservation and Packaging Innovations:

The primary objectives of advancements in food preservation and packaging are to prolong the duration of shelf life, minimise food wastage, and preserve the nutritious content of food products. In the field of packaging, notable advancements include Modified Atmosphere Packaging (MAP), hoover packaging, and intelligent packaging equipped with embedded sensors for freshness monitoring. These technologies are designed to ensure that consumers are provided with products that are both safe and of high quality, while simultaneously mitigating the environmental consequences associated with packaging.

· Clean Label and Natural Ingredients:

The demand for clean-label products is on the rise among consumers, prompting the food processing industry to embrace natural ingredients that have undergone little processing. The driving force behind this transition is motivated by a strong inclination towards openness and a predilection for nourishing healthful dietary options. Food processors are engaging in the process of reformulation in order to remove artificial additives, preservatives, and synthetic colours from their goods. This strategic action is in accordance with the growing customer preference for healthier alternatives. Join the league of successful Food processing companies in Gujarat. Implement state-of-the-art technologies and witness unprecedented growth. Get in touch with Modern Food Products today!

· Plant-Based and Alternative Proteins:

The emergence of plant-based and alternative protein sources represents a notable transformation in consumer dietary preferences. Food processors are utilising innovative techniques to create plant-based meat alternatives that mimic the sensory attributes, such as taste and texture, of conventional meat products. These inventions play a significant role in promoting sustainability since they effectively mitigate the environmental consequences associated with traditional meat production, all the while accommodating the needs of an expanding group of individuals who follow vegetarian or flexitarian diets.

· Nanotechnology in Food Processing:

The utilisation of nanotechnology in food processing allows for the meticulous manipulation of food characteristics on a molecular scale, resulting in improved sensory attributes such as taste and texture, as well as enhanced nutritional composition. Nanoencapsulation is a technique that facilitates the precise delivery of nutrients to specific targets, hence enhancing the nutritional content of food products through the addition of vital vitamins and minerals. Furthermore, the application of nanosensors is being employed to enhance quality control measures, thereby guaranteeing the safety and freshness of food products across the whole supply chain.

· High-Pressure Processing (HPP):

HPP is a food preservation method that uses elevated pressure levels to eliminate pathogenic microorganisms and prolong the shelf life of food products. This technology achieves these objectives without subjecting the food to thermal treatments, hence preserving its nutritional composition and sensory attributes. The utilisation of this approach is increasingly being recognised for its ability to generate newly produced, secure, and minimally treated goods, thereby satisfying the growing need for uncontaminated and consumer-friendly food items.

Final Thoughts:

The food processing business is currently experiencing a significant transformation propelled by technological advancements, a focus on sustainability objectives, and the changing demands of consumers. These developments are not only exerting a significant influence on the sector but also fundamentally altering our perspectives and patterns of food consumption. The future of food processing encompasses a range of cutting-edge technologies, including automation, robotics, 3D printing, and nanotechnology.

These innovations hold great potential to revolutionise the global food industry and significantly impact the methods by which we sustainably nourish our growing population. Please remain engaged as we see the gradual progression of this transforming expedition into the forthcoming realm of sustenance. Ready to secure a top place in the Food processing industry in Vadodara? Modern Food Products’ expert team in Vadodara is prepared to optimize your operations. Reach out for personalized advice and solutions.

#Food processing companies in Gujarat#Food processing industry in Vadodara#Best food product company in Vadodara#Food product industry in Vadodara#Food Product company in Gujarat#Food product company in India

8 notes

·

View notes

Text

North Carolina State University researchers have demonstrated a technique that allows people who manufacture metal machine parts with 3D printing technologies to conduct automated quality control of manufactured parts during the finishing process. The technique allows users to identify potential flaws without having to remove the parts from the manufacturing equipment, making production time more efficient. "One of the reasons people are attracted to 3D printing and other additive manufacturing technologies is that these technologies allow users to quickly replace critical machine components that are otherwise difficult to make outside of a factory," says Brandon McConnell, co-corresponding author of a paper on the work. "And additive manufacturing tools can do this as needed, rather than dealing with supply chains that can have long wait times. That usually means using 3D printing to create small batches of machine parts on demand." McConnell is an assistant research professor in NC State's Edward P. Fitts Department of Industrial and Systems Engineering.

Read more.

#Materials Science#Science#North Carolina State University#3D printing#Metals#Defects#Additive manufacturing

12 notes

·

View notes