Don't wanna be here? Send us removal request.

Text

Skills Needed to Be a Good Welder

Welding is a highly skilled profession honed with hours of practice and dedication, but the key to become a very good welder lies in some required attributes in the person.

Understand instructions/drawings:

Planning any fabrication or maintenance welding revolves around understanding the drawing or WPS (welding procedure sheet) which lays out clear instruction to a welder to ensure high quality execution. This makes it essential that you know how to read these instructions and follow them.

Mathematical skills:

Welding is a skill that requires understanding precise numbers. You will use basic math skills to determine measurements and angles and also calculate the strength of each weld.

Knowledge of various welding techniques:

Employers are often looking for experienced welders with good knowledge of different welding methods. Most common among them are MMAW (Manual metal arc welding), MIG (metal inert gas) & TIG (tungsten inert gas).

Ability to perform related fabrication tasks:

Welding is just one part of any welder’s job, as a welder also needs to handle tasks which come before and after the actual task of welding. Such all-round skills make you indispensable and turn you into a sought-after welder.

Strong interpersonal skills:

Welders need to interact with many people, like their supervisor, welding engineer, suppliers and also clients. The ability to communicate efficiently and effectively are very important to a welder.

Attention to detail:

A welder also needs to have an eye for detail, however minute. Nothing can escape your attention as small flaws can also create a big impact, even to the extent of causing a major failure.

A good work ethic.

A good work ethic is one of the strongest personal qualities you can bring to the table as you are vital to ensuring that the job is completed on time.

0 notes

Text

Difference between Arc Welding and Argon Gas Welding

Arc Welding (MMAW or SMAW- Manual or Shielded Metal Arc Welding Process)

In arc welding process (Shielded Metal Arc Welding process or Manual Metal Arc Welding process) the arc is established between parent metal and a flux coated welding electrode using electrical energy to melt and deposit weld metal. This process is one of the most used in the world.

Arc Welding Process advantages (MMAW / SMAW):

• Of all welding processes, this one is the simplest.

• Equipment used is portable & its cost is economical

• Offers a variety of applications & a wide availability of electrodes for all metals

• Welding can be done both indoor & outdoors

Limitations of SMAW process:

• Given a 10-minute cycle, welding happens only for 6 minutes. This results in lower productivity

• Process is slow. This requires a frequent change of welding electrode

• Moisture from flux coatings can create weld-related problems

Argon Gas welding (GTAW or TIG welding):

Argon gas welding (GTAW or Tungsten Inert Gas Welding) uses a consumable Tungsten electrode as the heat source and a filler wire to complete the welding, shielding is provided by an inert gas.

Advantages in GTAW / TIG Process:

• No slag inclusion & clear visibility of arc and job.

• Offers high quality welding with thin base material

• Root run of thick materials- known as cleanest welding process.

• Ideal for Aluminum, Stainless steel & Titanium

Limitations in GTAW:

• Slowest process compared to Arc welding & other processes

• Risk of adding tungsten to weld deposit which is hard & brittle.

• Requires inert gas shielding.

The basic difference is that in Arc welding a flux coated welding electrode is used for welding. In Arc Gas welding or TIG welding, an arc is struck between a non-consumable Tungsten electrode and base material. Then a filler wire is used with Inert gas shielding to complete the weld. Arc welding is a faster process in comparison to Arc Gas welding (or) TIG process.

Reclaim. Do not Replace.

0 notes

Text

The Difference between Overlay Welding and Hard Facing

In welding two metal surfaces are joined with the application of heat, to get a completely homogenous joint. Welding electrodes used in this process consists of a core wire and flux coating & welding happens by striking arc with the flux coated electrode using a welding power source.

Flux coated welding electrodes can be classified by their application in various industries.

1. Joining and overlaying of different base materials

2. Hard facing of worn-out components

Industries use 4 types of welding electrodes in different applications like overlaying, joining and hard facing of components:

1. Electrodes for welding steel: This includes electrode for welding & overlaying all grades of steels including all types of carbon steels, alloy steels consisting of manganese steels, stainless steels & nickel alloys.

2. Electrodes for welding cast iron: These are specially formulated nickel-based special alloys used for repair welding & over laying of cast iron parts.

3. Electrodes for welding non-ferrous Alloys: This type of welding electrode is used for welding and for overlaying different grades of aluminum, copper and its alloys.

4. Electrodes for hard facing: This type of electrode is used to combat all seven wear factors or wear problems in an application.

Friction Abrasion

Impact Erosion

Corrosion Cavitation

Heat

Weld overlay & hard facing look quite similar, but the essential difference with overlay is that we get different properties of the welding electrode on a welded surface, while in hard facing, we deposit carbides to ensure increased hardness & wear resistance of any given application.

ADFL serves industries by manufacturing and supplying all types of manual metal welding electrodes with specially made LH alloys.

Reclaim, do not Replace

0 notes

Text

Five Important Tips for the Best Aluminium Welding Results

Aluminium:

Aluminum ore, Bauxite is found in all Parts of world.. It was able to be processed as usable Aluminum because of availability of low cost Electricity.

Aluminium – Useful Properties:

• Low weight -1/3Rd weight compared to steel of equal volume

• Several grades are stronger than MS

• Reflects light –accepts mirror polish for High reflectivity

• Conducts heat –Used in radiators & other heat transfer devices.

• Resists corrosion –Thanks to its oxide film

• Conducts electricity -60% effective compared to Cu

• Easy to fabricate –By forming & cutting-Can be stamped, rolled, drawn or punched

• Easy to cast in complex shapes-Automobile water pumps, Pistons etc

• Nontoxic –So its excellent for pots & pans

• Easy to weld –By Gas torch, ARC, TIG & MIG process

Problem’s to Tackle in Aluminium Welding:

• Low strength & Lower Melting Point

• A thick Aluminum Oxide film on the surface

• Falls apart at high temperatures

• High conductivity

• Doesn’t show color-Does not become red hot when heated.

Strategies to Weld Aluminium:

1. Combating Low strength & Lower Melting Point:

Welding alloys available with bonding temperature a full 100 Deg less than Al

Through Surface alloying technique –Low melt filler can used for welding.

Joints will be much stronger than base material itself

2. Tackle the thick Aluminum Oxide film on the surface

Rub aluminum with Emery paper or Stainless steel brush to remove oxide film.

Can use chemical cleaning with solution like 15% Sol of NaOH . In case of brazing use carburizing flame & in MMAW DC+

3. Aluminum falls apart at high temperatures

Can use Temperature indicating crayons

Use a acetylene flame & blacken the surface .Preheat till blackness disappears. Tells the temperature is 370 Degree.

4. Tackling High conductivity

Use DC + Polarity while doing arc welding

5. Do not show color-Does not become red hot when heated?

Use temperature indicating flux which will start flowing – Showing base metal is ready for welding.

Hence with above five strategies, weld repairs and fabrication can be successfully carried Aluminium components.

0 notes

Text

Types of Electrodes Used in Welding Processes

Electrodes or Manual Metal Arc Welding electrodes basically consist of a core wire and flux coating. The welding happens by striking arc with a flux coated electrode using a welding power source.

The core wire will be made of the type of base metal it needs to be weld and flux coating protects the weld pool with a gas shielding; a protective slag to slow cool the weld pool & it also seals any contamination from atmospheric air. Further flux also allows strike and re-strike of electrode and also insulate the welding core wire from rust.

So, flux-coated welding electrode can be classified by the purpose it’s used in industry.

· Joining and build for different base materials

· Wear-facing or hardfacing on worn out components in Industry

So if you classify types welding electrodes predominantly industry uses 4 types of welding electrodes for various applications for joining and hardfacing components.

· Electrodes for welding steel: This includes electrodes for welding all grades of steels including all types of carbon steels, alloy steels consisting of manganese steels, stainless steels & nickel alloys.

· Electrodes for welding cast iron: These are specially formulated nickel-based special alloys used for repair welding of cast iron parts.

· Electrodes for welding non-ferrous alloys: This type welding electrodes are used for the welding of all weldable grade parts made of aluminium and copper and its alloys like brass and bronze.

· Electrodes for hard facing (or) Wear protection: This type of electrodes are basically manufactured to combat all the seven wear factors, listed below.

Friction Abrasion

Impact Erosion

Corrosion Cavitation

Heat

ADFL serves various industries with the manufacture and supply of all types manual metal welding electrodes and specially made Low Heat Input electrodes - LH Alloys

0 notes

Text

Things You Must Know Before Buying a Plasma Cutting System

Before buying a Plasma cutting systems, there are some questions that need to be asked and answered.

1) What is type of cutting that is planned: handheld, automated (like on a CNC table) or both?

This is an important question because we get air plasma cutters which are capable of doing both, but some are limited to only one type cutting. A cutter which does both obviously gives you the most versatility. But everything depends on your requirement, so you need to see if you will be doing both types of cutting, or be switching between the two methods. If you plan to switch, not all cutters make it easy, so your choice would need to factor that in.

Even if you have no plans to do any automated cutting right now, do check if there might be the remotest of possibilities in the future when you would need to do so. If yes, then you will need to pick a system which does not use a high-frequency starting circuit. Such a system would use a spark to start the plasma arc which can cause interference with your other hardware like CNC and cause them to lock up.

2) What type of metals do I need to cut and of what thickness?

You would know the type of cutting you will need to do as well as the general thickness of material you would be cutting. Industry experts make a recommendation here. When you have a specific requirement in cut capacity, get a system that matches your requirement at least 80 per cent of the time, if not more. To illustrate, if you usually cut material which is one-inch thick, and rarely cut anything of two-inch thickness, you would be right to choose a one-inch system. You would also need to consider the base metal you would need to cut, whether it is stainless steel, aluminium or any other.

3) Where will the system be used, indoors or outdoors?

You would also need to consider whether you will need to move the system around a lot or carry it to another location, on a regular basis. Depending on this, you will need to pick a system which is lightweight and portable if you move it around a lot, or a heavy system which is used on a specific factory floor or shop area. Lightweight systems today compete with regular machines in power and performance and do not force a user to compromise on any functionality. Some of these systems, like our Powermax30 AIR come equipped with an integrated air compressor.

4) What is the voltage of electric power (230V or 440V) you will be using? If it is from a generator, how powerful is the generator?

It helps to know the answers to these questions and plan ahead on how your system will be powered. If you are in using it in an area where you have access to a regular 230V outlet only, you will be buying a system which uses power at that voltage. But, if you plan to move the system between locations and have access to a higher voltage at one of the places, it makes sense for you to buy a system which can be switched between these powers. You may also want to use a system which can work on a generator or withstand power fluctuations and can compensate for them, when needed if your power supply is prone to such fluctuations.

5) How long can I use the system continuously, or what is my system’s duty cycle?

This question needs to be asked, based on the amount of cutting you need to do. The system has a central core which houses highly sensitive components which cannot be overheated. You may employ a fan to cool this centre efficiently and consistently to extend the duty cycle and use the system for longer periods.

Finally, instead of a question, we offer two tips:

(1) Do consider whether your new system will be easy to operate, or not so easy.

(2) Take the cost of the system’s consumables into account to estimate the operating costs and factor that in, to arrive at your final choice.

We do hope that answering these five questions has helped you to choose the right Plasma cutting machine for your requirements.

0 notes

Text

The Most Important Issues in Rotary Kiln Maintenance

Cement Industry uses rotary kilns for pyro-processing the raw mixture of finely crushed limestone (calcium carbonate + silica-bearing minerals) to manufacture cement. Kiln or kiln shell is at the heart of the cement making process; the kiln’s capacity usually defines the capacity of a cement plant. Kiln is made of structural steels with a lining of heat resistance coating called castables. The temperature of a kiln goes above 1200 degrees during the process.

The two important maintenance issues in kilns are hot spot and red spot problems appearing in the kiln shell due to the excessive heat during the process.

Hot Spot in Kiln

Hot spot is an isolated area in the rotary kiln where the kiln shell temperature is close to 550 deg. It is not visible and can be detected by shell scanner or portable infra-red pyrometer. In pure laymen’s terms, a hot spot is like a warning sign that action is needed. Periodically the kiln is stopped due to hotspot and inspected for any cracks. But with today’s improved technology the shell temperature is monitored continuously with computer-aided sensors to ensure that any hot spot is immediately identified and necessary precautions are taken.

Red Spot in Kiln

Red spot is area visible at night meaning temperature above 550 degrees. Red spot means immediate action with stoppage of rotary kiln as it means there is a crack in the shell. So, any hot spot eventually becomes a red spot causing cracks in kiln shell.

Generally, cracks which are perpendicular to rotary kiln and not of significant lengths and depth, are repaired by welding & but if the cracks are circumferential in nature, the particular portion is cut and removed & new shell of the same length is inserted, aligned & welded. Also, for most cases of red spot, kiln shell replacement is the preferred method.

Welding is the chosen method for types of repairs, kiln shell cracks & kiln Shell replacement. For corrosion caused by high temperature, wear protection solution is also widely used. Ador Fontech specializes in all these repairs.

1 note

·

View note

Text

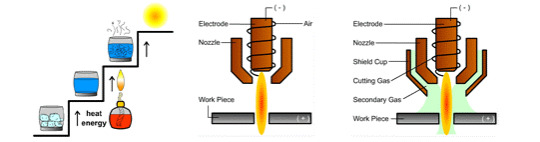

Principle of Plasma Cutting:

Electricity and pressurized gas combine to form a plasma arc of ionized gas. This super-hot plasma instantly melts metal. The gas shapes the arc and blows molten metal away, leaving a smooth cut edge.

Plasma Cutting Pictorial Depiction:

Plasma Capabilities:

Plasma Cutting Advantages…

Cut and gouge any electrically conductive metal – MS, SS, AL, alloys, others

Cut through rust, paint, coatings and stacked metal.

Cut with air. No gas required.

Cut fast and clean up to 50mm, no pre-heating.

Easy to use “plug and play” & drag cutting

Easy to automate.

Small heat affected zone

Plasma Cutting Disadvantages…

Can’t heat metal for bending.

Can’t efficiently cut much thicker than 75mm MS

Requires sufficient electrical power to work.

Summary:

Oxy-fuel and plasma cutting are all well-established thermal processes used for cutting steel. Each has advantages and shortcomings, dependent on specific business needs.

Oxyfuel has the lowest capital and operating cost, though the costs per part in the end are higher due to slow cutting speeds and lower cut quality which often requires more secondary operations. Oxy-fuel is primarily used for cutting only thick carbon steel (greater than 50mm) when cut quality is not a requirement.

But Plasma cutting system provides a good balance in terms of capital cost and an optimal mix of cut quality, productivity and operating costs. It has significant thickness range and material flexibility and provides the highest cutting speeds. Hence with this inherent advantages Plasma cutting Equipment’s are preferred for Cutting applications in Industry.

Ador Fontech offers Hypertherm Plasma cutter for all your repair and reclamation services which is built to withstand heavy duty use in industrial environments.

0 notes

Text

Types & Effects of Thermal Spray Coating

Thermal Spray process is ideal for laying extremely thin, dense and hard protective coatings. In comparison, Arc welding process is ineffective and economical on account of the possibility of distortion and removal of large quantity of metal during machining even when a thin overlay is required.

Even a gas welding process causes unwanted distortions and delays.This makes a Thermal spray process the preferred solution for this kind of applications. In thermal spray method, there are four types of processes.

1. Thermospray Combustion Powder Spray systems 2. Electric Arc wire spray process 3. High velocity Oxy-Fuel Process 4. High Energy Plasma Process.

Thermospray Combustion powder (Spray& fuse grade powders) systems

This technique applies to the arranging of coating materials, including self-fluxing alloys,fine ceramics, self-bonding materials and other special alloys. This process uses fuel gas and Oxygen to achieve the coating using specialized thermal spray equipment.

Key Benefits: Resists wear & can help salvage worn out components Resists high temperatures and enhances electrical properties Cost reduction with better performance

Electric Arc wire spray process

We can coat a range of metallic alloys & pure metal for the restoration of corrosion wear. This process uses Twin arc electric arc spray system, with compressed Air.

Key benefits: Very simple & easy to maintain High spray rates with low gas consumption Coating intricate shapes & improving machinability

High velocity Oxy-Fuel Process

This process uses High velocity Oxy-fuel systems to achieve excellent bonding. In this process, we get dense coating with homogenous structures.

Key Benefits:

Thin & thick coating possible –even hard carbide and super alloy coating can be given Process can be fully automated with a robot Excellent for multiple wear factors

High Energy Plasma Process

This uses high energy plasma spray systems to coat material, this process we can coat metals, alloys, ceramics, cements, carbides & other non-metals.

Key benefits: Coating possible using different layered material High deposition rates and excellent bonding Coating for internal geometry and process can be automated.

Ador Fontech limited name is synonymous with total solutions with all above thermal spray systems for all maintenance and repair applications in plant and at our premises. We stand true to our concept of Life Enhancement of Industrial components to the complete satisfaction of customers.

1 note

·

View note