Don't wanna be here? Send us removal request.

Text

5 Tips to Maintain Your Marine Engine Repairs

5 Tips to Maintain Your Marine Engine Repairs

A well-maintained marine engine ensures a smooth, trouble-free boating experience. By taking preventive measures and adopting proper maintenance habits, you can extend your engine’s lifespan, enhance performance, and avoid costly repairs. Here are five essential tips to help you maintain your marine engine effectively.

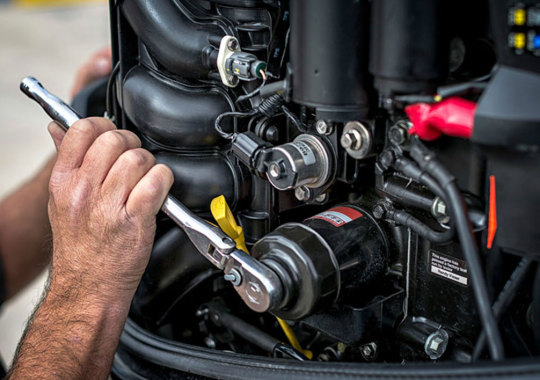

1. Perform Regular Inspections

Routine visual inspections are critical for identifying potential issues before they escalate. Here’s what to look for:

Hoses and Belts: Check for signs of wear, cracking, or loose connections.

Fluid Levels: Ensure oil, coolant, and hydraulic fluid levels are within the recommended range.

Corrosion and Leaks: Look for rust, salt buildup, or any signs of leaking fuel, oil, or coolant.

Regular inspections help you catch small problems early, preventing major engine failures down the line.

2. Change the Engine Oil and Filter Regularly

Clean engine oil is vital for lubrication and cooling, reducing wear on internal components. Over time, oil becomes contaminated, losing its effectiveness. To keep your engine running smoothly:

- Change the oil and oil filter according to the manufacturer’s recommendations (typically every 50-100 hours of operation).

- Use high-quality marine-grade oil to ensure proper performance and protection against corrosion.

Neglecting oil changes can lead to overheating, increased friction, and costly engine damage.

3. Maintain the Cooling System

The cooling system prevents your engine from overheating during operation. Proper maintenance includes:

Flushing the Cooling System: After each outing, especially in saltwater, flush the cooling system to remove salt, sand, and debris that can clog passages.

Inspecting the Water Pump: Regularly check the water pump impeller and replace it if it shows signs of wear. A faulty impeller can cause overheating and engine failure.

- Ensure the coolant levels are adequate and use marine-specific antifreeze to prevent corrosion.

4. Use Fresh, High-Quality Fuel

Fuel quality plays a significant role in engine performance and longevity. To avoid fuel-related issues:

- Always use fresh, ethanol-free fuel or a stabilizer to prevent fuel degradation.

- Regularly inspect and replace fuel filters to prevent clogs and ensure a clean fuel supply.

- Avoid running the engine on old or contaminated fuel, as this can lead to carburetor or fuel injector damage.

5. Follow the Manufacturer’s Maintenance Schedule

Every marine engine comes with a manufacturer-recommended maintenance schedule. This schedule outlines specific tasks such as:

- Spark plug replacement

- Gear oil changes

- Timing belt checks

Adhering to this schedule ensures that all components receive proper care, reducing the risk of breakdowns and costly repairs.

Conclusion

Maintaining your marine engine requires consistent effort, but the rewards are well worth it. By performing regular inspections, changing oil and filters, maintaining the cooling system, using high-quality fuel, and following the manufacturer’s maintenance schedule, you can keep your engine running smoothly and enjoy a worry-free boating experience. Proactive care not only saves money but also enhances safety and reliability on the water.

0 notes

Text

5 Common Outboard Engine Problems and How to Fix Them

Outboard engines are powerful, efficient, and essential for enjoying a day on the water, whether you're fishing, cruising, or water sporting. However, like any mechanical system, they can sometimes experience issues that affect performance. Understanding common outboard engine problems and knowing how to address them can save you time, money, and frustration. Here are five frequent outboard engine issues and how to fix them.

1. Engine Won't Start

One of the most common and frustrating outboard engine problems is when the engine refuses to start. This can happen for a variety of reasons, but the good news is that many causes are relatively simple to diagnose and fix.

Possible Causes and Fixes:

Battery Issues: If the battery is dead or weak, the engine won’t have enough power to start. Check the battery’s charge level and connections. Clean the terminals and, if necessary, replace the battery if it no longer holds a charge.

Fuel Supply Problems: Ensure there is enough fuel in the tank and that the fuel valve is open. Check for clogged fuel lines or a dirty fuel filter. Replace or clean the fuel filter, and check the fuel lines for leaks or blockages.

Ignition System: If there’s no spark, the issue may lie with the spark plugs, ignition coils, or wiring. Inspect and clean the spark plugs, or replace them if they are worn or damaged. Ensure the ignition system components are functioning correctly.

2. Engine Stalls or Cuts Out

An engine that starts but then stalls or cuts out while running can be particularly troubling. This can be caused by problems with fuel delivery, the carburetor, or the ignition system.

Possible Causes and Fixes:

Fuel System Blockages: A clogged fuel filter or gummed-up carburetor can restrict fuel flow, causing the engine to stall. Replace or clean the fuel filter, and clean the carburetor using carburetor cleaner.

Fuel Quality Issues: Old or stale fuel can cause the engine to stall. Always use fresh fuel, and consider adding fuel stabilizer when storing the boat for long periods.

Faulty Fuel Pump: If the fuel pump isn’t working correctly, the engine may lose power. Check for leaks, cracks, or blockages in the fuel pump and replace it if necessary.

Air Intake Problems: Ensure the air filter is clean and free of debris. A clogged air filter can restrict airflow to the engine and cause it to stall.

3. Overheating Engine

Overheating is a common issue, especially during long periods of use or on warm days. An overheated engine can cause severe damage, so it’s important to address this issue immediately.

Possible Causes and Fixes:

Clogged Cooling System: The most common cause of overheating is a clogged water intake or cooling system. Check the water intake for debris, seaweed, or trash, and clean it if needed. Ensure the water pump is working properly.

Water Pump Impeller Failure: The water pump impeller is responsible for circulating coolant through the engine. If it wears out or breaks, the engine may overheat. Inspect and replace the impeller if necessary.

Low Water Levels: Ensure that the engine is always submerged at the correct depth to draw water into the cooling system. If you're running the boat in shallow water, you may not be getting sufficient cooling.

4. Loss of Power or Reduced Speed

A lack of power or poor acceleration can be caused by various issues in the engine. This can affect both fuel efficiency and overall performance, making it harder to reach top speed.

Possible Causes and Fixes:

Clogged or Dirty Carburetor: A dirty carburetor can prevent the engine from getting the right air/fuel mixture, leading to poor performance. Clean the carburetor or have it serviced by a professional if you're unsure how to do it yourself.

Fuel Quality: As with other engine issues, poor fuel quality can lead to power loss. Ensure that you're using fresh, high-quality fuel and consider adding a fuel treatment to improve combustion efficiency.

Throttle Linkage Issues: If the throttle linkage is damaged or out of alignment, it can prevent the engine from reaching full power. Inspect the throttle mechanism and cables for wear or damage and replace or adjust them as necessary.

Spark Plug Problems: Worn, fouled, or incorrectly gapped spark plugs can cause misfiring and poor engine performance. Inspect and replace spark plugs regularly to maintain peak performance.

5. Water in the Fuel

Water in the fuel can cause the engine to misfire, stall, or run rough. Water can enter the fuel tank through condensation or from contaminated fuel, and it can damage the fuel system and engine components if not addressed.

Possible Causes and Fixes:

Contaminated Fuel: Water can contaminate the fuel if the fuel tank has a crack or if fuel is purchased from a contaminated source. Drain the fuel tank and replace it with fresh, clean fuel.

Fuel Water Separator: Install or clean the fuel water separator, which is designed to filter out water and debris from the fuel. Make sure it is functioning properly and change the filter regularly.

Water Drainage: If water has entered the fuel system, you may need to drain the carburetor and the fuel lines to ensure all water is removed. Use a fuel additive designed to absorb water if you're unable to fully drain the system.

0 notes

Text

5 Tips to Maintain Your Marine Engine Repairs

A well-maintained marine engine ensures a smooth, trouble-free boating experience. By taking preventive measures and adopting proper maintenance habits, you can extend your engine’s lifespan, enhance performance, and avoid costly repairs. Here are five essential tips to help you maintain your marine engine effectively.

1. Perform Regular Inspections

Routine visual inspections are critical for identifying potential issues before they escalate. Here’s what to look for:

Hoses and Belts: Check for signs of wear, cracking, or loose connections.

Fluid Levels: Ensure oil, coolant, and hydraulic fluid levels are within the recommended range.

Corrosion and Leaks: Look for rust, salt buildup, or any signs of leaking fuel, oil, or coolant.

Regular inspections help you catch small problems early, preventing major engine failures down the line.

2. Change the Engine Oil and Filter Regularly

Clean engine oil is vital for lubrication and cooling, reducing wear on internal components. Over time, oil becomes contaminated, losing its effectiveness. To keep your engine running smoothly:

- Change the oil and oil filter according to the manufacturer’s recommendations (typically every 50-100 hours of operation).

- Use high-quality marine-grade oil to ensure proper performance and protection against corrosion.

Neglecting oil changes can lead to overheating, increased friction, and costly engine damage.

3. Maintain the Cooling System

The cooling system prevents your engine from overheating during operation. Proper maintenance includes:

Flushing the Cooling System: After each outing, especially in saltwater, flush the cooling system to remove salt, sand, and debris that can clog passages.

Inspecting the Water Pump: Regularly check the water pump impeller and replace it if it shows signs of wear. A faulty impeller can cause overheating and engine failure.

- Ensure the coolant levels are adequate and use marine-specific antifreeze to prevent corrosion.

4. Use Fresh, High-Quality Fuel

Fuel quality plays a significant role in engine performance and longevity. To avoid fuel-related issues:

- Always use fresh, ethanol-free fuel or a stabilizer to prevent fuel degradation.

- Regularly inspect and replace fuel filters to prevent clogs and ensure a clean fuel supply.

- Avoid running the engine on old or contaminated fuel, as this can lead to carburetor or fuel injector damage.

5. Follow the Manufacturer’s Maintenance Schedule

Every marine engine comes with a manufacturer-recommended maintenance schedule. This schedule outlines specific tasks such as:

- Spark plug replacement

- Gear oil changes

- Timing belt checks

Adhering to this schedule ensures that all components receive proper care, reducing the risk of breakdowns and costly repairs.

Conclusion

Maintaining your marine engine requires consistent effort, but the rewards are well worth it. By performing regular inspections, changing oil and filters, maintaining the cooling system, using high-quality fuel, and following the manufacturer’s maintenance schedule, you can keep your engine running smoothly and enjoy a worry-free boating experience. Proactive care not only saves money but also enhances safety and reliability on the water.

0 notes

Text

Maintaining Your Boat's Engine

Boat engines are important components of the boating experience. They are used to move the boat through the water, and if they are not maintained correctly, they can be expensive to repair. These small machines can malfunction and damage the entire boat, so it is best to have them checked out regularly. This can prevent a multitude of problems, including a broken engine.

Some of the most common components of a boat's engine include: filters, fuel, oil, and the propeller. It is important to check the oil level as well as replace it with new lubricant. You should also inspect your fuel lines for wear and tear. If they are worn, they can disrupt the combustion process, causing the entire engine to malfunction.

The water intake and cooling system are also crucial components of a boat's engine. Unlike car engines, boat engines do not have radiators, so they rely on the use of water for coolant. Make sure to inspect your bilge pump as well. Also, make sure to drain the heads, and the live wells.

If you are not familiar with a boat's engine, you should consult the manufacturer's manual. They should have information on things like the best oil lubricant, fuel stabilizer, and the propeller. To get the most out of your boat, you should follow the manufacturer's recommendations for fogging your engine, cleaning your propeller, and checking the battery's level.

Another item to check out is the air filter. It is important to clean out the filter from time to time, as it helps the engine run better. A properly functioning air filter will help prevent foreign materials from getting into the combustion chamber.

In addition to these basic maintenance items, you may want to consider installing a rustproofing solution in your engine's water jacket. Rust is something that is often overlooked, but it can result in a costly repair. When a rustproofing product is used on the gelcoat of your engine, it can remove rust within a few seconds, and it will also help the engine last longer.

Lastly, you should also consider storing your boat properly. For example, you should take all necessary steps to ensure that your boat is stored in an enclosed space during the winter months. While this is a small task, it can help avoid costly repairs. Before you head out for a trip, it is also important to have a checklist to make sure that all of the boat's essentials are covered.

As a general rule, you should have a thorough inspection of your boat's engine before each outing. Taking these basic measures can help protect your vessel from the worst of the weather, and you will be glad you did.

Finally, make sure to check your bilge pump and the engine's battery. Your boat's battery will get a lot of action, and it is a good idea to check it periodically for signs of corrosion.

Having a checklist before heading out for a new season will ensure that you are prepared to tackle whatever weather the lake brings your way. Besides, it's a fun activity to do, and you will definitely enjoy the time spent on the water with friends and family.

0 notes

Text

Interesting Facts About The Outboard Motor

Have you ever wondered about the different components of an outboard motor? Read on to learn about the three cylinders, the Driveshaft housing, the Skeg, and the Tiller. Once you have a basic understanding of the outboard motor, you will be more likely to appreciate the many features of this engine. Its origins are fascinating and are sure to intrigue any boater. There are many other interesting facts about the outboard motor, so we've listed a few of the most fascinating ones.

Driveshaft housing

The outboard motor comprises a case extending generally vertically and supporting the engine and propeller. The driveshaft extends through the driveshaft housing and is supported in the case for rotation about its axis. The driveshaft housing has a generally box-shaped cross-section along its length and has an elongated upper portion. A rearwardly extending shoe portion is provided to provide the exhaust discharge.

The lower unit of the outboard motor houses the propeller and a gear connected to it. The driveshaft housing encases the bearings that allow the driveshaft to spin freely. The water pump is located on the top of the lower unit and runs through the driveshaft. The impeller sticks onto the driveshaft and sucks up water in the gear case and forces it up the midsection to the powerhead.

Three cylinders

A three-cylinder outboard motor has one more advantage over its four-cylinder counterpart: more torque. Even though the two types have similar horse power, the torque produced by a three-cylinder engine is greater at low RPM and partial throttle. The extra torque translates to a faster hole shot, which can mean the difference between getting on a plane and missing it. So, why do you need more torque from your outboard?

A three-cylinder outboard motor is designed with horizontal cylinders and produces 40 to 50 horsepower. This engine weighs 86 kilograms (190 lb.), and has three separate carburetors. The three cylinders are linked by a camshaft, which opens the cylinder valves and exhaust gas valves. Fuel is ignited in each cylinder by spark plugs. The three cylinders of an outboard motor are often found in smaller boats.

Skeg

If you're interested in outboard motors, you'll be happy to know that they were developed by self-taught engineers. Ole Evinrude was one of these people. He began building marine inboard engines at an early age. His success was rewarded when his father ordered that his son inherit the family farm. He later built the first commercially available outboard. This type of outboard is still widely used today.

The first outboard motor was invented in 1922 by the Johnson Motor Company. This Norwegian mechanical genius had some machine-shop experience and an interest in horseless carriages. His innovative design would soon win him a lucrative contract with the U.S. government. It was a simple way to create a small internal-combustion engine for boats. In addition, it was light weight and didn't require batteries.

Tiller

One of the most interesting facts about the outboard motor is that the invention of the engine is credited to Ole Evinrude. He was a Norwegian immigrant who first manufactured the outboard motor, thereby launching the outboard motor industry. While his father hoped he would inherit the family farm, Evinrude soon learned about boats and tinkered with the parts of sailing ships. He eventually became a registered patent holder for his marine propulsion system in 1911.

In 1922, the Johnson Motor Company introduced the first outboard motor at a New York Boat Show. It was dubbed the Light Twin and Waterbug. The engine was constructed from die-cast aluminum and was more powerful than its predecessors. It was lightweight, required no batteries to ignite, and ran at higher rpms than its predecessors. It was also used in racing boats. This innovation led to the development of several outboard motors, including the Yamaha F-Series.

0 notes

Text

Outboard Motors - which one is best 2-Stroke or 4-Stroke?

The engine is one of the most necessary parts of your boat. Without it, you are not going to go very far. Outboard motors are the most common type of propulsion used on boats today. This motor is mounted to the stern end of the boat, with an attached propeller in the water. There are many choices and considerations that you need to make when it comes to purchasing an outboard motor for your boat. The type or power of the engine you get depends on the size of your boat, the speed you want, and what the boat will be used for.

The two types of outboard motors available are 2-Stroke and 4-Stroke engines. There are positives and negatives to each of these engine types. Because of the lightweight, 2-Stroke engines are chosen when good top-end speed and acceleration are needed. 4-Stroke engines run smoother and more economical and are usually chosen for use on lakes and rivers.

2-Stroke Outboard Motors:

Boaters would be most likely to choose a 2-Stroke outboard engine if they are interested in speed, performance, and acceleration. This may be the engine of choice if you own a smaller boat that may not be able to hold the weight of a 4-Stroke engine. A 2-Stroke engine is also suitable if you are more familiar with engine repairs, or even want a motor that is easy to repair and can be brought anywhere to be fixed. If you are not required to operate in a body of water that is for four-stroke engines only, you may want to purchase a 2-Stroke. If you would like the most power for the weight of the engine or are interested in more speed, acceleration, and performance; a 2-Stroke engine is for you.

4-Stroke Outboard Motors:

You are most likely to use a 4 stroke engine if you are interested in trolling along on a quiet, smooth ride. These engines are better for use on bigger boats. If the water in your area requires a "4-Stroke only" boat, it is probably a good idea to go with this engine. If you would rather give up engine speed and acceleration for a cleaner engine, you may want to purchase a 4-Stroke. Also, if you are interested in less pollution and smoke, and don't want to have to mix oil; a 4-Stroke engine is for you.

You can find 2-Stroke Outboard Motors of Evinrude, Yamaha, Nissan, and Mercury Manufacturers in the market. And 4-Stroke Outboard Motors Manufacturers such as Johnson, Honda, Mercury, Nissan, Suzuki, Tohatsu, and Yamaha in the market.

Both 2 and 4-Stroke outboard motor have their own set of advantages and disadvantages. You need to decide how you are going to use your motor, and what you want it to do for you. Because 4-Stroke engines are newer, they are continually improving to make purchase and repair easier on the boater.

0 notes

Text

Tips For Buying Used Outboard

Are you looking at buying a used outboard motor? If you are looking at buying a used outboard you should consider all of the options available to you. Some questions you should be asking firstly yourself is - What will I mainly be using the outboard for? How many hours will I be doing each year? How much can I spend? How much can I afford for maintenance?

If you are someone who needs an outboard motor for the long run, then you will want an efficient outboard motor. A four-stroke outboard or a direct-injected two-stroke, like a Johnson V4 Mercury Optimax, Evinrude Etec, or Yamaha HPDI will be the best.

When buying used outboard the cost is a huge factor. You need to make sure that the used outboard is in excellent condition, especially if you are on a tight budget. For instance, a used outboard motor over 5 years old will need to have the Powerhead gaskets replaced straight away, or within the next few years. Outboard Powerhead gaskets on used outboards can cost around $1000 - $1500. If you did not budget for this when shopping for a used outboard it can put a stop to your boating season if you do not have the finances to have the Powerhead serviced. As a rule of thumb, fuel-injected two-stroke outboards and four-stroke outboards are a few hundred dollars more to service than carburetor two-stroke outboards. This is an important area to consider when shopping for your second-hand or used outboards.

Used outboards are for sale for a reason - You need to find out why that is. Quite possibly it is a genuine reason, the owner might do large hours and wants the extra fuel efficiency, and the owner might want a quieter outboard as the old two-strokes might be quite noisy. Or, the outboard might have an underlying problem or issue and that is why it is for sale. This is why getting used outboards inspected before you buy them is very important! A used outboard inspection should be carried out by an experienced technician or outboard mechanic. They should go over the outboard motor from top to bottom. Carrying out a compression test, ignition system test, look in the motor with a borescope to inspect cylinder bore condition, check gear oil, engine mounts, running quality and charging system, etc.

The best place to buy used outboards from is a marine dealer or workshop, you might pay a little bit more but you will usually have the reassurance of a warranty or guarantee. After you have purchased the used outboard, it is very important to make sure it is installed correctly on the boat. Engine height and propeller selection are very important with used outboards and outboard motors in general. Also, you need to make sure it is serviced, the oil system is clean and operational and you are using the correct fuel for the outboard.

0 notes

Text

Comparison of Outboard and Inboard Motor

A well-maintained outboard motor will be more reliable and occupies a fraction of the hull space needed for an outboard motor. The outboard motors are light, compact, and are easy to maintain. One of the primary advantages of the outboard motors over inboard motors is that the latter can be taken ashore and serviced conveniently at the comfort of a garage or workshop.

The outboard motor must suit the size of the boat and should perform the work expected from it. Planning hulls are normally powered by an engine of specified horsepower and the hull won’t accelerate below that planning speed. The speed of the boat varies and is limited due to different external environments equal speed through the water can be achieved by motors of very different power output.

When choosing a motorboat, select one that has sufficient power to work on day-to-day activities under normal conditions and must have additional power to push the boat when the climatic conditions are not in your favor. A small motor worked at its limit speed for a longer time will be noisier, smellier, thirstier when compared to a large boat working in similar conditions. Also, it wears out too quickly.

Most of the outboard motors used are two-stroke engines and have a petrol/oil mix. The proportion of oil to petrol varies from 25:1 and 50:1. Within some limits, the proportions are not critical. The oil helps to lubricate the crankcase, connecting rod bearings, and cylinder linings. Relatively, the excessive presence of oil in the mixture will make it difficult for the motor to start and produces smoky exhaust. Also, too little oil will cause the engine to overheat and seize.

An outboard motor runs well on low-octane petrol. If the mixture is allowed to stand, deposits are formed on the walls and passages of the carburetor. Carry spare petrol and oil, use it when needed. Mix them properly before filling them in the petrol tank. If not mixed properly, the sparking plugs will oil up, and the engine will not fire.

If the tank has been left to stand for a while before connecting to the engine, tilt it to one side to integrate the mixture. Shaking will stir up the deposits in the tank, which might block the carburetor. If the tank of the outboard motor is partially filled air above them will condense to form water beneath the fuel. Preventing this helps the motor to have a longer lifetime.

0 notes

Text

Steps to be followed for new outboard maintenance

It is always expensive to invest money in purchasing new boat engine. You can increase the life of your outboard motor by cleaning your outboard motor frequently. Outboard motors should be cleaned periodically if the boat is used every day. If the boat is not used for a long period of time then you should do outboard maintenance.

Water pump

When you are doing maintenance in outboard water pump always check water flow when you flush the outboard motor. You can easily check the water flow by keeping the finger in the water stream which comes out from the water pump. The water coming out from the water pump should be warm. If the water stream is not strong it indicates the presence of debris in the water pump.

Drain fuel

To drain the fuel you should disconnect the fuel line so that the engine burns the fuel present in the carburettor. After draining the fuel turn off the battery switch and also turn off the key. You should use a brand new outboard fuel to use your boat again. Make sure that you use sufficient amount of fuel for you outboard motor so that you won’t waste too much of outboard fuel.

Maintenance check

A quick maintenance check is necessary, when you are working on an outboard motor. Some of the important parts to be checked during maintenance are fuel line and primer bulb. You should also check for any sign of wear, corrosion of parts and cracks on the outboard motor.

Cleaning all outboard parts

Engine cowling should be removed so that you can check the water leakages and fuel. If there is any water leakage you can consult with an outboard mechanic for service. You should wipe all the parts of the outboard parts with WD-40. After doing these things you should replace the cowling in its position and cover the outboard engine.

Advantage of doing maintenance on outboard engine is you don’t have to worry about outboard engine breakdown. Regular outboard motor maintenance will not only save you a lot of money, but it will also protect you in case of any emergency situations. Whenever you purchase a new outboard motor you will get an outboard motor maintenance manual and other outboard care guides. Always read all the things which are mentioned in the outboard maintenance manual because maintenance procedure will vary based on the outboard manufacturer.

0 notes

Text

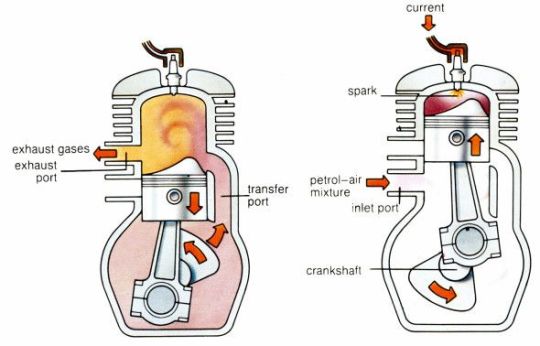

Working principle of a two stroke outboard motor

Outboard engine is the most important part in a boat. Outboard engine is used mostly in marine propulsion in all the types of boat. These engines have a spark ignition system and an internal combustion engine

Outboard engines are attached to the rear end of the boat, which makes them to propel through water. There are three important components in an outboard engine; they are gear case assemblies, outboard mid section and outboard power powerhead. The gear is connected to the propeller and drive shaft. Power gears have internal combustion engines which is a very important component that makes the boat to move. The midsection of the outboard engine contains tilt/trim mechanism, steering and housing assemblies.

Outboard engines are classified into two types one is 2 stroke outboard engines and another one is 4 stroke outboard engines. Both these outboard engine has its own advantages and disadvantages. 4 stroke outboard engines in widely used in most of the boats.

2 Stroke outboard engines are lighter in weight and also it is faster than a 4 stroke engine. 2 stroke engines are available for a cheaper price which is the market, which is worth the money. 2 stroke engine is has a simple design and also its makes very less problems.

In 2 stroke outboard engine the crank shaft take only one revolution to complete the entire process cycle of the engine. This happens when the cycle starts with a compression stroke and combining with combustion stroke at the end. This mechanism makes the 2 stroke outboard engine to generate high specific power.

The 2 stroke outboard engine can be easily attached to a boat and it can run in any direction. The outboard engines which will not usually run in a reverse direction but because of its design it will run. If the engine is runs in the reverse direction for longer period of time, then it will cause internal damages to the outboard engine parts. This damage happens due to the piston pin effect, which in turn reduces the piston slap.

Even though the 2 stroke engine has some drawback, most of the people still prefer it because it is fun to ride. Four stroke outboard engines are dominating the market for the past few years, but 2 stroke outboard engines are still used widely. Outboard motor manufactures uses advanced technology to increase its power and also to find a way to reduce the pollution from these engines. Most of the companies started experimenting with crankcase volume and changing the exhaust pipes of the outboard engine to make it more efficient.

0 notes

Text

Things to be checked when you buy an outboard propeller

If you recently bought a new boat and you are thinking about buying an outboard propeller. Consider the following things if you are a first time boater, because you probably don’t know about the functions and feature of outboard propeller. Very common thing that you can see in new boaters is they have lot of confusions about outboard propellers. There are many different types of outboard propellers available with wide range of features. This makes it complex to choose the right outboard propeller for your need. You should have the basic knowledge about outboard propeller before you buy it for your boat. Here are the important things to be checked before buying the outboard propeller is listed.

Outboard motor RPM

The RPM of the outboard motor is a very important thing to be considered before buying the outboard propeller. These include the calculation of how revolutions that your engine is able to provide per minute. For a four stroke outboard motor the RPM is 6000 and for a two stroke motor the RPM is 5500. You should choose the outboard propeller based on the RPM of your outboard engine.

Features of the boat

The next thing to consider before choosing the propeller is to know about your boat characteristics and features. If you have boat which works at low speed, you may need a high pitched propeller to achieve better performance. The pitch of the propeller is the distance that the propeller moves in water for each revolution it takes.

Number of passengers

The number of passengers that your boat holds will directly affect the performance of the boat. If your boat has to carry more number of passengers, then you should choose to buy a low pitched propeller.

Number of propeller blades

Choosing the propeller based on its blade number will vary according to your needs. You can choose a three blade propeller to increase your boat speed. Buying a four blade propeller for your boat will enhance the boat handling at an optimum speed.

The material of propeller

Whenever you buy a propeller for your boat make sure that material of the propeller is resistance. There are many propellers available in the markets which are made from different materials like aluminium and steel. Investing in steel propeller is the best option for your boat. Aluminium propellers are available at affordable price but they are very less resistant when comparing to propellers that are made from steel. A propeller made from stainless steel has good durability and gives long time performance.

0 notes

Text

A Brief History of Mercury Outboard and insight on mercury outboard rebuild process

Mercury outboard has been found as one of the favorite choices for Boat owners and fisherman for many years now. Its exceptional design and functionality have made this possible to get the strong and loyal customer base over these years. Mercury Marine Company is made into one of the world’s leading Outboard Engine brand by its constant innovation and enhanced marine Engine motors. The other brands associated under the Mercury name Brand are Mercury, Mercury Racing, Mercruiser, and Mariner outboards.

They produce Outboard Motors ranging from 2 to 400 horsepower, MerCruiser Sterndrives and inboards range from 100 to 450 horsepower and then Mercury Racing outboards produces up to 400 horsepower (300 kW) and sterndrives to 1,750 horsepower (1,300 kW). And even they provide engines, boats, services, and parts for commercial and recreational for marine application.

Short History of Mercury

Mercury Marine Company is founded in 1939 as Kiekhaefer Mercury and based in Fond du Lac, Wisconsin, USA. The founder Carl Kiekhaefer bought this company when it was dying with losses along its 300 rejected outboard pieces. The original idea is to produce magnetic separators for the dairy industry. For that, he decided to repair and build the defective outboard motors to sell them and get money in order to start their new business of manufacturing magnetic separators. He never had interest in Outboard engine business, but the response to the repaired rejected outboard Engine was so overwhelming, that he ends up in the Outboard manufacturing business. From that period this company has never seen a turnaround and has been successfully running with many brands under it till now.

Mercury Outboard Rebuild

Mercury outboards are built to run for years, whether it is fresh or salt water. Though the outboard engine can run for years in straight, the engine or the parts of the motors can get some repaired and damaged overusing. Buying a new outboard motor can cost high, but there is one more way to give another chance to the old mercury outboard that is rebuilding the mercury outboard.

Not only mercury outboard, but any other brand of outboard motors can also experience some issues over the time. Starting problem, overheating, excessive vibration, an improper turning of the propeller, engine cut off, etc are some of the issues can be raised by the old Outboard motors. Rebuild Outboard Motors means rebuilding and remanufacturing the entire engine like lower units, cylinders, powerheads, and head to give it a new life and run for some more years. Rebuild of Mercury outboard is done in accordance with OEM specification. And there are many companies which offer a complete Mercury Outboard Rebuild. They will analysis and inspect the outboard engine for the defects and damage to fix it.

1 note

·

View note