Laura Graham // Digital Fabrication for Fashion & Textiles // Massey

Don't wanna be here? Send us removal request.

Text

HELLO !

I welcome you to my blog which I have been working on in November of 2018 where I have been attending an elective at Massey University where we have been inducted into the Wellington Fab lab and shown their many digital fabrication processes. Each week we were to create a wearable outcome using the digital processes we had learnt that week. Week one was vinyl cutting, week two digital embroidery and week three laser cutting.

Please take a look through and if you have any questions or reccomendations I would love to converse. I have used tags to order my posts in weeks, digital fabrication processes and wearable outcomes if you would like a more focused search. I would highly recommend scrolling right to the bottom to start reading in order to get the posts in a chronological order.

- Laura Graham.

1 note

·

View note

Text

FINAL THOUGHTS

These past three weeks have been an absolute whirlwind but I couldn’t be happier with all the knowledge I have gained in such a small time. The fast pace of the course kept me on my feet, constantly iterating my designs and gaining understanding of all the unlimited possibilities that can be done with the four digital fabrication machines: a vinyl cutter, 3D printer, digital embroidery machine and laser cutter. This course has definitely broadened my horizons and given me a lot of confidence in my own abilities of being able to execute such thought out pieces in really limited time frames. I feel more ambitious and fearless in the designs I want to make next, knowing that these digital fabrication tools are available and accessible. I am looking forward to pushing my comfort zone with these processes and applying them to the designs I will be creating in my second year. I am super thankful that I got to do this experimentation so early in my degree and so I can really build upon these processes to amplify my garments. While it took a bit of problem solving to think of how to use some of the digital fabrication tools meaningfully with sustainability in mind, I seemed to get there in the end of each week and produce something I was really proud of. I would recommend to everyone who is interested to really take advantage of the resource that is the Fab Lab. Their help and open source creativity has really encouraged me to share my own ideas and processes more freely in the hopes of benefiting others. Overall, this course has been unforgettable in the knowledge and insight I have gained and I cannot wait to see where this will take me. My three wearable outcomes are each special to me in the experiences I had making them and the satisfaction I feel when getting to look at the progress i have made.

0 notes

Text

USE, SELL or SHARE ?

An integral part of the Fab Lab framework is that all work made using their digital fabrication tools is encouraged to be shared in the style of open source consumption. I think this is a fantastic point of view as designing and all creative practice benefit from exterior influences in the form of artist models and shared experimentation. My blog is made to be open, easily shared and encouraging to any viewers who may want to endeavour on any similar processes to what I have been doing these last 3 weeks.

In terms of the categories of ‘use’, ‘sell’ and ‘share’, I think that all three of my wearable outcomes can comfortably fit in each of these.

USE:

Because I used my own self as a template for measurements, I fit each of my wearable outcomes well and intend to wear them each. I find wearing my creations is really important to my further iteratory process in that nobody gets a better understanding of clothing than the wearer who lives in it. I hope that by wearing and therefore using my wearable outcomes this will help me in finding the successes of what I have done and also what I could improve on. Also because I used embellishment through the processes of vinyl cutting, screen printing and digital embroidering to personalise and make more meaningful the garments, I really gravitate to both my rabbit printed kimono and my four-way modular top. After the effort, time, detail and personalisation I have put into these two outcomes particularly, I look forward to wearing them and experiencing the full effect of them in their diversity and individuality.

SELL:

I think that the modular clothing style has real potential to experience a revival in the upcoming ten years or so. With the impending horror of climate change and global warming, there is a real demand for using sustainable methods in processing items, such as clothing, that usually create so much waste. This article gives us a better understanding as to why “the clothing industry is the second largest polluter in the world ... second only to oil” : https://sites.psu.edu/erkertarclblog/2018/02/02/the-second-most-environmentally-destructive-industry-is-not-what-you-may-think/ My modular garments are attractive to environmentally minded consumers as they can be worn diversely due to their changeability, which has longterm positive effects in developing an emotional connection to the garment and prolonging its life, reducing the need for a larger closet, and decreasing the need for indulging in fast fashion. I can imagine these garments to be easily marketable based on these factors with the addition of possible personalisation.

SHARE:

My open blog where I have documented all of my processes for each week and wearable outcome is a great place to start in sharing my ideas, tips, instructions and results. As someone who works well with written instruction, I have made sure that I have explained my processes as simply and understandable as possible so that if someone were to learn from these, they could follow along smoothly. Because some of my patterns are determined on individual size (especially my sandal) I have tried to give my best recommendations on how to take one’s own measurements and transfer it into something wearable and nicely fitting. I would love to discuss anything I have been working on with others if they have any questions or suggestions as I think the sharing process can be super helpful in learning from others to elevate one’s own designs so as to not make any of the same mistakes. This is beautiful in that through open source conversation, everyone together can work towards more sustainable and successful outcomes where there is really no possibilities to what could be invented.

0 notes

Text

FURTHER IDEAS FOR SANDAL

Though I am happy with my third week wearable outcome of laser cut sandals, there are some iterations I have noted that I would make to the shoe to improve the execution:

One thing I would do to improve the quality of the shoe is to laser cut the perimeter of the shoe outline shape on the fabric piece with slits. I did not do this as I originally intended to use the extra space I had allowed for the perimeter as a kind of seam allowance which I could stitch around the woollen blanket padding pieces. Because the laser cutter was booked up after I had used it, I had to make ends meet by simply cutting the outline with scissors and glueing the edges to prevent fraying which worked well but I know it would have looked a bit neater if I had used the laser cutter to do it earlier.

Another thing I would adapt on would be the padding. Because the sandal’s bottom is so flat, this can be very uncomfortable for some people with big arches in their feet. By layering more padding around the inner area where the foot arch is located, this may be more comfortable for the wearer. I do not think this step is essential as most sandals are quite flat anyway, but it would just be something I would consider and test next time.

Something Leo recommended me for my sandal on Wednesday was that I could potentially 3D print a grip for the bottom of my sandal in the flexible filament they have in some of the 3D printers. This idea really excited me and I intended to do it but unfortunately I did not have enough time to get it done before the presentation and before I go back home as it would take about 6 hours to print each sandal grip. If I were to make another prototype for this sandal idea I would certainly be keen to try this out.

I found this already made shoe grip design on Thingiverse but found even after changing the measurements in Netfab that the shape was a little off and Craig said to fix this I would either have to shave the sides of the 3D print down in a different software program or do it manually with scissors after it has printed (which would mean it would cost a little more than it needed to). I decided then that in another world where I had more time I would have definitely sculpted by own sandal grip design in Autodesk Fusion where I could use my already measured Illustrator file to ensure the correct measurements.

0 notes

Text

MY LASER CUT SANDALS

Here are my sandals ! I am actually really happy with them, especially in that they were made in only a day and a half ! With the two different strapping ties I am showing that these sandals are modular in that they can be altered by different colours and materials, but also different ways of tying and organising through the slits. They are comfy enough but I wouldn’t exactly recommend going on a long walk in them. I am also pretty impressed at the fit as it seems my calculations and measurements worked out pretty on point. Overall I am super proud of what I have accomplished and am glad I pushed myself out of my usual boundary of just sewing to construct a wearable outcome. Although I didn’t get to spend as much time as I had hoped on it, I am really taken by the digital fabrication tool of laser cutting and will definitely keep it in mind when designing in the future. I see a lot of possibilities ready to be transformed into real successful items with that piece of equipment.

1 note

·

View note

Text

PUTTING THEM TOGETHER

I had most of my trouble putting the shoes together. If I had more time I would definitely be making more iterations. I intended to stitch the navy polyester fabric onto the wool blanket padding but here I found a few road bumps. Ideally I would do this on a machine but because some of the stitches are so close to the edge making it difficult to avoid them when stitching, I opted for taking my time hand stitching. I cut slits around the perimeter of the allowance I had given the cut navy fabric to ease the curves for stitching but the perfectionist I am didn't find the edges adequate enough in that the curves were a bit distorted. As my last option I cut the shape out of this fabric in scissors and sealed the edges with glue. This worked well in that it matches the wood perfectly, but if I were to do it again I would have skipped this and just cut it out with the laser earlier. I still added the padding underneath but cut it a bit smaller so the fabric could slip right over it and be sealed nicely to the wooden pieces. Unfortunately during this time of processing I was a bit overwhelmed and forgot to document what I was doing. I am pleased however with what I came up with in solution to my found problems and think it looks close to what I expected.

This has definitely made me curious as to how shoemakers work with and bind such hard materials. I will definitely be doing some research about this in the near future as I would like to try again with this concept some time.

0 notes

Text

LASER CUTTING MY SANDALS

During class on Tuesday I was fortunate enough to have the time to cut out the wooden sole of my sandals. I cut out four in total, two for the left foot and two for the right foot. I managed to get this 4mm thick plywood from the leftovers bin which was conveniently the perfect size for my design. I found the laser cutting process quite simple by following my notes thoroughly and getting a hang of it earlier with our sampling.

The above two photos show a zoom into the engraving that I did. I think this process looks beautiful on the wood and am impressed by how precise the laser is with lines such as these. Using my own initials was my own interpretation of personalisation for these, but there are endless possibilities for designs that could not only be personalised but i am thinking now some deeper engraving may help with the sandal’s grip.

I layered up the plywood soles twice to get develop a sturdier and stronger base for the shoe by super glueing them together. While not particularly the most environmentally friendly of methods, this did hold them together extraordinarily good and I am happy I layered them up.

Here I have cut one of my two fabric layers for my sandals. You can see the slits are very subtle but from gripping at them a bit I am feeling they are very strong and I have faith they will uphold my tying of the laces later. I ended up cutting the are around the shoe with an allowance for when i put some padding underneath for comfort. I am unsure of how I will attach this slotted fabric around the padding with such an odd shape, but for now I am thinking stitching may be the best option.

Here I have my left shoe pieces. This demonstrates the different layers to the sandal base. From left to right is my laser cut plywood two layers thick, a wool blanket scrap I found in the fashion scraps bin which I have cut to size for padding, and a piece of my fabric for the top with laser cut slits for strapping. at this point I don’t have much time left to complete my shoe but I do have some ideas for what I would change or add in the future as after all this is only my first prototype. Something I would do more research on is shoe rubber grips and also the form of the foot as these sandals I am making are very flat and may not be particularly comfortable to wear due to limited support of the foot. However, I am super proud of the progress I have made in such a short time and think there is real potential in this concept.

0 notes

Text

WEEK 3 IDEA

This week I want to push myself a bit further and create a wearable outcome that is not constructed through sewing. I set myself this challenge because I want to extend my boundaries since I already know I am capable at pattern making and sewing clothing. I also intend to use my digital fabrication process this week (laser cutting) to actually help in creating the outcome itself rather than as a meaningful embellishment as I had been working with before.

I only have a day and a half to create this as we did not learn the process until Tuesday and I would like to have it done by Thursday morning for the presentation and because I am moving out of my flat and going back home to New Plymouth in the weekend. This leaves me with a very limited time span but I am determined to complete something in this time as best as I can.

Because my interest and major is in fashion, I still want to make something directly related to it. Something I have been interested in designing and making for some time is shoes. To get a head start on what I might create this week, I have been collecting over the weekend these images of modular shoes and sandals which I have drawn some inspiration from.

Alexander Reed Footwear. I adore these shoes and would absolutely wear them myself. The design of them is really appealing in that they modular links are not overwhelming and this really sets them apart visually. I hope to find a photo which might give me a better look into how the links interact.

Morpurgo RIY Footwear. This modular shoe design is effortless in its appearance and has a nice put togetherness that is very minimal and refined. The bottom section which I imagine to be quite flexible and gelatinous is feel, stretches snuggly around the moulded circles to achieve an interchangeable sole of the shoe.

Sseko Designs. This modular sandal has inspired me most in it’s design. I love how the sandal base itself is not modular but it is the strapping techniques and colours which can differentiate styles and be swapped or adapted on by each individual. I really feel a strong sense of personalisation here, which is something I have been exploring with my past two wearable outcomes. What connects me so much about personalising clothing is that I feel fashion is such fun and readily available way to express individuality. I love with modular designs the interaction, freedom and creative control the designer is giving each wearer to have their own fun with the base design.

I did this quick little sketch above inspired mostly by the Sseko sandals. Since doing the laser cutting samples on Tuesday, I have found that because the laser melts the edges of synthetic fabrics, sealing them, the cuts alone are very strong and I may not need the elastic loops I thought I would for the fabric laces to tie onto. Instead I will cut short 2cm slits around the perimeter of the sandal with another couple of slits for a jandal appearance.

I traced and measured my foot as accurately as possible and then transferred it into Illustrator where I used the rulers and guides in there to maintain as similar shape and measurements as possible. Using my foot again as a guide I determined where I will put the slits where the ties can wrap under the cut out areas of fabric. I also made another copy of this but without the slits and instead with my initials (LG) set for engraving at the bottom of the foot. I will use this seperate file to cut the plywood which I intend to have as the bottom structure of the sandal.

0 notes

Text

ARE LASERS ECO-FRIENDLY ?

As I was learning of all the incredible possibilities and potential in laser cutting, I began wondering why it isn't used in the industry with the exception of some high-end or avant grade collections. I think it would be a success in commercial and mass-market stores also, not only in terms of the aesthetics of the pieces but also in reducing human error in wastage and the efficiency of the process. I wondered then if I was missing big negative point to this so ventured into a bit of researching. My immediate doubt in laser cutting was that maybe it is not as environmentally sustainable as I thought but this article gave me peace of mind that it actually has a lot of positive points for it in terms of sustainability in not only the garment industry but also hardware and even space discovery !

https://www.yorkshireprofiles.co.uk/can-laser-technology-be-eco-friendly/

Another helpful source was this one by a woodwork site which gave a simple and honest description of the pros and cons of using lasers to cut wood.

http://www.woodguide.org/guide/laser-cutter/

Here is a quick run down on the pros and cons of laser cutting technology in the contexts of sustainability and investing:

PROS:

Laser cutting is quick: Laser cutters can cut at a speed of 5 to 15 mm a second, the thinner the material the faster.

Low production cost: Laser cutting reduces the need for manpower compared to general power tools, therefore reducing a cost in employment.

Low footprint: Just like water jet cutting, laser cutting wastes much less material than mechanical cutting.

CONS:

High investment: If you want to work with thick or large materials, the cost for buying laser cutters can add up fast.

High energy: Laser cutting consumes more energy than traditional mechanical cutting. This energy is not so much in the cutting itself but in the cooling needed for laser cutters. Cooling can take more than 10 times the power needed for the laser.

0 notes

Text

LASER CUTTING SAMPLES

Here are the four samples Alice and I were able to make after our tutorial on the laser cutter. It was a great choice to work together again to get a good understanding of the different material types we were working with. Alice wanted to test her two materials on the left, while my wood and fused polyester are shown on the right.

SUCCESSFUL LOADED FABRIC SETTINGS:

Alice’s light polyester cotton blend (top left): 0.2mm poly cotton.

My polyester with cotton fusing: 0.9mm cotton denim.

My 4mm found plywood: 4mm poplar.

I think the engraving looks great and very professional looking in the wood. This certainly could be used for a whole range of nice, organic looking designs.

This fabric cut really nicely, but the engraving is very hard to see. I think this is because engraving kind of pulls a layer from the fabric but because this was fused with a dark black fusing tape, we can only see a bit of that coming through.

I also love how the thin fabric cut and sealed the synthetic fibres of our two polyester cotton blend fabrics. i think this could definitely be utilised more in fashion for a no fraying edge.

I would definitely have liked more time to sample with the laser cutter as I have been able to do the past two weeks with the other machines, but because of very limited timing and hot demand for the machine, I would definitely like to come and revisit the machine to unlock further potential.

I especially see huge potential in cutting pattern pieces out of fabric with the laser cutter. Seen here are the perfectly sealed edges that could potentially eliminate the step of overlocking in some cases. Not to mention, the unlimited design potential of both cutting the garment pattern piece but also cutting fine detail and embellishment into it at the same time. This would also be a great success in sharing the files and making them available for everyone to use and having the pattern cut perfectly with little hassle.

1 note

·

View note

Text

LASER CUTTING PROCESS

Before using the laser cutter, here are some essential rules that must be followed to make sure the process goes smoothly:

Do not cut any pvc, mdd, metallic materials or wood thicker than 10mm.

Make sure every material you cut is first measured to ensure the laser is focused and the tip of the laser will not rub across the material when moving around.

If you have a fabric material that could move around, tape it down on the cutting surface so it does not get pushed and crumpled by the laser.

All materials must be really flat, bent wood will not work.

Always turn on both of the extractions when cutting to ensure a steady flow and prevent (mostly) any fires.

If a fire does occur, press the big red button to stop the machine and use the fire extinguisher to deal with it quickly if possible.

THE LASER CUTTER

1). Focus lens to get exact thickness of your material. To do this, press the bottom right triangular button, this will move the laser into the centre. Then use the white stick to measure laser down onto the material using the up and down arrows.

2). In Illustrator, select ‘Create from template’ and pick the large laser template. This allows you to see the exact bed size and shape of the laser cutter.

3). Once you have drawn up your design and checked its measurements so it fits on your material how you want, go to Windows - Graphic styles and select what mode you want each part of your design to be done in. There are THREE modes that can be utilised when using the laser cutter: Rastoring: This mode creates a consistent gradient for your material. The colour black represents the depth and power of the laser, and the greys are in betweens until white which is no lasering at all. Cutting: Quite obviously is the cutting mode. This is represented by the colour red on Illustrator. Engraving: This mode makes light imprints on the material, and works on fabric by taking the dye colour out leaving a nice effect. Engraving is represented by the colour blue in the Graphic styles menu.

4). Once happy with your design and your material is placed, measured and flat, you can put the cutting screen down and get ready to print.

5). Press print on Illustrator as you would do normally and go to settings. Here you will find the laser cutter which you will open. A new screen will load where in Manual settings you can load the material settings that will best suit the material you are using. Once you have picked the best suited option, press ‘Apply’ and ‘OK’.

6). Go into the laser cutting software and there will be a preview of your design. An option that is helpful to use is the laser positioner where you can click somewhere on a part of your design and the laser will move so you can see if your design is fitting nicely where you want it on your material. you can also estimate the time which can give insight into how well your design was made so that it can run as quickly as possible.

7). Before pressing start you must turn on the bed and top extractions. This is essential and must always be done.

8). The big green play button on the computer gets the cutting started, and the machine can be paused any time on either the computer or machine itself.

9). Once your design has been cut, before making your material off of the bed, make sure it has been cut. If it hasn't the settings may have been wrong for the material and you can try another in the exact same place to get it cut through properly.

10). And now you have a nicely cut, engraved or rastored material ready for you to use !

I was really shocked that the process was not as entirely complex as I had originally thought since the end result is so neatly done. This makes me think that accessibility to laser cutting machines are why they may seem quite unapproachable over my original idea that they may just be very difficult to work. It is also nice that this machine uses Adobe Illustrator and not a knew software I would need to learn or convert to. This definitely helps in making the process quicker. I think my biggest difficulty this week in using the laser cutter will be that there is only one and a lot of people trying to use it. This is especially hard to work with because there are people who were in the groups before us who have not caught up with their previous work and so also need to use the single laser cutting machine.

0 notes

Text

LASER CUTTING RESEARCH

Ahead of week 3 where my group and I will be on the laser cutter to make our final wearable outcome, I have been saving some images from Pinterest which may serve as inspiration, and will give me a better idea of the properties and application of this digital fabrication machine.

Balenciaga, Paris Fashion Week, Fall 2014. I think this piece is stunning in how the knit and faux leather fuse together and collaborate to make a multifaceted dress. The skill involved to do something like this is incredible and I imagine a lot of iterations were run through before they constructed the full successful piece.

Louis Vuitton, Paris Fashion Week, Spring 2012. In the past when I have looked at laser cut fashion I have found the results quite harsh and geometric (not in a bad way, just very solid in it’s cuts). I really like the femininity achieved through this dress by Louis Vuitton, showing how quite complex designs can be intricately cut for a lovely decorative effect.

Haider Ackermann, Paris Fashion Week, Fall 2010. This is a lovely detail here where the laser cutting embellishment can be zipped away from the main garment. This brings up again the idea of modular fashion and gets me thinking of how I can use laser cutting to allow a wearable piece to be changed and adapted on for a modular outcome.

Carven, Fall 2012. This photo is wonderful in showing how a previously simple garment can be elevated and amplified so much with the aid of laser cutting. This truly adds value to the garment and allows changeability in that different colours can be worn underneath the dress to suit different occasions or moods.

A common thread between all of these looks, as well as the general search for laser cut garments, is that they are all done by well known high-end designers and are presented at huge International Fashion weeks. This is a huge point of difference to the production of my wearable outcome this week ! By noticing this commonality in the majority of laser cut garments shown online, this makes me think that laser cutting technology is mostly seen as unapproachable to the general public. As someone whose love for art has erupted from humble beginnings of craft through my childhood, I wonder how laser cutting can become something many people can have access to and experiment with.

This makes me want to create something simple yet effective in my outcome, and give a thorough rundown on how to do it so that the process of laser cutting can be seen as more achievable and less complex than commonly thought.

0 notes

Text

MY FOUR-WAY MODULAR TOP

WEEK TWO WEARABLE

Here is my wearable outcome for week 2, a top that can be flipped and reversed to be worn fours ways. This top also includes designs elevated by digital embroidery which make a point of difference for each side of the top. It is tied to close and can fit a range of different shaped and sized bodies. Its adaptability in being able to be worn multiple ways and the personalised embroidery collaborate together to form a garment with a long and versatile life span, combating the epidemic of fast-fashion.

I am super happy with how this top has come out and proud of the amount of work I have been able to achieve this week. I loved learning about modular clothing and definitely think this is something I would like to go further with in my work.

0 notes

Text

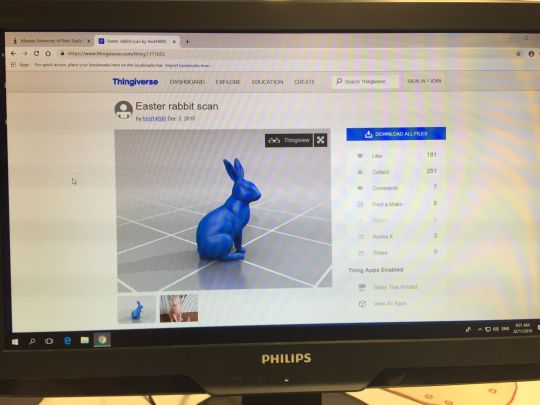

3D PRINTING WORKSHOP (2)

Our second workshop on 3D printing went through the steps of taking your design (which you may have sculpted on Fusion 360 earlier but here we found already made designs online) to the printers !

THINGIVERSE

1.) Log into Windows.

2.) Open Chrome or Firefox and search ‘Thingiverse’.

3.) Once in Thingiverse, find a file you would like to print and save it as an STL somewhere you will remember.

I chose to print this cute little rabbit, following my theme. This could be wearable as earrings or a nice pendant.

NETFAB

4.) Open up the ‘Netfab’ program on the computer.

5.) To scale up or down check measurements on left and press a button up top that looks like a circle with graph arrows and the left and bottom.

6.) If there are errors press the red repair button (looks like a first aid cross) to send an automatic repair script to attempt at fixing it.

7.) To save, press file - export part - and save as STL again.

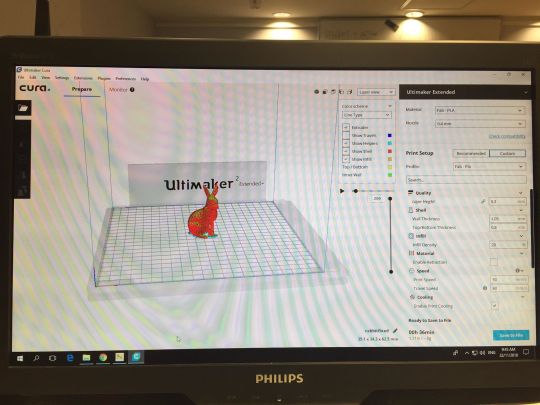

ULTIMAKER CURA

8.) Open ‘Ultimaker Cura’ and open your saved file. Have it in layer view and line type to have best visibility.

9.) On right hand side of the screen are some essential settings for a successful print.

PRINTER: Choose your printer. MATERIAL: Fab-PLA is the usual one you will pick. NOZZLE: Most of the printers use a standard 0.6 mm nozzle. LAYER HEIGHT: This is the thickness of layers. For a prototype print this would be around 0.3 but a a more detailed print would be 0.1. This number must be a multiple of the nozzle size, so in this case, 0.6. WALL THICKNESS: 0.6 to 1.8 is good. TOP/BOTTOM THICKNESS: A multiple of the layer height. 0.6 to 1.2. INFILL DENSITY: This is the density percentage of the inner lattice. 12% to 30% is good, but will be determined most by how your design is shaped and other factors. PRINT SPEED: For a 0.6 mm nozzle, a speed off between 40 and 55 mm/s is efficient. TRAVEL SPEED: This can be up to 90mm/s though smaller objects could do with less speed due to the vibrations occurring. BUILD PLATE ADHESION TYPE: If printing straight on the glass and your object is small, a brim plate is helpful. this can be cut away later.

Save and convert your edited file into a GCODE and put it on an SD card ready to put in the printer. Here the steps are very easy to follow, and in no time it will start printing !

My printed rabbit ! It is so cute and sweet, I love it. Doing this workshop was really exciting for me as it made something I had felt seemed so unattainable into something I truly think I could accomplish. This in the fab lab really reinforces their philosophy of sharing such seemingly impossible equipment and making it achievable and accessible for everyone.

1 note

·

View note

Text

CREATING MY PATTERN

I created the pattern above for my four way reversible top out of two different second hand bedsheets. I made the pattern based on the images I have found of the woman wearing something similar in the LIFE photos I found earlier in the week, along with some basic measurements of myself. I would love to see this pattern on different sizes other than 12 but have been unable to find any different sized mannequins as of yet. However, I do think this pattern could work for a couple of different sizes, a women’s 10 until 16 on estimate.

It is essential for this pattern to be cut on a four layered fold along side the centre front as well as the neck hole. By doing so, the pattern is cut nicely and the general shape is just one piece. For one of my sheets, I cut the ties with the rectangle together as shown in my drawing, but for my other sheet, since it was the scraps from my kimono I made last week, I had to cut them separately from the main body, making sure every scrap was used so I would be able to get enough ties together.

Here is a photo of my finished pattern played out flat to see how we got here from the original cut pattern. It is evident how simple this top’s pattern really is, especially with the pay off of fitting four individual top designs into only one garment. The concept of modular clothing is sure to leave an emptier closet and fuller wallet.

0 notes

Text

DESIGN DRAWING

Here are some drawings I did to how I plan for my top to look like by the end of this week, included are the four different sides of the top which can be worn.

1). A PLAIN LIGHT BLUE SIDE

2). A LIGHT BLUE SIDE WITH THE PRINTED/EMBROIDERED RABBIT FACE.

3). A SKY BLUE SIDE WITH THE EMBROIDERED POCKET.

4). A SKY BLUE SIDE WITH AN EMBROIDERED SPACE PATTERN.

0 notes

Text

EMBROIDERING MY DESIGNS

I went through a lot of designs before reaching my final three embroidery images. I found that through importing from Adobe illustrator into Inkscape, this caused a lot of issues in that the image size would change and be distorted. This made it very difficult for me to accomplish screen printing a silhouette and then embroidering on top of it due to the change in sizes which I then couldn't line up nicely. Also in Inkstitch I received a lot of errors through the process, mostly that some of my line work was too small to be stitched by the machine. This took away any fine detail I had included in my original designs.

The design above I was super excited about due to the prospect I could print the rabbit silhouettes in white and then embroider the stars and outlines on top. I had a lot of difficulties in getting the lines to be big enough to be stitched and no matter what size the Inkstitch program did not allow me to embroider this design. So moving on, I decided to simplify my designs a bit where the line work would be available to embroider. I am glad this worked out as it did because I think the more simplified designs are more successful in the end.

I made this big rabbit face to be a feature on the garment, giving versatility in the modular designs by being more impactful than the subtler embroidery I did on other sides of the garment. When choosing what I would like to embroider, I had to keep in mind that the image would need to be attractive as the front of the garment and also the back.

To make sure the sizing of the vinyl cut printing stencils and the embroidery, I found it easiest to fix my prior issue of not being able to match them up by embroidering first on a piece of calico and measuring the height and width of the embroidered rabbit. I then redrew the silhouette in Illustrator and made sure it cut in the vinyl following the exact measurements of the embroidered rabbit. I tested this a couple of times between printing and embroiding to get the positioning to match up as close to possible before doing my final copy on the garment.

I decided to incorporate a pocket on one of the sides of my reversible top to give it a point of difference. I know this may seem unusual if it were to be worn the other way round with the pocket on the back, but I don’t really see much of a problem with that. I printed a little design of two bunnies looking up at a star. The soft material of the sheets, alongside the nice blue I feel makes this side of the top feel very luxurious. It instantly reminds me of fancy monogrammed pyjamas one might have. Embroidery is such a luxurious technique to add to clothing, and the added personalisation of one’s initials would surely add value and elicit a longer life for the clothing.

For my last embroidery design I took inspiration from Valentino’s and Emilio Pucci’s cosmic designs I had been looking at. While not as expensive looking or perfectly done, I do think my constellation designs have a nice charm about them. For at least one of the sides I wanted a consistent pattern to be present, so these stars and moons were perfect for that. To do this I drafted up some designs in Illustrator and transferred them to Inkscape where I separated them into three seperate documents which could fit in the smaller frame of the digital embroidery machine. I then spaced out each set of stars, changing the colours between navy, yellow and orange to reach my result.

Once I got a hang of Inkstitch and the digital embroidery machine, I really enjoyed using it. As someone who has spent days on end hand embroidering, I definitely feel I could save some time by using this in the future, and gladly would as the machine runs well and gives a great, neat outcome. I am excited to use the machine again in my work for next year.

1 note

·

View note