Don't wanna be here? Send us removal request.

Text

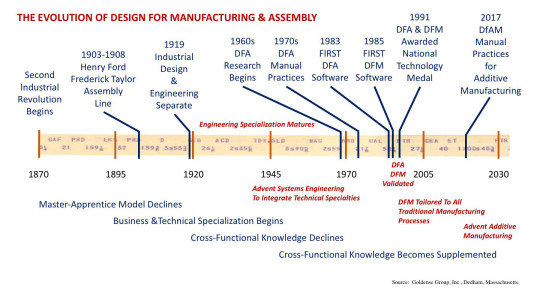

A History of Design for Manufacturing and Assembly

This article documents a short history of the evolution of Design for Manufacturing and Assembly [DFM/A]. The conclusion postulates how the advent of additive manufacturing may affect the body of knowledge and current competitive landscape which is largely subtractive manufacturing.

This article begins at the start of the second industrial revolution, which was the beginning of task specialization after centuries of the Master-Apprentice Model. A hundred years later, cross-functional knowledge had largely been lost. New specialty "bridge" organizations then began forming to perform the integrative and optimization tasks between major business and technical functions, Design for Manufacturing and Assembly included.

Engineering was "throwing designs over the wall" to manufacturing that required many iterations to finally become producible. Engineering and product development organizations no longer understood the ease or difficulty of producing what they had designed. Enter Design for Manufacturing and Assembly.

#DFM#DFMA#dfa#dfam#design#designer#designengineer#engineering#engineeringmanagement#manufacturingengineering#manufacturing#additivemanufacturing#ROI

2 notes

·

View notes

Text

The Importance of Product Design

When was product design not important? Product design has always been important. It is almost a law of nature. When was quality not important? This too is practically a law of nature. The elevation of both areas began back in the 1980s.

For industrial design, service firms such as Design Continuum, IDEO, and a couple-dozen others formed into an industry as enabling 3D and surface design technologies also came of age. And user-interface (UI) engineering began its related roots as electronic devices emerged.

For product quality, first Deming, Juran, Crosby, and others brought great techniques. Then came Jack Welch at GE, and Six Sigma spread widely a decade later.

Currently, factors indicate that the competencies of product design are on the way to their next heyday. Several new groups of design requirements are converging in the same timeframe.

https://www.machinedesign.com/industrial-automation/importance-product-design

#product design#innovation#management#leadership#performance#industrial design#design#designer#product development#user interaction#3dprinting#nanotechnology

0 notes

Text

Adapting the “Master-Apprentice Model” to the 21st Century

Hardly a day goes by without overhearing the word apprentice, apprenticing, or apprenticeships. In some cases, it is simply renaming long-standing training programs to be in vogue with the buzzword of the day. Much of it is something new, however, for both good and not so good reasons. • The Original Model • The Specialization Model • The Collaborative Model • The Displacement Model

[Machine Design, January 2019 Issue]

https://www.machinedesign.com/industrial-automation/adapting-master-apprentice-model-21st-century

#innovation#management#leadership#performance#designthinking#product development#manufacturing#Product Management#learning#apprentices#apprenticeship#work#workshop

0 notes

Text

Onshoring, Nearshoring, Offshoring, and Now Reshoring

#BusinessStrategy often goes in cycles. Costs of making #Products in #Mexico, the #PacificRim, and elsewhere are often equal now/again to making products in the #UnitedStates.

Revisiting #Outsourcing #BusinessModel.

https://www.machinedesign.com/community/onshoring-nearshoring-offshoring-and-now-reshoring

#Business Strategy#business model#outsourcing#offshoring#offshore#nearshore#nearshoring#onshore#onshoring#reshore#reshoring#manufacturing#production#product cost#target cost#logistics#transportation

0 notes

Text

The Power of Awards, Product Announcements to Boost Market Capitalization

R&D Management

These are exciting times for product developers in many industries, not just for all the new technologies and capabilities being incorporating into new products and product lines these days, but also for the management science around the practices and processes used from creation through launch.

There is a long time lag from the initial concept, through funding and development, then waiting for several years of sales and profits to analyze the results. Four to a dozen years pass, depending on your product life cycle. Until big data and analytics first achieved critical mass a decade ago, it was hard to find good data sets to analyze. Moore's Law doubling rates these past ten years, coupled with ever-improving analytics and early AI capabilities, has really improved what can be researched. As well, these data are available to a much wider global audience of business researchers. We are entering a period where management science in research and development stands to blossom. Still far from a comprehensive understanding of the impacts of most decisions and techniques, multiple studies in related areas are beginning to emerge for many important R and D topics.

The impact of innovation announcements and awards on the stock price of public companies is an emerging area of study.

https://www.rdmag.com/article/2018/10/power-awards-product-announcements-boost-market-capitalization

#industrial design#awards#product marketing#product management#product strategy#return on investment#innovation#finance#Stock valuation#market cap#marketing#ceo#cto#cxo#cfo

0 notes

Text

The R&D Spending Performance 8-8-8 Webinar Series

https://conta.cc/2CNcO8Q

#innovation#r&d spending#performance#research and development#product development#engineering#spending#strategy#return on investment

0 notes

Text

The R&D Spending Performance 8-8-8 Webinar Series

With big data capabilities now a decade old, and much wider access to internet-based data repositories by global researchers, studies have been increasing. The "science of R&D Spending" is still a long way from being stitched together, but studies are beginning to corroborate findings in certain areas. For example, studying the effects of industry awards has become popular. The award givers are interested in knowing the value of their awards, while the award applicants/winners want to know if it was worth all the time and cost to apply. We'll cover several findings. One category of award lead to a 1% increase in stock price. This example is representative of The R&D Spending Performance 8-8-8 Webinar Series as a whole. In three one-hour sessions, we'll be sharing findings with some substance behind them on the emerging management science of R&D Spending.

Each webinar presents the essence of the subject matter on each topic and provides complete references, citations, and additional sources of information to enable you to dive deeper into any specific topic where you wish further information. If you are looking for "just the facts" without any spin or someone trying to sell you something, these webinars are just for you.

The first program focuses on factors that will negatively impact spending and spending performance. Some of them are controllable, some are not. We discuss eight conditions ranging from spending decisions in boom and bust periods, to overspending and underspending, to the impacts of variable spending and negative events on output and productivity, that lessen output and outcomes.

The second program focuses on key performance indicators [KPIs] that have R&D spending in their calculation. The metrics range from corporate metrics that are either reported to Wall Street or used by analysts and CFOs, to measures that help to divvy-up funds across business units of different purposes and performance levels, to measures that improve the ranking of investments, to measures that can be used to modulate overspending or underspending for corporate and industry considerations.

The third program focuses on factors that will positively influence spending and spending performance. All of them are within your control. Does your company have its arms around these? We describe eight actions ranging from good CXO behaviors, to data sciences and digital posturing, to timing new product announcements and actively competing for awards, that increase output and outcomes.

http://www.goldensegroupinc.com/webinars/WB02-r-and-d-spending-performance-8-8-8-product-development-productivity.shtml

#innovation#r&d spending#performance#research and development#product development#product design#engineering#trends#return on investment#metrics#innovation metrics

0 notes

Text

Product Design Awards Increase Company Value

Studies show that Announcements and Awards boost Stock Prices and Market Cap.

Do you submit your products to Award Show Competitions? It is great for both Company Culture and Corporate Performance.

https://www.machinedesign.com/industrial-automation/product-design-awards-increase-company-value

#innovation#open innovation#design#product design#product development#productivity#performance#stock valuation#stock price#stock prices#market cap#marketing#awards#winners#competitive advantage

0 notes

Text

8 Great Innovation Practices Webinar - Thursday September 27, 2018

The webinar will open by making the case that innovation output levels have been declining steadily for forty years, a 65% decline over the period. We will look at changes to portfolio management practices and R&D spending allocations over the past 2-3 decades. Then we will turn the corner and look at the eight-year stretch of spending going on right now. This will put a smile on your face. We'll then describe each of the eight practices, and why they qualify as Great Practices which is the focus of the program. There will be two polls.

#innovation#Product Management#productivity#product design#new products#product development#engineering#design engineering#manufacturing#performance#business performance#cto

0 notes

Text

Corporate Innovation KPIs | Demo Recording | 4 Minutes | 9 KPIs That Capture Innovation Performance

A handful of great #company #metrics for #Research & #Development and #ProductDevelopment. #CEO #CTO #CFO #ProductManagement #Financial #Management. #Corporate #Innovation #KPIs

http://www.goldensegroupinc.com/webinars/W007-bradford-goldense-9-KPIs-that-capture-innovation-performance.shtml

0 notes

Text

Breakthrough Innovation | Demo Recording | 4 Minutes | 10 Techniques

10 Techniques that achieve #NextGen, #Disruptive, #Radical, New-To-The-World/Industry, or #Breakthrough #Innovation from #productmanagement and #productdevelopment in #corporations.

http://www.goldensegroupinc.com/webinars/W006-bradford-goldense-10-techniques-that-achieve-breakthrough-innovation.shtml

0 notes

Text

DFAM: Design for Additive Manufacturing Arrives

A lot is happening in Design for Manufacturability (DFM) and Design for Assembly (DFA) these days. The body of knowledge originated in the early 1970s and has been growing steadily ever since. #3Dprinting is soon to become #3Dproduction. 2018 is the inflection point of #3D #transformation. #AdditiveManufacturing (AM) will soon require a methodology for systematically designing products to optimize how they are produced using AM. #RapidPrototyping and 3D printing are about validating #design parameters and basic #concepts of #production. The production process adds a whole level of design detail. Initial Design for Additive Manufacturing (DFAM) work began about three years ago. The DFAM Wikipedia page began in September 2016. Seminars are starting. https://www.machinedesign.com/3d-printing/dfam-design-additive-manufacturing-arrives

0 notes

Text

The 6 Types of Manufacturing Processes: The Impact of Additive Manufacturing

3DPrinting, in large volumes for the same part, becomes #AdditiveManufacturing.

Within 3 to 5 years, #engineering and #manufacturing leaders will look out at their #production floors and wonder if they should tool-up or modify an assembly line for their #NewProduct --- or just buy the #AM or #MetalAM machines they need for the volume they anticipate instead. https://www.machinedesign.com/3d-printing/6-types-manufacturing-processes-impact-am

0 notes

Text

Metal AM: Metal Additive Manufacturing Hits Critical Mass

Rapid prototyping technology, building parts by creating a series of successive layers, began in the 1980s in Japan and immediately became a subject of interest in the U.S. The first patent, which coined the term stereo lithography (SLA), was granted in 1986 to Chuck Hull in the U.S. His 3D Systems company created the first prototype equipment in 1987 and launched the first commercial equipment in 1988. By the early 1990s, a half-dozen technologies based on layering principles were in the early stages of commercialization. Many subsequent approaches evolved from using liquids as the base material to using powders. Until the advent of powders, it was technically impossible to consider metal prototypes. The race to achieve metal prototypes now began. Twenty-five years later, the industry has achieved metal additive prototypes and is on the cusp of widespread Metal Additive Manufacturing (Metal AM). http://www.machinedesign.com/3d-printing/metal-am-metal-additive-manufacturing-hits-critical-mass

0 notes

Text

9 KPIs That Capture Innovation Performance

The number of distinct metrics that are being used to measure R&D and product development total close to 1000. There are metrics for projects, products, processes, technologies, functional and technical disciplines, degrees of innovation, and more. GGI has pioneered improved metrics and KPIs for innovation and execution since the 1980s. We continually research industry usage. For this webinar, we have selected 9 metrics that go a long way to capturing overall corporate innovation performance.

Discussing the innovation body of knowledge is one of the more enjoyable topics of business. At the same time, mastery has a large payback and makes everyone proud. Join us for some practical and contemplative discussions on subjects relevant to corporate innovation performance.

http://www.goldensegroupinc.com/webinars/W007-bradford-goldense-9-KPIs-that-capture-innovation-performance.shtml

#innovation metrics#innovation#portfolio#portfolio management#product portfolio#product strategy#productivity#product#product design#product development#business strategy#business analytics#business intelligence#research and development#Applied research#Advanced Development#competitive advantage#kpis#kpi#big data

1 note

·

View note

Text

The 6 Types of Manufacturing Processes

3D Printing has achieved the status of a manufacturing process. Additive Manufacturing is here and growing rapidly. Reliable materials now span Plastics, Composites, and Metals. Next Generation Production Productivity is close at hand.

Posted on Machine Design 7/20/18. Will publish in the August 2018 printed issue.

http://www.machinedesign.com/3d-printing/6-types-manufacturing-processes

#3D#3DPrinting#additive manufacturing#manufacturing#business strategy#business process#Metals#Composites#Plastics#Resins#production#productivity#product design#product development#innovation#disruptive innovation#breakthrough#next gen rp#next generation#new products#products#design#design review

1 note

·

View note

Text

GGI Introduces New Webinar Programs on Innovation Productivity -- Starting With "The Innovation Performance 10-9-8 Webinar Series"

Needham, Massachusetts - PRWeb - June 28, 2018 - Beginning in the summer of 2018, GGI will launch a series of individual and bundled webinar programs that provide a convenient alternative to traveling to participate in our in-person Summits and Masterclasses.

The Innovation Performance 10-9-8 Webinar Series

GGI's inaugural webinar offerings will be on three subjects: Breakthrough Innovation, Innovation KPIs, and Innovation Best Practices.

On the third Thursday of July, August, and September 2018, please consider joining us at 2:00 PM Eastern Time for a one hour synthesis of these three important innovation productivity areas.

Each webinar will present the essence of the subject matter on the topic; and provide complete references, citations, and additional sources of information so participants can dive deeper into any specific topic where they wish further information.

10 Techniques That Achieve Breakthrough Innovation - July 26, 2018

This webinar focuses on ten differentiable techniques that have evolved since Clayton Christensen first coined "Disruptive Innovation" in the 1990s. These ten techniques are all disruptive in some way across the spectrum of disruption: Breakthrough, Disruptive, Radical, Transformational, New-To-The-World, New-To-The-Industry, and Next Generation.

9 KPIs That Capture Innovation Performance - August 23, 2018

This webinar focuses on nine Key Performance Indicators (KPIs) that together capture the lion's share of overall innovation performance. These nine KPIs span investment levels, innovation levels, execution ability, productivity, and overall business performance.

8 Practices That Boost Corporate Innovation - September 27, 2018

This webinar focuses on eight processes, tools, and techniques that are known to increase innovation creativity and execution, and/or the value of investments in innovation, in corporations. Some are strategic and soft in nature, such as communication and messaging. Some are tactical, such as combining products and IP in business plans. Others are process-oriented and spur raw innovation or the early detection of errors.

GGI Experience

Founded in 1986, GGI has consulted to over 200 medium and large companies. Some 500 companies have participated in GGI's educational events. Since 1998 the company has performed primary and secondary research on R&D, product development, innovation, and metrics. With several hundred published articles and research reports, and an equal number of public and conference presentations, GGI is well qualified to offer value-added one-hour webinars to corporate innovation leaders and practitioners.

Brad Goldense, GGI's President and webinar presenter, taught practicing managers and executives for nineteen years in the Masters in Engineering Management program at The Gordon Institute of Tufts University weekend graduate-level program. Mr. Goldense, an engineer and MBA with four technical certifications and forty-years of experience, is proficient in disseminating practical knowledge and insights to professionals who are responsible for strategy and bottom-line performance.

For the past five years, Mr. Goldense has written "Goldense on R&D-Product Development," the inside back page article on engineering strategy and management for Informa's monthly Machine Design magazine. He is a frequent speaker at the International Forum on Design for Manufacture and Assembly for three decades, and at the R&D 100 Conference that is held in conjunction with the R&D 100 Awards each year. Brad is a member of the judging panel for Design World's Leadership in Engineering Achievement Program - LEAP Awards.

——————————————

If you are looking for content without spin, and knowledge that can be put to practical use, our educational webinars will not disappoint.

0 notes