Don't wanna be here? Send us removal request.

Text

Heat pipe heatsink

The heat pipe heatsink is composed of sealing tube, suction core and steam channel. The core-pulling is enclosed in the wall of the sealing tube and saturates the saturated volatile liquid. The liquid can be distilled water, ammonia, methanol or acetone. The heat pipe heatsink filled with ammonia, methanol, acetone and other liquids still has good heat dissipation capacity at low temperature. When the heat pipe heatsink runs, it’s evaporating section absorbs the heat generated from the heat source (the power semiconductor device, etc.), making the liquid in the core boil into steam. The heated steam moves from the evaporating part of the heat pipe heatsink to the cooling part, where it condenses into a liquid. The condensed liquid returns to the evaporation section through the capillary action of the suction core on the wall, repeating the above continuous cooling cycle.

Compared with other traditional ways of heat dissipation, heat pipe heatsink has the following advantages

Heat pipe heatsink has fast thermal response speed and heat transfer capacity more than 1000 times that of copper tube of the same size and weight;

Heat pipe heatsink small volume, light weight;

High heat dissipation efficiency, can simplify the heat dissipation design of electronic equipment, such as variable air cooling for self-cooling;

Heat pipe heatsink does not need external power supply, work without special maintenance;

Good isothermal, thermal balance, evaporation and cooling section of the temperature gradient is quite small, can be approximately regarded as 0;

heat pipe heatsink runs safely and reliably, without polluting the environment.

Reforge is a manufacturer of heat pipe heatsinks with advanced heat pipe technology, looking for heat pipe heatsinks, please contact us, we provide customized and standard heat pipe heatsinks.

0 notes

Text

Analysis on the use of heat sinks with different materials

Copper and aluminum composite heat sink water components should be deoxidized copper tube, the heat dissipation part for new aluminium alloy, after hydraulic pipe, close combination of copper and aluminum foil, the corrosion resistance of copper tube and aluminum fins the good heat dissipation effect of combined into an organic whole, so as to make the product with the resistance to corrosion, heat fast, thermal efficiency is high, one of the key recommendation is the national ministry of construction of energy saving heating heat sink

Light steel heat sink must be cold-rolled low carbon steel, the wall thickness of more than 1.5mm, but one-sided increase in the wall thickness and reduce the thermal strength of the metal, reduce the heat dissipation power and heat conduction performance of the product, heat dissipation effect is lower than the copper-aluminum composite heat sink.

3. The traditional cast iron heat sink for the recovery of waste steel melting and casting, metal thermal strength is low, large weight, high energy consumption, low heat dissipation power, contrary to the purpose of the introduction of energy saving technology, has been the national ministry of construction eliminated products.

0 notes

Photo

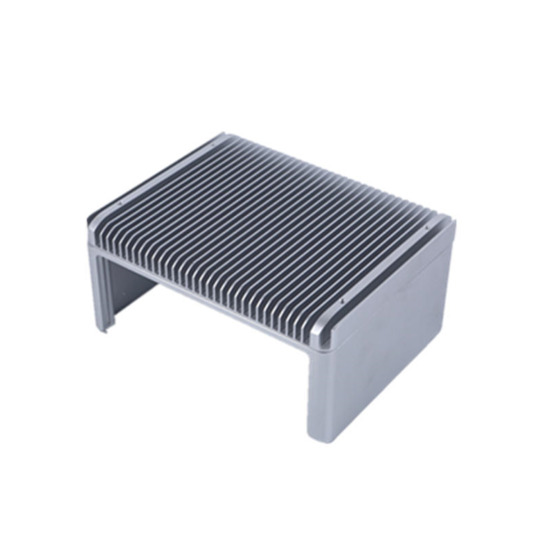

Drforge heat sink#aluminum heat sink # #aluminum extrusion#

0 notes

Photo

#Drforge heat sink##Drforge aluminum heat sink##Drforge extruded heat sink#

0 notes

Text

Aluminum extruded heat sink

Soft and easy machining aluminium because itself have long been used in the heat sink market. According to the characteristics of the aluminum, extrusion technology used heat sink meaning is, simply said after aluminium ingot heating, the aluminum liquid under high pressure through the groove of the extrusion mould, make the heat sink in the early embryo, but again to heat sink in the early embryo cutting, cross cutting, such as processing and then made into our common to the heat sink. Extruded aluminum heat sink of low cost, technical threshold requirement is not high also, but due to the limitation of itself material thickness and the ratio of the length of the cooling fins cannot exceed 1:18, so within the limited space, it is difficult to increase the cooling area, so the extruded aluminum heat sink cooling effect is poorer, it is hard to do today's rising high frequency CPU. # heat sink types##extruded heat sink##aluminum heat sink##Drforge heat sink#

0 notes

Text

Welcome to Tangs Machinery

Drforge is a technology-leading custom automotive industrial heatsink, uninterruptible power supply heatsink, wind turbine heatsink, photovoltaic inverter heatsink, power electronic heatsink, induction heater heatsink, computer heatsink, mobile phone heatsink, motor Manufacturers of thermal management solutions for equipment heatsinks, multi-function electric heatsinks, power equipment heatsinks, communication base station heatsinks, etc.

Our main products are heat pipes, heat sinks, heatsinks, aluminum extrusions, copper or brass extrusions, heatsink extrusions, metal stampings, metal castings, metal mesh and other LED heat sinks, metal parts, Lighting, Computers and Data Processing Centers, Consumer Electronics and Power Electronics, Power, Semiconductors, Communications, Transportation, Aerospace and Avionics, Business Machines and Equipment, Injection Molding, Automotive, Renewable Energy and Energy Conversion, Medical and Test Equipment , food service industry.

The Drforge plant is a major supplier of heat pipes and heatsinks in mainland China and has exported its products to Europe, North America, South America, Africa and Asia for about 12 years. If you want to import all kinds of heatsinks, aluminum or copper heat sinks, aluminum heatsinks, aluminum extrusion profiles, metal stampings and castings from China, please contact me immediately, (plus form inquiry) we can become your reliable supply. Business.Warmly welcome OEM and ODM!

1 note

·

View note