#what is bopp tape

Explore tagged Tumblr posts

Text

alt text under the cut:

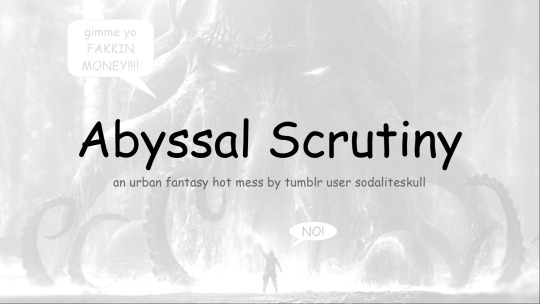

SLIDE ONE

TEXT: Abyssal Scrutiny: an urban fantasy hot mess by tumblr user sodaliteskull

(IMAGES: the background shows a washed out image of a person standing before Cthulhu. They are minuscule in comparison. A speech bubble coming out of Cthulhu's mouth reads, "gimme yo FAKKIN MONEY!!!!"to which the person is responding, "NO!")

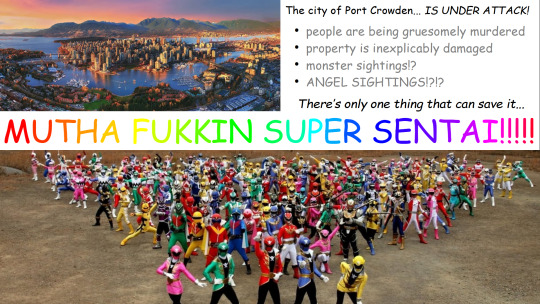

SLIDE TWO

TEXT: The city of Port Crowden... IS UNDER ATTACK!

people are being gruesomely murdered

property is inexplicably damaged

monster sightings!?

ANGEL SIGHTINGS!?!?

There's only one thing that can save it... MUTHA FUKKIN SUPER SENTAI!!!!!

(IMAGES: in the upper left hand corner is a picture of Vancouver, standing in for the fictional city of Port Crowden. Along the bottom is an image from the 35th anniversary of the Super Sentai media franchise, showing nearly 200 precursors to the Power Rangers)

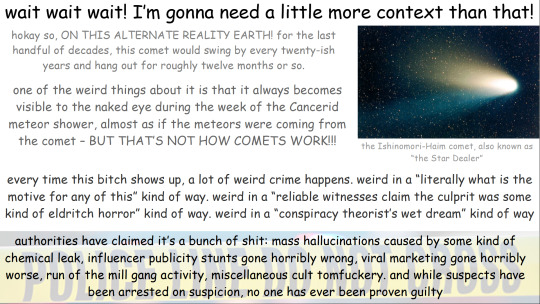

SLIDE THREE

TEXT: wait wait wait! I'm gonna need a little more context than that!

hokay so, ON THIS ALTERNATE REALITY EARTH! for the last handful of decades, this comet would swing by every twenty-ish years and hang out for roughly twelve months of so.

one of the weird things about it is that is always becomes visible to the naked eye during the week of the Cancerid meteor shower, almost as if the meteors were coming from the comet - BUT THAT'S NOT HOW COMETS WORK!!!

every time this bitch shows up, a lot of weird crime happens. weird in a "literally what is the motive for any of this" kind of way. weird in a "reliable witnesses claim the culprit was some kind of eldritch horror" kind of way. weird in a "conspiracy theorist's wet dream" kind of way

authorities have claimed it's a bunch of shit: mass hallucinations caused by some kind of chemical leak, influencer publicity stunts gone horribly wrong, viral marketing gone horrible worse, run of the mill gang activity, miscellaneous cult tomfuckery. and while suspects have been arrested on suspicion, no one has ever been proven guilty

(IMAGE: a picture of comet Hale-Bopp, standing in for the Star Dealer comet)

the Ishinomori-Haim comet, also know as "the Star Dealer"

(IMAGE: along the bottom is a faded out photo of "POLICE LINE DO NOT CROSS" tape)

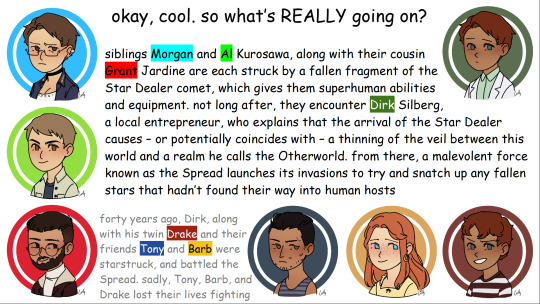

SLIDE FOUR

TEXT: okay, cool. so what's REALLY going on?

siblings Morgan and Al Kurosawa, along with their cousin Grant Jardine are each struck by a fallen fragment of the Star Dealer comet, which gives them superhuman abilities and equipment. not long after, they encounter Dirk Silberg, a local entrepreneur, who explains that the arrival of the Star Dealer causes - or potentially coincides with - a thinning of the veil between this world and a realm he calls the Otherworld. from there, a malevolent force known as the Spread launches its invasions to try and snatch up any fallen stars that hadn't found their way into human hosts.

forty years ago, Dirk, along with his twin Drake and their friends Tony and Barb were starstruck, and battled the Spread. sadly, Tony, Barb, and Drake lost their lives fighting

(IMAGES: Picrews of the characters mentioned. Morgan has short brown hair, brown eyes, tan skin, glasses, and is associated with the colour blue. Al has short sandy brown hair, brown eyes, tan skin, and is associated with the colour green. Grant has short dark brown hair and beard, dark brown eyes, olive skin, glasses, and is associated with the colour red. Dirk has short ruddy brown hair, hazel eyes, olive skin, and is associated with the colour green. Drake has short ruddy brown hair, hazel eyes, olive skin, and is associated with the colour red. Tony has short black hair and stubble, light brown eyes, olive skin, and is associated with the colour blue. Barb has long ginger hair, blue eyes, fair skin covered in freckles, and is associated with the colour yellow.)

SLIDE FIVE

TEXT: this is just a Power Rangers reskin, isn't it?

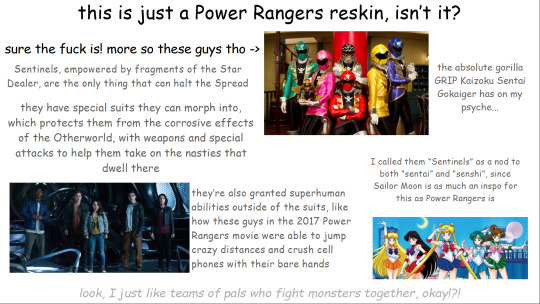

sure the fuck is! more so these guys tho -> (IMAGE: a team photo of the Gokaigers. Gokai Red is seated with his arms crossed, while Gokai Yellow is to his left, and Gokai Pink is to his right, holding the mechanical bird Navi in her arms. Gokai Silver is standing behind Gokai Red, while Gokai Blue is to the left of Gokai Yellow, and Gokai Green is to the right of Gokai Pink)

the absolute gorilla GRIP Kaizoku Sentai Gokaiger has on my psyche…

Sentinels, empowered by fragments of the Star Dealer, are the only thing that can halt the Spread

they have special suits they can morph into, which protects them from the corrosive effects of the Otherworld, with weapons and special attacks to help them take on the nasties that dwell there

they are also granted superhuman abilities outside of the suits, like how these guys in the 2017 Power Rangers movie were able to jump crazy distances and crush cell phones with their bare hands (IMAGE: a screenshot from the aforementioned movie, showing Billy, Jason, Trini, Zack, and Kimberly standing in the Command Centre)

I call them "Sentinels" as a nod to both "sentai" and "senshi", since Sailor Moon is as much an inspo for this as Power Rangers is (IMAGE: a promotional image from the 90's Sailor Moon anime, showing Sailor Venus, Sailor Mars, Sailor Moon, Sailor Mercury, and Sailor Jupiter striking their signature poses against the background of a Tokyo night skyline)

look, I just like teams of pals who fight monsters together, okay!?!

SLIDE SIX

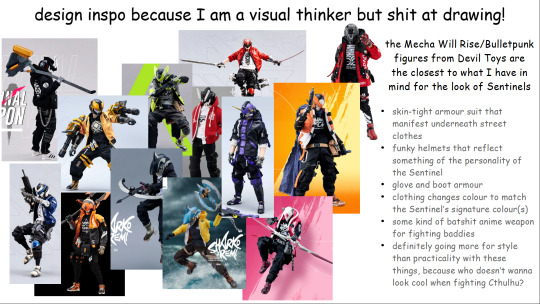

TEXT: design inspo because I am a visual thinker but shit at drawing!

the Mecha Will Rise/Bulletpunk figures from Devil Toys are the closest to what I have in mind for the look of Sentinels

skin-tight armour suits that manifest underneath street clothes

funky helmets that reflect the personality of the Sentinel

glove and boot armour

clothing changes colour to match the Sentinel's signature colour(s)

some kind of batshit anime weapon for fighting

definitely going more for style than practicality with these things, because who doesn't wanna look cute when fighting Cthulhu?

(IMAGES: thirteen figures from Devil Toys, all of which are wearing cyberpunk/techwear fashion in an assortment of colours, all of them wearing mecha style helmets, while some of them are wielding some kind of over-the-top weapon)

SLIDE SEVEN

TEXT: so I take it you aren't talking about butter?

nope! this ceaseless wave of nightmare fuel wants one thing and one thing only: to monch and cronch on fallen stars. they are single minded in their pursuit, closer to a fire consuming whatever is flammable in its path rather than an intelligence that is working towards a goal

At least, that was the case, until these tarot themed weirdos showed up and started bossing the Spread around! (IMAGES: arrows pointing to four figures - the Empress, a woman with long black hair and pale purple skin and dark purple eyes, associated with the colour silver. the High Priestess, with long pale green hair, darker green skin, and even darker green eyes, associates with the colour purple. the Magician, with a short ocean blue afro, sky blue skin, and pale blue eyes, wearing glasses and associated with the colour red. and the Fool, with long orange hair tied in a pony tail, khaki skin, and golden eyes, associated with the colour yellow)

the Spread are hard to categorize, as they're all chaotically shifting messes of tentacles and teeth. the only exceptions are the very rare, very powerful, and distinctly humanoid looking Abominations

(IMAGES: five pictures of eldritch horrors looming in nightmarish landscapes, representing the Spread. there's a lot of tentacles and pustules and assorted other body horror going on in each image. representing an Abomination is a humanoid figure somehow both skeletal and fleshy, with a mass of tentacles coming out of its back)

SLIDE EIGHT

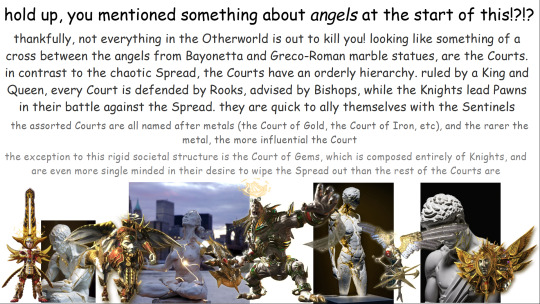

TEXT: hold up, you mentioned something about angles at the start of this!?!?

thankfully, not everything in the Otherworld is out to kill you! looking like something of a cross between the angles from Bayonetta and Greco-Roman marble statues, are the Courts. in contrast to the chaotic Spread, the Courts have an orderly hierarchy. ruled by a King and Queen, every Court is defended by Rooks, advised by Bishops, while the Knights lead Pawns in their battle against the Spread. they are quick to ally themselves with the Sentinels

the assorted Courts are all named after metals (the Court of Gold, the Court of Iron, etc), and the rarer the metal, the more influential the Court

the exception to this rigid societal structure is the Court of Gems, which is composed entirely of Knights, and are even more single minded in their desire to wipe the Spread out than the rest of the Courts are

(IMAGES: several different enemy angels from the Bayonetta games, all of them looking like mythological monsters made of white marble and wearing crimson and gold armour, with statuesque faces in places where they should not be. behind them are several white marble statues with veins of gold running through them, almost giving them the effect of the Japanese style of Kintsugi, wherein one uses gold to mend cracks in pottery)

SLIDE NINE

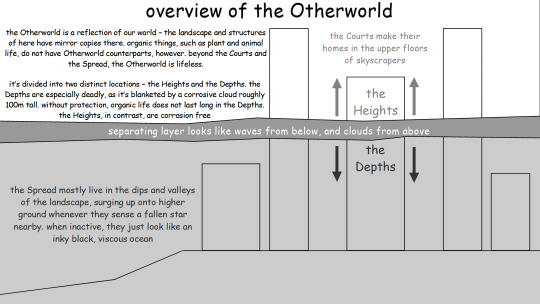

TEXT: overview of the Otherworld

the Otherworld is a reflection of our world - the landscape and structures of here have mirror copies there. organic things, such as plants and animal life, do not have Otherworld counterparts, however. beyond the Courts and the Spread, the Otherworld is lifeless.

it's divided into two distinct locations - the Heights and the Depths. the Depths are especially deadly, as it's blanketed by a corrosive cloud roughly 100m tall. without protection, organic life does not last long in the Depths. the Heights, in contrast, are corrosion free.

(IMAGE: a rough outline of five buildings on a flat plateau, to the left of which slopes down off screen)

the Heights

the Courts make their homes in the upper floors of skyscrapers

(IMAGE: the three tallest buildings are poking up into the Heights, while everything else in the city resides in the Depths)

separating layer looks like waves from below, and clouds from above

the Depths

the Spread live in the dips and valleys of the landscape, surging up onto higher ground whenever they sense a fallen star nearby. when inactive, they just look like an inky black, viscous ocean

SLIDE TEN

(IMAGE: the background is the person standing before Cthulhu image from the first slide, only washed out to the point where it's barely visible)

TEXT: so sum this shit up for me…

a comet swings by every twenty years and (potentially!?!?) shits debris all over the place

if a comet dropping hits a person, they become a Sentinel

if it lands on the ground, the fragment shifts the area around it into the Otherworld

drawn by the power of the fallen star, the Spread destroy everything in their path to get to it, people and buildings alike

in order to protect those around them, Sentinels need to hunt down these comet fragments and find a way to safely dispose of them

but how are Morgan, Al, and Grant going to deal with all this?

does Dirk have ulterior motives for helping them?

if Sentinels happen every time, why no mention of the team from twenty years ago?

what is going on with that tarot team?

if they've been fighting the Spread this long, why haven't the Courts succeeded yet?

all these questions (and more!) will be answered… once I actually fucking write this thing!

#comic sans wip intro#comic sans presentation#wip intro#story introduction#writers on tumblr#voidyelling.txt#sentinel.exe

6 notes

·

View notes

Text

MillenniumPackaging: Revolutionizing Packaging with BOPP Self-Adhesive Tapes

In the modern world of packaging, businesses demand reliable, cost-effective, and efficient solutions to ensure that their products are secure, well-presented, and protected during storage and transportation. One of the most trusted products in the packaging industry is the BOPP self-adhesive tape—a versatile, durable, and highly efficient solution for a wide range of packaging needs. MillenniumPackaging, a leader in the packaging industry, is at the forefront of providing high-quality BOPP (Biaxially Oriented Polypropylene) self-adhesive tapes that cater to businesses across different sectors.

What Is BOPP Self-Adhesive Tape?

BOPP self-adhesive tape is a type of packaging tape made from Biaxially Oriented Polypropylene (BOPP) film that has an adhesive layer applied to one side. The BOPP film itself is a lightweight, clear plastic material known for its exceptional strength, flexibility, and durability. The tape is often used for sealing boxes, cartons, and other packaging materials to ensure secure and tamper-evident closure.

Key features of BOPP self-adhesive tape include:

High Tensile Strength: BOPP tapes are designed to withstand pressure and handling, ensuring your packages stay secure throughout the entire shipping and storage process.

Excellent Adhesion: These tapes provide superior adhesion to a variety of surfaces, including cardboard, plastic, metal, and more, making them suitable for a wide range of applications.

Clarity and Aesthetic Appeal: BOPP self-adhesive tapes are available in transparent versions, which allow the packaging design or product labels to remain visible while still providing a secure seal.

Temperature Resistance: BOPP tapes can withstand varying temperatures, making them ideal for both cold and warm environments.

Cost-Effectiveness: Compared to other types of packaging tapes, BOPP tapes are relatively affordable, providing great value for high-quality performance.

Why Choose MillenniumPackaging for Your BOPP Self-Adhesive Tape Needs?

MillenniumPackaging has earned a solid reputation as a trusted manufacturer and supplier of packaging materials, particularly in the area of BOPP self-adhesive tapes. The company’s dedication to quality, efficiency, and customer satisfaction makes it the go-to choice for businesses looking for durable and reliable packaging solutions.

Here’s whyMillenniumPackaging stands out in the industry:

Superior Quality Control

At MillenniumPackaging, quality is paramount. Each roll of BOPP self-adhesive tape is manufactured using the highest standards of quality control. The company ensures that every tape roll undergoes stringent testing to guarantee consistent adhesive strength, film clarity, and durability. This attention to detail means businesses can trust MillenniumPackaging’s tapes to perform flawlessly every time.

Customizable Solutions

Every business has unique packaging needs. MillenniumPackaging understands this and offers customizable BOPP self-adhesive tapes in various sizes, thicknesses, and adhesive types to meet specific requirements. Whether you need clear, printed, or color-specific tapes, MillenniumPackaging has a solution that can be tailored to your brand’s needs, offering flexibility and personalisation for your packaging process.

Versatile Applications

MillenniumPackaging's BOPP self-adhesive tapes are used in a wide variety of industries. From e-commerce businesses looking for affordable, reliable packaging materials to logistics companies requiring tamper-proof seals, the versatility of BOPP tapes makes them a go-to choice for:

E-commerce: Securely sealing packages for online orders, ensuring customer satisfaction and product protection.

Manufacturing: Packaging components, products, or subassemblies for distribution.

Retail: Packing merchandise, sealing boxes for shipping, and improving brand visibility through custom printed tapes.

Food & Beverage: Sealing boxes and packages for hygiene and safety.

Pharmaceuticals: Ensuring tamper-proof packaging for medicines and medical supplies.

Eco-Friendly Options

As sustainability becomes an increasingly important factor in packaging decisions, MillenniumPackaging is committed to offering eco-friendly BOPP tapes. Their products are made using environmentally responsible materials and processes that minimize waste, making them a great option for businesses looking to reduce their environmental footprint.

Cost-Effective Pricing

MillenniumPackaging strives to provide competitive pricing without sacrificing the quality or performance of its products. Their BOPP self-adhesive tapes are not only durable and reliable but also affordable, making them an excellent choice for companies seeking a high-quality, cost-effective packaging solution.

Fast and Reliable Delivery

MillenniumPackaging understands the importance of time in business operations. With efficient production processes and a reliable delivery network, they ensure that businesses receive theirBOPP self-adhesive tapes on time and in full, enabling seamless packaging operations and preventing delays in the supply chain.

Excellent Customer Support

MillenniumPackaging is not just a supplier; they are a partner to their customers. Their dedicated customer service team is always ready to assist with product inquiries, provide technical support, and offer advice on the best packaging solutions for your needs. This focus on customer support ensures that businesses have the resources they need to optimize their packaging processes.

Applications of MillenniumPackaging’s BOPP Self-Adhesive Tapes

Sealing Cartons and Boxes: MillenniumPackaging's BOPP self-adhesive tapes are ideal for securely sealing cartons and boxes, ensuring that items stay intact during transportation and handling.

Bundling and Packaging: The strong adhesive and flexibility of BOPP tapes make them perfect for bundling products together and packaging irregularly shaped items.

Branding and Marketing: Custom printed BOPP tapes allow businesses to showcase their brand’s logo and messaging directly on the packaging, providing an opportunity to reinforce brand identity and customer loyalty.

Tamper-Evident Seals: The transparency and strong adhesive properties of BOPP tapes make them ideal for use in creating tamper-evident seals, particularly for the food, beverage, and pharmaceutical industries.

Conclusion

MillenniumPackaging has proven itself as a reliable and innovative manufacturer of BOPP self-adhesive tapes, providing businesses across various industries with efficient, cost-effective, and secure packaging solutions. With a focus on quality, versatility, and customer satisfaction, MillenniumPackaging ensures that their tapes meet the highest standards and deliver superior performance. Whether you're sealing e-commerce orders, packaging industrial products, or ensuring the security of food and pharmaceutical items, MillenniumPackaging’s BOPP self-adhesive tapes offer the perfect solution for your needs.

Visit:-https://milleniumpackaging.in/bopp-self-adhesive-tapes/

0 notes

Text

Polypropylene Film: A Versatile Material for Modern Applications

Polypropylene film, a durable and flexible plastic material, has become an integral part of various industries worldwide. Its versatility, cost-effectiveness, and superior performance characteristics make it an ideal solution for a wide range of applications, from packaging to industrial uses. At San-East, we specialize in providing high-quality polypropylene films tailored to meet diverse industry needs, ensuring that our customers get the most out of this multifaceted material.

In this blog, we’ll explore the different types of polypropylene films, their properties, applications, and why they are essential in today’s modern manufacturing landscape.

Understanding Polypropylene Film

Polypropylene (PP) is a thermoplastic polymer that is widely used in the production of films, fibers, and molded products. Polypropylene film, derived from this polymer, is created through a process known as extrusion. During extrusion, the polypropylene material is melted and stretched into thin sheets or films, which can then be further treated to achieve the desired properties. The result is a material that is not only lightweight but also boasts excellent mechanical strength, chemical resistance, and moisture barrier properties.

There are two primary types of polypropylene film: cast polypropylene (CPP) and biaxially oriented polypropylene (BOPP). While they share common characteristics, each has unique features that make them suitable for different applications.

1. Cast Polypropylene (CPP) Film

Cast polypropylene film is made by casting the melted polymer onto a chilled roller, resulting in a film with excellent clarity, softness, and flexibility. CPP film is typically used for food packaging, textile packaging, and stationary due to its ability to maintain its form even at lower temperatures. This type of film also offers excellent heat-sealing capabilities, making it a popular choice in industries where packaging integrity is critical.

Some notable advantages of CPP film include:

High transparency: The clear nature of CPP film makes it an excellent choice for packaging where product visibility is important.

Good moisture barrier: CPP films provide a reliable barrier against moisture, helping to preserve the quality of the packaged products.

Flexibility and tear resistance: It can easily conform to different shapes without tearing, making it suitable for wrapping items of varying sizes.

Low-cost production: Compared to other types of films, CPP offers an economical solution without compromising on quality.

2. Biaxially Oriented Polypropylene (BOPP) Film

Biaxially oriented polypropylene film, commonly referred to as BOPP, is created by stretching polypropylene film in both the machine direction and the transverse direction. This process aligns the molecules in two directions, which significantly improves the film’s tensile strength, clarity, and resistance to wear and tear. BOPP films are widely used in the food packaging industry, label production, and in the manufacture of adhesive tapes.

Key characteristics of BOPP film include:

Exceptional strength: Due to its biaxial orientation, BOPP film is far stronger and more durable than other plastic films.

Excellent clarity and gloss: The film’s high clarity and gloss provide an attractive appearance for consumer goods packaging.

Superior barrier properties: BOPP films offer excellent protection against moisture, grease, and various gases, helping to preserve the freshness of food products.

Recyclability: BOPP film is environmentally friendly and can be recycled, making it a sustainable option for companies looking to reduce their environmental impact.

The Properties That Make Polypropylene Film Stand Out

Polypropylene film’s wide acceptance across industries is due to a combination of its physical, chemical, and mechanical properties. Here’s a closer look at what makes polypropylene film so special:

1. Lightweight and Durable

Polypropylene film is incredibly lightweight, making it easy to handle and transport. Despite its light weight, it offers impressive strength and durability, allowing it to withstand harsh conditions without breaking or tearing.

2. Chemical Resistance

Polypropylene film has excellent resistance to a variety of chemicals, including acids, bases, and solvents. This makes it ideal for packaging products that may come into contact with such substances, especially in industrial or laboratory settings.

3. Heat Resistance

Polypropylene films can withstand high temperatures without melting or losing their structural integrity. This property is particularly important for food packaging, where materials often need to endure various processing conditions such as sterilization or cooking.

4. Moisture Barrier

Polypropylene films provide an effective barrier against moisture, which is crucial for applications like food packaging where maintaining freshness and preventing spoilage is a priority.

5. Flexibility and Transparency

Polypropylene films can be produced in various thicknesses, offering flexibility for different uses. Their high transparency also makes them ideal for clear packaging that showcases the product inside.

Common Applications of Polypropylene Film

Thanks to its versatility, polypropylene film is used in numerous industries. Let’s take a look at some of its most common applications:

1. Packaging Industry

One of the largest consumers of polypropylene film is the packaging industry. Both CPP and BOPP films are widely used in food packaging, offering excellent moisture and oxygen barrier properties. Polypropylene film is also favored for its clarity, which allows for attractive packaging designs that enhance product visibility on store shelves.

In addition to food packaging, polypropylene film is commonly used for wrapping textiles, cosmetics, and electronics due to its ability to protect products from environmental factors such as moisture, dust, and dirt.

2. Labels and Tapes

BOPP films, in particular, are a popular choice for the production of self-adhesive labels and tapes. Their high clarity and gloss make them perfect for creating visually appealing labels for consumer goods. Additionally, the strength of BOPP film ensures that labels and tapes remain intact even under harsh conditions, making them ideal for shipping and logistics.

3. Stationary and Graphic Arts

Polypropylene films are also widely used in the stationary industry for products like document covers, folders, and binding sheets. The film’s durability, resistance to water, and attractive appearance make it an excellent material for items that require both functionality and aesthetics.

4. Medical and Pharmaceutical Applications

Polypropylene films are often utilized in the medical and pharmaceutical industries for packaging sterile equipment and medicines. The film’s ability to resist moisture and contaminants helps ensure that medical supplies remain sterile and uncontaminated until they are needed.

5. Industrial Uses

In addition to packaging and consumer goods, polypropylene films have various industrial applications. They are often used as insulation materials in cables and capacitors, thanks to their electrical insulating properties. Polypropylene film is also used for protective overlays, laminates, and surface protection in industries such as automotive and construction.

Why Choose San-East for Polypropylene Film?

At San-East, we understand the importance of quality and reliability in the materials you choose for your business. Our polypropylene films are manufactured to the highest standards, ensuring that they meet the specific needs of your industry. Whether you’re looking for film solutions for packaging, labeling, or industrial uses, we’ve got you covered.

We offer both CPP and BOPP films, customized to your specifications. With a focus on sustainability, we are committed to providing recyclable polypropylene films that help reduce the environmental impact of plastic waste.

Conclusion

Polypropylene film is an essential material in modern manufacturing and packaging, offering unmatched versatility and performance across various industries. Its lightweight, durable, and environmentally friendly properties make it the material of choice for companies around the globe.

At San-East, we pride ourselves on delivering high-quality polypropylene films that meet your business needs. Contact us today to learn more about our products and how we can help you improve your operations with our top-notch polypropylene films.

0 notes

Text

BOPP Tapes: Versatile and Reliable Packaging Solutions

In the world of packaging and sealing solutions, BOPP (Biaxially Oriented Polypropylene) tapes have emerged as a highly versatile and beneficial option. These specialized tapes offer a range of advantages that make them a popular choice for various industries. Let's delve into the details of BOPP tapes and explore their key benefits. What are BOPP Tapes? BOPP tapes are a type of pressure-sensitive adhesive tape, primarily made from biaxially oriented polypropylene (BOPP) film. The biaxial orientation process gives these tapes superior strength, durability, and clarity compared to traditional packaging tapes. BOPP tapes are designed to provide a reliable and secure sealing solution for a wide range of applications. Strength and Durability One of the primary advantages of BOPP tapes is their exceptional strength and durability. The biaxial orientation process enhances the tensile strength and tear resistance of the tape, making it highly resistant to ripping, tearing, and breaking. This makes BOPP tapes ideal for heavy-duty packaging applications, ensuring the integrity of the sealed products during transportation and storage. Clarity and Aesthetics BOPP tapes are renowned for their crystal-clear appearance, which can greatly enhance the visual appeal of your packaging. The transparent nature of the tape allows the underlying packaging material to be clearly visible, creating a professional and polished look. This can be particularly beneficial for products where aesthetics and branding are crucial, such as in the retail or e-commerce industries. Versatility and Adaptability BOPP tapes are incredibly versatile, suitable for use on a wide range of surfaces and materials, including cardboard, paper, plastic, and more. This adaptability allows for seamless integration with various packaging solutions, making them a go-to choice for businesses across multiple industries. Reliable Adhesion BOPP tapes are equipped with a powerful pressure-sensitive adhesive that ensures a secure and long-lasting seal. This adhesive provides a strong bond, preventing the tape from peeling or coming undone during handling and transportation. This reliability is essential for maintaining the integrity of your packaged products. If you're interested in exploring the benefits of BOPP tapes for your packaging needs, I highly recommend checking out Rinkuplastic. As a leading manufacturer and supplier of BOPP tapes, Rinkuplastic offers a wide range of high-quality products to suit your specific requirements. Rinku Plastics BOPP tapes are designed to provide exceptional performance, with features like superior tensile strength, excellent clarity, and reliable adhesion. Their team of experts can also assist you in selecting the right BOPP tape solution for your business, ensuring that you get the best value and performance for your investment

0 notes

Text

What type of adhesive is Bopp?

Bopp adhesive refers to a type of adhesive used with BOPP (Biaxially Oriented Polypropylene) films. These films are widely used in packaging applications due to their clarity, strength, and resistance to moisture and chemicals. The adhesives used with BOPP films can vary depending on the specific application, but they generally fall into a few main categories:

Water-Based Acrylic Adhesives: These adhesives are environmentally friendly and offer good adhesion properties. They are commonly used for labels and tapes that require a clear and strong bond.

Hot Melt Adhesives: These adhesives are applied in a molten state and solidify upon cooling. They provide a strong bond and are often used in applications where quick adhesion is needed, such as in packaging tapes.

Solvent-Based Adhesives: These adhesives use organic solvents to dissolve the adhesive components. They offer excellent adhesion and durability but are less environmentally friendly due to the release of volatile organic compounds (VOCs).

UV-Curable Adhesives: These adhesives are cured using ultraviolet light, offering fast curing times and strong adhesion. They are used in applications where precision and speed are important.

The choice of adhesive depends on the specific requirements of the application, such as the need for clarity, strength, environmental considerations, and the type of BOPP film being used.

1 note

·

View note

Text

BOPP Bags: What They Are and Why Your Business Needs Them

Introduction

Welcome to our guide on BOPP bags, an essential packaging solution for businesses worldwide. In this comprehensive resource, we’ll delve into the benefits of BOPP bags, explore their manufacturing process, and highlight why your business needs them for optimal packaging. Join us as we uncover the key features and advantages of BOPP bags in today’s dynamic market landscape.

What are BOPP Bags?

BOPP, short for Biaxially Oriented Polypropylene, is a specialized packaging material renowned for its stability and versatility. BOPP bags are among the most prevalent packaging solutions due to their durability and reliability. These bags are manufactured by weaving and coating organic fabric during the production process, resulting in a robust packaging option.

In summary, BOPP bags offer a combination of stability, durability, and customization options, making them indispensable for packaging requirements across industries.

Manufacturing Process

Manufacturers employ a reverse printing technique to create these bags, wherein multi-colored films are inserted into cylinders. Subsequently, the bag is layered with woven materials, precisely cut, and sewn according to the customer’s specifications. For a more in-depth understanding of the manufacturing process, we encourage readers to refer to our detailed article [“The Intricacies of BOPP Bag Manufacturing: A Comprehensive Guide”] where we delve into each step with thorough explanations and visuals.

As a BOPP printed bag manufacturer, we prioritize providing diverse options to meet your packaging needs. Customers have the flexibility to choose from a wide range of colors to craft distinctive designs for their bags. The printing process occurs within a specialized machine known as an etched cylinder, ensuring precise application of brand logos and graphics onto the bags.

How Are They Diverse From Woven Bags?

BOPP bags and woven bags differ significantly in material composition, construction method, visual appeal, barrier properties, and cost considerations.

Material Composition: BOPP bags are made from Biaxially Oriented Polypropylene, while woven bags typically consist of woven polypropylene or other materials.

Construction Method: BOPP bags are produced through an extrusion process, whereas woven bags are created by weaving polypropylene tapes together.

Visual Appeal: BOPP bags offer superior printability and clarity, ideal for vibrant graphics and logos.

Barrier Properties: BOPP bags provide excellent moisture resistance compared to woven bags.

Cost Considerations: While BOPP bags may seem more expensive initially, their durability and printing capabilities often justify the investment.

BOPP bags and woven bags serve as viable packaging solutions, each with distinct advantages. Depending on specific needs, businesses can choose the option that best aligns with their objectives and budget constraints.

Choosing the Right BOPP Bags for Your Business

When it comes to selecting the perfect packaging solution for your business, Formosa Synthetics Pvt. Ltd. understands the importance of making informed choices. BOPP bags, known for their durability, versatility, and visual appeal, offer a range of benefits for various industries. However, choosing the right BOPP bags requires careful consideration of several factors to meet your specific packaging needs.

Product Specifications

Packaging Requirements

Branding Needs

Environmental Considerations

Budget Constraints

In conclusion, choosing the right BOPP bags for your business involves considering various factors such as product specifications, packaging requirements, branding needs, environmental considerations, and budget constraints. At Formosa Synthetics Pvt. Ltd., we offer a wide selection of high-quality BOPP bags tailored to meet your unique packaging needs. Contact us today to discover how our BOPP bags can enhance your packaging strategy and elevate your brand presence.

Conclusion

In conclusion, BOPP bags represent the epitome of modern packaging solutions, offering unmatched durability, versatility, and customization options essential for businesses across diverse sectors. At Formosa Synthetics Pvt. Ltd., we recognize the pivotal role packaging plays in shaping consumer perceptions and enhancing brand identity. With a meticulous focus on quality and innovation, our BOPP bags are meticulously crafted to meet the evolving needs of today’s dynamic market. Whether it’s safeguarding products during transportation or amplifying brand visibility through vibrant custom designs, our BOPP bags offer a winning combination of reliability and aesthetic appeal. Trust Formosa Synthetics Pvt. Ltd. to elevate your packaging strategy, ensuring your products stand out in the competitive marketplace while delivering exceptional value to your business.

Read More

#BOPPbags#packaging#manufacturing#business#branding#environment#FormosaSynthetics#productprotection#customization#marketpresence

0 notes

Text

Buy Printed Bopp Tape

Introduction :-

In today’s competitive market, standing out is crucial for businesses to capture the attention of their target audience. From product quality to branding, every aspect plays a vital role in shaping the perception of your brand. When it comes to packaging, the use of high-quality materials not only ensures the safety of your products but also serves as a powerful branding tool. One such material that combines functionality with branding opportunities is Printed Biaxially Oriented Polypropylene (BOPP) Tape. And when it comes to sourcing top-notch printed BOPP tape, look no further than Top Tite.

What is Printed BOPP Tape?

Before delving into the benefits of printed BOPP tape, let’s understand what it is. BOPP tape is made from biaxially oriented polypropylene film, which is known for its exceptional strength, durability, and resistance to tearing and moisture. Printed BOPP tape takes this a step further by allowing businesses to customize the tape with their branding, logos, or any other design elements. This not only serves a functional purpose in securing packages but also acts as a powerful marketing tool, effectively promoting your brand with every package that leaves your facility.

Enhance Brand Visibility

In today’s crowded marketplace, building brand recognition is essential for business success. Printed BOPP tape offers a unique opportunity to enhance your brand visibility every time a package is shipped or received. By featuring your logo, slogan, or other brand elements prominently on the tape, you ensure that your brand remains top-of-mind for customers and partners alike. This continuous reinforcement of your brand identity helps establish credibility and trust, ultimately leading to increased customer loyalty and repeat business.

Professional Appearance

First impressions matter, especially in business. When customers receive a package that is neatly sealed with custom-printed BOPP tape, it conveys professionalism and attention to detail. This can significantly impact the perception of your brand, instilling confidence in the quality of your products and services. Whether you’re shipping products to retail partners or directly to consumers, the use of printed BOPP tape elevates the unboxing experience, leaving a lasting impression that sets your brand apart from the competition.

Customization Options :-

At Top Tite, we understand that every business is unique, which is why we offer a wide range of customization options for printed BOPP tape. From choosing the width and length of the tape to selecting the color scheme and design elements, our team works closely with you to create a tape that perfectly aligns with your brand identity. Whether you prefer a minimalist design or a bold, eye-catching pattern, we have the expertise and resources to bring your vision to life.

Durability and Security :-

n addition to its branding benefits, printed BOPP tape offers the same level of durability and security as traditional BOPP tape. Its strong adhesive ensures that packages remain securely sealed during transit, protecting your products from damage or tampering. This peace of mind is invaluable, especially when shipping fragile or valuable items. With printed BOPP tape from Top Tite, you can rest assured that your packages will arrive safely and intact, preserving the integrity of your brand.

Cost-Effectiveness :-

Despite its many benefits, printed BOPP tape remains a cost-effective packaging solution for businesses of all sizes. Compared to other branding methods, such as custom packaging or labels, printed BOPP tape offers a more affordable option without sacrificing quality or impact. With low minimum order quantities and competitive pricing, Top Tite makes it easy for businesses to incorporate custom branding into their packaging strategy without breaking the bank.

Conclusion :-

In conclusion, printed BOPP tape offers a powerful combination of functionality and branding opportunities for businesses looking to enhance their packaging game. From increasing brand visibility to conveying professionalism and security, printed BOPP tape from Top Tite delivers tangible benefits that can positively impact your bottom line. With our customizable options, durability, and cost-effectiveness, there’s no better choice for businesses looking to make a lasting impression with their packaging. So why wait? Elevate your brand with printed BOPP tape from Top Tite today!

0 notes

Text

Unleashing Excellence: CPP Kanplas - Your Premier BOPP Tape Manufacturer

Introduction

At CPP Kanplas, we take pride in being the leading BOPP tape manufacturer that caters to your packaging needs with unparalleled quality and innovation. In a market flooded with options, we stand out as your go-to partner for superior BOPP tapes that guarantee durability, strength, and reliability.

Crafting Quality BOPP Tapes

Unrivaled Manufacturing Process

Our commitment to excellence begins with our state-of-the-art manufacturing process. Utilizing cutting-edge technology, we ensure that every inch of our BOPP tape is crafted to perfection. From raw material selection to the final product, precision is our mantra.

Innovative Design and Durability

What sets CPP Kanplas apart is our dedication to delivering BOPP tapes that not only adhere to industry standards but also exceed them. Our tapes boast innovative designs, providing maximum tensile strength and adhesion for a variety of applications.

Why Choose CPP Kanplas?

Extensive Product Range

We understand that different industries have diverse packaging requirements. That's why we offer an extensive range of BOPP tapes, catering to a wide spectrum of needs. Whether you require tapes for heavy-duty industrial use or delicate packaging, CPP Kanplas has you covered.

Customization Options

We recognize that one size does not fit all. At CPP Kanplas, we offer customizable BOPP tape solutions to meet your unique specifications. Choose from a variety of widths, lengths, and colors, ensuring that your packaging needs are met precisely.

Industry-Leading Quality Control

Rigorous Testing

Our commitment to quality extends beyond the manufacturing process. Every batch of BOPP tapes undergoes rigorous testing to ensure they meet and exceed industry standards. We leave no room for compromise when it comes to delivering excellence.

Eco-Friendly Practices

Sustainable Packaging Solutions

In an era where environmental consciousness is paramount, CPP Kanplas leads the way in providing eco-friendly packaging solutions. Our BOPP tapes are not only high-performing but also environmentally responsible, aligning with global sustainability goals.

Client Success Stories

Testimonials

Don't just take our word for it—hear what our satisfied clients have to say. Our success stories speak volumes about the trust our clients place in us. Join the ranks of businesses that have experienced the CPP Kanplas difference.

Conclusion

In conclusion, when it comes to choosing a BOPP tape manufacturer, CPP Kanplas emerges as the clear choice for those who demand nothing but the best. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry.

#BOPP Tape Manufacturer#cpp#cast polypropylene cpp films#laminated cpp film#cpp transparent film#cpp kanplas

0 notes

Text

Welcome to Vikentape – Your Premier Source for Elastic Solutions in Surat, Gujarat, India. As leading Elastic Tapes Wholesalers & Wholesale Dealers, we take pride in delivering unrivaled quality. Explore our extensive range, including knitted elastic, woven elastic, BOPP tape, face mask elastic, and more. Trust us as your go-to Elastic Manufacturer & Exporter, providing excellence in every strand. Elevate your projects with Vikentape's commitment to top-notch products – Your trusted partner for premium elastic solutions worldwide. "top elastic tape manufacturers in surat, elastic tape manufacturers in india, Woven Elastic Manufacturers & Suppliers in India"

#top elastic tape manufacturers in surat#elastic tape manufacturers in india#Woven Elastic Manufacturers & Suppliers in India

0 notes

Text

What are BOPP Adhesive Tapes? Its Benefits for Commercial Packaging

BOPP adhesive tapes, or Biaxially Oriented Polypropylene tapes, are a popular choice for commercial packaging due to their remarkable versatility and numerous benefits. These tapes are made from polypropylene, a thermoplastic polymer, and are processed through a biaxial orientation technique, which imparts superior strength and durability to the material. As a result, BOPP adhesive tapes have become an indispensable tool in the world of packaging, offering a range of advantages for businesses engaged in various industries.

What are the benefits of BOPP Tapes?

Let us see what BOPP Tapes has to offer in terms of benefits as explained in this blog by Packman Packaging India’s leading BOPP Tapes manufacturer and supplier.

· One of the primary benefits of BOPP adhesive tapes lies in their exceptional strength and resilience. The biaxial orientation process involves stretching the polypropylene film in both the machine and transverse directions, aligning the polymer molecules, and enhancing the tape’s tensile strength. This makes BOPP tapes ideal for securing packages of different sizes and weights, ensuring that they remain intact during transportation and handling.

· Commercial packaging often involves exposure to various environmental conditions, including changes in temperature and humidity. BOPP adhesive tapes excel in such scenarios due to their resistance to moisture and heat. These tapes maintain their adhesive properties even in challenging environments, ensuring that packages remain securely sealed. This resilience is particularly crucial for businesses engaged...

Read Here: https://www.packman.co.in/blog/bopp-self-adhesive-tapes-benefits/

#buy corrugated boxes#packman packaging#buy courier bags online#corrugated box manufacturers#corrugated boxes#buy corrugated boxes online#packmanpackaging#tamper proof courier bags#corrugated box suppliers#corrugated box wholesalers

0 notes

Text

The Versatility of Brown Kraft Paper: Jagannath Polymers

In the world of packaging and eco-friendly materials, brown kraft paper stands out as a versatile and sustainable choice. Jagannath Polymers, a leading name in the industry, is your go-to source for top-quality brown kraft paper products. Let's delve into the world of brown kraft paper and explore the many benefits it offers.

Eco-Friendly Excellence

One of the most significant advantages of brown kraft paper is its eco-friendly nature. Made from unbleached wood pulp, it retains its natural brown color, avoiding harmful chemicals commonly used in paper whitening. This makes it an excellent choice for businesses that prioritize sustainability and wish to reduce their environmental footprint.

Strength and Durability

Brown kraft paper is well-known for its exceptional strength and durability. It can withstand heavy loads and is resistant to tearing and puncturing, making it an ideal choice for packaging. Whether you're shipping fragile goods or heavy-duty industrial items, Jagannath Polymers' brown kraft paper can handle the job with ease.

Versatile Applications

Jagannath Polymers offers a wide range of brown kraft paper products suitable for various applications. From wrapping and cushioning materials to crafting, artistic projects, and even eco-friendly shopping bags, brown kraft paper has a multitude of uses. Its natural, rustic appearance adds an appealing touch to your products, making them stand out in the market.

Customizable Solutions

What sets Jagannath Polymers apart is their commitment to customer satisfaction. They offer customizable solutions, allowing businesses to order brown kraft paper products tailored to their specific needs. Whether you need rolls, sheets, or unique dimensions, Jagannath Polymers can provide the perfect brown kraft paper for your requirements.

In conclusion, brown kraft paper is a sustainable and versatile choice for a wide range of applications. When you're looking for high-quality brown kraft paper products, Jagannath Polymers is your trusted partner. They combine eco-friendliness, durability, and customization to meet the diverse needs of businesses across various industries. Make the environmentally responsible choice and explore the world of brown kraft paper with Jagannath Polymers.

For More Info: packing slip envelopes

bopp adhesive packing tape

packing tape for sale

0 notes

Text

Sticky Solutions: Unveiling the Brilliance of BOPP Adhesive Tape Film and the Innovations by China's Premier Manufacturers

In the realm of fastening and bonding solutions, one material has emerged as a true hero, effortlessly binding objects together while offering unmatched versatility - Biaxially Oriented Polypropylene Adhesive Tape Film, or BOPP adhesive tape film. As industries continue to seek robust and reliable bonding solutions, China BOPP adhesive tape film manufacturers have risen to the forefront, leading the charge with their innovative contributions and unwavering commitment to delivering top-tier products.

BOPP Adhesive Tape Film: The Bonding Marvel

BOPP adhesive tape film stands as a testament to human ingenuity, combining the exceptional mechanical properties of polypropylene with the adhesive prowess of modern technology. This specialized film is crafted through biaxial orientation, resulting in remarkable tensile strength, clarity, and dimensional stability. What truly sets BOPP adhesive tape film apart is its ability to be coated with adhesives, turning it into a versatile bonding agent suitable for a myriad of applications. From sealing boxes that traverse continents to crafting labels that adhere faithfully, BOPP adhesive tape film is a quiet champion that bonds the world together.

China BOPP Adhesive Tape Film Manufacturers: Trailblazers of Innovation

At the heart of the adhesive tape revolution are China's visionary manufacturers. These manufacturers have harnessed cutting-edge technology and industry insights to craft BOPP adhesive tape film that transcends expectations. Their products cater to a diverse array of industries, from logistics and packaging to crafting and construction. China BOPP adhesive tape film manufacturers have earned a reputation for consistently delivering solutions that marry performance and reliability, making them pivotal players in the global adhesive tape market.

Sustainability is also at the forefront of their priorities. By adopting eco-friendly production practices and exploring biodegradable adhesive options, these manufacturers are not only setting standards for product excellence but also contributing to a more sustainable future.

The Making of BOPP Adhesive Tape Film

Creating BOPP adhesive tape film involves a complex interplay of science and engineering. The process starts with extruding molten polypropylene through a flat die, forming a thin web. This web is then biaxially stretched to impart strength and clarity. The film is subsequently coated with adhesives, transforming it into a bonding agent that adheres securely to various surfaces. The result is a tape that bonds with precision and holds steadfast.

Innovations that Stick

China BOPP adhesive tape film manufacturers are not content with conventional solutions; they are driven by innovation. From high-tack adhesives that grip tightly to challenging surfaces to low-residue formulations that ensure clean removal, these manufacturers are redefining the possibilities of adhesive tape. They understand that bonding is more than just sticking; it's about creating enduring connections that withstand the test of time and conditions.

A Global Impact

The impact of BOPP adhesive tape film reverberates worldwide. It is the unsung hero that seals packages, constructs buildings, and affixes labels across continents. Its contributions are seen in the seamless function of everyday objects and the efficiency of industrial operations.

Final Reflections

BOPP adhesive tape film is a testament to the versatility of materials and the innovative spirit of industry leaders. China's manufacturers have embraced the challenge of creating a superior bonding solution and transformed it into an opportunity for progress. As the world continues to seek reliable and resilient adhesive solutions, it is certain that BOPP adhesive tape film will remain an essential component, reflecting China's commitment to shaping the future of bonding technology.

0 notes

Text

Introducing the Special Edition Box 3D Film Wrapping Packaging Machine

Introduction: In today's fast-paced world, efficient and precise packaging is crucial for businesses to meet the demands of consumers and maintain a competitive edge. The Box 3D Film Wrapping Packaging Machine has emerged as an innovative solution, transforming the packaging process and delivering superior results in terms of efficiency, productivity, and product protection. This article will explore the key features, benefits, and applications of the Box 3D Film Wrapping Packaging Machine, highlighting how it is revolutionizing the industry.

What is box 3D film wrapping packaging machine?

The Box 3D Film Wrapping Packaging Machine is a type of packaging equipment that is specifically designed for wrapping or packaging various products using a 3D film. It is a versatile machine that can handle different types of packaging materials, such as OPP or BOPP films, to securely wrap and seal boxes or products.

This machine is equipped with advanced features and mechanisms to automate the packaging process, improving efficiency and productivity. It typically consists of a conveyor system that transports the box or product through the packaging area, where the 3D film is wrapped tightly around it. The film is then sealed to create a secure and tamper-evident packaging. The machine may also include additional features like tear tape applicators for easy opening, adjustable settings for different box sizes, and controls for temperature, speed, and tension.

The Box 3D Film Wrapping Packaging Machine is commonly used in various industries, including food and beverage, cosmetics, pharmaceuticals, and electronics. It offers benefits such as improved packaging consistency, enhanced product protection, and increased production efficiency compared to manual wrapping methods.

There are various types of Box 3D Film Wrapping Packaging Machines available in the market, each designed to cater to different packaging needs and requirements. Here are a few common types:

1.Fully Automatic Box 3D Film Wrapping Machine: This type of machine is fully automated, requiring minimal human intervention. It incorporates advanced technology and features like automatic film sealing, cutting, and tension control. These machines are suitable for high-volume production environments.

2.Semi-Automatic Box 3D Film Wrapping Machine: This type of machine combines automatic and manual processes. While some functions such as sealing and cutting may be automated, the loading and feeding of boxes or products may require manual intervention. Semi-automatic machines are often chosen for medium-scale production operations.

3.Compact Tabletop Box 3D Film Wrapping Machine: This type of machine is smaller in size and designed to be placed on a tabletop or workbench. It is suitable for lower volume production or where space is limited.

4.Customizable Box 3D Film Wrapping Machine: Some manufacturers offer customizable machines that can be tailored to specific packaging requirements. These machines can accommodate different box sizes, film materials, and additional features like tear tape applicators or printing capabilities.

It's important to select the appropriate type of Box 3D Film Wrapping Packaging Machine based on factors such as production volume, packaging specifications, and available space in the facility. Consulting with the machine manufacturer or supplier can help determine the most suitable type for specific packaging needs.

Working Flow of the Box 3D Film Wrapping Packaging Machine:

Set Up and Configuration: The first step in utilizing the Box 3D Film Wrapping Packaging Machine is the initial setup and configuration. Operators will need to ensure that the machine is placed in the appropriate location within the packaging facility and properly connected to the power source. They will also need to configure the machine's settings, such as temperature, speed, and tension, according to the specific packaging requirements.

Loading and Positioning: Once the machine is set up, the next step is to load the boxes or products onto the conveyor system. The operator will position each item correctly to ensure that it passes through the packaging zone smoothly and reliably. The machine's conveyor system can be adjusted to accommodate different box sizes and product shapes, ensuring flexibility in packaging operations.

Film Placement and Wrapping: With the products in position, the Box 3D Film Wrapping Packaging Machine will then initiate the wrapping process. The machine pulls the film from the roll and positions it correctly around the product. It utilizes 3D film technology, ensuring that the film wraps tightly around the box or product, providing a secure seal and protection against dust, moisture, and tampering. The tension and speed of the film can be adjusted to ensure optimal wrapping results.

Heat Sealing and Cutting: As the film is wrapped around the product, the Box 3D Film Wrapping Packaging Machine employs heat sealing technology to create a secure bond. The heated elements within the machine generate the necessary temperature to melt the film and fuse it together, creating a tight seal. Once the seal is complete, the machine will then cut the film precisely, ensuring a clean finish that is ready for storage or distribution.

Tear Tape Application (Optional): Some models of the Box 3D Film Wrapping Packaging Machine are equipped with tear tape applicators. In such cases, the tear tape is automatically applied to the film during the wrapping process. The tear tape provides a convenient opening mechanism for end consumers, allowing them to easily open the packaging without the need for additional tools.

The working flow of the Box 3D Film Wrapping Packaging Machine involves a series of steps that streamline the packaging process and deliver superior results. From initial setup and configuration to the final output of securely wrapped products, the machine's automated processes, versatility, and precise wrapping capabilities revolutionize the packaging industry. By adopting this advanced packaging solution, businesses can significantly improve efficiency, productivity, and product protection, ultimately enhancing customer satisfaction and gaining a competitive advantage in their respective markets.

The working principle of the Box 3D Film Wrapping Packaging Machine is based on the integration of various mechanisms and technologies to automate the process of wrapping boxes or products with film.

1.Conveyor System: The machine is equipped with a conveyor system that moves the boxes or products through the packaging zone. The conveyor system can be adjusted to accommodate different box sizes and product shapes, ensuring smooth and consistent movement.

2.Film Roll and Dispensing Mechanism: The machine is equipped with a film roll holder and dispensing mechanism. The film roll is placed on the machine, and the dispensing mechanism feeds the film onto the product surface.

3.Film Wrapping Mechanism: The film wrapping mechanism is responsible for initiating the wrapping process. It pulls the film from the roll and positions it correctly around the box or product. The mechanism ensures that the film wraps tightly around the item, providing a secure seal and protection.

4.Heat Sealing Mechanism: Once the film is in position, the machine utilizes a heat sealing mechanism to create a secure bond. This mechanism consists of heated elements that generate the necessary temperature to melt the film and fuse it together. The heat sealing process creates a tight seal around the box or product.

5.Cutting Mechanism: After the heat sealing process, the machine incorporates a cutting mechanism to trim the film precisely. The cutting mechanism ensures a clean finish, with no excess film, ready for storage, transportation, or display.

6.Tear Tape Applicator (Optional): Some models of the Box 3D Film Wrapping Packaging Machine are equipped with tear tape applicators. The tear tape is automatically applied to the film during the wrapping process, providing a convenient opening mechanism for end consumers.

7.Control System: The machine's control system allows operators to configure various settings, such as temperature, speed, tension, and film length. This control system ensures optimal wrapping results, customization to specific packaging requirements, and consistent performance.

What is OPP and BOPP packaging film?

OPP (Oriented Polypropylene) and BOPP (Biaxially Oriented Polypropylene) are types of packaging films commonly used in the packaging industry. Here's a brief explanation of each:

1.OPP Film: OPP stands for Oriented Polypropylene. It is a versatile and widely used packaging film that is made from polypropylene materials. OPP film is known for its transparency, excellent tensile strength, and moisture-resistant properties. It provides good protection against moisture, dust, and scratches, making it suitable for a range of packaging applications. OPP film is commonly used for wrapping various products like food items, cosmetics, CDs/DVDs, and more.

2.BOPP Film: BOPP stands for Biaxially Oriented Polypropylene. BOPP film is a variant of OPP film that undergoes a biaxial stretching process during manufacturing. This stretching process imparts enhanced mechanical characteristics to the film, including improved clarity, higher tensile strength, and superior stiffness. BOPP film offers excellent barrier properties against moisture, gases, and odors, making it suitable for applications that require high-quality packaging. BOPP film is commonly used for packaging snacks, confectionery, tobacco products, textiles, and more.

Both OPP and BOPP films can be further customized with different surface finishes, such as matte, glossy, or holographic, to enhance their appearance and shelf appeal. They can also be printed with high-quality graphics and logos to create visually appealing packaging designs.

OPP and BOPP films are widely preferred in the packaging industry due to their versatility, durability, cost-effectiveness, and superior packaging properties.

What is the sealing temperature of OPP and BOPP film?

The sealing temperature for OPP (Oriented Polypropylene) and BOPP (Biaxially Oriented Polypropylene) packaging films can vary depending on factors such as film thickness, machine type, and packaging requirements. However, in general, the sealing temperature for OPP and BOPP films typically ranges between 110°C (230°F) to 150°C (302°F).

The sealing temperature is critical to achieving a proper seal when using OPP or BOPP films. If the temperature is too low, the film may not seal properly, resulting in weak seals that can easily open or peel. If the temperature is too high, it can lead to film distortion or even burning, compromising the integrity of the packaging.

To determine the ideal sealing temperature for a specific OPP or BOPP film, it is recommended to conduct trial runs and make adjustments based on the packaging machine and film specifications. Additionally, manufacturers and suppliers of OPP and BOPP films usually provide guidelines regarding the recommended sealing temperatures for their specific products.

It is important to note that the sealing temperature can also be influenced by other factors such as dwell time (the duration for which the heated sealing jaw applies pressure), pressure, and film speed. These parameters can be adjusted as well to optimize the sealing process and ensure a secure and reliable seal for the packaging.

Features of the Box 3D Film Wrapping Packaging Machine:

1.Versatility and Customization: One of the standout features of the Box 3D Film Wrapping Packaging Machine is its versatility. It can accommodate a wide range of packaging materials such as OPP and BOPP films, allowing businesses to choose the most suitable film for their specific needs. The machine can be easily customized to handle different box sizes and product shapes, providing businesses with flexibility in their packaging operations. Whether it's boxes, pouches, or shrink-wrapped products, the Box 3D Film Wrapping Packaging Machine can handle various packaging applications with precision.

2.Enhanced Product Protection: Products packaged using the Box 3D Film Wrapping Machine benefit from enhanced protection during storage and transportation. The tightly sealed 3D film provides a barrier against dust, moisture, and tampering, ensuring the integrity of the packaged goods. This level of protection is particularly vital for industries such as food and beverage, pharmaceuticals, and electronics, where product freshness, safety, and security are paramount.

3.Improved Efficiency and Productivity: By automating the packaging process, the Box 3D Film Wrapping Machine significantly improves efficiency and productivity. Manual packaging tasks, which are time-consuming and prone to human error, are eliminated, allowing workers to focus on other critical aspects of production. The machine's high-speed capabilities and consistent wrapping quality result in faster processing times, enabling businesses to meet tight deadlines and manage higher production volumes.

4.User-Friendly Operation: The Box 3D Film Wrapping Packaging Machine offers a user-friendly operation that requires minimal training. Its intuitive controls and clearly labeled mechanisms make it easy for operators to set desired parameters such as temperature, speed, and tension. Additionally, many machines incorporate features like tear tape applicators, making it convenient for end consumers to open the packaging without requiring additional tools. This user-friendly design not only improves operational efficiency but also enhances the overall customer experience.

5.Applications in Various Industries: The Box 3D Film Wrapping Machine finds applications across a wide range of industries. In the food and beverage industry, it is used for packaging items like cereal boxes, snack bars, and beverage cartons. In the cosmetics industry, it protects items such as perfumes, creams, and cosmetics sets. Pharmaceuticals utilize the machine for the packaging of medicines, syringes, and medical devices. Even electronic items like mobile phones, tablets, and accessories can benefit from the precise and secure packaging provided by this machine.

Conclusion: The Box 3D Film Wrapping Packaging Machine has revolutionized the way products are packaged, offering businesses unparalleled efficiency, precision, and product protection. Its automated processes, versatility, and customizable features make it an indispensable tool for optimizing the packaging process in various industries. By embracing this innovative machine, businesses can streamline their operations, reduce costs, and ultimately enhance customer satisfaction. As the demand for efficient and precise packaging continues to rise, the Box 3D Film Wrapping Packaging Machine stands as a game-changer in the world of packaging.

#3Dpackagingmachine#3Dfilmwrappingmachine#3Dfilmwrappingpackagingmachine#BOPPfilmwrappingmachine#3dimensionfilmwrappingmachine#3Dfilmwrappingequipment#3Dfilmwrappingpackingline#BOPPfilm#3Dfilmwrappermachine#Box3Dfilmwrappingmachine#Box3Dfilmwrappingpackagingmachine

1 note

·

View note

Text

Bopp Films Manufacturer

Welcome to [Cosmofilms], your premier destination for top-notch Biaxially Oriented Polypropylene (BOPP) films that redefine packaging standards. As the industry's leading BOPP films manufacturer, we take pride in offering you an unparalleled range of packaging solutions that combine innovation, quality, and sustainability. In this comprehensive guide, we will delve into the intricacies of BOPP films, their exceptional features, diverse applications, and the reasons why we stand out as the preferred choice for industries worldwide.

Unveiling the Excellence of BOPP Films BOPP films, derived from polypropylene, undergo a specialized biaxial orientation process that equips them with outstanding mechanical properties and remarkable optical clarity. These films have earned their reputation for being incredibly versatile, making them the ideal choice for a wide range of applications across various industries.

Our Commitment to Clarity and Printability When it comes to packaging, aesthetics matter. That's why our BOPP films are engineered to provide crystal-clear transparency, allowing your products to shine through with unmatched clarity. What's more, our advanced printing techniques ensure that your branding and graphics remain vibrant and captivating on every package. At [Cosmofilms], we believe that packaging is not just about protection, but also about leaving a lasting impression.

Ensuring Product Freshness with Superior Barrier Properties In a rapidly evolving market, product quality and freshness are paramount. Our BOPP films offer superior barrier properties, acting as an effective shield against moisture, gases, and external contaminants. Whether it's food, electronics, or pharmaceuticals, our BOPP films extend the shelf life of your products while preserving their integrity and appeal.

Versatility Beyond Compare The beauty of BOPP films lies in their versatility, making them a true asset for numerous applications. From heat-sealable food packaging to high-tensile adhesive tapes, our BOPP films cater to a diverse spectrum of industries. With customizable thickness options and tailored features, we provide solutions that align precisely with your product's unique requirements.

Embracing Sustainability with BOPP Films In an age where sustainability is a priority, BOPP films rise to the occasion by being fully recyclable and contributing to reduced carbon footprints. Unlike traditional packaging materials, BOPP films can be recycled easily, fostering a circular economy and minimizing environmental impact. By choosing BOPP films from [Cosmofilms], you not only enhance your products but also play a pivotal role in preserving the planet.

#cosmo films#cosmo films company profile#bopp packaging material#antifog film#cpp film density#cpp film full form#cosmo films contact number#bopp labels#cpp film raw material#keyword

0 notes

Text

What kind of adhesive tape ought I to use?

Numerous varieties of specialized adhesive tapes are getting from China Bopp adhesive tape film suppliers, which have hundreds, if not thousands, of different applications. Therefore, it cannot be easy to comprehend which sort to order based on your needs.

Among the principal cassettes with unique properties are:

Reversible tapes

These tapes have two affixed sides, making them ideal for adhering two surfaces together if their edges do not join them or if the tape is not visible. Double-sided tape is a highly flexible tape available in various widths, colours, thicknesses, and adhesives and can withstand temperature extremes of up to 160oC. Standard double-sided tapes are suitable for lightweight applications, but specialized double-sided tapes are significantly more robust.

Foam adhesive tapes

These frequently provide water tightness and are therefore found in door and window seals. As a result, foam tapes are sometimes used to increase a home's energy efficiency, as they serve to retain the heat inside. Foam adhesive tapes are ideal for areas with movement, such as doors, where they may be required to expand and compress due to their cushioning properties. Foam adhesives are available with either a single- or double-sided adhesive.

Temperature-resistant adhesives

The utilization of high-temperature adhesives is highly specialized. High-temperature adhesives are used on circuit boards, for insulation, and in the aerospace industry. They can typically withstand temperatures between -70°C and 180°C.

Anti sliding tapes

Typically, these varieties of adhesive tape are used for safety and health purposes. Their most common application is on the edge of stairs or steps, as their primary property is a high-friction surface that prevents slippage. They are available in yellow, black, and glow-in-the-dark hues for increased visibility and, consequently, heightened awareness of potential hazards.

Tapes for glass/surface protection

As they are designed to cover larger surfaces, they are typically sold on wider rolls than other types of tape. During redecorating, construction, or do-it-yourself projects, protective adhesive bandages can be used to protect glass, wood, and carpet and keep windows, floorings, work surfaces, and kitchen units clean and undamaged.

0 notes

Text

INDUSTRIAL ADHESIVE TAPE

As one of the professional industrial tape manufacturers in China, Egret supplies many types of industrial adhesive tape. Particularly, applied to refrigerator, air conditioning, ducting work, building, insulation industries. Not to mention our advantage of coating abilities, we also have capabilities to slit, cut, rewind, die cutting and other converting services. Important to realize, our strong adhesive tape is aluminum foil tape, PE tape, po film, PET tape, MOPP/TPP tape, PVC non-adhesive tape.

Choose Egret as Your Industrial Adhesive Tape Supplier

Choose Egret as Your Industrial Adhesive Tape Supplier. Egret mfg offers many kinds of adhesive tapes, including Aluminum foil tape, PE white tape, PET blue tape, Masking paper tape, Cloth tape, PVC air conditioner tape, Vinyl electrical tape, Double-sided tissue tape, TPP/MOPP tape, Foam tape (VHB,PE,PU, EPDM, NBR, PVC,EVA,etc), BOPP packing tape, Kraft paper tape, PE protective film, PVC duct tape, etc. We mix and produce our own formula adhesive to save cost & improve adhesion.

Moreover, Egret has 10 adhesive coating lines. Likewise, 15 slitting machines with huge capacity. Additionally, our products certified with UL, ROHS, REACH, BS, CE, etc.

Furthermore, we’re Top 1 seller for aluminum foil tape in refrigerator industry in China. Especially, Egret is a golden supplier of Samsung, Toshiba, Haier, Midea, Arcelik, Hisense, etc

Features Of Industrial Adhesive Tape

What are the benefits & features of Egret adhesive tape?

Egret adhesive tape can replace of the bolts and nuts, to make it clean looking.

High adhesion and excellent tack

Good aging resistance for both indoor & outdoor use

Joints/seams sealing against moisture and vapor barrier

Easy hand tear for workers to use on-site

Excellent heat & light reflecting of aluminum foil backing

Combination of baking material ensures high flexibility and conformability

Extremely easy for hand-tear, easy-used by workers

Neat and invisible looking to be excellent alternative to metal fasteners, welding

0 notes