#welding solutions for automotive

Explore tagged Tumblr posts

Photo

Percussion Welding: A Comprehensive Solution for Many Industries

https://percussionwelder.com/ - Percussion welding is a versatile and reliable method of joining metal components. It offers several advantages for use in the medical, electronic, and automotive industries as compared to other traditional methods such as laser or resistance micro welding. Call us today at 303.536.7838 for more details.

Contact Us Percussion Welder 7100 Broadway, Building 2, Unit RS Denver, CO 80221 Ph No: 303-536-7838 Email: [email protected] URL: https://percussionwelder.com/

0 notes

Text

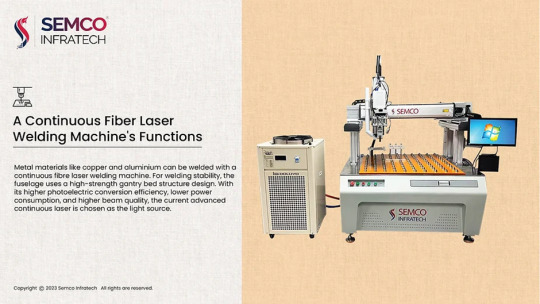

A Continuous Fiber Laser Welding Machine's Functions

Metal materials like copper and aluminum can be welded with a continuous fiber laser welding machine. For welding stability, the fuselage uses a high-strength gantry bed structure design. With its higher photoelectric conversion efficiency, lower power consumption, and higher beam quality, the current advanced continuous laser is chosen as the light source.

Benefits of the fiber laser apparatus include its small size, convenient use, and compact structure. Welding equipment can be efficiently integrated with other equipment in the system thanks to its versatile laser output mode. High speed and precision are ensured by the highly responsive servo motor output, which works with the high-precision and high-strength screw linear module as the operating transmission mechanism.

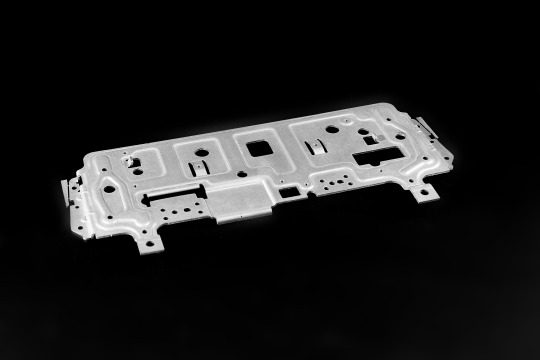

In the field of new energy lithium battery PACK modules, this makes the laser welding machine an essential piece of equipment. With its outstanding beam quality, quick welding speed, and gorgeous, sturdy welding pool, the continuous fiber laser welding machine offers the ideal, stable, and effective welding solution for the lithium battery welding process.

Unlocking the Advantages: Your Guide to the Equipment's Benefits

Perfect welding: Easy adjustment, fine focusing, imported optical lenses, high-precision laser welding head.

High-quality fiber laser: Internationally recognized, with years of industrial application, a long lifespan, and no maintenance required.

Energy efficiency: Low power consumption, high electro-optic conversion efficiency, and excellent beam quality.

Adjustable power: A continuous 2000-watt (adjustable) pure fiber laser that can penetrate materials with depths ranging from 0.1-3 mm.

Precision control: A precise servo system ensures welding accuracy.

User-friendly interface: Easy-to-learn PC industrial computer with a welding CNC programming system.

Wide range capabilities: large surface stroke welding, a gantry frame motion structure, high machine tool precision, and a stable, long-lasting service life.

Enhanced functionality: Data-saving call functions, strong drawing and editing graphics capabilities, and compatibility with a range of input formats.

Exploring Equipment Indicators and Parameters: Key Features

This welding equipment offers a range of features that make it versatile and reliable for various applications:

Material Compatibility: Welds materials with thicknesses ranging from 0.5 mm to 2.0 mm, suitable for diverse projects.

Workspace Flexibility: Effective travel range spans 870 mm in the X-axis and 600 mm in object workpiece height.

Adjustable Welding Speed: Operates at speeds of up to 10 mm/s, ensuring welds meet specific requirements.

Power Options: Offers adjustable laser power levels, including 2 KW, 3 KW, and 6 KW.

Durability: Features an optical fiber working medium with a service life exceeding five years.

Material Versatility: Suitable for welding nickel strips, copper sheets, and aluminum rows.

Welding Modes: Offers both continuous and pulse modes for versatile welding processes.

Spot Welding Capabilities: Achieves contact surface melting depths ranging from 0.5 mm to 1 mm, ensuring strong welds with tensile strength exceeding material destructive strength.

Characteristics of the Equipment

This welding equipment offers advantageous features for a seamless and efficient welding experience:

Maintenance-Free Operation: Reduces downtime and maintenance costs.

Adjustable Parameters: Allows for easy modification of welding parameters, including motion speed.

Fault Alerts: Real-time fault alarm prompts for immediate issue resolution.

Flexible Operation: Offers automatic and manual operation modes, supporting arc and straight-line interpolation.

Laser Processing: Enables the creation of various plane graphics such as points, straight lines, circles, and squares.

Durable Components: Equipped with imported lenses in the welding field mirror to withstand high laser-generated temperatures.

User-Friendly System: Easy-to-learn operating system simplifies manual operation.

Smoke and Slag Control: Built-in air-blown wind knife ensures welding quality.

Cooling System: A water-cooled cycle in the welding head ensures stable welding effects.

Precision Mechanism: High-precision screw transmission and high-speed servo motors ensure accuracy and responsiveness.

Environmental Conditions

To ensure optimal performance and safety, adhere to these specifications for the operating environment:

Ambient Temperature: Operates effectively between 5°C and 35°C.

Humidity: Maintain relative humidity levels between 20% and 90% to prevent condensation and corrosion.

Air Source Pressure: Requires a compressed air source with a pressure range of 0.5 to 0.6 Mpa.

Power Supply Voltage: A stable voltage of 380V at 50Hz or 60Hz is required.

Total Power: Consumes ≤10KW of power to prevent electrical overloading.

Load-Bearing Capacity: The installation area must support up to 500 kg/m².

Grounding Type: Direct grounding ensures safety and minimizes electrical hazards.

Installation Environment: Requires a flat, vibration-free, and shock-free area for precise and stable operations.

Adhering to these specifications ensures reliable operation, extending the equipment’s service life while preventing potential issues related to environmental conditions.

Final Thoughts

The continuous fiber laser welding machine represents a revolutionary step forward in welding technology. Its ability to deliver precise, efficient, and versatile welding solutions makes it an essential tool across industries, including automotive, aerospace, and renewable energy. By understanding its functions, benefits, and operational requirements, manufacturers can fully leverage this equipment to enhance productivity, reduce costs, and achieve superior product quality.

Investing in a continuous fiber laser welding machine is not just about adopting advanced technology—it's about future-proofing your manufacturing processes for the demands of tomorrow.

#Fiber Laser Welding Machine#Fiber Laser Welding Technology#High-Precision Welding Machines#Laser Welding for Copper and Aluminum#Industrial Laser Welding Equipment#Applications of Fiber Laser Welding#High-Strength Welding Equipment#Lithium Battery PACK Welding Solutions#Laser Welding for Automotive Manufacturing#Spot Welding vs. Continuous Laser Welding

0 notes

Text

Metal Welding Services in Miami: What to Know

Metal Welding Services in Miami: What to Know

If you’re searching for top-notch metal welding services near me in Miami, finding a professional and reliable service provider is key. Miami’s booming construction, automotive, and marine industries demand high-quality welding solutions for various projects. Let’s explore what makes metal welding services in Miami stand out and what you should look for when selecting a provider.

What Are Metal Welding Services?

Metal welding involves joining two or more metal parts through heat, pressure, or both. Welding is an essential process in industries like construction, automotive, manufacturing, and shipbuilding. Miami is home to a range of experienced welding professionals who cater to diverse project needs, including:

Structural welding: For buildings and bridges.

Automotive welding: For vehicle repairs and customization.

Marine welding: Specializing in ships and boats.

Custom metal fabrication: Tailored designs for unique projects.

Why Choose Professional Metal Welding Services in Miami?

Miami is a hub for skilled welders offering precision, durability, and expertise. Here are some key benefits of choosing local welding services:

Expertise in Various Techniques: Certified professionals in Miami use advanced techniques such as TIG, MIG, and stick welding for high-quality results.

Access to High-Quality Materials: Miami welding shops have access to durable metals like aluminum, stainless steel, and carbon steel.

Compliance with Local Regulations: Professionals ensure projects adhere to Miami’s building and safety codes.

Fast Turnaround Times: Local services minimize delays, ensuring your project is completed on time.

Types of Metal Welding Services Offered in Miami

Whether you’re working on a large-scale construction project or need small repairs, Miami’s welding professionals provide a range of services:

Residential Welding: Gates, fences, and railings.

Commercial Welding: Storefronts, signs, and structural supports.

Industrial Welding: Heavy machinery, pipelines, and tanks.

Repair Services: Fixing broken metal parts for boats, vehicles, or equipment.

How to Find the Best Metal Welding Services Near You

Finding the right welding service in Miami can be overwhelming. Here are some tips to help you choose the best provider:

Check for Certifications: Look for welders certified by organizations like the American Welding Society (AWS).

Read Reviews and Testimonials: Online reviews on platforms like Google and Yelp can give insights into the quality of service.

Compare Pricing: Request quotes from multiple providers to ensure competitive pricing without compromising quality.

Ask About Experience: Providers with extensive experience in your specific project type are likely to deliver better results.

Inspect Their Equipment: Modern, well-maintained equipment indicates a commitment to quality.

Top-Rated Welding Companies in Miami

Here are some highly recommended welding services in Miami to consider:

Miami Welding & Fabrication: Specializing in custom designs and structural welding.

South Florida Marine Welding: Experts in marine welding and aluminum fabrication.

Elite Welding Services: Known for precision welding and on-site services.

Benefits of Choosing Local Welding Services

Opting for a local welding service in Miami comes with several advantages:

Quick Response Times: Local businesses can provide on-site services faster.

Knowledge of Miami’s Environment: Welders understand the impact of Miami’s humid climate on metal structures.

Supporting Local Economy: Working with local providers strengthens the community.

Common Metals Used in Welding Projects

Miami welding services work with a variety of metals depending on the project requirements. Common metals include:

Aluminum: Lightweight and corrosion-resistant, ideal for marine and automotive projects.

Stainless Steel: Strong and resistant to rust, perfect for construction and decorative purposes.

Carbon Steel: Durable and cost-effective, suitable for heavy-duty industrial applications.

Copper: Used for electrical and plumbing applications.

How Much Do Metal Welding Services Cost in Miami?

The cost of metal welding services in Miami varies based on factors like:

Type of Project: Custom designs or large-scale industrial jobs may cost more.

Materials Used: Exotic metals like titanium are more expensive.

Complexity of Work: Intricate designs or repairs require more time and expertise.

On average, welding services in Miami range from $75 to $150 per hour, but it’s best to request a detailed quote for accurate pricing.

Tips for Maintaining Welded Metal Structures

To ensure the longevity of your welded metal structures, follow these maintenance tips:

Regular Inspections: Check for signs of wear, rust, or cracks.

Cleaning: Use appropriate cleaners to remove dirt and prevent corrosion.

Apply Protective Coatings: Paint or galvanize metal surfaces to enhance durability.

Avoid Overloading: Prevent excessive stress on welded joints.

Why Miami’s Climate Matters for Welding Projects

Miami’s coastal location and humid climate can affect metal structures over time. Professional welders in Miami understand these challenges and take necessary precautions, such as:

Using corrosion-resistant materials.

Applying protective coatings to combat rust.

Ensuring proper welding techniques to withstand environmental stressors.

Conclusion

When searching for metal welding services near me in Miami, it’s important to choose a provider with expertise, modern equipment, and a proven track record. Whether you need custom fabrication, industrial repairs, or marine welding, Miami’s professionals offer reliable solutions to meet your needs. By selecting a trusted local welding service, you can ensure your project is completed efficiently and to the highest standard.

2 notes

·

View notes

Text

How ERW Pipes Are Revolutionising the Steel Pipe Industry

In the world of steel pipes, Electric Resistance Welded (ERW) pipes have emerged as a game-changer. Their versatility, strength, and cost-effectiveness make them the preferred choice across numerous industries, from construction to oil and gas. ERW pipes are reshaping the steel pipe industry, offering innovative solutions to meet the growing demands of modern infrastructure and industrial projects.

For businesses in Gujarat, finding a reliable ERW pipe supplier in Gujarat, distributor, dealer, or provider is crucial to ensure seamless operations. In this blog, we will explore how ERW pipes are revolutionizing the steel pipe industry and highlight the role of key players like distributors and dealers in regions such as Vadodara and Gujarat.

What Are ERW Pipes?

ERW pipes are manufactured using high-frequency electric resistance welding, a process that fuses steel plates or coils together to form pipes. Unlike seamless pipes, ERW pipes are welded longitudinally, resulting in a sturdy and uniform product suitable for a wide range of applications.

Key Features of ERW Pipes:

High Strength: ERW pipes offer excellent strength-to-weight ratios, making them suitable for high-pressure applications.

Precision: The manufacturing process ensures consistent wall thickness and diameter.

Cost-Effectiveness: Compared to seamless pipes, ERW pipes are more affordable without compromising quality.

Versatility: They are available in various sizes, thicknesses, and materials to suit diverse needs.

Applications of ERW Pipes

The versatility of ERW pipes has made them indispensable in several industries:

1. Construction

Used in structural applications such as scaffolding, roofing, and fencing.

Their lightweight nature and durability make them ideal for modern building projects.

2. Oil and Gas

Widely employed for transporting oil, gas, and water due to their corrosion resistance and strength.

3. Automotive Industry

Used in manufacturing components like chassis and exhaust systems.

4. Agriculture

Commonly used in irrigation systems and bore wells.

5. Infrastructure Development

Essential for the construction of bridges, roads, and industrial facilities.

Why ERW Pipes Are Revolutionizing the Industry

The steel pipe industry is undergoing a transformation, and ERW pipes are at the forefront of this change. Here are some reasons why:

1. Enhanced Manufacturing Techniques

The production process for ERW pipes has evolved significantly. Advanced technology ensures precision, efficiency, and minimal wastage, reducing the overall cost of production. This efficiency has allowed ERW pipe providers in Gujarat to offer high-quality products at competitive prices.

2. Sustainability

ERW pipes are more eco-friendly compared to traditional steel pipes. The production process generates less waste, and the pipes themselves are recyclable. As industries shift towards sustainable practices, the demand for ERW pipes is set to increase.

3. Customizability

ERW pipes can be tailored to meet specific project requirements. Whether it is the diameter, thickness, or material grade, custom solutions offered by ERW pipe suppliers in Gujarat ensure optimal performance for every application.

4. Cost-Effective Solutions

For businesses seeking durable yet affordable piping solutions, ERW pipes are an ideal choice. Their cost-effectiveness makes them a popular option among industries looking to optimize expenses without compromising quality.

The Role of ERW Pipe Suppliers, Distributors, and Dealers

1. Ensuring Quality and Consistency

Reliable ERW pipe distributors in Gujarat play a vital role in maintaining quality standards. They source pipes from trusted manufacturers and ensure they meet industry specifications. This consistency builds trust among clients and end-users.

2. Timely Delivery

Infrastructure and industrial projects often operate on tight schedules. ERW pipe dealers in Vadodara ensure timely delivery, minimizing downtime and project delays. Their efficient logistics and supply chain management make a significant difference.

3. Customized Solutions

Understanding the unique requirements of various industries, ERW pipe providers in Gujarat offer tailored solutions. Whether it is a specific pipe dimension or a large bulk order, they cater to diverse needs.

4. Comprehensive Support

From product selection to after-sales services, distributors and dealers provide end-to-end support. This guidance ensures that clients choose the right products for their applications.

Why Choose Tube Trading as Your ERW Pipe Partner?

As a trusted name in the industry, Tube Trading stands out as a leading ERW pipe supplier in Gujarat. Our commitment to quality, innovation, and customer satisfaction has earned us a reputation as a reliable partner for businesses across various sectors.

What Sets Us Apart?

1. Extensive Product Range:

We offer a wide variety of ERW pipes in different sizes, materials, and grades to suit diverse applications.

2. Unmatched Quality:

Our pipes undergo rigorous quality checks to ensure they meet international standards.

3. Customized Solutions:

From tailored dimensions to bulk orders, we cater to specific client requirements.

4. Efficient Logistics:

With a robust supply chain network, we ensure timely delivery, even for large-scale projects.

5. Customer-Centric Approach:

Our team is dedicated to providing personalized support, helping clients choose the best products for their needs.

Future Trends in the ERW Pipe Industry

The ERW pipe industry is poised for significant growth in the coming years. Key trends include:

1. Increased Demand in Emerging Markets

Regions like Gujarat are witnessing rapid industrial and infrastructural development. This surge in construction projects is driving the demand for ERW pipes.

2. Technological Advancements

Innovations in manufacturing processes will further enhance the quality and efficiency of ERW pipes, making them even more competitive in the market.

3. Focus on Sustainability

As industries prioritize eco-friendly practices, the recyclable nature of ERW pipes will contribute to their growing popularity.

Conclusion

ERW pipes are revolutionizing the steel pipe industry with their strength, versatility, and cost-effectiveness. Their applications span across numerous sectors, making them indispensable in modern infrastructure and industrial projects.

For businesses in Gujarat, partnering with a reliable ERW pipe distributor in Gujarat or ERW pipe dealer in Vadodara is essential to ensure access to high-quality products and excellent service. At Tube Trading, we pride ourselves on being a trusted ERW pipe provider in Gujarat, offering top-notch products and solutions to meet your needs.

Contact us today to learn how we can support your projects with the best ERW pipes in the industry.

#ERW pipe provider in Gujarat#ERW pipe dealer in Vadodara#ERW pipe distributor in Gujarat#ERW Pipe supplier in Gujarat

4 notes

·

View notes

Text

Buy MS Seamless Pipe from Leading Manufacturers in Delhi

When it comes to purchasing MS seamless pipes in Delhi, finding a reliable and trusted supplier is essential for ensuring quality and performance. Mild Steel (MS) seamless pipes are widely used in various industries, such as construction, oil and gas, plumbing, and manufacturing, due to their strength, durability, and resistance to corrosion.

In this article, we’ll explore why MS seamless pipes are important, their applications, and how you can find the best suppliers in Delhi.

What Are MS Seamless Pipes?

MS seamless pipes are made from mild steel, a low-carbon steel known for its flexibility and weldability. These pipes are manufactured without any seams or joints, providing a smoother finish and superior strength compared to welded pipes. The seamless construction ensures that the pipe can withstand high pressure and temperature without weakening, making it ideal for demanding applications.

Applications of MS Seamless Pipes

MS seamless pipes have a variety of uses across multiple industries, such as:

Construction: Used for building frames, scaffolding, and structural support due to their high tensile strength.

Oil & Gas Industry: Perfect for transporting fluids and gases under high pressure, ensuring safety and efficiency.

Water Supply: MS seamless pipes are used in water distribution systems as they prevent leakage and can handle large volumes of water.

Automotive: Employed in making parts for vehicles due to their strength and lightweight properties.

The versatility of MS seamless pipes makes them essential in industries where strength and reliability are paramount.

Why Buy MS Seamless Pipes from Leading Manufacturers?

Purchasing MS seamless pipes from leading manufacturers offers several advantages:

Guaranteed Quality: Leading manufacturers ensure that the pipes meet international standards, providing high durability and strength.

Wide Range of Sizes: Established suppliers offer a variety of sizes and specifications to cater to different industrial needs.

Competitive Pricing: Leading suppliers often provide the most competitive prices due to their ability to source materials and manufacture in bulk.

After-Sales Support: Trusted manufacturers provide excellent customer service, helping you with installation, maintenance, and any other post-purchase concerns.

Where to Buy MS Seamless Pipes in Delhi?

If you’re looking for the best MS seamless pipe supplier in Delhi, Udhhyog is a top choice. Udhhyog is known for its wide selection of MS seamless pipes at the lowest prices in India. They cater to both large industrial needs and small business requirements, ensuring that every customer finds the right solution.

Why Choose Udhhyog?

High-Quality Products: Udhhyog ensures that their pipes meet stringent quality standards, making them durable and efficient for various uses.

Competitive Pricing: By leveraging their strong supply chain, Udhhyog offers MS seamless pipes at highly competitive rates, helping businesses cut costs without compromising on quality.

Wide Availability: As one of the leading suppliers in Delhi, Udhhyog ensures that you can easily get the sizes and specifications you need for your project.

Reliable Service: Udhhyog prides itself on excellent customer service, offering prompt delivery and responsive after-sales support.

How to Order from Udhhyog?

Ordering MS seamless pipes from Udhhyog is straightforward. You can visit their website to explore their product range, check specifications, and place an order. You can also contact their sales team for any specific inquiries or bulk orders. Udhhyog offers flexible payment options and ensures timely delivery across India, making procurement easier for businesses

#MSSeamlessPipes#MSPipes#SeamlessPipes#PipeFittings#IndustrialPipes#SteelPipes#DelhiSuppliers#DelhiManufacturers#DelhiBusiness#ConstructionMaterials#OilAndGas#WaterSupplyPipes#AutomotiveParts#BuyMSSeamlessPipes#SteelAtLowestPrices#Udhhyog#MSSeamlessPipeSupplier#MSSteelPipesIndia#PipeSuppliersIndia#SteelManufacturersDelhi

5 notes

·

View notes

Text

The Benefits of Micro Coil Heaters - Hindon Electricals

In the world of industrial heating, precision and efficiency are paramount. Micro coil heaters, often referred to as small but mighty, are innovative heating elements designed to provide localized heating with exceptional control and reliability. Here are some of the key benefits of using micro coil heaters, proudly offered by Hindon Electricals, your trusted micro coil heater manufacturers:

1. Precision Heating

Micro coil heaters excel in providing precise temperature control. Their compact size allows for targeted heating, which is ideal for applications requiring exact thermal management. This precision reduces the risk of overheating and ensures consistent product quality, making them indispensable in industries like plastic welding, packaging, and medical device manufacturing.

2. Energy Efficiency

These heaters are designed to deliver high thermal conductivity while minimizing energy consumption. The efficiency stems from their ability to generate heat quickly and maintain the desired temperature with minimal fluctuation. This results in lower energy costs and a more sustainable operation, aligning with modern energy-saving initiatives.

3. Compact Design

The small footprint of micro coil heaters makes them perfect for applications where space is limited. Their compact design does not compromise performance, allowing for easy integration into machinery and equipment without requiring significant modifications. This flexibility is particularly beneficial in high-density manufacturing environments.

4. Rapid Response Time

One of the standout features of micro coil heaters is their rapid response time. They can quickly reach the desired temperature, which is crucial in processes that require fast thermal cycling. This capability enhances productivity and reduces downtime, leading to more efficient manufacturing cycles.

5. Versatility

Micro coil heaters are highly versatile, suitable for a wide range of applications. They can be customized in terms of shape, size, and wattage to meet specific requirements. This adaptability makes them an excellent choice for industries such as aerospace, automotive, and electronics, where diverse heating needs are common.

6. Durability and Longevity

Constructed with high-quality materials, micro coil heaters offer excellent durability and longevity. They are designed to withstand harsh operating conditions, including high temperatures and corrosive environments. This reliability reduces maintenance costs and ensures long-term performance.

Conclusion

Micro coil heaters provide numerous benefits, including precision heating, energy efficiency, and versatility. Their compact design and rapid response time make them ideal for various industrial applications, ensuring efficient and reliable performance. As industries continue to seek innovative solutions for their heating needs, Hindon Electricals stands out as a premier micro coil heater manufacturer, committed to delivering superior heating solutions for modern manufacturing processes.

2 notes

·

View notes

Text

Sheet metal is where creativity meets craftsmanship. It's the magic of transforming ordinary metal sheets into extraordinary creations. From sleek automotive designs to cutting-edge electronics, sheet metal plays a pivotal role in shaping our world. With cutting, bending, punching, and welding at our fingertips, we craft your visions into reality. Whether you're prototyping, mass-producing, or seeking bespoke solutions, sheet metal delivers the versatility and precision your project deserves. Elevate your innovation with sheet metal, where imagination takes form.

8 notes

·

View notes

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF: TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada: Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic: Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak: Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser: Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD: LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India CNC punching services in pune Best MIG Welding Machine Pre-Treatment for Surface Preparation in pune Best CNC bending services India Best SS fabrication services in India Best spot welding services in pune Best tube, pipe, and angle cutting services in pune Best automotive manufacturers in pune Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

Welded studs play a crucial role in the realm of metal fabrication and construction. These specialized fasteners provide a secure and reliable method for joining metal components together. Welded studs are designed to be welded onto surfaces, creating a durable and long-lasting connection. With their versatility and strength, they find applications in various industries, including automotive, aerospace, manufacturing, and infrastructure. Whether used for structural purposes or as anchor points for other components, welded studs offer a robust solution that withstands the test of time. Their ease of installation and ability to handle heavy loads make them an essential component in many construction projects. From enhancing structural integrity to improving efficiency, welded studs are a vital element in the world of metalworking.

Rockwood Machinery is one of the top welded studs suppliers in UAE. With their skilled team of welders, aluminum fabrication professionals, and installation crew, they work alongside their suppliers and workers to assist manufacture and develop large-scale metal structures and systems.

#tanzania#flashnetTanzania#proudlyTanzania#cybersecurity#networksecurity#dataprotection#endpointprotection#datacenter#vpn#bcdr#managedwifi#acronics#bitdefender#sophos#sopohs#cloud#managedserviceprovider#managedservices#managedit#msp#techsupport#cloudservices#itsolutions#zoho#microsoft#office#microsoftoffice#MoveToCloud#cloudcomputing

2 notes

·

View notes

Text

Lithium Ion Battery Products of Eco Power

Eco Power Group is more than a lithium battery company. We design, manufactures, and sell advanced lithium-ion energy storage electrification solutions for different types of lithium ion battery.

Our expertise of custom lithium ion battery is based on its know-how in electrochemistry and battery management system to provide safe, efficient and sustainable solutions to various industries such as automotive, commercial transportation, off-highway vehicles/equipment, rail, air, marine, energy storage, solar energy systems, communication equipement, and more.

We are your experienced partner of lithium ion battery wholesale, from the feasibility study to the conception and the final installation with our complete product portfolio.

If you are considering to buy lithium ion battery, we are highly welcome you to consult and cooperate with us.

Different Types of Lithium Ion Battery Products

On-board energy solution at Eco Power Group with complete reference from cell to system to be the best fitting solution for your lithium ion battery types.

Battery Cell

This type of custom lithium ion battery cell is the very basic energy storage unit. Based on many years experience from cell design, battery materials and simulation, we are always at the cutting edge of technology. Our li ion batteries for sale comply with the strict safety standards UN 38.3, which guarantees our customers high quality and safety even after years of operation of charging lithium ion batteries.

Battery Module

In terms of battery modules for different types of lithium ion battery, there we offer standard modules with metal sheet plate for electric vehicle applications, Custom lithium ion battery module with binding tape for energy storage, and VDA size modules for passenger vehicles.

Battery Pack

Standard battery packs for commercial vehicles. Standard battery packs of charging lithium ion batteries in series with DNV certification for marine propulsion. Customized power li ion charging voltage systems for forklift applications ,etc.

Battery Energy Storage System

With a team of experienced engineers, we provide end to end custom lithium ion battery services starting from customer requirement analysis going through battery pack design, testing, prototype production and serial production. During the design phase we focus on the application area requirements as much as the li ion charging voltage battery design itself.

Why Choose The Lithium Ion Battery From Eco Power?

Quality

Our established quality management system of lithium ion battery wholesale, certified according to the international standard DIN EN ISO 9001: 2008, guarantees compliance with our high quality standards.

01

Customised Solution

Customised solutions for lithium ion battery replacement energy storage or mobile applications of electromobility.

02

Experience

As one of the leading lithium ion battery companies, we have more than 10years experience in lithium li ion voltage battery industry with hundreds of different application scenario. With our high quality lithium ion batteries for sale, you can trust us with your project .

03

Technical Support

From customer request input all the way to delivery final different types of lithium ion battery product, we will assign project technical consultant to accompany our customer to solve all of li ion charging voltage questions or problems during the whole process.

04

What Does A Lithium Ion Battery Module Do?

Battery module of li ion batteries for sale contains the energy storing battery cells by laser-welded technology, the mechanically stable against shock demonstrates high productivity and flexibility to make sure the long term performance of li ion charging voltage battery system.

How A Lithium Ion Battery System Works?

A battery system of li ion charging voltage consists of lithium battery cell connected in series to reach the system voltage and parallel to achieve greater capacity.

The li ion battery voltage and capacity can be verified by different combination of packs. The pack contains a fuse and a slave BMS. High security and provide lithium ion cell voltage and temperature to master BMS.

The Lithium-Ion battery system with charging lithium ion batteries in parallel is a composite set of battery electronics, high voltage circuits, overcurrent protection devices, battery boxes and interfaces with other external systems such as cooling, high voltage, auxiliary low voltage and communications.

What Is The Difference Between Lithium Ion Battery Pack And Power Bank?

This kind of battery pack of lithium ion battery types cannot be a power bank, but a power bank can be a li ion battery charging voltage pack with added electronic circuitry to prevent over charging, over discharge, etc to protect the batteries.

A lithium ion battery pack in series is merely a bunch of batteries connected in Series/Parallel configuration with one positive and one negative terminal.

A power bank contains one or more batteries in mostly parallel but could also be a Series/Parallel configuration. These types of li ion batteries for sale are connected to a battery management circuit (module) which controls the charging of the batteries. All this is housed in a compact enclosure.

2 notes

·

View notes

Photo

Cutting Edge Automotive Micro Welding

Percussion Welder offers high-quality automotive micro-welding solutions for various applications. Our advanced technology and experienced team ensure precision, durability, and cost-effectiveness for your welding needs.

https://percussionwelder.com/automotive/

0 notes

Text

What is Precision Sheet Metal Fabrication? A Complete Guide

Precision sheet metal fabrication is a specialized manufacturing process that involves cutting, bending, and assembling thin metal sheets to create precise components for various industries. This process ensures high accuracy, durability, and efficiency, making it essential for applications in automotive, aerospace, electronics, and construction.

Understanding Precision Sheet Metal Fabrication

Precision sheet metal fabrication refers to the advanced methods used to shape and form metal sheets into intricate designs with exact tolerances. This process utilizes cutting-edge technology, including CNC machines, laser cutting, waterjet cutting, and robotic welding, to ensure high-quality results.

Typical metals used in this process include:

Aluminium – Lightweight and corrosion-resistant

Stainless Steel – Strong, durable, and heat-resistant

Copper & Brass – Great for electrical applications

Carbon Steel – Offers strength and versatility

Key Processes in Precision Sheet Metal Fabrication

Cutting

Techniques like laser cutting, plasma cutting, and waterjet cutting help achieve precise shapes with minimal material waste.

Bending

Using press brakes and CNC bending machines, metal sheets are shaped into desired forms without compromising structural integrity.

Welding & Assembly

MIG, TIG, and robotic welding ensure strong and seamless joints, creating high-quality finished products.

Finishing & Coating

Powder coating, anodizing, and electroplating enhance durability and aesthetics, providing a corrosion-resistant surface.

Benefits of Precision Sheet Metal Fabrication

✔ High Accuracy & Consistency – Advanced machinery ensures uniformity across all parts.

✔ Cost-Effective Production – Reduces material waste and improves production efficiency.

✔ Versatile Applications – Used in industries like medical devices, telecommunications, and defence.

✔ Custom Fabrication – Tailored solutions meet specific design and functional requirements.

Applications of Precision Sheet Metal Fabrication

🔹 Aerospace Industry – Lightweight and durable components for aircraft manufacturing.

🔹 Automotive Sector – Precision parts for engines, frames, and body panels.

🔹 Electronics Industry – Metal casings, enclosures, and heat sinks.

🔹 Construction & Architecture – Custom metalwork for buildings and structures.

Conclusion

Precision sheet metal fabrication plays a vital role in modern manufacturing, ensuring high-quality, durable, and cost-effective metal components. Whether you need customized metal enclosures, automotive parts, or aerospace components, precision fabrication guarantees the best results.

Contact us today to discuss your fabrication needs and get expert solutions tailored to your industry.

Visit us today to explore our advanced manufacturing capabilities and see how we can bring your project to life!

0 notes

Text

High-Quality TP309S Stainless Steel Pipes & Tubes in Japan – Kogyo Steel's Excellence

Because of their exceptional resistance to oxidation and corrosion, TP309S stainless steel pipes and tubes are now the material of choice for high-temperature applications. Industries like heat treatment, power generating, and chemical processing make extensive use of this grade of stainless steel. Kogyo Steel is a prominent Manufacturer of TP309S stainless steel pipes and tubes in Japan, offering premium goods that satisfy international requirements. The main characteristics, uses, and benefits of TP309S stainless steel pipes and tubes are examined in this article, along with the reasons Kogyo Steel is the best supplier in Japan.

Features of TP309S Stainless Steel Pipes & Tubes

Austenitic stainless steel TP309S is renowned for its superior mechanical and heat-resistant qualities. Among its primary attributes are:

High Temperature Resistance: Suitable for heat-intensive applications, it can tolerate temperatures of up to 1000°C.

Superior Corrosion Resistance: Provides outstanding defence against oxidation and sulfidation in hot conditions.

Good Formability and Weldability: It is perfect for intricate manufacturing operations since it is easily moulded and welded.

Strength and Durability: Offers exceptional mechanical strength and a long service life.

Applications of TP309S Stainless Steel Pipes & Tubes

TP309S stainless steel pipes and tubes are extensively utilized in many industrial sectors because of their exceptional qualities. Here are a few of the most important uses:

Heat treatment and power generation

Because of its ability to withstand high temperatures, it is utilized in furnace parts, heat exchangers, and boiler components.

Perfect for applications that need to be exposed to high temperatures for extended periods of time.

Long-term performance is ensured by its resistance to creep deformation and thermal fatigue.

The Petrochemical and Chemical Sector

Utilized in corrosive material storage tanks, processing machinery, and chemical reactors.

Appropriate for chemical situations with high temperatures when oxidation and carburization resistance are crucial.

Offers durability and safety under demanding processing circumstances.

The automotive and aerospace sectors

Because of its great resistance to heat and oxidation, it is used in exhaust systems, turbochargers, and heat shields.

Used in aerospace applications where materials with great strength and low weight must be able to tolerate high temperatures.

Helps automotive applications use less fuel and emit fewer pollutants.

Why Pick Japan's Kogyo Steel?

As a dependable provider of TP309S stainless steel pipes and tubes, Kogyo Steel has established a solid name as a Renowned Manufacturer of TP309S stainless steel pipes and tubes in Japan. Customers trust Kogyo Steel for the following reasons:

Superior Products: They provide stainless steel tubes and pipes that satisfy global quality requirements.

Competitive Pricing: Provides affordable options without sacrificing functionality.

On-Time Delivery: A robust supply chain and logistics network guarantee on-time delivery.

Professional advice in choosing the appropriate stainless-steel goods is given by knowledgeable technical support.

Conclusion

Because of their exceptional resistance to heat and corrosion, TP309S stainless steel pipes and tubes are extensively utilized in a variety of industries. Kogyo Steel is a reputable supplier in Japan that provides premium TP309S stainless steel pipes and tubes that are suited to industrial needs. Kogyo Steel offers the best solutions to guarantee effectiveness and longevity, whether you require stainless steel pipes for power generation, chemical processing, or automotive applications. Kogyo Steel is the best source for high-quality TP309S stainless steel pipes and tubes in Japan. For More Details CLICK HERE

0 notes

Text

STR-HW850 Handheld Laser Welder: Reshaping the New Benchmark in Industrial Manufacturing

In today's rapidly evolving technological landscape, the industrial manufacturing sector is undergoing unprecedented transformation. Efficiency, intelligence, and environmental protection have become the keywords of this new era. With its profound technical accumulation and innovative spirit, strongest Laser proudly introd

uces the STR-HW850 Handheld Laser Welder. This all-in-one device, integrating laser welding, precision cutting, and laser derusting, not only redefines the application boundaries of handheld laser equipment but also brings an unprecedented ultimate experience and efficiency improvement to industrial manufacturing, leading the new trend of intelligent manufacturing.

I. Technological Innovation, Reshaping Application Boundaries

The STR-HW850 Handheld Laser Welder is equipped with a 3000W high-power single-mode laser with excellent beam quality and high energy concentration, capable of easily penetrating 10mm thick metal plates to achieve high-quality, high-strength welding results. This technological breakthrough enables the STR-HW850 to excel in numerous fields such as aerospace, automotive manufacturing, shipbuilding engineering, electronics, and electrical appliances, ensuring precise connection and processing of components and enhancing the safety and reliability of overall structures. Meanwhile, the STR-HW850 is also equipped with an intelligent constant temperature control system and dual-circuit refrigerant direct cooling technology, ensuring the device remains stable under long-term, high-load operation and significantly extending the device's service life.

II. Multi-functional, Enhancing Production Efficiency

The STR-HW850 Handheld Laser Welder is not only an exceptional laser welding device but also an all-in-one device integrating welding, cutting, and derusting. In terms of laser welding, the STR-HW850 can easily meet the welding needs of various metallic materials, achieving high-quality welding results for both thin and thick plates. In precision cutting, leveraging the high precision and high energy density characteristics of the laser beam, the STR-HW850 can achieve smooth edges and burr-free precision cutting, directly satisfying the production needs of most components. Whether metal sheets or thick-walled pipes, they can be easily handled, demonstrating exceptional cutting performance. In laser derusting, the laser beam of the STR-HW850 precisely acts on the rust layer, quickly stripping it without damaging the substrate, while stimulating microstructural changes on the surface of the substrate to enhance its corrosion resistance, providing a new solution for surface treatment.

III. Energy-saving and Environmentally Friendly, Supporting Green Development

In the current global context advocating energy conservation and emission reduction, the STR-HW850 Handheld Laser Welder has become a green pioneer in the industrial manufacturing sector with its efficient energy utilization and environmentally friendly production methods. The STR-HW850 adopts advanced laser energy conversion technology, optimizing the internal structure and operating mode of the laser to achieve efficient utilization of laser energy. Compared to traditional laser equipment, the STR-HW850 significantly reduces energy loss during laser generation, transmission, and focusing, converting each unit of electrical energy into as much laser energy as possible, thereby enhancing the device's energy utilization rate and reducing energy consumption. Additionally, the STR-HW850 adopts a modular design approach, finely dividing the components of the laser, which not only facilitates device maintenance and upgrades but also further improves the overall operating efficiency of the device by reducing energy transmission losses and heat accumulation between components.

IV. Intelligent Operation, Simplifying Workflows

The STR-HW850 Handheld Laser Welder is equipped with an intelligent operating system, making device operation simpler and more efficient. Users can achieve automated device operation through simple settings and adjustments. Meanwhile, the STR-HW850 supports the preset and customization of multiple welding modes and process parameters, satisfying welding needs for different materials and application scenarios. Furthermore, the STR-HW850 features remote monitoring and fault diagnostic capabilities, allowing users to monitor and remotely operate the device via mobile phones or computers, significantly enhancing device reliability and maintainability.

V. Wide Application, Supporting Industrial Upgrading

The STR-HW850 Handheld Laser Welder, with its exceptional performance and multifunctionality, plays a crucial role in numerous fields such as aerospace, automotive manufacturing, shipbuilding engineering, electronics, and electrical appliances. In the aerospace field, the STR-HW850's precision welding and cutting capabilities ensure precise connection and processing of components, enhancing the safety and reliability of overall structures. In automotive manufacturing, the STR-HW850 efficiently completes welding and cutting tasks for critical components such as the body and chassis, improving production efficiency and reducing manufacturing costs. In shipbuilding engineering, the STR-HW850's laser derusting function effectively removes rust layers from the hull surface, improving the hull's corrosion resistance and service life. In the electronics and electrical field, the STR-HW850's laser welding and cutting functions meet the manufacturing needs of precision electronic components, enhancing product quality and reliability.

Conclusion

The advent of strongest Laser's STR-HW850 Handheld Laser Welder not only provides industrial manufacturing with a new tool option but also injects robust momentum into the advancement of intelligent manufacturing. With its powerful multi-functional capabilities, it leads the new trend in industrial manufacturing and provides global industrial users with more flexible, efficient, and energy-saving production solutions. In the future, as intelligent manufacturing deepens, the STR-HW850 will undoubtedly play a crucial role in more fields, helping enterprises achieve transformation and high-quality development. strongest Laser will continue to uphold the innovation concept, continuously increase R&D investment, promote continuous innovation and industrial upgrading of laser technology, and provide users with more comprehensive, efficient, and intelligent laser processing services.

0 notes

Text

Are you looking for 304 Stainless Steel Welded Pipes

Seminox Pipes & Tubes PVT. LTD is a trusted manufacturer and supplier of 304 stainless steel welded pipes, providing high-quality piping solutions for a wide range of industries. With a focus on precision, durability, and customer satisfaction, the company ensures that its products meet international industry standards. 304 stainless steel welded pipes are known for their excellent corrosion resistance, high strength, and durability. These pipes are widely used in industries such as food processing, pharmaceuticals, petrochemicals, water treatment, construction, and automotive due to their superior resistance to oxidation and rust. The combination of chromium and nickel in 304 stainless steel enhances its strength and makes it suitable for both high and low-temperature applications. Seminox manufactures 304 stainless steel welded pipes with strict quality control measures, ensuring compliance with ASTM A312 and ASME SA312 standards. These pipes offer a smooth surface finish, high weldability, and excellent mechanical properties, making them ideal for structural and fluid transportation applications. Their non-reactive nature also makes them suitable for hygienic environments like food and beverage industries. With advanced production facilities and a dedicated team of professionals, Seminox Pipes & Tubes PVT. LTD continues to deliver premium 304 stainless steel welded pipes, ensuring reliability, efficiency, and long-lasting performance for various industrial applications.

0 notes

Text

How to Choose the Right OEM Metal Fabrication Service?

Selecting the right OEM metal fabrication service is a critical decision for businesses looking to produce high-quality, customized metal components. Whether you’re in the automotive, construction, or electronics industry, finding a reliable partner can make a significant difference in product quality, production timelines, and cost-effectiveness. With numerous service providers available, it’s essential to carefully evaluate your options to ensure your business needs are met effectively.

To start, understanding what OEM metal fabrication entails is crucial. Original Equipment Manufacturer (OEM) fabrication involves creating specific metal parts or assemblies according to a client’s unique design and specifications. These components often serve as integral parts of larger products, meaning precision and quality are non-negotiable. Therefore, the choice of an OEM partner should prioritize technical expertise, state-of-the-art facilities, and a proven track record in delivering customized solutions.

When evaluating potential providers, assess their experience and specialization. Some OEM fabrication services cater to specific industries, such as aerospace or automotive, while others offer a broader range of capabilities. A company with experience in your sector is more likely to understand your requirements, industry standards, and potential challenges. Furthermore, look into their portfolio to see if they’ve successfully executed similar projects in the past. This will give you confidence in their ability to meet your expectations.

Another critical factor to consider is the technology and equipment used by the fabrication service. Advanced machinery and software ensure precision, efficiency, and scalability. For instance, laser cutting, CNC machining, and robotic welding systems enable the production of complex designs with minimal errors. A company equipped with modern tools is better positioned to deliver consistent, high-quality results, which is vital in maintaining the integrity of your products.

In addition to technical capabilities, a reliable OEM fabrication partner should offer excellent customer service and clear communication throughout the project. From the initial consultation to the final delivery, they should collaborate with you to ensure your designs are accurately executed. Look for a company that values transparency, provides regular progress updates, and is willing to address any concerns promptly. Strong communication helps prevent costly errors and ensures the final product meets your expectations.

Cost is, of course, a significant consideration. While it’s tempting to choose the lowest-priced provider, remember that quality and reliability often come at a reasonable cost. An experienced OEM metal fabrication service will provide detailed quotes that outline material costs, labor, and other expenses. Compare these quotes carefully, and prioritize value over the lowest price. A reputable provider will balance affordability with quality, ensuring your investment pays off in the long run.

Lastly, don’t overlook the importance of certifications and compliance. Reputable OEM fabrication companies adhere to industry regulations and quality standards, such as ISO certifications. These certifications demonstrate their commitment to maintaining high standards and delivering safe, reliable products.

Choosing the right OEM metal fabrication service requires thorough research, careful evaluation, and a focus on quality. By selecting a provider with industry expertise, advanced capabilities, and a commitment to collaboration, you can ensure your business benefits from exceptional metal fabrication solutions that meet your exact needs.

0 notes