#water ring type vacuum pump

Explore tagged Tumblr posts

Text

Maximizing Efficiency - Selecting the Ideal Vacuum Pump with Meekaj Vacuum Systems Pvt Ltd

In today's competitive industrial landscape, efficiency and reliability are paramount. At Meekaj Vacuum Systems Pvt Ltd, we specialize in providing cutting-edge vacuum pump solutions that empower businesses to optimize their operations and achieve greater success.

The Importance of Industrial Vacuum Pumps

Industrial vacuum pumps serve as the backbone of various manufacturing processes, from packaging and forming to material handling and more. Industrial vacuum pump supplier in India understands the critical role that vacuum pumps play in industrial settings and offers a comprehensive range of solutions to meet diverse needs.

Enhancing Performance with Single-Stage Water Ring Vacuum Pumps

For applications requiring consistent vacuum levels and reliable performance, Meekaj Vacuum Systems Pvt Ltd offers singlestage water ring vacuum pumps. These pumps are ideal for industries such as pharmaceuticals, food processing, and chemical processing, where precision and efficiency are paramount.

Boosting Efficiency with Two-Stage Liquid Ring Vacuum Pumps

For industries that demand higher vacuum levels and increased efficiency, Meekaj Vacuum Systems Pvt Ltd provides twostage liquid ring vacuum pumps. These pumps are designed to handle challenging applications with ease, offering superior performance and durability.

Meeting Diverse Needs with Water Ring Type Vacuum Pumps

Meekaj Vacuum Systems Pvt Ltd understands that each industry has unique requirements, which is why we offer a range of water ring type vacuum pumps to cater to diverse applications. Whether it's handling corrosive gases, vapors, or solids, our water ring pumps deliver exceptional performance and reliability.

With a reputation for excellence and a commitment to customer satisfaction, Meekaj Vacuum Systems Pvt Ltd is the preferred choice for water ring type vacuum pump manufacturers. Contact us today to learn more about how our products can elevate your operations and drive success.

#water ring type vacuum pump manufacturers#twostage liquid ring vacuum pumps#singlestage water ring vacuum pumps#Industrial vacuum pump supplier in India

0 notes

Text

The Advantages of Liquid Ring Vacuum Pumps Over Other Pump Types

Industrial vacuum pumps are regarded as important equipment in some industrial applications. If the vacuum pump you are using happens to be just ideal for that kind of process it does not just get the work done but rather also makes the operator more advanced, cost effective and reliable while at work.

Users view liquid ring vacuum pumps as the top choice for vacuum pumps. They're adaptable and exact yet tough enough to tackle some of the most demanding jobs in chemical processing, food and drink production, power generation, and drug manufacturing. In this blog, we will discuss how these liquid ring vacuum pumps are better than other pumps?

Let’s dive right in..!!

Advantages of Liquid Ring Vacuum Pumps

Top-Notch Reliability

The most special thing about liquid ring vacuum pumps is that they are very durable. You can use these pumps in any condition including processes involving wet gases, vapors, and even small solid particles. But if we talk about other vacuum pumps, they will either fail after being used in robust conditions or will require frequent maintenance. While liquid ring vacuum pumps work smoothly in every condition without any wear and tear.

For industries that want a reliable product, liquid ring vacuum pump manufacturers offer the assurance that you can trust the vacuum pump blindly.

Ability to Handle Diverse Applications

Liquid ring vacuum pumps are highly versatile. They are capable of tackling saturated gases, vapors as well as explosive gases. If you have noted, dry pumps really lag behind in regions where it rains and the climatic conditions become wet and there is a great wastage of time and resources used in the same process. Under these circumstances, results are given best by liquid ring pumps.This adaptability makes them ideal for industries like:

Chemical processing: For vapor recovery and distillation.

Pharmaceuticals: For vacuum filtration and drying processes.

Power plants: For condenser air extraction and vacuum priming.

Unlike other pumps, these pumps do not require additional components and modifications to work in a wide range of applications, thus you can save your money here.

Minimal Maintenance Requirements

With their simple design, liquid ring vacuum pumps are remarkably easy to maintain. It does not have those complex moving parts that mechanically may easily go bad. Also, the liquid ring acts both as a lubricant and a sealant: once again, minimizing chances of frequent regular maintenance or replacement.

In contrast, pumps like rotary vane or diaphragm pumps may involve complex components that demand regular upkeep, leading to downtime and higher operational costs.

Eco-Friendly and Safe Operation

Today's modern industries always give top priority to safety and sustainability. And Liquid ring vacuum pumps contribute to this.

These vacuum pumps are environmentally friendly, their liquids can be used again so you can minimize water wastage. In addition to that, manufacturers of liquid ring vacuum pumps make them in a manner that they take the least possible energy and generate the maximum possible output.

Apart from this, these pumps handle flammable and corrosive gases very carefully without any risk of spark. That is why these pumps are especially used in chemical and petrochemical industries today.

Quiet and Smooth Performance

Unlike other vacuum pumps that can produce significant noise and vibration, liquid ring pumps operate quietly and smoothly. These pumps are no less than a ward for those industries where noise pollution is the highest. Especially in food and beverage or pharmaceutical industries, noise pollution is also reduced by using these pumps.

Cost-Effective in the Long Run

Although a liquid ring vacuum pump system may have an initial investment comparable to other pump types, the ultimate value comes far more easily after the initial investment. Less operating cost, outstanding performance, and energy efficiency generally make significant savings possible in the long term.

With the best manufacturers of liquid ring vacuum pumps, a business ensures that the purchased equipment is quality and has worth.

Resistant to Wear and Corrosion

It is robust enough to withstand corrosive liquids and gases. Liquid ring pumps are made up of stainless steel or cast iron which can handle very high abrasion and aggressive chemical particulate concentration; thus suitable for handling those corrosive or reactive materials, and several industries demand this pump to handle such extremely corrosive liquids or gaseous chemicals.

Conclusion

So if you are also looking for the right vacuum pump for your industry then you may not find a better option than the liquid ring vacuum pump. In this blog we have shared all the information about this pump that we have experienced ourselves in the industries and heard from the industrial workers. From reliability and versatility to eco-friendliness and cost-effectiveness, these pumps deliver unparalleled value.

Whether you are in chemical manufacturing, power generation, or any other industry that requires strong vacuum solutions, you can be sure to get the best quality and durable systems when you partner with reputed liquid ring vacuum pump manufacturers.

1 note

·

View note

Text

From the Liquid Ring Vacuum Pump to the Two-Stage counterpart, the Water Ring Vacuum Pump to the reliable Oil Sealed Vacuum Pump – each type brings a unique edge to meet your industrial needs. Unleash efficiency with precision-engineered

technology.

For more details, visit- https://www.acmeairequipments.com/vacuum-pump-different-types-applications/

0 notes

Text

Innovative Vacuum Pump Solutions by Indo Air Compressor

In the fast-evolving industrial world, vacuum pumps are essential in optimising processes across various sectors, from food packaging to pharmaceutical production. Indo Air Compressor leads the market with its innovative, high-performance vacuum pump solutions, offering unmatched efficiency, durability, and energy-saving benefits. Indo Air’s vacuum pump meets diverse industry needs with precision and eco-friendly designs. In this article, discover how Indo Air Compressor, leading vacuum pump manufacturer in India, transforms processes and delivers powerful solutions tailored to modern industry demands.

Understanding Vacuum Pump

A vacuum pump removes air or gas from a sealed area, creating a vacuum. This ability to control air pressure is necessary in food packaging, electronics manufacturing, and medical laboratories. By using vacuum pumps, industries can work with precise environmental control, improving quality and efficiency in their work.

Why Indo Air Compressor

Indo Air Compressor is a top choice for vacuum pump for several reasons:

Advanced technology with modern design and technology makes their pumps efficient and easy to operate.

Each vacuum pump is designed to save energy and lower operational costs.

Each pump is tested for quality to meet industry standards.

Indo Air, leading vacuum pump manufacturers in India, offers various applications for different needs, allowing businesses to find the perfect fit.

Types of Vacuum Pump by Indo Air Compressor

Indo Air provides several air compressors, each suited to specific tasks and industries.

Rotary vane vacuum pumps:

These pumps are widely used for stable vacuum levels in electronics, food packaging, and other industries requiring constant suction. This vacuum pump is known for its efficiency and reliability.

Liquid ring vacuum pumps:

For applications that handle moisture, liquid ring pumps are a great choice. They use a liquid seal to compress gases, which makes them durable and resistant to corrosive substances. This type is used in the pharmaceutical and water treatment industries.

Scroll vacuum pumps:

Scroll pumps work with minimal noise and vibration, making them ideal for sensitive settings like medical labs and research facilities. They are compact, energy-efficient, and provide a high level of performance.

Dry screw vacuum pumps:

This vacuum pump works without oil or liquids, making it easy to maintain and environmentally friendly. They’re perfect for clean environments, like food processing or pharmaceuticals, where contamination is a concern.

Key Features of Vacuum Pumps

Vacuum pump manufacturers in India meet industry demands, focusing on features that make them user-friendly, durable, and energy-efficient.

Quiet operation:

Indo Air pumps are built with noise reduction, allowing them to run quietly. This feature benefits environments like hospitals and research labs, where low noise is important.

Compact design:

Many Indo Air pumps are prepared to be compact, so they fit easily into small spaces. This is helpful for businesses with limited room for equipment.

Low maintenance:

Indo Air’s pumps are built to be durable and require minimal upkeep, which can save time and maintenance costs. This is valuable for businesses aiming to keep working costs low.

Energy efficient:

With a focus on saving energy, Indo Air’s pumps help reduce electricity use, making them cost-effective and eco-friendly.

Industries Benefiting from Vacuum Pumps

Various industries depend on vacuum pump for their unique needs, from preserving food to maintaining sterile medical environments.

Food processing:

Vacuum pumps are used in packaging and preserving food, as they help remove air to extend product shelf life. Indo Air’s rotary vane and liquid ring pumps are especially useful in food processing to maintain hygiene standards.

Healthcare and pharmaceuticals:

In pharmaceuticals, a vacuum pump helps in drying, filtration, and sterilisation processes. Indo Air’s dry screw and scroll pumps meet strict cleanliness requirements, ensuring products stay safe and pure.

Electronics manufacturing:

Vacuum pumps are essential in electronics, where creating a controlled environment is essential for production. Indo Air’s pumps provide the precise vacuum levels needed for high-quality electronics.

Laboratories and research:

Indo Air’s quiet, compact pumps are ideal for labs, providing reliable performance without causing disruption. These pumps are used in various experiments and testing processes in research settings.

Why Choose Indo Air’s Vacuum Pump:

Choosing a quality vacuum pump can greatly impact your business operations. Indo Air Compressor is committed to efficiency, quality, and innovation. Here’s why Indo Air’s vacuum pumps are a smart investment:

Cost-effective: Indo Air’s pumps help reduce long-term costs by saving on energy.

Reliable and long-lasting: Indo Air pumps are known for durability, requiring fewer repairs or replacements.

Eco-friendly: Indo Air’s energy-saving designs help businesses reduce their carbon footprint.

Customizable solutions: With various pumps available, Indo Air offers options that meet specific industry needs.

Conclusion

Indo Air Compressor’s vacuum pump solutions blend technology, efficiency, and reliability. From food production to scientific research, these pumps meet the demands of modern industries while promoting energy efficiency. Indo Air is a trusted name with quality products designed to help businesses operate smoothly and sustainably. For industries seeking reliable and cost-effective vacuum solutions, Indo Air Compressor offers products that deliver consistent, high-quality performance while supporting a more sustainable future.

0 notes

Text

China Supplier POPPET TYPE SOLENOID VALVE GS020600V for steam turbine

"China Supplier POPPET TYPE SOLENOID VALVE GS020600V for steam turbine Deyang YOYIK have power plant professional accessories, non-standard pieces, to spare parts for processing. Only need to figure the number of other companies need drawings and drawings number. If you have any questions or concerns, please contact us. YOYIK has a good talent pool, the company is developing, you need to support, in order to witness its growth.

Yoyik can offer many spare parts for power plants as below:

DF-POPPET TYPE SOLENOID VALVE GS020600V-DF

Isolation valve F3DG5S2-062A-220DC60-DFZK rotary vacuum pump P-545 centrifugal pump types DFB80-50-20 OPC solenoid valve Z2804076 piston vacuum pump PVH74QIC-RSM-1S-1X-C25-31 oil pump cost 16G2AT-HMP(25)-DK025-1400 wet solenoid directional valve 4WE10D3X/CG220NZ4 multi stage centrifugal pump DFBII100-80-230 Globe valve J961H-25 end suction centrifugal pump DFB125-80-250-03 O-RING φ140/φ133.4 Xφ3.5 oil transfer gear pump DLZB820-R65-3 axial piston pumps PVH74(QI)C-RM-10-C14 BLADDER NXQ-AB-100/10 mechanical seal pump 109-20SIC/SIC mechanical seal pump BGM37G/50R-G9 vacuum cleaner P-1753 Low pressure oil pump SDV10-1P7P twin screw pump DLZB820-R64A-12 O-ring C8689067 industrial centrifugal pump DFB100-65-260 piston pumps PVH74RO1A-RSM-1S-10-C25-3 Elastomer W096317-VTN piston hydraulic pump A10VS071DRS/32R-VPB22U99 vane pump parts F3.SV.20.4.1.A stator cooling water pump coupling cushion 65-250B coil 300AA00309A 110VDC mechanical seal BKM79.4143B piston pumps PVH74QIC-RSM-IS-10-C25-31 stainless steel Throttle valve (flange) 50BJ-1.6P with reverse flange screw pump stainless KF80KZ/15F4 hydraulic vane pump F3-V10-1S4S-1B20 stainless steel globe valve (flange) 100FJ-1.6PA2 solenoid valve 4WE6Y6X/EG220NZ4/B08V Dome valve insert seal DN200, P/N. P5524C-01 Braking Magnet DF22025 POPPET TYPE SOLENOID VALVE GS020600V

300MW turbine DC Emergency pump impeller 70YB-45 solenoid valve 4WE10Y33/CG24N9K4 pressure hose S100-AC-AC-0020 pressure hose SMS-12/15-1219-C roots vacuum pump P-540 electric pump for lubrication 2CY-29/3.3 pressure hose S110-AC-AL-0050 hydraulic oil 300S90B vickers vane pump F3-SV10 copper sleeve P-1825 electric motor centrifugal water pump YCZ50-250A solenoid valve D1VW20BV-750*B510 centrifugal pump types DFB80-80-220-03 flexible coupling HSNS210-40A vacuum pump 220v MO1225OBGCC15A pump mechanical seal 8b1d pressure hose SMS-12/20-305mm-B servo valve 072K4160 servo valve HY-SFF8.05 centrifugal pump suction IS80-50-200 pump mechanical seal G50 AC explosion-proof motor YB2-100L1-4/2.2KW/380V/1420r/min HYDROGEN DRYER COMPRESSOR 300FS1/2-F reciprocating piston pump PV2R3-94-RBAF1 hydraulic electric pump 200AY150 vane vacuum pump F3-V10-1S6S-1C-20 O-ring C8689543 pressure hose SMS-20-1524mm-B chemical pump centrifugal 65-250B mechanical seal for water pump BKM(FX)103055 vacuum hand pump P-1916 DDV valve D634-327C the diaphragm KS0125ZMAW16BQ13UNOER pressure hose SMS-15-305mm-C vacuum pump 2S-185A hydraulic pump piston PVH74ROIA-RSM-IS-10-C25-3 POPPET TYPE SOLENOID VALVE GS020600V

DFYLSYC-2024-7-15-A

"

0 notes

Text

Digital Autoclave LMDA-A200

Labmate Digital Autoclave is a vertical pulse vacuum steam sterilizer with a 1500L stainless steel chamber and a Siemens PLC control system. Operating at 139℃ with a working pressure of 0.25 MPa, it features a motorized or sliding door, pneumatic sealing, and a double door interlock function. The piping system includes an angle type valve, water ring vacuum pump, and 0.22µm high-efficiency medical-grade filters.

0 notes

Text

The Best Vacuum Pump for Erectile Dysfunction: A Comprehensive Guide

Are you struggling with erectile dysfunction (ED) and looking for a solution that doesn't involve pills or invasive procedures? You're not alone. Many men experience difficulties with their sexual health at some point in their lives. Fortunately, vacuum pumps offer a safe and effective way to manage ED and regain confidence in the bedroom. In this guide, we'll explore everything you need to know about the best vacuum pumps for ED, from how they work to choosing the right one for you.

Understanding Erectile Dysfunction

Erectile dysfunction, often referred to as impotence, is the inability to achieve or maintain an erection sufficient for sexual intercourse. It can be caused by various factors, including age, stress, underlying health conditions, and lifestyle habits. ED can have a significant impact on self-esteem and intimate relationships, but it is treatable with the right approach.

How Vacuum Pumps Help with ED

Vacuum pumps, also known as penis pumps or vacuum erection devices (VEDs), are non-invasive devices designed to create a vacuum around the penis, drawing blood into the area and facilitating an erection. By using suction to increase blood flow to the penis, vacuum pumps can help men achieve and maintain erections suitable for sexual activity.

Types of Vacuum Pumps

There are several types of vacuum pumps available, including manual and battery-operated models. Manual pumps require the user to create suction by hand, while battery-operated pumps offer automated suction for convenience. Additionally, some pumps come with accessories such as constriction rings to help maintain erections.

Key Features to Look for

When choosing a vacuum pump for ED, it's essential to consider key features such as comfort, ease of use, and safety. Look for pumps with adjustable pressure settings, comfortable sleeves or cushions, and a reliable vacuum mechanism. Additionally, consider factors such as durability, portability, and discretion.

Choosing the Right Size

Vacuum pumps come in various sizes to accommodate different penile lengths and girths. It's crucial to choose a pump that fits comfortably and securely to ensure optimal results. Measure your penis carefully and refer to sizing charts provided by manufacturers to select the right size for you.

How to Use a Vacuum Pump

Using a vacuum pump is relatively straightforward, but it's essential to follow instructions carefully to avoid injury or discomfort. Start by applying lubricant to the base of the penis and inserting it into the pump's cylinder. Create a vacuum by pumping or activating the device, and continue until an erection is achieved. Once finished, remove the pump and, if desired, use a constriction ring to maintain the erection.

Safety Precautions and Tips

While vacuum pumps are generally safe when used correctly, it's essential to take precautions to prevent injury or adverse effects. Avoid over-pumping, as this can cause bruising or damage to the penis. Use only as directed by the manufacturer and consult a healthcare professional if you have any concerns or experience discomfort.

Maintenance and Care

Proper maintenance and care are essential to ensure the longevity and effectiveness of your vacuum pump. Clean the device thoroughly after each use with mild soap and water, taking care to remove any lubricant or bodily fluids. Store the pump in a clean, dry place away from direct sunlight or extreme temperatures.

Benefits of Using a Vacuum Pump for ED

Using a vacuum pump for ED offers numerous benefits, including non-invasiveness, effectiveness, and minimal side effects compared to other treatment options. Vacuum pumps can also be used safely in conjunction with other therapies, such as medications or lifestyle changes, to enhance results and improve overall sexual health.

Potential Side Effects and Risks

While vacuum pumps are generally safe for most men, they may cause some side effects or risks, including bruising, numbness, or decreased sensitivity. These effects are usually temporary and can be minimized by using the pump properly and following safety guidelines. However, if you experience persistent or severe symptoms, seek medical attention promptly.

Conclusion

In conclusion, vacuum pumps offer a safe, effective, and non-invasive solution for managing erectile dysfunction and improving sexual health. By understanding how vacuum pumps work, choosing the right device, and following safety guidelines, men can regain confidence and enjoy fulfilling intimate relationships. If you're struggling with ED, consider incorporating a vacuum pump into your treatment plan under the guidance of a healthcare professional.

Remember, you're not alone in your journey towards better sexual health, and there are solutions available to help you overcome obstacles and live life to the fullest.

Whether you're new to using a vacuum pump or considering upgrading to a more advanced model, there's a solution out there that's right for you. Take control of your sexual health and explore the benefits of vacuum pumps for ED today!

Frequently Asked Questions (FAQs)

Q: Are vacuum pumps safe to use? A: Yes, vacuum pumps are considered safe when used correctly and according to manufacturer instructions.

Q: How long does it take to see results with a vacuum pump? A: Results may vary, but many men experience improvements in erectile function within a few weeks of regular use.

Q: Can vacuum pumps cure erectile dysfunction permanently? A: While vacuum pumps can help manage ED symptoms, they do not cure the underlying causes of the condition. However, they can provide temporary relief and improve sexual function.

Q: Can I use a vacuum pump if I have a medical condition or take medications? A: It's essential to consult with a healthcare professional before using a vacuum pump, especially if you have underlying health conditions or take medications that may affect sexual function.

Q: Are vacuum pumps covered by insurance? A: In some cases, vacuum pumps may be covered by insurance, particularly if prescribed by a healthcare provider for the treatment of erectile dysfunction.

1 note

·

View note

Text

CVD Diamond Gems: The Sustainable Alternative to Mined Diamonds

Have you ever encountered it before, the CVD diamond?

This type of synthetic diamond is only a relatively new kid on the block, having existed for less than a decade since scientists stumbled across a technique for making a diamond that has the same chemical composition as a naturally grown diamond but requires much less effort and time. Not all diamonds grow towards the earth’s surface for thousands of years and need pressure and temperature, which can only be found deep. Of course, producers have attempted the same diamond growth process in this deep geological chamber to produce inexpensive and eco-friendly stones for engagement rings. They have done one of the steps that resulted in developing CVD diamonds. More information can be found here, so keep reading through the article.

Understanding the CVD Diamond Gems

It is necessary to understand the meaning of CVD. A CVD diamond is created by a process called chemical vapour deposition. This process begins with a diamond seed crystal in a vacuum chamber, typically made from a high-quality synthetic diamond. Natural gas, such as methane, is then pumped into the chamber and broken down into carbon atoms that accumulate on the crystal and form a diamond. In addition to natural gas, the crystal is treated with high temperatures and pressures within the chamber to remove any colouration and make the diamond colourless.

Advantages of purchasing CVD

Well, there are a few benefits to purchasing this.

Eco-Friendly

CVD diamonds are grown in a lab, becoming a more responsible alternative to mined diamonds. Mining natural gemstone can have diverse, devastating environmental outcomes, such as soil erosion, water pollution, and deforestation.

Grading and Certification

CVD diamond gems are just as valued as natural diamonds since they undergo the same grading and certification procedures. This helps build trust and authenticity among consumers, who would then not be afraid to purchase the product.

Versatile Applications

CVD-manufactured diamonds can exhibit a nearly unlimited number of uses other than jewellery. They may also find applications in producing electronic components, optical devices, and cutting tools.

Cost-Effective

Compared to traditional diamonds, CVD diamonds are a bit more expensive at first, but they remain cheaper in the end because of their lower cost of production.

High Quality

The similarity between CVD diamonds’ physical, chemical, and optical characteristics and those of natural diamonds is apparent. Glass gemstones are resistant to scratching and have a high refractive index, which warrants their application in jewellery.

Widely Available

Although CVD diamonds are becoming increasingly popular and readily available, they must replace mined diamonds. It means that consumers can choose from different merchandise for diamond jewellery.

Ethical

Forced labour, child labour, and exploitation in natural diamond mining are other human rights violations associated with this kind of diamond mining. Customers can ensure that they buy only diamonds unrelated to the mentioned unethical acts by picking up CVD diamonds.

In Conclusion,

It's time to be practical and choose wisely so fashion does not affect the environment. Numerous environmental laws are in place to safeguard mining areas, in addition to the efforts of numerous corporations to enhance their diamond mining methods. Accidents and rule infractions do, however, still occur when looking for rough gemstones.

In the end, natural diamonds are found hundreds of metres below the surface. Truly sustainable diamond mining is unfeasible due to the energy and ecological disruptions needed to access this non-renewable resource.

1 note

·

View note

Text

Get a Customized Vacuum Pump Solution at Meekaj Vacuum Systems Pvt Ltd

When it comes to choosing a vacuum pump for your manufacturing or industrial process, it is important to make the right choice. Vacuum pumps are a crucial element in a variety of applications and choosing the right one can make all the difference in terms of efficiency and productivity. If you are searching for a reliable supplier of vacuum pumps in India, Meekaj Vacuum Systems Pvt Ltd is a name you can trust. Here, we will delve into what makes Meekaj Vacuum Systems Pvt Ltd stand out as one of the leading water ring type vacuum pump manufacturers in India, specializing in single stage vacuum pumps, double stage vacuum pumps, and water ring type vacuum pumps.

At Meekaj Vacuum Systems Pvt Ltd, we are dedicated to providing high-quality vacuum pumps that meet the needs of our clients across various industries. Our range of vacuum pumps includes single stage vacuum pumps, double stage vacuum pumps, and water ring type vacuum pumps, all of which offer superior performance and reliable long-term operation. As one of the leading vacuum pump suppliers in India, we understand the needs of our clients and provide customized vacuum pump solutions to meet their specific requirements. Our team of experts works closely with clients to understand their applications and recommend the most suitable vacuum pump to meet their needs. With our focus on quality, reliability, and efficiency, we have become the preferred choice for many clients across India. Our vacuum pumps are designed and manufactured using the latest technology and highest quality materials, ensuring long-term reliability and optimal performance.

Enhancing Efficiency & Productivity with Our Range of Single Stage & Double Stage Vacuum Pumps

As double stage vacuum pumps manufacturers, we understand the importance of providing efficient and reliable solutions for our clients. Our double stage vacuum pumps are designed to meet the needs of various industries, including pharmaceuticals, chemical, and food processing. Our pumps offer high pumping speeds and low ultimate vacuum levels, ensuring optimal performance and high efficiency. We also specialize in water ring type vacuum pumps, which are ideal for applications requiring constant vacuum levels. Our water ring type vacuum pumps are designed to operate efficiently and reliably in harsh environments, ensuring long term performance and increased durability.

#water ring type vacuum pump manufacturers#single stage vacuum pumps#vacuum pump suppliers in India#double stage vacuum pumps manufacturers

0 notes

Text

What is a stainless steel flange?

Stainless steel flanges play a crucial role in various industrial applications, serving as essential components in piping systems. These robust connectors facilitate the assembly and disassembly of pipes, providing a secure and leak-proof connection. At Bullion Pipes & Tubes LLP, we take pride in being the foremost Stainless Steel Flange Manufacturer, Supplier, Stockist, and Exporter on a global scale. Our commitment to quality and precision has positioned us as industry leaders, providing a diverse range of stainless steel flanges to cater to the unique requirements of projects worldwide.

In this blog post, we will delve into the intricacies of ss flanges, exploring their uses, and key characteristics.

Understanding Stainless Steel Flanges

Stainless steel flanges are integral parts of piping systems designed to connect pipes, valves, pumps, and other equipment. These versatile components are crafted from high-quality SS Flanges, known for its exceptional corrosion resistance, durability, and strength. The use of stainless steel ensures that flanges can withstand harsh environmental conditions and maintain their structural integrity over time.

Key Features of Stainless Steel Flanges:

Corrosion Resistance: Stainless steel flanges offer excellent resistance to corrosion, making them ideal for use in environments with exposure to moisture, chemicals, and harsh weather conditions.

Strength and Durability: The inherent strength of stainless steel ensures that flanges can withstand high pressures and maintain their structural integrity over an extended period.

Temperature Resistance: Stainless steel flanges exhibit remarkable temperature resistance, allowing them to perform reliably in both extreme heat and cold conditions.

Stainless Steel Flanges Specifications

Specifications

ASTM A182, A240 / ASME SA182, SA240

Standards

ANSI Flanges, ASME Flanges, DIN Flanges, EN Flanges, BS Flanges, JIS Flanges, AWWA Flanges etc.

Dimension

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc

Size Range

1/2" (15 NB) to 48" (1200NB)

Pressure / Class

150#, 300#, 600#, 900#, 1500# & 2500#.

Type

Slip On Flanges, Weld Neck Flanges, Blind Flanges, Socket Weld Flanges, Orifice Flanges, Ring Type Joint Flanges, Threaded Flanges, Reducing Threaded Flanges, Lap Joint Flanges, Long Weld Flanges, Spectacle Blind Flanges, Paddle Blind Flanges, Ring Spacer Flanges, Backing Ring Flanges, Nipoflanges, Weldoflange, Flangeolet, Bleed, Drip & Vent Ring Flange, Forged Flange, Raised Face Flanges, Tongue and Groove Flange, Male & Female Flange, Reducing Flange, ANSI Plate Flange, High Hub Blind Flange, Square Flange, Expander Flange, Gasket Flange, Swivel Flange, Heavy Barrel Flange, Forged Steel Flange, Taylor Flange, Wire Seal Flange, Galvanized Flange, Drilled Flange, MS Flange, and Vacuum Flange

Flange Face Type

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Applications of Stainless Steel Flanges

Stainless Steel Flanges' durability, corrosion resistance, and high strength make them suitable for a range of applications. Here are some common applications of ss flanges:

Piping Systems

Chemical Processing Industry

Oil and Gas Industry

Water Treatment Plants

Power Generation

Food and Beverage Industry

Aerospace Industry

Shipbuilding

Pharmaceutical Industry

Construction Industry

Automotive Industry

Other Applications

Final Words!

Stainless steel flanges are indispensable components in various industrial applications, ensuring the integrity and efficiency of piping systems. When it comes to reliability, quality, and a diverse range of options, Bullion Pipes & Tubes LLP is your go-to partner.

Explore our comprehensive range of stainless steel flanges and experience the unmatched quality and service that has made us a global leader all across the globe in various countries such as Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and many other regions. Contact us today at [email protected] or [email protected] for all your stainless steel flange needs, and let Bullion Pipes & Tubes LLP be your trusted partner in success.

0 notes

Text

Single Stage Water Ring Vacuum Pump by Kakati Pumps: A Powerful Solution for Industrial Applications

Kakati Pumps is a leading name in the field of industrial pump solutions, offering cutting-edge technology for a variety of applications. Among their extensive range of pumps, the Single Stage Water Ring Vacuum Pump stands out as an essential and reliable solution for industries that require efficient vacuum systems. Known for their robustness, ease of maintenance, and energy efficiency, Kakati’s Single Stage Water Ring Vacuum Pump plays a crucial role in a variety of sectors, including chemical, pharmaceutical, food processing, and power plants.

The Single Stage Water Ring Vacuum Pump is a type of rotary displacement pump that operates on the principle of water ring technology. Unlike traditional vacuum pumps that use mechanical seals or dry stages, a water ring pump relies on water as a sealing medium. The pump creates a vacuum by utilizing the centrifugal motion of a rotating impeller within a casing that is partially filled with water.

As the impeller rotates, it forms a ring of water inside the pump casing. This water ring moves outward, trapping air and gases, and then expelling them through a discharge port. This design results in a smooth, efficient suction process that generates a vacuum without the need for lubrication or heavy maintenance. The single-stage configuration means that only one impeller is used in the process, making it a simple yet effective solution for achieving a reliable vacuum.

Key Features of Kakati’s Single Stage Water Ring Vacuum Pump

Energy Efficiency: Kakati Pumps’ Single Stage Water Ring Vacuum Pumps are designed with energy efficiency in mind. The water ring technology minimizes the power consumption required to create the vacuum, making these pumps cost-effective to operate over the long term.

Low Maintenance: The water-sealing method reduces wear and tear on the internal components, which translates into less frequent maintenance. With fewer moving parts compared to other types of vacuum pumps, these pumps offer reliable performance with minimal upkeep.

Versatile Applications: Kakati Pumps’ water ring vacuum pumps are ideal for a variety of industries, including chemical processing, distillation, evaporation, and vacuum drying. They are particularly well-suited for handling vapors, gases, and liquid-ring applications.

Compact and Durable: The single-stage design results in a compact, space-efficient pump that fits well in both large-scale industrial setups and smaller facilities. Its durable construction ensures long-lasting performance even in harsh industrial environments.

Self-Priming and Quiet Operation: The self-priming nature of the water ring pump ensures reliable suction, even when the pump is started dry. Moreover, the operation is generally quieter compared to other vacuum pumps, contributing to a more comfortable work environment.

Benefits of Using Kakati’s Single Stage Water Ring Vacuum Pump

Low Risk of Contamination: Since the vacuum is generated using water, the chances of contamination are reduced compared to oil-lubricated pumps. This makes Kakati’s water ring pumps ideal for applications in sensitive industries such as pharmaceuticals and food processing.

Effective Handling of Wet and Vapory Loads: These pumps are designed to handle wet and vapor-laden gases efficiently, which is a common requirement in industries such as chemical production or solvent recovery. Their ability to function in these conditions without losing efficiency makes them a popular choice.

Cost-Effective Performance: The single-stage design not only reduces the initial investment but also helps lower ongoing operational costs. Less power consumption and fewer maintenance requirements contribute to substantial savings over time.

Why Choose Kakati Pumps?

Kakati Pumps has earned a strong reputation for producing high-quality, reliable pumps that meet the demanding needs of industrial applications. Their commitment to innovation and customer satisfaction ensures that businesses get the best solutions tailored to their specific requirements. With a proven track record in providing efficient pumping systems, Kakati Pumps remains a trusted partner for industries worldwide.

Whether you're looking to improve your existing vacuum system or need a new installation, Kakati Pumps’ Single Stage Water Ring Vacuum Pump offers an ideal solution for maintaining reliable and cost-effective vacuum conditions in a wide range of industrial processes.

For more information or to inquire about purchasing a Single Stage Water Ring Vacuum Pump, contact Kakati Pumps today.

0 notes

Text

From the Liquid Ring Vacuum Pump to the Two-Stage counterpart, the Water Ring Vacuum Pump to the reliable Oil Sealed Vacuum Pump – each type brings a unique edge to meet your industrial needs. Unleash efficiency with precision-engineered technology.

For more details, visit- https://www.acmeairequipments.com/vacuum-pump-different-types-applications/

0 notes

Text

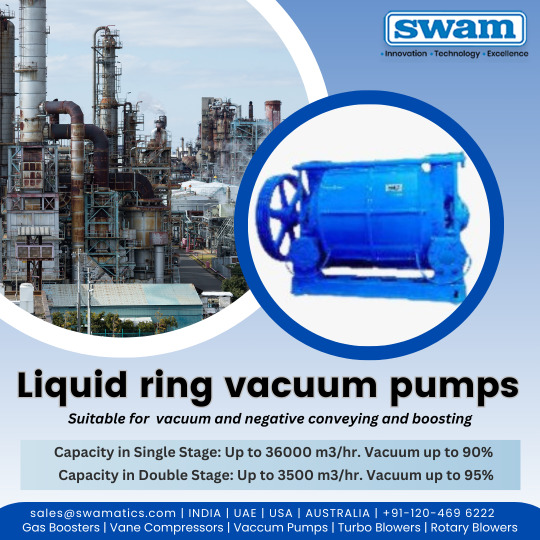

Liquid ring pumps are considered as one of the most versatile and popular types of industrial vacuum pumps. Due to its versatility, these pumps are extensively used for various applications in different industries.

SWAM Liquid ring pumps provide lower maintenance and lower life cycle costs and greater overall value to their clients. These pumps have improved variable port design, enabling a wider range of operations, higher efficiency, saving of water and simpler seal line piping.

For more details, reach out to us at:

#LRVP#Liquidring#Vacuumpump#Distillation#AshHandling#Longlife#lessmaintenance#Wasteoil#swamatics#swam

0 notes

Text

Pleasure Devices For Men And Women

Pleasure devices, often referred to as sex toys, come in a wide range of styles and functions to cater to the diverse preferences and needs of individuals. Here's an overview of popular types for both men and women:

For Women Vibrators: Devices that provide vibration to stimulate the clitoris, vagina, or both. They come in various shapes, sizes, and intensities. Bullet Vibrators: Small, discreet, and often used for clitoral stimulation. Rabbit Vibrators: Dual-stimulation vibrators with an insertable shaft and a clitoral stimulator. Wand Massagers: Powerful vibrators often used externally for intense stimulation. Dildos: Non-vibrating toys designed for insertion into the vagina. They can be made from various materials, including silicone, glass, and metal. Realistic Dildos: Shaped and textured to resemble a penis. G-Spot Dildos: Curved to target the G-spot for enhanced pleasure. Clitoral Stimulators: Toys specifically designed to stimulate the clitoris without insertion. Suction Toys: Use air pulses to create a suction sensation. Vibrating Panties: Underwear with built-in vibrators for hands-free stimulation. Kegel Balls: Small, weighted balls inserted into the vagina to help strengthen pelvic floor muscles, which can enhance sexual pleasure.

For Men Masturbation Sleeves: Devices that simulate the feeling of vaginal, oral, or anal sex. Fleshlights: Popular brand of realistic sleeves. Tenga Eggs: Single-use sleeves with various internal textures. Prostate Massagers: Devices designed to stimulate the prostate gland, which can lead to intense orgasms. Aneros: Well-known brand offering various models. Vibrating Prostate Massagers: Combine prostate stimulation with vibration for added pleasure. Cock Rings: Rings worn around the base of the penis to restrict blood flow, which can enhance erection hardness and duration. Vibrating Cock Rings: Include a vibrating component for additional stimulation. Penis Pumps: Devices that create a vacuum around the penis to increase blood flow and size temporarily.

For Both Anal Toys: Toys designed for anal play, suitable for all genders.

Butt Plugs: Tapered toys for gradual insertion. Anal Beads: String of beads that can be inserted and removed for varied sensation. Remote-Controlled Toys: Toys that can be controlled remotely via a partner or a smartphone app, allowing for shared play over distances.

Couples' Toys: Designed to be used by partners together.

Wearable Vibrators: Insertable vibrators that can be worn during intercourse to stimulate both partners. Double-Ended Dildos: Dildos with two ends for simultaneous use by both partners.

Considerations for Use Material: Opt for body-safe materials like medical-grade silicone, ABS plastic, and stainless steel. Hygiene: Clean toys thoroughly before and after use with appropriate toy cleaners or mild soap and water. Lubrication: Use water-based lubricants with silicone toys to avoid damage. Silicone-based lubricants can be used with non-silicone toys. Storage: Store toys in a clean, dry place, preferably in individual pouches to prevent material degradation and contamination.

These devices can enhance pleasure and intimacy, offering a wide range of experiences for solo or partnered play.

0 notes

Text

China supply POPPET TYPE SOLENOID VALVE GS021600V for power plant

"China supply POPPET TYPE SOLENOID VALVE GS021600V for power plant YOYIK professional production and processing. Deyang YOYIK strong technical force, technical experience, good at operating the technical backbone of many, for hundreds of thermal power plants, hydropower stations, metallurgical enterprises overhaul to provide quality equipment selection, construction design, installation commissioning, after-sales service, and provides A lot of accessories and so on. Deyang YOYIK for power plants, steel accessories are as follows:

Yoyik can offer many spare parts for power plants as below:

DF-POPPET TYPE SOLENOID VALVE GS021600V-DF

piston hydraulic pump SY400-YB-22 O-ring C8689101 solenoid valve4WE10D5X/EG220N9K4centrifugal pump vertical 50-250-007 600MW turbine AC Auxiliary oil pump (TOP)Ball bearing sleeve 125LY-36 BFP Emergency pump mechanical seal 70YB-45 mechanical rubber seal N0330/2100/K/M/506B Pneumatic head diaphragm 125ZMAW16BQ vacuum pump price P-1759 vane type pump F3-SDV20-1P11P-1A globe check Throttling valve LJC100-16 vacuum pump ac ZS-185 fuel pump YH50-32-160 mechanical seal DFB125-80-250-05 Servo valve DJSV-001A electric hydraulic pump 65AY50X9 pressure hose SMS-10/N1/4-1829mm-B Adjustment valve ZKFKP-250-65-14 reciprocating piston pump PVH074R01AB10A2500000001E010A Regulating valve 0125ZMAW16KQ13UEXERH pressure hose SMS-12/20-610mm-C centrifugal pump suction CZ65-250A mechanical seal pump BGM37G/60R-G9 solenoid valve GS06-06-000 bearing bush 3 108 (88/100 (130) 300MW turbine main oil pump O-ring 70LY-343 repair coupling ACF090N4IRBP transfer oil pump 3G806GR40 high pressure piston pump PVH74(QI)C-RM-IS-10-C14 mechanical seal rings 125-80-250 vacuum pumps 30WS EH oil pump PVH098R01AD30A twin screw pump HSND210-36 non-return valve DY25.PC268-DF metering piston pump WD-PVH98QIC Fluoro Rubber O-Ring OR0020013 POPPET TYPE SOLENOID VALVE GS021600V

radial piston pump PD060PC02SRS5AC00E1200000 high pressure oil pump 125LY-35-8 solenoid valve DG4V-5-2AJ-M-U-H6-20 unloading valve HTCVC40.0 radial piston pump hydraulic A10VS0100DFLR/31RVPA12NOO pressure hose SMS-15/N1/4-915mm-B electric motor with hydraulic pump 65AY50X11 industrial centrifugal pump DFB80-520-240 pressure hose SMS-15-2438mm-C metering piston pump PVH74QIC-RSF-1S-10-C25 accumulator oil-return globe valve SHV16 oil pump 65AY50X12 rotary piston pump A10VSO100DFR1/32R roots vacuum pump P-1264 axial piston pumps PVH141R13AF30A230000002001AB01A Electrohydraulic servo valve MOOG-J761-003 fuel pump DLZB820-R65-2 servo valve J761-004A chemical pump centrifugal DFB 80-50-220 OPC solenoid valve coil Z2804076solenoid valve dc screw pump 3Gr70×2 mechanical seal for pump LTJ-8B1D-FA1D56 pump centrifugal DFB80-520-240 water pump 65-250A double mechanical seal N.D.E L270 lubricants oil pump 2CY45/9-1A Solenoid valve 4WE6HA62/EW230N9K4 bladder 25l MOC: Neoprene & Butyle gear pump hydraulic 70LY-34*3 chemical centrifugal pump 65-250A electric transfer oil pump 200D43X3 pressure hose SMS-12/15-305mm-B vaccum pump WS-30 mechanical seal 43 mm AZ40-160B OPC SOLENOID VALVES G130519 Check valve A29581 POPPET TYPE SOLENOID VALVE GS021600V

DFYLSYC-2024-7-15-A

"

0 notes

Text

How to Properly Maintain Your Pool & Spa Equipment for Longevity

Owning a pool and spa can be a source of immense pleasure and relaxation, especially during the scorching summer months. However, ensuring that your pool and spa equipment remains in tip-top condition is crucial for both your enjoyment and the longevity of your investment. Neglecting maintenance can lead to costly repairs or even the premature replacement of your equipment.

In this comprehensive guide, we will explore the key steps to properly maintain your pool and spa equipment to ensure it operates efficiently and lasts for years to come. By following these maintenance practices, you can enjoy crystal-clear water and a trouble-free swimming and relaxation experience.

1. Regular Cleaning

Regular cleaning is the foundation of good pool and spa equipment maintenance. Neglecting this aspect can lead to clogged filters, reduced circulation, and cloudy water. Here's how to tackle cleaning effectively:

Skimming: Remove leaves, insects, and debris from the water's surface using a skimmer net. Doing this daily prevents these particles from sinking and causing further issues.

Vacuuming: Use a pool or spa vacuum to clean the floor and walls. This should be done weekly or more often if you notice excessive debris accumulation.

Basket Maintenance: Skimmer and pump baskets collect debris that can obstruct water flow. Check and clean these baskets regularly to ensure your equipment functions efficiently.

Tile Scrubbing: Calcium buildup can occur on pool and spa tiles. Use a tile brush and a calcium remover solution to scrub away these deposits periodically.

2. Water Chemistry

Maintaining proper water chemistry is crucial for preserving your equipment and ensuring a safe swimming environment. Here's how to manage water chemistry effectively:

Regular Testing: Invest in a reliable water testing kit to check pH, chlorine, alkalinity, and calcium hardness levels. Testing should be done at least once a week.

Balancing Chemicals: Adjust the chemical balance as needed to keep the water within recommended ranges. pH levels should be between 7.4 and 7.6, while chlorine levels should be 1-3 ppm.

Shock Treatment: Perform shock treatments when necessary to eliminate harmful bacteria and algae. This is particularly important after heavy pool usage or severe weather.

Sanitizers: Use high-quality pool and spa sanitizers to keep the water clean and clear. Chlorine, bromine, or alternative sanitizers are available, so choose one that suits your preferences and needs.

3. Filter Maintenance

The filtration system is essential for removing impurities from the water. Proper filter maintenance is key:

Regular Cleaning: Different types of filters (sand, cartridge, or DE) require periodic cleaning or backwashing. Follow the manufacturer's instructions for your specific filter type.

Cartridge/DE Filter: Clean cartridge filters by removing and hosing them off. For DE filters, you'll need to perform a more thorough cleaning by disassembling and cleaning the grids.

Pressure Gauge: Keep an eye on the filter pressure gauge. A significant increase in pressure could indicate a clogged filter and a need for cleaning.

Upgrade Options: Consider upgrading to a more efficient filter system if your current one is outdated. Modern filters offer better filtration and water conservation.

4. Pump and Motor Care

The pool pump and motor play a crucial role in circulating water and powering the filtration system. Take care of them to ensure they function properly:

Lubrication: Lubricate pump o-rings and gaskets with a silicone-based lubricant to prevent leaks and maintain a proper seal.

Regular Inspection: Inspect the pump and motor for any signs of leaks, unusual noises, or damage. Address any issues promptly to prevent further damage.

Professional Servicing: Schedule annual professional servicing to check motor bearings and seals. This proactive step can extend the life of your equipment and save you money in the long run.

5. Heater and Spa Equipment

If you have a spa or pool heater, proper maintenance is essential for energy efficiency and longevity:

Regular Cleaning: Clean the heater's burners or coils to prevent corrosion and soot buildup. Follow the manufacturer's recommendations for cleaning frequency.

Spa Equipment: Inspect and clean spa jets, blowers, and controls to ensure they function correctly. Remove debris and ensure proper water circulation for a relaxing spa experience.

Pool Cover: Consider using a pool cover when the pool or spa is not in use. A cover reduces heat loss, minimizes evaporation, and helps keep debris out of the water.

6. Winterization and Seasonal Care

Properly preparing your pool and spa equipment for the offseason is essential to protect it from the elements:

Lower Water Levels: Lower the water level in the pool and spa to prevent freezing and potential damage to pipes and equipment

Drain and Store: Drain and store hoses, pool accessories, and chemicals in a cool, dry place. Proper storage prevents damage and maintains the quality of these items.

Winter Cover: Install a winter cover to protect your pool and spa from debris, leaves, and harsh weather conditions. Ensure it's securely fastened to keep your equipment safe.

Professional Services: For complex equipment or if you're uncertain about winterization, consider professional winterization services to ensure everything is done correctly.

Conclusion

Maintaining your pool and spa equipment might seem like a chore, but it's a crucial investment in the longevity and enjoyment of your aquatic oasis. By following these comprehensive maintenance guidelines, you'll not only save money on repairs and replacements but also ensure that your pool and spa remain inviting and crystal clear. A well-maintained pool and spa enhance the overall value of your property, providing you with years of relaxation and enjoyment. Make maintenance a priority, and your pool and spa will reward you with years of trouble-free use.

0 notes