#water jet loom machine manufacturer in Gujarat

Explore tagged Tumblr posts

Text

Achieve exceptional fabric quality with Paramount Looms. Our machines deliver consistent results and superior performance.

#fabricquality #textiles #weaving #powerloom #surat

#fabricquality#textiles#weaving#powerloom#surat#power loom manufacturer in surat#power loom manufacturer in india#rapier loom machine manufacturer in surat#rapier loom machine manufacturer gujarat#air jet loom manufacturer in gujarat#air jet loom manufacturer in surat#jacqaurd machine manufacturer in india#yarn weaving machine manufacturer in india#water jet loom machine manufacturer in gujarat#power loom manufacturer in gujarat

1 note

·

View note

Text

The Brief Introduction of Shuttleless Loom

Many characteristics of weaving looms in Gujarat include the nature of material formation, the method of weft insertion (choosing), the kind of losing tool, the variety of colors of weft threads and many more. All these characteristics may be utilized, the form of yarn hired, the width of the woven material produced, and the range of sheds shaped simultaneously with the warp of the weaving system.

Weaving looms may be differentiated into travel looms and shuttleless looms via the utilization of the weft insertion technique. In order to incorporate the warp, the experience loom makes use of standard timber or plastic shuttles. As a result in their full-size length and weight, the shuttle looms produce substantial vibrations, noise, an excessive amount of strength, a sluggish jogging pace, and repeated selection back and forth.

Diverse techniques are utilized to incorporate the weft into shuttleless looms; therefore, these machines can be categorized as follows:

Machine for weaving rapiers

Machine for pneumatic/air-jet braiding

The water turbine weaving apparatus

Machine for weaving projectiles

Machine for multi-shed/multiphase weaving

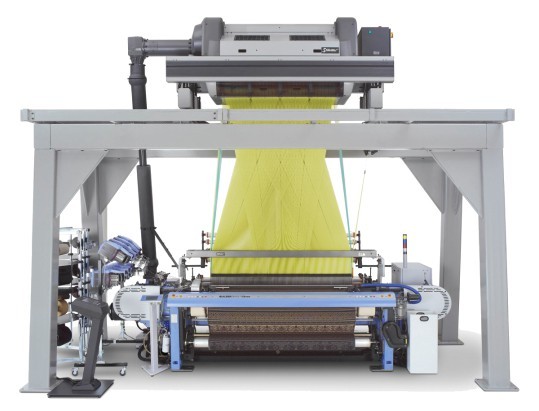

Rapier-powered weaving machines are widely diagnosed for their reliability, flexibility, and efficiency. Weft is extracted from the weft package through the usage of a rigid or supple rapier. The rapier loom is specially designed to facilitate shade trade in variegated weft fabric. It is specially proper-proper for production of yarn-dyed fabrics, double-layer velour, terry fabric, and ornamental fabric. Surprisingly several manufacturers are engaged inside the rapier weaving region.

It is broadly mentioned that the air-jet loom is the maximum efficient and fruitful approach for weaving across the complete shed. The advent of the weft takes place through the implementation of a fluid known as a flow. The air-jet weaving gadgets are supplied with compressed air thru a valuable compressor situated within the weave chamber, or an area with character integrated compressors. This substance is applied in the production of mild to medium-weight fabric, together with denim, terry towel fabric, and furnishing fabric. The spectrum of capacity used for air-jet weavers has grown extensively in tandem with technological development.

Water is hired as the weft insertion medium in water jet looms with a purpose to set off frictional traction on the weft through the water jet. This facilitates the creation of the weft from the fixed package into the shed, wherein it’s far woven. Water major-supplied water is pressurized by using character injection pumps mounted on water jet weaving machines; effluent is discharged into a receptacle. The water jet loom is mostly relevant to hydrophobic chemical fiber filament fabric because of its excessive output and speed.

The weft thread’s apex is grasped by means of the gripper projectile all through projectile loom weaving, which ultimately draws the thread throughout the shed. The advantages of the projectile loom are consistent weave insertion, advanced fabric quality, and decreased yarn waste. It is appropriate for weaving fabrics with multicolored wefts, dense and great fabric, huge fabric, and fabric woven with unique yarns. A high degree of accuracy is vital with regard to the overall performance and dimensions of the feeding and clamping mechanisms. Despite numerous attempts, only the Sulzer projectile weaving device has executed giant business penetration.

There are several styles of multi-shed or multiphase looms, with air-jet, chain belt, or rapier weft insertion being appropriate for weaving single-variety, high-quantity fabrics. The fundamental feature of a shuttleless loom is the segregation of the weft bundle from the go back and forth or the transportation of a minimal amount of weft. This enables the insertion of weft at high speeds through substituting the good sized and weighty shuttle with a diminutive and lightweight weft inserter. As the weft delivers, weft cones or applications are applied immediately, and the weft accumulator offers access to the weft insertion mechanism, thereby disposing of the need for the loom to regularly load the weft. As a result, shuttleless looms are extraordinarily beneficial for increasing fabric varieties, modifying fabric structure, lowering material defects, improving material fine, lowering pollution, enhancing working conditions, and holding electricity.

The investigation and development of shuttleless weaving generation on an international scale started out for the duration of the 19th century. Numerous shuttleless weaves have been brought to the market when you consider that then, and the generation has advanced at a rapid rate. Presently, trip looms have been substituted with shuttleless looms in developed industrialized nations. Attention textile industry professionals. Elevate your weaving method with the best shuttle loom manufacturer in Gujarat by means of Weavetech. Enhance your production performance and great these days. Contact us now for inquiries and orders.

Read More:- The Brief Introduction of Shuttleless Loom

0 notes

Text

Discover the craftsmanship of Paramount Looms, a premier power loom manufacturer based in Surat, Gujarat, and across India. Our rapier loom machines, air jet looms, and water jet looms expertly weave vibrant, multi-colored threads with precision. Experience the seamless integration of traditional weaving techniques and cutting-edge technology through our high-quality yarn weaving machines and electronic jacquard machines.

#power loom manufacturer in surat#rapier loom machine manufacturer gujarat#rapier loom machine manufacturer in surat#air jet loom manufacturer in surat#water jet loom machine manufacturer in gujarat#yarn weaving machine manufacturer in india#jacqaurd machine manufacturer in india

0 notes

Text

Paramount Loom is a leading manufacturer of power looms based in Surat, renowned for its commitment to quality and innovation in the textile industry. With a strong focus on innovation, they offer a wide range of high-quality looms including power shuttle, rapier, dobby, water jet, air jet, and electronic jacquard models. If you are looking for a power loom manufacturer that can provide you with the best products and services, then you need to look no further than Paramount Looms. Their products are known for their durability, precision, and ability to enhance productivity, making Paramount Loom a significant contributor to the textile industry's growth in Surat and beyond. Contact us today to learn more about our products and how we can help you achieve your textile manufacturing goals.

#power loom manufacturer in surat#air jet loom manufacturer in gujarat#water jet loom machine manufacturer in gujarat

0 notes

Text

Transform Your Manufacturing with the Power Loom Revolution! Our power loom machines automate weaving, boosting speed and efficiency compared to traditional hand looms. Upgrade your capabilities – Contact us to elevate your manufacturing efficiency!

#power loom manufacturer in surat#power loom manufacturer in india#rapier loom machine manufacturer gujarat#water jet loom machine manufacturer in gujarat#rapier loom price#rapier loom machine manufacturer india#air jet loom manufacturer in gujarat#rapier loom machine manufacturer in surat#air jet loom manufacturer in surat#power loom manufacturer in gujarat#power loom

0 notes

Text

Power looms have been the backbone of the textile industry, facilitating the manufacture of materials in an efficient manner. Explore the complete range of textile machinery at our Power Looms Machine Manufacturer. Revolutionize your weaving processes with cutting-edge technology. Visit Paramount Looms and embark on a journey of transformation!

#power loom manufacturer in surat#power loom manufacturer in india#yarn weaving machine at best price in india#rapier loom machine manufacturer india#air jet loom manufacturer in gujarat#water jet loom machine manufacturer in gujarat#air jet loom manufacturer in surat#rapier loom machine manufacturer in surat#rapier loom price#rapier loom machine manufacturer gujarat

0 notes

Text

#power loom manufacturer in surat#rapier loom machine manufacturer gujarat#air jet loom manufacturer in gujarat#rapier loom price#rapier loom machine manufacturer in surat#power loom manufacturer in india#water jet loom machine manufacturer in gujarat#yarn weaving machine at best price in india#rapier loom machine manufacturer india#air jet loom manufacturer in surat

0 notes

Text

#power loom manufacturer in Surat#yarn weaving machine manufacturer in india#water jet loom machine manufacturer in gujarat#rapier loom machine manufacturer gujarat#electronic jacquard machine manufacturer in india#rapier loom machine manufacturer in surat#air jet loom manufacturer in Gujarat

0 notes

Text

What are 3 Modern Power Looms- Types, Advantages & Uses

The landscape of India's textile manufacturing sector is experiencing an unprecedented surge, fueled by dynamic shifts in fashion preferences and trends. In contrast to the labor-intensive hand-crafting of fabrics that once consumed considerable time, the contemporary era has ushered in a wave of transformative technological advancements and machinery innovations. These innovations have not only streamlined the manufacturing process but have also broadened the horizons of fabric, lace, and material production. Amid this transformative backdrop, the power loom has emerged as a seminal and widely acclaimed innovation within the textile industry. Functioning as a cornerstone of textile production, the power loom stands as a testament to the industry's capacity to craft an extensive array of fabrics, each boasting diverse textures and compositions. This groundbreaking apparatus has transcended conventional limitations, enabling the swift, efficient, and seamless creation of fabrics. Embark on a journey of textile innovation with Weavetech, the pioneering force behind revolutionizing fabric production in Gujarat. Are you ready to elevate your textile manufacturing endeavours to new heights? Discover the potential of our cutting-edge Power Loom technology, poised to redefine the very fabric of your operations.

Electronic Jacquard Loom Machine:

The Jacquard is like a superstar in India's Textile Manufacturing Industry. It's a game-changing invention that has a rich history. Imagine an Electronic Jacquard Loom Machine as a super-smart weaver. It uses special punch cards, kind of like a secret code, to control how threads move. What's really cool is that it can create many different designs and patterns all at once, just by changing these punch cards. Think of it as a magic loom that weaves not just fabric, but stories. With this machine, fabric becomes an art canvas, and every thread is like a brushstroke. It's a blend of old traditions and modern tech, coming together to create something truly unique. Elevate Gujarat's textile game with Weavetech's cutting-edge Electronic Jacquard Loom Machines in Gujarat. Unleash design diversity and precision like never before.

Advantages

Versatile Designs

Time Efficiency

Customization

Reduced Waste

Consistency

Complex Weaves

Increased Productivity

Skilled Labor

Data-Driven Insights

Competitive Edge

Uses

Textile Design

Apparel Production

Home Furnishings

Interior Decor

Automotive Industry

Industrial Applications

Artistic Creations

Traditional Crafts

Luxury Fabrics

Innovation

Fashion Accessories

Water Jet Loom Machine:

At the heart of textile weaving, the water jet loom machine emerges as a masterful tool, weaving fabrics with finesse. Employing the fluid prowess of water, it deftly guides the weft through the warp, seamlessly intertwining threads. This hydro-powered journey showcases the ingenuity of yarn propelled by the forces of nature. Venturing to East Asia, the Rapier Loom machine claims its throne. An emblem of efficiency, it boasts widespread adoption due to its eco-conscious energy usage and remarkable weaving speed. This technology-driven marvel exemplifies a harmonious blend of innovation and sustainability, propelling fabric creation into a new era of excellence. Are you also looking for water jet loom machines in Gujarat? If yes, then get in touch with Weavetech as we offer everything that fulfills your textile production needs and requirements.

Advantages

High weaving speed due to water jet weft insertion.

Versatile for weaving a wide range of fabric types.

Reduced yarn breakage and fabric wear.

Precision in weaving complex patterns and designs.

Cost-effective maintenance and energy consumption.

No need for a shuttle, minimizing stress and noise.

Environmentally friendly with reduced noise and vibration.

Minimal friction, leading to less wear and tear.

Smooth color changes for diverse design options.

Efficient yarn usage, reducing wastage.

Integration of modern technology for enhanced efficiency.

Uses

Weaving a variety of textiles, from delicate to heavy fabrics.

Crafting intricate patterns and designs with precision.

Efficient production of clothing and apparel.

Creating home textiles like curtains and linens.

Designing upholstery fabrics for furniture.

Manufacturing technical textiles for industrial applications.

Producing textiles for automotive interiors.

Crafting fashion accessories like scarves and ties.

Weaving fabrics for traditional and cultural garments.

Creating customized fabrics for art and installations.

Bullet Looms:

Embedded with a precision ball bearing foundation and a dynamic spherical base, the bullet loom surges with heightened RPM potential. Engineered to excel, these looms unleash fabric creation at an accelerated pace, all while upholding impeccable quality and seamless transmission. Operating at an impressive velocity of up to 180 RPM, this bullet loom orchestrates a symphony of speed without compromising the integrity of the machine or the weaving process. Weavetech invites you to experience the power of innovation with our top-tier Bullet Machines. Unleash the potential of high-speed weaving without compromise, setting new standards for quality in every thread. Join us in redefining fabric manufacturing in Gujarat today.

Advantages

Enhanced RPM capability due to ball bearing and spherical base.

High-speed fabric production without compromising quality.

Smooth transmission for uninterrupted weaving.

Consistent and impeccable fabric output.

Efficient production of fabrics at a rapid rate.

Reduced risk of harming machine parts or weaving process.

Ideal for maintaining quality in fast-paced textile manufacturing.

Precision engineering ensures dependable performance.

Versatile application for various types of fabrics.

Enables seamless weaving at up to 180 RPM.

Uses

Rapid production of fabrics with high-speed weaving.

Ideal for creating textiles without compromising quality.

Efficient for industries requiring fast-paced manufacturing.

Suitable for producing a wide range of fabric types.

Enables consistent and reliable fabric output.

Precise weaving for intricate patterns and designs.

Perfect for applications where speed and quality are crucial.

Well-suited for high-demand textile production.

Enables seamless transmission during fast weaving.

Facilitates smooth operation at speeds up to 180 RPM.

Step into the future of textile manufacturing excellence with Weavetech. Our high-quality machinery is meticulously crafted to redefine industry standards. Elevate your production capabilities today and unlock a world of innovation with Weavetech. Your journey towards unmatched quality begins here.

Original Source: https://weavetech.com/blog-detail/43/what-are-3-modern-power-looms--types-advantag/

0 notes

Text

What Are The Different Types Of Weaving Machines?

There are several fabrics getting produced in textile manufacturing industries including woven fabrics, non-woven fabrics, and knitted fabrics. To produce all those fabrics, heavy machinery is used by the textile manufacturing industries of Gujarat. Let's talk about different types of weaving machines in this blog. If you are looking for an industry that deals with those weaving machinery, then you must connect with Weavetech as they are a well-known name for many years in this industry. Presently, there are several weaving machines that are dominating the textile market. However, majorly they are divided into three basic types- Circular, Shuttle, and Narrow Fabric.

Let's Look At Some Weaving Machines

Shuttle loom: This machine is mainly controlled via electronic and used to weave warp and weft patterns. This loom is a kind of micro wood or plastic that contains bobbins that are filled with yarn. It is fluttered across the loom back and forth to form interlacement that helps in producing fabric easily and more efficiently. This is getting used by many of the famous textile manufacturing industries of India as this is cheaper as compared to their counterparts and makes textile production cost-effective. This is also easy to operate and worker-friendly.

Rapier loom: The rapier loom is one of the most used textile manufacturing machinery in India. This is a kind of special package of yarn that supplies the weft threads for the machine. It has finger-like carriers called rapiers and these are used to carry the filling yarns toward the other end. The rapier loom machine is highly suitable for weaving High GSM & Heavy Density Plain, Twill, and Dobby fabrics like suitings, shirtings, furnishing, liners, etc. Weavetech offers India's fastest & first guideless high-speed rapier dobby looms made with European technology. The rapier loom machine is the largest-selling and most successful Indian Rapier loom and weaving machine.

Projectile loom: A projectile loom is a kind of shuttle less weaving machine that is designed as bullet-shaped metal devices and hence getting known as a projectile loom. This machine can produce different kinds of fashionable fabrics and reduce external noise when in motion. Hence, this feature makes it environmentally friendly and a preferable choice for textile manufacturing industries. Furthermore, the projectile loom is also energy efficient as it consumes approximately 3 Kilo-Watt/Hour which is great compared to other textile machinery. Get in touch with Alidhra Weavetech as they have a complete textile machinery solution.

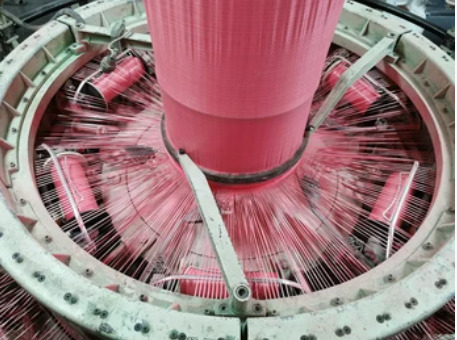

Circular loom: This machine contains several circulating shuttles that move around the periphery disseminating the weft. The major concern of this machine is producing tubular fabric and thereby getting used to produce seamless fabric products such as clothing, fire hose, hosiery, sacks, etc. The modern circular machine uses electromagnets for high-speed fabric production. The speed of this loom is manageable and hence preferred by many of the textile manufacturing industries in Gujarat.

Ribbon loom: A ribbon loom is a kind of narrow fabric loom that is highly efficient to weave more than forty pieces together. This loom has a jacquard fitted at the top of them, which is controlled by a stack of perforated cards. Weavetech offers a Rapier Jacquard Loom / Jacquard Machine (650 RPM). The weaving machine & jacquard machine are perfectly integrated into a seamless single control panel to provide ease of operation while ensuring error-free weaving. Kindly connect with Weavetech today to know more about textile machinery. This fabric loom also helps in the effective processing of complex patterns like brocade and matelassé, etc.

Water jet loom: A water jet loom is similar to an air jet loom that uses water instead of air to transfer the yarn around the shed. This jet loom is faster than any other kind of jet loom and it can weave very quickly whilst the yarn is not damaged here as well. Furthermore, the water jet room is less noisy than the air jet l22oom and rapier loom and consumes comparatively less power. One of the major drawbacks of this weaving machine is that it is suitable for only hydrophobic nature yarns such as polyester PET, Acetate PET, and Polyester PET.

If you are looking for the best textile machinery in India, then get in touch with Weavetech today. Alidhra Weavetech is a global and leading organization grounded in 25 years of experience in supplying indigenously designed weaving and twisting machinery solutions to the world.

#textile manufacturing industries#textile manufacturing industries of India#rapier loom machine#high-speed rapier dobby looms

0 notes

Text

What Are The Different Types Of Weaving Machines?

There are several fabrics getting produced in textile manufacturing industries including woven fabrics, non-woven fabrics, and knitted fabrics. To produce all those fabrics, heavy machinery is used by the textile manufacturing industries of Gujarat. Let’s talk about different types of weaving machines in this blog. If you are looking for an industry that deals with those weaving machinery, then you must connect with Weavetech as they are a well-known name for many years in this industry. Presently, there are several weaving machines that are dominating the textile market. However, majorly they are divided into three basic types- Circular, Shuttle, and Narrow Fabric.

Let’s Look At Some Weaving Machines

Shuttle loom: This machine is mainly controlled via electronic and used to weave warp and weft patterns. This loom is a kind of micro wood or plastic that contains bobbins that are filled with yarn. It is fluttered across the loom back and forth to form interlacement that helps in producing fabric easily and more efficiently. This is getting used by many of the famous textile manufacturing industries of India as this is cheaper as compared to their counterparts and makes textile production cost-effective. This is also easy to operate and worker-friendly.

Rapier loom: The rapier loom is one of the most used textile manufacturing machinery in India. This is a kind of special package of yarn that supplies the weft threads for the machine. It has finger-like carriers called rapiers and these are used to carry the filling yarns toward the other end. The rapier loom machine is highly suitable for weaving High GSM & Heavy Density Plain, Twill, and Dobby fabrics like suitings, shirtings, furnishing, liners, etc. Weavetech offers India’s fastest & first guideless high-speed rapier dobby looms made with European technology. The rapier loom machine is the largest-selling and most successful Indian Rapier loom and weaving machine.

Projectile loom: A projectile loom is a kind of shuttleless weaving machine that is designed as bullet-shaped metal devices and hence getting known as a projectile loom. This machine can produce different kinds of fashionable fabrics and reduce external noise when in motion. Hence, this feature makes it environmentally friendly and a preferable choice for textile manufacturing industries. Furthermore, the projectile loom is also energy efficient as it consumes approximately 3 Kilo-Watt/Hour which is great compared to other textile machinery. Get in touch with Alidhra Weavetech as they have a complete textile machinery solution.

Circular loom: This machine contains several circulating shuttles that move around the periphery disseminating the weft. The major concern of this machine is producing tubular fabric and thereby getting used to produce seamless fabric products such as clothing, fire hose, hosiery, sacks, etc. The modern circular machine uses electromagnets for high-speed fabric production. The speed of this loom is manageable and hence preferred by many of the textile manufacturing industries in Gujarat.

Ribbon loom: A ribbon loom is a kind of narrow fabric loom that is highly efficient to weave more than forty pieces together. This loom has a jacquard fitted at the top of them, which is controlled by a stack of perforated cards. Weavetech offers a Rapier Jacquard Loom / Jacquard Machine (650 RPM). The weaving machine & jacquard machine are perfectly integrated into a seamless single control panel to provide ease of operation while ensuring error-free weaving. Kindly connect with Weavetech today to know more about textile machinery. This fabric loom also helps in the effective processing of complex patterns like brocade and matelassé, etc.

Water jet loom: A water jet loom is similar to an air jet loom that uses water instead of air to transfer the yarn around the shed. This jet loom is faster than any other kind of jet loom and it can weave very quickly whilst the yarn is not damaged here as well. Furthermore, the water jet room is less noisy than the air jet l22oom and rapier loom and consumes comparatively less power. One of the major drawbacks of this weaving machine is that it is suitable for only hydrophobic nature yarns such as polyester PET, Acetate PET, and Polyester PET.

If you are looking for the best textile machinery in India, then get in touch with Weavetech today. Alidhra Weavetech is a global and leading organization grounded in 25 years of experience in supplying indigenously designed weaving and twisting machinery solutions to the world.

#weaving machine#textile manufacturing machine#machine manufacturing#textile machine#twisting machine#rapier loom

0 notes

Text

What Are The Different Types Of Weaving Machines?

There are several fabrics getting produced in textile manufacturing industries including woven fabrics, non-woven fabrics, and knitted fabrics. To produce all those fabrics, heavy machinery is used by the textile manufacturing industries of Gujarat. Let's talk about different types of weaving machines in this blog. If you are looking for an industry that deals with those weaving machinery, then you must connect with Weavetech as they are a well-known name for many years in this industry. Presently, there are several weaving machines that are dominating the textile market. However, majorly they are divided into three basic types- Circular, Shuttle, and Narrow Fabric.

Let's Look At Some Weaving Machines

Shuttle loom: This machine is mainly controlled via electronic and used to weave warp and weft patterns. This loom is a kind of micro wood or plastic that contains bobbins that are filled with yarn. It is fluttered across the loom back and forth to form interlacement that helps in producing fabric easily and more efficiently. This is getting used by many of the famous textile manufacturing industries of India as this is cheaper as compared to their counterparts and makes textile production cost-effective. This is also easy to operate and worker-friendly.

Rapier loom: The rapier loom is one of the most used textile manufacturing machinery in India. This is a kind of special package of yarn that supplies the weft threads for the machine. It has finger-like carriers called rapiers and these are used to carry the filling yarns toward the other end. The rapier loom machine is highly suitable for weaving High GSM & Heavy Density Plain, Twill, and Dobby fabrics like suitings, shirtings, furnishing, liners, etc. Weavetech offers India's fastest & first guideless high-speed rapier dobby looms made with European technology. The rapier loom machine is the largest-selling and most successful Indian Rapier loom and weaving machine.

Projectile loom: A projectile loom is a kind of shuttleless weaving machine that is designed as bullet-shaped metal devices and hence getting known as a projectile loom. This machine can produce different kinds of fashionable fabrics and reduce external noise when in motion. Hence, this feature makes it environmentally friendly and a preferable choice for textile manufacturing industries. Furthermore, the projectile loom is also energy efficient as it consumes approximately 3 Kilo-Watt/Hour which is great compared to other textile machinery. Get in touch with Alida Weavetech as they have a complete textile machinery solution.

Circular loom: This machine contains several circulating shuttles that move around the periphery disseminating the weft. The major concern of this machine is producing tubular fabric and thereby getting used to produce seamless fabric products such as clothing, fire hose, hosiery, sacks, etc. The modern circular machine uses electromagnets for high-speed fabric production. The speed of this loom is manageable and hence preferred by many of the textile manufacturing industries in Gujarat.

Ribbon loom: A ribbon loom is a kind of narrow fabric loom that is highly efficient to weave more than forty pieces together. This loom has a jacquard fitted at the top of them, which is controlled by a stack of perforated cards. Weavetech offers a Rapier Jacquard Loom / Jacquard Machine (650 RPM). The weaving machine & jacquard machine are perfectly integrated into a seamless single control panel to provide ease of operation while ensuring error-free weaving. Kindly connect with Weavetech today to know more about textile machinery. This fabric loom also helps in the effective processing of complex patterns like brocade and matelassé, etc.

Water jet loom: A water jet loom is similar to an air jet loom that uses water instead of air to transfer the yarn around the shed. This jet loom is faster than any other kind of jet loom and it can weave very quickly whilst the yarn is not damaged here as well. Furthermore, the water jet room is less noisy than the air jet l22oom and rapier loom and consumes comparatively less power. One of the major drawbacks of this weaving machine is that it is suitable for only hydrophobic nature yarns such as polyester PET, Acetate PET, and Polyester PET.

If you are looking for the best textile machinery in India, then get in touch with Weavetech today. Alidhra Weavetech is a global and leading organization grounded in 25 years of experience in supplying indigenously designed weaving and twisting machinery solutions to the world.

0 notes

Text

A Glimpse of Paramount Looms

A promising power loom machine company in India, Paramount Looms uses its equipment to weave super-fine fibres. By using its cutting-edge products to expedite tedious textile creation processes, it has made an incredibly beneficial contribution to the textile industry.

We provide a comprehensive range of textile equipment, which break new ground in the creation of productive textiles. Do you require assistance using or operating the weaving machine? Call now to get help from our professionals!

#yarn weaving machine manufacturer in india#power loom manufacturer in india#power loom manufacturer in surat#rapier loom machine manufacturer gujarat#water jet loom machine manufacturer in gujarat

0 notes

Text

What types of fabrics are made in a water jet loom?

The top-class fabric was produced by using a high-speed semi-automated water jet power loom. It was created by using simple and effective technology.

Water jet weaving is only suitable for weaving hydrophilic filament yarn and polyester in nature. The finest water jet power loom is adequate for weaving high-quality, heavy-density, twisted fabrics, including draperies, tablecloths, vests, chiffon, umbrella cloths, home textiles, and all other sorts of heavy fabrics made of POY, FTY, twisted yarn, and spandex-covered yarn ranging in density from 20 D to 1800 D.

To know more, consult the best Paramount looms manufacturer in Gujarat, India.

#waterjet loom machine manufacturer#water jet loom machine manufacturer in india#water jet loom machine manufacturer in gujarat#water jet loom machine manufacturer in surat#yarn weaving machine at best price in india

0 notes

Text

What is Water Jet Loom Machine?

A water jet loom machine is a power loom machine that is extensively used in the textile industry. The weft is inserted using water spray in a shuttle-less loom type known as a water jet loom machine. It has a speed up to 1000rpm depending on the yarn. A top-class fabric was produced by using a high-speed semi-automated water jet power loom. It was created by using simple and effective technology. Water jet weaving is only suitable for weaving hydrophilic filament yarn and polyester in nature. The finest water jet power loom is adequate for weaving high-quality, heavy-density, twisted fabrics, including draperies, tablecloths, vests, chiffon, umbrella cloths, home textiles, and all other sorts of heavy fabrics made of POY, FTY, twisted yarn, and spandex-covered yarn ranging in density from 20D to1800D. Paramount Looms is a leading waterjet loom machine manufacturer in Surat, Gujarat, India. We offer a wide range of waterjet loom machines that are designed and fabricated using the latest technology and quality components. We have a team of experienced professionals who provide comprehensive after-sales service and support to our customers. Contact us for more information like the water jet loom machine price, the working principle of the water jet loom, and many more.

#water jet loom machine manufacturer in surat#water jet loom machine manufacturer in gujarat#water jet loom machine manufacturer in india

0 notes

Text

Paramount Looms is a water jet loom machine manufacturer based in Surat, Gujarat, India. We have been designing, developing, and manufacturing water jet looms since our inception.

Our mission is to provide our customers with the highest quality water jet looms and spare parts at the most competitive prices.

We also offer comprehensive after-sales service and support to ensure that our customers are completely satisfied with their purchases.

If you are in the market for a water jet loom, we invite you to browse our website or contact us to learn more about our products and services.

#"water jet loom machine manufacturer in Surat#water jet loom machine manufacturer in Gujarat#Water jet loom machine manufactures in India.

0 notes