#vci packaging company

Explore tagged Tumblr posts

Text

VCI Anti Corrosion Oil

Application

Protect Metal Surface

Protection for Gear Box & Fuel Tank

Used in Automobile Component

Pressed Components

Shop Us :- https://safepack.shop/

0 notes

Text

Global VCI Shrink Film Market: Trends, Growth Projections, and Industry Outlook

The VCI (Volatile Corrosion Inhibitor) shrink film industry is expanding due to increasing demand for corrosion protection in metal packaging across industries like automotive, aerospace, and electronics. These films provide moisture resistance, rust prevention, and secure packaging for sensitive metal components. Key trends include the development of biodegradable VCI films, multi-layer coextruded films for enhanced durability, and customized shrink wraps for industrial applications.

Old Report Source: https://www.plasticsnewsdirectory.com/company/910976/news/3548011/vci-shrink-film-market-set-to-soar-projected-cagr-of-4-50-leads-to-usd-154-6-million-by-2034

0 notes

Text

BENZ Packaging VCI Paper: The Ultimate Solution for Corrosion Protection

In today’s fast-paced industrial world, ensuring the longevity and reliability of metal components is paramount. Corrosion, the gradual destruction of materials by chemical and electrochemical reactions with their environment, poses a significant threat to various industries. This is where Volatile Corrosion Inhibitor (VCI) paper from BENZ Packaging steps in, providing an innovative and effective solution to combat corrosion. In this blog, we will explore the features, benefits, and applications of BENZ Packaging VCI paper and understand why it is a preferred choice for corrosion protection.

Understanding VCI Paper

VCI paper is a specialized packaging material infused with corrosion inhibitors. These inhibitors vaporize and form a thin, protective layer on metal surfaces, preventing moisture, oxygen, and other corrosive elements from initiating the corrosion process. BENZ Packaging’s VCI paper is engineered to offer superior corrosion protection for a wide range of metals, including ferrous and non-ferrous metals.

Features of BENZ Packaging VCI Paper

Advanced VCI Technology: BENZ Packaging incorporates cutting-edge VCI technology, ensuring that the corrosion inhibitors are uniformly distributed within the paper. This guarantees consistent and reliable protection for metal components.

Multi-Metal Protection: BENZ Packaging VCI paper is designed to protect various metals, including steel, iron, copper, brass, and aluminum. This versatility makes it suitable for multiple industries with diverse metal protection needs.

Eco-Friendly: BENZ Packaging is committed to sustainability. Their VCI paper is made from recyclable materials and is itself recyclable, minimizing environmental impact and aligning with eco-friendly practices.

Customizable Options: Understanding that different applications require different specifications, BENZ Packaging offers customizable VCI paper options in terms of size, thickness, and performance levels to meet specific customer needs.

Safe and Non-Toxic: The VCI chemicals used in BENZ Packaging’s paper are non-toxic and safe for both users and the environment. This ensures that the paper can be handled without special precautions and is safe for use in various applications.

Benefits of Using BENZ Packaging VCI Paper

Effective Corrosion Protection: The primary benefit of BENZ Packaging VCI paper is its ability to effectively prevent corrosion. By forming a protective molecular layer on the metal surface, it inhibits the electrochemical reactions that lead to rust and corrosion.

Cost Savings: Preventing corrosion with VCI paper reduces the need for expensive rust removal processes and replacements of corroded parts. This results in significant cost savings for businesses.

Extended Product Lifespan: By protecting metal components from corrosion, VCI paper helps extend their lifespan, ensuring that they remain functional and reliable over longer periods.

Easy to Use: BENZ Packaging VCI paper is easy to apply, either by wrapping, interleaving, or placing it in close proximity to the metal parts. This simplicity enhances operational efficiency and reduces labor costs.

Reduced Environmental Impact: With its eco-friendly properties, BENZ Packaging VCI paper helps companies reduce their environmental footprint. The use of recyclable materials and non-toxic chemicals supports sustainable practices.

Versatility: The ability of BENZ Packaging VCI paper to protect various metals makes it a versatile solution for different industries, from automotive and electronics to heavy machinery and defense.

Applications of BENZ Packaging VCI Paper

Automotive Industry: In the automotive sector, protecting engine parts, transmission components, and other critical metal parts from corrosion is essential. BENZ Packaging VCI paper ensures that these components remain in pristine condition during storage and transit.

Electronics and Electricals: The electronics industry relies on metal contacts and connectors, which are susceptible to corrosion. BENZ Packaging VCI paper safeguards these sensitive components, ensuring their reliability and performance

Heavy Machinery: Heavy machinery and equipment, often stored and transported in challenging environments, benefit greatly from the corrosion protection offered by BENZ Packaging VCI paper. It helps maintain the integrity and functionality of these high-value assets.

Defense Sector: In the defense sector, the reliability and performance of metal components are crucial. BENZ Packaging VCI paper provides the necessary protection for weapons, ammunition, and other metal parts, ensuring their readiness and effectiveness.

Metal Fabrication: Metal fabricators use BENZ Packaging VCI paper to protect raw materials and finished products from corrosion. This ensures that the metals retain their quality and are ready for use in various applications.

Export Packaging: For businesses involved in exporting metal components, BENZ Packaging VCI paper offers peace of mind by ensuring that the products reach their destination without corrosion-related damage, thus maintaining their quality and value.

Why Choose BENZ Packaging VCI Paper?

Proven Expertise: BENZ Packaging has established itself as a leader in the packaging industry, with a proven track record of providing high-quality corrosion protection solutions.

Commitment to Quality: BENZ Packaging is dedicated to delivering products that meet the highest standards of quality and performance. Their VCI paper undergoes rigorous testing to ensure its effectiveness in various conditions.

Customer-Centric Approach: BENZ Packaging understands the unique needs of its customers and offers tailored solutions to meet those needs. Their customer-centric approach ensures that businesses receive the best possible corrosion protection for their specific applications.

Innovation and Sustainability: BENZ Packaging continuously invests in research and development to enhance the performance of their VCI products. Their commitment to sustainability ensures that their solutions are environmentally responsible.

Global Reach: With a strong presence in India and a growing international footprint, BENZ Packaging is well-positioned to serve customers worldwide, providing reliable corrosion protection solutions across different markets and industries.

Conclusion

In an industrial landscape where the integrity and reliability of metal components are critical, BENZ Packaging VCI paper price emerges as an indispensable solution. Its advanced technology, versatile applications, and numerous benefits make it a preferred choice for businesses looking to protect their metal assets from corrosion. Whether in the automotive, electronics, heavy machinery, or defense sectors, BENZ Packaging VCI paper provides the peace of mind that comes with knowing that metal components are safeguarded against the detrimental effects of corrosion

0 notes

Text

VCI Bags Manufacturer and Supplier

We specialize in providing advanced Volatile Corrosion Inhibitor (VCI) bags, designed to protect your valuable metal products from rust and corrosion. Our VCI bags release corrosion-inhibiting molecules that form an invisible, protective layer on metal surfaces, preventing rust and ensuring the longevity of your products.

Why Choose Our VCI Bags?

Superior Corrosion Protection:

Our VCI technology offers unmatched protection, ensuring your metal parts remain rust-free during storage and transportation.

High-Quality Materials:

Made from durable plastics, our VCI bags are available in various sizes, shapes, and thicknesses to suit any application, from small electronic components to large machinery parts.

Custom Solutions:

We provide customized VCI packaging solutions, including flat bags, gusseted bags, and zipper bags, tailored to fit your specific requirements.

Environmentally Friendly Options:

Our eco-friendly VCI bags are recyclable and biodegradable, helping you achieve your sustainability goals without compromising on protection.

Easy to Use:

Simply seal your metal parts in the VCI bag and let our advanced technology do the rest.

Cost-Effective:

Our VCI bags reduce the need for additional protective coatings or treatments, saving you time and money.

Non-Toxic and Safe:

Our VCI chemicals are non-toxic and do not leave any harmful residues on your products.

Enhanced Visibility:

Clear VCI bags allow for easy inspection of contents without breaking the protective seal.

Industries We Serve:

Our VCI bags are trusted by leading companies in the automotive, aerospace, electronics, machinery, and manufacturing industries, ensuring their metal products remain rust-free during storage and transportation.

Protect your investments and ensure the integrity of your products with our innovative VCI solutions. Contact us today to learn more and get started on safeguarding your metals with the best in VCI technology!

0 notes

Text

VCI Bags Manufacturer and Supplier

We specialize in providing advanced Volatile Corrosion Inhibitor (VCI) bags, designed to protect your valuable metal products from rust and corrosion. Our VCI bags release corrosion-inhibiting molecules that form an invisible, protective layer on metal surfaces, preventing rust and ensuring the longevity of your products.

Why Choose Our VCI Bags?

Superior Corrosion Protection:

Our VCI technology offers unmatched protection, ensuring your metal parts remain rust-free during storage and transportation.

High-Quality Materials:

Made from durable plastics, our VCI bags are available in various sizes, shapes, and thicknesses to suit any application, from small electronic components to large machinery parts.

Custom Solutions:

We provide customized VCI packaging solutions, including flat bags, gusseted bags, and zipper bags, tailored to fit your specific requirements.

Environmentally Friendly Options:

Our eco-friendly VCI bags are recyclable and biodegradable, helping you achieve your sustainability goals without compromising on protection.

Easy to Use:

Simply seal your metal parts in the VCI bag and let our advanced technology do the rest.

Cost-Effective:

Our VCI bags reduce the need for additional protective coatings or treatments, saving you time and money.

Non-Toxic and Safe:

Our VCI chemicals are non-toxic and do not leave any harmful residues on your products.

Enhanced Visibility:

Clear VCI bags allow for easy inspection of contents without breaking the protective seal.

Industries We Serve:

Our VCI bags are trusted by leading companies in the automotive, aerospace, electronics, machinery, and manufacturing industries, ensuring their metal products remain rust-free during storage and transportation.

Protect your investments and ensure the integrity of your products with our innovative VCI solutions. Contact us today to learn more and get started on safeguarding your metals with the best in VCI technology!

0 notes

Text

Antirodent Master batch and Films

Masterbatches Kinetic Polymers is one of the leading manufacturer of Conductive Master Batch Compound based on Polypropylene which are used for making conductive PP Corrugated sheets used for packaging boxes and partition for electro static safe products.

We are regularly supplying this product to various companies across India.

We can offer you the following at the competitive prices.

Anti Static Masterbatch for PP / HDPE / LDPE & HIPS – ABS Conductive Master Batch Compound based on PP / LDPE / LLDPE / PVC / & EVA VCI Masterbatch – Nitrite based and Nitrite free for LDPE/ LLDPE / & HDPE Fim Antirodent Master batch for PVC / LDPE / & PP Anti Microbial Masterbatch for PP / & HIPS Slip Masterbatch for LLDPE & EVA Anti Block Masterbatch for LLDPE & EVA Foaming Agent Masterbatch for PVC / & LDPE Nucleating Agent Masterbatch for HDPE & PP

0 notes

Link

0 notes

Text

Rain-Proof Your Packaging: Strategies for Protecting Your Goods During Rainy Season

Introduction:

Rainy seasons can pose significant challenges for businesses involved in packaging and transportation. Ensuring the protection of goods from moisture damage becomes crucial to maintain their quality and preserve customer satisfaction. In some areas like Pune & Mumbai, where heavy rainfall is common, it is essential to implement effective strategies and partner with a reliable packaging company that specializes in rain-proof packaging solutions in Pune.

The Impact of Rainy Seasons on Packaging

The increased humidity and moisture levels during rainy seasons can lead to product damage, products get rusty, Corrugate boxes loose its strength, and compromised packaging aesthetic. Understanding the specific challenges and risks associated with rainy seasons is crucial for implementing effective protection strategies.

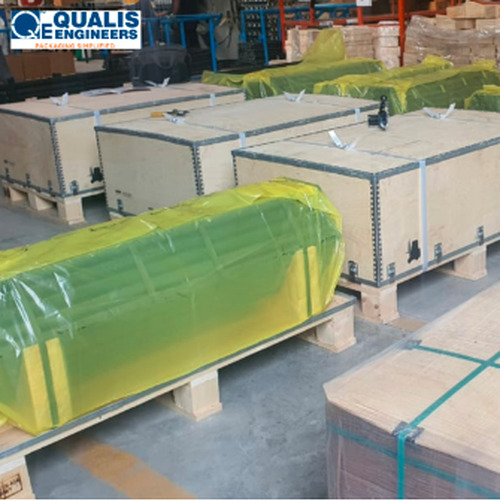

Innovative Packaging Systems for Rainy Seasons

Qualis Engineers offer innovative packaging systems in Pune specifically tailored for rainy seasons. These systems include waterproof materials, moisture-resistant coatings, and advanced sealing techniques to protect goods from water ingress and damage.

Strategies for Ensuring Your Products Stay Dry and Undamaged

It is safe to say that there are no cost-effective, fully waterproof packaging options. However, there are strategies for making standard packaging more water-resistant and providing greater protection for your products. If the time of year, shipping destination, or both give you reason to believe your package may be delivered on a rainy day, try one or more of the following:

1. Ship in Corrugated Cartons

2. Use Aluminium Foil Bags / VCI bags

Usage of the VCi bags will prevent the castings or raw material in M S form .

3. Use of stretch film

Shipping cartons are not fully waterproof. We need to cover the carton box by stretch film to prevent it from the outer moisture and water drops in transit.

Also stretch film application will give strength to the whole packages during transit.

Products which can be used to protect your good during RainStretch Wrap Machine

A stretch wrap machine is a valuable asset for rain-proof packaging. It wraps goods tightly with stretch film, providing a secure and waterproof covering. This machine ensures consistent and efficient wrapping, saving time and effort compared to manual methods.

Shrink Wrap Machine

Stretch Wrap Hand Tools

Stretch wrap hand tools, such as dispensers and tensioners, are convenient and effective for manually wrapping goods with stretch film. These tools ensure proper tension and coverage, enhancing the rain-proofing of the packaging.

Conclusion

Protecting goods during rainy seasons is paramount to preserving their quality and ensuring customer satisfaction. By partnering with a dependable packaging company and implementing rain-proofing strategies, you can safeguard your goods against moisture damage. Choose innovative packaging systems, utilize moisture-resistant materials, reinforce sealing and cushioning techniques, and consider climate-controlled storage and transportation options. Rain-proof your packaging and deliver your goods with confidence, regardless of the weather conditions.

0 notes

Text

The Future of Volatile Corrosion Inhibitors (VCI) Packaging: Trends and Forecast (2022-2029)

The volatile corrosion inhibitors (VCI) packaging market is projected to experience significant growth over the forecast period. According to the mentioned statistics, the market is expected to grow at a compound annual growth rate (CAGR) of 6.1% from 2022 to 2029, reaching a value of USD 1,175 million.

The increasing demand for effective and suitable metal packaging solutions is driving the growth of the VCI packaging market. Factors such as rising metal prices and the need for proper protection of metal products from developing countries contribute to this demand. Manufacturers are focusing on product development and expanding their portfolios to meet the specific requirements of consumers.

VCI packaging manufacturers are introducing new and cost-effective products targeted at specific applications, attracting the attention of consumers. Companies like the Mondi Group are also investing in the development of VCI packaging solutions to capitalize on the growing demand. Additionally, the rising demand for eco-friendly and sustainable VCI packaging creates opportunities for paper packaging industry leaders to enter the market.

For More Insights on this Market, Get A Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-9166

VCI bags, particularly large volume bags, are witnessing increased adoption by metal component and part manufacturers. This trend drives the demand for VCI packs, contributing to the market’s growth. Manufacturers are expanding their range of VCI packaging products by introducing new types and combinations to better meet the needs of end consumers. Among the VCI packaging products, VCI paper is expected to grow at the highest CAGR, while VCI film is expected to experience modest growth.

The development and adoption of VCI packaging products are influenced by the availability of packaging materials in the market and the increasing demand for packaging various metal products. As market understanding evolves, VCI paper and other bio-based VCI products are expected to gradually replace VCI film, which was previously used occasionally for packaging.

Overall, the VCI packaging market is anticipated to witness substantial growth, driven by the need for effective metal packaging solutions and the introduction of innovative products. The market’s trajectory will be shaped by factors such as metal prices, consumer demand, and advancements in packaging materials.

Investment of Emerging Economies in Manufacturing Sectors

The VCI packaging market is highly based on industries where metal parts and components are mostly used. Globally, the VCI packaging market is likely to grow due to demand from the primary metal & metal works industries. Owing to the adoption of VCI liquids and powders, the automotive industry is expected to witness a sluggish growth in the future.

Are you looking for customized information related to the latest trends, drivers, and challenges? @ https://www.futuremarketinsights.com/customization-available/rep-gb-9166

The aerospace & components industries are projected to increase the consumption of VCI packaging during the forecast period. The emerging countries are boosting the demand for VCI packaging by investing in the aerospace, metal, and electrical & electronics industries. Other processing industry are also shifting towards VCI liquid and powder to protect metal products & components due to new easy techniques for removal & applicators.

Competitive Landscape

Companies operating in the volatile corrosion inhibitors packaging market are aiming at expansions and strategic partnerships with other manufacturers to expand their product manufacturing capabilities, product portfolio and global presence.

In May 2021, Northern Technologies International Corp. business unit launched Natur-VCI a biodegradable and compostable vapor corrosion inhibitor film which is manufactured to shield both types of metals which showcase ferrous and non-ferrous properties during shipment and short-term storage.

On June 2019, Cortec Corp. launched EcoCorr® Film, which is a biodegradable, compostable VCI packaging film that provides contact, barrier, and vapor corrosion inhibition.

In April 2019, Daubert Cromwell Inc. introduced environmental-friendly Clear Pak brand VCI films with Clear Pak 5000 to protect steel, aluminum, and copper.

Get 20% Discount @ https://www.futuremarketinsights.com/request-discount/rep-gb-9166

Key Players:

Cortec Corporation

Armor Protective Packaging

Branopac India Pvt. Ltd.

Daubert Cromwell, LLC

Haver Plastics Co Ltd.

Muller LCS Inc.

NTIC (Zerust Excor)

Mondi Group

Volatile Corrosion Inhibitors Packaging Market by Categor

By Product:

VCI Paper

VCI Film

Stretch

Shrink

Sheet

VCI Bags

Flat

Gusseted

Zipper

Foam

Others

By Material:

Paper

Polyethylene

Others

By End-user Industry:

Aerospace & Defense

Primary Metal

Electricals & Electronics

Automotive

Heavy Equipment

Metal Works

Others

0 notes

Text

Volatile Corrosion Inhibitors (VCI) Industry Current Trends and Challenges Analysis by 2023-2030

The volatile corrosion inhibitors (VCI) market is a rapidly growing industry that specializes in the production and supply of chemicals that are used to prevent corrosion in various metallic surfaces. These inhibitors work by forming a protective layer on the surface of the metal that prevents oxidation and rust formation. They are primarily used in the packaging and storage of metals, such as steel, aluminum, and copper.

For Sample Report Click Here:-https://www.marketinforeports.com/Market-Reports/Request-Sample/498147

The VCI market is driven by the increasing demand for corrosion inhibitors in various industries, such as automotive, aerospace, electronics, and oil and gas. The growth of these industries has led to an increased use of metals, and the need to protect them from corrosion has become paramount.

The market is segmented by product type, application, and region. The product types include paper, plastic, and metal-based VCIs. The applications include packaging, metalworking fluids, and corrosion inhibitors. The market is also segmented by region, with North America, Europe, Asia Pacific, and Rest of the World being the key regions.

Some of the major players in the VCI market include Cortec Corporation, Daubert Cromwell, Zerust, and Armor Protective Packaging. These companies are continuously engaged in research and development activities to improve the performance and effectiveness of their products.

Overall, the VCI market is expected to continue to grow in the coming years, driven by the increasing demand for corrosion inhibitors in various industries and the ongoing development of new and innovative VCI products.

0 notes

Text

The Best VCI Packaging Company In Gurgaon- Benz Packaging

BENZ Packaging is one of the best VCI Packaging Company in Gurgaon have unique focus on products that are specially designed to preserve and protect steel & metals against rust, corrosion or even tarnish during transportation and storage. BENZ Packaging Solutions VCI Products represent the finest solution for Export and Sea Worthy Packaging.

0 notes

Text

#vci_paper#vci packaging company#advertising#vci paper suppliers#anti rust paper#marketing#vci paper manufacturers india

0 notes

Text

vci films for corrosion resistance manufacturer and supplier in India

VCI Packaging, or Vapor Corrosion Inhibitor packaging film, is a poly packaging film manufactured with added VCI chemistry. VCI molecules protect metals from corrosion by forming a thin, invisible layer on the surface.VCI Packaging, or Vapor Corrosion Inhibitor packaging film, emits molecules that settle on metal surfaces and form an invisible layer that protects from corrosion. It protects by interrupting the electrochemical corrosion process caused by moisture, oxygen, and contaminants in the atmosphere.BENZ Packaging Solutions is the original VCI film company that invented VCI-infused plastic technology. To prevent rust using VCI film, wrap metal/metal parts in VCI film or place them in a VCI poly bag and seal — there’s no messy grease or oil to apply. Once metal/metal parts are enclosed, the VCI activates to form a layer of protection on the surface of the metal parts that displaces moisture and repels rust. Viola — it’s easy, peasy!

Find here VCI Films, VCI Shrink Film manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying. VCI film is a packaging that consists of polyethylene film that’s been impregnated with Vapor Corrosion Inhibitors molecules. Anti-corrosive VCI film use for Packaging of metals, engineering items, electronic products and automotive parts. Available in 100µ+ thickness. We are on the leading VCI Film manufacturer & supplier in Faridabad, Gurgaon, Haryana, Delhi and Agra. Keep your electronics safe from moisture with VCI film packaging.

0 notes

Text

Ford Ids Software Free

obdexpress 04/10/2020 05:01AM

Ford Ids Updates

Ford Ids Software Subscription

Software Download Links; Step 1: Download Diagnostic Software Then Install Diagnostic Software: IDS 119 Full FDRS 25.6.3 FDRS 25.6.3 is not for ETIS users. Step 2: Download VCI Software Then Install VCI Software: VCI Software 1.0.0.10: VCI Firmware What's New - contains Details on this new software. Step 3: Download Diagnostic Software Updates. Jan 29, 2018 Ford IDS v108.01 function: Confirmed! 1.Able to download the very latest calibration files/software from Ford server if the network connection available at the time of connecting to vehicles 2.Read and decode fault codes. If you can see the windows process “XMLRegistryD.exe” in the windows task manager, then kill the windows process “XMLRegistryD.exe” before you run the “Ford-License for IDS.exe” License. While you install the License “Ford-License for IDS.exe”, if you see the picture 1, then you should do the step 1, step 2, step 3. Ford IDS V118 V117 V113 software, free download What is Ford IDS? Ford Integrated Diagnostic System also short called Ford IDS,uses Ford proprietary software to run on a Windows based PC (Laptop, Mini Laptop, Desktop, Netbooks, etc.) with the Vehicle Communication Module (VCM) or other Ford diagnostic device,such as vxdiag vcx, and the Vehicle Measurement Module (VMM). Please select Country.

IDS V117 is tested working fine with Ford VCM2 clone, this post is available with the newest IDS software new features, free download links and how to install.

IDS V117 Free download + Installation Guide

Step 1: Download Diagnostic Software, then Install Diagnostic Software:

IDS 117 Full

FDRS 23.5.7

Step 2: Download VCI Software, then Install VCI Software:

VCI Software 1.0.0.7

Step 3: Download Diagnostic Software Updates (if available) Then Run Diagnostic Software Updates:

Update IDS 117.04

See IDS Update Release Dates below:

Step 4: Download VMS Then Install VMS (Optional - VCMM Users Only)

VMS v1.1.1034.0

Click here for VMS Manual

After Installing: Diagnostic Software Updates will pop up on Mondays and Thursdays when available.

VCI firmware what's new - contain details on this new software.

IMPORTANT: Changes to VCM II and VCMM

VCM II & VCMM Device Software (“VCI Software”)

VCI Software

Previously, installing IDS or FDRS would install everything that is needed in order to use a VCM II/VCMM with any of the Ford diagnostic software (IDS, FDRS & VMS). There is now a new package separate from

IDS and FDRS, called VCI Software.

This VCI Software package WILL NEED to be downloaded in order to use your VCM II or VCMM, regardless of whether this is the first time you have downloaded IDS/FDRS.

This will improve download and installation time, as previously you were downloading and installing these components with BOTH IDS and FDRS.

You WILL NOT need to download and install this package every release, only when there is an update to the loaded code on the device.

VCI Launcher

When launching the VCI Manager, you will be prompted to select which device (VCM II or VCMM) you intend to use.

Only the devices of the selected type will appear in the VCI Manager. If you wish to switch device type, you will have to close the VCI Manager and select the other device.

Note: If the device is already connected via USB, you will bypass the selection screen.

Figure 1: The VCI Launcher desktop icon

Figure 2: The main screen of the VCI Launcher

Figure 3: A side-by-side comparison showing the VCM II Manger and the VCMM Manager

Changes to IDS

IDS now requires you to select your device type at the launch of IDS.

If you wish to switch devices while in IDS, you need to navigate to what was previously the Wireless device manager (the green arrows in the upper right hand corner), select the button at the bottom left which says “VCI Type” and select which device you wish to use. You can do this at any time while in the IDS tool.

Note: It is recommended if you previously pinned IDS to the task bar, that you unpin it in R115, and then re-pin it while on the device selection screen.

Figure 4: The device selection screen when launching IDS.

Figure 5: The new device manager screen. Note the icon in the top right, the VCI Type button in the bottom left, and the VCI Launcher selection window.

VCI Software Uninstaller

There is now a new component included in the VCI Software package called VCI Software Uninstaller.

This gives you the ability to uninstall all Ford Diagnostic components (IDS, FDRS, VMS, CFR, and VCI Software) from one central location, rather than having to uninstall each component individually.

This uninstaller can be accessed by going to StartFord Motor CompanyVCI Software Uninstaller. After following the prompts, you can select which software applications you wish to uninstall.

Note: If you are removing all components, it is recommended you select “Remove Uninstaller Data” to remove successfully all Ford components from the PC.

Ford Ids Updates

Figure 6: The location of the VCI Software Uninstaller

Figure 7: The main screen of the VCI Software Uninstaller

Best Ford VCMII with IDS V117 source:

Ford Ids Software Subscription

OBDexpress.co.uk Office Blog all rights reserved Free Download & Install IDS V117 Ford VCM2

1 note

·

View note

Link

PKG Company has been a stretch film supplier and stretch wrap machine supplier since 1992. Our knowledgeable and trained staff is experienced in helping to identify the most cost effective stretch wrap packaging for the application. Our stretch film solutions include hand pallet wrap, bundling stretch films, pre-stretched stretch films, machine grade stretch films, as well as specialty stretch films such as meat film, laundry stretch films and PVC printing films, UVI stretch films and VCI stretch films.

1 note

·

View note

Link

"The worldwide Anti-rust Packaging market research has many advantages for businesses, including pro

0 notes