#two stage vacuum pump

Explore tagged Tumblr posts

Text

Pompetravaini Single Stage and Two Stage Liquid Ring Vacuum Pumps

Our Pompetravaini Single and Two Stage Liquid Ring Vacuum Pumps deliver high-efficiency vacuum solutions for industrial needs. These equipment are designed especially for reliability and long-lasting performance. Check out our different types of liquid ring vacuum pumps and their specifications.

#industrial vacuum pumps#vacuum pumps#industrial equipment supplier#vacuum pumps australia#liquid ring vacuum pumps#Pompetravaini Vacuum Pumps#Pompetravaini Single and Two Stage Liquid Ring Vacuum Pumps#vacuum pumps Suppliers

1 note

·

View note

Text

Trusted Vacuum Pump Solutions for Demanding Industrial Environments

In the world of industrial applications, the importance of reliable vacuum pump solutions cannot be overstated. Meekaj Vacuum Systems Pvt Ltd stands out as a leader, committed to delivering superior quality and innovative vacuum pump technologies to businesses across various sectors. With a focus on durability and efficiency, Meekaj ensures that their products not only meet but exceed industry standards, making them an ideal choice for businesses seeking dependable vacuum solutions.

Meekaj's expertise in manufacturing a wide array of vacuum pumps is evident in the precision engineering of their products. The company's dedication to innovation has led to the development of advanced systems that cater to the unique needs of their clients. Among their offerings is the two-stage liquid ring vacuum pump, known for its robust performance and ability to handle demanding applications with ease. This pump is particularly suited for environments where consistent vacuum levels and reliability are crucial.

Most Reliable vacuum pump suppliers in Gujarat

As one of the leading vacuum pump suppliers in Gujarat, Meekaj Vacuum Systems has built a reputation for excellence and customer satisfaction. Their commitment to quality is reflected in their comprehensive product range, which includes the single-stage water ring vacuum pump. This model is designed to provide efficient and reliable operation, making it a preferred choice for industries requiring stable and effective vacuum solutions.

Moreover, Meekaj Vacuum Systems is recognized among the top water ring vacuum pump manufacturers, offering products that are engineered to ensure optimal performance and long-term reliability. Their pumps are tailored to meet the diverse needs of industries, ensuring minimal downtime and enhanced operational efficiency.

Choosing Meekaj means partnering with a company that values innovation, reliability, and customer satisfaction. Their expert team is dedicated to providing solutions that match the specific requirements of their clients, ensuring that each product supports optimal industrial operations. Explore Meekaj Vacuum Systems' offerings today and experience the transformative impact of their cutting-edge vacuum pump solutions on your business.

#water ring vacuum pump manufacturers#vacuum pump suppliers in Gujarat#single-stage water ring vacuum pump#two-stage liquid ring vacuum pump

0 notes

Text

How does a rotary vane vacuum pump work?

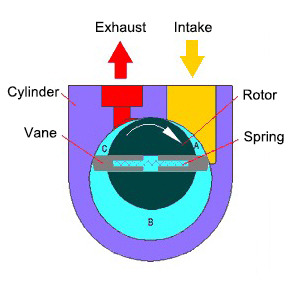

Oil sealed rotary vane vacuum pump working principle

A rotary vane vacuum pump (referred to as a rotary vane pump) is an oil-sealed mechanical vacuum pump. Its working pressure range is 101325~1.33×10-2 (Pa), which belongs to the low vacuum pump. It can be used alone or as a backing pump for other high vacuum pumps or ultra-high vacuum pumps. It has been widely used in production and scientific research departments such as metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum, and medicine.

The rotary vane pump can pump out the dry gas in the sealed container, and if it is equipped with a gas ballast device, it can also pump out a certain amount of condensable gas. But it is not suitable for pumping gas with high oxygen content, corrosive to metal, and chemical reactions to pump oil and dust particles.

The rotary vane pump is one of the most basic vacuum-obtaining equipment in vacuum technology. Rotary vane pumps are mostly small and medium-sized pumps. There are two types of rotary vane pumps: single-stage and two-stage. The so-called two-stage is to connect two single-stage pumps in a series structure. Generally, it is made into two stages to obtain a higher vacuum degree. The relationship between the pumping speed and the inlet pressure of the rotary vane pump is stipulated as follows: when the inlet pressure is 1333Pa, 1.33Pa, and 1.33×10-1 (Pa), the pumping speed value shall not be lower than 95%, 50% and 20%of the nominal pumping speed of the pump.

The rotary vane pump is mainly composed of the pump body, rotor, rotary vane, end cover, spring, and so on. A rotor is eccentrically installed in the cavity of the rotary vane pump, the outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small gap between the two), and two rotary vanes with springs are installed in the rotor slot. When rotating, relying on the centrifugal force and the tension of the spring to keep the top of the rotary vane in contact with the inner wall of the pump chamber, the rotation of the rotor drives the rotary vane to slide along the inner wall of the pump chamber.

The two rotating vanes divide the crescent-shaped space surrounded by the rotor, the pump chamber, and the two end covers into three parts A, B, and C, as shown in the figure. When the rotor rotates in the direction of the arrow, the volume of space A communicating with the suction port increases gradually, and it is in the process of suction. And the volume of space C communicating with the exhaust port is gradually reduced, just in the process of exhausting. The volume of space B in the middle is also gradually decreasing, which is in the process of compression. Since the volume of space A gradually increases (that is, expands), the gas pressure decreases, and the external gas pressure at the inlet of the pump is higher than the pressure in space A, so the gas is inhaled.

When space A is isolated from the suction port, it turns to the position of space B, the gas starts to be compressed, the volume gradually decreases, and finally communicates with the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas passes through the oil layer in the tank and is discharged into the atmosphere. The purpose of continuous pumping is achieved by the continuous operation of the pump.

One stage rotary vane vacuum pump working principle

The single-stage rotary vane pump has only one working chamber, and the pump is mainly composed of a stator, a rotary vane, and a rotor. The rotor is installed eccentrically in the pump chamber, and two rotating vanes are installed in the rotor groove, which is close to the cylinder wall due to the elastic force of the spring (there is also a centrifugal force of the rotating vanes after rotation). The rotor and vanes divide the stator cavity into suction and discharge.

When the rotor rotates in the stator cavity, the volume on the side of the air inlet is gradually expanded periodically to inhale the gas, while the volume on the side of the exhaust port is gradually reduced to compress the inhaled gas and discharge it from the exhaust valve.

The vent valve is immersed in oil to prevent atmospheric air from entering the pump. The vacuum pump oil enters the pump chamber through the oil hole and the exhaust valve so that all the moving surfaces in the pump chamber are covered with oil, forming a seal between the suction chamber and the exhaust chamber.

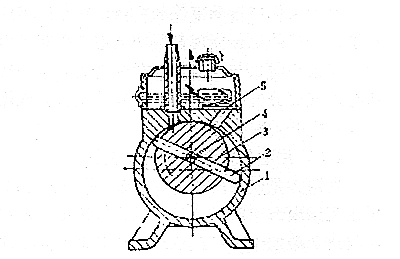

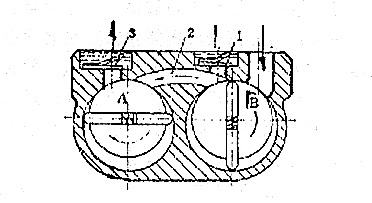

Two stage rotary vane vacuum pump working principle

In order to improve the ultimate vacuum of the pump, in addition to improving the machining accuracy of the pump body, rotor, and rotary vane, and minimizing the assembly gap and harmful space, the most effective way is to connect two single-stage pumps in series to form a two-stage pump.

The pump consists of two working chambers. The two chambers are connected in series and rotate in the same direction at the same speed. A chamber is the front stage of B chamber. A is the low vacuum stage and B is the high vacuum stage. The pumped gas enters the front stage through the high vacuum stage (B ), and is discharged out of the pump through the exhaust valve. The front stage (A) is the same as the single-stage pump, oil enters the pump chamber at any time, while the high vacuum stage (B) only has a small amount of oil when it starts to work, and no oil enters the pump chamber after working for a period of time. When the pump starts to work and the pressure of the inhaled gas is relatively high (such as starting to pump air from atmospheric pressure), the gas is compressed through the B chamber, and the pressure increases sharply, and a part of the compressed gas is directly discharged from the auxiliary exhaust valve (1) , and the other part is discharged through the front stage.

When the pump works for a period of time, when the pressure of the gas inhaled by the B chamber is low, even though it is compressed by the B chamber, the pressure cannot reach above one atmospheric pressure, and the auxiliary exhaust valve 1 cannot be discharged, and all the inhaled gas will enter The front-stage A room is discharged through the exhaust valve 3 through the continuous compression of the A room.

After the pump works for a period of time since the pressure of the high-vacuum stage air intake is greatly reduced, the outlet pressure is also very small, so the pressure difference between the inlet and outlet of the B chamber is also small, and the amount of compressed gas returned is correspondingly reduced; at the same time, the latter stage The oil molecules that are easy to evaporate in the pump are continuously sucked away by the front-stage A chamber, and the partial pressure of the oil vapor is reduced. Therefore, the oil pollution of the two-stage pump is smaller than that of the single-stage pump, and the ultimate vacuum degree will be greatly improved.

1 Stage vs. 2 Stage Rotary Vane Vacuum Pump

1 stage rotary vane pump consists of a single rotor with multiple vanes that rotates within a cylindrical chamber. As the rotor spins, centrifugal force pushes the vanes against the chamber wall, creating a seal and forming variable-volume chambers. The pumping action occurs through the expansion and compression of gas in these chambers, resulting in the generation of a vacuum.

Simplicity: 1-stage pumps have a straightforward design with fewer moving parts, making them compact, lightweight, and easy to operate and maintain.

Cost-Effective: These pumps are typically more affordable compared to 2-stage pumps, making them a cost-effective option for applications that do not require extremely low vacuum levels.

Suitable for Low to Medium Vacuum: 1-stage pumps are ideal for applications that require vacuum levels within the range of approximately 100 to 1,000 mbar (millibar).

Efficient for Low Gas Loads: They perform well when handling low gas loads, making them suitable for applications where gas flow rates are not excessive.

In a 2 stage rotary vane pump, the pumping process is divided into two sequential stages, each with its own set of vanes. The first stage, known as the high-vacuum stage, operates similarly to a 1 stage pump, creating an initial level of vacuum. The gas discharged from the first stage then flows into the second stage, where further compression occurs, resulting in even lower vacuum levels.

Higher Vacuum Levels: 2 stage pumps are capable of achieving significantly higher vacuum levels compared to 1 stage pumps. They can reach vacuum levels as low as 0.1 mbar or even lower.

Improved Gas Handling: These pumps are effective in handling higher gas loads and can efficiently evacuate larger volumes of gas.

Enhanced Backstreaming Resistance: The two-stage configuration provides better resistance to backstreaming, preventing oil or contaminants from reaching the vacuum chamber or system.

Suitable for High Vacuum Applications: 2 stage pumps are well-suited for applications requiring high vacuum levels, such as analytical instruments, vacuum coating, and semiconductor manufacturing.

#rotary vane vacuum pump#two stage rotary vane vacuum pump#rotary vane vacuum pump working principle

0 notes

Text

i love the BNHA fandom with my whole heart (heartussy) and will (and HAVE) happily get into fights about how it’s just a passionate fanbase and that any popular media is gonna attract the same but the ONE, the ONE thing i will agree with the haters on (or rather, give the haters as free ammo bc this never occurs to them) is that western fans have the WORST entitlement and manners when it comes to fucking LEAKS. twitter and tiktok have been UNBEARABLE today because everyone is either reposting the leak pages (which are still very much illegal, japan does not fucking play with that!!!!), colouring them and reposting them or already pumping out fanfart, and tagging it all under spoilers. spoilers are NOT the same as fucking leaks. they are TWO SEPERATE THINGS. we call them leaks because the leakers have to pay money in order to access the pages before the magazine is available for public sale. people go to jail for this. it is illegal. and beyond that—it’s fucking rude!!!!!! volume 40 didn’t go on sale until today, but for the past week twitter has just been shared pages from it—i’ve seen fans who live in japan try to gently remind their part of the timeline to please not share the pages, because we don’t exist in a vacuum—we share our fandom spaces with other fans in other countries!!!! and like, okay, you could make the argument that this is just fandom culture with BNHA now. but that doesn’t mean it doesn’t suck balls!!!! and i say it’s entitled because it’s always the same like, mega-fan accounts that start it, you know? the ones that are big Bakugou stans or otherwise shippers or the powerscaling dudebros and i get it on one hand, i do, it’s that like… excitement, right? there’s your favourite character and oh look! he’s going through it!!! or oh look!!! something is happening that could be taken in a shippy way and yayyy it’s so inspiring and fun/horrible and angst, let’s celebrate/mourn! but it’s just—it’s boring!!!! it’s boring, i find it boring. by the time the chapter’s released properly, no one ever wants to talk about it, because they’ve already had that conversation over third-party translated, paraphrased summaries. like?????? idk. it’s not part of the fandom that’s ever going to go away unfortunately, and i am complicit in it because i also read leaks but like—at this stage it’s a self-preservation tactic, because the alternative is to literally just not be online, or block half of the fandom!!!! and i don’t want to do that!!!!!! i want to be apart of things!!!!! i just want this fandom to be better at them!!!!!!!! ugh. everyone sucks LOL. love u tho i prommy… even when u annoy me LOL. 🫶🏽

#im so mad bc i actually wanna talk about these leaks and also how hori seems to be like—walking back almost on like#the abuse he’s shown in the past? although i guess that’s not a leaky convo 🧐 but still

27 notes

·

View notes

Text

From the Liquid Ring Vacuum Pump to the Two-Stage counterpart, the Water Ring Vacuum Pump to the reliable Oil Sealed Vacuum Pump – each type brings a unique edge to meet your industrial needs. Unleash efficiency with precision-engineered

technology.

For more details, visit- https://www.acmeairequipments.com/vacuum-pump-different-types-applications/

0 notes

Text

Ecoab Double Stage Vacuum Pump VP245

The Ecoab Double Stage Vacuum Pump VP245 is a highly efficient and reliable device, specifically designed for applications that require deep, precise vacuum levels. Widely used across various industries such as HVAC (Heating, Ventilation, and Air Conditioning), refrigeration, and laboratory settings, this pump stands out for its robust construction and superior performance. Its double-stage design allows it to achieve a significantly deeper vacuum compared to single-stage pumps, making it ideal for demanding tasks where precision and efficiency are critical.

Key Features of the Ecoab Double Stage Vacuum Pump VP245

Minimum Order Quantity: 1 piece

Type: Oil Lubricant Vacuum Pump

Model Name/Number: VP245

Brand: Ecoab

Number of Stages: Double Stage

Max Flow Rate: 5 CFM (50 LPM)

Power: 1/2 HP

Usage/Application: HVAC& R (Heating, Ventilation, Air Conditioning, and Refrigeration)

Phase: Single Phase

Material: Cast Iron

Mounting: Portable

Capacity: 5 CFM (50 Hz)

Weight: 8.5 kg

Cooling System: Air-cooled

Size/Dimension: 320 x 134 x 232 mm

Oil Tank Capacity: 400 ml

Packaging Type: Corrugated Box

These features position the Ecoab VP245 as an indispensable tool for professionals in the HVAC&R sectors. Its portability, combined with its robust cast iron construction, makes it easy to transport while ensuring durability in industrial environments.

Working Principle of the Double Stage Vacuum Pump VP245

The Ecoab double-stage vacuum pump operates on a two-stage compression process, which is the key to its ability to reach much deeper vacuum levels compared to single-stage pumps. Understanding this double stage vacuum pump working principle is vital to appreciate the effectiveness and superiority of this device.

First Stage: The first stage operates similarly to a single-stage pump. It draws in air from the system, compressing it to a lower pressure. This initial stage prepares the air for further compression by reducing the air's pressure significantly, although not yet achieving a deep vacuum.

Second Stage: In the second stage, the already compressed air is further reduced to a much lower pressure. This additional compression allows the pump to achieve the deeper vacuum levels necessary for high-precision applications.

This two-stage process not only improves the vacuum depth but also enhances the pump's overall efficiency. By removing moisture and non-condensable gases more effectively, the Ecoab double stage vacuum pump ensures optimal system performance. This is particularly important in air conditioning systems, where the complete removal of moisture is crucial to maintaining efficiency and preventing long-term damage to components.

Applications in AC Systems: Double Stage Vacuum Pump for AC

One of the primary uses of the Ecoab VP245 double-stage vacuum pump is in the HVAC industry, particularly in AC systems. Here, removing moisture and air from cooling systems is critical for system efficiency. The VP245 ensures that no non-condensable gases or moisture remain in the system, which can impair the functionality of AC systems and refrigeration units.

Moisture-Free Systems: Moisture in HVAC systems can cause damage over time, leading to inefficiency, corrosion, and even failure. By reaching a deep vacuum, the VP245 helps eliminate this risk, ensuring the system's longevity and operational efficiency.

Efficiency: The pump’s ability to create a deeper vacuum ensures that HVAC systems run more efficiently, as air and moisture that impede the system's cooling capacity are effectively removed.

Durability: Designed for industrial applications, the VP245 is built to handle the rigorous demands of large HVAC and refrigeration systems. Its double-stage compression process is an important factor in maintaining the durability and reliability of these systems.

Price Range of Ecoab 2 Stage Vacuum Pumps in India

When it comes to pricing, the Ecoab 2 stage vacuum pump price in India varies based on the model, capacity, and specific application needs. The VP245 typically falls within a mid-range price bracket, offering excellent value for money considering its capabilities.

Price Range: INR 5,000 to INR 50,000

Factors Affecting Price:

Model specifications

Capacity and flow rate

Application-specific features (such as for industrial or laboratory use)

Higher-end models with advanced features and greater capacity are generally priced at the upper end of this range, while smaller units intended for less intensive tasks will be available at more affordable prices.

Advantages of the Ecoab VP245 Double Stage Vacuum Pump

The Ecoab VP245 offers a range of advantages, especially in industries where precision and efficiency are paramount:

Deeper Vacuum Levels: The double-stage pump design allows for a more profound vacuum, which is crucial for high-precision applications, particularly in the HVAC&R sectors.

Efficient Removal of Moisture and Non-Condensable Gases: This ensures optimal system performance and longevity by eliminating factors that could lead to corrosion or inefficiency.

Portability: Despite its robust build, the VP245 is designed for portability, making it easy for technicians to carry and operate in various locations. This feature is particularly beneficial for fieldwork, where equipment must be both reliable and transportable.

Durability: The cast iron construction provides enhanced durability, allowing the pump to withstand heavy-duty usage in demanding environments.

Ease of Use: With user-friendly controls and a compact design, the VP245 is easy to operate, even for those who may not have extensive experience with vacuum pumps.

Why Choose the Ecoab Double Stage Vacuum Pump VP245?

The Ecoab VP245 Double Stage Vacuum Pump stands out as a top choice for professionals working in HVAC&R, refrigeration, and other industries requiring deep, reliable vacuum levels. Its features and benefits align with the high standards of these industries, ensuring optimal performance in demanding environments. Here’s why choosing the VP245 is a smart decision:

Superior Performance: The double stage vacuum pump working mechanism ensures deeper vacuum levels, making it more effective for industrial applications that demand precision.

Reliable Construction: With a cast iron body, the VP245 is built to last, ensuring longevity even in rugged conditions.

Affordable Pricing: The Ecoab VP245 offers excellent value for its price, striking a balance between cost and performance. Its broad price range ensures that there are models available for both light and heavy-duty applications.

Portability and Convenience: The portable design ensures ease of use for technicians on the go, while its air-cooling system enhances efficiency during operation.

More information click on the link :- click here

contact no:-91-9717732520

0 notes

Text

Repiet Air Solution is manufacturing the Screw Air Compressor its India based company engaged in offering a comprehensive range of Air Compressors which have unmatched quality. Repiet Air is rated as one of the most reliable and reputed brands in High Pressure Air Compressors, Two Stage Air Compressors, Single Stage Air Compressors and Vacuum Pumps

1 note

·

View note

Text

Enhancing Transformer Maintenance with High Vacuum Pumping Systems

Transformer maintenance is a critical aspect of ensuring the reliability and efficiency of electrical power systems. Among the essential tools used in this maintenance are high vacuum pumping systems and two-stage transformer vacuum pumps. These devices play a pivotal role in maintaining the integrity of transformers by ensuring they are free from moisture and other contaminants that can degrade their performance. This article delves into the features, benefits, and applications of the ZJ Series High Vacuum Pumping System and the Two-Stage Transformer Vacuum Pump with Roots Pump, highlighting their importance in transformer maintenance.

The Importance of Vacuum Systems in Transformer Maintenance

Transformers are vital components in power distribution networks, and their performance is heavily dependent on the quality of their insulation. Moisture, air, and other gases can significantly impair the dielectric strength of transformer oil and solid insulation materials. The presence of these contaminants can lead to partial discharges, reduced efficiency, and even catastrophic failures. Vacuum systems are employed to evacuate these contaminants, ensuring that transformers operate under optimal conditions.

ZJ Series High Vacuum Pumping System

The ZJ Series High Vacuum Pumping System is designed to provide efficient and reliable vacuum pumping for transformer maintenance. This system is crucial for creating a high vacuum environment, which is essential for the degassing, dehydration, and drying of transformers.

Features of the ZJ Series High Vacuum Pumping System

High Vacuum Capability: The ZJ Series is capable of achieving a high vacuum level, essential for removing moisture and gases from transformers.

Robust Construction: The system is built with durable materials, ensuring longevity and reliable performance even in demanding conditions.

Efficient Operation: With advanced vacuum technology, the ZJ Series offers efficient operation, reducing the time required for vacuum processes.

User-Friendly Interface: The system includes an intuitive control panel, making it easy to operate and monitor.

Portable Design: Designed for portability, the ZJ Series can be easily transported and used in various locations, providing flexibility in maintenance activities.

Benefits of the ZJ Series High Vacuum Pumping System

Effective Moisture Removal: By creating a high vacuum environment, the ZJ Series effectively removes moisture from transformers, enhancing their insulating properties.

Improved Transformer Performance: Ensuring that transformers are free from contaminants helps maintain their efficiency and reliability.

Extended Transformer Lifespan: Regular use of the ZJ Series in maintenance routines helps preserve the integrity of transformer insulation, prolonging their operational life.

Cost Savings: By reducing the frequency of maintenance and preventing transformer failures, the ZJ Series contributes to significant cost savings.

Two-Stage Transformer Vacuum Pump with Roots Pump

The Two-Stage Transformer Vacuum Pump with Roots Pump is a sophisticated system designed to provide high-efficiency vacuum pumping for transformer maintenance. This system combines the advantages of a two-stage vacuum pump with the superior performance of a Roots pump, making it highly effective for transformer evacuation processes.

Features of the Two-Stage Transformer Vacuum Pump with Roots Pump

Two-Stage Design: The two-stage design allows for deeper vacuum levels, enhancing the efficiency of moisture and gas removal.

Roots Pump Integration: The inclusion of a Roots pump significantly increases the pumping speed and vacuum capability, ensuring rapid and effective evacuation.

Durable Construction: Built with high-quality materials, the system is designed to withstand rigorous operating conditions, ensuring long-term reliability.

Advanced Control Systems: The system features advanced controls for precise operation and monitoring, providing users with detailed information on the vacuum process.

Energy Efficiency: The two-stage vacuum pump with Roots pump is designed for energy-efficient operation, reducing power consumption while delivering high performance.

Benefits of the Two-Stage Transformer Vacuum Pump with Roots Pump

Enhanced Vacuum Efficiency: The combination of a two-stage vacuum pump and a Roots pump provides superior vacuum efficiency, ensuring thorough removal of contaminants.

Rapid Evacuation: The high pumping speed of the Roots pump allows for faster evacuation times, improving the overall efficiency of transformer maintenance.

Improved Transformer Reliability: By ensuring transformers are free from moisture and gases, the system helps maintain their reliability and performance.

Long-Term Cost Savings: The system’s efficient operation and ability to prevent transformer failures lead to long-term cost savings in maintenance and repair.

Versatile Applications: Suitable for a wide range of transformer maintenance tasks, the system provides versatility in various operational scenarios.

Applications of High Vacuum Pumping Systems and Two-Stage Transformer Vacuum Pumps

Both the ZJ Series High Vacuum Pumping System and the Two-Stage Transformer Vacuum Pump with Roots Pump are used in various applications to ensure the reliability and efficiency of transformers.

Transformer Maintenance and Repair: These systems are essential for ensuring that transformers remain free from moisture and gases during maintenance and repair operations.

Power Generation Plants: In power generation facilities, maintaining transformer dryness is critical for ensuring the reliable operation of transformers and uninterrupted power supply.

Transmission and Distribution Networks: In substations and transformer stations, these vacuum systems help in maintaining the quality of transformer insulation, reducing the risk of power outages and equipment failures.

Industrial Facilities: Industrial operations rely on transformers for power distribution. Regular moisture control using vacuum systems is critical to ensure smooth and efficient industrial processes.

Choosing the Right Vacuum System for Transformer Maintenance

When selecting a vacuum system for transformer maintenance, several factors should be considered:

Vacuum Capability: Assess the required vacuum level for the specific maintenance tasks. High vacuum systems like the ZJ Series and two-stage systems with Roots pumps are ideal for thorough evacuation.

Operational Environment: Consider the operating conditions and environmental factors. Robust and durable systems are essential for demanding environments.

Efficiency and Speed: Look for systems that offer efficient and rapid evacuation to minimize downtime and improve maintenance efficiency.

Energy Efficiency: Energy-efficient systems help in reducing operational costs. Look for systems designed for energy-efficient operation.

Portability and Flexibility: For on-site maintenance activities, portable and easy-to-transport systems provide added flexibility.

Conclusion

Maintaining the quality of transformer insulation is crucial for the reliable and efficient operation of transformers. High vacuum pumping systems and two-stage transformer vacuum pumps with Roots pumps offer robust solutions for controlling moisture and ensuring the optimal performance of transformers. By understanding the features and benefits of these systems, maintenance professionals can make informed decisions to enhance the reliability of their electrical infrastructure and ensure a stable and efficient power supply. Effective moisture control not only improves transformer performance but also contributes to cost savings and extended operational life, making these vacuum systems indispensable tools in the maintenance of electrical power systems.

0 notes

Text

Tekman: A Leading Name in Industrial Vacuum Pump Manufacturing

Tekman has established itself as a pioneer in the industrial vacuum pump manufacturing industry, consistently delivering high-quality and reliable solutions tailored to meet the diverse needs of its customers. With a strong commitment to innovation and excellence, Tekman stands out as a brand that customers trust for their critical vacuum pump requirements.

Excellence in Helium Leak Detection

The solutions designed by Tekman for Helium Leak Detection offer unmatched accuracy and precision. For companies where even the smallest leak can cause serious operational problems, these detectors are indispensable. The prompt and accurate identification of leaks by Tekman's helium leak detectors minimizes downtime and boosts overall productivity. You may be sure that Tekman will provide the highest level of dependability in meeting your helium leak detection requirements.

Cutting-Edge Helium Leak Testing Machines

Apart from leak detectors, Tekman provides cutting-edge Helium Leak Testing Machines. Because these devices are made to withstand stringent testing procedures, any possible leaks will be found before they have a chance to do any harm. The essential leak testing that Tekman's helium leak testing equipment provides surpasses the highest standards and is utilized in a variety of industries, including aerospace and automotive. Selecting Tekman means going with a company that values accuracy and superiority in every machine they make.

Innovative Helium Recovery Systems

Yet another example of Tekman's dedication to efficiency and sustainability is the Helium Recovery System. By recovering and recycling helium, these systems greatly lower waste and operating expenses. Tekman's recovery systems enable enterprises to optimize their helium utilization, guaranteeing that no helium is wasted. Helium is an invaluable resource. You can rely on Tekman to deliver environmentally friendly solutions that are also highly effective.

Leading Dry Vacuum Pump Manufacturer

Tekman, a well-known manufacturer of dry vacuum pumps, provides a selection of dry vacuum pumps to meet the unique requirements of different sectors. These pumps are perfect for cleanroom settings and applications where contamination must be prevented because they are made to function without the need for any lubricants. Industries all over the world use Tekman's dry vacuum pumps because of their reputation for dependability, efficiency, and little maintenance needs.

Superior Single Stage Oil Sealed Vane Pumps

The Single Stage Oil Sealed Vane Pump from Tekman is a product that epitomizes the company's commitment to excellence and dependability. These pumps are employed in many industries, including food processing and pharmaceuticals, where strong vacuum performance is necessary. The oil-sealed vane pumps from Tekman are designed to provide dependable and consistent performance, guaranteeing the seamless and effective running of your business. You receive more than just a pump when you work with Tekman—you get a reliable solution.

Global Reach and Industry Expertise

With a global presence and a reputation for being a top manufacturer of industrial vacuum pumps, Tekman serves a diverse range of sectors across national boundaries. Their in-depth knowledge of the sector enables them to recognize and respond to the unique problems encountered by companies globally. Tekman's products are widely regarded for their dependability and efficiency, meeting the exacting demands of many industries such as aerospace and semiconductors. Because of its dedication to quality and excellence, Tekman is now the go-to partner for global industries looking for cutting-edge vacuum solutions.

Customization for Specialized Applications

Recognizing that no two applications are alike, Tekman provides specialized vacuum solutions to satisfy particular industry requirements. Their capacity to customize goods, such as dry vacuum pumps and helium leak testing machines, to meet particular needs guarantees that customers get the most effective and efficient solutions. Tekman's engineering team collaborates closely with clients to create equipment that satisfies precise requirements, whether it is for a crucial environmental application or a high-precision manufacturing process. This degree of personalization distinguishes Tekman as a company that goes above and beyond to cater to the unique requirements of its customers.

Advanced Manufacturing Processes

Modern production techniques are used by Tekman to provide the best quality possible in each product. Every stage, from the first stages of design to the last assembly, is painstakingly regulated to adhere to strict industry requirements. With the newest technology, Tekman's state-of-the-art production facilities can precisely and consistently build complicated components. The success of Tekman's Single Stage Oil Sealed Vane Pumps and other vacuum solutions, which are recognized for their dependability and effectiveness in harsh industrial settings, demonstrates this dedication to excellence.

Robust Quality Assurance

Ensuring quality is a fundamental aspect of Tekman's activities. To guarantee it satisfies the highest requirements for performance and dependability, every product is put through a rigorous testing and inspection process. Thorough testing procedures are applied to Tekman's helium leak detectors and helium recovery systems to ensure faultless operation even in the most demanding circumstances. Customers may feel secure knowing that they are investing in the greatest products when they know that every Tekman product meets performance, longevity, and safety expectations thanks to the company's commitment to quality assurance.

Strong After-Sales Support and Maintenance Services

Tekman's dedication to client happiness doesn't stop at the transaction. They provide strong post-purchase support, such as technical help and maintenance services, to make sure your vacuum systems keep performing at their best. To ensure minimal downtime and peak performance, Tekman's team of skilled experts is ready for on-site assistance, troubleshooting, and routine maintenance. Because of their commitment to providing after-sales support, Tekman is a reliable partner for companies that depend on their vacuum technology for essential operations.

#industrial vacuum pump manufacturing#Helium Leak Detection#Helium Leak Testing Machines#Helium Recovery System#manufacturer of dry vacuum pumps

0 notes

Text

9 Useful Tips To Unclog A Kitchen Sink Properly

A clogged kitchen sink is a common household issue that can quickly disrupt your daily routine. The buildup of food particles, grease, and other debris can create a stubborn blockage, making it difficult to use your sink effectively. While a clogged sink might seem like a minor inconvenience, it can lead to more significant problems if not addressed promptly by plumbers North Brisbane. In some cases, standing water can attract pests and create an unpleasant odour, making your kitchen an uncomfortable place to be.

This list has several effective methods to unclog your kitchen sink without having to resort to drastic measures.

Use Boiling Water

One of the simplest and most effective methods to unclog a kitchen sink is by using boiling water. This method works best for minor clogs caused by grease and soap scum. Start by boiling a large pot of water. Carefully pour the boiling water directly into the drain in two to three stages, allowing the hot water to work through the clog and break down the grease and soap residue. If the water doesn't drain, give it a few minutes to cool down and try again. This method is not suitable for sinks connected to PVC pipes, as the heat could damage them.

Baking Soda and Vinegar

The combination of baking soda and vinegar is a natural and effective way to unclog your sink. Begin by removing any standing water from the sink. Pour about a cup of baking soda down the drain, followed by an equal amount of white vinegar. The mixture will fizz and bubble, working to break down the clog. Let it sit for at least 15 minutes, then flush the drain with hot water. For stubborn clogs, you may need to repeat this process a few times.

Plunger

A plunger is a handy tool for unclogging sinks. Make sure you use a cup plunger, which is specifically designed for sinks. First, fill the sink with enough water to cover the plunger's cup. Place the plunger over the drain and press down firmly to create a seal. Pump the plunger up and down vigorously for about 30 seconds. The pressure created should dislodge the clog. Once the water starts to drain, run hot water to clear any remaining debris.

Plumber's Snake

A plumber's snake, or drain auger, is a more advanced tool that can handle tougher clogs. Insert the snake into the drain and turn the handle to extend it further into the pipe. When you encounter resistance, you’ve likely reached the clog. Twist and push the snake to break up the blockage. Slowly retract the snake, bringing up the debris. Flush the drain with hot water to clear any remnants of the clog.

Dish Soap and Hot Water

If grease is the culprit, dish soap and hot water can be very effective. Pour a generous amount of dish soap down the drain, followed by a pot of boiling water. The soap will help dissolve the grease, while the hot water will flush it away. Repeat this process a few times until the drain flows freely. This method works well for minor grease clogs and can be a good preventive measure if used regularly.

Wet-Dry Vacuum

A wet-dry vacuum can be a powerful tool for unclogging a sink. Set your vacuum to the liquid setting and create a tight seal over the drain using the hose attachment. Turn the vacuum on to the highest setting to suction out the clog. This method works well for clogs caused by small, solid objects like food particles. Afterwards, run hot water to ensure the clog is completely cleared.

Remove and Clean the P-Trap

The P-trap is the curved pipe under your sink that traps debris and prevents sewer gases from entering your home. Over time, it can become clogged with food particles and grease. Place a bucket underneath the P-trap to catch any water, then use a wrench to loosen the nuts on either end of the trap. Remove the trap and clean out any debris. Rinse it thoroughly before reattaching it. This method is effective for clogs located in the lower section of your drain system.

Salt and Baking Soda

Salt combined with baking soda can help break up a clog. Mix half a cup of table salt with half a cup of baking soda and pour the mixture down the drain. Let it sit for several hours, or overnight if possible. Follow with a pot of boiling water. The abrasive action of the salt, combined with the chemical reaction of the baking soda, can dislodge the clog and clean the pipe.

Enzyme Cleaners

Enzyme-based drain cleaners are a safe and environmentally friendly option for unclogging sinks. These cleaners use natural enzymes to break down organic material. Follow the instructions on the product for the best results. Typically, you’ll need to pour the cleaner down the drain and let it sit for several hours or overnight. Enzyme cleaners are effective for maintaining a clear drain and can be used regularly as a preventive measure.

A clogged kitchen sink can be a frustrating and inconvenient problem, but with the right tools and methods, you can address the issue effectively. From simple solutions like boiling water and dish soap to more advanced tools like a plumber's snake or wet-dry vacuum, there are various ways to tackle a clog. Understanding the causes of clogs and taking preventive measures can help keep your sink and pipes in good working order.

0 notes

Text

Rotary Vane Vacuum Pumps & Compressors | Vacuum Pumps

Vacuum Pumps provide single and two-stage Rotary Vane Vacuum Pump designed especially for installation into small vacuum packaging machines. Shop today!

#vacuum pumps#industrial vacuum pumps#industrial equipment supplier#Rotary Vane Vacuum Pumps#vacuum pumps australia

0 notes

Text

Compact and Reliable Single Stage Vacuum Pumps for Consistent Industrial Vacuums

Meekaj Vacuum Systems Pvt Ltd stands as a premier provider of advanced vacuum pump solutions, catering to the industrial sector in India with a diverse range of high-performance products. As a reputable industrial vacuum pump supplier in India, we specialize in delivering reliable and efficient vacuum pump systems that are essential for a wide range of industrial applications, ensuring optimal performance and productivity.

Discover innovation and precision engineering with Meekaj Vacuum Systems, one of the leading water ring vacuum pump manufacturers in Ahmedabad. Our water ring vacuum pumps are designed to meet the rigorous demands of industrial processes, offering robust performance, energy efficiency, and durability for seamless operation in challenging environments.

Enhance Your Industrial Efficiency with Meekaj’s Two Stage Liquid Ring Vacuum Pumps

Experience the power and efficiency of single stage water ring vacuum pumps from Meekaj Vacuum Systems, engineered to deliver exceptional performance and reliability in various industrial settings. Our single-stage pumps are known for their compact design, low maintenance requirements, and high suction capacity, making them an ideal choice for applications that demand consistent vacuum levels.

Meekaj Vacuum Systems two stage liquid ring vacuum pump, designed to handle demanding industrial processes with precision and efficiency. Our two-stage pumps offer increased vacuum levels, reduced energy consumption, and enhanced reliability, making them the preferred choice for applications that require higher vacuum capabilities and optimal operational efficiency.

Meekaj Vacuum Systems prioritizes customer satisfaction and technical excellence, ensuring that our vacuum pump solutions meet the highest standards of quality and performance. Whether you require an industrial vacuum pump supplier in India, water ring vacuum pump manufacturers in Ahmedabad, single-stage pumps, or two-stage models, Meekaj Vacuum Systems is your trusted partner for cutting-edge vacuum solutions that drive success in your industrial operations.

#two stage liquid ring vacuum pump#single stage water ring vacuum pumps#water ring vacuum pump manufacturers in Ahmedabad#industrial vacuum pump supplier in India

0 notes

Text

Vertical turbine pumps happen to be one of the most usually used deep well pumps. They are used in a wide range of applications such as water treatment in industries, in cooling towers of power plants, for pumping water into fields for irrigation purposes, etc. Yet, not many people are aware of the incredible features and working capacity of these pumps. As among the foremost vertical sump manufacturers in India, Flowmore happens to be here to guide you with the working attitude of these pumps and how to choose the vertical pumps that best suit your application requirements.

What is a vertical turbine pump?

A vertical turbine pump is a subcategory of centrifugal pumps. These pumps are specially designed to pump water from deep reservoirs and underground borewells. They are also known as shaft turbo pumps, sump pumps or deep-sea turbo pumps. These pumps are connected to the engine at ground level by a long vertical shaft, hence the name vertical turbine pumps. It transports fluid/water from deep groundwater reservoirs to ground level. Vertical turbine pumps are used in a wide range of industrial environments and are proven pumps. The efficiency and ease of maintenance of these pumps make them an excellent choice for various industrial requirements. These pumps are mainly used in chemical processing, petrochemical, power generation, oil and gas exploration, mining and seawater desalination industries.

How do vertical turbine pumps work? The Principle of functioning

Vertical turbine pumps move in a specific direction and cause gas molecules to collide with moving solid surfaces. These pumps have a fast-spinning fan that hits the gas molecules and blows them from the inlet to the outlet. This action happens to cause a vacuum-like status inside the pump chamber. Most Vertical turbine Pumps India have manifold stages. Each stage has two blades: a rotor blade that spins at high speed and a stator blade. This mechanical action of the blade transfers kinetic energy to the gas molecule. The gas molecule hits the rotor surface again and moves towards the exit.

Structure of vertical turbine pumps

Vertical turbine pumps happen to be designed with open and closed impellers. The diffuser bowl bearings are lubricated by the transferred liquid.

0 notes

Text

The Evolution and Impact of Modern Vacuum Technology: A Deep Dive into Single Stage Rotary Vane Pumps and Dry Vacuum Pumps

In the realm of industrial machinery, vacuum pumps hold a significant position due to their diverse applications and essential functions. From maintaining contaminant-free environments in semiconductor manufacturing to facilitating efficient operations in the pharmaceutical industry, vacuum pumps are indispensable. Among the various types, single stage rotary vane pumps and dry vacuum pumps stand out for their unique features and broad range of uses. This blog explores these two categories, delving into their mechanisms, applications, and the leading manufacturers that drive innovation in vacuum technology.

Understanding Single Stage Rotary Vane Pumps

Single stage rotary vane pumps are a type of positive displacement pump that utilizes rotating vanes to create a vacuum. These pumps are known for their simplicity, reliability, and efficiency, making them a popular choice in various industries.

Mechanism and Functionality

A single stage rotary vane pump consists of a rotor housed within a cavity. The rotor is offset within the cavity, creating a crescent-shaped gap. As the rotor turns, the vanes extend and retract, trapping air and compressing it against the pump casing to create a vacuum. The single stage design means that the compression process occurs in one step, which simplifies the construction and maintenance of the pump.

Key Features

Compact Design: Single stage rotary vane pumps are typically compact and lightweight, making them easy to integrate into existing systems.

High Efficiency: These pumps are designed to provide high efficiency, ensuring that they can achieve and maintain the desired vacuum levels with minimal energy consumption.

Durability: Built with robust materials, single stage rotary vane pumps are designed to withstand harsh operating conditions, ensuring longevity and reliability.

Applications of Single Stage Rotary Vane Pumps

1. Laboratory and Research

In laboratories, single stage rotary vane pumps are commonly used for applications such as vacuum filtration, degassing, and distillation. Their ability to provide consistent and reliable vacuum levels is crucial for maintaining the accuracy and precision required in scientific research.

2. Medical Industry

The medical industry utilizes these pumps in a variety of equipment, including vacuum-assisted wound closure systems and diagnostic devices. The compact and reliable nature of single stage rotary vane pumps makes them ideal for critical medical applications.

3. Industrial Processes

In industrial settings, single stage rotary vane pumps are used in processes such as packaging, drying, and material handling. Their efficiency and durability ensure that they can handle the demands of continuous operation in a manufacturing environment.

Single Stage Oil Sealed Vane Pumps: Enhancing Performance

Single stage oil sealed vane pumps operate on the same principle as the standard rotary vane pump but with an added layer of oil sealing. This design enhances the performance and longevity of the pump by providing better sealing and lubrication.

Advantages of Oil Sealing

Improved Vacuum Levels: The oil seal reduces leaks, allowing the pump to achieve higher vacuum levels.

Enhanced Lubrication: Oil serves as a lubricant for the moving parts, reducing wear and extending the life of the pump.

Reduced Maintenance: The oil sealing system minimizes the need for frequent maintenance, making these pumps more cost-effective in the long run.

The Role of Dry Vacuum Pumps in Modern Industry

Dry vacuum pumps represent a significant advancement in vacuum technology, offering a cleaner and more efficient alternative to traditional oil-sealed pumps. As their name suggests, dry vacuum pumps operate without the use of oil or other sealing fluids, which presents several advantages.

Types of Dry Vacuum Pumps

1. Dry Screw Vacuum Pump

Dry screw vacuum pumps use two intermeshing screws to trap and compress air, creating a vacuum. The absence of oil in the compression chamber means that the pumped gases remain uncontaminated, making these pumps ideal for sensitive applications.

2. Dry Rotary Vane Pump

Similar to the oil-sealed rotary vane pump, the dry rotary vane pump uses rotating vanes to create a vacuum. However, these pumps are designed to operate without oil, which reduces contamination and maintenance requirements.

Advantages of Dry Vacuum Pumps

Contamination-Free Operation: The absence of oil eliminates the risk of contamination, which is critical in industries such as pharmaceuticals and food processing.

Lower Maintenance: Without the need for oil changes and other fluid maintenance, dry vacuum pumps require less upkeep, reducing downtime and operating costs.

Environmental Benefits: Dry vacuum pumps are more environmentally friendly, as they eliminate the need for oil disposal and reduce the risk of oil leaks.

Applications of Dry Vacuum Pumps

1. Semiconductor Manufacturing

In the semiconductor industry, maintaining a contaminant-free environment is crucial for producing high-quality products. Dry vacuum pumps are used in processes such as wafer fabrication and coating, where even the slightest contamination can affect product performance.

2. Pharmaceutical Production

The pharmaceutical industry relies on dry vacuum pumps for processes such as freeze-drying and vacuum distillation. The contamination-free operation ensures that the purity and quality of pharmaceutical products are maintained.

3. Food Processing

In food processing, dry vacuum pumps are used for applications such as packaging and dehydration. Their ability to operate without oil ensures that food products remain uncontaminated and safe for consumption.

Leading Manufacturers of Vacuum Pumps

Several manufacturers are at the forefront of developing innovative vacuum pump technologies, providing high-quality solutions for various industries.

1. Edwards Vacuum

Edwards Vacuum is renowned for its range of vacuum solutions, including both single stage rotary vane pumps and dry vacuum pumps. Their commitment to innovation and quality has made them a trusted partner for businesses worldwide.

2. Leybold GmbH

Leybold GmbH offers a comprehensive portfolio of vacuum pumps, including single stage oil sealed vane pumps and dry screw vacuum pumps. Their focus on advanced technology and customer satisfaction ensures that they provide reliable and efficient solutions.

3. Pfeiffer Vacuum

Pfeiffer Vacuum is known for its high-performance vacuum pumps, catering to a diverse range of industries. Their dry vacuum pumps are designed to deliver exceptional performance while minimizing environmental impact.

Conclusion

The evolution of vacuum technology, from single stage rotary vane pumps to advanced dry vacuum pumps, has significantly impacted various industries. These pumps are essential for maintaining efficiency, reliability, and cleanliness in critical processes, ensuring that industries can meet their production and quality standards.

Single stage rotary vane pumps, with their compact design and high efficiency, remain a staple in laboratories, medical devices, and industrial processes. The addition of oil sealing further enhances their performance, making them suitable for more demanding applications.

On the other hand, dry vacuum pumps represent a leap forward in vacuum technology. Their contamination-free operation, lower maintenance requirements, and environmental benefits make them an attractive choice for industries such as semiconductor manufacturing, pharmaceuticals, and food processing.

As technology continues to advance, the future of vacuum pumps looks promising. Innovations in energy efficiency, automation, and sustainability will further enhance the performance and versatility of these essential devices. Leading manufacturers like Edwards Vacuum, Leybold GmbH, and Pfeiffer Vacuum will continue to play a pivotal role in driving this progress, ensuring that businesses worldwide can rely on cutting-edge vacuum solutions to meet their evolving needs.

In conclusion, understanding the different types of vacuum pumps and their applications is crucial for selecting the right solution for specific industrial needs. Whether opting for a single stage rotary vane pump for its simplicity and reliability or a dry vacuum pump for its contamination-free operation and environmental benefits, businesses can leverage these technologies to enhance their operations and achieve their goals.

0 notes

Text

From the Liquid Ring Vacuum Pump to the Two-Stage counterpart, the Water Ring Vacuum Pump to the reliable Oil Sealed Vacuum Pump – each type brings a unique edge to meet your industrial needs. Unleash efficiency with precision-engineered technology.

For more details, visit- https://www.acmeairequipments.com/vacuum-pump-different-types-applications/

0 notes

Text

Double Stage Vacuum Pump (VP245) 5CFM

Vacuum pumps are an essential tool in a variety of industries, playing a critical role in applications that require the removal of gases and air from sealed environments. One of the most efficient and widely used types of vacuum pumps is the double-stage vacuum pump, and the VP45 model exemplifies superior performance, reliability, and advanced technology. From HVAC and refrigeration maintenance to laboratory applications, this pump stands out for its high vacuum capabilities. In this article, we’ll dive into the details of the double-stage vacuum pump VP45, its working mechanism, applications, and pricing, particularly in the Indian market.

What is Double Stage Vacuum Pump ?

A double-stage vacuum pump, like the VP45, operates in two phases to achieve higher vacuum levels. Unlike single-stage pumps that only compress air once, a double-stage vacuum pump compresses the air twice, resulting in a deeper vacuum. This deeper vacuum level is essential for processes that demand high precision, such as air conditioning (AC) system maintenance, refrigeration system evacuation, and scientific research applications.

The VP45 model is particularly notable for its advanced design, offering greater vacuum efficiency and reliability for professionals. Its double-stage design makes it capable of reaching low pressure levels (high vacuum), making it suitable for applications that single-stage pumps may not be able to handle.

Key Features of the Double Stage Vacuum Pump VP 245 ?

The VP45 double-stage vacuum pump comes equipped with several features that make it an ideal tool for both professionals and hobbyists in industries such as HVAC, refrigeration, and laboratories. Here are some of the standout features:

Two-Stage Operation: The two-stage mechanism provides a higher level of vacuum precision compared to single-stage pumps, making the VP45 more suitable for demanding applications.

Robust Construction: The VP45 is built from high-quality materials designed to withstand the rigors of daily use. Its heavy-duty construction ensures durability and longevity.

Efficient Cooling System: To prevent overheating, the VP45 is equipped with an efficient cooling system that keeps the pump functioning optimally during extended use.

Oil-Mist Filter: The VP45 includes an oil-mist filter to reduce oil mist emissions, keeping your work environment cleaner and more efficient.

Low Noise Operation: Unlike many industrial machines, the VP45 operates quietly, allowing for a less disruptive working environment.

Thermal Protection: The pump is equipped with a thermal protection system that prevents it from overheating, ensuring long-lasting performance even in high-demand situations.

Double Stage Vacuum Pump Working ?

Understanding how a double-stage vacuum pump works is essential for grasping its advantages over single-stage models. Here's how it operates:

Stage One: In the first stage of the process, the pump reduces the atmospheric pressure in the system by compressing the air from the vacuum chamber. This stage works similarly to a single-stage vacuum pump and reaches a basic vacuum level by expelling the air through an exhaust port.

Stage Two: The second stage kicks in to further reduce the pressure. This stage compresses the remaining air, removing it completely to create a much deeper vacuum. By performing this second compression, the VP45 can achieve much lower pressure levels, allowing it to reach higher vacuums than single-stage pumps.

Oil Lubrication: The pump uses oil as a lubricant and sealant, which plays a crucial role in reducing wear and tear on the moving parts while maintaining an airtight seal. This ensures smooth, long-lasting performance.

Rotary Vane Mechanism: The VP45 features a rotary vane design where rotating vanes trap air in compartments. As the rotor spins, the vanes push the air towards the exhaust, where it’s expelled. This process repeats continuously, but in two stages, to achieve a more complete vacuum.

Appilcations of Double Stage Vacuum Pumps

Double-stage vacuum pumps like the VP45 have a broad range of applications, thanks to their ability to achieve high levels of vacuum. Here are some of the key industries and tasks that benefit from the use of a double-stage vacuum pump:

1. Air Conditioning (AC) and Refrigeration

In air conditioning (AC) systems, a vacuum pump is used to remove moisture and air from the refrigerant lines before charging the system with refrigerant gas. This process ensures the system runs efficiently and prevents contamination that can damage components over time. The double-stage vacuum pump for AC systems ensures that the system is evacuated to the necessary vacuum depth, eliminating moisture and air.

2. HVAC Systems

For HVAC professionals, the VP45 is an invaluable tool. It ensures that the refrigerant system is properly evacuated, which is critical for the overall health and efficiency of the system. A properly vacuumed system reduces the risk of leaks, corrosion, and inefficient operation.

3. Laboratories

In laboratories, vacuum pumps are used for a variety of tasks, such as vacuum filtration, freeze drying, and creating controlled environments for experiments. The VP45’s ability to achieve deeper vacuums makes it ideal for these applications.

4. Industrial Applications

Many industrial applications, such as food packaging, require a vacuum environment. The VP45 can be used to create a vacuum that preserves food products by removing air, thus extending their shelf life.

5. Medical Equipment

Double-stage vacuum pumps are also used in medical equipment, such as autoclaves, to ensure sterile environments by removing air and steam from medical devices during sterilization processes.

2 Stage Vacuum Pump Price in India

The price of a 2-stage vacuum pump in India varies depending on the brand, features, and capacity. For the VP45, prices generally range depending on the retailer and any additional features or accessories included.

Higher-end models, which may come with advanced features such as digital displays, enhanced oil filtration systems, or additional capacity, are typically priced at the upper end of this range. Lower-end models with fewer features but still offering the essential double-stage mechanism will be closer to the starting price.

Factor Influencing the price of a Double Stage-Vacuum Pump

Several factors impact the price of a double-stage vacuum pump like the VP45:

Brand: Well-known brands with a reputation for high-quality performance and durability often have higher price points.

Capacity: Pumps with larger capacities can handle more demanding tasks, which may increase the price.

Features: Additional features such as oil filtration systems, thermal protection, and advanced cooling systems can raise the price.

Several factors impact the price of a double-stage vacuum pump like the VP45:

Brand: Well-known brands with a reputation for high-quality performance and durability often have higher price points.

Capacity: Pumps with larger capacities can handle more demanding tasks, which may increase the price.

Features: Additional features such as oil filtration systems, thermal protection, and advanced cooling systems can raise the price.

More information :- CLICK HERE

CONTACT :- 91-9717732520

0 notes