#tubular air heater

Explore tagged Tumblr posts

Text

Check out Marathon's Tubular Air Heater, designed to deliver optimal heating performance for various industrial applications. With its advanced technology and energy-efficient design, our tubular air heater ensures superior heat transfer, reduced energy consumption, and enhanced productivity.

0 notes

Text

Airex Tubular Air Heater Element U Shape 750W Bakery Equipment , 18"

Price: (as of – Details) About The Product Airex Brand Air Heater Element U Shape Used in Poultry, bakery equipment, baking machine, electric ovens, hot case, griller machine, industrial ovens. Material – Stainless Steel 304 Grade Can be Designed as per your requirment. Airex Brand Air Heater Element U Shape Used in Poultry, bakery equipment, baking machine, electric ovens, hot case, griller…

View On WordPress

0 notes

Text

Tubular Air Heaters & Electric Heating Elements in UAE

View tubular air heaters and electric heating elements, Reach out to us today to know more about our products call Now +971543925281

0 notes

Photo

Lamborghini Islero

Built as a replacement for the 400GT, the Islero was introduced at the 1968 Geneva Auto Show. Its name, like the earlier Miura and Espada models, was inspired by Spanish bullfighting. Styling is by Carrozzeria Marazzi, and aluminum bodywork is wrapped over a tubular steel chassis. The car had impressive performance for the era, including a 0-60 time of about six and a half seconds and a top speed in excess of 150 mph. A three-spoke steering wheel frames a suite of Jaeger instrumentation, including a 200-mph speedometer, 8k-rpm tachometer, ammeter, fuel-level indicator, oil and water temperature gauges, and an oil pressure gauge. The clock was also rebuilt and the wiring for the wipers, turn signals, and headlights was repaired. A three-spoke steering wheel frames a suite of Jaeger instrumentation, including a 200-mph speedometer, 8k-rpm tachometer, ammeter, fuel-level indicator, oil and water temperature gauges, and an oil pressure gauge. The clock was also rebuilt by the current owner and the wiring for the wipers, turn signals, and headlights was repaired. The 3.9L quad-cam V12 was rated for 325 horsepower when new and is paired with a five-speed manual transmission. Induction is handled by six Weber carburetors. The engine was removed for cosmetic detailing by the owner, including repainting the air cleaner housings and coolant expansion tank. The clutch slave cylinder was also repaired and a new ignition coil, spark plugs, and heater hoses were installed.

93 notes

·

View notes

Text

Flexible Tubular Heaters: The Ultimate Solution for Versatile Heating Applications

Introduction to Tubular Heaters

Tubular heaters have become a cornerstone in the world of industrial and commercial heating due to their efficiency, durability, and adaptability. Among these, flexible tubular heaters stand out as an innovative solution designed to meet the needs of specialized applications. These heaters offer unparalleled versatility, allowing engineers and manufacturers to implement efficient heating solutions in complex environments.

What Are Flexible Tubular Heaters?

Flexible tubular heaters are a subtype of tubular heaters characterized by their ability to bend and conform to specific shapes. Unlike rigid heaters, they can be molded to fit irregular or confined spaces without compromising performance. These heaters typically consist of a resistance wire encased in a high-grade metal sheath, surrounded by insulation material to ensure efficient heat transfer.

Key Features of Flexible Tubular Heaters

Flexibility: The ability to bend these heaters makes them ideal for applications requiring custom configurations, such as curved surfaces or intricate machinery.

Durability: Constructed with robust materials like stainless steel or Incoloy, flexible tubular heaters can withstand extreme temperatures, corrosive environments, and mechanical stress.

High Efficiency: The insulation and precise construction ensure maximum heat transfer while minimizing energy loss, making them an energy-efficient choice.

Customizability: Flexible tubular heaters can be manufactured to meet specific length, wattage, and voltage requirements, catering to diverse industrial needs.

Applications of Flexible Tubular Heaters

The adaptability of flexible tubular heaters allows them to be utilized across a wide range of industries. Some of their most common applications include:

Industrial Equipment: These heaters are used in molding, die-casting, and plastic extrusion machines, where precise and uniform heating is critical.

Food Processing: In food production, flexible tubular heaters provide consistent heating for equipment such as fryers, ovens, and warming trays.

Medical Devices: The compact and customizable design makes these heaters suitable for medical instruments requiring controlled heating, such as sterilizers and diagnostic devices.

HVAC Systems: Flexible tubular heaters play a significant role in heating air or liquids in HVAC systems, ensuring efficient climate control.

Renewable Energy Applications: They are employed in systems like solar panels and wind turbines to prevent freezing or condensation, ensuring optimal performance.

Advantages of Using Flexible Tubular Heaters

Space Efficiency: Their ability to conform to tight or unusual spaces makes them a practical choice for compact equipment designs.

Ease of Installation: Flexible tubular heaters can be easily installed without extensive modifications to the existing setup, saving time and reducing costs.

Enhanced Safety: The high-quality insulation and protective sheath minimize risks of short circuits, overheating, or accidental burns.

Long Service Life: Engineered to resist wear and tear, these heaters provide reliable performance over extended periods, reducing maintenance costs.

Choosing the Right Flexible Tubular Heater

Selecting the appropriate tubular heater for your application involves considering several factors, such as:

Temperature Requirements: Determine the maximum operating temperature needed for your application.

Watt Density: Higher watt density allows for faster heating, but it must align with the material's tolerance.

Environment: Consider factors like exposure to moisture, chemicals, or extreme conditions to choose the right sheath material.

Shape and Size: The heater’s dimensions should match the application for optimal performance.

Future of Tubular Heaters

As industries continue to demand efficient and adaptable heating solutions, flexible tubular heaters are expected to see increased adoption. Advances in materials and manufacturing technologies will likely lead to even greater durability, efficiency, and customizability, solidifying their role in modern heating applications.

Conclusion

Flexible tubular heaters represent a perfect blend of innovation and functionality. Their adaptability, efficiency, and reliability make them an indispensable asset across various industries. Whether it’s for precise industrial heating or specialized medical applications, these heaters deliver consistent and efficient performance. As the demand for sophisticated heating solutions grows, flexible tubular heaters will continue to be a preferred choice for engineers and manufacturers worldwide.

#tubular heater manufacturers#tubular heater manufacturer in india#tubular heater manufacturers in bangalore

0 notes

Text

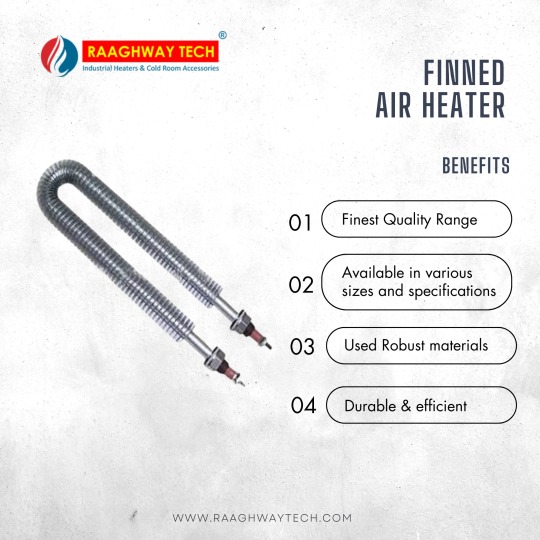

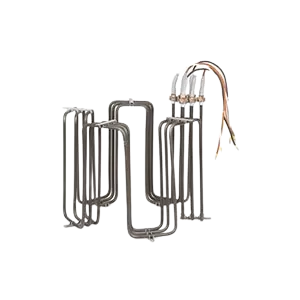

Maximize Heat Transfer Efficiency with Finned Air Heaters

Industrial heating systems require reliable and efficient solutions to maintain consistent performance, especially in applications demanding high heat transfer rates. Among the many options available, finned air heaters stand out as a versatile and effective choice for air heating applications. Designed to optimize heat transfer, these heaters play a crucial role in industries such as HVAC, drying processes, and industrial ovens.

In this blog, we’ll explore what finned air heaters are, how they work, their advantages, and their wide-ranging applications. We’ll also explain why Raghav Industries is your trusted partner for premium finned air heaters.

What is a Finned Air Heater?

A finned air heater is a heating element designed to maximize heat transfer by increasing the surface area exposed to air. The heater consists of a resistance wire embedded within a tubular element, surrounded by metal fins. These fins enhance the heat exchange process by efficiently transferring heat from the heating element to the surrounding air.

Finned air heaters are commonly used in forced air systems, where they provide consistent and efficient heating for a wide range of industrial and commercial applications.

How Does a Finned Air Heater Work?

The core heating element in a finned air heater generates heat when electrical current passes through the resistance wire. The fins attached to the element act as heat exchangers, rapidly transferring heat to the surrounding air. When air is forced over the fins using a fan or blower, the heated air is distributed evenly, ensuring consistent temperature control.

This design ensures efficient heat transfer, making finned air heaters ideal for applications where rapid and uniform air heating is required.

Key Features of Finned Air Heaters

1. Enhanced Heat Transfer

The addition of fins significantly increases the surface area of the heating element, allowing for faster and more efficient heat transfer.

2. Durable Construction

Finned air heaters are built with high-quality materials, such as stainless steel or Incoloy, ensuring resistance to corrosion, oxidation, and wear.

3. Uniform Heating

These heaters provide consistent and uniform heat distribution, eliminating hotspots and ensuring reliable performance.

4. Energy Efficiency

Designed to optimize heat transfer, finned air heaters deliver high performance while consuming minimal energy.

5. Versatility

Available in various sizes, configurations, and wattages, finned air heaters can be customized to suit specific applications.

Benefits of Finned Air Heaters

1. Improved System Efficiency

By maximizing heat transfer, finned air heaters enhance the overall efficiency of air heating systems, reducing energy consumption and operational costs.

2. Long Service Life

The robust construction and use of premium materials ensure that these heaters withstand demanding industrial conditions, offering a long operational lifespan.

3. Low Maintenance Requirements

Finned air heaters are designed for durability and reliability, requiring minimal maintenance and reducing downtime.

4. Adaptability

These heaters can be customized to fit a variety of industrial setups, making them suitable for a wide range of applications.

5. Cost-Effectiveness

Their energy-efficient design and low maintenance needs translate into long-term cost savings for businesses.

Applications of Finned Air Heaters

Finned air heaters are used across diverse industries and applications, including:

1. HVAC Systems

In heating, ventilation, and air conditioning systems, finned air heaters ensure efficient temperature control and air distribution.

2. Drying Processes

These heaters are ideal for drying materials in industries such as textiles, paper, and food processing.

3. Industrial Ovens

Finned air heaters are used to maintain consistent temperatures in ovens for baking, curing, or annealing processes.

4. Dehumidification Systems

By providing controlled heating, these heaters aid in moisture removal for improved air quality and equipment longevity.

5. Space Heating

In large industrial or commercial spaces, finned air heaters deliver efficient and uniform air heating.

6. Air Handling Units

These heaters are integral components in air handling systems, ensuring optimal performance and energy efficiency.

Why Choose Raghav Industries for Finned Air Heaters?

Raghav Industries, based in Delhi, India, is a trusted manufacturer and supplier of high-quality finned air heaters. Here’s why our products are the preferred choice for businesses:

1. Superior Quality Materials

Our finned air heaters are constructed using premium materials like stainless steel and advanced insulation, ensuring durability and reliable performance.

2. Customization Options

We offer finned air heaters in various sizes, wattages, and configurations to meet the unique needs of your application.

3. Energy-Efficient Design

Our heaters are engineered to maximize heat transfer while minimizing energy consumption, helping businesses save on operational costs.

4. Expert Craftsmanship

With years of experience, we ensure that every heater we produce meets the highest standards of quality and performance.

5. Comprehensive Support

From product selection to installation and after-sales service, we provide complete support to ensure customer satisfaction.

How to Choose the Right Finned Air Heater

Selecting the right finned air heater depends on several factors, including:

Application Type: Determine whether the heater will be used for HVAC, drying, or another application.

Size and Wattage: Choose a heater that matches the heating requirements of your system.

Material Compatibility: Ensure the heater’s materials are suitable for the operating environment, especially if exposed to moisture or corrosive elements.

Airflow Requirements: Consider the airflow rate to optimize heat transfer and ensure uniform heating.

Our team at Raghav Industries can help you find the perfect solution for your specific needs.

The Importance of Reliable Heating Solutions

Efficient and reliable heating is critical for maintaining productivity and reducing operational costs in industrial environments. Finned air heaters offer a unique combination of high efficiency, durability, and versatility, making them a valuable asset for a wide range of applications.

Conclusion

Finned air heaters are a powerful and efficient solution for air heating applications across various industries. Their ability to deliver uniform heat transfer, combined with their durability and energy efficiency, makes them an indispensable tool for businesses looking to optimize their heating systems.

At Raghav Industries, we are committed to providing premium finned air heaters tailored to your specific needs. With our products, you can enhance operational efficiency, reduce energy consumption, and achieve reliable heating performance.

Learn more about our Finned Air Heaters here.

#finnedairheaters#airheaters#industrialheaters#heating#heatingsystem#industrialheater#industrialheating#industrial#manufacturing

0 notes

Text

Heat Master International Leading the Way in Industrial Heating Solutions

Heat Master International stands at the forefront of innovation in the industrial heating sector, offering a wide range of high-performance products designed to meet the demanding needs of various industries. Specializing in open coil heaters, flanged tubular heaters, industrial ovens, dryers, furnaces, dehydrators, and heat exchangers, Heat Master International is dedicated to providing efficient, reliable, and cost-effective heating solutions. Their products are engineered for precision, durability, and optimal performance, making them a trusted choice for companies looking to enhance their operations.

Open coil heaters are a popular choice for applications that require high heat output and rapid temperature changes. Heat Master International’s open coil heaters are designed with versatility in mind. These heaters feature a compact design and are made with high-quality materials that ensure efficient heat transfer. Whether used in industrial machinery, air heating systems, or in-process heating, these open coil heaters deliver exceptional performance while minimizing energy consumption. Their rugged construction and ease of maintenance make them ideal for tough industrial environments.

Flanged tubular heaters from Heat Master International are designed to provide consistent and reliable heating in high-temperature industrial settings. These heaters are engineered for heavy-duty use, with a flange connection that allows for secure installation in tanks, pipes, or large industrial equipment. With a variety of configurations available, Heat Master International offers custom solutions to meet specific heating requirements. Their flanged tubular heaters are built to withstand extreme conditions, ensuring longevity and minimal downtime.

Industrial ovens are crucial for a wide array of manufacturing processes, from curing and drying to heat treating and coating. Heat Master International’s industrial ovens are built to provide even, precise heat distribution, ensuring consistent results across large batches. Designed for efficiency, these ovens help businesses improve product quality and reduce energy costs. With customizable options such as temperature controls, ventilation systems, and insulation, Heat Master’s industrial ovens meet the diverse needs of industries including automotive, aerospace, and electronics.

For industries where moisture control is essential, Heat Master International’s industrial dryers offer fast and efficient drying solutions. Whether for drying textiles, food products, or other materials, these dryers are engineered to provide quick moisture removal without damaging the product. Their design ensures optimal airflow and temperature distribution, which results in uniform drying and high throughput. Heat Master’s industrial dryers are perfect for sectors such as food processing, pharmaceuticals, and textiles, where precision and energy efficiency are paramount.

Industrial furnaces are essential in sectors that require heat treatments, metal melting, or high-temperature processing. Heat Master International’s industrial furnaces are designed to handle extreme temperatures and provide stable heat for critical processes. Built with high-quality insulation and advanced controls, these furnaces can maintain precise temperatures for extended periods, ensuring uniform heating and reducing energy consumption. They are widely used in metalworking, ceramics, and glass manufacturing, offering both reliability and cost-effectiveness for heavy-duty industrial applications.

Heat exchangers play a vital role in many industrial processes by transferring heat from one medium to another, improving energy efficiency, and reducing operational costs. Heat Master International’s heat exchangers are designed to maximize heat recovery, minimize energy waste, and maintain consistent performance even in the most demanding environments. Alongside their heat exchangers, Heat Master also offers dehydrators that effectively remove moisture from products while maintaining their quality. These systems are perfect for industries such as food processing, pharmaceuticals, and chemicals, where precise moisture control is essential.

Heat Master International is committed to delivering high-quality industrial heating products that meet the rigorous demands of various industries. From open coil heaters to industrial ovens and heat exchangers, their products are designed for reliability, efficiency, and long-lasting performance. With a focus on innovation and customer satisfaction, Heat Master International continues to be a trusted partner for businesses seeking to optimize their heating systems and improve operational efficiency. Whether you need precise temperature control, energy savings, or robust heating solutions, Heat Master International has the products and expertise to meet your needs.

0 notes

Text

Excel Heaters - Leading Industrial Heater Manufacturer in Mumbai, India

When it comes to industrial heating solutions, Excel Heaters has built a reputation as one of the leading manufacturers in Mumbai, India. With years of experience and a commitment to quality, Excel Heaters provides efficient, reliable, and cost-effective heating solutions for a wide range of industrial applications.

About Excel Heaters

Based in Mumbai, Excel Heaters has been at the forefront of designing and manufacturing industrial heaters. The company is known for its innovative approach, ensuring that each product meets the specific needs of its customers. With a focus on quality and durability, Excel Heaters serves industries such as manufacturing, pharmaceuticals, food processing, petrochemicals, and more.

Why Choose Excel Heaters?

Choosing the right industrial heating solution is critical for the efficiency and safety of your operations. Here’s why Excel Heaters is a trusted name in the industry:

Expertise and Experience Excel Heaters boasts a team of skilled engineers and technicians with years of experience in the heating industry. They understand the unique requirements of different industries and provide tailored solutions.

High-Quality Products Quality is a top priority at Excel Heaters. The company uses high-grade materials and advanced manufacturing processes to ensure that every product meets international standards.

Wide Range of Solutions Excel Heaters offers a comprehensive range of industrial heaters, including immersion heaters, cartridge heaters, band heaters, tubular heaters, and custom-designed solutions.

Customer-Centric Approach The team at Excel Heaters works closely with customers to understand their specific needs, providing personalized guidance and support throughout the process.

Competitive Pricing Despite offering premium-quality products, Excel Heaters ensures competitive pricing to make their solutions accessible to businesses of all sizes.

Product Range

Excel Heaters specializes in a wide variety of industrial heaters designed to cater to diverse applications.

1. Immersion Heaters

Immersion heaters are ideal for heating liquids such as water, oils, and chemicals. Excel Heaters’ immersion heaters are designed for efficiency, durability, and safety, making them suitable for both industrial and commercial use.

2. Cartridge Heaters

Cartridge heaters are compact and efficient, perfect for heating small spaces or specific components. They are widely used in plastic molding, packaging, and other precision applications.

3. Band Heaters

Band heaters are designed for cylindrical surfaces, such as barrels, pipes, and tanks. Excel Heaters’ band heaters ensure even heat distribution and are available in various sizes and configurations.

4. Tubular Heaters

Versatile and durable, tubular heaters are used in applications ranging from air and gas heating to ovens and drying systems. Excel Heaters customizes tubular heaters to meet specific requirements.

5. Customized Solutions

For unique industrial processes, Excel Heaters offers custom-designed heating solutions. The team works closely with clients to develop heaters that align with their operational needs and efficiency goals.

: Industries Served

Excel Heaters caters to a wide range of industries, ensuring that their heating solutions contribute to improved productivity and operational efficiency.

Manufacturing Excel Heaters provides heating solutions for machinery, tools, and processes in various manufacturing industries.

Pharmaceuticals Precision heating is critical in pharmaceutical processes. Excel Heaters offers solutions that meet the stringent quality standards of this sector.

Food Processing For applications like drying, baking, and pasteurization, Excel Heaters delivers safe and efficient heating solutions tailored to the food industry.

Petrochemicals and Chemicals The petrochemical and chemical industries require robust and reliable heating solutions. Excel Heaters’ products are built to handle extreme conditions in these sectors.

Automotive From molding to assembly, Excel Heaters supports the automotive industry with high-performance heating equipment.

Commitment to Sustainability

Excel Heaters is dedicated to sustainability and energy efficiency. By designing heaters that consume less power and offer long-lasting performance, the company helps its clients reduce their environmental footprint.

After-Sales Support

Excel Heaters believes in building long-term relationships with its customers. The company offers exceptional after-sales support, including maintenance, troubleshooting, and spare parts supply. Their responsive team ensures that clients can rely on their heaters for uninterrupted operations.

Looking Ahead

With a vision to become a global leader in industrial heating solutions, Excel Heaters continues to innovate and expand its product range. The company invests in research and development to stay ahead of industry trends and deliver cutting-edge solutions to its customers.

Contact Excel Heaters

If you’re looking for reliable, high-quality industrial heaters in Mumbai, India, Excel Heaters is the name you can trust. Their team is ready to assist you in finding the perfect heating solution for your needs.

0 notes

Text

Why Tubular Heater Elements Are Perfect for Harsh Environments

In industries that operate in extreme conditions, reliable heating solutions are critical. Tubular heater elements stand out as the ideal choice for these environments. These versatile heaters are designed to withstand high temperatures, corrosive conditions, and heavy-duty usage, making them perfect for industries such as petrochemical, manufacturing, and food processing.

Key Features of Tubular Heater Elements

Durability in Extreme Conditions: Tubular heater elements are built to resist wear and tear caused by extreme heat, moisture, and chemical exposure. Their rugged construction ensures a longer lifespan, reducing the need for frequent replacements.

Customizable Designs: These heaters can be tailored to fit specific industrial requirements, whether it’s in shape, size, or wattage. This makes them adaptable to various applications, such as heating tanks, ovens, or even air ducts.

Energy Efficiency: Tubular heater elements are designed to provide efficient heating with minimal energy wastage. This feature is vital in reducing operational costs for businesses.

Tubular Heater Elements in Qatar

In Qatar, where industries like oil and gas dominate, the demand for resilient heating solutions is high. According to a report by Mordor Intelligence, the oil and gas market in Qatar is expected to grow at a CAGR of 3.1% from 2023 to 2028. Tubular heater elements are integral in maintaining optimal operations in these industries, especially in applications like tank heating and pipeline temperature regulation.

Tubular Heater Elements for Other Regions

Globally, tubular heaters are extensively used in regions with harsh climates or demanding industrial processes. They are critical in industries like pharmaceuticals, automotive, and metalworking, ensuring consistent performance under challenging conditions.

Why Choose Sanvi Heat?

At Sanvi Heat, we specialize in providing top-quality tubular heater elements tailored for harsh environments. Our products combine durability, efficiency, and innovation to meet the unique demands of industries in Qatar and beyond. With a commitment to excellence, we ensure timely delivery and unmatched customer support.

Contact Sanvi Heat today for durable and energy-efficient tubular heater elements. Let us help you power your operations seamlessly, even in the toughest environments.

0 notes

Text

Improving Industrial Heating Systems with Temperature Sensors

In industrial heating systems, accurate temperature control is essential for both safety and efficiency. industrial temperature sensors are integral components in these systems, providing the data needed to adjust heat output and maintain consistent temperatures. Whether used with electrical tubular heaters or finned tubular heaters, industrial temperature sensors play a key role in ensuring that heating systems operate effectively.

Temperature sensors applications in industrial heating systems vary widely. They can be used to monitor air temperatures in HVAC systems, maintain heat levels in chemical processing plants, or control the heating of materials in food production facilities. In all of these applications, the goal is the same: to ensure precise temperature control while minimizing energy use.

Brass Coil Heaters are commonly used in industrial environments to provide large-scale heating. These heaters are designed to warm air as it passes through the duct, making them ideal for heating large spaces. However, without the integration of temperature sensors, it can be difficult to maintain consistent heat levels, leading to inefficiencies and potential safety hazards.

In conclusion, controller manufacturers are essential components of any modern heating system. By providing real-time feedback on temperature levels, these sensors ensure that electrical tubular heaters and finned tubular heaters operate efficiently and safely, delivering consistent heat in a wide range of industrial applications.

0 notes

Text

Tubular heater manufacturers produce heaters with a metal tube encasing a heating element, ensuring efficient and reliable heating. These heaters are widely used in industrial, commercial, and residential applications due to their durability and versatility. They offer consistent temperature maintenance and are ideal for heating liquids, air, and surfaces. Manufacturers focus on high-quality materials and precision to meet various heating needs and industry standards.

#TubularHeaters#HeatingSolutions#IndustrialHeating#HeatingEfficiency#EnergyEfficiency#HeatingTechnology#HeaterManufacturers#HeatTransfer#HeatingElements#HeatingSystem#DurableHeaters#CustomHeating#HeatingApplications

0 notes

Text

Check out Marathon's Tubular Air Heater, designed to deliver optimal heating performance for various industrial applications. With its advanced technology and energy-efficient design, our tubular air heater ensures superior heat transfer, reduced energy consumption, and enhanced productivity.

0 notes

Text

Tubular Air Heaters & Electric Heating Elements in UAE

View tubular air heaters and electric heating elements, Reach out to us today to know more about our products call Now +971543925281

0 notes

Text

The Ultimate Guide to Industrial Heating Elements

Industrial heating elements are essential components of heating systems used in a wide range of industrial applications. In this comprehensive guide, we'll explore everything you need to know about Industrial Heating Elements, including their types, applications, and key considerations for selection and maintenance.

Understanding Industrial Heating Elements

1. What are Industrial Heating Elements?

Industrial heating elements are devices designed to generate heat for various industrial processes. They are typically made from materials with high electrical resistance, such as nichrome, kanthal, or stainless steel, which produce heat when an electric current passes through them.

2. Types of Industrial Heating Elements

a. Tubular Heating Elements

Tubular heating elements consist of a metal sheath (usually stainless steel) encasing a heating coil or resistor. They are versatile and commonly used in applications such as water heating, air heating, and process heating due to their durability and high heat transfer efficiency.

b. Cartridge Heating Elements

Cartridge heating elements are cylindrical in shape and contain a heating coil embedded in a ceramic or metal cartridge. They are used in applications requiring high temperatures and precise heat distribution, such as injection molding, hot stamping, and packaging equipment.

c. Band Heating Elements

Band heating elements wrap around cylindrical or flat surfaces to provide direct heating. They are used in applications such as plastic extrusion, injection molding, and food processing, where uniform and controlled heating is essential for product quality.

3. Applications of Industrial Heating Elements

a. Manufacturing Processes

Enclosure heater with thermostat are widely used in manufacturing processes such as molding, extrusion, forging, and annealing. They provide the necessary heat for shaping, curing, and finishing various materials and products.

b. Chemical Processing

In chemical processing plants, heating elements are employed for tasks such as heating reactors, distillation columns, and heat exchangers. They facilitate chemical reactions, separation processes, and temperature control in diverse chemical processes.

c. Food and Beverage Industry

Industrial heating elements play a vital role in the food and beverage industry for applications such as cooking, baking, drying, and sterilization. They ensure the safe and efficient production of food products while maintaining quality and compliance with hygiene standards.

Key Considerations for Selection and Maintenance

1. Temperature Range and Power Rating

When selecting industrial heating elements, consider the required temperature range and power rating to ensure compatibility with the intended application and operating conditions.

2. Material Compatibility

Choose heating elements made from materials that are compatible with the heating medium and operating environment to prevent corrosion, contamination, or degradation.

3. Installation and Mounting Options

Consider the installation and mounting options available for different types of heating elements, such as flange mounting, threaded connections, or clamping mechanisms, to ensure ease of installation and maintenance.

4. Maintenance and Inspection

Regular maintenance and inspection of industrial heating elements are essential to ensure optimal performance and longevity. Inspect for signs of wear, damage, or corrosion, and replace any faulty components promptly to prevent downtime and maintain productivity.

Conclusion

In conclusion, industrial heating elements are indispensable components of heating systems used across various industries. Whether it's tubular heating elements for general heating applications, cartridge heating elements for high-temperature processes, or band heating elements for precise heating requirements, selecting the right heating element is crucial for achieving optimal performance and efficiency in industrial operations. By understanding the types, applications, and key considerations for selection and maintenance of industrial heating elements, businesses can ensure reliable and effective heat generation for their manufacturing processes.

0 notes

Text

Industrial Heaters: Essential Solutions for Diverse Applications

Industrial heaters play a critical role in a variety of manufacturing processes, ensuring the efficient functioning of systems in industries like chemical processing, food production, pharmaceuticals, and more. These heaters are designed to provide consistent and controlled heating, which is crucial for maintaining optimal temperatures for production processes, drying, curing, and other tasks. The demand for industrial heaters has increased significantly, with more industries turning to specialized heaters to meet their specific needs.

Types of Industrial Heaters

Industrial heaters come in various types, each designed for specific applications. The most common types of industrial heaters include:

Electric Heaters: These heaters are widely used for applications requiring precise temperature control. Electric heaters are renowned for their dependability, straightforward installation, and low maintenance requirements.They are available in different forms such as strip heaters, band heaters, and tubular heaters.

Gas Heaters: These heaters operate by burning natural gas or propane to generate heat. Gas heaters are commonly used in large-scale industrial applications where high temperatures are needed. They are ideal for industries such as metalworking, chemical processing, and textiles.

Oil Heaters: These heaters utilize oil as the medium to transfer heat. They are preferred for their high thermal efficiency and ability to operate at high temperatures. Oil heaters are commonly found in the chemical and pharmaceutical industries.

Immersion Heaters: These heaters are submerged directly into the liquid to heat it. They are used in tanks or vessels containing liquids like water, oil, and other chemicals. Immersion heaters are essential in industries that deal with liquid heating.

Air Heaters: These heaters are used for heating air in ventilation systems. They are typically used in large factories or warehouses where maintaining a constant temperature is vital for product quality and employee comfort.

Importance of Industrial Heaters

The importance of industrial heaters cannot be overstated. They ensure that industrial operations run smoothly by maintaining the required temperature conditions. For example, in the food industry, heaters are used to pasteurize products or maintain a consistent temperature during cooking or drying. In the chemical industry, heaters provide the heat needed for reactions or distillation processes.

Industrial heaters are also essential for maintaining energy efficiency. They help companies optimize their energy usage by ensuring that the heating process is carried out in the most efficient manner possible. Many modern industrial heaters are designed with advanced features such as thermostats, temperature controllers, and energy-saving modes to minimize energy consumption.

Choosing the Right Heater

When selecting an industrial heater, several factors need to be considered:

Heating Capacity: The heater must be capable of providing the required temperature for the specific application. A heater that is too small will struggle to reach the desired temperature, while a heater that is too large may result in energy wastage.

Material Compatibility: Different heaters are suited to different materials. It's crucial to choose a heater that is compatible with the material being heated, whether it's metal, liquid, or air.

Energy Efficiency: Industrial heaters can consume a significant amount of energy. Opting for energy-efficient models can reduce operating costs in the long run.

Safety Features: Since heating equipment can pose safety risks, selecting heaters with safety features such as over-temperature protection, safety shutoffs, and insulation is important.

Heaters Suppliers in India

India is home to numerous reputable heaters suppliers who offer a wide range of industrial heating solutions. These suppliers provide high-quality products tailored to meet the specific needs of industries across the country. The industrial heating market in India has seen substantial growth, driven by increased demand for energy-efficient and cost-effective heating solutions.

Heaters suppliers in India are equipped with state-of-the-art technology to manufacture heaters that comply with international quality standards. These suppliers offer a variety of industrial heaters, ranging from electric and gas heaters to more specialized units like immersion and air heaters. Many suppliers also provide custom solutions to cater to unique industrial requirements.

Moreover, with the growing emphasis on sustainability and reducing energy consumption, heaters suppliers in India are focusing on developing products that are energy-efficient, cost-effective, and environmentally friendly. Many suppliers also offer services such as installation, maintenance, and after-sales support, ensuring that customers get the most out of their investment.

Conclusion

Industrial heaters are integral to the smooth functioning of various industries, providing efficient and controlled heating solutions. From food processing to chemical manufacturing, heaters ensure that the right temperatures are maintained for optimal product quality and process efficiency. Choosing the right heater depends on factors such as heating capacity, material compatibility, energy efficiency, and safety features. With numerous heaters suppliers in India offering advanced, customized, and energy-efficient solutions, businesses can find the perfect heater to meet their specific needs and enhance their operations. As industries continue to evolve, the demand for industrial heaters is set to rise, and suppliers in India are well-positioned to meet these needs with high-quality, reliable, and cost-effective heating solutions.

0 notes

Text

A Detailed Guide to Industrial Heaters

Introduction

Industrial heaters are indispensable in various manufacturing and processing industries, providing the essential heat needed for processes ranging from drying to intricate chemical reactions. This guide delves into the different types of industrial heaters, their applications, and important factors to consider when selecting the appropriate heater for your specific requirements.

Types of Industrial Heaters

Electric Heaters:

Resistance Heaters: These heaters produce heat through electrical resistance. Common variants include strip heaters, tubular heaters, and cartridge heaters, typically used in plastic molding and packaging.

Induction Heaters: They generate heat using electromagnetic fields to warm conductive materials, commonly used in metalworking for processes like forging and annealing.

Infrared Heaters: Emit infrared radiation to heat objects directly, making them ideal for paint curing and drying tasks.

Gas-Fired Heaters:

Direct-Fired Heaters: These allow combustion gases to come into direct contact with the material being heated, suitable for large spaces like warehouses and greenhouses.

Indirect-Fired Heaters: Use a heat exchanger to keep combustion gases separate from the process air, which is essential in environments where contamination must be avoided, such as in food processing.

Oil-Fired Heaters:

These heaters are typically used in locations where natural gas is unavailable and are commonly employed in the oil and gas industry to heat drilling fluids and other processes.

Steam Heaters:

These heaters use steam as the heating medium and are often found in industries where steam is readily available, such as chemical processing and food manufacturing.

Circulation Heaters:

Designed to heat a flowing liquid or gas, these heaters are used in applications like water heating, fuel oil heating, and viscous fluid heating.

Applications of Industrial Heaters

Manufacturing: Heating for molding, extrusion, and curing processes.

Food Processing: Employed in pasteurization, drying, and baking.

Chemical Processing: Used for reactor heating, distillation, and evaporation.

Oil and Gas: Essential for heating pipelines, drilling fluids, and tanks.

HVAC: Utilized in space heating and air handling units.

Selecting the Right Industrial Heater

When choosing an industrial heater, several factors must be considered:

Temperature Requirements: Identify the exact temperature needed for your application, as different heaters offer various temperature ranges.

Medium to be Heated: Determine whether you need to heat air, liquid, or solid materials, as each medium requires specific heater types for efficient heating.

Environment: Consider whether the heater will be used indoors or outdoors and any potential hazardous conditions.

Energy Source: Choose between electric, gas, or oil-fired heaters based on the availability and cost of energy sources.

Control Requirements: Assess the level of control needed; some processes require precise temperature control, while others are more flexible.

Installation and Maintenance: Evaluate the ease of installation and maintenance, as some heaters may require more frequent maintenance than others.

Future Trends in Industrial Heating

Energy Efficiency: Advances in materials and technology are leading to more energy-efficient heaters, reducing operational costs and environmental impact.

Automation: Integration with IoT and smart technologies for automated monitoring and control, enhancing precision and efficiency.

Sustainable Energy Sources: Increasing use of renewable energy sources, such as solar-powered industrial heaters.

Conclusion

Industrial heaters are vital for numerous industrial processes, ensuring efficient and effective operations. By understanding the various types of heaters, their applications, and the key considerations for selection, businesses can make informed decisions to optimize their processes. With technological advancements, the future of industrial heating promises greater efficiency, automation, and sustainability.

#business#ecommerce#b2bmarketing#industrial heater#Immersionheaters#Tubularheaters#CeramicBandHeaters#ihm#ihmonline

1 note

·

View note