#trimethylbenzene

Explore tagged Tumblr posts

Text

The 10 hydrocarbons found in highest concentration are listed in Table 4.2.

"Environmental Chemistry: A Global Perspective", 4e - Gary W. VanLoon & Stephen J. Duffy

#book quotes#environmental chemistry#nonfiction#textbook#hydrocarbons#voc#volatile organic compounds#taipei#toluene#xylene#benzene#ethylbenzene#trimethylbenzene#ethyl methylbenzene#hexane#heptane

0 notes

Text

Investigating Market Drivers in the Mesitylene Industry

Mesitylene and Its Unique Structural and Chemical Properties

Introduction

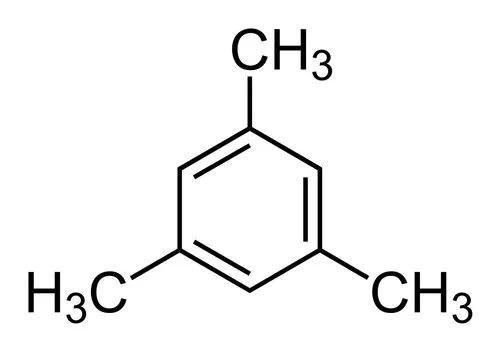

Mesitylene, also known as 1,3,5-trimethylbenzene, is an organic compound composed of an aromatic benzene ring where three of the hydrogen atoms are substituted with methyl groups. It is a colorless liquid with a mild petroleum-like odor. 1,3,5-trimethylbenzene occurs naturally in coal tar and petroleum, but it can also be synthesized in a laboratory through various chemical processes. This compound exhibits distinctive molecular structure and reactivity patterns that make it useful for both industrial and research applications.

Molecular Structure

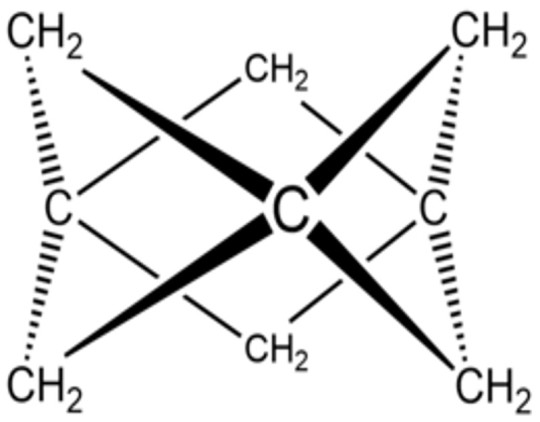

1,3,5-trimethylbenzene has a unique molecular shape compared to other substituted benzenes. The three methyl groups are evenly positioned around the benzene ring at the 1, 3, and 5 positions. This symmetric arrangement makes 1,3,5-trimethylbenzene a planar, non-chiral molecule with D3h point group symmetry. The methyl substituents cause the benzene ring to be electron rich, stabilized by inductive and mesomeric effects. This extra stabilization means 1,3,5-trimethylbenzene is more resistant to electrophilic aromatic substitution than benzene itself. The symmetry and steric effects of the methyl groups also influence the compound’s reactivity towards specific reaction sites on the ring.

Spectroscopic Analysis

Modern analytical techniques have provided deeper insight into mesitylene’s molecular and electronic structure. NMR spectroscopy effectively distinguishes between protons on the ring versus those on the methyl groups. Signals from the equivalent ring protons appear as a singlet, while methyl protons show an AA’BB’ spin system. IR and Raman spectroscopy detect the characteristic vibrational modes of aromatic and alkane functional groups in 1,3,5-trimethylbenzene.

Perhaps the most useful information comes from UV-Vis spectroscopy. The absorption spectrum exhibits intense π-π* and n-π* transition bands in the ultraviolet region. Compared to benzene, these bands are red-shifted due to delocalization of the methyl substituent’s electrons into the aromatic π system. Computational methods can simulate 1,3,5-trimethylbenzene electronic structure and optimize geometric parameters like bond lengths, angles and torsional angles between substituents. Combined spectroscopic-computational analyses verify 1,3,5-trimethylbenzene properties on a fundamental quantum mechanical level.

Conclusion

In summary, mesitylene displays a unique arrangement with three methyl groups evenly positioned around a benzene ring that lends it distinctive structural and chemical characteristics. Its industrial uses leverage properties impacted by this symmetric molecular framework. Spectroscopic tools reveal electronic structure insights complementing theoretical models. Continued investigation of 1,3,5-trimethylbenzene properties enhances our understanding of substituted aromatics and structure-reactivity principles with applications in synthetic chemistry.

0 notes

Text

Toluene and Derivatives Market Analysis: Assessing Growth Opportunities

Toluene and its derivatives are essential chemicals with diverse industrial applications, playing crucial roles in sectors such as chemicals, petrochemicals, paints, coatings, and pharmaceuticals. This blog explores the dynamics of the global toluene and derivatives market, analyzing key drivers, applications across industries, emerging trends, and future growth opportunities.

Understanding the Toluene and Derivatives Market:

Toluene (C7H8) is a colorless, aromatic hydrocarbon solvent derived from petroleum and coal tar. It serves as a precursor for various chemicals and industrial products, including benzene, xylene, toluene diisocyanate (TDI), and trimethylbenzene, among others.

Market Dynamics:

Benzene and Xylene Production: Toluene is a primary raw material in the production of benzene and xylene, which are essential chemicals used in manufacturing plastics, resins, synthetic fibers, and pharmaceuticals.

Toluene Diisocyanate (TDI) Production: Toluene is a key feedstock for the production of TDI, a crucial component in polyurethane foams, coatings, adhesives, and flexible foam products used in construction, automotive, and furniture industries.

Solvents and Coatings: Toluene finds extensive use as a solvent in paints, coatings, adhesives, inks, and cleaning agents due to its excellent solvency properties, fast evaporation rate, and compatibility with various resins.

Pharmaceuticals and Chemicals: Toluene derivatives are utilized in the production of pharmaceuticals, dyes, explosives, rubber chemicals, and specialty chemicals, contributing to diverse industrial applications.

Applications Across Industries:

Chemicals and Petrochemicals: Benzene, xylene, TDI, trimethylbenzene production.

Coatings and Paints: Solvent in paints, coatings, adhesives, and inks.

Polyurethane Industry: TDI for polyurethane foams, sealants, and adhesives.

Pharmaceuticals and Specialty Chemicals: Intermediate chemicals for various applications.

Market Trends:

Focus on Sustainable Feedstocks: Industry shifts towards bio-based and renewable feedstocks for toluene derivatives production to align with sustainability goals and reduce environmental impact.

Technological Advancements: Innovations in production processes, catalyst technologies, and recycling methods enhance efficiency, reduce costs, and promote circular economy practices in the toluene and derivatives market.

Regulatory Compliance: Stringent regulations and standards related to chemical safety, emissions, and product quality drive investments in cleaner production methods and product innovations.

Future Prospects:

The global toluene and derivatives market is poised for continued growth, driven by increasing demand from key industries, technological advancements, and sustainability initiatives. Investments in R&D, green chemistry, and circular economy models will shape the market's evolution and competitiveness.

Conclusion:

Toluene and its derivatives play indispensable roles in various industrial sectors, offering versatile solutions for chemical manufacturing, coatings, polyurethane production, and specialty chemicals. Navigating the market requires awareness of trends, regulatory landscapes, and technological innovations. With a focus on sustainability, innovation, and market diversification, the toluene and derivatives market presents promising opportunities for growth and advancements in global industrial processes and products.

0 notes

Text

Analyzing Mesitylene Production Cost Report

Latest report titled “Mesitylene Production Cost Report” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Mesitylene. Mesitylene, also known as 1,3,5-trimethylbenzene, is an aromatic hydrocarbon compound with various industrial applications, including as a solvent, intermediate in chemical synthesis, and component in fuel additives. Understanding the production cost of mesitylene is essential for manufacturers to ensure profitability, competitiveness, and sustainability. This article aims to explore the intricacies of mesitylene production cost, examining the underlying factors, recent trends, and strategies for cost optimization.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/mesitylene/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Mesitylene production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of Mesitylene Production Process:

From Distillation Process: This report presents the detailed production methodology and cost analysis of Mesitylene industrial production across Mesitylene manufacturing plants. The production process begins with the treatment of acetone with sulfuric acid, where sulfuric acid acts as a dehydrating agent. This reaction causes the distillation of acetone, ultimately yielding mesitylene or 1,3,5-trimethylbenzene as the final product.

Product Definition:

Mesitylene, or 1,3,5-trimethylbenzene, is an aromatic hydrocarbon with the chemical formula C9H12. It is a colorless, flammable liquid with a distinctive odor, consisting of a benzene ring with methyl groups attached at the 1st, 3rd, and 5th positions. Insoluble in water, it is soluble in various organic solvents such as ethanol, ethyl ether, and acetone. Mesitylene's melting and boiling points are approximately -44.8 °C and 164.7 °C, respectively, with a density of 0.86 g/cm3 at 25 °C. Primarily used as a chemical intermediate and solvent, mesitylene is vital in the production of coatings, printing chemicals, sealants, and adhesives. It serves as a combustible additive in fuels and finds applications in plastics, dyestuffs, inks, and toners. Naturally occurring in coal tar, mesitylene is also synthetically produced by distilling acetone. Its versatility and role in various chemical processes make it a valuable compound in the chemical industry.

Market Drivers:

The demand for mesitylene is primarily driven by its role as a chemical solvent in various downstream industries, including dyestuffs, plastics, and petrochemicals. Its use in formulating adhesives, sealants, and dyestuff chemicals contributes significantly to its demand in the chemical market. Additionally, its incorporation in the production of petrochemicals and fuels enhances its global demand. Mesitylene is characterized as a volatile and combustible fluid with strong solvency properties. Its applications in manufacturing plastics, coating chemicals, and derivatives like mesityl oxide further bolster its demand and impact its overall procurement.

1. Overview of Mesitylene Production:

Mesitylene can be produced through several methods, including the catalytic alkylation of benzene with propylene, the thermal cracking of hydrocarbons, and the dehydrogenation of 2,4,6-trimethylcyclohexanone. Among these methods, catalytic alkylation is the most common industrial process for mesitylene production.

Catalytic Alkylation Process:

Raw Material Preparation: The primary raw materials for mesitylene production include benzene and propylene. Benzene, a widely available aromatic hydrocarbon, serves as the aromatic ring precursor, while propylene, a by-product of petroleum refining, acts as the alkylating agent.

Alkylation Reaction: Benzene and propylene are fed into a reactor containing a solid acid catalyst, such as aluminum chloride or zeolites. Under controlled temperature and pressure conditions, propylene reacts with benzene to form mesitylene and other alkylated benzene compounds.

Separation and Purification: The reaction mixture undergoes separation to isolate mesitylene from other reaction products and unreacted starting materials. Separation techniques such as distillation, extraction, and chromatography are employed to purify mesitylene to the desired level.

Refining and Quality Control: The purified mesitylene undergoes further refining steps to remove impurities and ensure product quality. Quality control measures, including analytical testing and certification, verify compliance with industry standards and specifications.

Packaging and Distribution: The refined mesitylene is packaged into drums, containers, or tankers for distribution to end-users in various industries, including chemical manufacturing, pharmaceuticals, and coatings.

2. Factors Influencing Mesitylene Production Cost:

Several factors influence the production cost of mesitylene:

Raw Material Costs: The prices of raw materials such as benzene and propylene directly impact production costs. Fluctuations in raw material prices, influenced by market demand, supply availability, and geopolitical factors, can affect overall production expenses.

Catalyst Usage and Regeneration: The cost of solid acid catalysts used in the alkylation process, as well as the frequency of catalyst regeneration or replacement, impact production costs. Catalyst efficiency, activity, and stability are critical factors affecting process economics.

Energy Consumption: The production process involves energy-intensive operations such as heating, mixing, and distillation. Energy costs, including electricity, steam, and fuel, significantly contribute to production expenses and are subject to market fluctuations.

Process Efficiency: The efficiency of the alkylation reaction, separation, and purification processes affects production yields, product quality, and resource utilization. Optimization of reaction conditions, catalyst activity, and process parameters can improve efficiency and reduce production costs.

Labor Costs: Skilled labor is required for operating production equipment, monitoring processes, and performing quality control tests. Labor costs, including wages, benefits, and training expenses, constitute a significant portion of production costs.

3. Recent Trends in Mesitylene Production Cost:

Recent trends in the chemical industry have influenced mesitylene production costs:

Technological Advancements: Advances in catalysis, process intensification, and automation have improved production efficiency and reduced costs. Continuous innovation in catalyst design, reactor engineering, and control systems contributes to cost competitiveness.

Feedstock Availability: Changes in the availability and pricing of feedstocks such as benzene and propylene, driven by shifts in petrochemical markets and refining capacities, impact production costs and supply chain dynamics.

Environmental Regulations: Compliance with environmental regulations, including emissions standards, waste management, and sustainability initiatives, necessitates investments in pollution abatement measures and regulatory compliance monitoring, increasing production costs.

Market Demand and Competition: Fluctuations in market demand, competitive pressures, and changing customer preferences influence pricing strategies and cost optimization efforts among mesitylene manufacturers. Cost-effective production methods and value-added services are essential for maintaining market share and profitability.

4. Strategies for Cost Optimization:

To optimize mesitylene production costs, manufacturers can implement various strategies:

Raw Material Optimization: Explore alternative feedstock sources, negotiate favorable pricing terms with suppliers, and invest in feedstock diversification to mitigate price volatility and supply chain risks.

Catalyst Selection and Regeneration: Evaluate catalyst performance, activity, and longevity to minimize catalyst usage and regeneration costs. Invest in catalyst research and development to improve efficiency and reduce catalyst-related expenses.

Energy Efficiency: Implement energy-saving technologies, equipment upgrades, and heat integration strategies to reduce energy consumption and lower operating costs. Conduct energy audits and optimization studies to identify opportunities for efficiency improvements.

Process Optimization: Continuously optimize reaction conditions, process parameters, and purification techniques to improve yield, selectivity, and product quality while reducing resource consumption and waste generation.

Supply Chain Management: Streamline supply chain logistics, optimize inventory management, and foster strategic partnerships with suppliers and distributors to reduce transportation costs and minimize supply chain disruptions.

Conclusion:

In conclusion, the production cost of mesitylene is influenced by a multitude of factors, including raw material costs, catalyst usage, energy consumption, process efficiency, and market dynamics. By understanding these factors and implementing strategic approaches for cost optimization, manufacturers can enhance competitiveness, improve profitability, and ensure the affordability and availability of mesitylene for various industrial applications. Continuous innovation, process optimization, and sustainability initiatives are essential for navigating challenges and sustaining long-term success in the mesitylene production industry.

Contact Us:

Company Name: Procurement Resource Contact Person: Leo Frank Email: [email protected] Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes

Text

Future-proofing Strategies in the Mesitylene Market

The Unique Properties of Mesitylene: An Organic Chemical Compound What is Mesitylene? Mesitylene, also known as 1,3,5-trimethylbenzene, is an organic compound consisting of a benzene ring with three methyl substituents arranged symmetrically around the ring. It is a clear, colorless liquid that is insoluble in water but soluble in organic solvents. Mesitylene is classified as an aromatic hydrocarbon and is rarely found in its unsubstituted form in nature. Chemical and Physical Properties Mesitylene has the chemical formula C9H12 and a molar mass of 120.194 g/mol. It is a component of various essential oils obtained from plants and it has a sweet, pleasant odor often described as reminiscent of hay or grass. Mesitylene is denser than water with a density of around 0.86 g/cm3. Its melting point is -35°C and boiling point is 165°C. Being an asymmetric molecule, mesitylene exists as three structural isomers - 1,3,5-trimethylbenzene, 1,2,4-trimethylbenzene, and 1,2,3-trimethylbenzene. However, 1,3,5-trimethylbenzene is the most stable and predominant isomer found in nature. Production and Industrial Uses Commercially, mesitylene is produced through catalytic methylation of toluene or disproportionation of xylenes. It finds a variety of industrial applications where its properties as a non-polar organic solvent are exploited. Mesitylene is used as an intermediate in the synthesis of dyes, pharmaceuticals, and fragrance chemicals. Due to its inert and non-reactive nature, it is also used as a solvent in the industries that manufacture rubbers, polymers, resins, coatings, and agrochemicals. Mesitylene is combined with other solvents to make paint thinners and industrial degreasing formulations. It also serves as an important raw material in the production of synthetic musks and is commonly added to perfumes and incense formulations for its pleasant odor. Safety Profile and Regulations Being a hydrocarbon, mesitylene is considered combustible and somewhat toxic if inhaled or ingested in large amounts. The recommended exposure limits for mesitylene in the workplace are set at 25 ppm over an 8-hour time-weighted average by the American Conference of Governmental Industrial Hygienists (ACGIH). Short-term exposure at concentrations above 250 ppm may cause irritation to eyes and respiratory tract in humans. Mesitylene is classified by the EPA (Environmental Protection Agency) as a VOC (volatile organic compound) due to its participation in atmospheric photochemical reactions and contribution to ozone depletion and smog formation. Most regulatory agencies require the amount of mesitylene in final products to be limited or substituted wherever possible by less hazardous alternatives. Proper precautions must be taken during the industrial handling and storage of mesitylene to prevent risks to human health and environment. Uses in Flavor and Fragrance Industry Mesitylene is a widely employed chemical in the flavor and fragrance industry. Its sweet, grassy aroma makes it a popular ingredient in the formulation of several perfume types including fougères, chypres and green floral fragrances. Mesitylene is commonly formulated at levels less than 1% to reinforce the top, heart and drydown notes of fragrances. In perfumery, it is frequently combined with galaxolide, hedione and other musks to lend a natural, green touch. The olfactory properties of mesitylene are also exploited in food and beverage flavors. It finds use as a flavoring agent in candy, baked goods, chewing gum, soft drinks and many other products to contribute notes of fresh hay or green grass. Mesitylene also enhances tobacco flavors and formulations. Its solvent properties further aid in the incorporation and stabilization of other aromachemicals in liquid fragrance and flavor concentrates.

0 notes

Text

Mesitylene Market Overview: A Holistic Approach to Industry Structure and Trends

Mesitylene, also known as 1,3,5-trimethylbenzene, is an aromatic hydrocarbon compound derived from petroleum. It finds wide applications as a solvent in chemical intermediates, agrochemicals, and coatings. Due to its high solvent properties and low toxicity, mesitylene is used as an effective solvent in agricultural chemicals such as insecticides, herbicides, and fungicides. The global mesitylene market is estimated to be valued at US$ 2,814.8 Mn in 2023 and is expected to exhibit a CAGR of 3.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity: The growing demand for crop protection solutions and need to increase agricultural yields is driving the growth of agrochemicals globally. Mesitylene plays a vital role as an effective solvent in various agrochemical formulations. Its use allows for slow and controlled release of active ingredients in insecticides, herbicides and fungicides applied on crops. This helps improve the efficacy of agrochemicals and maximize crop protection. With the rising world population and need to boost food production, demand for agrochemicals is expected to grow significantly. This growing demand for agricultural chemicals will support the adoption of mesitylene as a preferred solvent, presenting key opportunities for growth in the mesitylene market over the forecast period.

Porter’s Analysis Threat of new entrants: The mesitylene market is competitive in nature due to established players. However, high capital requirements and economies of scale pose challenges for new players. Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of substitutes. However, switching costs are low. Bargaining power of suppliers: Major suppliers have significant influence due to their integration across the value chain. Suppliers can impact prices. Threat of new substitutes: Substitutes like xylenes pose medium threat as they have similar properties but are cheaper. Competitive rivalry: The market is dominated by key global players. Intense competition exists regarding pricing and new product innovations.

SWOT Analysis Strength: Mesitylene has wide industrial applications. Established production facilities and distribution networks of key players improve economies of scale. Weakness: Fluctuating raw material prices and environmental regulations increase production costs. Dependency on a few feedstocks. Opportunity: Rising plastic and solvent demand from construction and automotive industries offer scope. Growing Asia Pacific market presents new avenues. Threats: stringent emission norms hamper growth. Easy availability of substitutes is also a concern.

Key Takeaways The global mesitylene market is expected to witness high growth over the forecast period supported by rising plastic and solvent consumption.

Regional analysis: The Asia Pacific region presently accounts for over 50% of the global market share due to rapid industrialization and growth of end-use industries in China and India. Established production facilities of leading players also contribute to the region’s large share. High demand for UPR, solvents, and MTBE in construction and automotive sectors drives the regional market.

Key players operating in the mesitylene market are Mitsubishi Gas Chemical Company (MGC), Dow, Versalis, Refinery of Sinopec Jinling (Sinopec), EXXON, Shell, Nantong Dingxi, Taicang Xinhu Chemical, and Jinchou PetroChem. Mitsubishi Gas Chemical Company (MGC) is a leading producer with integrated production facilities across Asia, Europe and North America.

#Mesitylene Market Share#Mesitylene Market Growth#Mesitylene Market Demand#Mesitylene Market Trend#Mesitylene Market Analysis

0 notes

Text

0 notes

Text

Mesitylene Market Impact: Environmental and Regulatory Considerations

Mesitylene, also known as 1,3,5-trimethylbenzene, is an organic compound derived from petroleum. It is a colorless clear liquid with an aromatic odor. Mesitylene is predominantly used as an intermediate in the production of various organic compounds such as polyamides, polyolefins, solvents, and fragrances. It finds applications as a solvent in pharmaceuticals, paints, insecticides and other chemical industries due to its high solubility and low toxicity. The mesitylene market is estimated to be valued at US$ 2,814.8 Mn in 2023 and is expected to exhibit a CAGR of 3.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: Rising demand from solvents and intermediates applications is driving the mesitylene market growth. Mesitylene is majorly used as a solvent in numerous industrial applications such as petrochemicals, pharmaceuticals, agrochemicals, paints & coatings, and others due to its properties like low toxicity, stability, and high solvency. Further, it is used as an intermediate in the production of various fragrances, polyamides, and polyolefins. Growing demand for polyamides and polyolefins from end-use industries like automotive and construction is fueling the consumption of mesitylene. In addition, rapid industrialization and expansion of the chemical industry in Asia Pacific is propelling the mesitylene demand. However, availability of alternative products and stringent environmental regulations regarding VOC emissions may hamper the market growth.

0 notes

Text

0 notes

Photo

From Wikipedia:

Since the 19th century, Solvent naphtha has denoted a product (xylene or trimethylbenzenes) derived by fractional distillation from petroleum; these mineral spirits, also known as "Stoddard Solvent", were originally the main active ingredient in Fels Naptha laundry soap. The naphtha in Fels Naptha was later removed as a cancer risk.

Light naphtha is used as a fuel in some commercial applications. One notable example is wick-based cigarette lighters, such as the Zippo, which draw "lighter fluid"—naphtha—into a wick from a reservoir to be ignited using the flint and wheel.

1958 Ad, Instant Fels Naptha Laundry Soap Granules for Automatic Washing Machines by classic_film on Flickr.

“Works Wonders with Washers…” Received Good Housekeeping seal of approval Published in Good Housekeeping magazine, February 1958, Vol. 146 No. 2

20 notes

·

View notes

Text

Jun 14, 2022 (Market Insight Reports) -- Latest Report 1,3,5-Trimethylbenzene Market by Type (Aromatics Separation, Isomerization Process), By Application (Plasticizer, Stabilizer, Curing Agent, Other, and Others), and Region (North America, Latin America, Europe, Asia Pacific, and the Middle East & Africa), Forecast From 2022 To 2028

0 notes

Text

Global 1,2,4-Trimethylbenzene Market With Top countries Data : Opportunities, Industry Verticals and Forecast Assessment 2021 to 2025

Market Overview The Global 1,2,4-Trimethylbenzene Market is foreseen to experience a fall from USD XX billion in 2020 to USD XX billion in 2021 at a CAGR of XX%. The descent is primarily the result of economic decline across countries unsettled due to ongoing Coronavirus outbreak, including controlling it. Thereafter, the 1,2,4-Trimethylbenzene market is likely to restore and expand at a CAGR of XX% from 2021, stretching up to USD XXX billion in 2024. BUY ANY 3 AND PAY FOR ONLY 2 Hurry Up To Grab This Exciting Offer…………! This Discount offer is valid till 31st March 2021 Get Free Sample Report @ https://ordientmarketresearch.com/sample-request/chemicals-and-materials/world-1-2-4-trimethylbenzene-market/OMR2155 The research document comprises market traits, opportunities, industry size, fragmentation, territorial breakdowns, market shares, ongoing trends, competitive landscape, and strategies for the 1,2,4-Trimethylbenzene market. The report also tracks essential information about the market and predict market expansion by the geographic landscape. It also positions the market under the extensive 1,2,4-Trimethylbenzene market framework and collates it with other alternative markets. This report also offers the planners, policymakers, senior leadership, and traders crucial details to estimate the global 1,2,4-Trimethylbenzene market as it arises from the COVID-19 closure. Market Scope The 1,2,4-Trimethylbenzene Industry sets out tendencies that affect various subsidiary industries. Therefore, the Global market has ruled for being one of the leading revenue generators over the past several decades. This industry has challenged every economic disruption and withstands the test of time. Though this could benefit to motivate new market players in the Global industry, the preference for product development and novel procedures could assist new participants in obtaining a stronghold. Browse Full Premium Report @ https://ordientmarketresearch.com/chemicals-and-materials/world-1-2-4-trimethylbenzene-market/OMR2155 1,2,4-Trimethylbenzene Market Research Report is Segmented as Follows: Product Types can be segregated as: Type 1 Type 2 Type 3 Applications can be segregated as: produce trimellitic anhydride produce mesitylene producing durene others Regions covered in this report are: North America United States Canada Europe Germany France U.K. Italy Russia Nordic Rest of Europe Asia-Pacific China Japan South Korea Southeast Asia India Australia Rest of Asia-Pacific Latin America Mexico Brazil Middle East & Africa Turkey Saudi Arabia UAE Rest of Middle East & Africa Checkout Inquiry For Buying or Customization of 1,2,4-Trimethylbenzene Market: https://ordientmarketresearch.com/enquiry/chemicals-and-materials/world-1-2-4-trimethylbenzene-market/OMR2155 Global 1,2,4-Trimethylbenzene Market Report provide in-depth information about the Leading Competitors involved in this report: FHR Eni Xinjiang Tianli Jinyang Chemical Jiangsu Hualun Jinling Petrochemical Lanzhou Petrochemical Jiangsu Zhengdan Nanjing Refinery Innovations in the technology field have contributed to the growth of the Global industry. The arrival of energy- and cost-efficient appliances have rejuvenated procedures in the 1,2,4-Trimethylbenzene industry. Economic expansion in developing countries as well have arisen as an advantage for the Global industry. Although strict rules that supervise global production and processing affect the growth rate of the Global industry. Enquire about Discount for This Report @ https://ordientmarketresearch.com/check-discount/chemicals-and-materials/world-1-2-4-trimethylbenzene-market/OMR2155 Reasons to buy this report: Obtain a genuinely global viewpoint along with the most extensive report obtainable on the 1,2,4-Trimethylbenzene market, including more than 50 ecologies. Develop regional and territorial schemes depending on local data and research. Recognize customers and clients based on the most recent market survey outcomes. Make use of the links between primary datasets for top-cl

#Global 1#2#4-Trimethylbenzene Market#1#4-Trimethylbenzene#4-Trimethylbenzene Market Comprehensive Analysis#4-Trimethylbenzene Market Comprehensive Report#4-Trimethylbenzene Market Forecast#4-Trimethylbenzene Market Forecast to 2028#4-Trimethylbenzene Market Growth#4-Trimethylbenzene Market in Asia#4-Trimethylbenzene Market in Australia#4-Trimethylbenzene Market in Canada#4-Trimethylbenzene Market in Europe#4-Trimethylbenzene Market in France#4-Trimethylbenzene Market in Germany#4-Trimethylbenzene Market in Israel#4-Trimethylbenzene Market in Japan#4-Trimethylbenzene Market in Key Countries#4-Trimethylbenzene Market in Korea#4-Trimethylbenzene Market in United Kingdom#4-Trimethylbenzene Market in United States#4-Trimethylbenzene Market Report#4-Trimethylbenzene Market Research#COVID 19 impact on 1

0 notes

Link

Excerpt from this story from Truthout:

State lawmakers in Pennsylvania are demanding an investigation into the public health impacts of fracking after a new study found evidence of harmful chemicals accumulating in the bodies of children and their families living near fracking wells in communities inundated by fossil fuel development.

Environmental Health News, a nonprofit news organization, released a series of in-depth reports last week based on a two-year study of fracking pollution in Pennsylvania’s Westmoreland County and Washington County, two heavily fracked counties in a state that has been at the epicenter of the shale gas boom for over a decade. Backed by an independent review board of scientists, watchdog journalists found toxic chemicals associated with fracking in air and water samples at levels that exceeded safety thresholds.

The study also found evidence that people living near gas wells and other fracking infrastructure bear a “body burden” from fracking in the form of industrial pollutants such as benzene, ethylbenzene, styrene and toluene that were detected in their bodies at elevated levels. Families living closer to fracking wells also had higher levels of chemicals, such as 1,2,3-trimethylbenzene, 2-heptanone and naphthalene, than families living further away. These compounds are linked to irritation of the skin, eyes and digestive track, along with a host of health problems associated with exposure to fracking chemicals and emissions.

The study’s scope is small — five households within a few miles of fracked natural gas wells — and the authors caution that more research is needed to show that the pollutants found in the bodies of residents came from the fracking industry. However, the study adds to a large body of research linking fracking to a variety of health problems ranging from asthma and migraines to cancer and increased infant mortality that has only grown as the fracking boom transformed large swaths of the United States over the past decade and as fossil fuel production skyrocketed. In Pennsylvania, research shows that low-income and rural families are most likely to be exposed to fracking pollution.

6 notes

·

View notes

Text

Future-Proofing Strategies for Businesses in the Mesitylene Market: A Roadmap to Success

Market Overview:

Mesitylene, also known as 1,3,5-trimethylbenzene, is an aromatic hydrocarbon. It is a colorless liquid that is widely used as a precursor in various industries such as solvents, gasoline additives, construction chemicals, and others.

Market Dynamics:

The demand for mesitylene is projected to increase significantly owing to expanding solvent applications in the paints & coatings industry. Mesitylene is primarily used as a solvent in paints & coatings due to its ideal evaporation rate and low odor. It is employed in formulations to decrease surface tension and improve adhesion. Furthermore, mesitylene also finds application as a gasoline additive to enhance the octane number. The growing petrochemical industry along with expansion of gasoline additive application is anticipated to propel the mesitylene market growth over the forecast period 2023-2030.

Major Driver: High demand from technical textiles industry boosting mesitylene market growth

The technical textiles industry has been witnessing strong growth over the past few years owing to wide application of textiles in various industries such as automotive, construction, agriculture and healthcare. Mesitylene is used as a solvent in the coating of technical textiles used in the manufacturing of various materials like conveyor belts, automotive filters and geosynthetics. Due to expansion of end use industries, the demand for technical textiles has surged globally which in turn is fueling consumption of mesitylene. Furthermore, mesitylene based coatings provide properties like durability, thermal and chemical resistance which makes technical textiles suitable for harsh and demanding industrial applications. Thus, the rising need for high performance technical textiles from different sectors is a major factor positively impacting the mesitylene market.

Significant Driver: Increasing demand from agrochemical industry augmenting mesitylene market growth

Agrochemicals have widespread application as pesticides, herbicides and fungicides in crop protection. Mesitylene is primarily consumed in the production of various agrochemical intermediates which are further used in formulation of agrochemical products. Changing weather conditions and growth in global population have intensified the need for higher agricultural yields, thereby driving the agrochemicals industry. With advancement of modern farming practices and awareness among farmers regarding crop protection measures, the agrochemical industry is witnessing steady expansion. Consequently, there is growing demand for mesitylene from this end-use sector. Thus, the rising consumption of agrochemicals globally acts as a prominent driver bolstering the mesitylene market.

Major Restrain: Stringent environmental regulations on VOC emissions limiting mesitylene usage

Mesitylene is classified as a volatile organic compound (VOC) due to its high vapor pressure and low water solubility. Excessive emissions of VOCs are hazardous for both environment and human health as they contribute to increased ground level ozone formation. Stringent norms by environmental agencies across the globe to curb VOC emissions from industrial facilities are restricting the use of mesitylene in various applications. For example, in Europe emission limit for VOCs has been set at 20 mg/Nm3 for coating processes under the directive on industrial emissions. Similarly, in countries like US and Canada, mesitylene usage is regulated under provincial and national VOC regulations. Thus, the tightening environmental oversight on VOC releasing industries poses a major challenge for mesitylene market.

Notable Opportunity: Potential applications in fuel additives and lubricants boosting demand

Mesitylene is emerging as a potential feedstock for manufacturing fuel and lubricant additives in industrial and automotive sectors owing to its physical and chemical properties. It can be utilized as a high-octane blending component in gasoline along with other oxygenated compounds. In addition, mesitylene based aromatic solvents effectively dissolve additives and impart viscosity index improvers in lubricating oils and greases. With automobile production rising consistently worldwide, demand for high quality fuels and lubricants is increasing. Furthermore, stringent fuel economy and emission standards by automakers are promoting the need for advanced fuel and lubricant formulations. This growing requirement for performance additives presents a new opportunities space for mesitylene producers and manufacturers.

Major Trend: Shift towards bio-based and hybrid mesitylene production technologies

Currently mesitylene is produced commercially through catalytic reforming of petroleum-derived aromatics or toluene disproportionation process which rely heavily on non-renewable crude oil. However, depleting fossil fuel reserves and rising environmental consciousness are prompting researchers to explore sustainable alternatives for mesitylene manufacturing. Leading companies in the market are investing in R&D activities to develop economical bio-based and hybrid mesitylene production technologies. For instance, Lanxess has introduced a hybrid route involving coupling of isoamylene, a bio-derived component, over zeolite catalysts to synthesize mesitylene. Similarly, green technologies based on lignin depolymerization or catalytic isomerization of plant-derived terpenes offer renewable pathways for mesitylene synthesis. Such emerging bio-friendly production methods will promote the market's transition towards a greener future.

#Mesitylene Market Share#Mesitylene Market Growth#Mesitylene Market Demand#Mesitylene Market Trend#Mesitylene Market Analysis

0 notes

Text

0 notes

Text

Excell Reports : Global 2-methoxy-1,3,5-trimethylbenzene (CAS 4028-66-4) Industry Trends and Forecast 2019–2025

Excell Reports has released its latest research-based report entitled “2-methoxy-1,3,5-trimethylbenzene (CAS 4028-66-4)” Market.' This comprehensive report provides a holistic approach to the market growth with a detailed and precise analysis of the overall competitive scenario of the “2-methoxy-1,3,5-trimethylbenzene (CAS 4028-66-4)” market worldwide along with the key trends and latest technologies, playing a prominent role in the 2-methoxy-1,3,5-trimethylbenzene (CAS 4028-66-4) market growth over the forecast period.

It also takes into account the market trends, aspects such as drivers, restraints, challenges, and opportunities that impact the market and presents statistical and analytical account on it. This research report features a comprehensive discussion about the current scenario to estimate trends and prospects of the 2-methoxy-1,3,5-trimethylbenzene (CAS 4028-66-4) market. Moreover, it provides dynamic and statistical insights pertaining to the market at both regional as well as global level.

In general, chemical manufacturers are trying to overcome challenges related to continuously changing regulatory landscape and customer demands. They are trying to innovate newer models & products, find new areas of manufacturing and consolidation so as to meet more customer demands, cut down cost and gain profits. Here the value plays an important role also as this defines a holistic approach from the raw material suppliers/manufacturers to the applications in which the products are used mainly.

This report studies 2-methoxy-1,3,5-trimethylbenzene (CAS 4028-66-4) in Global market, especially in North America, South America, China, Europe, Southeast Asia, Japan and India, Saudi Arabia, South Africa, with production, revenue, consumption, import and export in these regions, from 2013 to 2018, and forecast to 2023

For Free Sample Copy, click here: https://www.excellreports.com/request-for-sample/?id=6888

#methoxy-135-trimethylbenzene (CAS 4028-66-4) Market Forecast#2-methoxy-135-trimethylbenzene (CAS 4028-66-4) Market Share#2-methoxy-135-trimethylbenzene (CAS 4028-66-4) Market Trends#2-methoxy-135-trimethylbenzene (CAS 4028-66-4) Market Demand

0 notes