#tmt manufacturers

Explore tagged Tumblr posts

Text

The Essential Role of TMT Bar Manufacturers in Producing Strong, Reliable Steel

Building something that the sands of time don't change requires very high-grade materials, especially in the case of steel reinforcement. In this regard, TMT bar manufacturers are a very important part of construction. Through advanced technology and strict quality control measures, innovative technologies develop the required backbone for modern buildings.

Understanding TMT Steel: The Foundation of Modern Construction

TMT steel, or Thermo-Mechanically Treated steel, is a product that marks the pinnacle of development in construction materials. Specialized bars are treated with a highly sophisticated cooling process, which helps create a hard outer layer and keeps the core ductile. Top TMT saria manufacturers use cutting-edge technology to achieve precise temperature control and optimum mechanical properties in every batch produced.

Raw material selection during the process primarily involves choosing high-grade raw materials and then controlling the chemical composition to achieve desired strength and durability. Every process, starting from heating to quenching, needs high expertise and better equipment for uniformity across batches.

Quality Control: The Strong Foundation of Credible TMT Saria Manufacture

Quality control within the production chain is carried out by all reliable saria manufacturers for TMT steel. This not only includes check-ups on properties like yield strength, ultimate tensile strength, and elongation. All these analyses ensure that whatever batch is available, it strictly meets or satisfies the international threshold for constructional steel.

Modern testing laboratories help in the achievement of premium steel. Assessments of TMT steel include tests such as:

Metallurgical analysis to compare chemical composition

Bend tests and rebend tests to guarantee ductility

Ultrasonic test for internal flaws

Load test to check strength parameters

Impact on Construction Safety and Durability

The quality of TMT bars directly influences the structural integrity of buildings and infrastructures. Quality TMT bar manufacturers realize this responsibility and invest heavily in research and development towards product improvement. Excellence in their operations means that construction projects benefit from steel capable of withstanding environmental stresses and maintaining structural stability for decades.

Modern TMT saria manufacturer facilities have incorporated automated production lines that minimize human error while maximizing efficiency. This technological integration helps maintain consistent quality while meeting the growing demand for construction materials in rapidly developing regions.

Environmental Considerations and Sustainable Manufacturing

Increasingly, progressive TMT steel producers focus on sustainable manufacturing practices. This includes using energy-efficient production methods, recycling water used in the cooling process, and utilizing scrap steel as raw material whenever possible. Such practices not only reduce environmental impact but also often result in cost savings that benefit end consumers.

Selecting the Right Manufacturing Partner

Construction companies and developers need to consider the following crucial factors when selecting a TMT bar manufacturer:

Manufacturing Capacity: The site should have newer equipment and regularly produce the ability to fulfill order requirements

Qualification Certificates: Reliable producers maintain up-to-date industry quality certificates and always undergo third party quality audits

Technical Support: Quality manufacturers develop extensive technical product documentation and experienced technical support regarding specific applications

Research and Innovation: Companies undertaking research and development often manufacture the best products compatible with changing requirements in construction works

Future View

The construction sector is always changing, and new problems require creative answers. Forward-thinking producers of TMT bars make investments in the creation of cutting-edge steel types with higher corrosion resistance and strength-to-weight ratios. This ensures that construction projects meet increasingly demanding architectural and engineering requirements. Building materials are the foundation of safe, robust infrastructure, and the quality of these materials lies entirely in the hands of their manufacturers. As such, with the choice of proper TMT bar manufacturers, the construction industry would receive materials bound to last for generations.

#TMT bars#steel strength#reliable steel#construction steel#TMT manufacturers#quality steel#strong steel#manufacturing#steel quality#raw materials#construction bars#durable steel#TMT production#steel process#building materials#TMT technology#steel durability#reliable bars#infrastructure steel#construction TMT#steel standards

0 notes

Text

#steel manufacturers#tmt bars manufacturer#tmt bar manufacturers#tmt bar manufacturer#TMT Bars Manufacturers#tmt manufacturers#tmt steel manufacturer#steel bar manufacturer#Tmt Manufacturers In India

0 notes

Text

How TMT Manufacturers Ensure High-Quality Standards for Safe Construction

When we talk about construction, especially for high-rise buildings, bridges, or even your own home, one thing is certain: the materials used must be strong and reliable. One of the main elements of any construction project is TMT bars (Thermo-Mechanically Treated bars). These steel bars are not just any material but are the backbone of the entire structure, providing the strength needed to withstand environmental forces and daily wear and tear. So, ensuring that these bars are of top-notch quality is critical for safe construction. The key lies in the TMT bars manufacturing process, which guarantees that the bars are strong, flexible, and long-lasting, making them perfect for all kinds of construction projects.

But how do TMT manufacturers maintain such high standards? It’s not just about putting metal through machines; there’s a lot of precision, testing, and technology to ensure these bars meet safety requirements. Here’s how they do it.

Careful Selection of Raw Materials

High-quality TMT bars start with top-grade raw materials. Manufacturers can’t just pick any steel. They use the best steel parts to ensure the bars have the right strength from the beginning. This stage is crucial because any impurity or defect in the raw material can affect the final product’s performance. Leading manufacturers test the raw materials for consistency and purity before the manufacturing process even begins. This step ensures that the TMT bars have a strong foundation on which to build.

High-Tech Manufacturing Process

The magic really happens during the manufacturing process of TMT bars. After the raw steel is melted and cast, the bars are heated to extreme temperatures and then cooled down quickly using water in a process called quenching. This rapid cooling is what gives TMT bars their unique strength and flexibility. It’s like giving the steel a tough outer shell while keeping the core flexible, which is exactly what makes TMT bars so resistant to bending, breaking, or corrosion.

What makes this process even more impressive is the precision involved. Manufacturers use advanced technology to control the temperature and cooling rate, ensuring the bars are consistently strong throughout. If the cooling is too fast or too slow, the bar won’t have the desired strength, which is why experienced TMT manufacturers take extra care during this critical step.

Strict Quality Testing

Every TMT bar goes through a series of rigorous tests before it’s ready to hit the market. These tests ensure that the bars meet all safety standards and can handle the stress they’ll be exposed to in real-world construction. For example, one of the key tests is the bend and re-bend test, which checks if the bar can bend without cracking or losing its shape. This is especially important in areas that face seismic activity, where flexibility can prevent buildings from collapsing during earthquakes.

Additionally, manufacturers test for tensile strength (how much the bar can stretch before breaking) and elongation (how much it can bend without losing strength). By putting the bars through such tough testing, manufacturers ensure that every bar that leaves their facility can handle the demands of any construction project.

Following Industry Standards

Reputable TMT manufacturers like JSW ensure that their products meet national and international standards. In India, for example, TMT bars are often manufactured according to the IS 1786 standard, which specifies the requirements for high-strength steel bars. These standards help ensure that the bars are strong, consistent, and safe for construction projects.

So, the safety of any building or structure depends heavily on the quality of the materials used, and TMT bars play a huge role in this. The TMT bars manufacturing process is designed with precision and care, ensuring that the bars are strong, flexible, and reliable. From selecting the best raw materials to using advanced technology and conducting rigorous tests, the manufacturers take every step to ensure that the bars meet high-quality standards. This commitment to quality not only makes construction safer but also helps build structures that last for decades.

0 notes

Text

Birla TMT Bars: The Symbol of Excellence in India

Birla TMT Bars: The Symbol of Excellence in India. Birla TMT Steel offers the strongest and highest quality thermo-mechanically trusted steel in India. With competitive pricing and ISO certification, their bars provide exceptional strength and temperature resistance, making them ideal for construction projects. https://www.comaron.com/blog/birla-tmt-steel-price-today

#saria price today#tmt bar#12mm steel rod price per kg#saria price#tmt bar rates today#steel bar rates today#construction steel bar#tmt manufacturers#Sariya TMT Steel#tmt steel company#sariya ka price

0 notes

Text

TMT Manufacturers In India

As a prominent TMT manufacturer based in Raipur, Chhattisgarh, Real Ispat takes pride in delivering top-notch TMT bars that cater to diverse construction needs across India. While our roots lie in Raipur, our commitment extends nationwide, including the dynamic market of India.

https://realgroup.org/tmt-manufacturers-in-india

#TMT Manufacturers in India#Sariya Manufacturers in India#550D TMT Bars Manufacturers in India#Corrosion Resistant TMT Bars Manufacturers in India#Ribbed TMT Bars Manufacturers in India

2 notes

·

View notes

Text

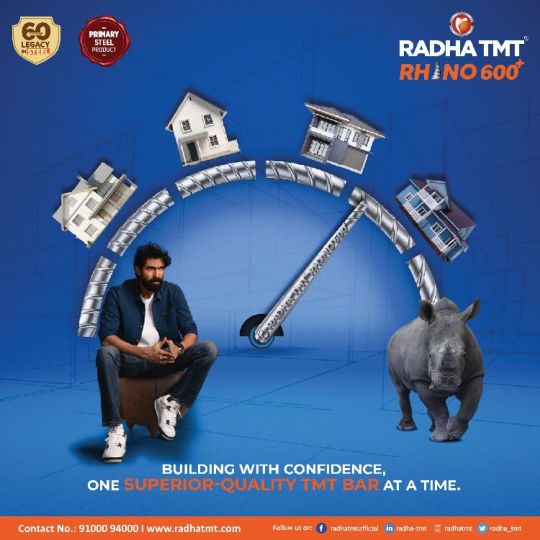

Radha Rhino 600+ is a superior quality TMT bar

Manufactured on resilient strength that builds homes with full power and confidence, Radha Rhino 600+ is a superior quality TMT bar! Choosing Radha Rhino 600+ is like choosing the premium raw material for your home's solid foundation!

Check us out at: www.radhatmt.com

#RadhaTMT#strength#quality#manufacturing#technology#superiorquality#TMT#radha#radhabars#tmtbars#foundation#steel#architect#Rhino600#infra#infrastructure

2 notes

·

View notes

Text

Partnering in bringing up a strong generation

The beautiful thought of providing the most excellent products with a proven benchmark of finest quality at the most affordable prices, thats the main reason that makes the brand KENZA a global leader in steel bars. With a beautiful tenure of over 28 years, the team Kenza lead by PK Moideen Koya and Mujeeb Rahaman, who converted their domain experience to an expertise in construction and devolopment projects devoloped the company. From trading companies to wholesale & retail outlets, Kenza has now grown as a socially committed organisation, adding goodness in providing education and health support to the need, home for poor. This makes Kenza an organization par excellence.

#Best tmt dealers in Kerala#Best TMT steel bars in kerala#Best tmt steel bars and suppliers#best tmt manufacturers and suppliers#tmt steel bars and suppliers#tmt steel dealers in kerala#top tmt steel bar company#top tmt steel bar manufacturing company#top tmt supplying company#tmt steel#TMT Steel Bars Manufacturing Company in Kannur#Tmt steel bars manufacturers in Kannur#Tmt steel bars supplying company in Kannur

2 notes

·

View notes

Text

Explore how top TMT bar manufacturers in Uttar Pradesh leading the steel market. Read the article to learn more.

https://writeupcafe.com/leading-the-market-top-tmt-bar-manufacturers-in-uttar-pradesh

0 notes

Text

How TMT Saria Manufacturer and Dowel Bars Are Essential in Concrete Road Projects

One of the most important infrastructure advancements in contemporary transportation is the creation of concrete roads. The quality of the materials utilized, especially TMT saria and dowel bars, which are the foundation of long-lasting road construction, is crucial to the success of these projects.

The Foundation of Strong Roads: Understanding Dowel Bars

Dowel bars serve as crucial load transfer devices in concrete pavements, effectively distributing weight across concrete slabs and preventing differential movement. These specially designed steel bars work silently beneath the surface, ensuring that roads maintain their structural integrity even under heavy traffic conditions and varying weather patterns.

Quality Materials from TMT Saria Manufacturer: Building Tomorrow's Infrastructure

Delivering premium building materials that satisfy exacting industry requirements is mostly dependent on skilled TMT saria manufacturers. Advanced technology and quality control procedures are included in their manufacturing processes to guarantee that every component satisfies precise requirements for performance, strength, and durability.

Essential Components in Modern Road Construction

Load Transfer Mechanism

Dowel bars create efficient load transfer systems between concrete slabs, reducing stress concentrations and preventing common road failures. This mechanism proves especially valuable in high-traffic areas where continuous heavy loads test pavement durability.

Reinforcement Structure

TMT saria provides essential reinforcement throughout the concrete structure. When combined with proper binding wire techniques, these materials create a robust framework that resists cracking and maintains structural integrity over time.

Temperature Management

Both dowel bars and TMT saria work together to manage thermal expansion and contraction, preventing common issues like concrete cracking and surface deterioration during extreme weather conditions.

Technical Specifications and Implementation

Proper Material Selection

Selecting the right dowel bars requires careful consideration of factors including:

Load-bearing requirements

Environmental conditions

Project specifications

Cost-effectiveness

Installation Procedures

Professional construction teams utilize specific techniques for installing dowel bars:

Precise spacing measurements

Proper alignment procedures

Quality binding wire application

Thorough testing protocols

Quality Assurance

Leading TMT saria manufacturers implement rigorous quality control measures:

Material testing

Strength verification

Dimensional accuracy checks

Coating integrity assessment

Benefits of Quality Materials in Road Construction

Long-term Durability

Using high-quality dowel bars and TMT saria significantly extends road lifespan, reducing maintenance requirements and overall lifecycle costs.

Enhanced Performance

Professional-grade materials ensure better load distribution, minimizing common issues like:

Joint deterioration

Slab movement

Surface cracking

Edge damage

Cost Efficiency

While premium materials from established TMT saria manufacturers may represent higher initial costs, they deliver substantial long-term savings through:

Reduced maintenance needs

Extended service life

Improved performance

Lower replacement frequency

Implementation Considerations

Project Planning

Successful concrete road projects require careful planning and material selection:

Accurate material quantity estimation

Proper storage facilities

Quality binding wire procurement

Professional installation teams

Quality Control

Maintaining high standards throughout construction demands:

Regular material testing

Professional installation supervision

Proper curing procedures

Ongoing monitoring

Future Maintenance

Planning for future maintenance needs includes:

Documentation of installed materials

Maintenance schedule development

Performance monitoring protocols

Repair strategy planning

Making Informed Choices for Road Construction

Selecting the right materials for concrete road projects requires careful consideration of multiple factors. Working with reputable TMT saria manufacturers ensures access to quality materials that meet project specifications and deliver long-term performance benefits.

Road construction professionals must prioritize quality when selecting dowel bars and related materials, as these components directly impact project success and longevity. By choosing certified materials and following proper installation procedures, construction teams can ensure the development of durable, high-performance concrete roads that serve communities for generations to come.

#TMT Saria#dowel bars#road projects#TMT steel#concrete roads#road durability#TMT manufacturers#TMT bars#bar strength#road stability#concrete support#dowel placement#road reinforcement#TMT road use#bar construction#dowel strength#TMT benefits#concrete durability#road longevity#bar manufacturers

0 notes

Text

TMT Bars Manufacturers in India

Building a modern India, With Kay2 Xenox TMT bars at its core, every skyscraper stands as a symbol of innovation, strength, and future readiness. Proud to be the backbone of a progressive nation!

#kay2xenox#tmt bars#best tmt bars#tmt bars manufacturers#TMT Bars Manufacturers#tmt manufacturers#tmt steel manufacturer#steel bar manufacturer#tmt saria manufacturers#Tmt Manufacturers In India#best tmt bars manufacturers in India

0 notes

Text

TopTech TMT: Dominating West Bengal’s TMT Bar Manufacturing Industry

TopTech TMT strengthens its position as the leading TMT bar manufacturer in West Bengal, ensuring top-quality products and innovative solutions for construction needs. Discover their excellence in the industry.

0 notes

Text

How Quality TMT Bars Can Enhance the Safety and Longevity of Structures

When constructing a building, the choice of materials plays a crucial role in ensuring its safety and durability. Among these materials, Thermo-Mechanically Treated (TMT) bars stand out as a key component in enhancing structural integrity. Here's why quality TMT bars are indispensable for your construction projects.

Unmatched Strength and Flexibility: TMT bars are known for their high tensile strength, which allows them to withstand heavy loads and stress. At the same time, their flexibility ensures they can absorb energy during seismic activities, making structures more resistant to earthquakes. Quality TMT bars strike the perfect balance between strength and ductility, making them ideal for all types of construction.

Superior Corrosion Resistance: Buildings are often exposed to moisture, especially in areas with high humidity or frequent rainfall. High-quality TMT bars are designed to resist corrosion, ensuring the reinforcement remains strong over time. This feature helps maintain the structural integrity of the building, reducing the risk of collapse due to weakened reinforcements.

Enhanced Bonding with Concrete: TMT bars have a unique ribbed design that ensures better bonding with concrete. This strong bond prevents the bars from slipping, ensuring that the structure remains stable even under extreme conditions.

Longevity and Cost-Effectiveness

Investing in high-quality TMT bars means fewer maintenance and repair costs in the long run. Their durability ensures the structure remains safe and functional for decades, offering excellent value for money. Using premium TMT bars is not just about meeting construction standards; it’s about building a safer, stronger, and more durable future. Prioritize quality TMT bars in your projects to ensure your structures stand the test of time.

0 notes

Text

TMT Manufacturers In India

As a prominent TMT manufacturer based in Raipur, Chhattisgarh, Real Ispat takes pride in delivering top-notch TMT bars that cater to diverse construction needs across India. While our roots lie in Raipur, our commitment extends nationwide, including the dynamic market of India.

https://justpaste.it/7wgsp

#TMT Manufacturers In India#TMT Manufacturers In Kerala#High Strength TMT Bars Manufacturers in Rajasthan#Best Quality TMT Bars Manufacturers In India#Best Quality TMT Bars Manufacturers In West Bengal#Premium Quality TMT Bars Manufacturers In India#Best TMT Manufacturers For House Construction In India

1 note

·

View note

Text

Maan Shakti - Designing Robust TMT Bars for Stronger Constructions

West Bengal’s construction industry has been rapidly progressing, with promises of skyscrapers and large-scale industrial houses. Real estate developers extensively use TMT bars to enhance structural strength. With the best-quality TMT bars, architectural endeavors in Kolkata are likely to progress rapidly. Maan Shakti functions as one of the best TMT bar manufacturers in Kolkata by supplying the best quality TMT bars for different constructions.

0 notes

Text

Iron ore pellets are small, refined balls of iron ore used in steelmaking. Made by processing fine iron ore into spheres, they offer efficiency and reduced waste.

#tmt bars#tmt bars manufacturers#tmt bar suppliers#tmt bar manufacturers in kolkata#best tmt bar in west bengal#best quality tmt bars in india

0 notes

Text

Top TMT bars manufacturers, like Ganesh Super, supply steel bars that are essential for modern construction. As expert manufacturers, we use thermo-mechanical treatment processes to ensure the bars offer high strength and flexibility. This makes the TMT bars ideal for various construction needs. We will ensure that your building materials meet the required safety and durability standards and that the constructed structure will stay standing for ages.

0 notes